Patents

Literature

3360results about "Graft polymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Activatable material

InactiveUS6846559B2Assist in flow controlPreventing fatigue crack growthSynthetic resin layered productsRecord information storageEpoxyElastomer

An activatable (e.g., heat expandable) material and articles incorporating the same is disclosed. The material includes an epoxy resin; an epoxy / elastomer hybrid or reaction product; a blowing agent; a curing agent; and optionally, a filler. In preferred embodiments, the material includes aramid fiber, nanoclay or both.

Owner:ZEPHYROS INC

Cationic and hybrid radiation curable pressure sensitive adhesives for bonding of optical discs

InactiveUS6180200B1Improve adhesionImprove adhesion qualityTelevision system detailsNon-macromolecular adhesive additivesAdhesive bondingPressure sensitive

Cationic and hybrid radiation-curable pressure sensitive adhesive compositions for digital versatile discs and other substrates, a method for bonding versatile digital disc layers together with a cationic or hybrid radiation-curable pressure sensitive adhesive, and a digital versatile disc bonded by cationic or hybrid radiation-curable pressure sensitive adhesive.

Owner:DSM IP ASSETS BV

Polypropylene type aqueous dispersion, polypropylene type composite aqueous emulsion composition and its use

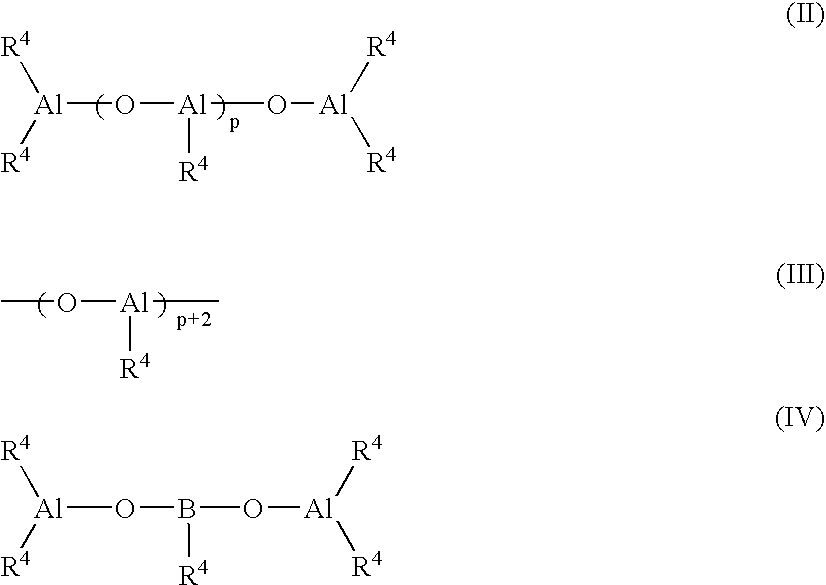

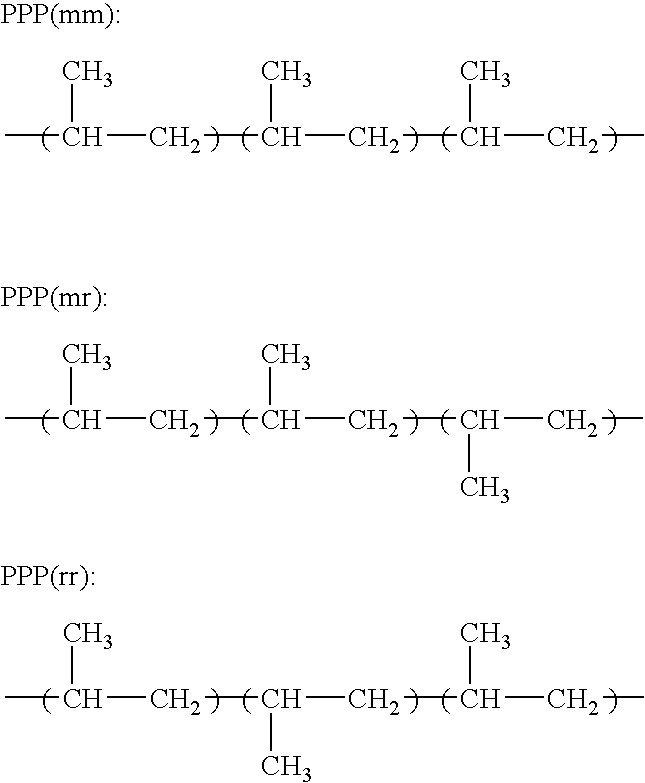

A polypropylene type aqueous dispersion comprising the following components (a) to (c): (a) a polypropylene type polymer100parts by weightand / or a modified polypropylene typepolymer(b) a surfactant1 to 100parts by weight, and(c) water100 to 1,000parts by weight,wherein the component (a) has a main chain having the following features (1) and (2) and dispersion particles in the dispersion have an average particle size of at most 0.5 μm, Feature (1) when observing a peak derived from a carbon atom of a methyl group in a propylene unit chain part comprising a head-to-tail bond by 13C-NMR and fixing a chemical shift of a peak top at a peak attributable to pentad expressed by mmmm to 21.8 ppm, a ratio (S1 / S) of an area S1 of a peak of a peak top at 21.8 ppm to a total area S of peaks at from 19.8 ppm to 22.1 ppm is at least 10% and at most 60%, and when an area of a peak (mmmr) of a peak top at 21.5 to 21.6 ppm is expressed as S2, 4+2S1 / S2>5, and Feature (2) a content ratio (mol ratio) of propylene unit (A): other olefin unit (B) is from 100:0 to 90:10.

