Patents

Literature

47 results about "Interior product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, the interior product (a.k.a. interior derivative, interior multiplication, inner multiplication, inner derivative, insertion operator, or inner derivation) is a degree −1 (anti)derivation on the exterior algebra of differential forms on a smooth manifold. The interior product, named in opposition to the exterior product, should not be confused with an inner product. The interior product ιXω is sometimes written as X ⨼ ω.

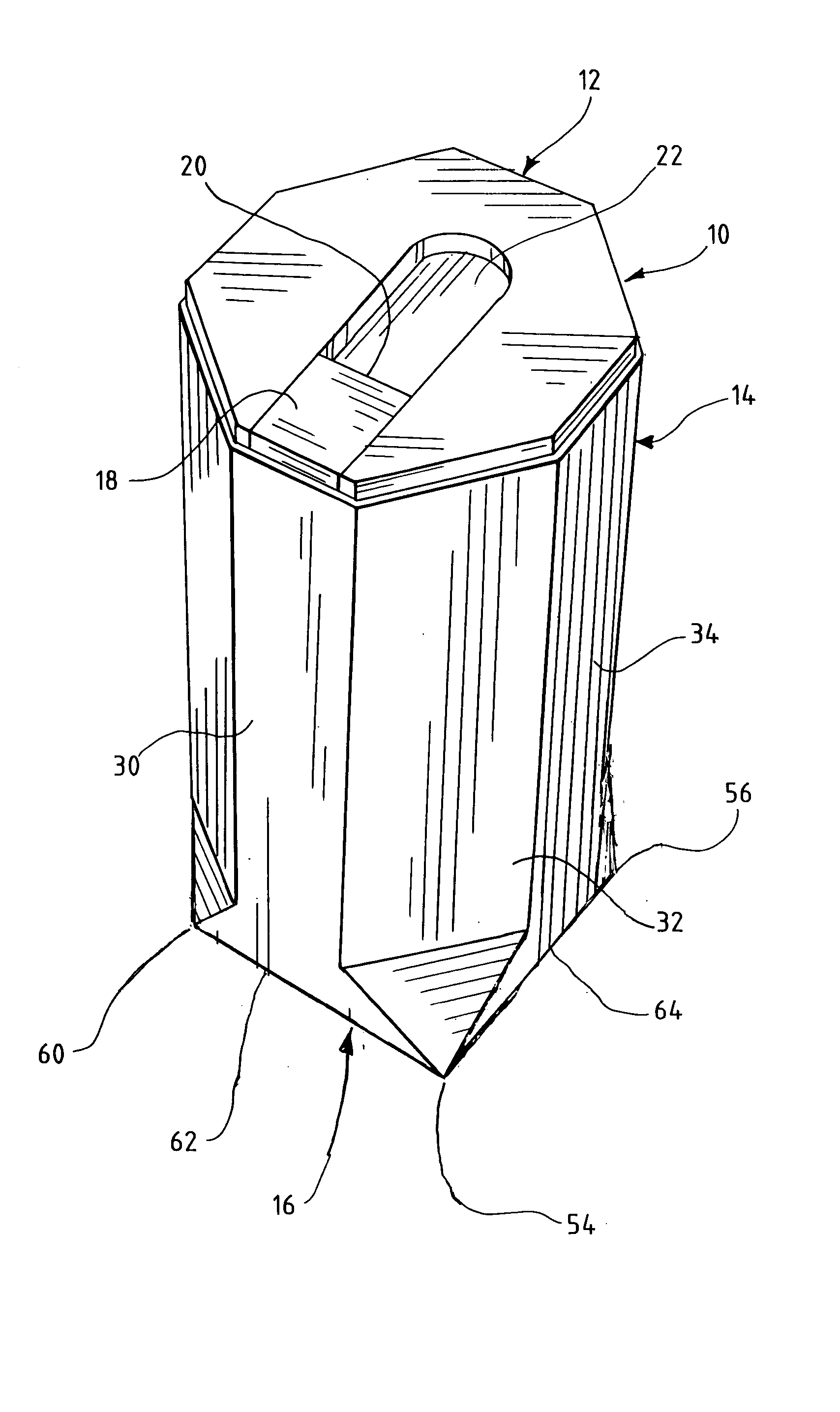

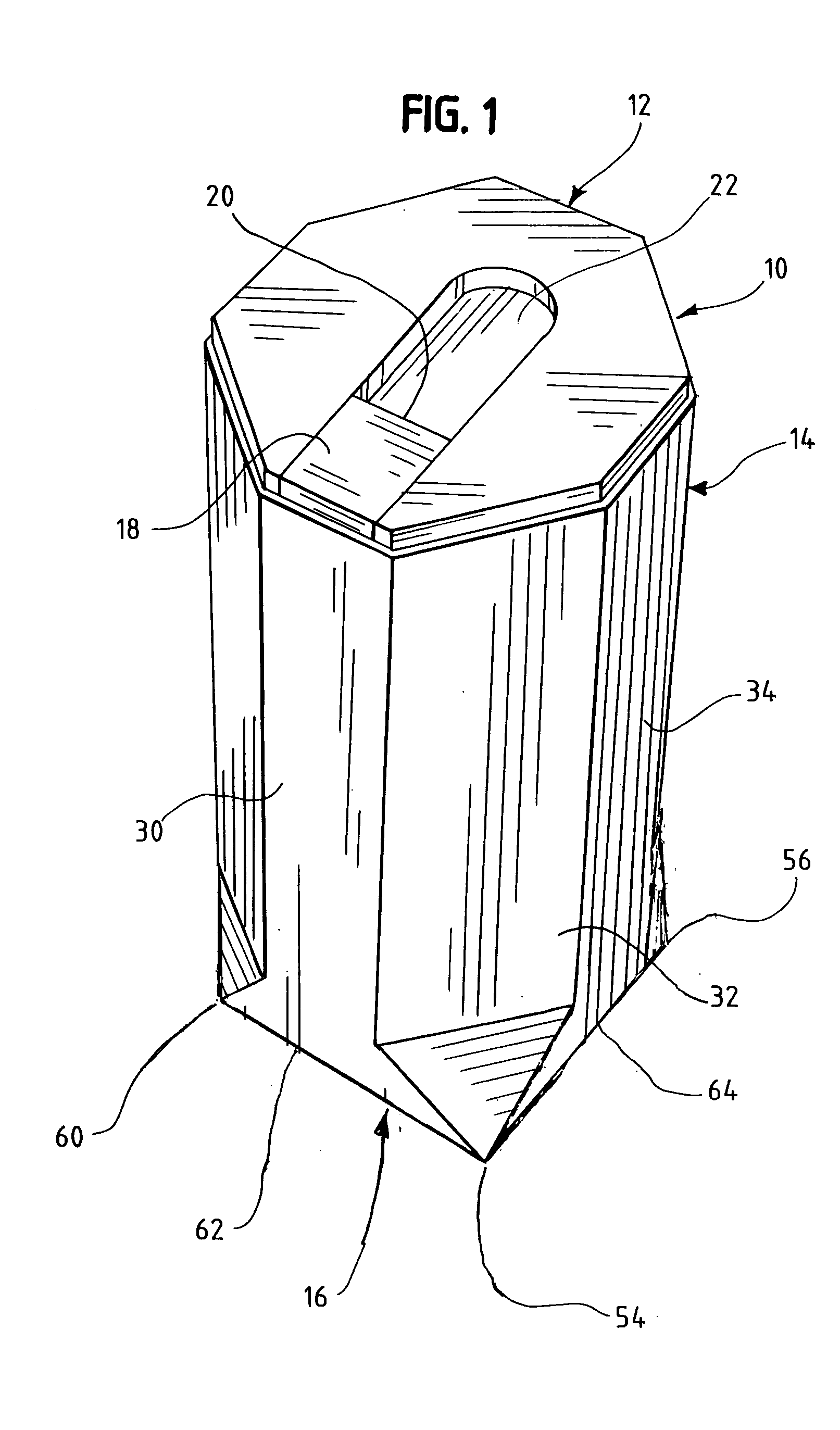

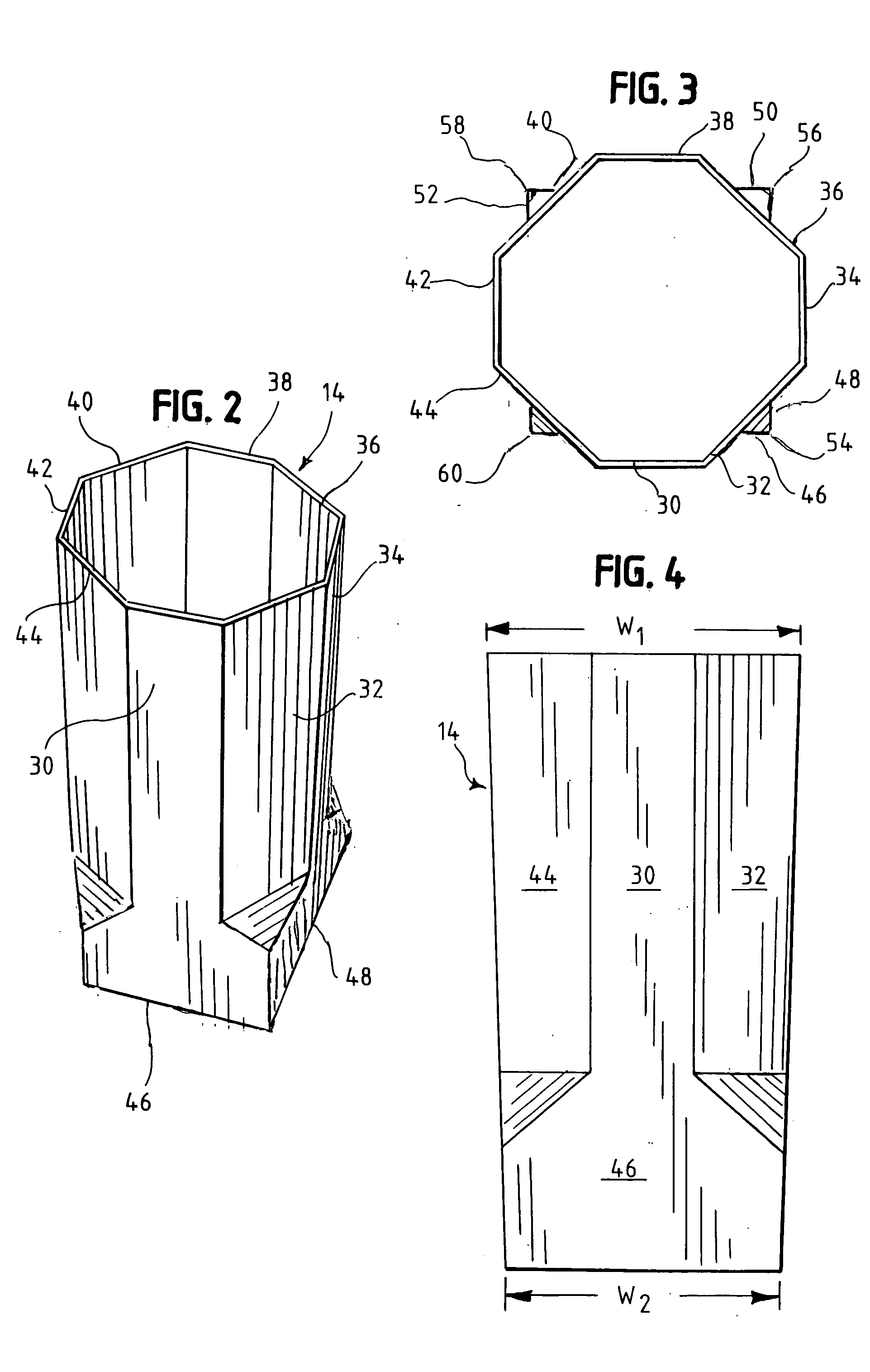

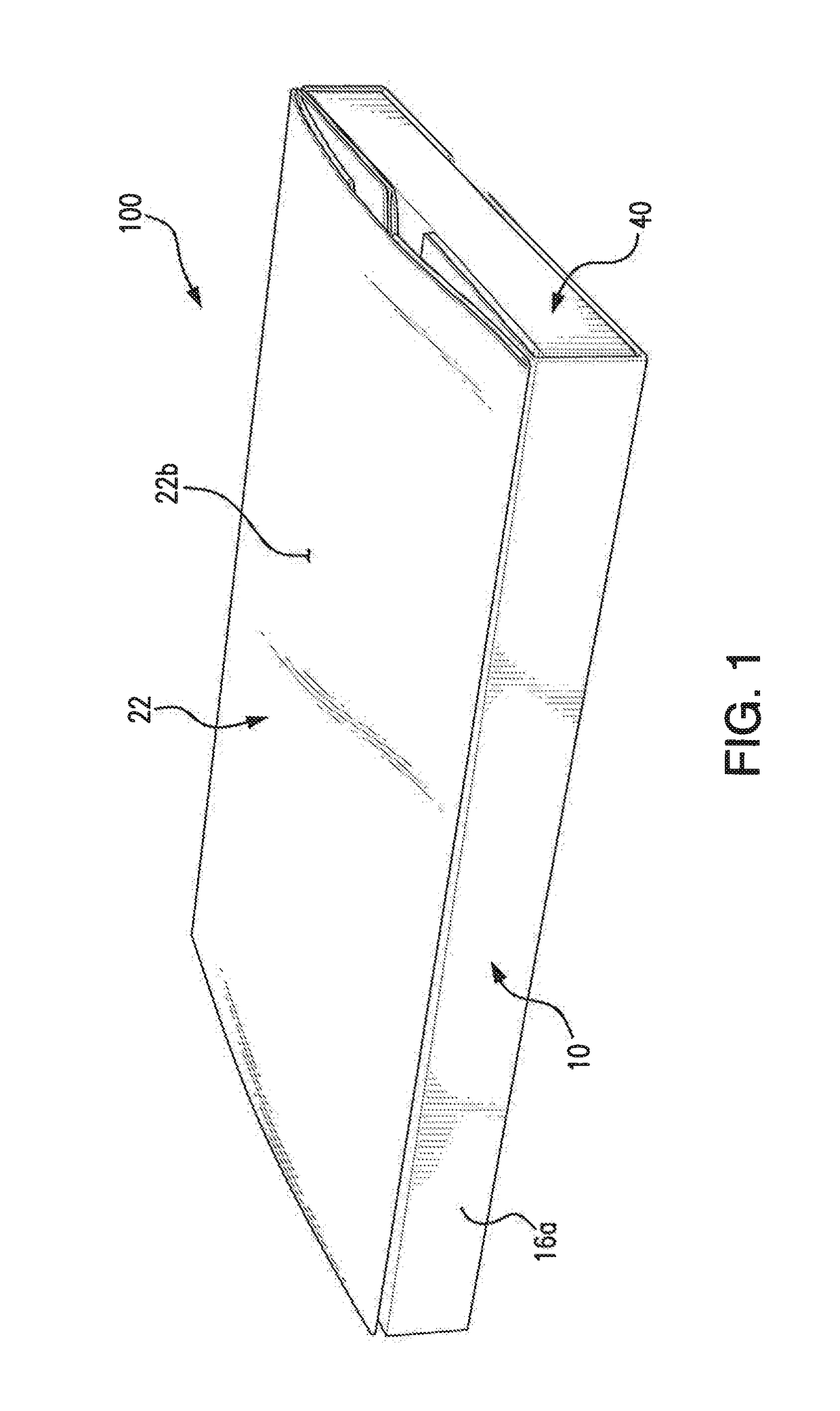

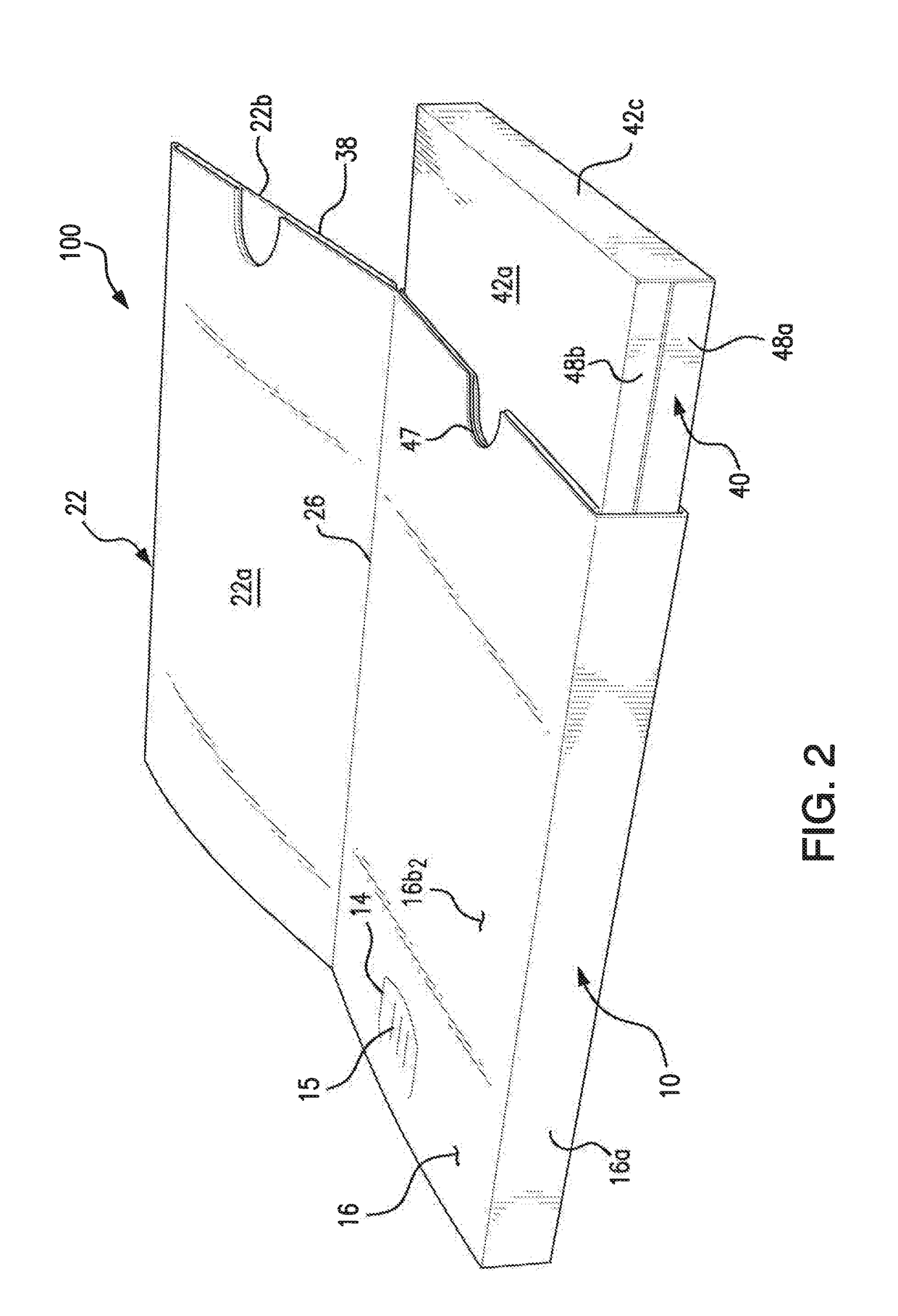

Multi-sided package with easily openable lid

An easily openable package defining an interior product storage region, includes first, second, third, fourth, fifth, sixth, seventh and eighth side panels forming an eight-sided body. Each side panel is separate from adjacent side panels by respective crease lines. The side panels define an octagonal upper periphery. A bottom wall is formed from a plurality of panels separated from the side panels by a horizontal crease line. The bottom wall has a four-sided foot print, defining four bottom wall corners. An eight-sided polymeric lid is affixed to the package at the upper periphery. The lid has an openable portion such that the interior product storage region is accessed by opening the openable portion of the lid. A method for forming the package is also disclosed.

Owner:TETRA LAVAL HLDG & FINANCE SA

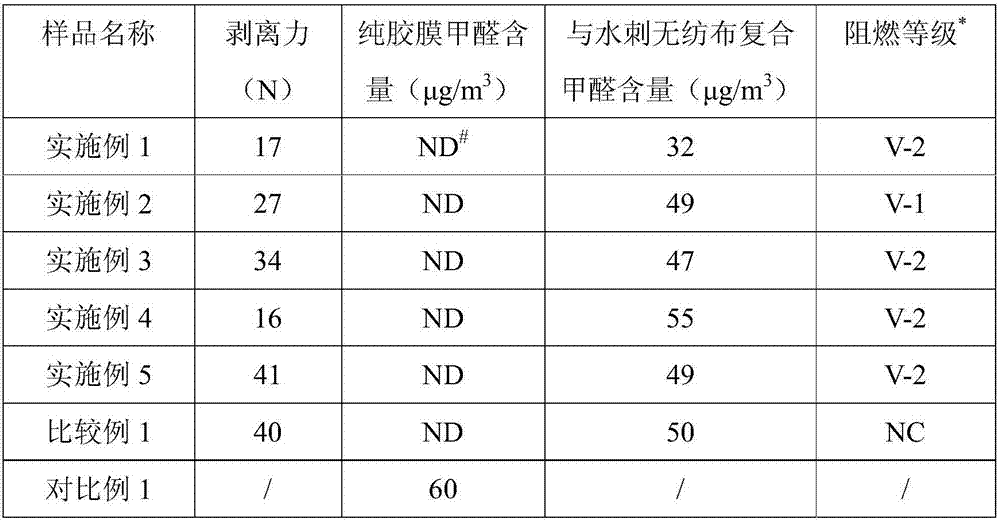

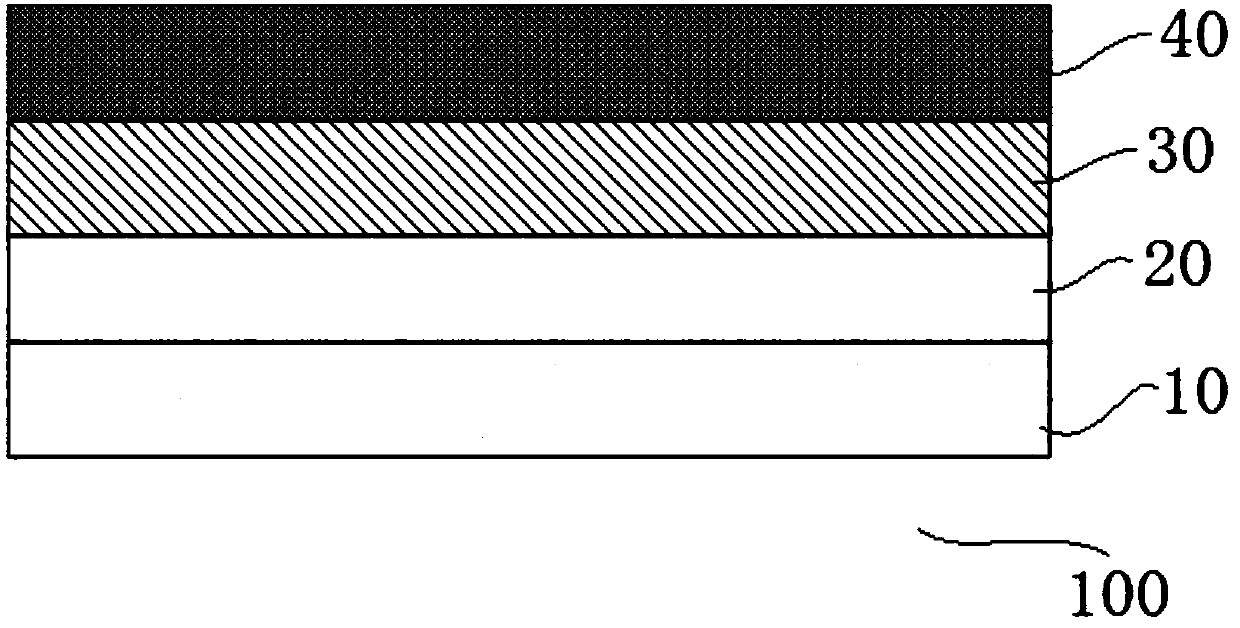

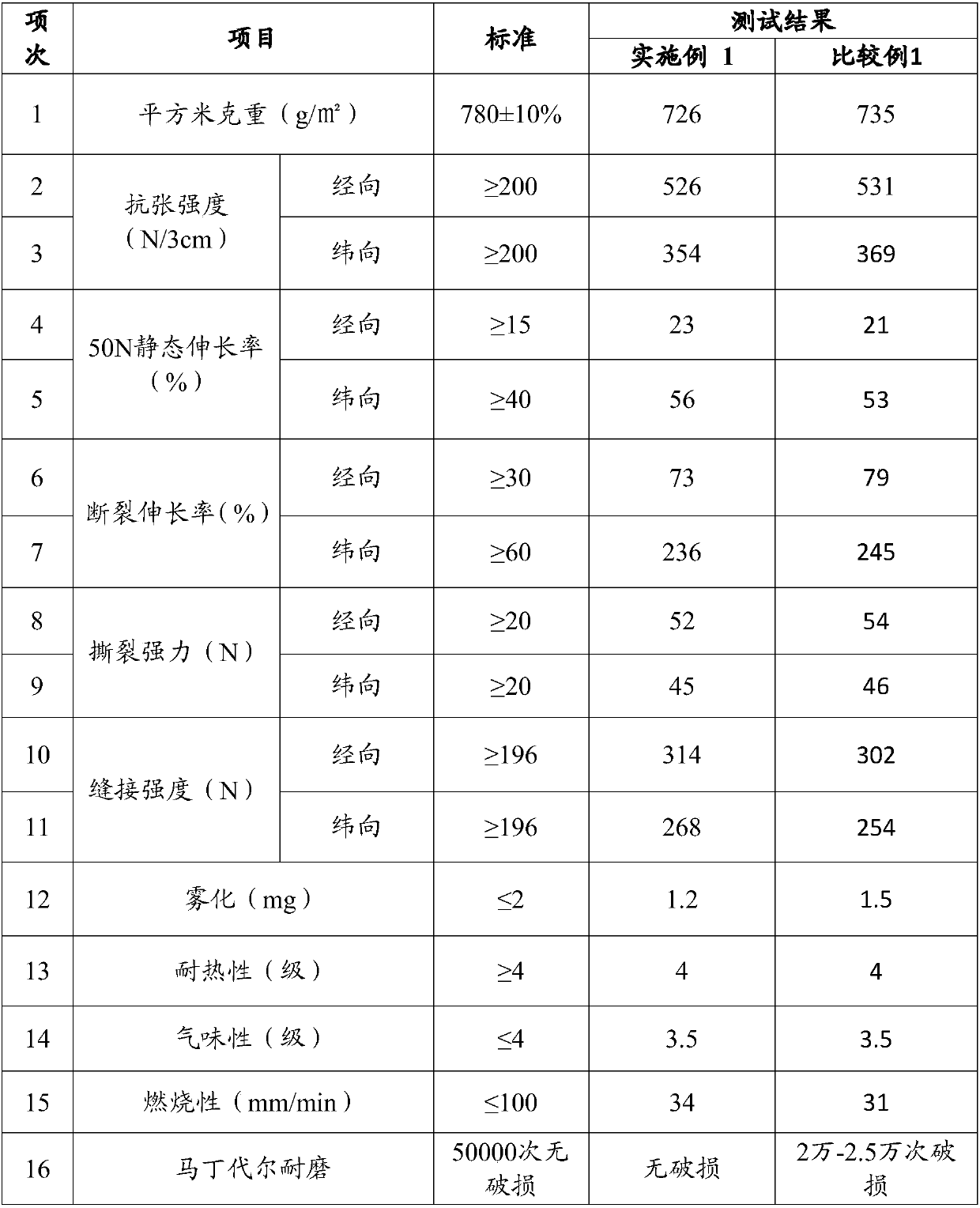

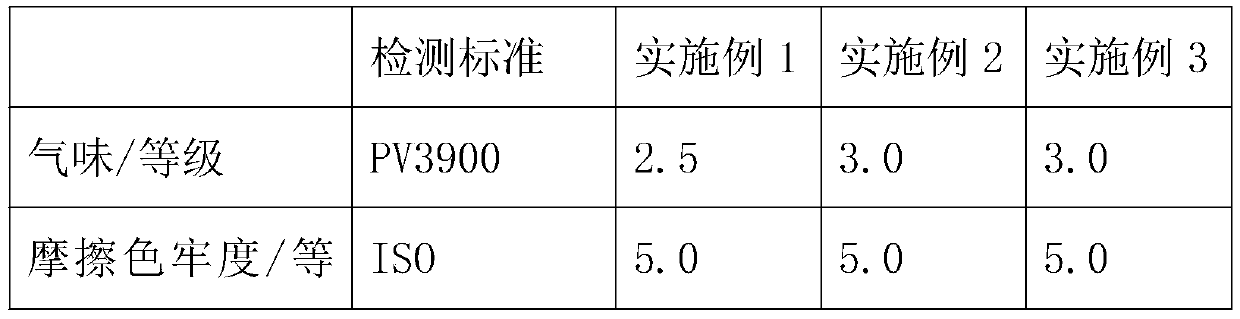

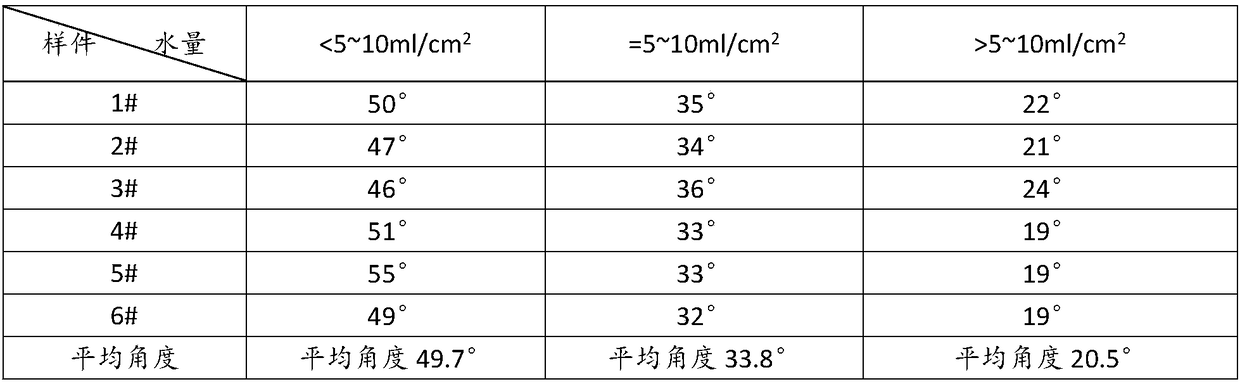

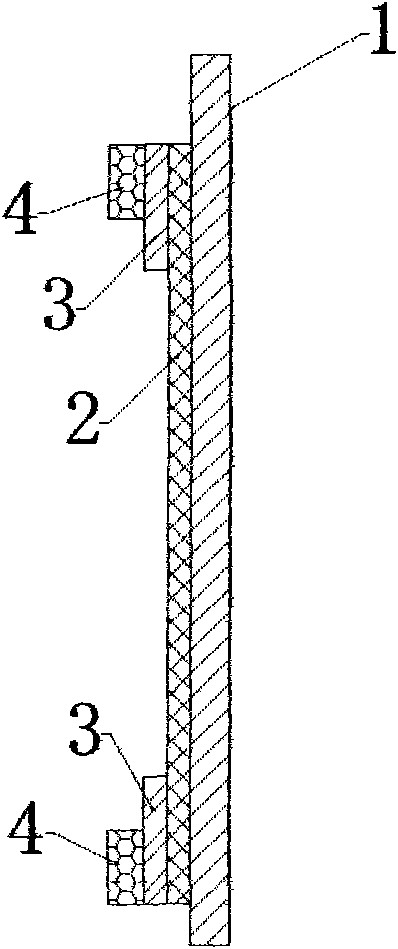

Environmentally friendly hot melt adhesive membrane for automotive interior products, preparation method and application

