Windshield wiper device

A technology of glass scraping and wiper, which is applied in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., and can solve problems such as irreparable and damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

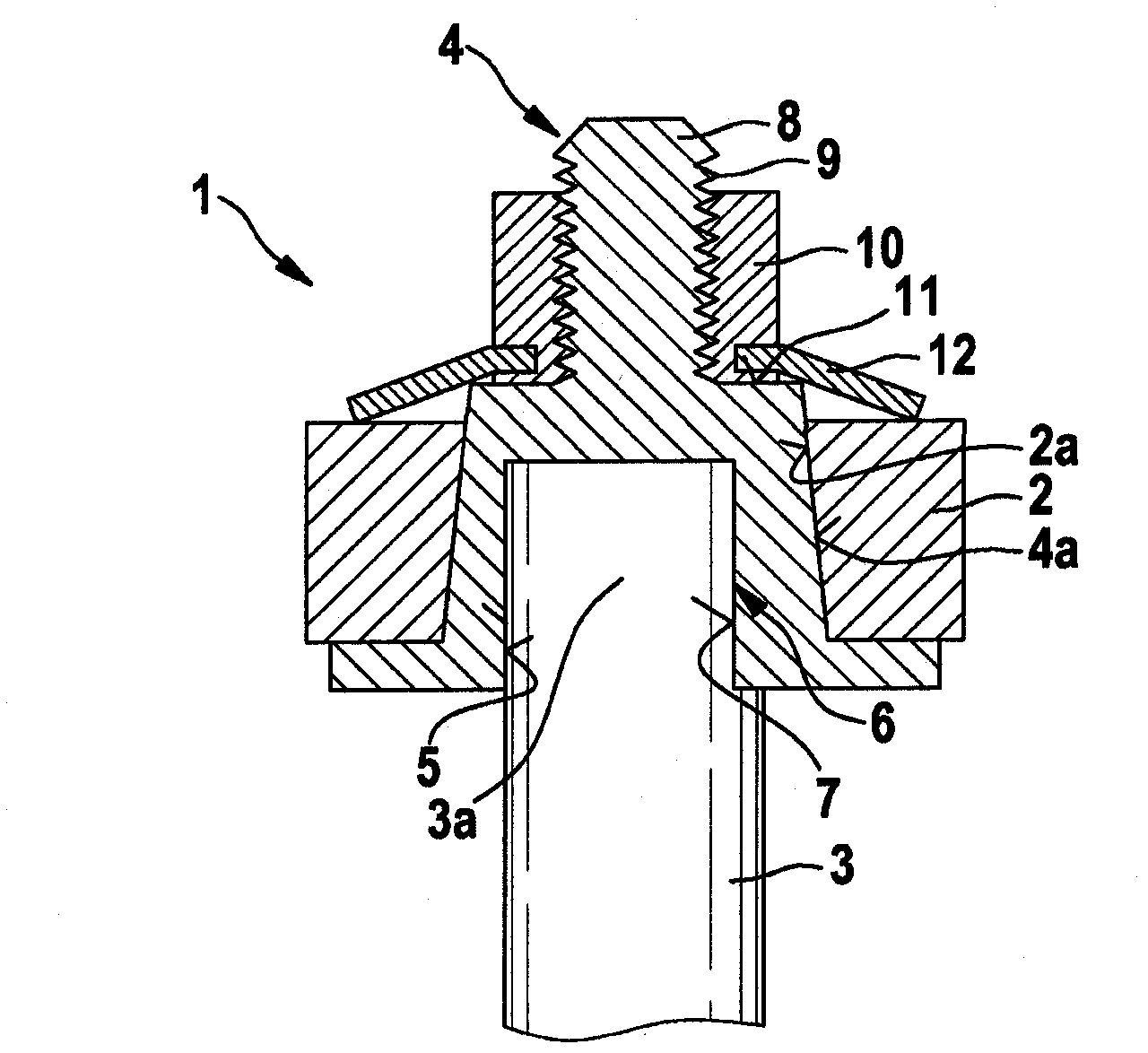

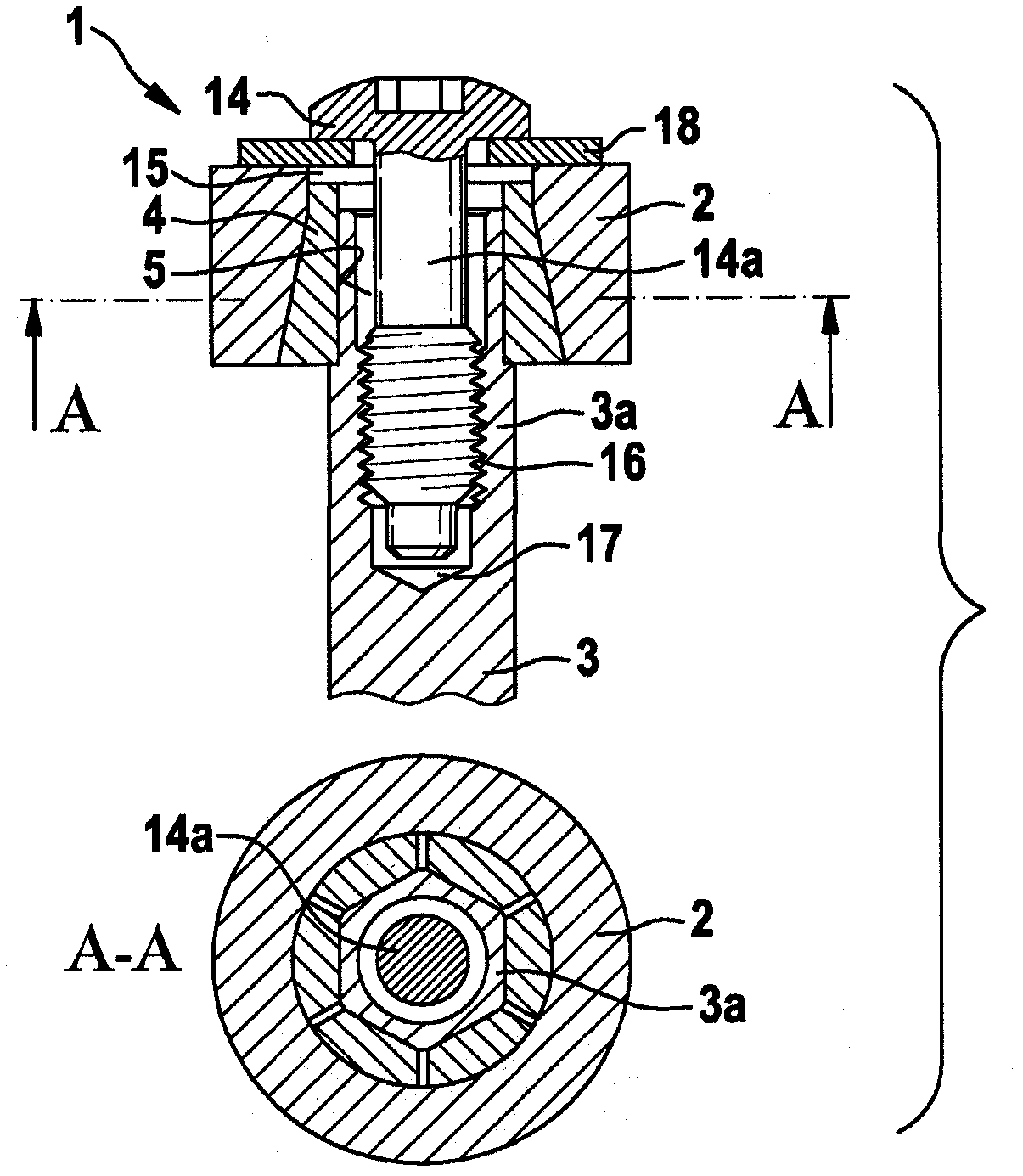

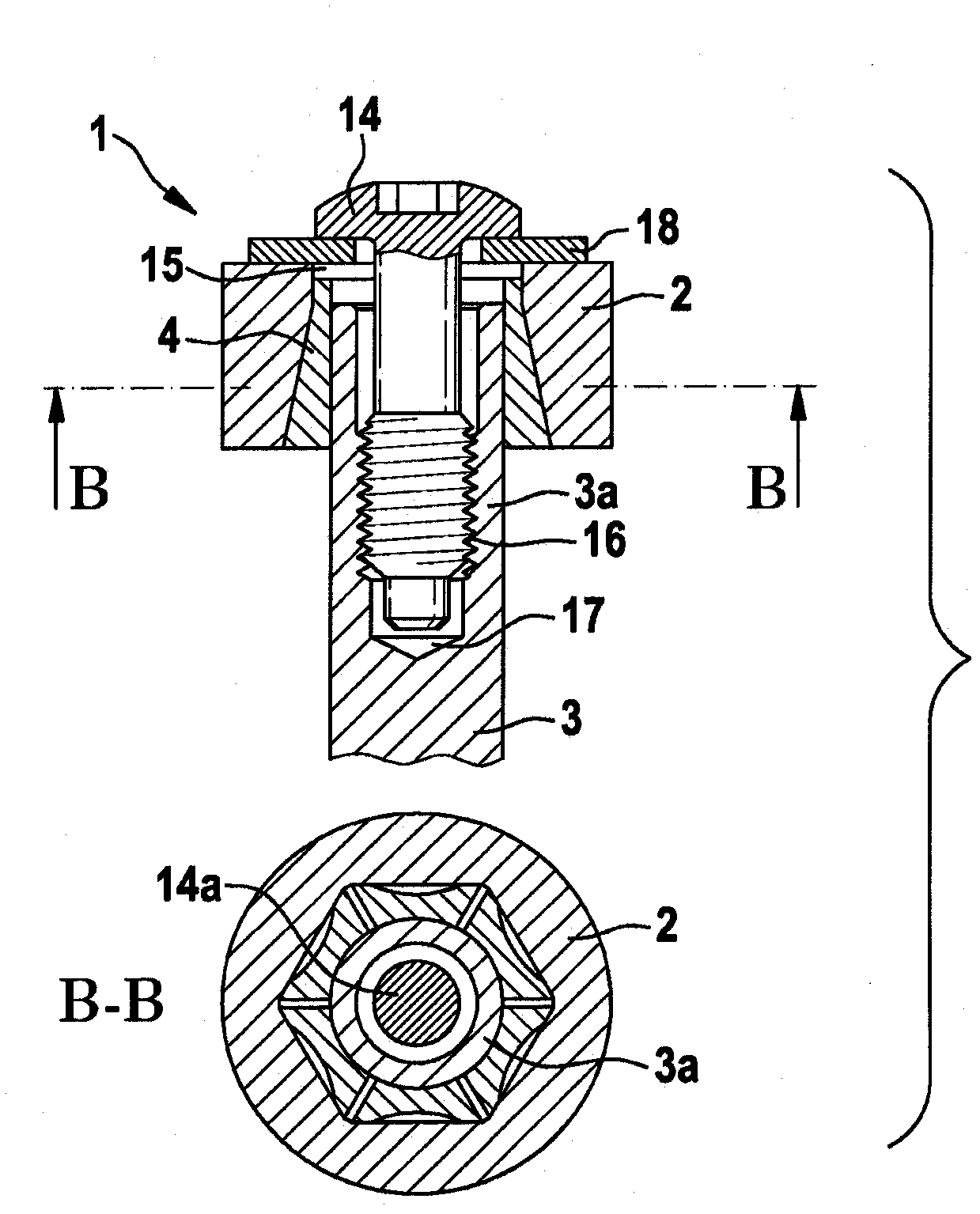

[0027] figure 1A fastening device 1 is shown for fastening a wiper arm 2 to an end section of a driven shaft 3 of a wiper motor of a windshield wiper device, not shown in further detail.

[0028] The fastening mechanism 1 has a connecting part 4 in which an insertion region formed complementary to the end section 3 of the driven shaft 3 is provided in the form of a recess 5 into which the end section is inserted. 3a.

[0029] A non-circular shape is provided as a coupling element in the recess 5 in the form of a support body 6 which is formed complementary to a flat portion 7 formed on the end section 3 a of the driven shaft 3 . This flat part 7 is milled out in the end section 3 a of the driven shaft 3 in a very simple manner. Due to the combination of the support body 6 and the flat part 7 , the coupling piece 4 is prevented from slipping on the driven shaft 3 . Rotation of the output shaft 3 in the connecting part 4 is only possible when a moment is applied which causes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com