Owner:MITSUBISHI CHEM CORP

Functionalized propylene copolymer adhesive composition

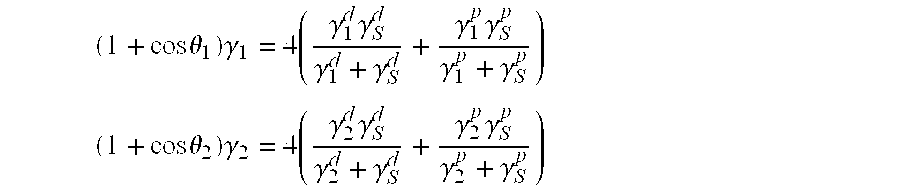

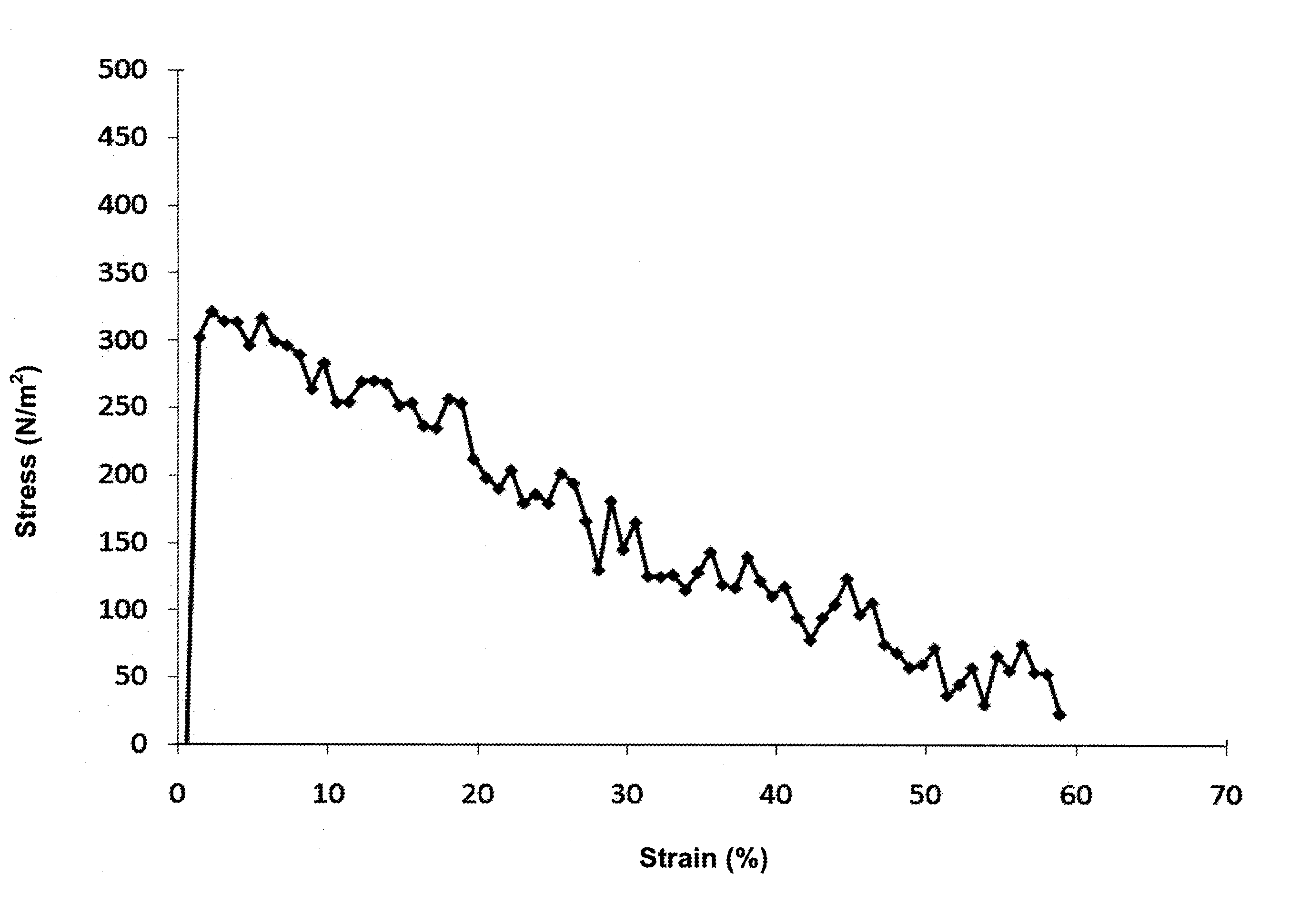

This invention relates to an adhesive composition comprising a functionalized random propylene polymer (FRPP) having at least 0.1 wt % of a functional group, a heat of fusion of between 0.5 and 70 J / g, and an mm triad tacticity index of at least 75%, where the adhesive has a T-Peel adhesion on a polar substrate at 20° C. of at least 175 N / m (1 lb / in) and a T-Peel adhesion on a non-polar substrate at 20° C. of at least 175 N / m (1 lb / in) where the polarity of the polar substrate is at least 0.10 units higher than the polarity of the non-polar substrate. Methods to produce the adhesive and articles comprising the adhesive are also disclosed.

Owner:EXXONMOBIL CHEM PAT INC

Ultraviolet curable organic silicon-acrylic resin electronic adhesive and application thereof

InactiveCN101812278AFast curingIncrease elasticityOther chemical processesCoatingsNon toxicityAdhesive

The invention provides an ultraviolet curable organic silicon-acrylic resin electronic adhesive, which comprises the following components: (1) 100 parts of doublebond-containing acrylic monomers or prepolymer, (2) 5 to 500 parts of doublebond-containing organic silicon resin with a molecular weight of 1,000 to 10,000, (3) 1 to 100 parts of vinyl compound modified inorganic nano particle, (4) 1 to 50 parts of radical ultraviolet initiator, (5) 1 to 100 parts of organosilan, (6) 0 to 200 parts of inorganic reinforcing agent, and (7) 0 to 50 parts of auxiliary agent, wherein the ultraviolet curable organic silicon-acrylic resin is prepared by carrying out ultraviolet curing on the materials, and the solid content thereof is 100 weight percent. The product produced by the invention has the excellent characteristics of firm bonding with metal, glass and plastic materials and electronic devices, good optical property, good elasticity, good weather resistance, safety, non-toxicity, convenient construction and the like, can replace traditional solvent electronic adhesives, and is used for protective coatings, protective adhesives, packaging materials and the like of electronic devices, integrated circuits, printed circuits, LED chips and the like.

Owner:SHANGHAI XIYI NEW MATERIAL SCI & TECHCO

Accelerated and toughened two part epoxy adhesives

InactiveUS20150184039A1High dynamic impact peel strengthFast curing timeMacromolecular adhesive additivesEpoxy resin adhesivesFiberGlass fiber

A 2K epoxy adhesive is provided that has rapid cure time and good strength characteristics. Both the epoxy resin composition and the hardener composition of the 2K epoxy comprise a reactive toughener. Such adhesives are useful in the manufacture and / or repair of large machinery (e.g., automobiles), and are useful for bonding like or unlike materials, such as metal and composites (e.g., carbon fiber or glass fiber composites).