ActiveCN107151539AHigh strengthEffective bondingNon-macromolecular adhesive additivesFilm/foil adhesivesOrganic solventElastic component

The invention discloses an environmentally friendly hot melt adhesive membrane for automotive interior products, a preparation method and application. The environmentally friendly hot melt adhesive membrane for the automotive interior products comprises the following components in parts by mass: 100 parts of an elastic component, 0.1-50 parts of a non-elastic component and 0.1-20 parts of composite filler. The melt index of the elastic component is 0.9-30 g / 10 min (190 DEG C, 2.16 kg), the melt index of the non-elastic component is 0.2-10 g / 10 min (190 DEG C, 2.16 kg), and the melt index of the elastic component is greater than that of the non-elastic component. The composite filler comprises bamboo charcoal fibers and flame-retardant filler. The environmentally friendly hot melt adhesive membrane is used for adhesion of the automotive interior products, does not contain any organic solvents, does not produce toxic or harmful gas, and has antibacterial property and flame retardancy. Compared with a common antibacterial or flame-retardant product, the environmentally friendly hot melt adhesive membrane for the automotive interior products is simple and convenient to process.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

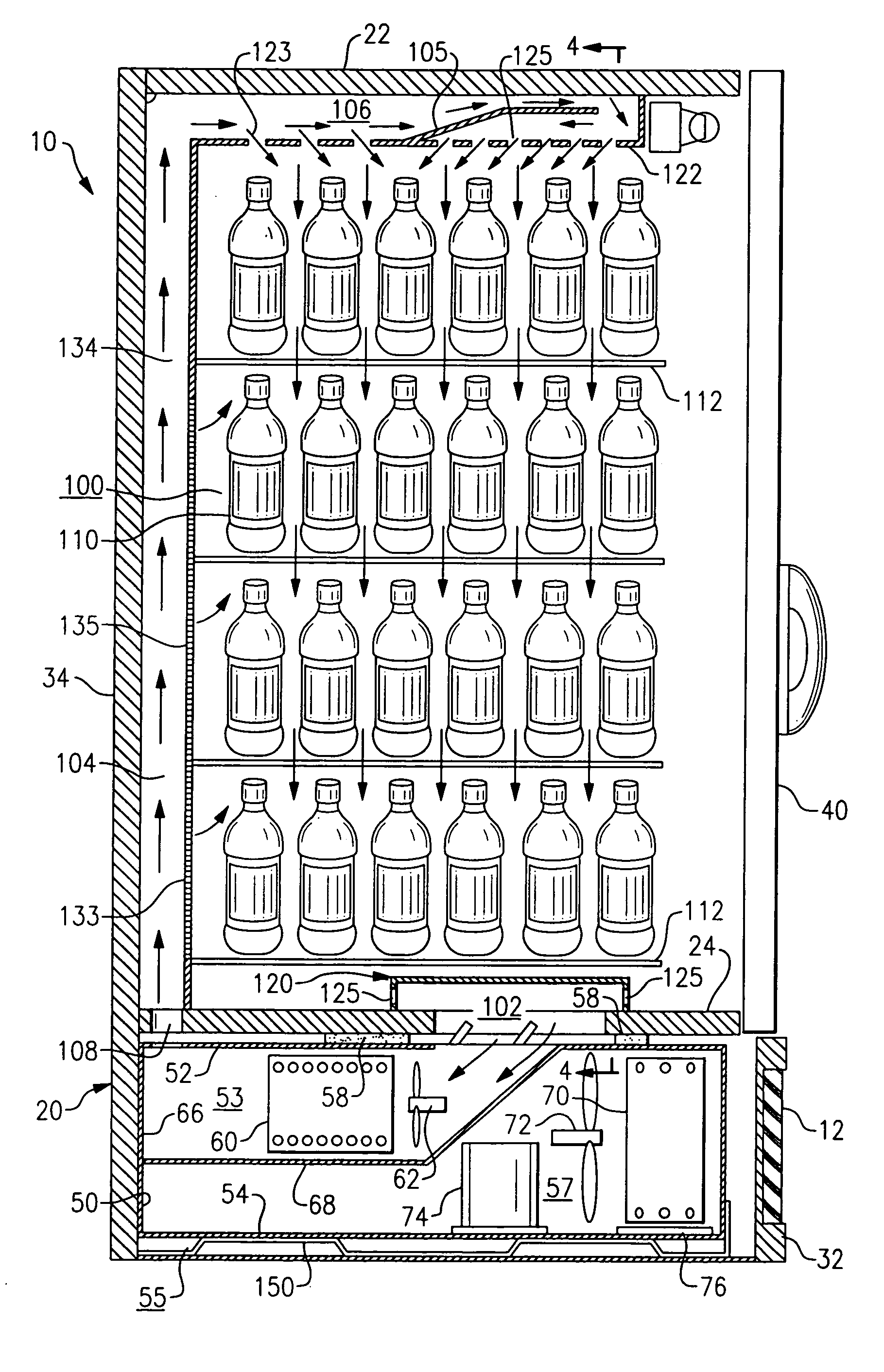

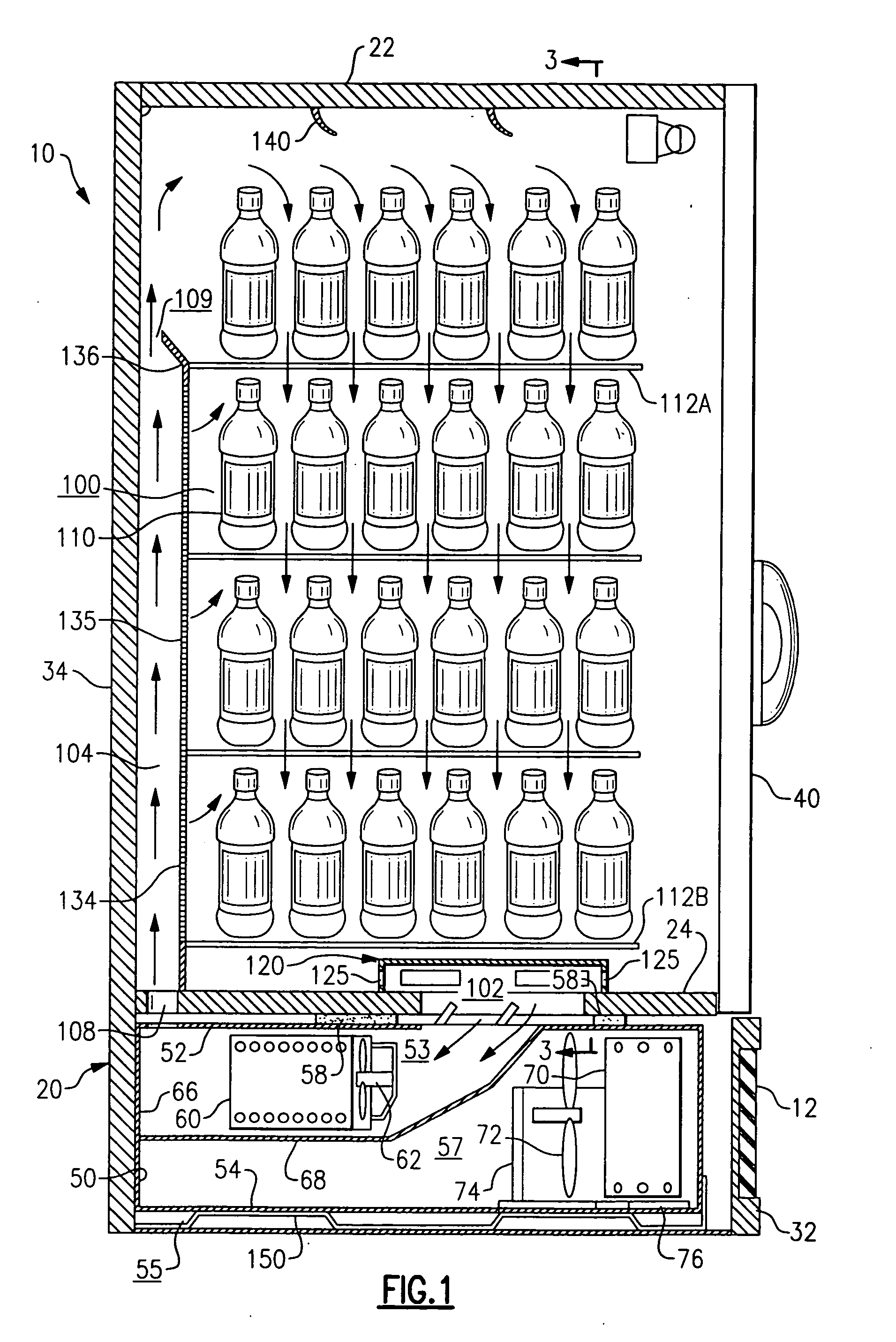

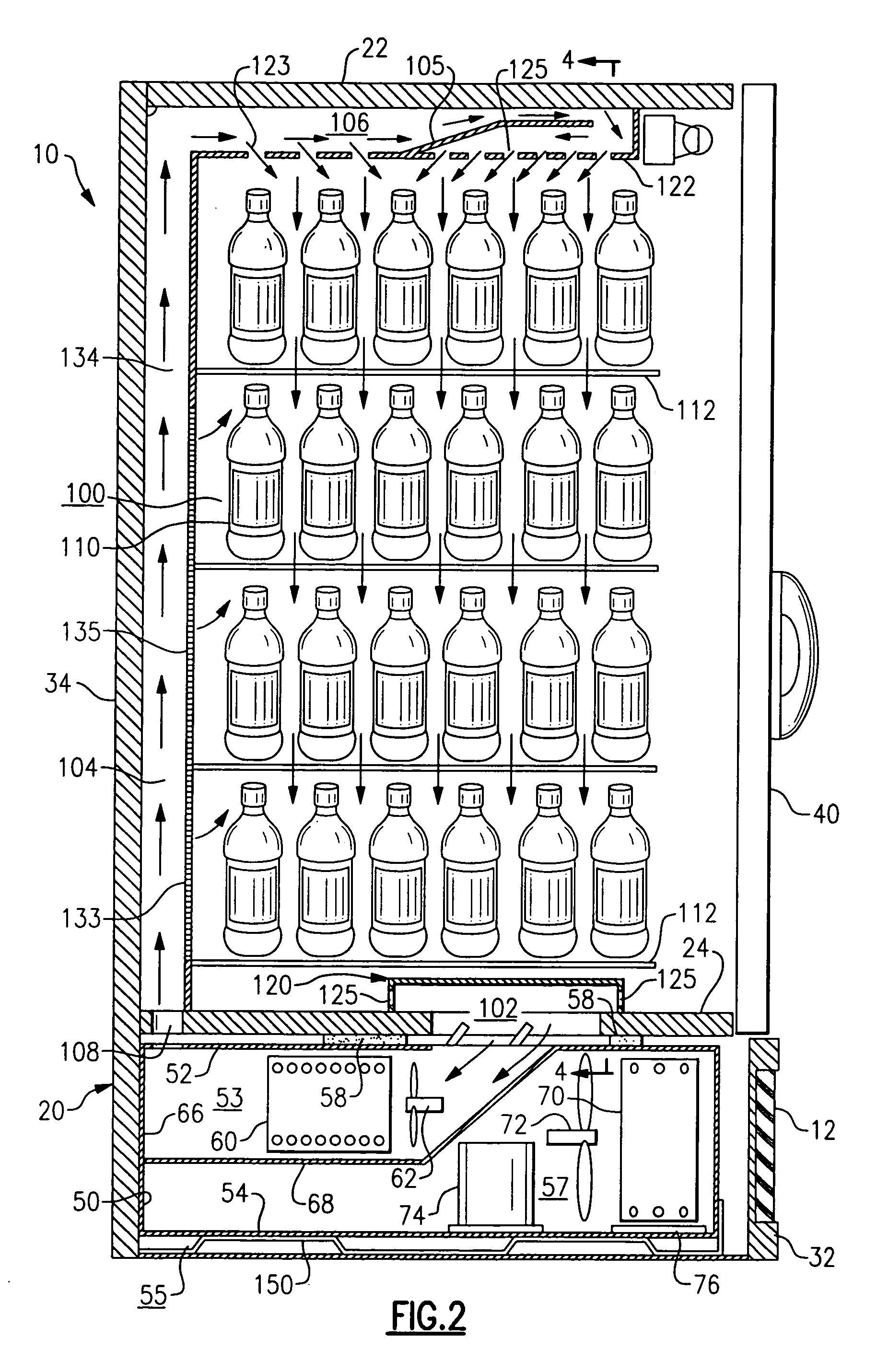

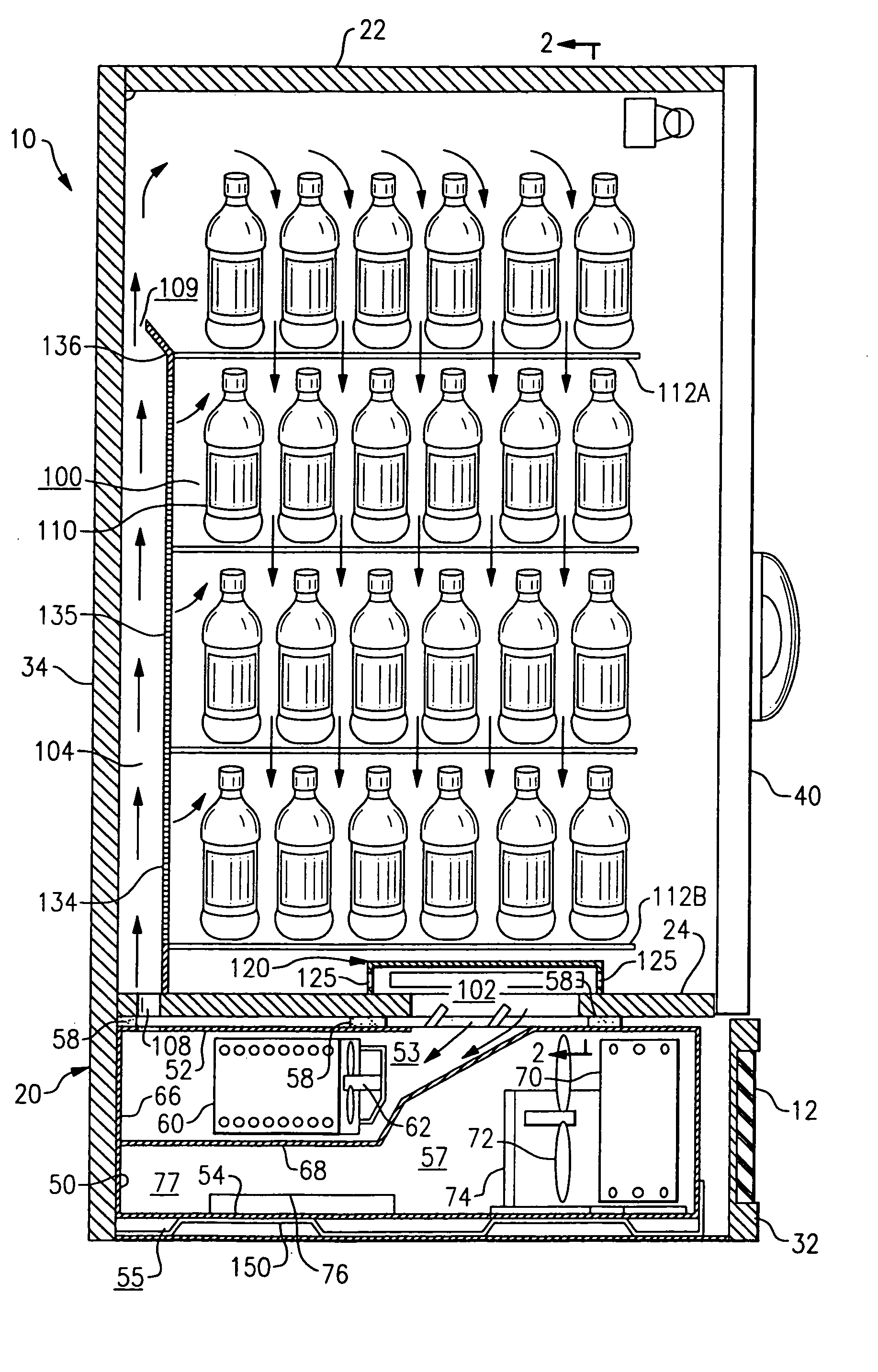

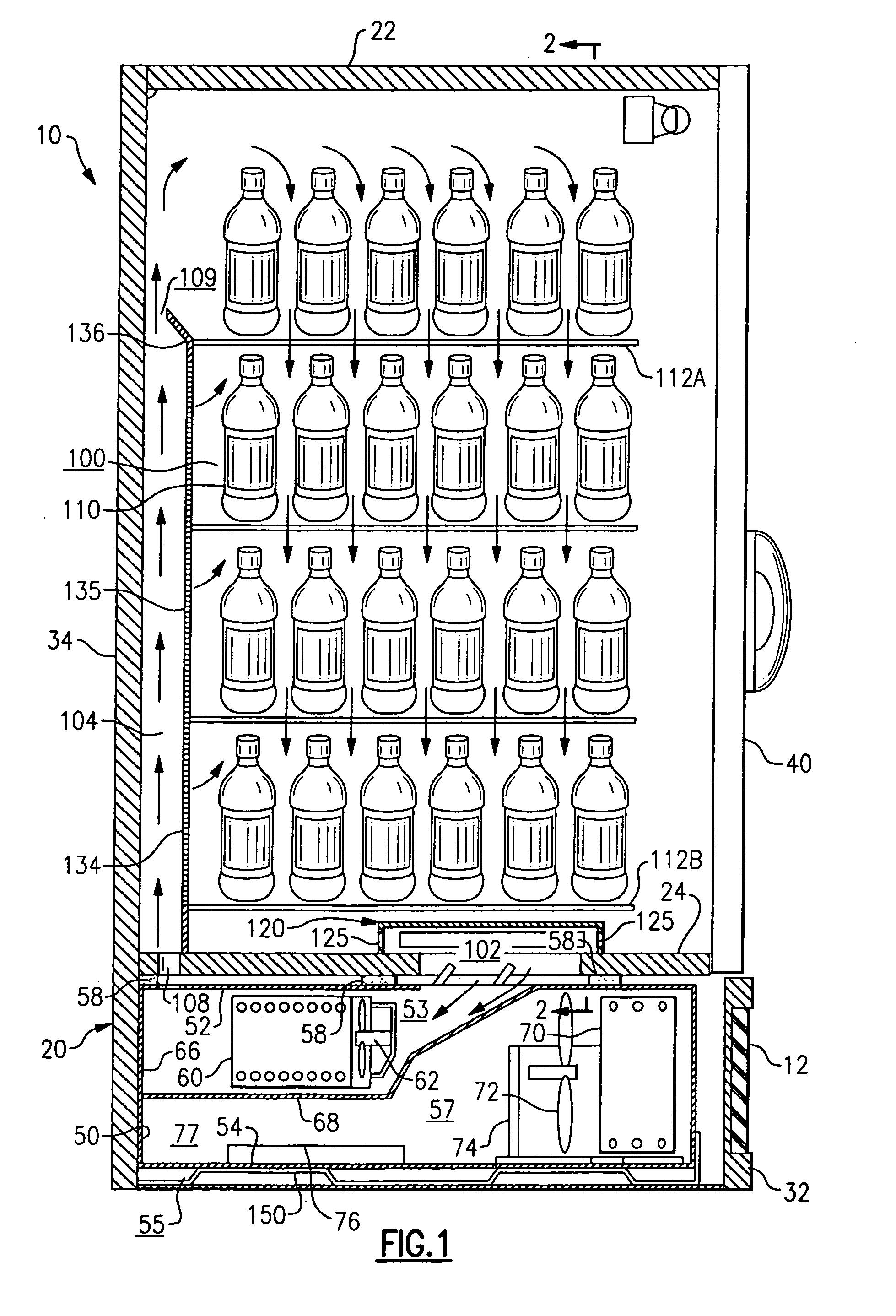

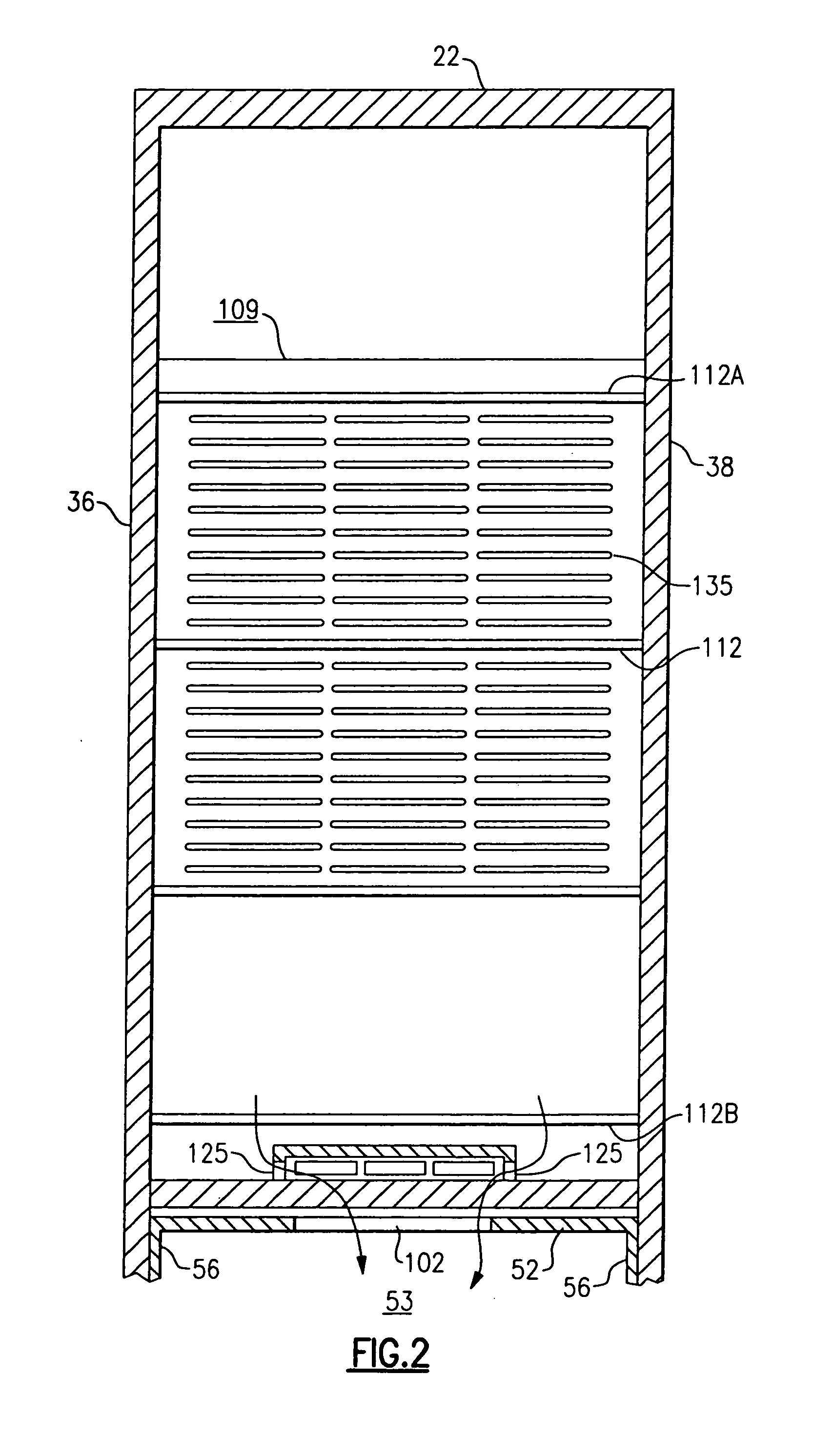

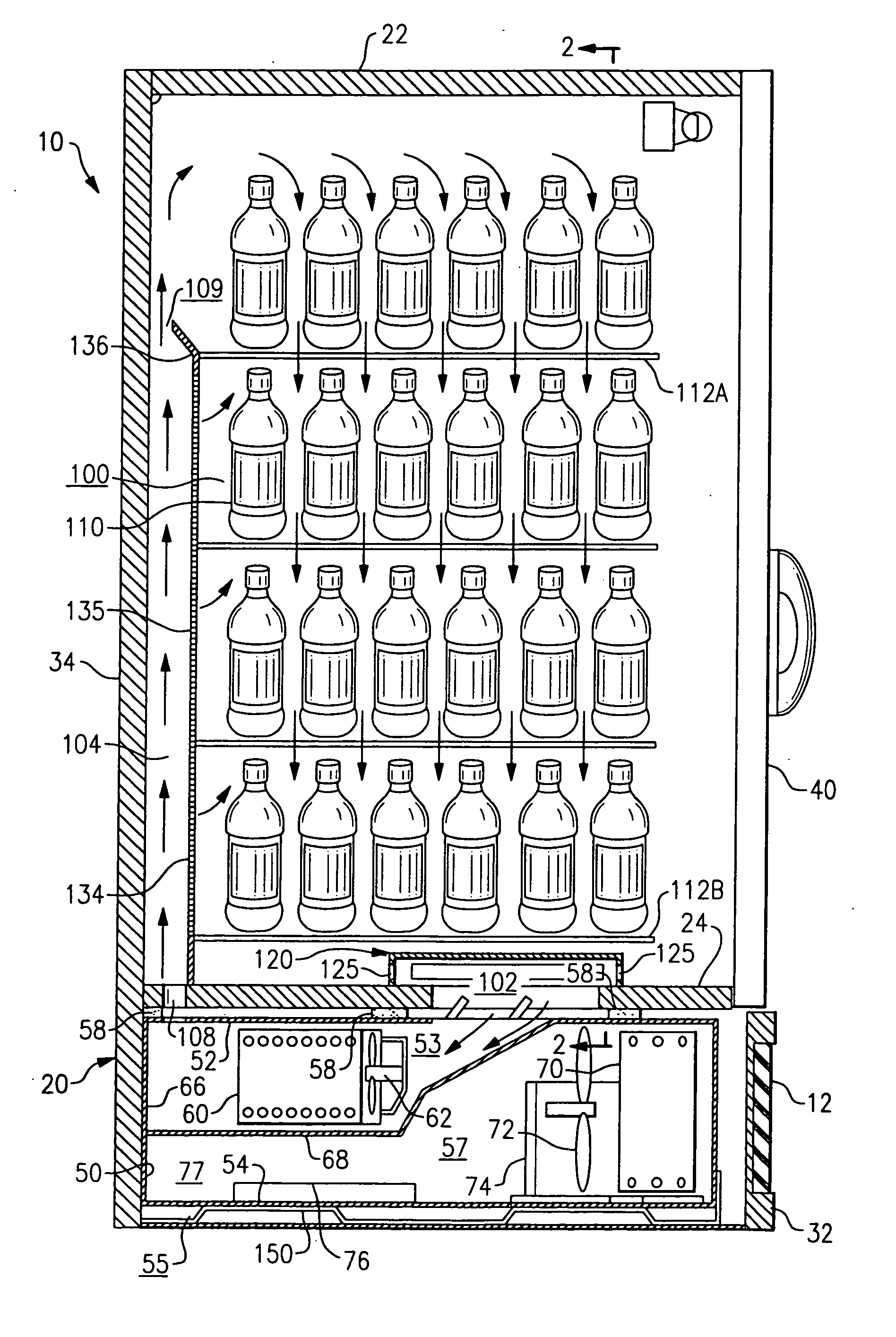

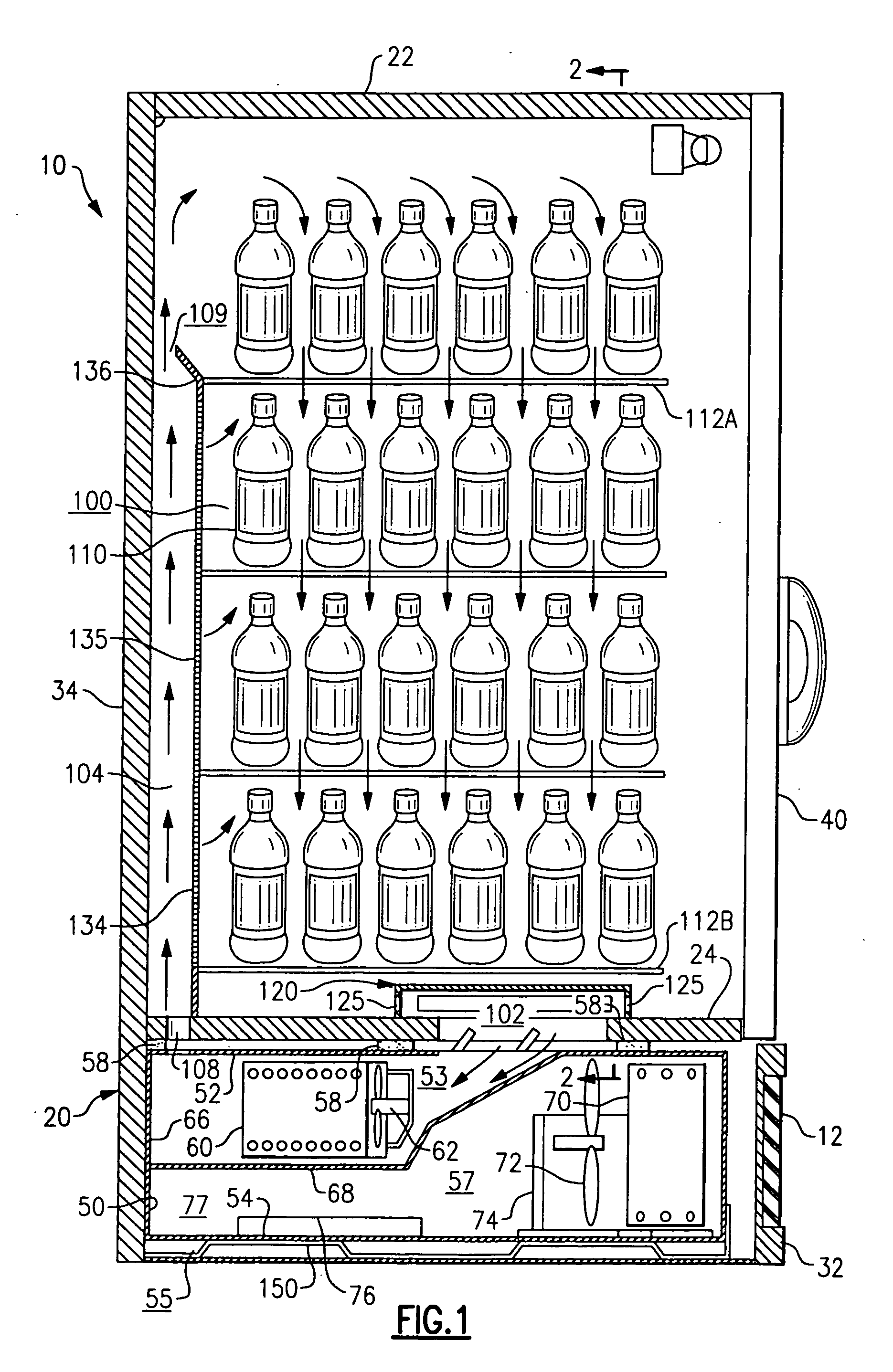

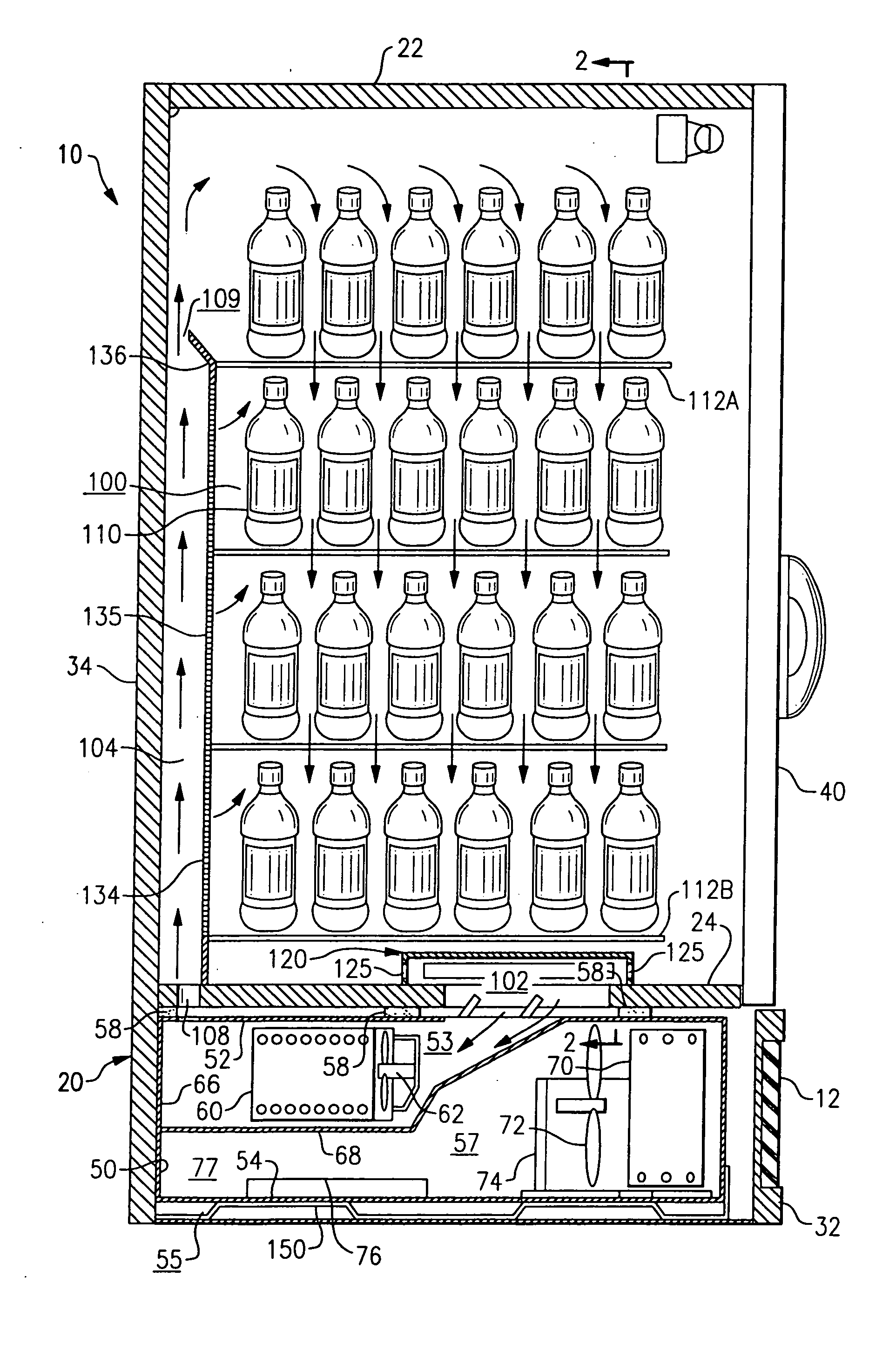

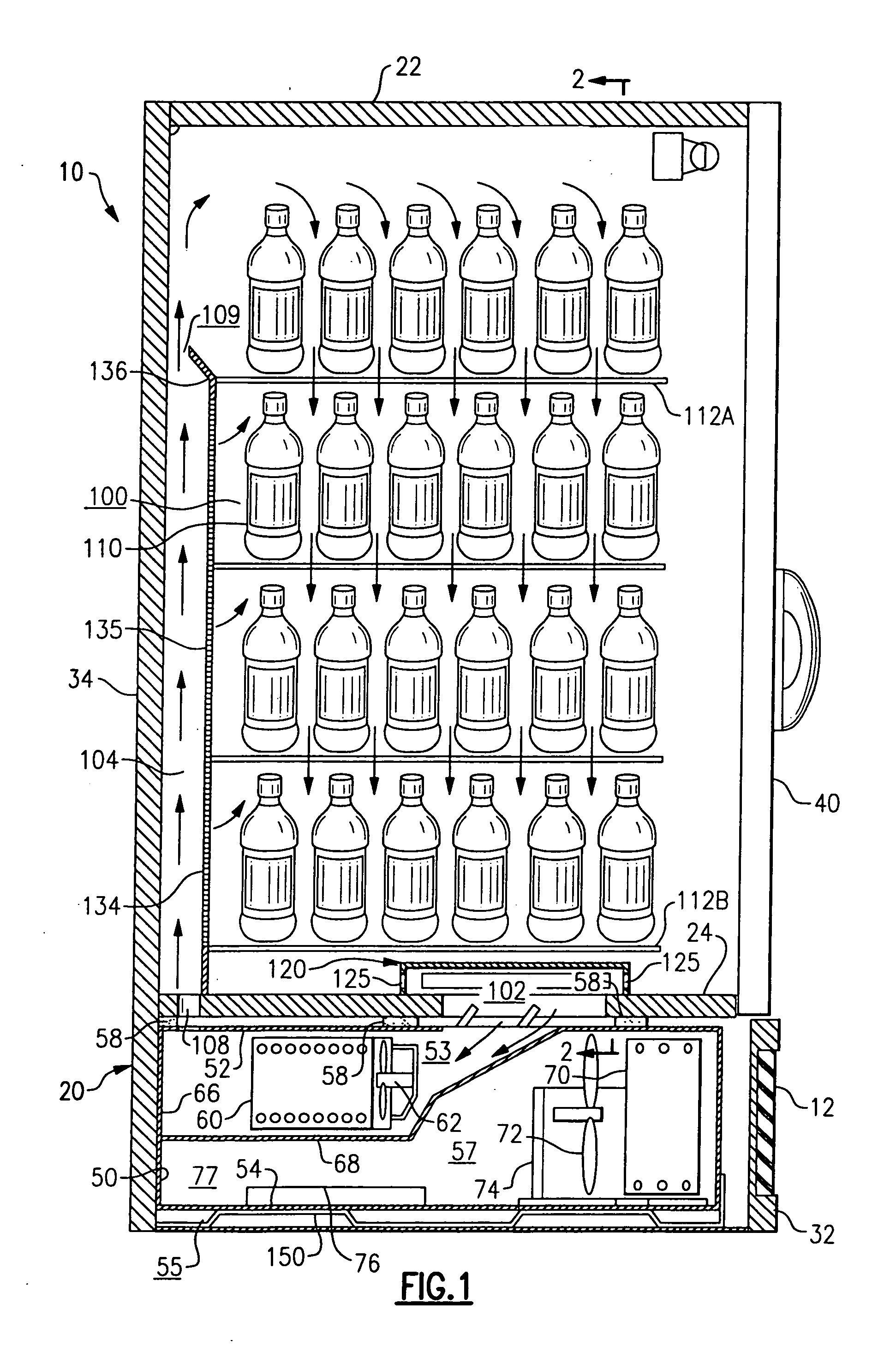

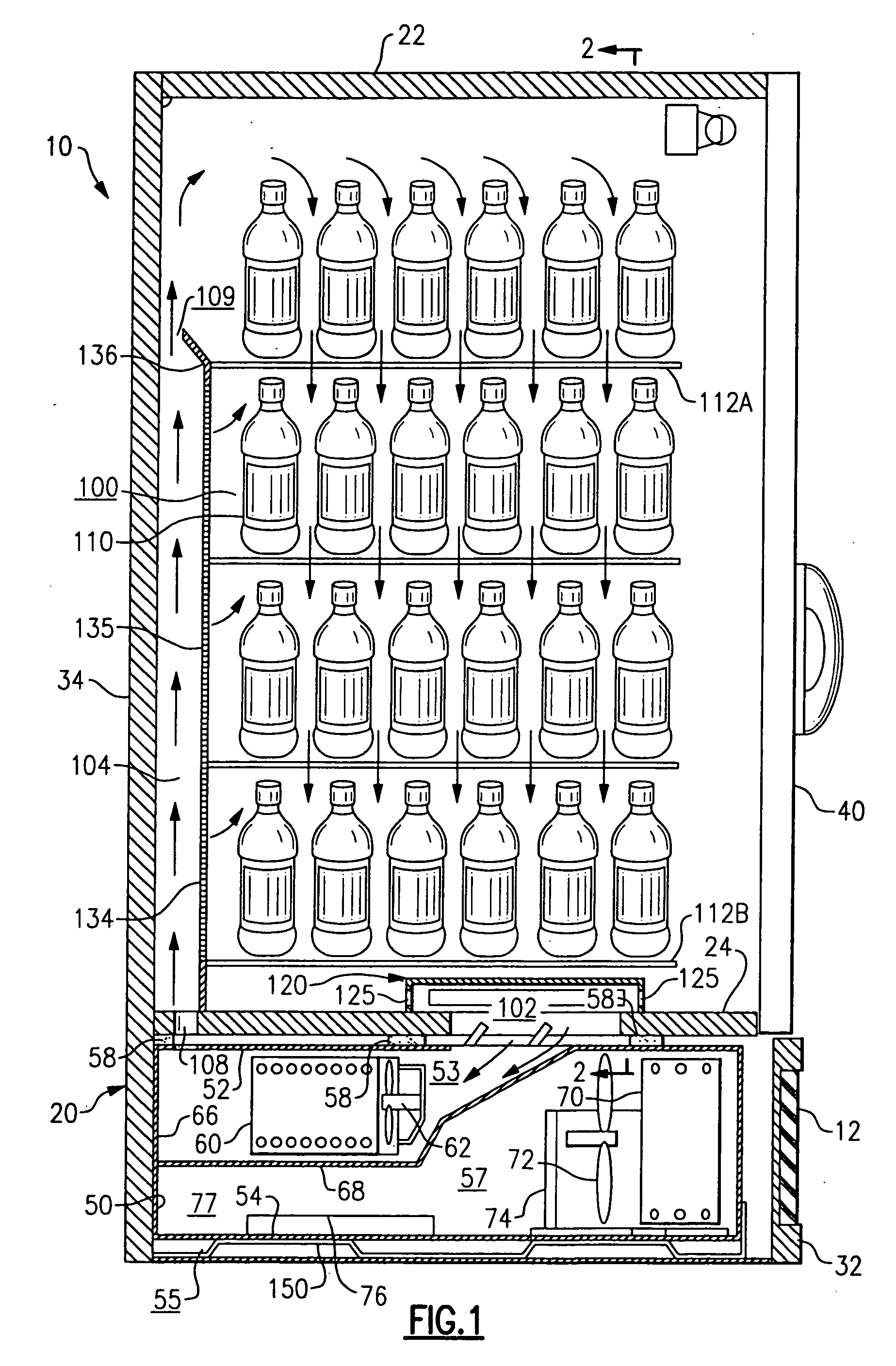

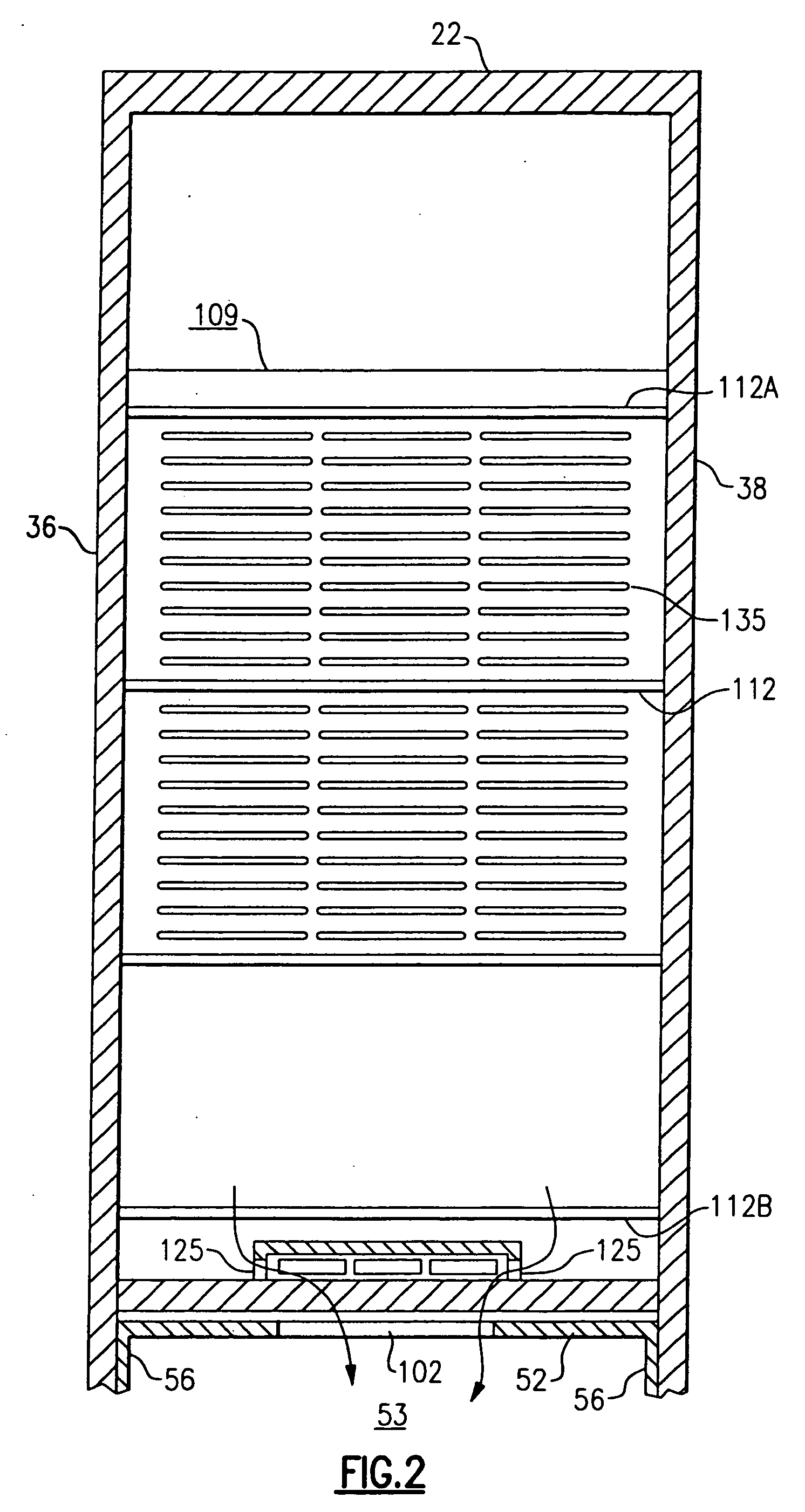

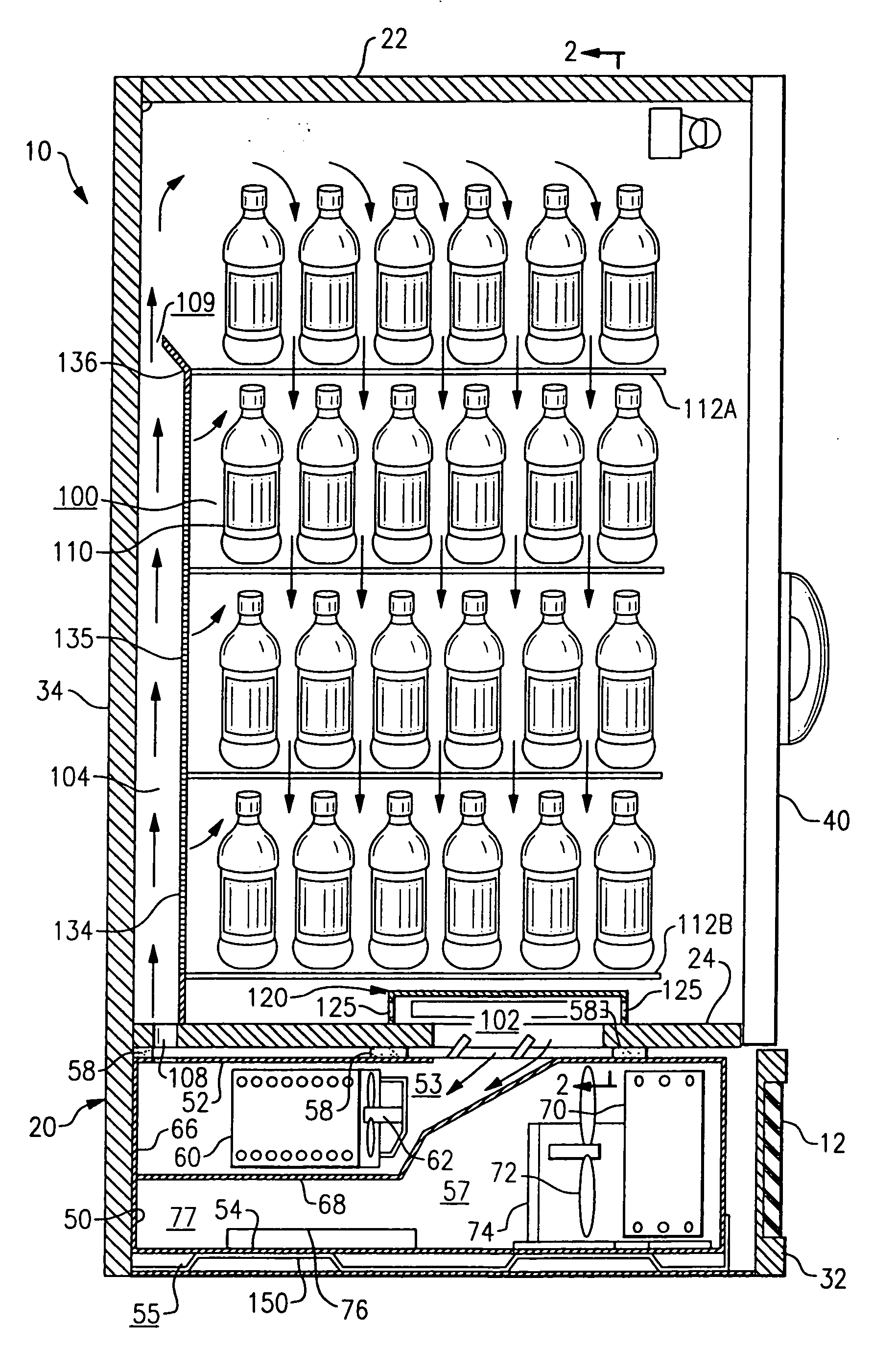

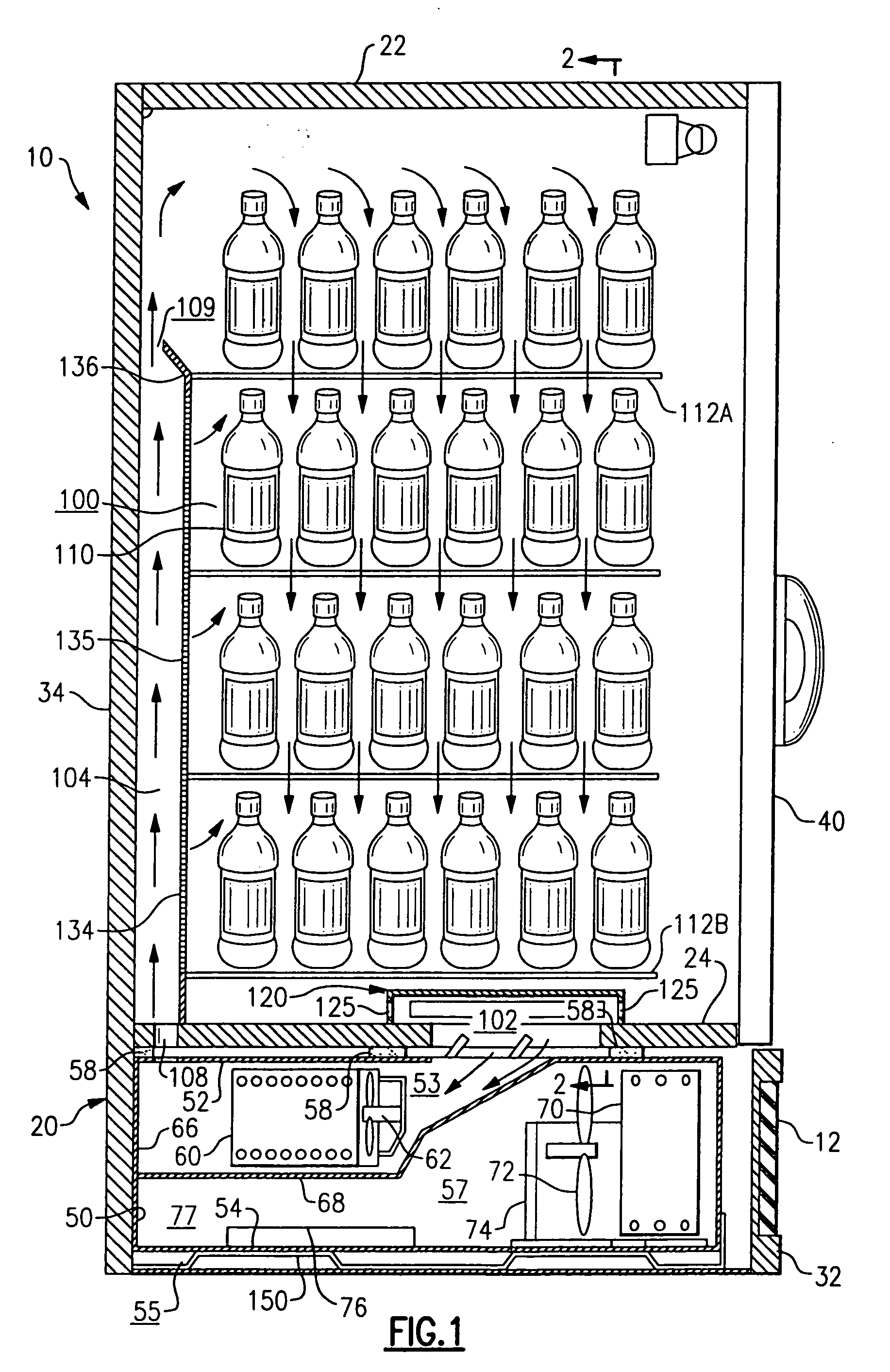

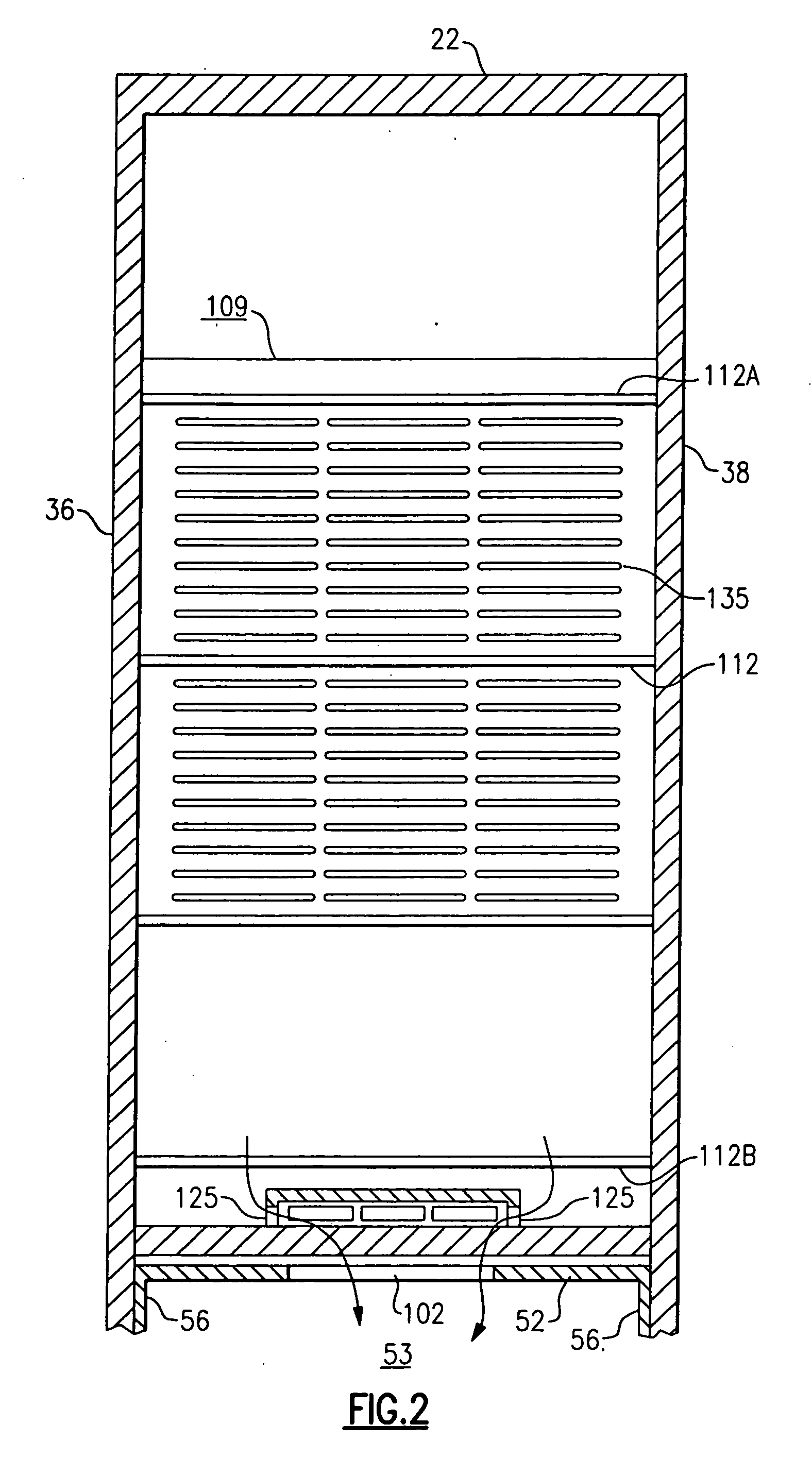

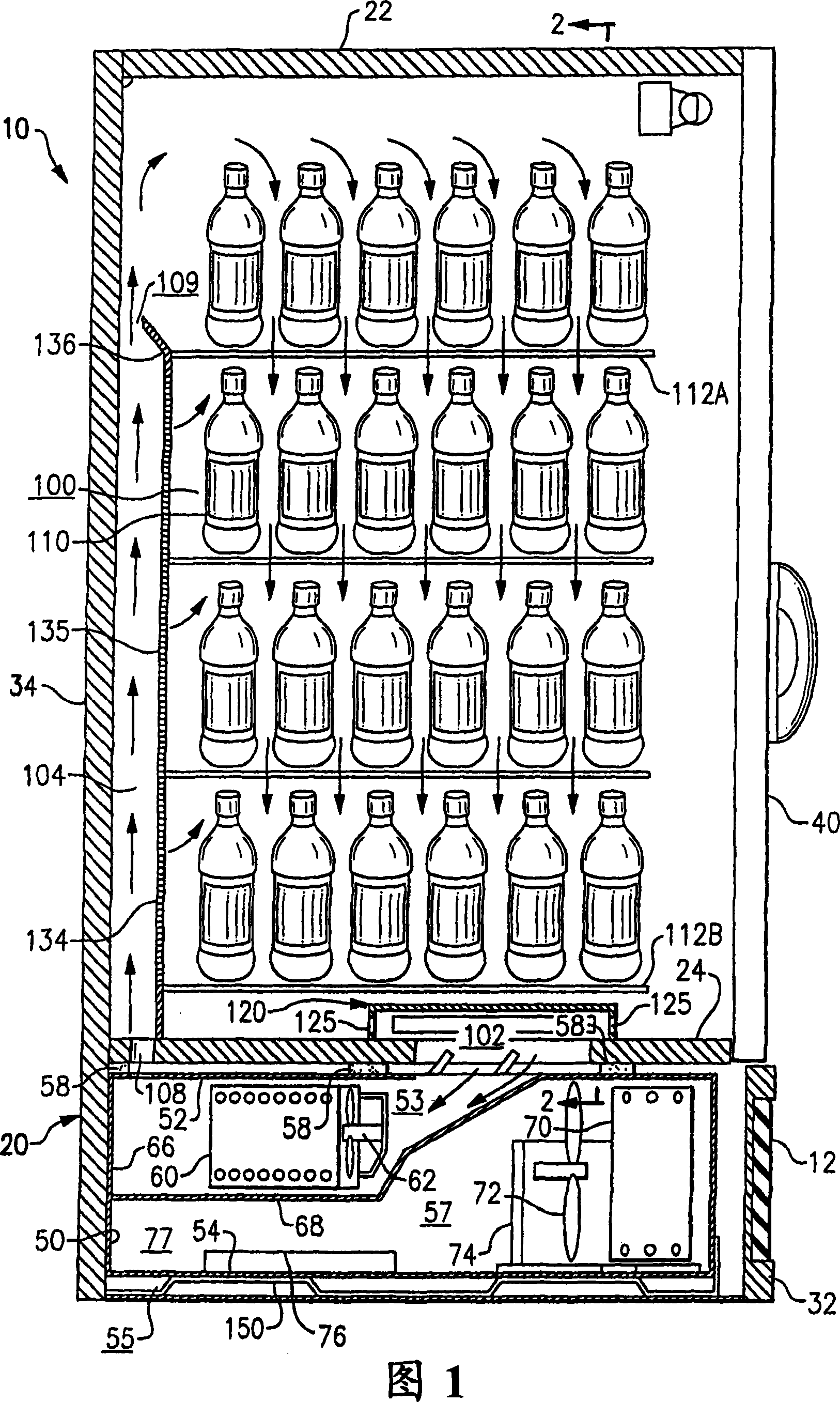

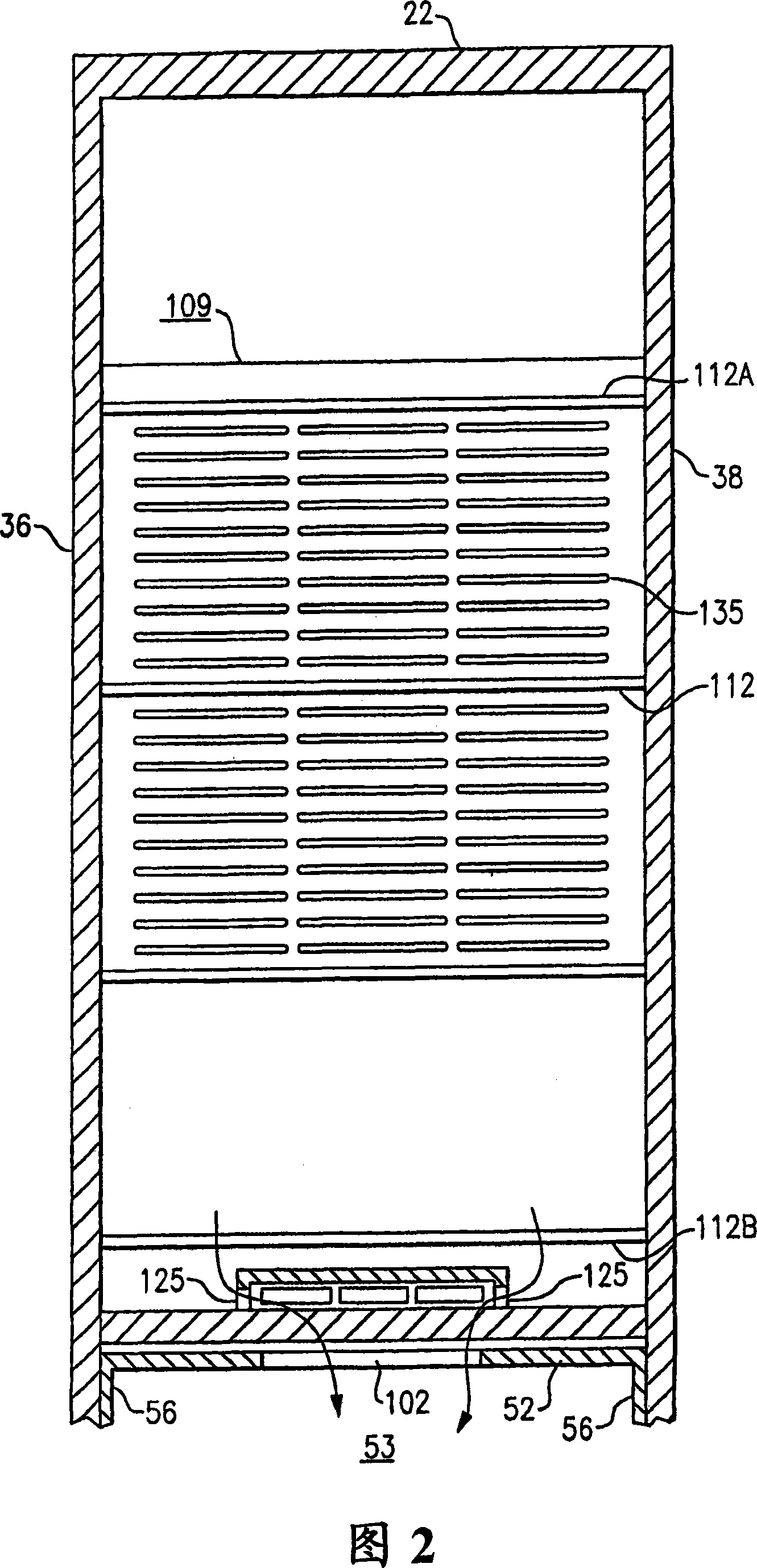

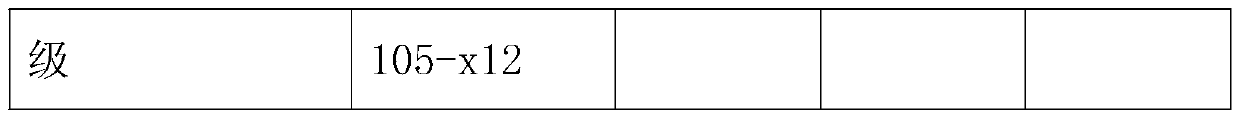

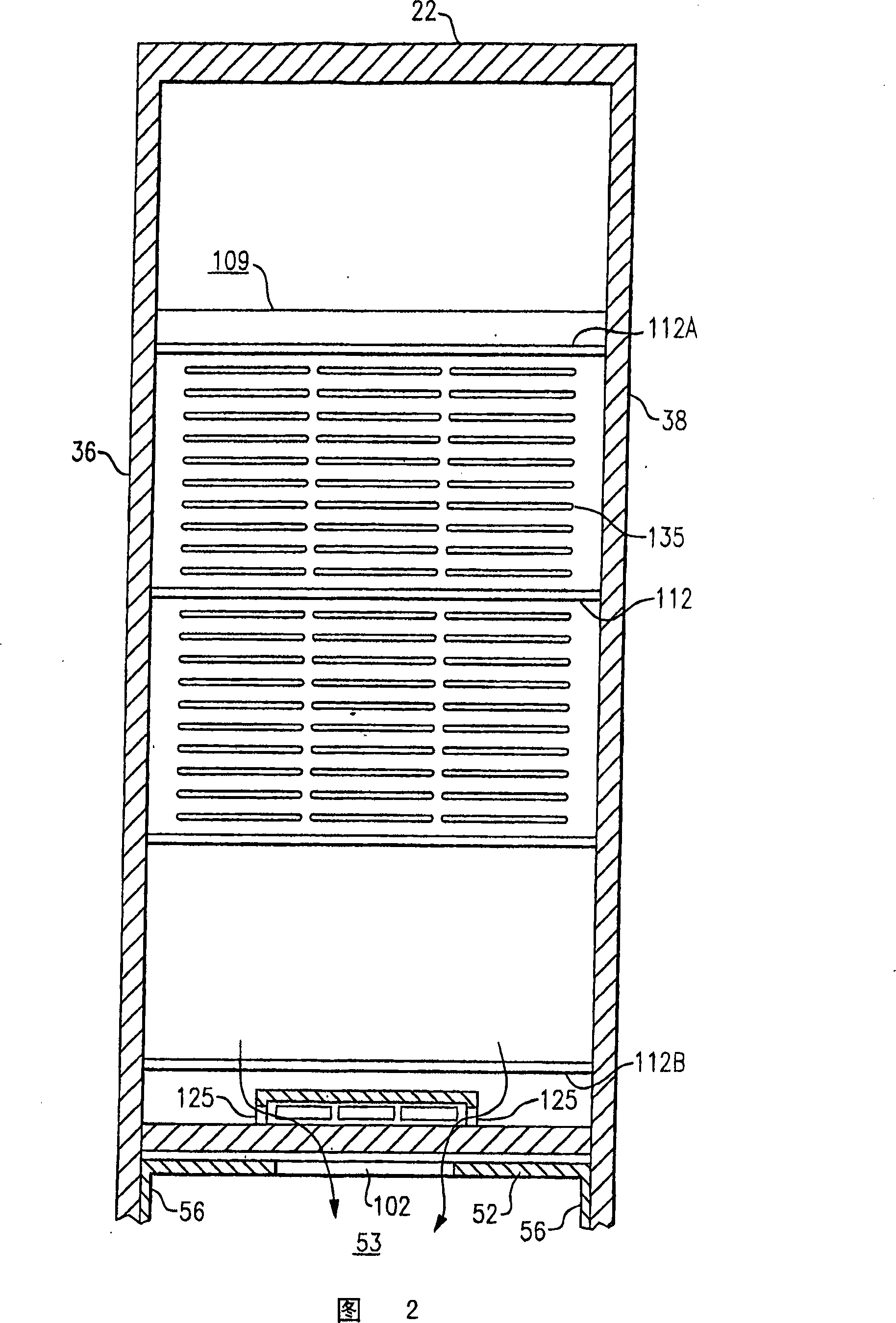

