Dispersible graphene nano-composite particle, and preparation method and application thereof

A technology of nanocomposite and dispersed graphite, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve high yield, mild reaction conditions, and good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing dispersible graphene nanocomposite particles, specifically: add 6 g of graphene oxide, 0.02 mol of nickel formate and 400 mL of deionized water into a 500 mL beaker, and ultrasonicate the mixture for 30 minutes. Then carry out spray drying and granulation in a spray dryer, set the spray drying temperature to 220°C, and the obtained tan solid powder is the target product, dispersible graphene-nickel nanocomposite particles which can be used as anti-wear and friction reducer for lubricating oil.

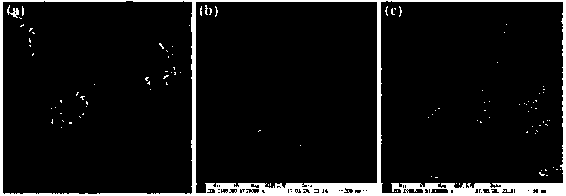

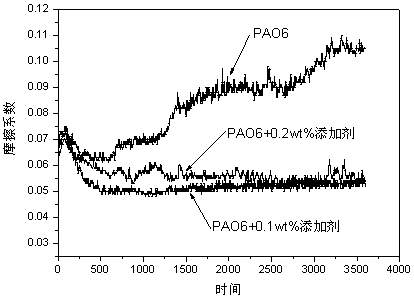

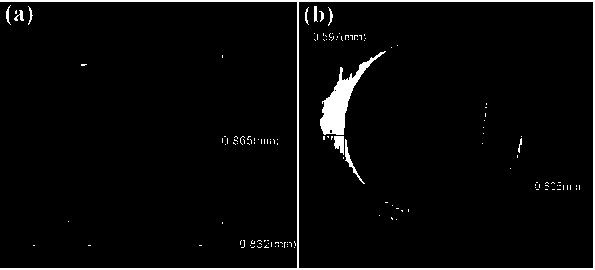

[0020] The scanning electron microscope picture and the transmission electron microscope of the prepared dispersible graphene nickel nanocomposite particle of embodiment 1 are shown in figure 1 . Depend on figure 1 (a) It can be seen that the prepared graphene-nickel nanocomposite particles are wrinkled paper balls; figure 1 (b and c) It can be seen that the nickel nanoparticles are uniformly loaded on the paper-like graphene. The graphene-nickel nanoco...

Embodiment 2

[0026] A method for preparing dispersible graphene nanocomposite particles, specifically: add 3 g of graphene oxide, 0.01 mol of copper formate, and 400 mL of deionized water into a 500 mL beaker, and ultrasonicate the mixture for 30 minutes. Then carry out spray-drying and granulation, set the spray-drying temperature to 220° C., and the obtained brown solid powder is the target product. The target product can be used as dispersible graphene-copper nano-composite particles of lubricating oil anti-wear and friction reducer.

Embodiment 3

[0028] A method for preparing dispersible graphene nanocomposite particles, specifically: add 12 g of graphene oxide, 0.004 mol of nickel acetylacetonate, and 400 mL of deionized water into a 500 mL beaker, and ultrasonicate the mixture for 30 minutes. Then carry out spray drying and granulation, set the spray drying temperature to 230° C., and the obtained tan solid powder is the target product. The target product can be used as dispersible graphene-nickel nano-composite particles of lubricating oil anti-wear and friction reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com