Owner:DOW GLOBAL TECH LLC

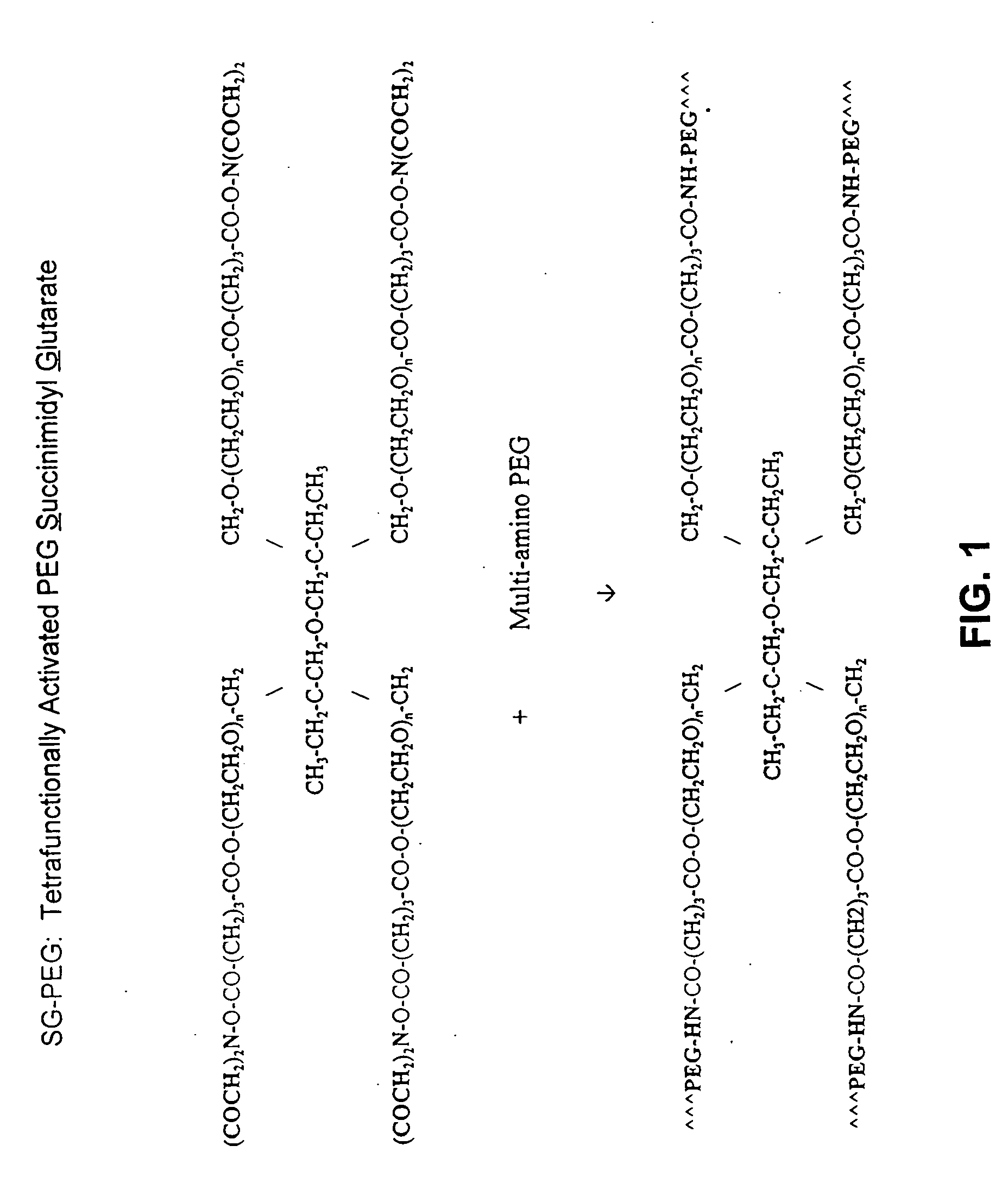

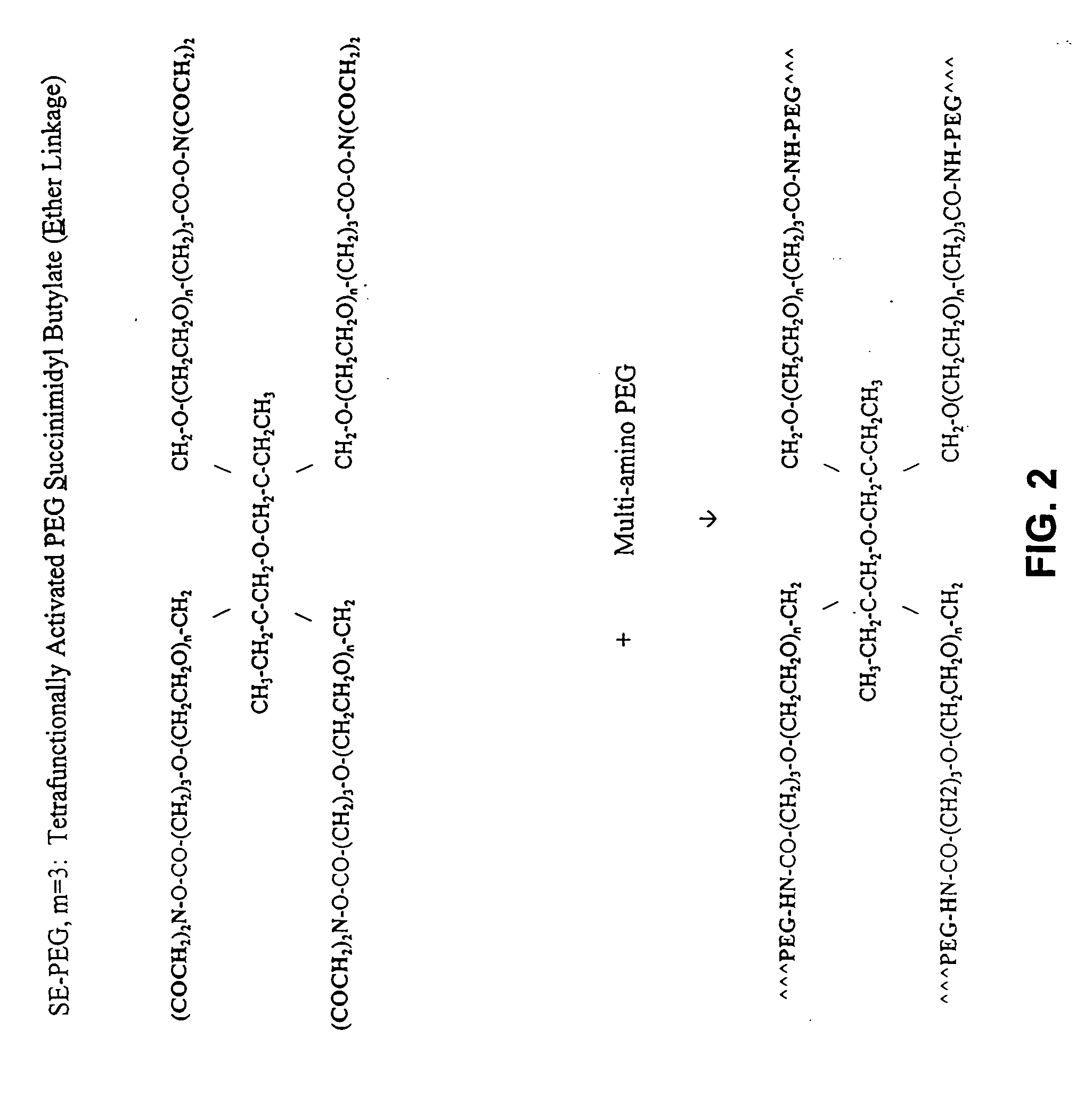

Compositions and systems for forming crosslinked biomaterials and methods of preparation and use

InactiveUS20060210602A1Organic active ingredientsProtein waste adhesivesActive agentBiological materials

Crosslinkable compositions are provided that readily crosslink in situ to provide biocompatible, nonimmunogenic crosslinked materials that may be used as adhesive compositions. The compositions comprise collagen and a plurality of crosslinkable components having reactive functional groups thereon, with the functional groups selected so as to enable inter-reaction between the components, i.e., crosslinking. Methods for preparing and using the compositions are also provided. Exemplary uses include tissue augmentation, biologically active agent delivery, bioadhesion, prevention of adhesions following surgery or injury, and coating of surgically acceptable patches and solid implants, the latter including sutures.

Owner:ANGIODEVICE INT GMBH

Preparation of graft modification protein-based adhesive

InactiveCN101302410ASolve application problemsIncrease added valueGraft polymer adhesivesAdhesiveRedox

The invention relates to a method for preparing graft modification protein adhesives, belonging to the adhesive technical field. The method obtains the graft modification protein adhesives by adopting redox system initiator to react for a period of time at a certain temperature and linking vinyl monomer branched chains on a protein trunk chain. During the production and use processes, substances such as formaldehydes and so on are not released, thereby the method is favorable for environmental protection; and simultaneously the method can increase the added value of protein products and has important economic value. Because more hydrophobic groups are linked on the protein trunk chain, the interaction between the graft modification protein adhesives obtained and molecular groups on the wood surface is stronger and the adhesives are difficult to damage by water molecules, thereby the graft modification protein adhesives have good bonding strength and superior water resistance. The method widens the application environment and solves the problem which disturbs actual application of the protein adhesives for a long time, consequently having obvious technical advance.

Owner:JIANGNAN UNIV

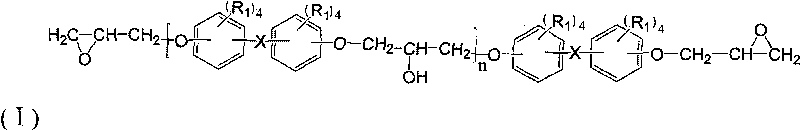

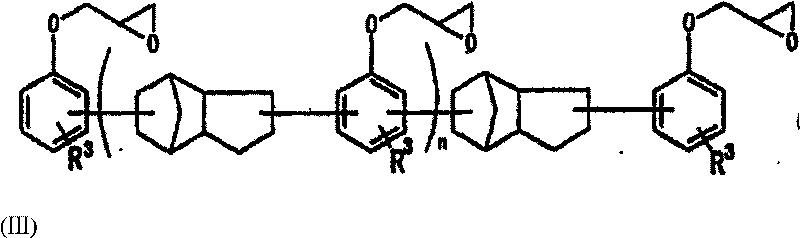

Heat-curable eproxy resin composition

InactiveUS20050159511A1Other chemical processesPolyureas/polyurethane adhesivesAdhesiveReactive diluent