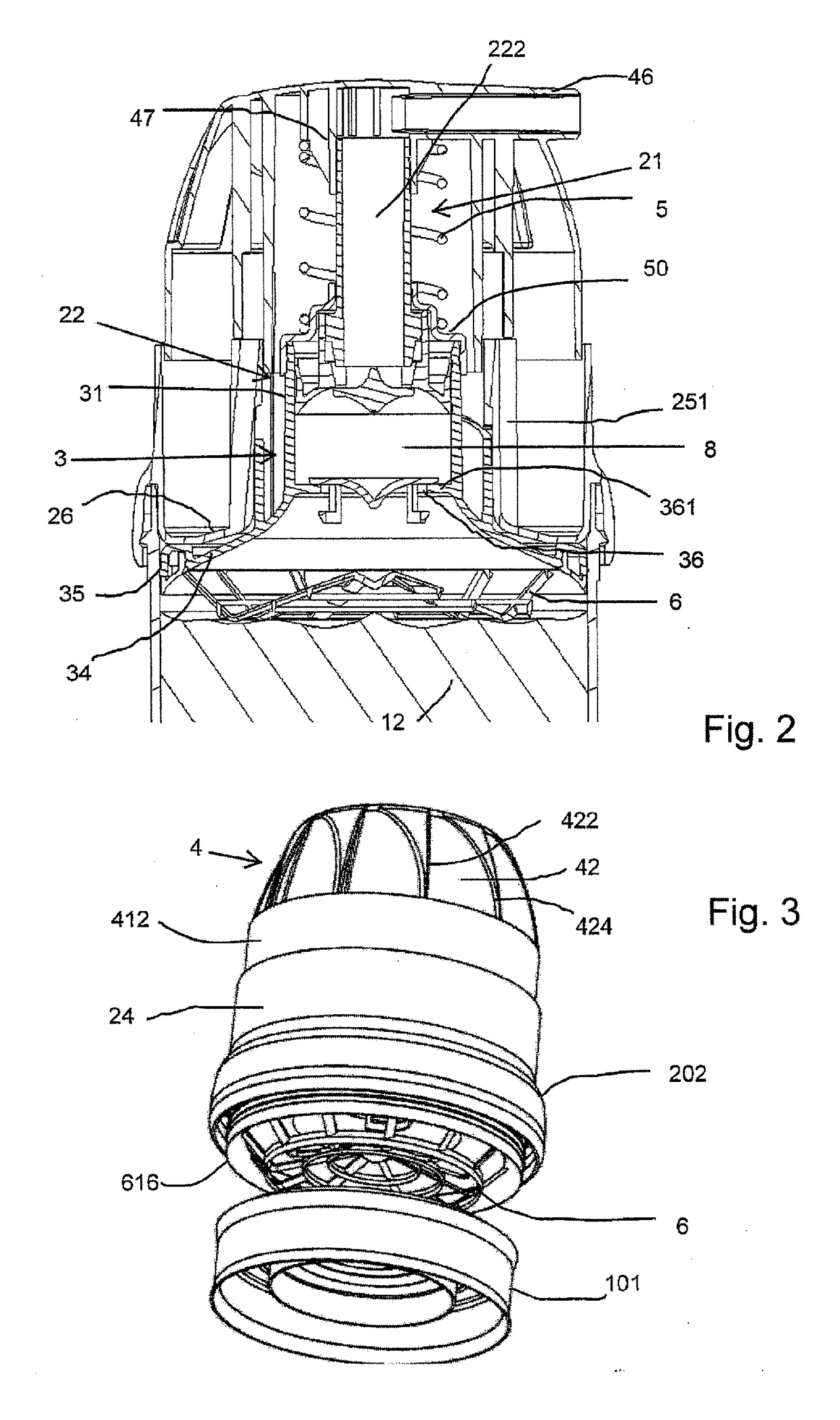

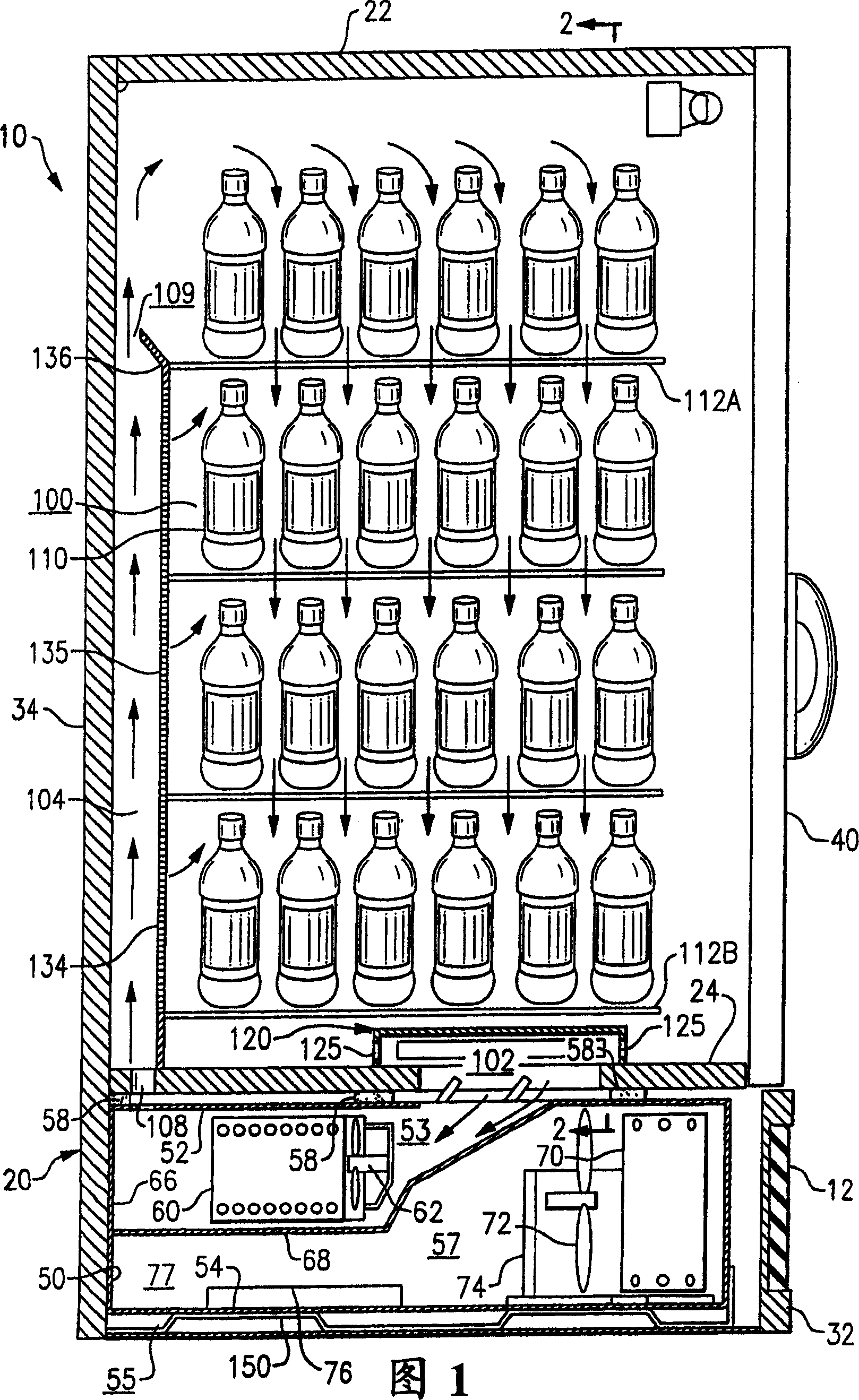

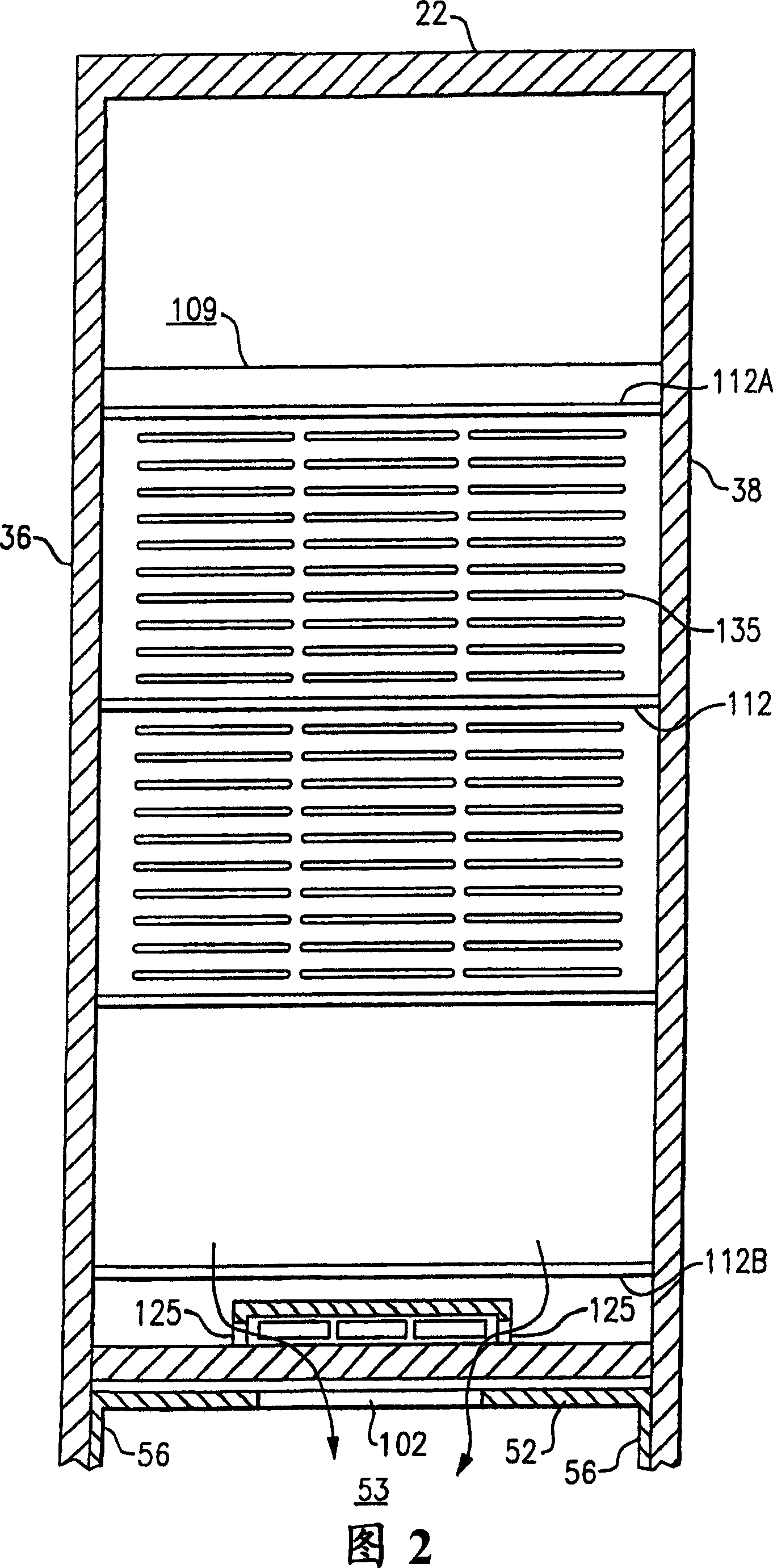

Refrigerated merchandiser

InactiveUS20060207279A1Reduce CooldownReduce variationShow cabinetsLighting and heating apparatusInterior spaceEngineering

A refrigerated merchandiser has a cabinet defining an interior product display space. A generally vertically extending air supply duct at the rear of the cabinet has an inlet for receiving the refrigerated air and an outlet at its upper end for passing the refrigerated air from the air supply duct into an upper region of the interior space along the top wall of cabinet. An evaporator fan in a compartment beneath the interior space draws air flow downwardly through the product display space and through a return air inlet in the lower wall separating the compartment from the interior space. A flow baffle may be disposed in the upper region of the interior space for directing the air downwardly into the interior space to pass through the product displayed therein and out the air return outlet in the lower wall.

