Assembled semi-trailer frame, semi-trailer and assembling method thereof

A semi-trailer and assembled technology, which is applied to vehicle components, transportation and packaging, and substructure, can solve problems such as low work efficiency, high labor intensity, and heavy semi-trailer weight, so as to reduce labor costs and improve manufacturing quality. Avoid the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

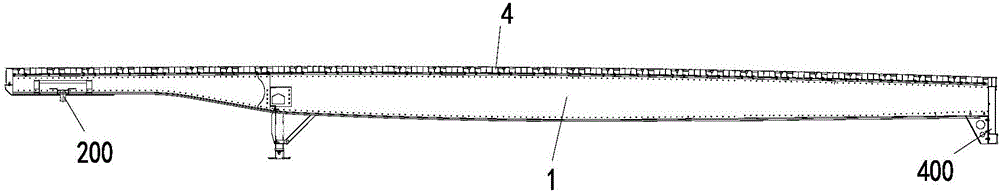

[0104] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0105] When describing the orientation of the present invention, the normal driving direction of the semi-trailer is taken as the front, the other side opposite to the front is the rear, the direction close to the longitudinal centerline of the semi-trailer frame is the inside, and the direction away from the semi-trailer frame is the longitudinal center. The direction of the line is outside.

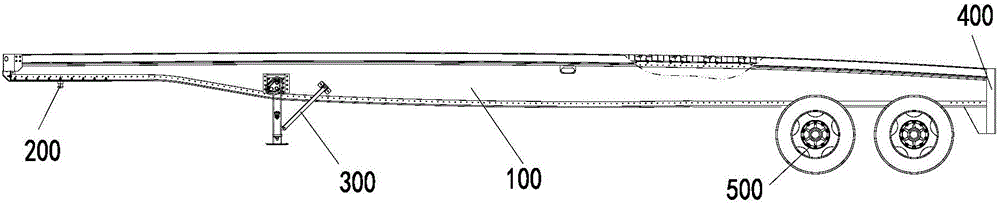

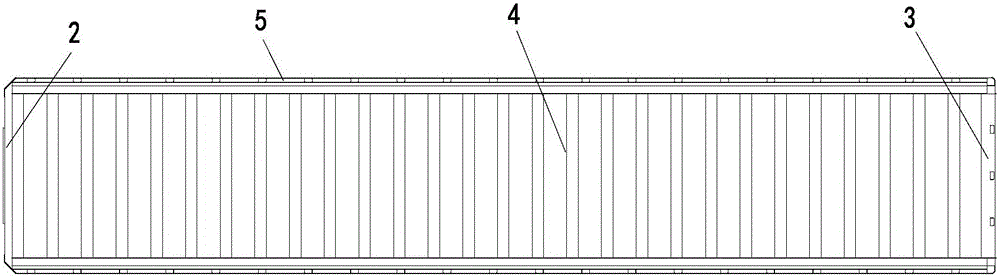

[0106] see Figure 1-Figure 30 , is an embodiment of the assembled semi-trailer frame, such as figure 1 Shown is a schematic structural view of a semi-trailer in this embodiment. The semi-trailer includes an assembled semi-trailer frame 100, a traction assembly 200, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com