The invention relates to compositions containing at least one epoxy resin A with on average more than one epoxy group per molecule; at least one epoxy adduct B with on average one epoxy group per molecule; at least one thixotropic agent C, based on a urea derivative in a non-diffusing support material; and at least one curing agent D for epoxy resins, which is activated by an increased temperature. According to preferred embodiments, the invention also relates to compositions containing at least one core-shell polymer E and / or filler F and / or reactive diluent G. The invention also relates to the use of said compositions as a single-component adhesive and to a method for producing the compositions. The invention further relates to the use of the thixotropic agent C, based on a urea derivative in a non-diffusing support material as an agent for increasing the impact resistance.

Owner:SIKA SCHWEIZ AG

Multi-staged binder for use in elastomeric coatings, caulks and sealants

InactiveUS6060532ALower Level RequirementsLow temperature flexibilityImpression capsOther chemical processesElastomerEmulsion

A method for using a thermoplastic elastomeric composition which contains a multi-staged emulsion polymer binder is provided. An elastomeric composition which contains a multi-staged emulsion polymer binder and a photosensitive composition and a method for using the elastomeric composition in elastomeric coatings, caulks, or sealants is also provided.

Owner:ROHM & HAAS CO

Adhesive polyethylene compositions and multi-layer laminated films using the same

InactiveUS6210765B1Improve adhesion strengthHigh heat sealing strength heatWrappers shrinkageShrinkage connectionsElastomerPolyamide

Disclosed is a specific adhesive polyethylene composition comprising [1] a modified ethylene / alpha-olefin copolymer resin or elastomer obtained by modifying a specific ethylene / alpha-olefin copolymer resin or elastomer, each of which comprises ethylene and an alpha-olefin of 3 to 20 carbon atoms, with an unsaturated carboxylic acid or anhydride, ester, amide, imide or metallic salt derivative of a unsaturated carboxylic acid thereof, [2] an unmodified ethylene / alpha-olefin copolymer resin and / or an unmodified ethylene / alpha-olefin copolymer elastomer and [3] a tackifier. Also disclosed is a multi-layer laminated film of 3 or more layers in which a layer of the above composition is interposed between an ethylene polymer layer and either a polyamide resin layer, an ethylene / vinyl alcohol copolymer layer or a layer of a mixture of polyamide resin and ethylene / vinyl alcohol copolymer. The adhesive polyethylene composition shows excellent adhesion strength to ethylene polymers, polyamide resins and ethylene / vinyl alcohol copolymers, high heat-sealing strength and heat resistance. The multi-layer laminated film shows excellent strength, heat resistance and gas barrier properties, and besides this film has heat shrinkability, so that the film is suitably used as a shrink film.