Owner:CARRIER CORP

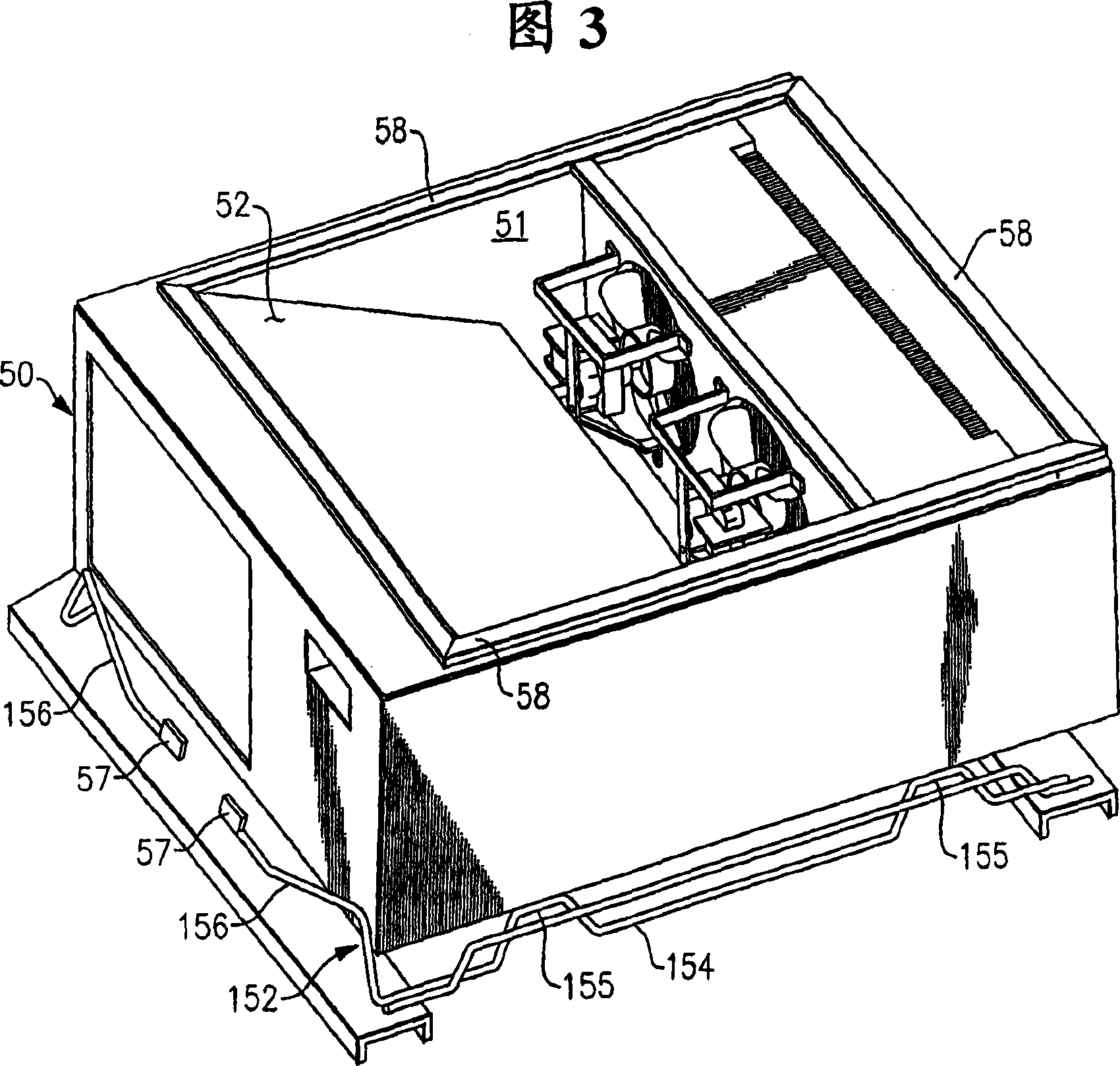

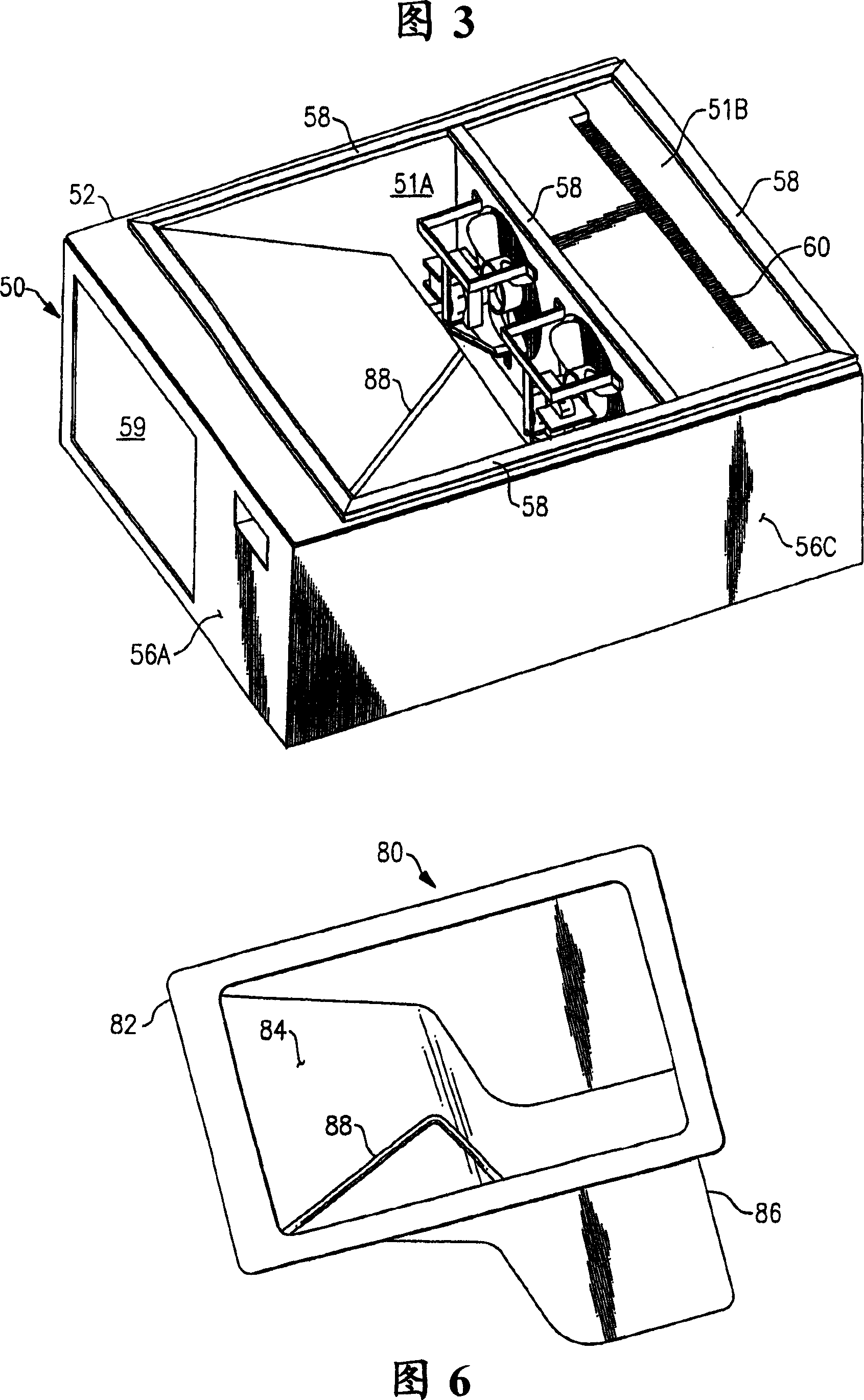

Modular refrigeration cassette with condensate evaporative tray

InactiveUS20060207278A1Speed up evaporationHigh speedShow cabinetsRefrigeration devicesInterior spaceRefrigeration

The interior space within a refrigeration unit cassette associated with a refrigerated merchandiser is divided by a division wall (68) into a first section in air flow communication with interior product display space, and a second section isolated from said first section and in fluid flow communication with the environment exterior of the cabinet. An evaporator module (160) is disposed within the first section, and a condenser module (170) is disposed within the second section. The division plate has a forward portion sloping downwardly from an upper forward region of the first section to an aft portion thereby forming a converging channel. The aft portion extends generally horizontally in spaced relationship above the base plate forming an exhaust channel. A condensate tray is disposed in the exhaust channel generally beneath the evaporator module to collect condensate draining from the evaporator module.

Owner:CARRIER CORP

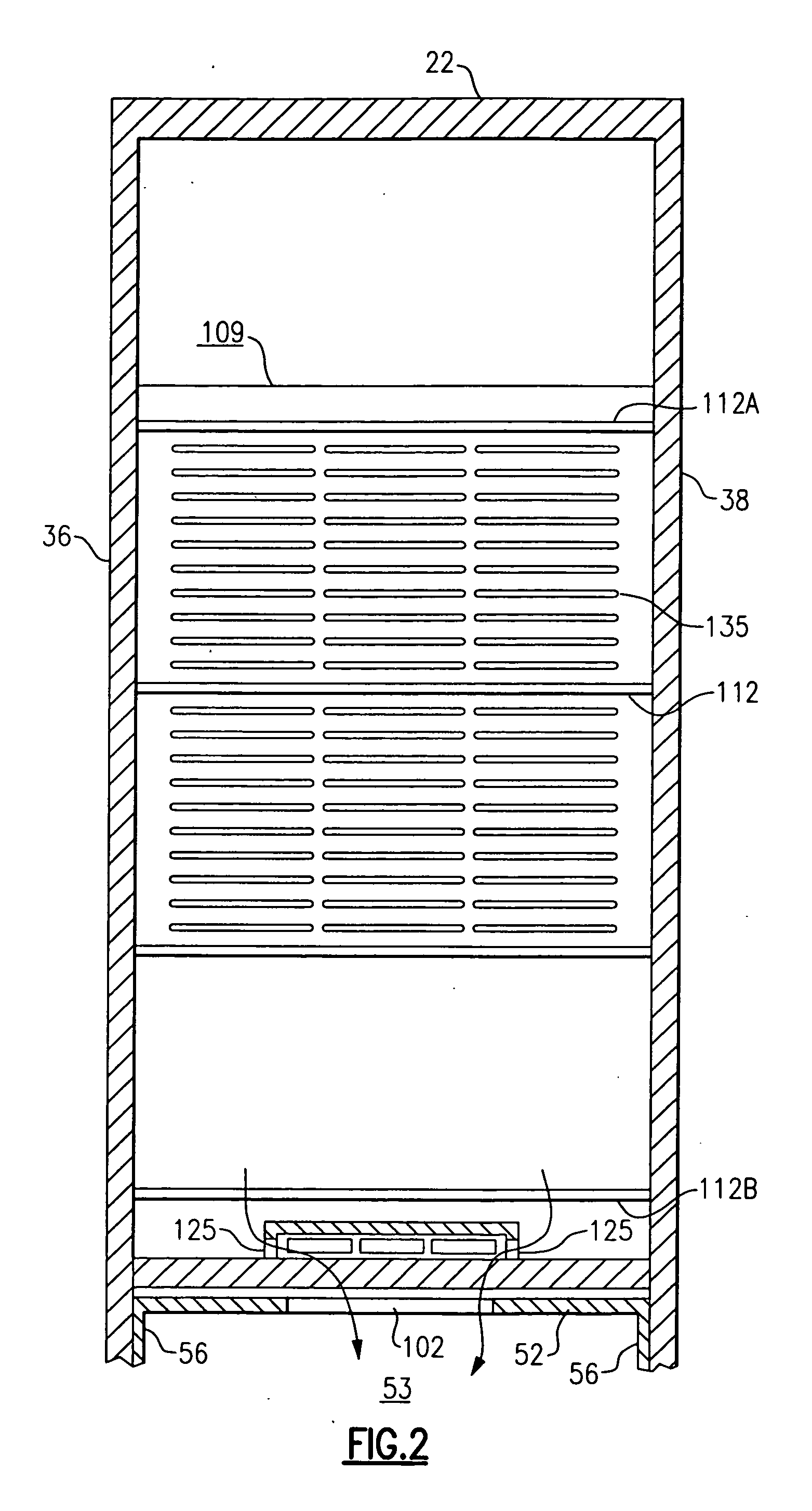

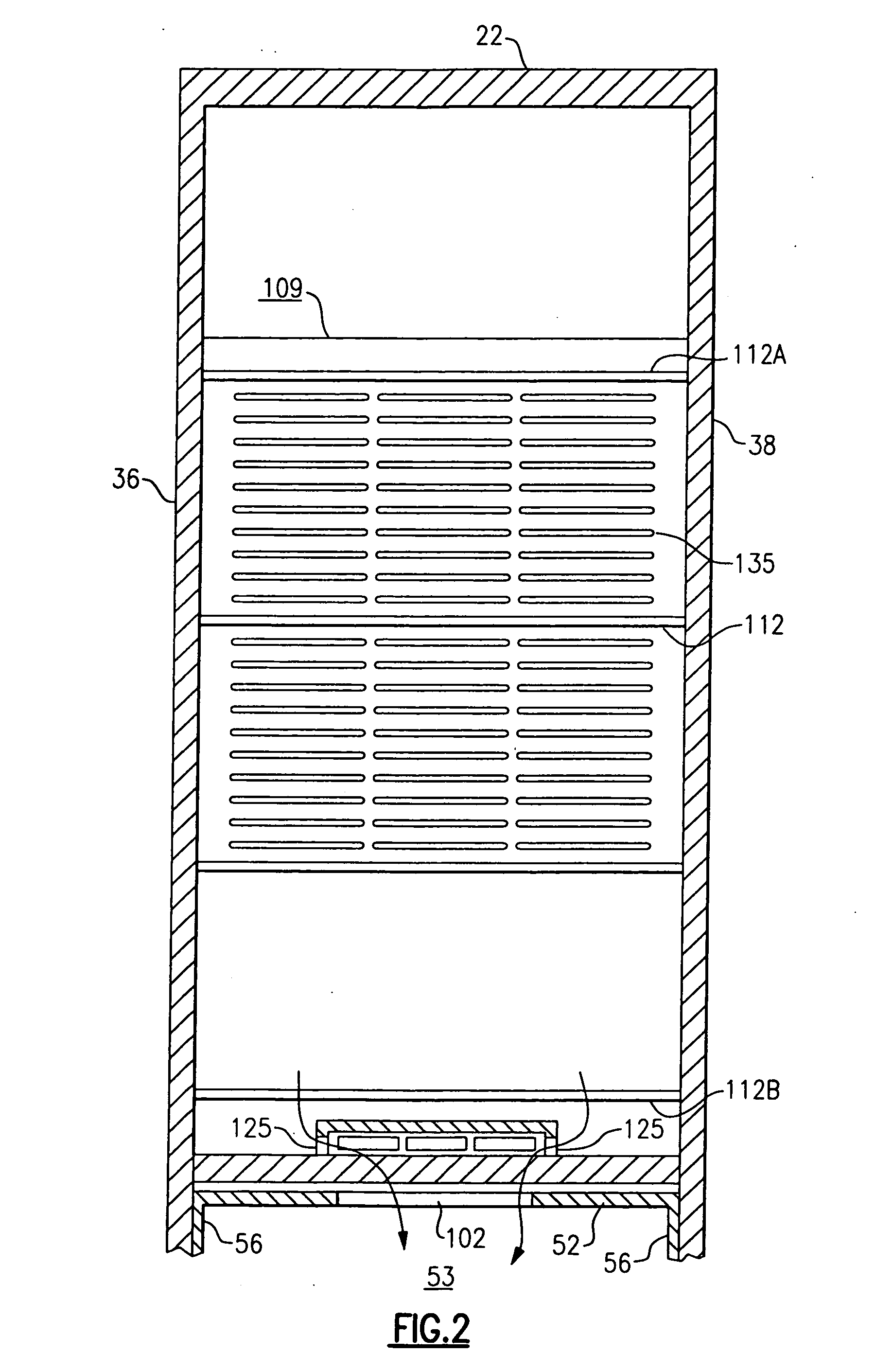

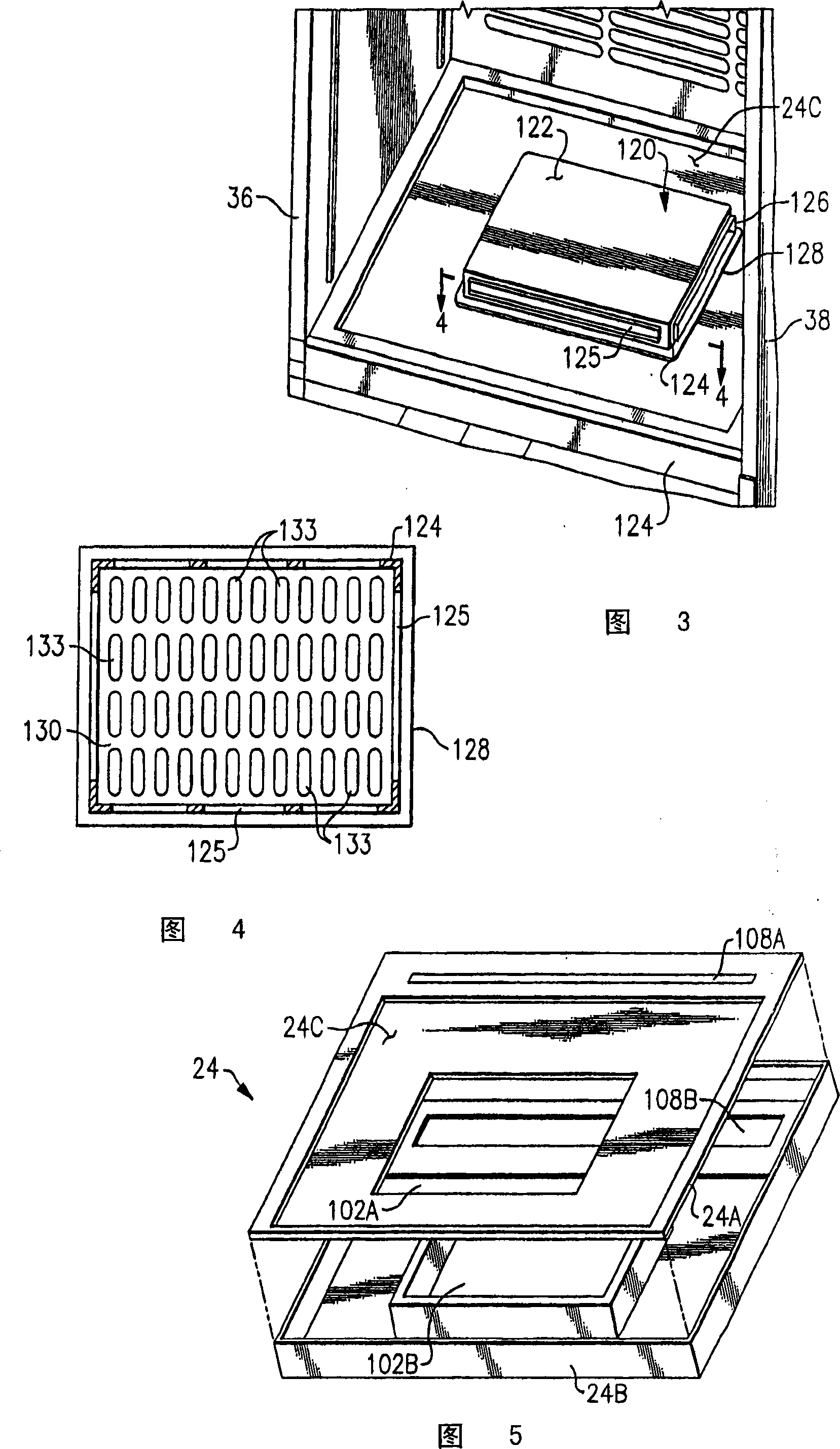

Bottom deck assembly for refrigerated merchandiser

InactiveUS20060207280A1Prevent drainageShow cabinetsLighting and heating apparatusEngineeringRefrigeration

A refrigerated merchandiser (10) includes a cabinet (20) defining an interior product display space (100) and a refrigeration unit (50) is disposed in operative association with the interior product display space in a compartment (55) beneath the lower deck (24). An opening in the lower deck provides an air return inlet (102) establishing a flow passage from the interior product display space (100) to the compartment (55) beneath the lower deck. A cover (120) includes a top plate member (122) disposed superadjacent the return air inlet and a downwardly extending peripheral side flange (124) disposed about the periphery of the top plate member (122). A plurality of air intake ports (125) are provided in the peripheral side flange (124). The lower deck (24) has a recessed upper surface (124C) facing the product display space (100). A grille plate (130) extends across the air return inlet.

Owner:CARRIER CORP

Sealing system for refrigeration cassette

InactiveUS20060207276A1Easy to disassembleShow cabinetsLighting and heating apparatusEngineeringRefrigeration

A refrigerated merchandiser (10) includes a cabinet (20) having a top wall (22), a lower wall (24), a rear wall (34), and side walls (36, 38) defining an interior product display space (100) housing a product (110) in a refrigerated environment for consumer selection. A refrigeration unit (50) is disposed in operative association with the interior product display space in a compartment (55) beneath the lower wall (24). A first opening in the lower wall provides an air return inlet (102) establishing a flow passage from the interior product display space (1000 to the compartment (55) beneath the lower wall. A sealing member (58) is disposed between the under surface of the lower wall (24) and the upper surface of the refrigeration unit cassette (50) about the first opening; and a positioning apparatus (150) for raising the refrigeration unit cassette (50) unit into sealing relationship with the lower wall.

Owner:CARRIER CORP

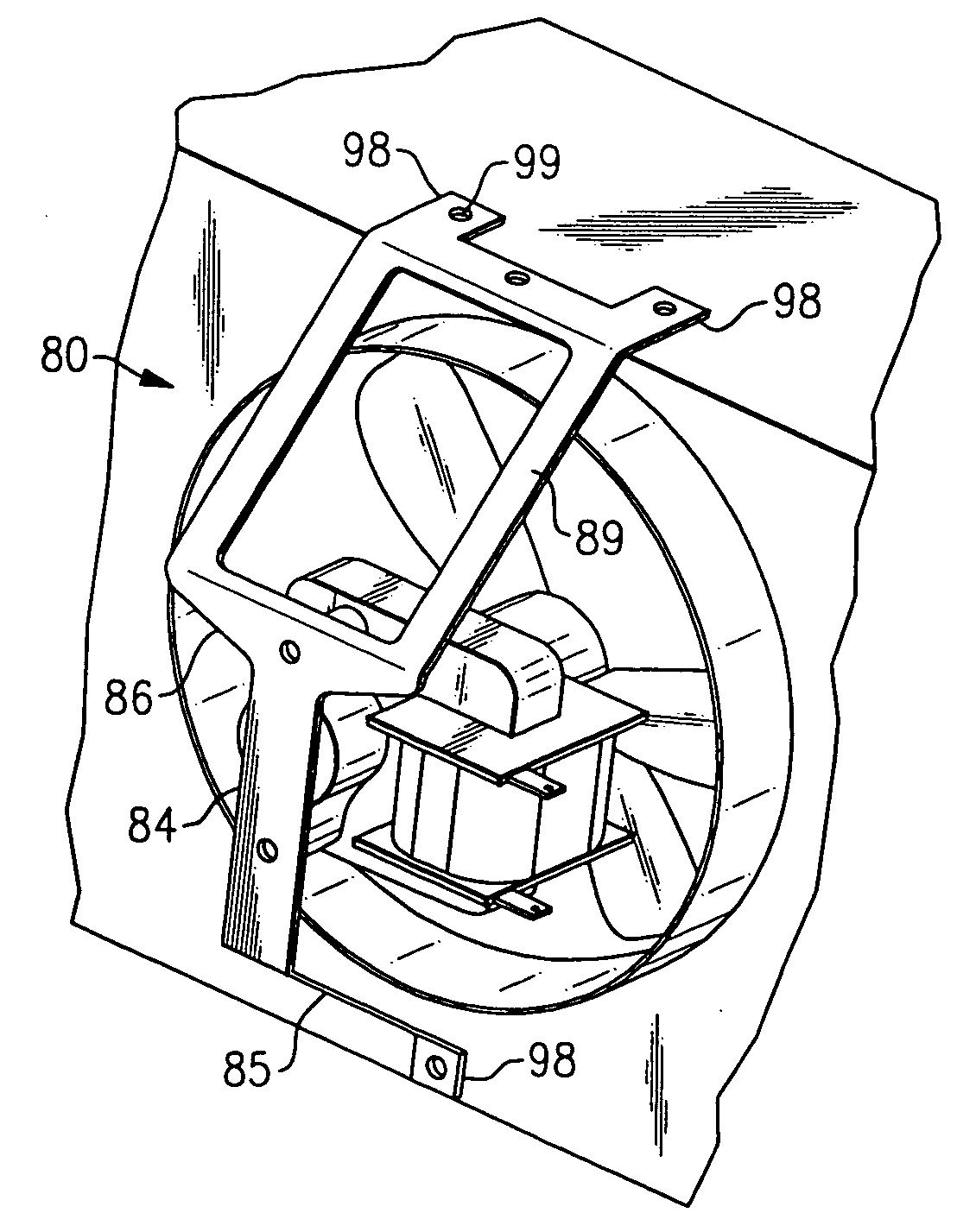

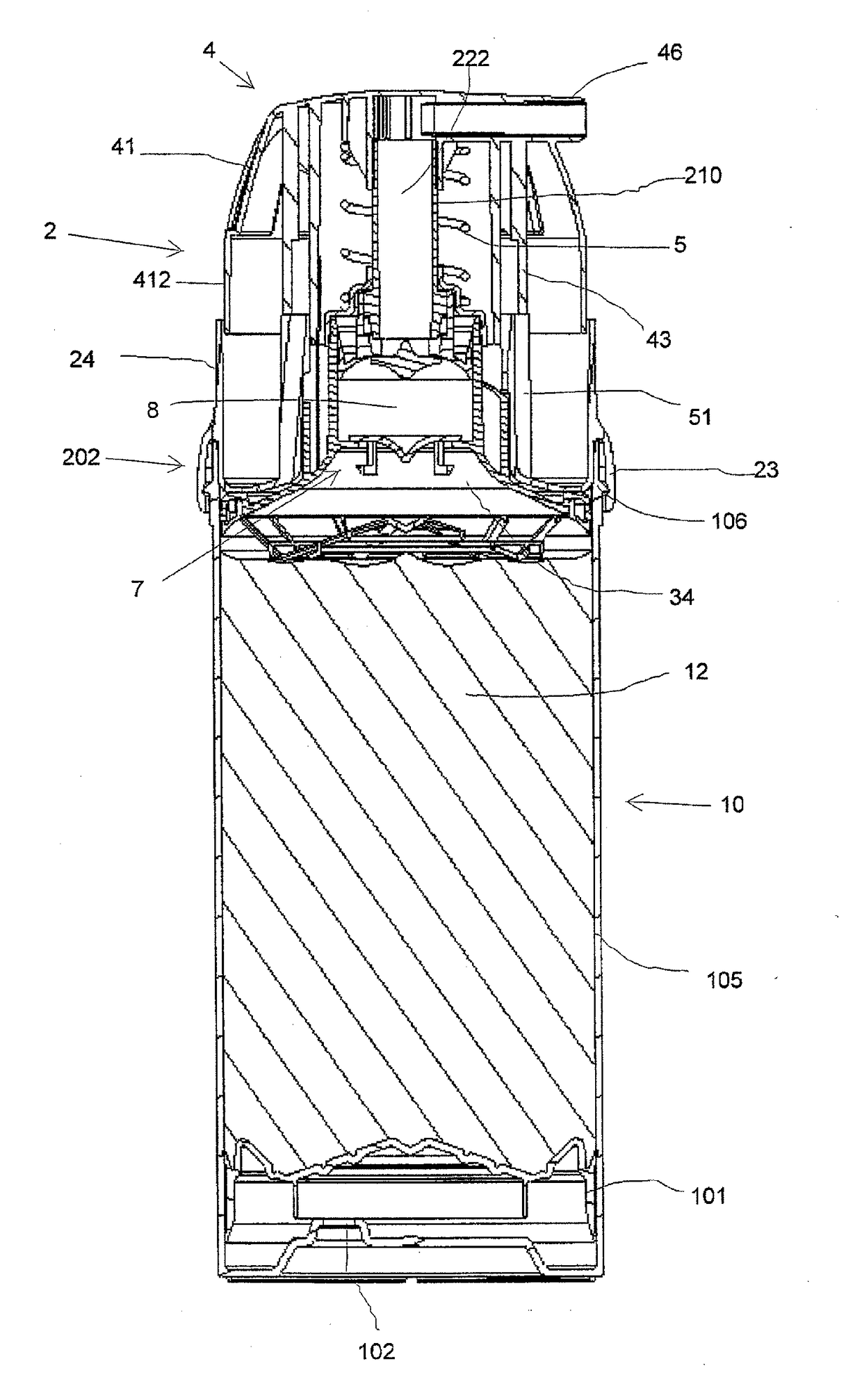

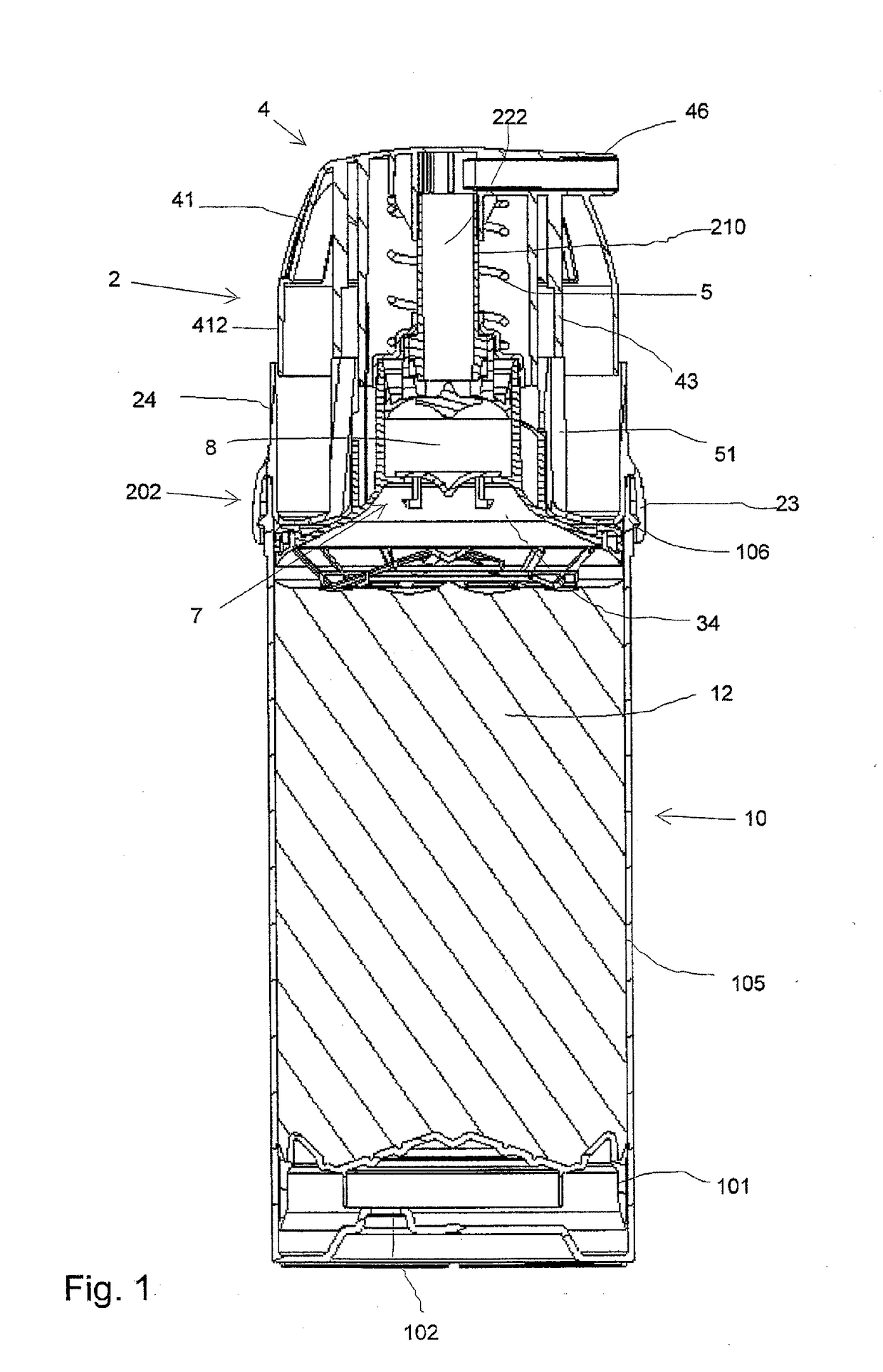

Evaporator fan/motor assembly support bracket

InactiveUS20060210396A1Low drag characteristicLow noise characteristicsMachine framesPump componentsElectric machineryEngineering

A refrigerated merchandiser (10) includes a cabinet (20) having a top wall (22), a lower wall (24), a rear wall (34), and side walls (36, 38) defining an interior product display space (100) housing a product (110) on shelves (112) in a refrigerated environment intended for selection by consumers. A refrigeration unit cassette (50) is disposed in operative association with the interior product display space in a compartment (55) beneath the lower wall (24). An evaporator fan (63) and its associated fan motor (61) are supported by a bracket (80) having a generally T-shaped body (82) with three legs (85, 87, 89) extending therefrom and mounted to a housing (96) of an evaporator (60) housed within the refrigeration unit cassette (50).

