Pressing die

A compression molding and integrated technology, applied in the field of compression molding, can solve the problems of not being able to find the cutting line, affecting the appearance, and falling off, so as to avoid health threats and environmental pollution, improve enterprise production efficiency, and have neat and beautiful edges. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

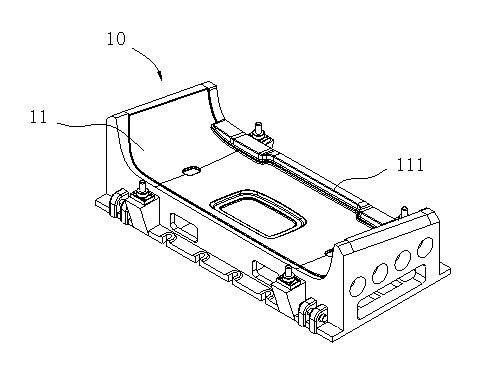

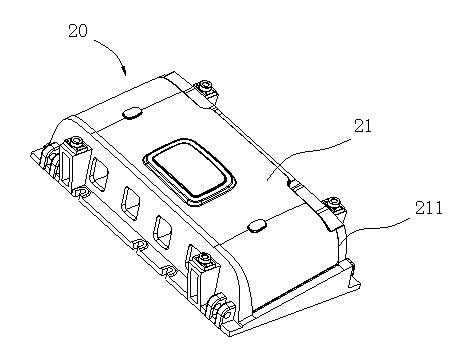

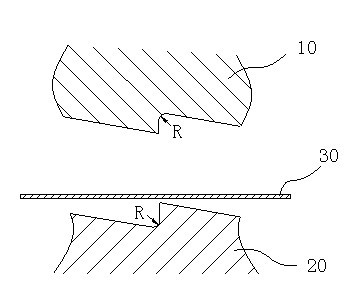

[0011] A pressing die, the pressing die includes an upper die 10 and a lower die 20, the profiles 11, 21 of the upper and lower dies 10, 20 are continuously provided with cutting edges 111, 211 that cooperate with each other along the cutting line of the product .

[0012] Further, in order to ensure that the cutting edges 111, 211 can cut edges smoothly and the edge surfaces do not interfere with each other, the mold clamping distance of the cutting edges 111, 211 is 10 to 20 wires.

[0013] Since the upper and lower molds 10, 20 are all integral cast iron structures, when processing the upper and lower molds 10, 20, you can choose to directly make the mold body by casting means, and then process its profiles 11, 21 by numerical control machining to make them The upper and lower molds 10 and 20 can be properly matched to ensure their accuracy and also solve the problem that the old-fashioned epoxy resin layer surface often loosens or even falls off between the reinforced stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com