Owner:MITSUI CHEM INC

TPE composition that exhibits excellent adhesion to textile fibers

InactiveUS6503984B2Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

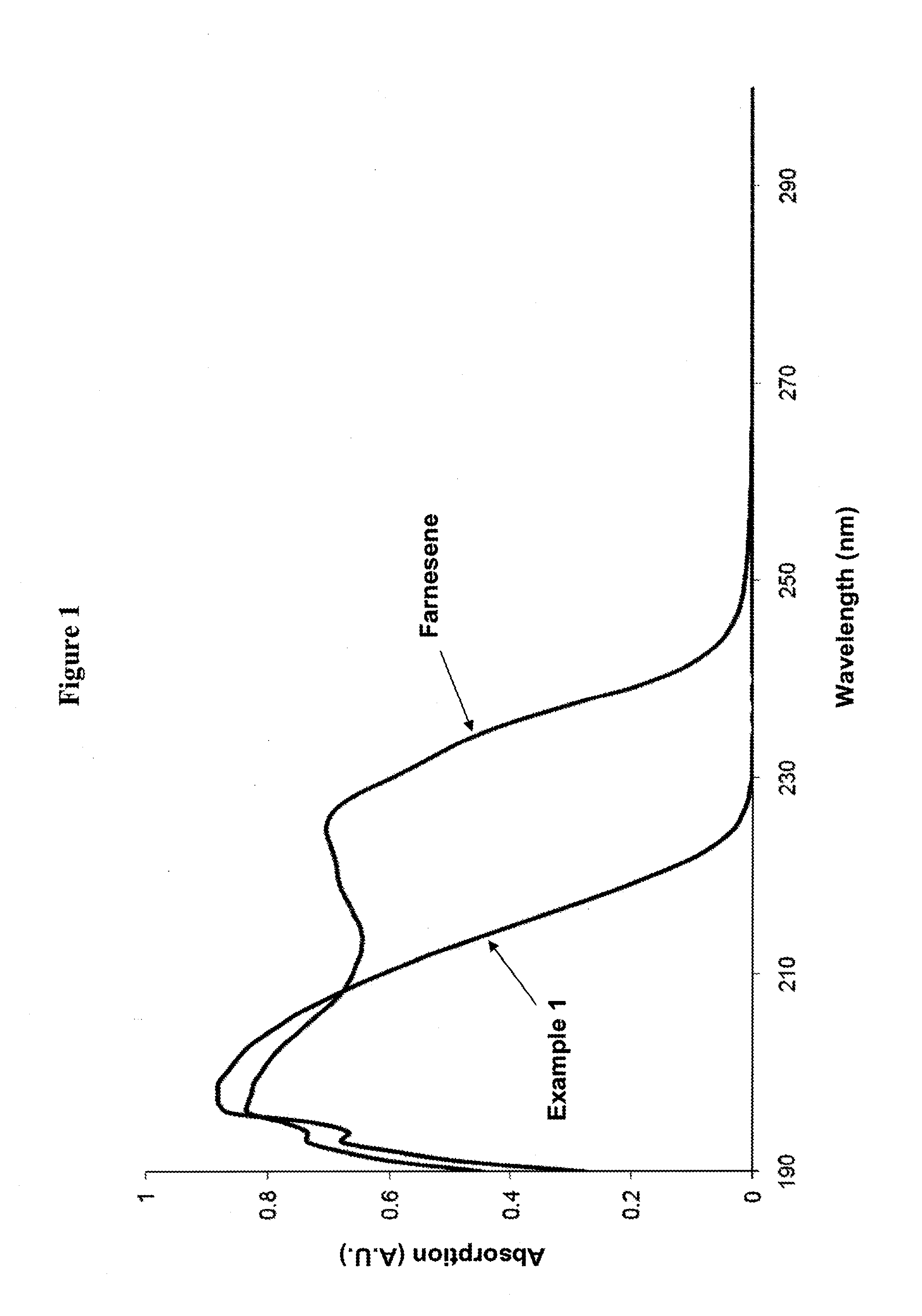

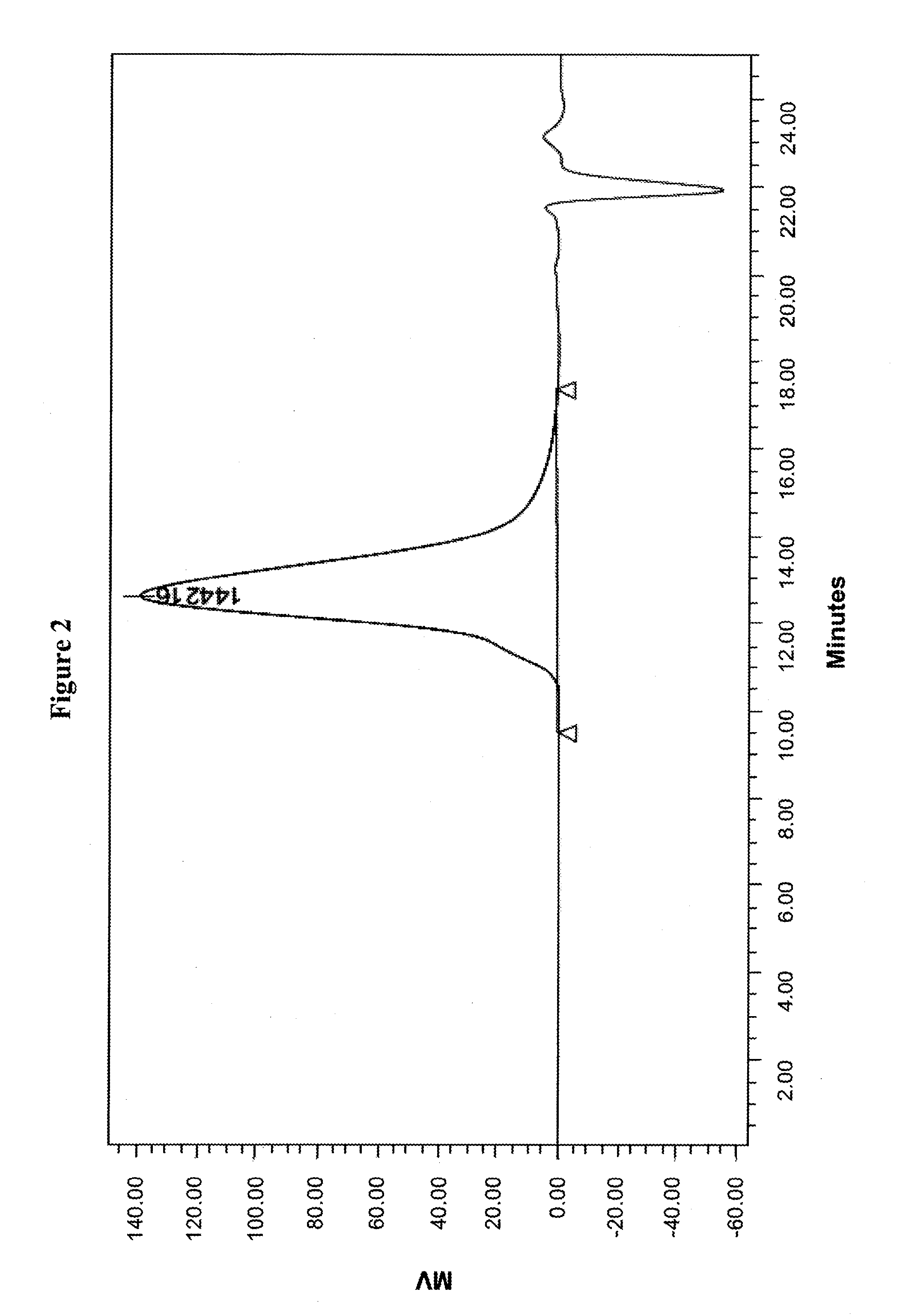

Adhesive compositions comprising a polyfarnesene

Adhesive composition comprises a polyfarnesene and a tackifier. The polyfarnesene can be a farnesene homopolymer derived from a farnesene (e.g., α-farnesene or β-farnesene) or a farnesene interpolymer derived from a farnesene and at least a vinyl monomer. In some embodiments, the at least one vinyl monomer is ethylene, an α-olefin such as styrene, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof. The composition disclosed herein can be used as a hot melt adhesive, a pressure sensitive adhesive or the like.

Owner:AMYRIS INC

Nano titanium dioxide/ acrylate composite emulsion and preparation method thereof

InactiveCN102516477AAvoid reunionStable structureCoatingsGraft polymer adhesivesPtru catalystPolymer chemistry

The invention discloses nano titanium dioxide / acrylate composite emulsion and a preparation method thereof. The method comprises the following steps of: hydrolyzing butyl titanate to generate nano titanium dioxide sol in absolute ethanol by using hydrochloric acid as a catalyst, adding a vinyl-containing silane coupling agent for modifying the sol, performing centrifugal