Water-based PP (polypropylene) treatment agent preparation method

A technology of treating agent and water-based wetting agent, applied in the field of preparation of PP treating agent and water-based PP treating agent, can solve the problems of poor water resistance, poor bonding applicability, high temperature pre-baking, etc., and improve the bonding performance. and the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

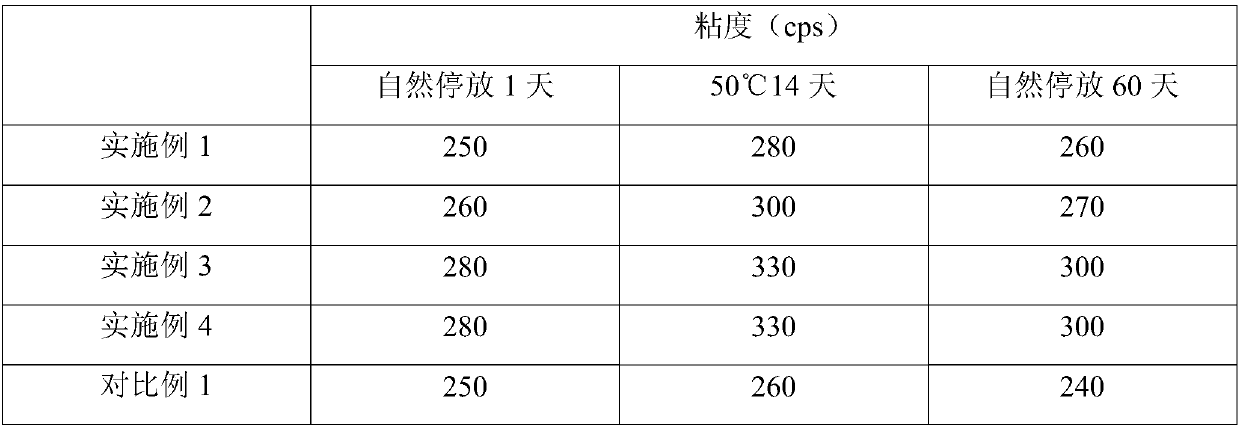

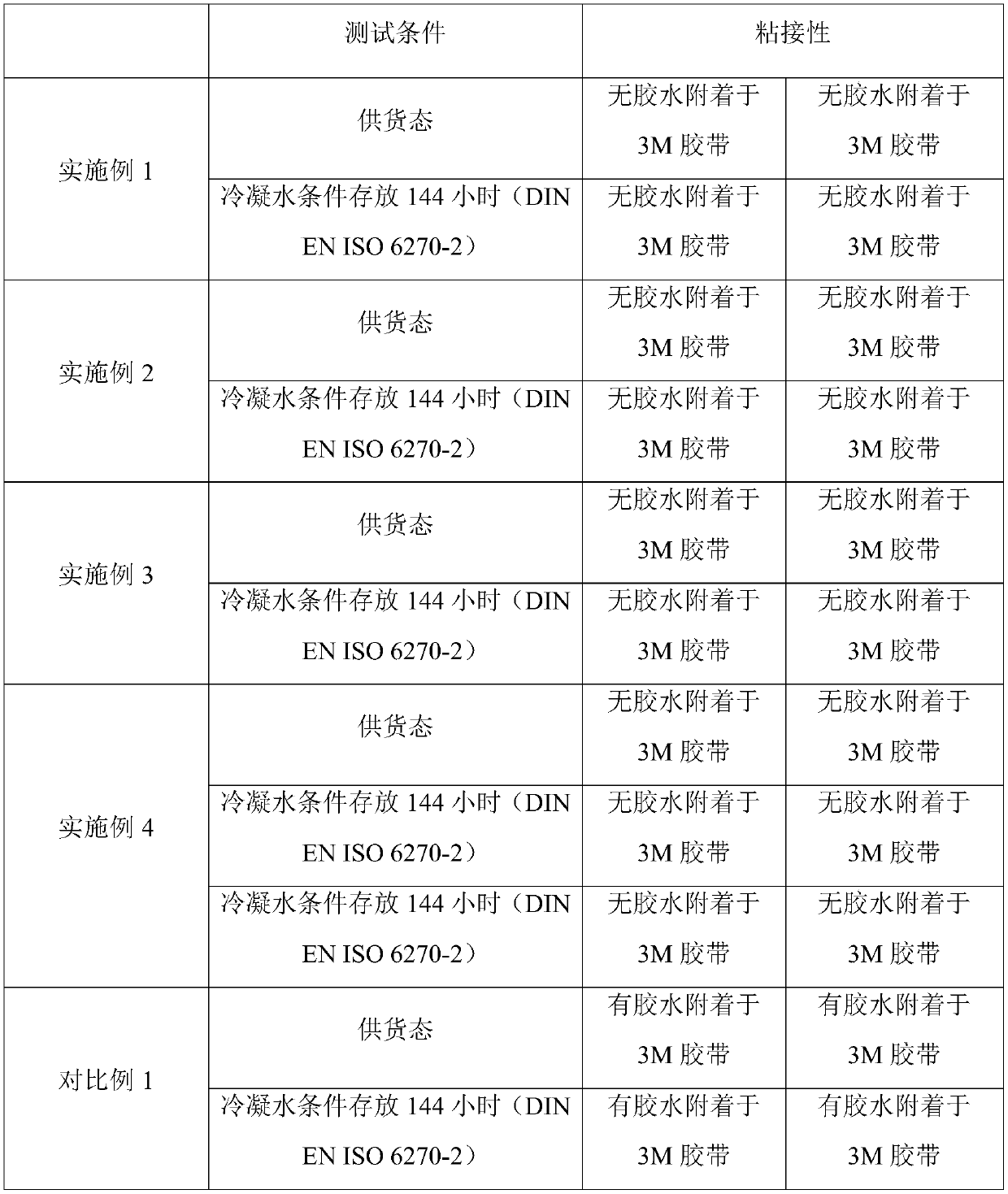

[0017] The preparation method of the water-based PP treatment agent of the present invention comprises the following steps: (a) adding 1 to 2 parts of silane coupling agent to 100 parts of chlorinated polyolefin emulsion (i.e. water-based chlorinated polypropylene emulsion), stirring to obtain the first Mixture; (b) add water-based wetting agent, water-based defoamer to the first mixture, stir to obtain the second mixture; (c) add polyurethane water-based thickener and water to the second mixture, control Its indexes are: the solid content is 8-15% (mass content), and the viscosity is 100-500cps. By adding a specific content and type of silane coupling agent to the chlorinated polyolefin emulsion for reaction coordination, and controlling the final solid content and viscosity, this can ensure the cross-linking reaction between the chlorinated polyolefin emulsion and the curing agent, thereby chlorinated The chain structure of polyolefin evolves into a network structure, thereb...

Embodiment 1

[0021] The present embodiment provides a kind of preparation method of aqueous PP treating agent, it comprises the following steps:

[0022] (a) to 100 parts of maleic anhydride-modified water-based chlorinated polypropylene emulsion (reference application number is 201710178027.3 method to make, so that the solid content of the water-based chlorinated polypropylene emulsion is 25 ~ 35%, the chlorine content is 12 ~18% and maleic anhydride content 1~2%), add 1 part of silane coupling agent (KH-450), and stir to obtain the first mixture;

[0023] (b) Add water-based wetting agent (KYC642) and water-based defoamer (AT-470) to the first mixture, and stir to obtain the second mixture; the mass content of water-based wetting agent and water-based defoamer in the second mixture Both are 0.1%;

[0024] (c) Add polyurethane water-based thickener (RM-2020) or / and water to the second mixture, and control the indicators as follows: solid content 8-15%, viscosity 100-500cps.

Embodiment 2

[0026] This example provides a preparation method of a water-based PP treatment agent, which is basically the same as that in Example 1, except that the addition amount of the silane coupling agent (KH-450) is 1.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com