Owner:CARRIER CORP

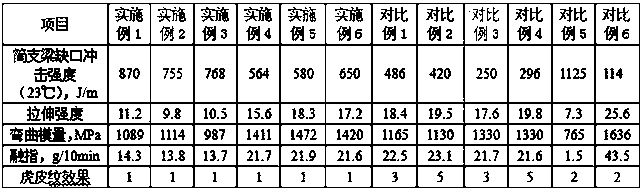

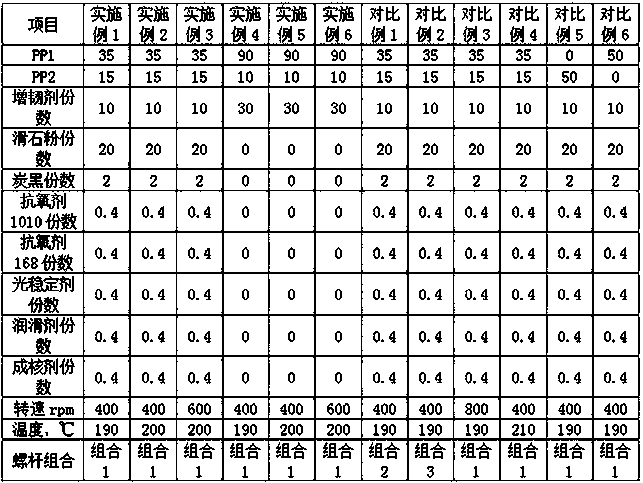

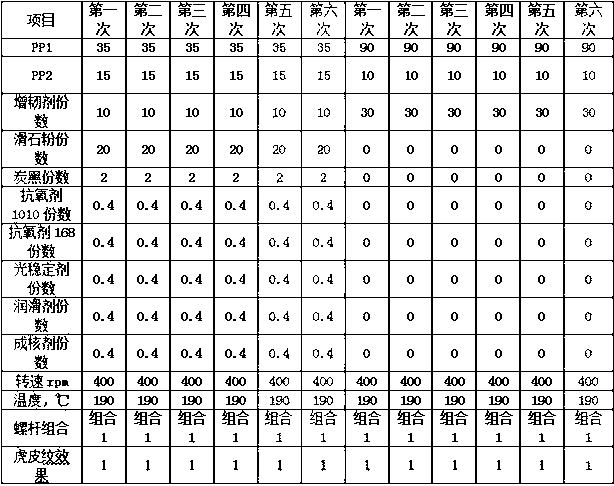

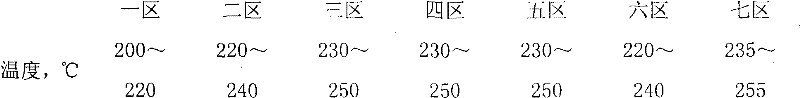

Method for eliminating tiger skin defect of polypropylene composition and polypropylene composition prepared thereby

The invention discloses a method for eliminating a tiger skin defect of a polypropylene composition and the polypropylene composition prepared thereby. The polypropylene composition comprises polypropylene resin, a toughening agent, a filler, a pigment and an auxiliary agent, wherein the polypropylene resin is formed by compounding high-flow polypropylene with the melt mass flow rate (MFR) of 30-120g / 10min and low-flow polypropylene with the melt mass flow rate (MFR) of 0.1-29g / 10min. By a preparation method, through a combined design of screws and adjustment of extrusion process parameters, the tiger skin defect of the prepared polypropylene composition can be eliminated; in addition, the preparation technology is stable and the repeatability is good. The polypropylene composition prepared by the method provided in the invention can be applied to automotive bumpers and interior products.

Owner:KINGFA SCI & TECH CO LTD +1

Modular refrigeration cassette

InactiveUS20060207277A1Reduce airflow lossGood chemical resistanceShow cabinetsRefrigeration devicesInterior spaceModularity

The interior space within a refrigeration unit cassette (50) associated with a refrigerated merchandiser (10) is divided by a division wall (68) into a first section in air flow communication with the interior product display space of the cabinet (20), and a second section isolated from said first section and in fluid flow communication with the environment exterior of the cabinet. An evaporator module (160) disposed within the first section, and a condenser module (170) and a compressor are disposed within the second section. The refrigeration cassette (50) is selectively insertable in to and out of the equipment compartment to facilitate servicing of the refrigeration equipment therein, including removal and replacement of the evaporator module (160) and the condenser module (170).

Owner:CARRIER CORP

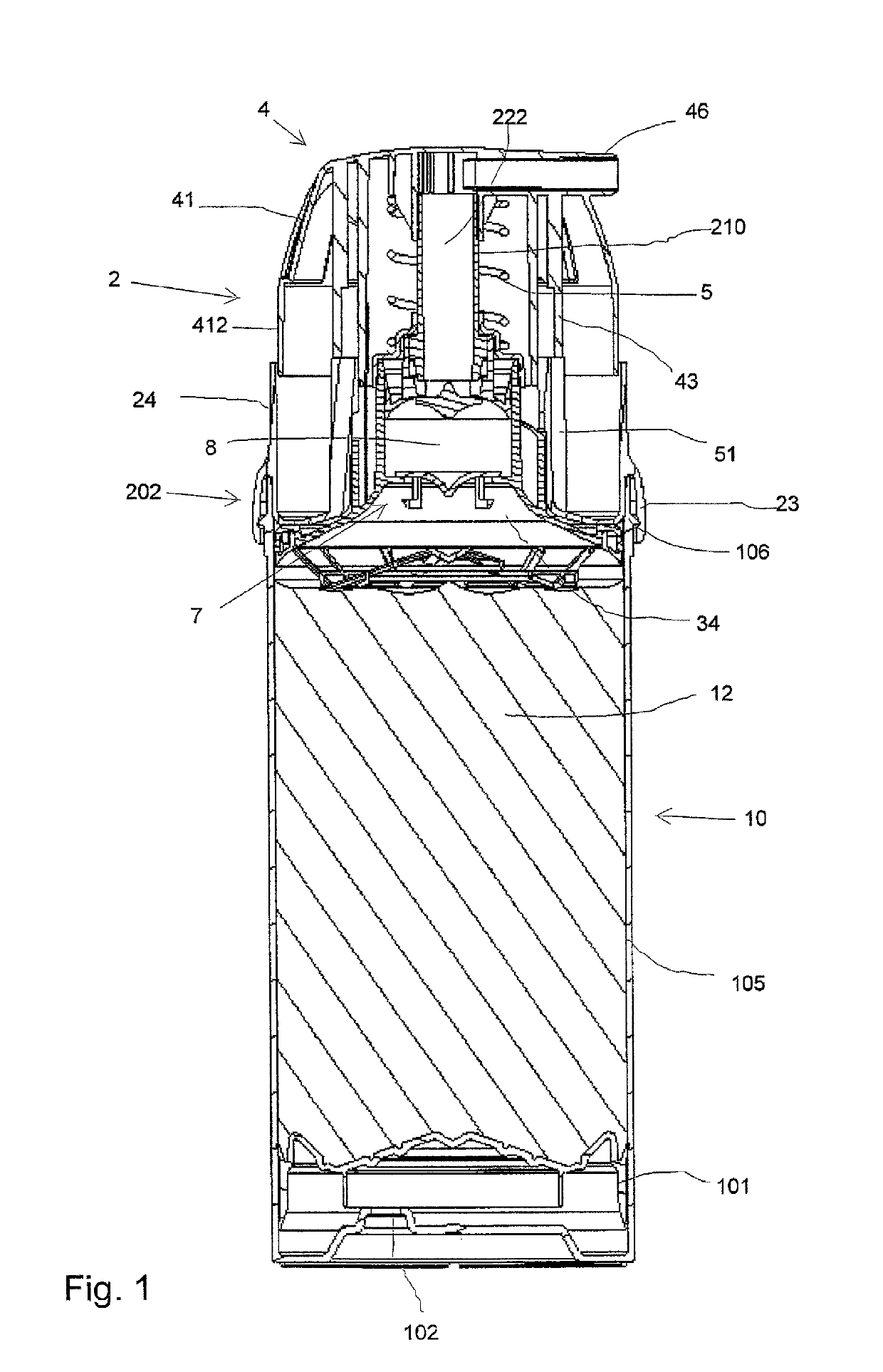

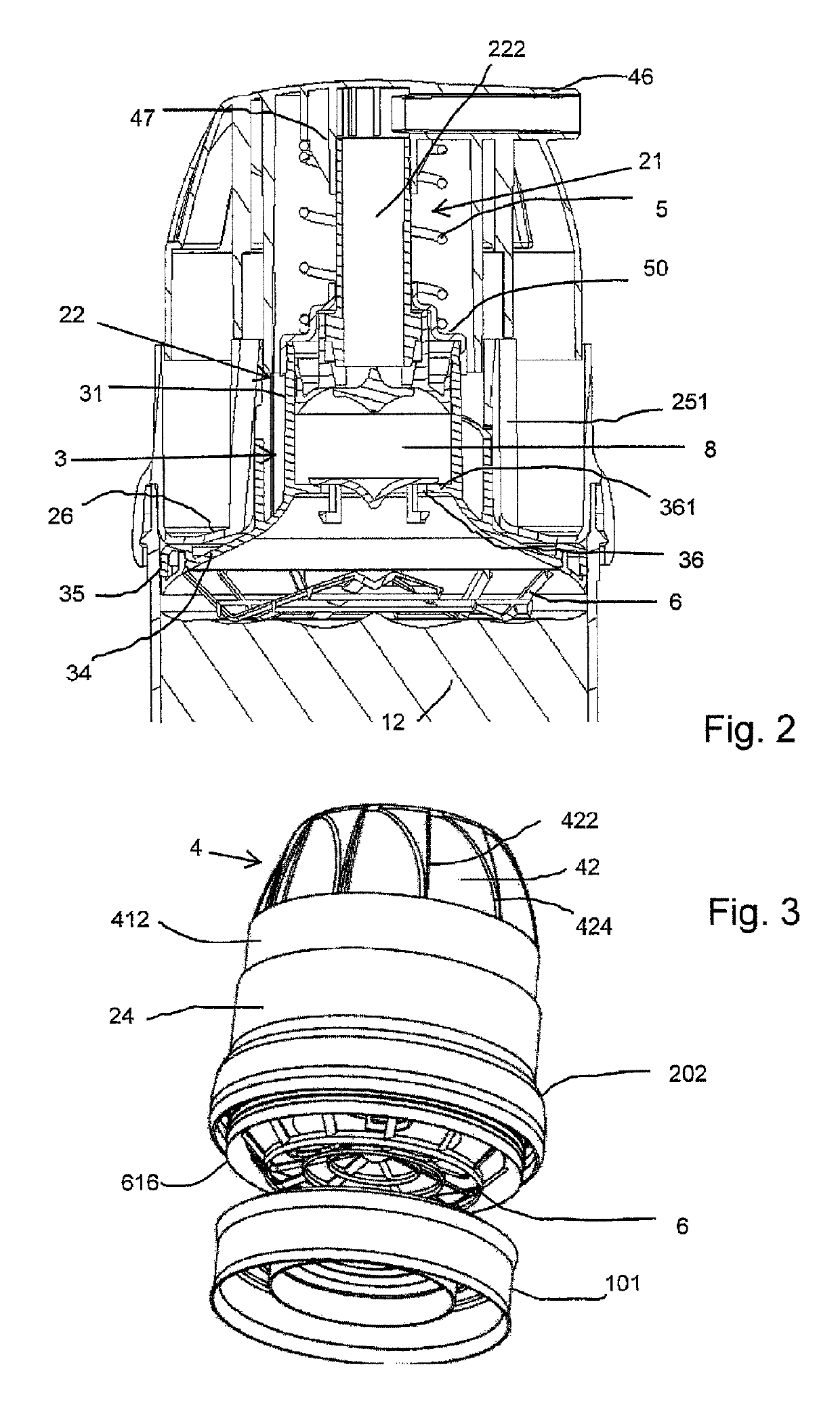

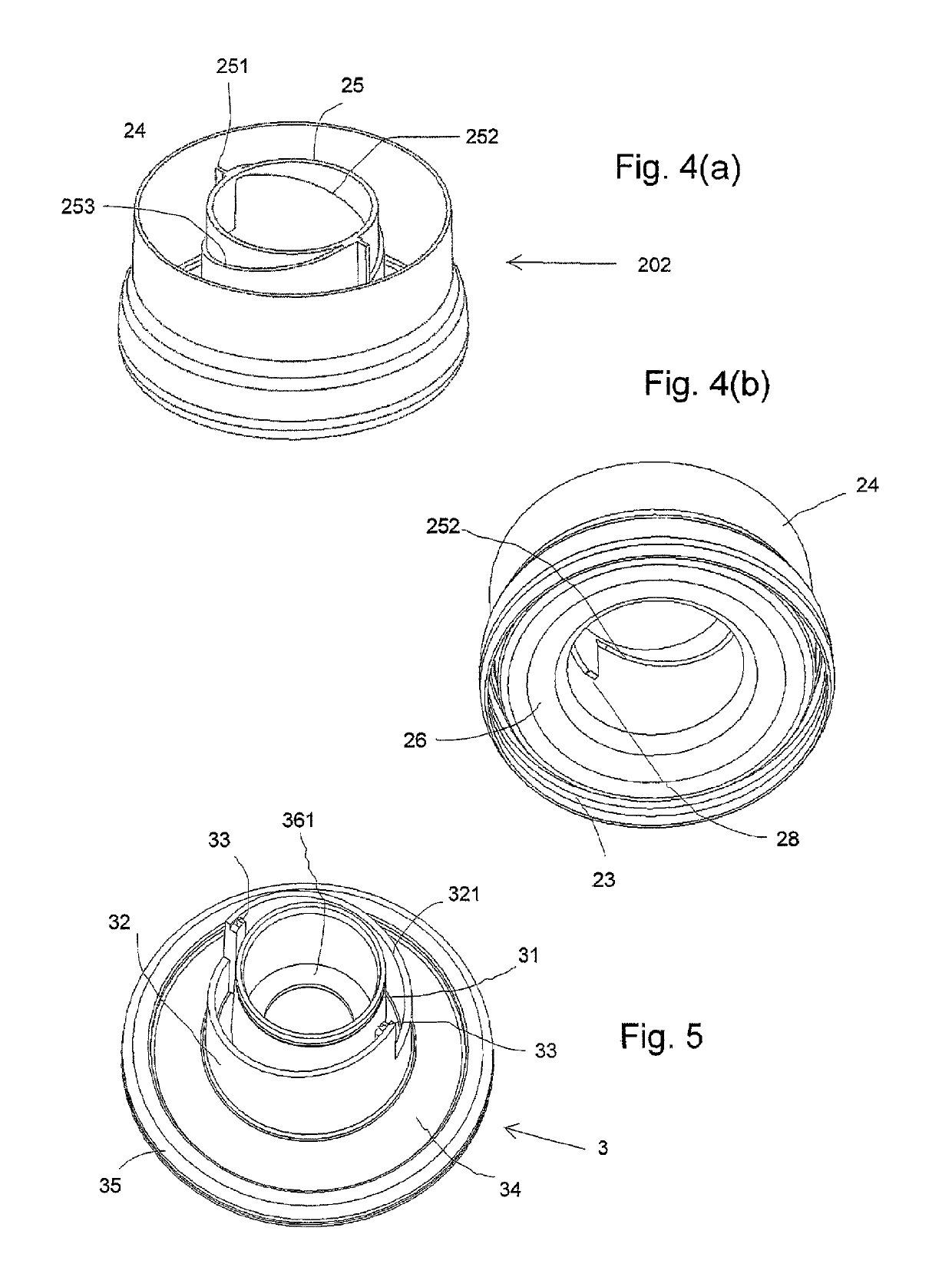

Airless pump dispensers

A dispenser for dispensing a flowable product from a container has a pump module mounted on the container at an opening thereof. The pump module includes a pump body, which defines a pump chamber and a pump chamber inlet for product to flow from the container interior into the pump chamber. A pump actuator is operable in a pumping stroke relative to the pump body to vary the volume of the pump chamber and dispense the product. The pump includes a movable body portion which is operable in a displacement stroke into the container. The movable portion has a displacement body with a product-engaging face directed onto an interior product space of the container upstream of the pump chamber inlet, to assist priming. Below this a disrupter member, a grid of narrow bars, projects to penetrate the product.

Owner:RIEKE PACKAGING SYST LTD

Sealing system for refrigeration cassette

A refrigerated merchandiser (10) includes a cabinet (20) having a top wall (22), a lower wall (24), a rear wall (34), and side walls (36, 38) defining an interior product display space (100) housing a product (110) in a refrigerated environment for consumer selection. A refrigeration unit (50) is disposed in operative association with the interior product display space in a compartment (55) beneath the lower wall (24). A first opening in the lower wall provides an air return inlet (102) establishing a flow passage from the interior product display space (100) to the compartment (55) beneath the lower wall. A sealing member (58) is disposed between the under surface of the lower wall (24) and the upper surface of the refrigeration unit cassette (50) about the first opening; and a positioning apparatus (150) for raising the refrigeration unit cassette (50) unit into sealing relationship with the lower wall.

Owner:CARRIER CORP

Package assembly

InactiveUS20170081098A1Enhance child-resistant featureAid removalDispensing apparatusPharmaceutical containersCartonInterior product

Disclosed are package assemblies and methods of making the same, wherein the assemblies can include, among other elements, an outer carton defining an interior product storage compartment; an inner product support card slidably received within the product storage compartment; the inner support card having a main body portion and one or more flaps; and one or more primary product packages, each being secured to one of the one or more flaps.

Owner:WESTROCK MWV LLC

Artificial leather treating agent, artificial leather and preparation method thereof, as well as vehicle provided with artificial leather

InactiveCN108049198AImprove wear resistanceEasy to prepareTextiles and paperPolycarbonate coatingsEmulsionFoaming agent

The invention provides an artificial leather treating agent, artificial leather and a preparation method thereof, as well as a vehicle provided with the artificial leather. The artificial leather treating agent comprises 90-110 parts by weight of polycarbonate resin emulsion and 8-9 parts by weight of an auxiliary, wherein the auxiliary comprises 4-6 pats by weight of a curing agent, 0.05-0.15 part by weight of a de-foaming agent, 1-2 parts by weight of a flatting agent and 1-3 parts by weight of a hand feeling agent. The artificial leather treating agent provided by the embodiment of the invention has the characteristics of being resistant to illuminate, low in atomization, low in odor and excellent in low temperature torsion resistance; the artificial leather prepared by the artificial leather treating agent has high wear resistance and meets the requirements for wear resistance of vehicle interior products; the preparation method of the artificial leather is simple, easy to controland suitable for large-scale popularization and application.

Owner:BAIC GRP ORV CO LTD

Bamboo-powder-added enhanced composite automotive interior product material and preparation method thereof

The invention discloses a bamboo-powder-added enhanced composite automotive interior product material. The material is prepared from, by weight, 100-103 parts of polylactic acid, 3.5-4 parts of nanometer antimony trioxide, 10-11 parts of decabromodiphenyl ethane, 25-27 parts of SEBS, 60-62 parts of kenaf fibers, 10.5-12 parts of bamboo powder, 5-6.5 parts of carboxymethyl cellulose, 4.5-5.5 parts of talcum powder, 8-9 parts of ethyl alcohol, 0.8-1 part of silane coupling agent kh550, 1-2 parts of stearic acid, 3-4 parts of polyacrylamide and a proper amount of water. The silane coupling agent is used for treating the bamboo powder, the talcum powder and other components to form soaking slurry, environment friendliness is achieved, the tenacity and strength of fibers are enhanced, the bonding performance and description performance of the bamboo powder and other components and the blend fibers can be improved, the processing technology is conveniently and industrially controlled, the following extrusion technology is good in liquidity, the prepared product is good in appearance and free of warping, good bending strength is achieved, and environment friendliness is achieved.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

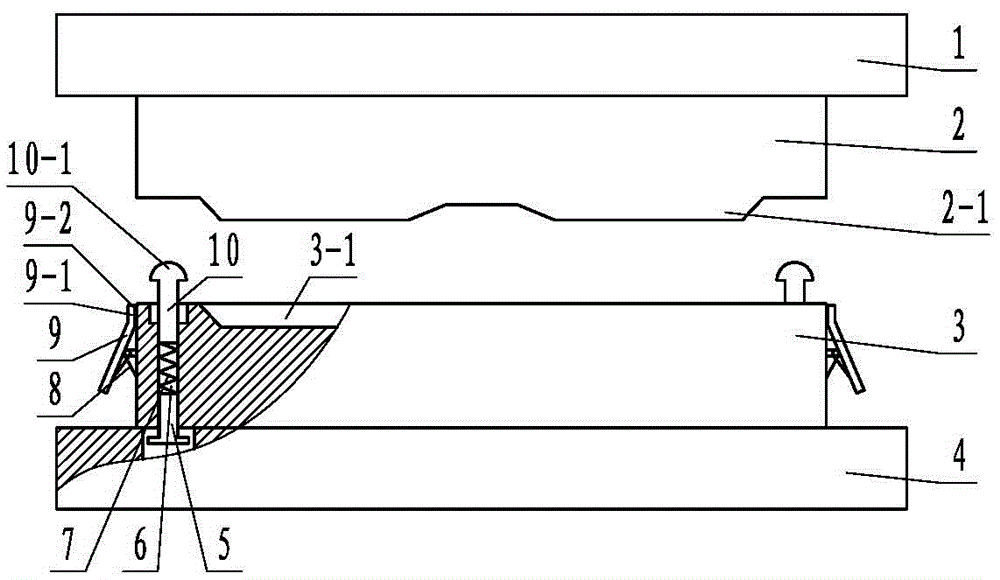

Cold forming mold for automobile carpet

The invention discloses a cold forming mold for an automobile carpet, and relates to the technical field of manufacturing of automobile interior products. The cold forming mold comprises an upper mold seat, an upper mold, a lower mold, a lower mold seat and a pressing device, wherein the pressing device adopts pressing arms hinged to the lower mold; torsion springs are mounted on articulated shafts of the pressing arms; two torsion arms of the torsion springs are respectively propped against the outer wall of the lower mold and the pressing arms; the lower mold is provided with a cavity; at least two movable support frames are symmetrically arranged on the two sides of the cavity on the lower mold; accommodating holes which are matched with the movable support frames in a sliding manner are formed in the lower mold; springs connected with the movable support frames are arranged inside the accommodating holes; and the upper ends of the movable support frames protrude from the top surface of the lower mold. According to the cold forming mold, the problem that a conventional cold forming mold for the automobile carpet is liable to cause tearing or winkles during carpet forming is solved.

Owner:LIUZHOU FUYINGHUA IND & TRADE CO LTD

Automotive wear-resistant plant fiber reinforced polypropylene micro-foaming material and preparation method thereof

The invention relates to an automotive wear-resistant plant fiber reinforced polypropylene micro-foaming material and a preparation method thereof. The material is prepared from, by weight, 40-80 parts of polypropylene, 10-25 parts of plant fibers, 1-8 parts of a compatibilizer, 1-10 parts of a wear-resistant auxiliary agent, 0.5-3 parts of a lubricant, 0.5-5 parts of a nucleating agent, 1-10 parts of a toughening agent, 1-5 parts of a foaming agent and 3-10 parts of other auxiliary agents. According to the automotive wear-resistant plant fiber reinforced polypropylene micro-foaming material and the preparation method thereof, through scientific formula design, the plant fiber reinforced polypropylene micro-foaming material with excellent anti-mildew performance and lightweight characteristics is obtained by means of a natural anti-mildew technology, and the product also has the advantages of low emission, rigidity and toughness balance and the like; meanwhile, the product has good apparent quality, meets the use requirements of automotive interior products, eliminates the hard plasticity of the finished products, improves the visual grade and handfeel comfort of the automotive plastic interiors, and is beneficial to creating the most comfortable automotive interior space.

Owner:NANJING JULONG SCI&TECH CO LTD

Bottom deck assembly for refrigerated merchandiser

InactiveCN101179965APrevent returnAvoid passingShow cabinetsLighting and heating apparatusEngineeringRefrigeration

A refrigerated merchandiser (10) includes a cabinet (20) defining an interior product display space (100) and a refrigeration unit (50) is disposed in operative association with the interior product display space in a compartment (55) beneath the lower deck (24). An opening in the lower deck provides an air return inlet (102) establishing a flow passage from the interior product display space (100) to the compartment (55) beneath the lower deck. A cover (120) includes a top plate member (122) disposed superadjacent the return air inlet and a downwardly extending peripheral side flange (124) disposed about the periphery of the top plate member (122). A plurality of air intake ports (125) are provided in the peripheral side flange (124). The lower deck (24) has a recessed upper surface (124C) facing the product display space (100). A grille plate (130) extends across the air return inlet.