washing, drying and grinding on the obtained product to obtain nano titanium dioxide, and thus obtaining the nano titanium dioxide / acrylate composite emulsion by using acrylate monomers of methyl methacrylate, butyl acrylate and the like as reaction monomers and adopting a method combining in-situ emulsion polymerization and seed emulsion polymerization. The nano titanium dioxide / acrylate composite emulsion prepared by the method has good storage stability and is stable in a polymerization reaction process; and a film formed by the composite emulsion has good hardness, impact strength and heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

Curable compositions for optical articles

InactiveUS20070191506A1Avoid birefringence problemsLow shrinkageOptical articlesCoatingsOligomerAdhesive

Owner:3M INNOVATIVE PROPERTIES CO

Transdermal pressure sensitive adhesive drug delivery system

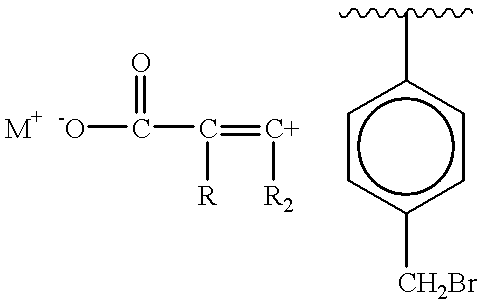

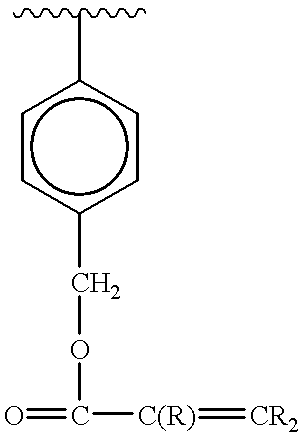

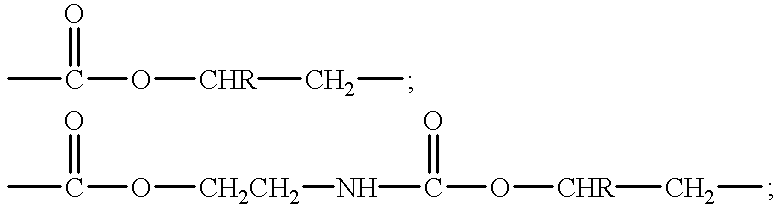

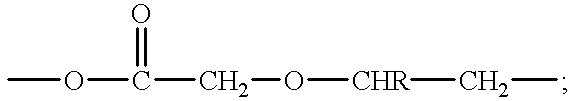

InactiveUS6174546B1Maintenance characteristicTrend downAdhesive dressingsAbsorbent padsMeth-Macromonomer

A transdermal drug delivery system is provided which includes an optionally crosslinked macromer-reinforced (meth)acrylic ester base copolymer pressure sensitive adhesive wherein the macromer includes repeat hydrophilic units.