Owner:CARRIER CORP

Airless pump dispensers

ActiveUS20170216862A1Evenly distributedIncrease shearLarge containersSingle-unit apparatusPump chamberActuator

A dispenser for dispensing a flowable product from a container has a pump module mounted on the container at an opening thereof. The pump module includes a pump body, which defines a pump chamber and a pump chamber inlet for product to flow from the container interior into the pump chamber. A pump actuator is operable in a pumping stroke relative to the pump body to vary the volume of the pump chamber and dispense the product. The pump includes a movable body portion which is operable in a displacement stroke into the container. The movable portion has a displacement body with a product-engaging face directed onto an interior product space of the container upstream of the pump chamber inlet, to assist priming. Below this a disrupter member, a grid of narrow bars, projects to penetrate the product.

Owner:RIEKE PACKAGING SYST LTD

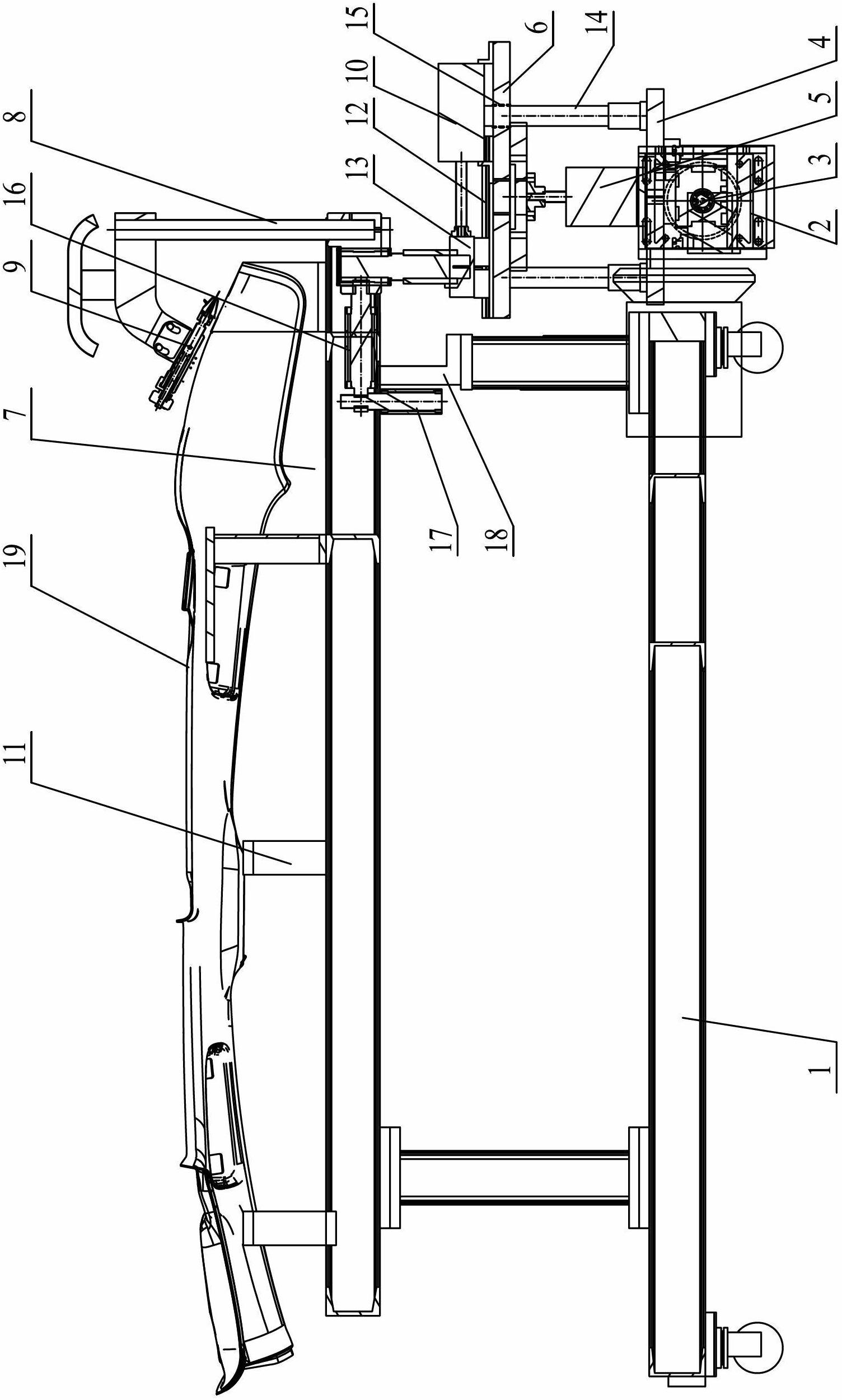

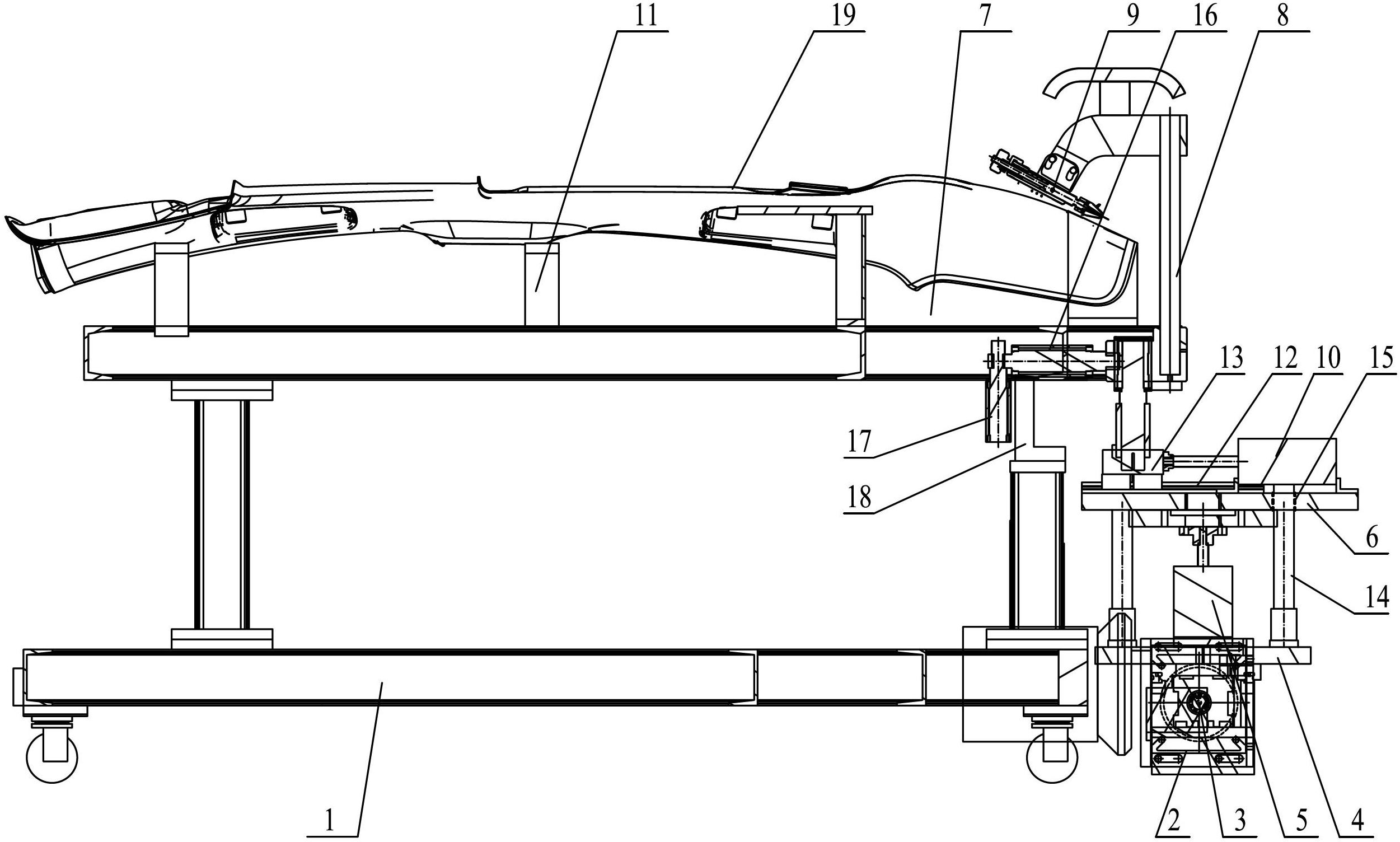

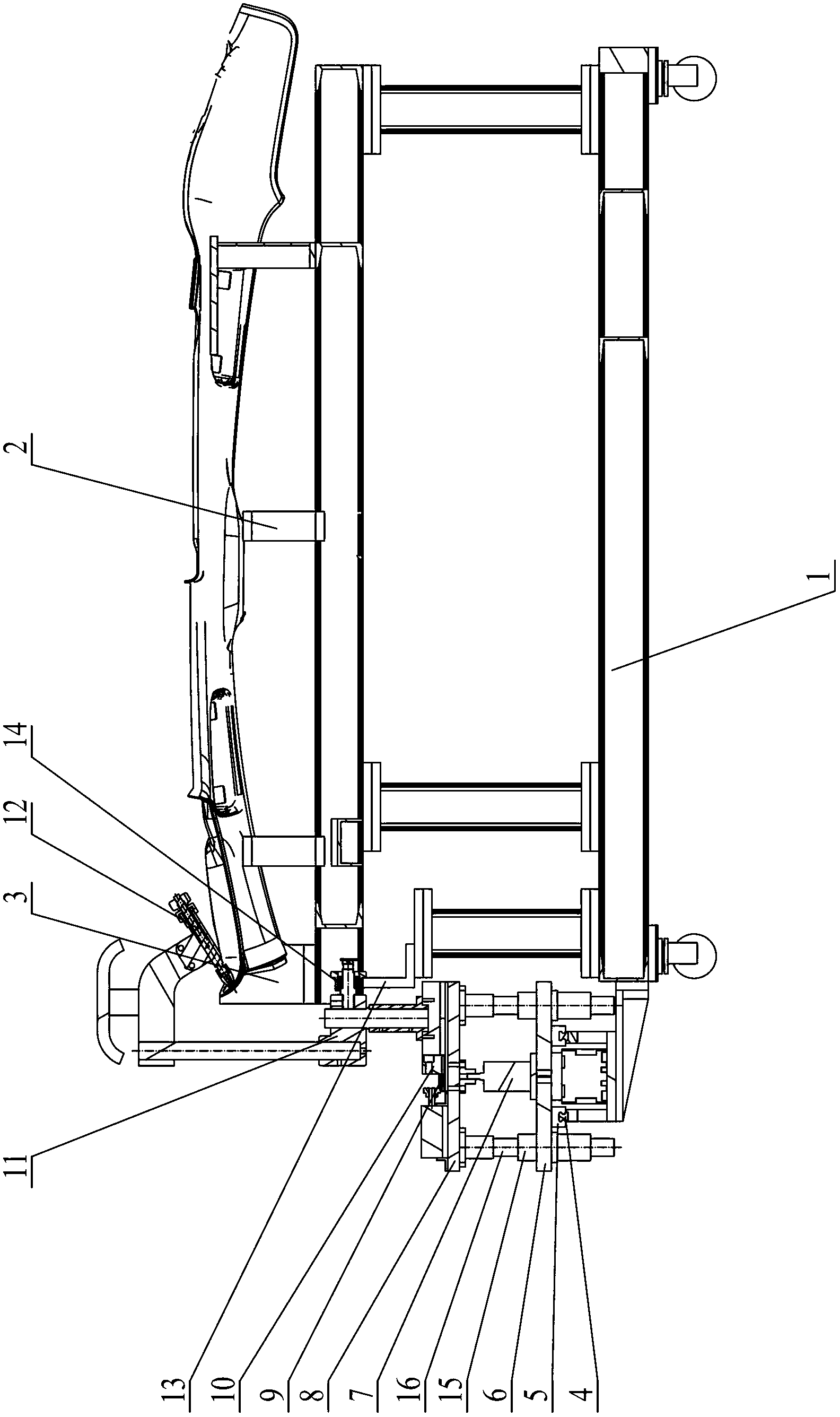

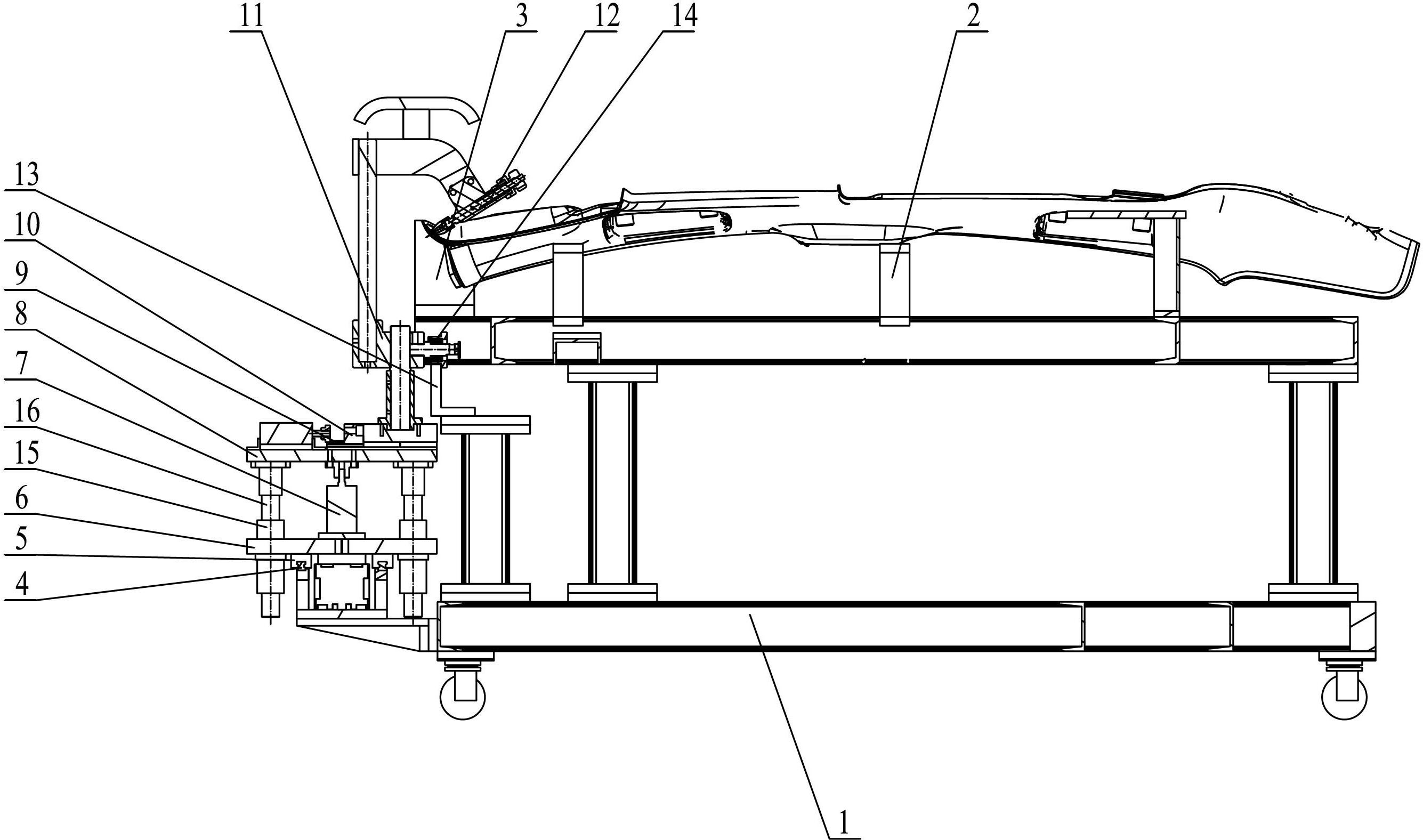

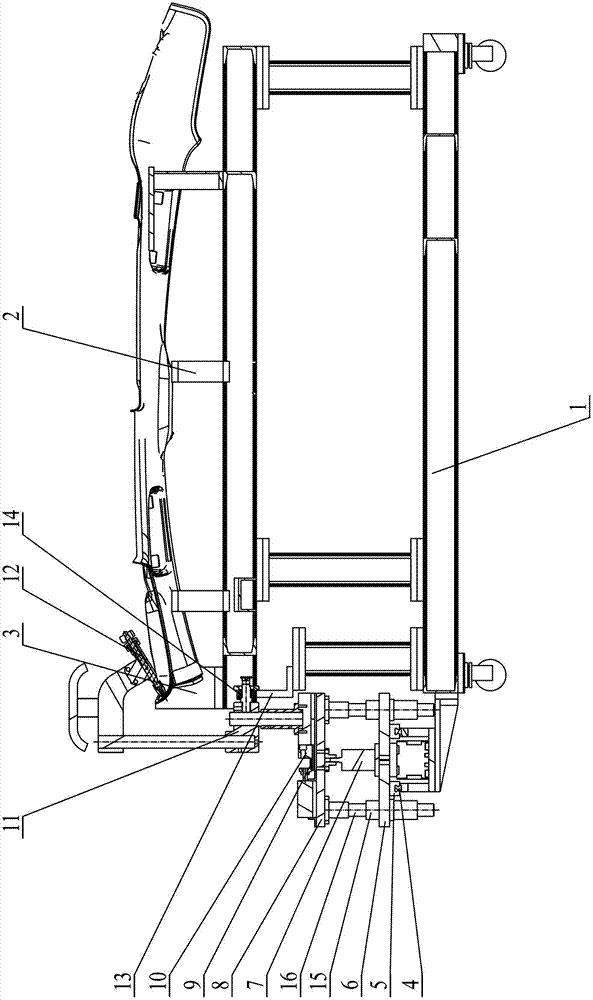

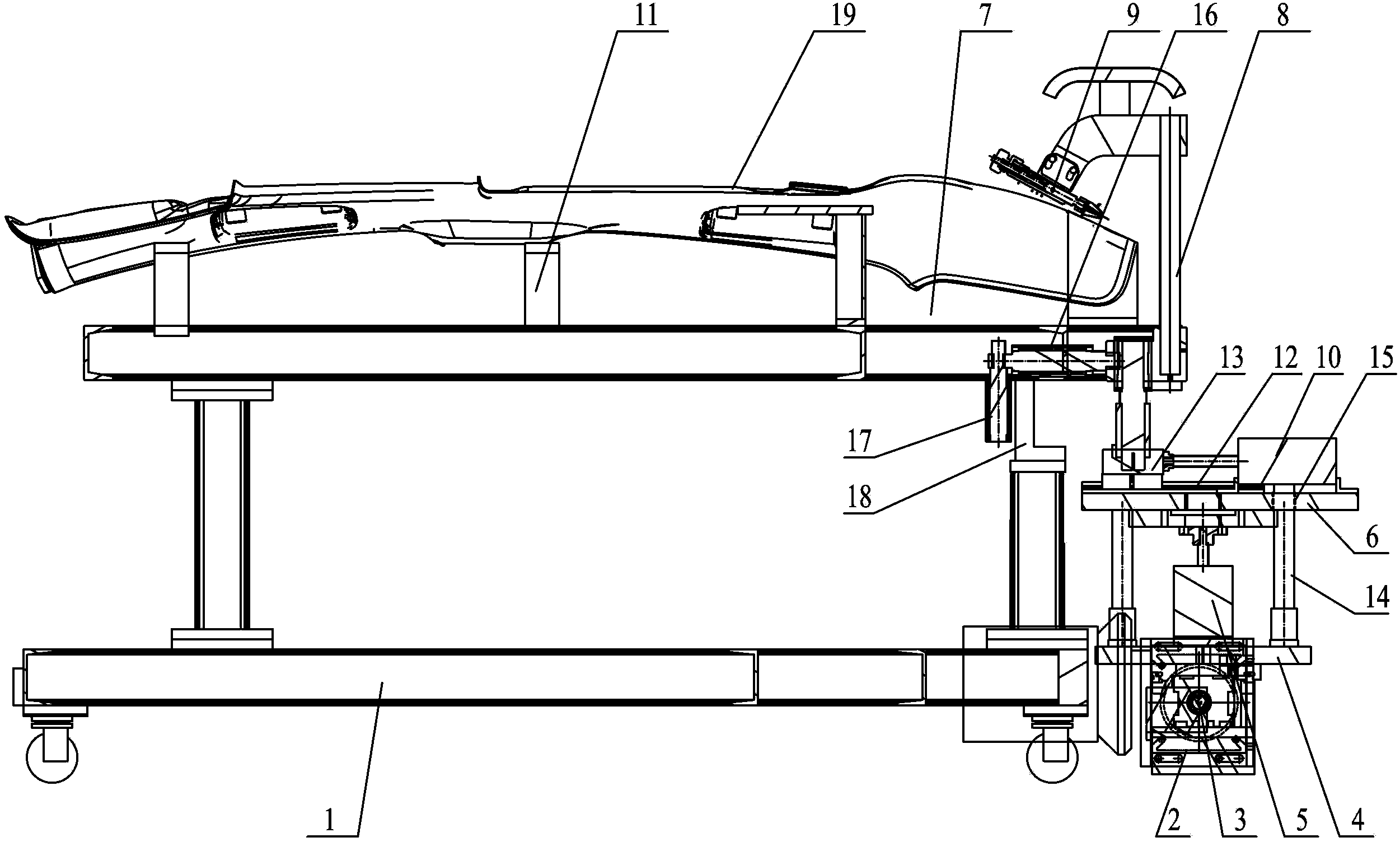

Afteredge cutting mechanism of automotive interior ceiling

ActiveCN102689320AEnsure stream productionSimple structureMetal working apparatusElectric machineryEngineering

The invention relates to an afteredge cutting mechanism of an automotive interior ceiling. A ceiling positioning tringle and a ceiling afteredge positioning moulding bed are fixed on a frame; a servomotor and a speed reducer are arranged on one side of the frame; a transmission screw rod is fixed on an output shaft of the speed reducer; a transmission screw is screwed on the transmission screw rod; a lifting mechanism mounting base is fixed on the transmission screw; a lifting driving air cylinder is fixed on the lifting mechanism mounting base; a horizontal translating mechanism mounting base is arranged above the lifting mechanism mounting base; a horizontal driving air cylinder and a horizontal linear rail are fixed on the horizontal translating mechanism mounting base; a horizontal sliding block is connected on the horizontal linear rail in a sliding manner; a cutting tool shank is fixed on the horizontal sliding block; and a cutting tool is mounted on the cutting tool shank. The afteredge cutting mechanism has a simple, compact and reasonable structure, ensures the flow production of an automotive interior product, and is high in degree of automation and accurate in product positioning.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

6000-mesh inorganic powder-filled modified pa (polyamide)6 master batch and preparation method thereof

The invention discloses a 6000-mesh inorganic powder-filled modified PA (Polyamide)6 master batch and a preparation method thereof and belongs to the technical field of high-molecular materials. The PA6 master batch comprises the following main raw materials: PA6, a surface treating agent, polyethylene wax, paraffin wax and 6000-mesh inorganic powder, and the preparation method of the PA6 master batch comprises the following steps of: putting the 6000-mesh inorganic powder into a high-speed mixer for agitation and dehumidification, adding the surface treating agent for mixing and agitation and putting in a cold mixer for cooling, putting the PA6, the polyethylene wax and the paraffin wax into the high-speed mixer in sequence for mixing and agitation, adding the modified 6000-mesh inorganic powder for mixing and agitation, putting in the cold mixer for cooling and discharging and pelleting with an extruder to prepare the 6000-mesh inorganic powder-filled modified PA6 master batch. The 6000-mesh inorganic powder-filled modified PA6 master batch and the preparation method thereof have the beneficial effects that after the 6000-mesh inorganic powder-filled modified PA6 master batch is mixed with matrix resin, a whole system has good compatibility, dispersibility, flowability and processing performance, and a produced product has good mechanical property, dimension stability, toughness and impact resistance and the 6000-mesh inorganic powder-filled modified PA6 master batch is particularly suitable for manufacturing PA6 water supply pipes, PA6 double-walled corrugated tubes, plastic turnover boxes and automotive interior products.

Owner:徐州腾飞工程塑料有限公司

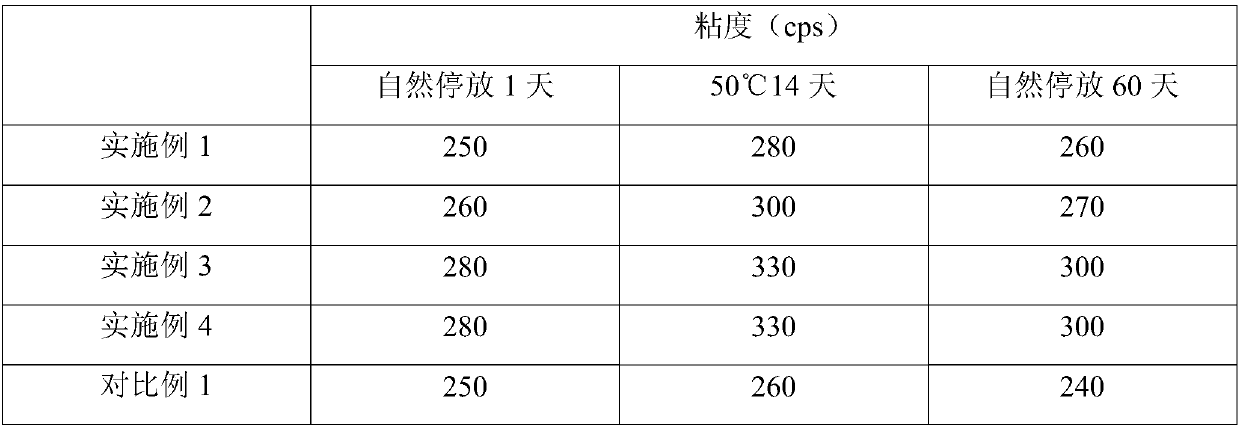

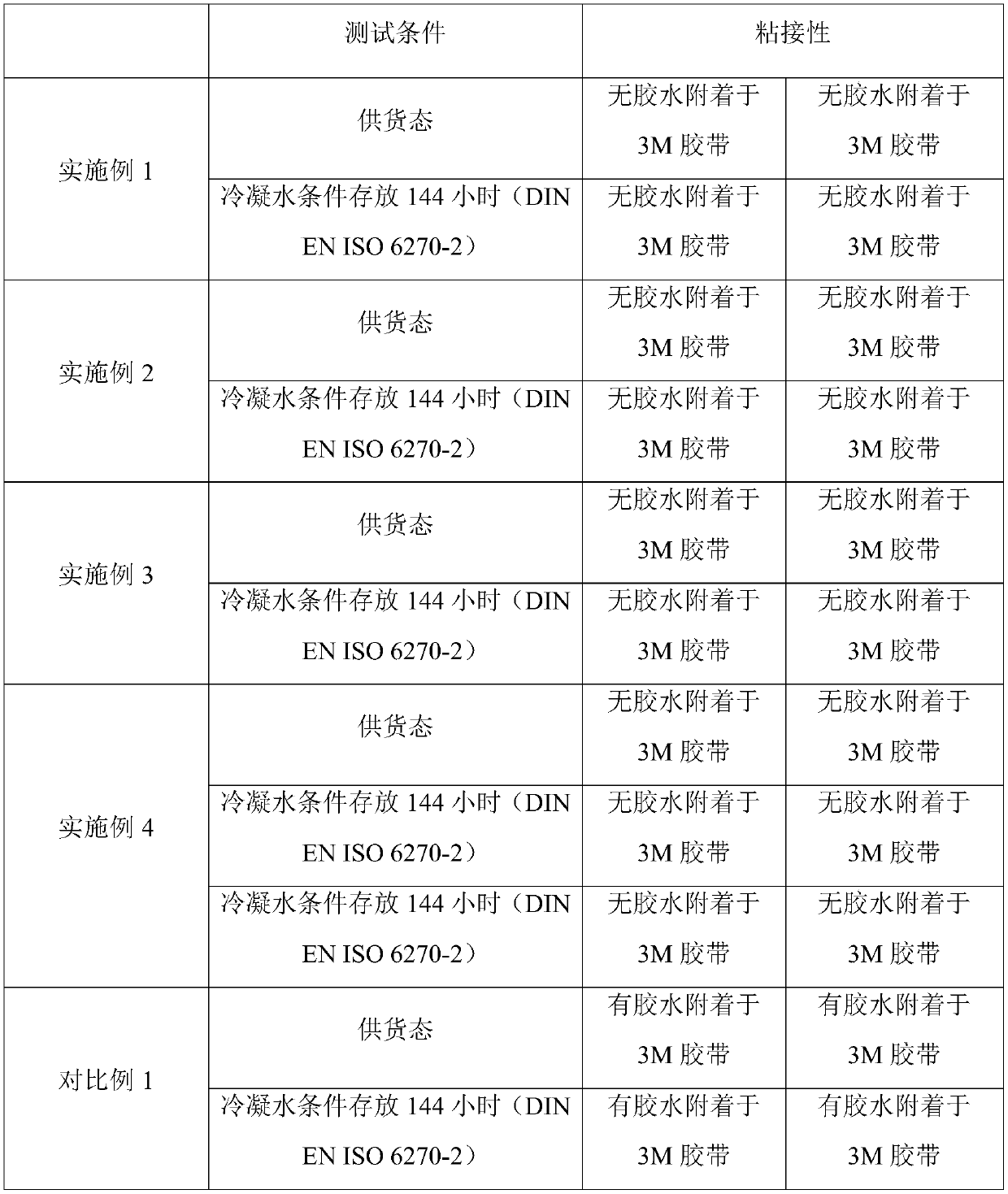

Water-based PP (polypropylene) treatment agent preparation method

ActiveCN109575854AGood adhesionImprove water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedPolyolefin

The invention relates to a water-based PP (polypropylene) treatment agent preparation method which includes the steps: (a) adding 1-2 parts of silane coupling agents into 100 parts of chlorinated polyolefin emulsion and stirring the silane coupling agents and the chlorinated polyolefin emulsion to obtain first mixture; (b) adding water-based wetting agents and water-based defoaming agents into thefirst mixture and stirring the water-based wetting agents, the water-based defoaming agents and the first mixture to obtain second mixture; (c) adding polyurethane water-based thickening agents or / and water into the second mixture, and controlling indexes: the solid content of 8-15% and the viscosity of 100-500cps. Therefore, crosslinking reaction of the chlorinated polyolefin emulsion and curingagents can be ensured, so that a chain structure of chlorinated polyolefin is evolved into a network structure, and the adhesion performance and the water resistance of a water-based PP treatment agent are improved. Moreover, crosslinking reaction auxiliary heating temperature is not higher than 80 DEG C, so that the water-based PP treatment agent can be applied to adhesion and flocking of automotive interior products.