Owner:ADHESIVES RES

High weather-proof thermosetting resin composite and prepreg and copper-clad laminate prepared thereby

InactiveCN101735456AImprove heat resistanceSmall coefficient of thermal expansionFibre treatmentPaper coatingEpoxyManufacturing technology

The invention relates to a high weather-proof thermosetting resin composite and prepreg and copper-clad laminate prepared thereby. The high weather-proof thermosetting resin composite comprises the following components in parts by weight: 10-40 parts of allyl compound, 8-80 parts of bismaleimide compound, 0-30 parts of epoxy resin and 0.05-5 parts of catalyst, wherein the molar ratio of allyl compound to bismaleimide compound is 1:2-4. The high weather-proof thermosetting resin composite provided by the invention has higher heat resistance, and the coefficient of thermal expansion (CTE) can be lowered to be below 2.0% to satisfy the requirements of manufacturing high multi-layer PCB. The prepreg prepared by the high weather-proof thermosetting resin composite has simple manufacture, better heat-resistant effect and high heat conductivity. The copper-clad laminate of the invention can be applied to heat-resisting and high multi-layer circuits and has simple manufacturing technology and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

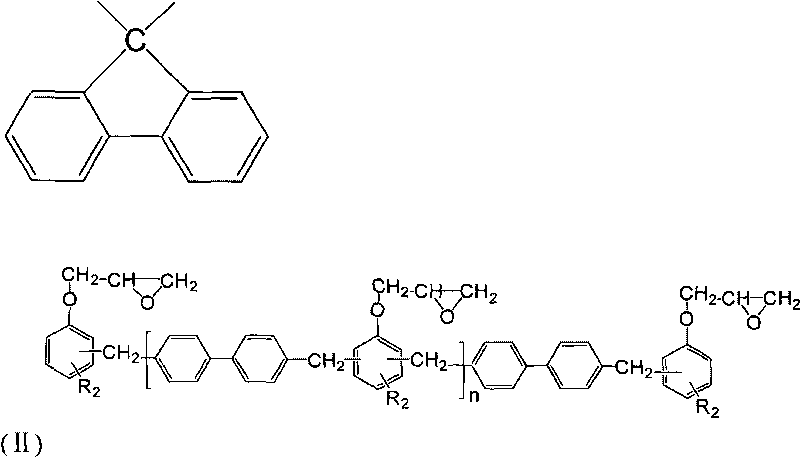

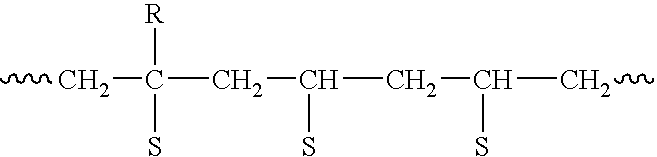

Preparation method of functional master batch of polyolefin and its application

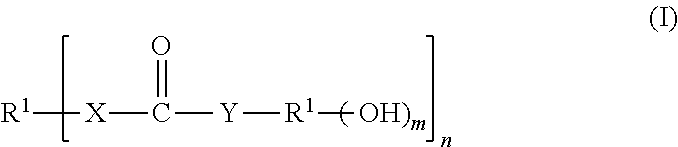

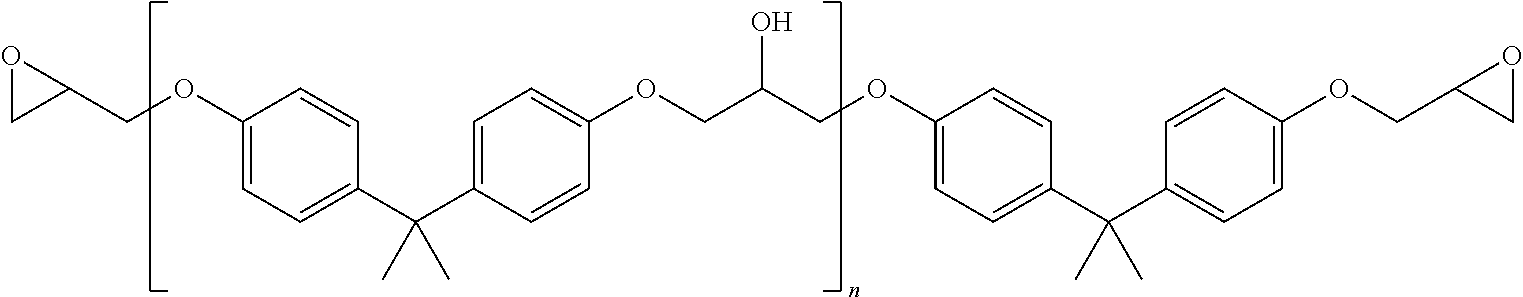

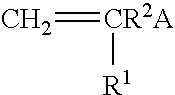

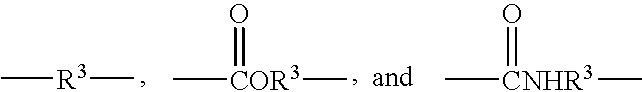

ActiveUS7282538B2Maintain good propertiesReducing flowability and spinnabilityThin material handlingGraft polymer adhesivesFiberPolymer science