Owner:苏州市陆氏新材料有限公司

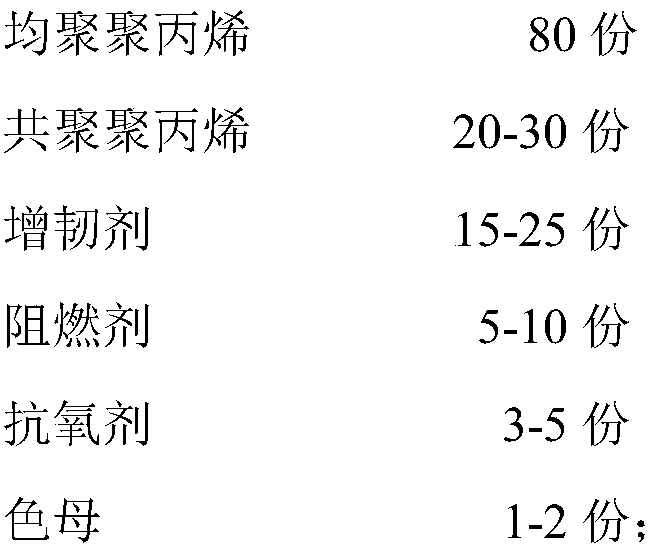

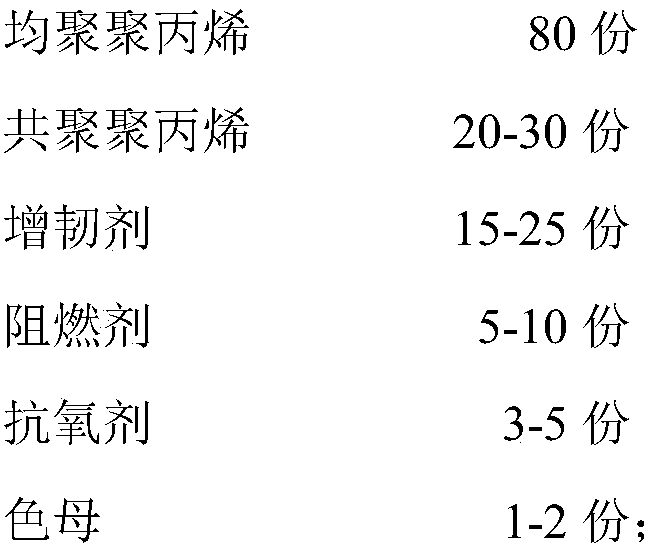

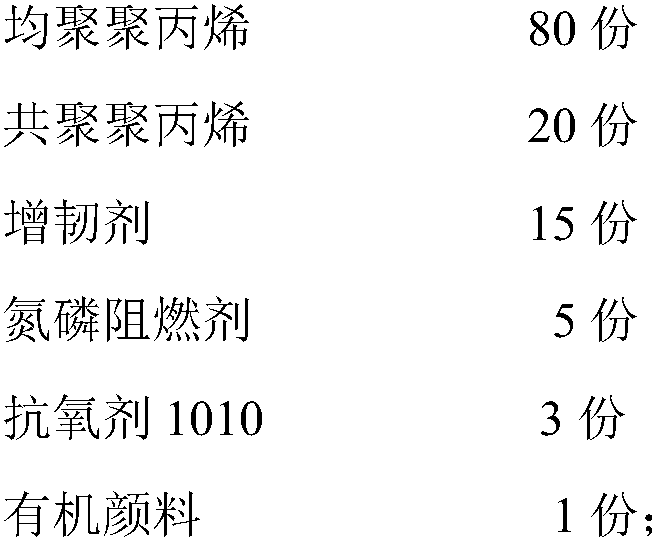

Toughened automobile interior composite material

The invention discloses a toughened automobile interior composite material. The toughened automobile interior composite material comprising, by weight, 80 parts of homo-polypropylene, 20-30 parts of co-polypropylene, 15-25 parts of toughening agents, 5-10 parts of flame retardants, 3-5 parts of antioxidants and 1-2 parts of color batch, wherein the toughening agents are one or more of EPDM, EPR and SBS. According to the composite material, one or more of the EPDM, the EPR and the SBS are used as the toughening agents for blending modification of the polypropylene, and the shock strength of thepolypropylene can be improved; the effect is optimal when the mass ratio of the EPDM to the EPR is 1-3:1; and in addition, the proper flame retardants and the antioxidants are added so that the oxidation resistance and the flame retardancy of automobile interior products are improved.

Owner:南京宸旭汽车部件有限公司

Front-edge cutting device for automotive interior canopy

ActiveCN102699936AEnsure stream productionSimple structureMetal working apparatusEngineeringFront edge

The invention relates to a front-edge cutting device for an automotive interior canopy. A canopy positioning module and a canopy front-edge positioning mould are fixed on the top end of a framework. An inner wire rail and an outer wire rail are fixed on the framework. An inner sliding block and an outer sliding block are connected on the inner wire rail and the outer wire rail in a manner of sliding, lift pedestals are fixed on the inner sliding block and the outer sliding block, and lift cylinders are installed on the lift pedestals. A left pedestal and a right pedestal are respectively fixed on the end parts of piston rods of the lift cylinders, a left wire rail and a right wire rail are fixed on the left pedestal and the right pedestal, a left sliding block and a right sliding block are connected on the left wire rail and the right wire rail in a manner of sliding, and a cutting knife rest is fixed on the left sliding block and the right sliding block. Cutting tools are installed on the cutting knife rest, a template is fixed on the framework, and wheels are rotationally installed on the cutting knife rest. The front-edge cutting device for the automotive interior canopy has the advantages of a simple, impact and rational structure, high degree of automation and accuracy in product positioning, and the automotive interior products are enabled to be produced in one process.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Modular refrigeration cassette with condensate evaporative tray

The interior space within a refrigeration unit cassette associated with a refrigerated merchandiser is divided by a division wall (68) into a first section in air flow communication with the interior product display space of the cabinet, and a second section isolated from said first section and in fluid flow communication with the environment exterior of the cabinet. An evaporator module (160) disposed within the first section, and a condenser module (170) and a compressor are disposed within the second section. The refrigeration cassette is selectively insertable in to and out of the equipment compaitulent to facilitate servicing of the refrigeration equipment therein, including removal and replacement of the evaporator module and the condenser module.

Owner:CARRIER CORP

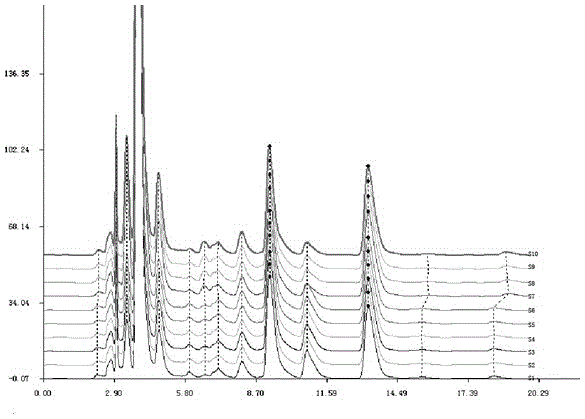

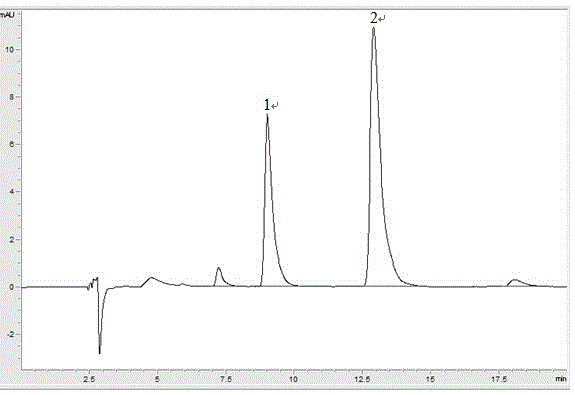

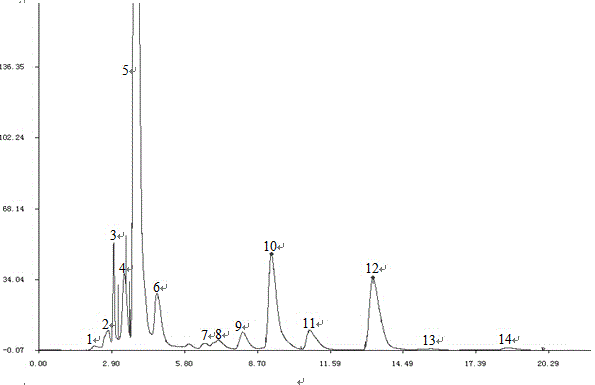

Establishment method of inducing callus cultured Allium sativum L. enzymatic hydrolysate HPLC fingerprint

The invention discloses an establishment method of inducing callus cultured Allium sativum L. enzymatic hydrolysate HPLC fingerprints. The establishment method of the inducing callus cultured Allium sativum L. enzymatic hydrolysate HPLC fingerprints specifically comprises the steps of preparing inducing callus cultured Allium sativum L. bulbs into solution for test products through steps such as solid-phase extraction, and performing high-performance chromatographic analysis and detection under certain conditions to obtain HPLC fingerprints of inducing callus cultured Allium sativum L. enzymatic hydrolysate. By analyzing the HPLC fingerprints of 10 batches of samples, characteristic common peaks are determined and standard fingerprints are obtained. The standard fingerprints can provide a reliable basis for variety identification and production quality control of inducing callus cultured Allium sativum L. The establishment method of the inducing callus cultured Allium sativum L. enzymatic hydrolysate HPLC fingerprints has the advantages that the operation is convenient, the stability is high, the specificity is strong, the repeatability is good, the characteristic peaks are more, the analysis efficiency is high, the truth identification of the inducing callus cultured Allium sativum L. can be realized by adopting the invention, and the interior product quality can be comprehensively, accurately and effectively evaluated.

Owner:TIANJIN NORMAL UNIVERSITY

Front-edge cutting device for automotive interior canopy

ActiveCN102699936BEnsure stream productionSimple structureMetal working apparatusEngineeringFront edge

The invention relates to a front-edge cutting device for an automotive interior canopy. A canopy positioning module and a canopy front-edge positioning mould are fixed on the top end of a framework. An inner wire rail and an outer wire rail are fixed on the framework. An inner sliding block and an outer sliding block are connected on the inner wire rail and the outer wire rail in a manner of sliding, lift pedestals are fixed on the inner sliding block and the outer sliding block, and lift cylinders are installed on the lift pedestals. A left pedestal and a right pedestal are respectively fixed on the end parts of piston rods of the lift cylinders, a left wire rail and a right wire rail are fixed on the left pedestal and the right pedestal, a left sliding block and a right sliding block are connected on the left wire rail and the right wire rail in a manner of sliding, and a cutting knife rest is fixed on the left sliding block and the right sliding block. Cutting tools are installed on the cutting knife rest, a template is fixed on the framework, and wheels are rotationally installed on the cutting knife rest. The front-edge cutting device for the automotive interior canopy has the advantages of a simple, impact and rational structure, high degree of automation and accuracy in product positioning, and the automotive interior products are enabled to be produced in one process.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Afteredge cutting mechanism of automotive interior ceiling

The invention relates to an afteredge cutting mechanism of an automotive interior ceiling. A ceiling positioning tringle and a ceiling afteredge positioning moulding bed are fixed on a frame; a servomotor and a speed reducer are arranged on one side of the frame; a transmission screw rod is fixed on an output shaft of the speed reducer; a transmission screw is screwed on the transmission screw rod; a lifting mechanism mounting base is fixed on the transmission screw; a lifting driving air cylinder is fixed on the lifting mechanism mounting base; a horizontal translating mechanism mounting base is arranged above the lifting mechanism mounting base; a horizontal driving air cylinder and a horizontal linear rail are fixed on the horizontal translating mechanism mounting base; a horizontal sliding block is connected on the horizontal linear rail in a sliding manner; a cutting tool shank is fixed on the horizontal sliding block; and a cutting tool is mounted on the cutting tool shank. The afteredge cutting mechanism has a simple, compact and reasonable structure, ensures the flow production of an automotive interior product, and is high in degree of automation and accurate in product positioning.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Carving method for automobile genuine leather interior

InactiveCN108859553AFine art status unchangedRealize the combinationDecorative surface effectsEngineeringDesign pattern

The invention discloses a carving method for an automobile genuine leather interior. The carving method comprises the steps that a genuine leather material with the thickness being 1.2-2mm is selectedas a base material; a pre-designed pattern is carved on the base material by using a carving method of leather carving; the base material with the pattern well carved is subjected to cutting, cuttingmouth opening and edge shoveling treatment according to the molding structure of the automobile interior, and a primary shape material is obtained, and the thickness of the base material is larger than or equal to 0.08mm after edge shoveling treatment is conducted; the primary shape material is pre-shaped to obtain a shaped material, that is, the primary shape material is shaped on a mold throughpretreatment, i.e., through a pre-produced automobile interior mold; and finally the shaped material and the automobile interior framework are subjected to coating and integrating. Combination of thegenuine leather curved leather face and automobile interior products with different models can be achieved through the genuine leather carving method, and the aim that the original elegant artistic state of genuine leather carving is not changed is realized.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

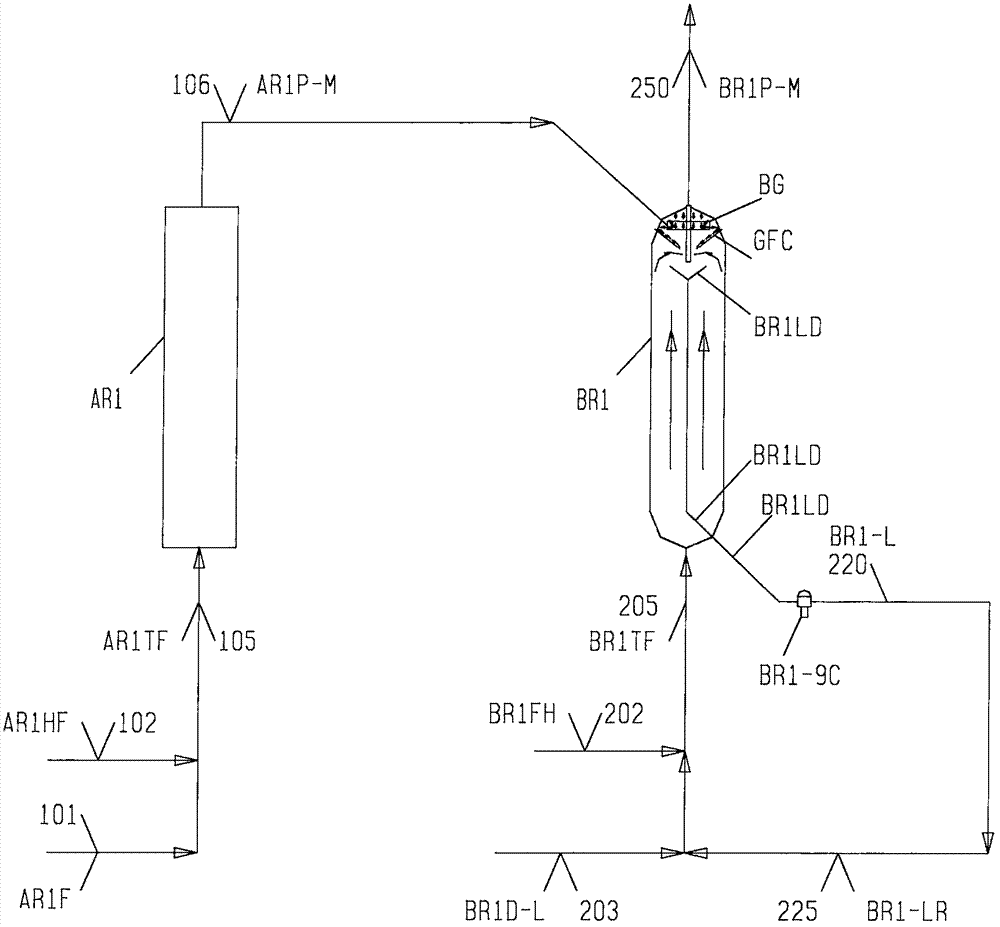

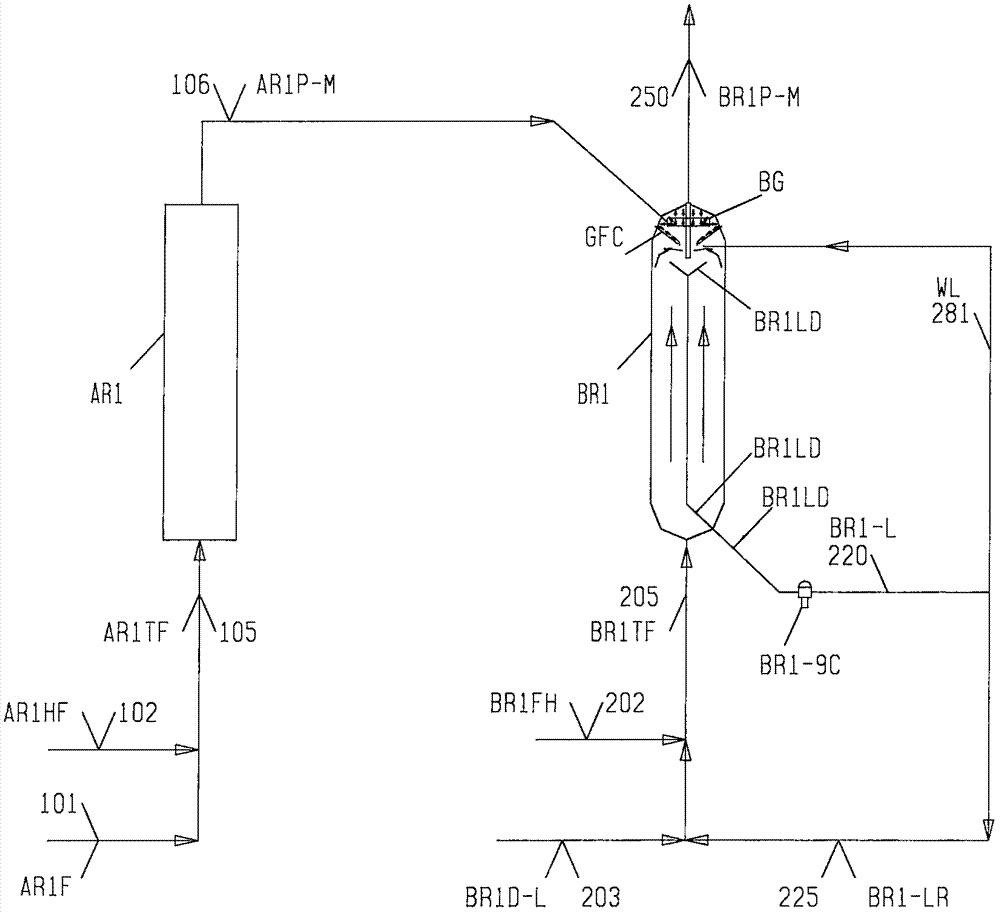

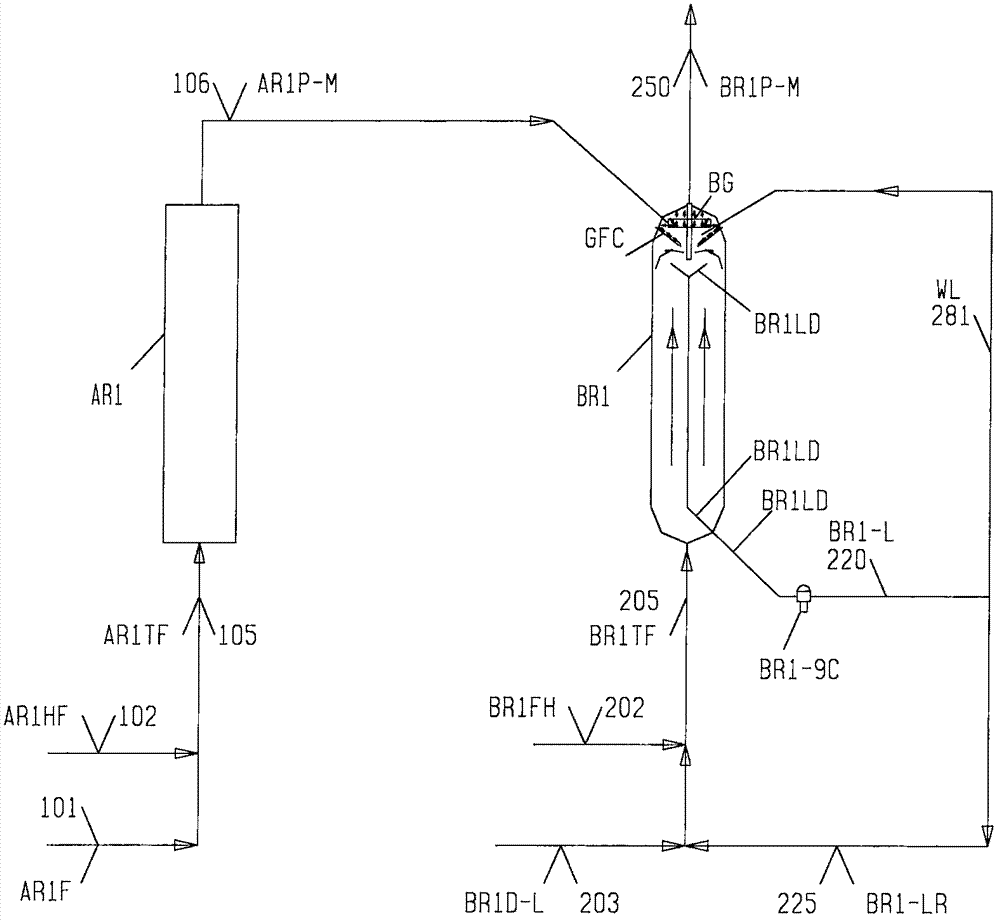

Backmixing-flow expanded-bed hydrogenation reactor system with distributor for hydrocarbon-containing gas-liquid upper feed

InactiveCN107970866ATreatment with hydrotreatment processesChemical/physical processesHydrogenReactor system

The invention provides a backmixing-flow expanded-bed hydrogenation reactor system with a distributor for a hydrocarbon-containing gas-liquid upper feed. The backmixing-flow expanded-bed hydrogenationreactor system is used for processing the hydrocarbon-containing gas-liquid upper feed AR1P-M and hydrogen-containing gas lower feed BR1FH and can also be used for processing hydrocarbon-containing liquid lower feed BR1D-L; the inner upper space of a backmixing-flow expanded-bed hydrogenation reactor BRXE is provided with a liquid collecting cup and a liquid eduction tube; the upper space of theliquid collecting cup is divided into an upper feed distribution zone KD1 and a liquid removing zone KD2 for an interior product BRXE-8P of the reactor BRXE; the KD1 is located above the KD2, and a guiding and flow-gathering ring is used for separating the KD1 and the KD2; liquid flowing out from the guiding and flow-gathering ring GFC is mixed with the product BRXE-8P; and then the obtained mixture falls down into a liquid collecting zone of the liquid collecting cup for liquid removal and separation. With such a structure, the system can eliminate gas gathering zones, prevent mutual interference and stabilize flow fields.

Owner:洛阳瑞华新能源技术发展有限公司

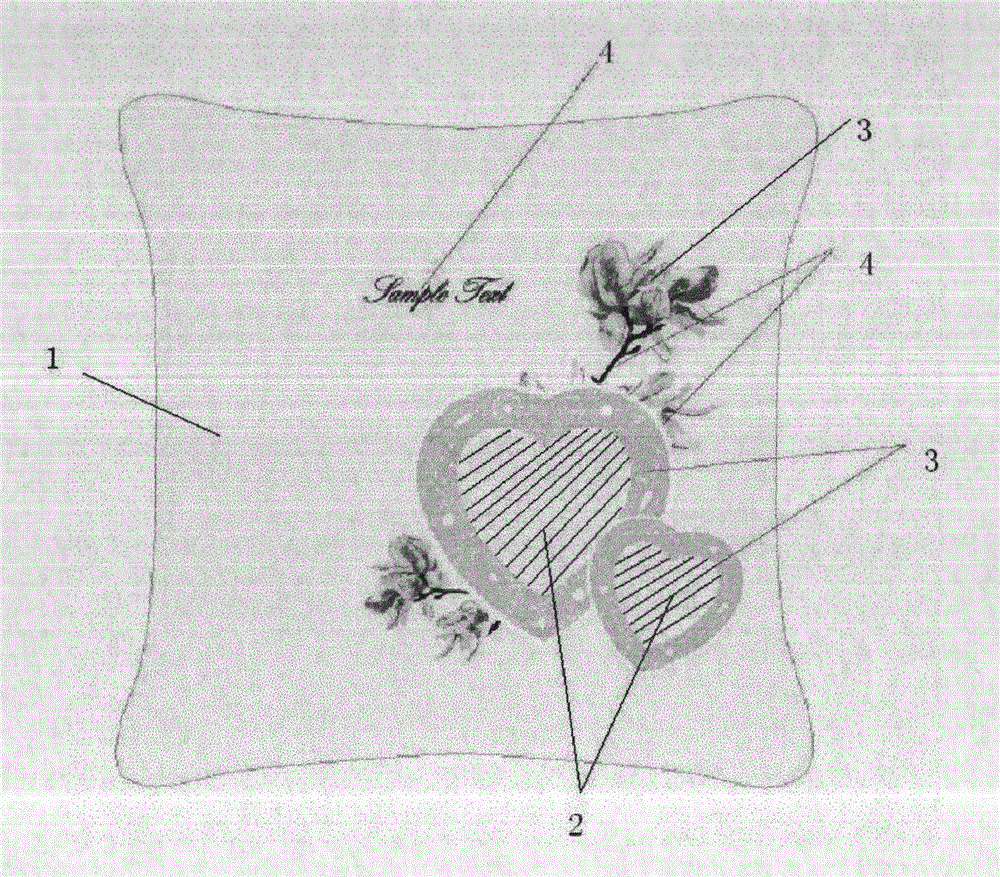

Preparation method and product of a personalized automotive interior decoration product

The invention discloses a manufacturing method for a personalized automotive interior. The manufacturing method comprises the following steps: (1) preparing a body layer of the automotive interior or cloth; (2) generating a picture in a computer and converting the picture to be in a print format of a heat printing machine; (3) printing out the picture by a printing machine using heat transfer printing ink; (4) printing the picture onto the body layer of the automotive interior or the cloth by using a heat press machine; and (5) embroidering a three-dimensional pattern layer onto the body layer by using a computer embroidering machine so as to enable the whole automotive interior to show a planar three-dimensional multi-layer picture. The invention further discloses the personalized automatic interior manufactured by the manufacturing method. The invention has the benefits as follows: personalized photos of customers such as favorite life photos, wedding photos, parent-child photos and the like can be vividly fused on the automotive interior in a heat transfer printing or embroidering way, so that the personalized automotive interior such as a throw pillow, a head rest, a waist rest, a CD board, a side window sunshade or the like can be obtained.

Owner:DONGGUAN HAODA AUTOMOBILE ARTICLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com