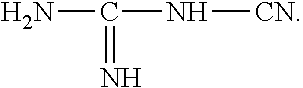

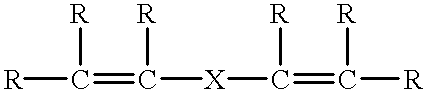

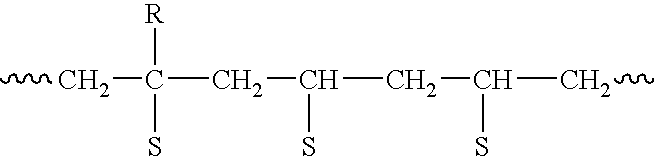

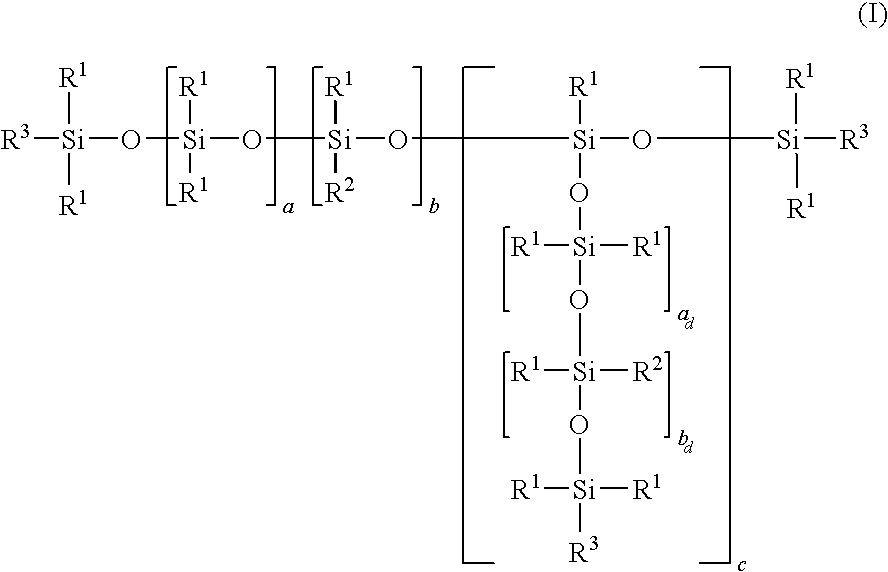

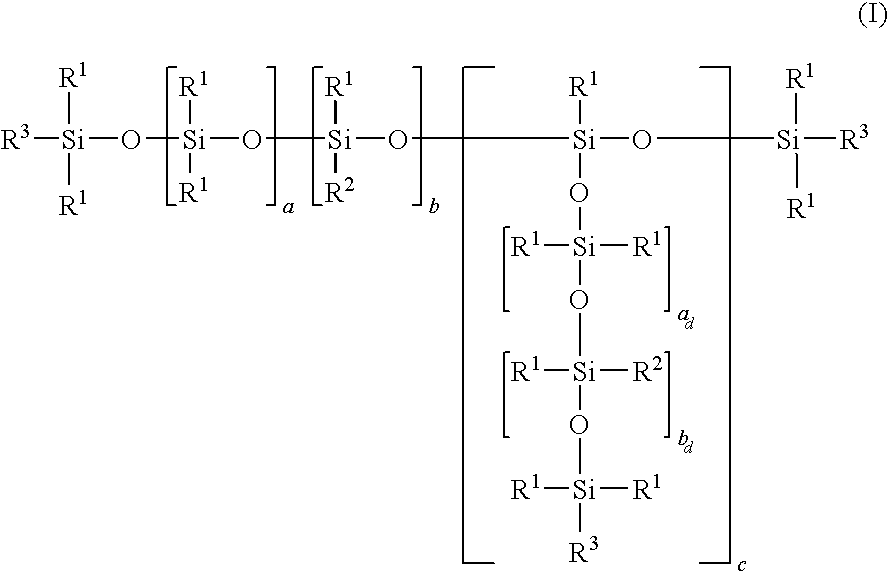

The present invention belongs to the field of polymerization and processing of polymer and relates to the preparation of a kind of functional polyolefin master batch. The functional master batch is produced by liquid phase, melt phase, or solid phase reaction after mixing the polyolefin resin, polyamine and guanidine salt oligomer, olefin monomer and initiator. The molecular structure of functional polyolefin master batch is shown below:wherein R is a polyamine and guanidine salt oligomer bonded onto polyolefin molecular chain by covalence bond, while S is one selected from hydrogen, chlorine, methyl, or phenyl group.Blending mentioned functional master batch with the corresponding polyolefin, the various antimicrobe products, such as fibers, film, pipe and other plastic articles can be obtained. Besides endowing products with excellent permanent antimicrobe property, it also provides fibers with good-dyeable and antistatic ability and bumpers with easy-paintable ability.

Owner:SHANGHAI SUJIE SCI TECH

Aqueous emulsion and use thereof

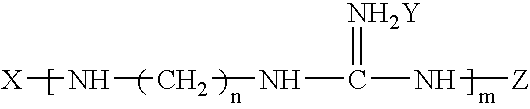

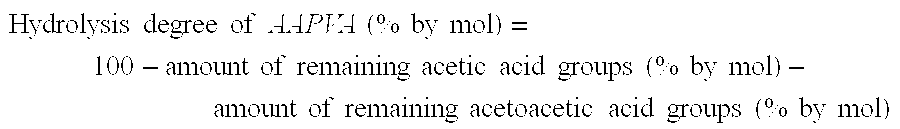

InactiveUS20050197441A1Improve polymerization stabilityNon-fibrous pulp additionGraft polymer adhesivesAcetic acidFiber

The present invention provides an aqueous emulsion having excellent polymerization stability and standing stability and a redispersible powder. Specifically, the present invention relates to an aqueous emulsion of a polymer obtained by polymerizing an acrylic monomer in the presence of a polyvinyl alcohol containing an acetoacetic ester group; wherein the polyvinyl alcohol containing an acetoacetic ester group has block character [η] of 0.3 to 0.6, hydrolysis degree of at least 97% by mol and acetoacetic esterification degree of 0.01 to 1.5% by mol, and the value obtained by dividing the maximum value by the minimum value of the respective average acetoacetic esterification degree for each of the polyvinyl alcohol containing an acetoacetic ester group separated by particle size of 44 to 74, 74 to 105, 105 to 177, 177 to 297, 297 to 500 and 500 to 1680 μm is 1.0 to 3.0. Also, the present invention relates to a redispersible fiber obtained by drying the aqueous emulsion.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

Compositions and systems for forming crosslinked biomaterials and methods of preparation of use

Crosslinkable compositions are provided that readily crosslink in situ to provide biocompatible, nonimmunogenic crosslinked materials that may be used as adhesive compositions. The compositions comprise collagen and a plurality of crosslinkable components having reactive functional groups thereon, with the functional groups selected so as to enable inter-reaction between the components, i.e., crosslinking. Methods for preparing and using the compositions are also provided. Exemplary uses include tissue augmentation, biologically active agent delivery, bioadhesion, prevention of adhesions following surgery or injury, and coating of surgically acceptable patches and solid implants, the latter including sutures.

Owner:ANGIODEVICE INT GMBH

Polymerizable composition and method for producing (METH) acrylic thermally conductive sheet

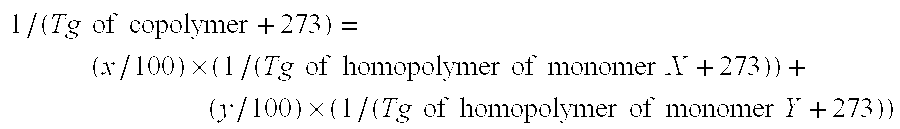

InactiveUS20070261785A1Good flexibilityExcellent in bleed resistanceLamination ancillary operationsLaminationPolymer scienceMeth-

A polymerizable composition which contains a component (A): a (meth)acrylic monomer, a component (B): a (meth)acrylic polymer having at least one functional group capable of undergoing a cross-linking reaction in its molecule, a component (C): a (meth)acrylic oligomer having at one terminal of its molecule a functional group capable of undergoing a cross-linking reaction, a component (D): a cross-linking agent having a functional group capable of undergoing a cross-linking reaction, a compound (E): a photopolymerization initiator and / or a thermal polymerization initiator, and a component (F): a thermally conductive filler, is disclosed. Further, a (meth)acrylic thermally conductive sheet having a pressure-sensitive adhesive layer prepared by polymerizing and cross-linking the polymerizable composition on a support is disclosed. The thermally conductive sheet prepared by using the polymerizable composition according to the invention is excellent in flexibility, adhesiveness and bleed resistance and can dissipate heat generated from a heat-generating body such as an electronic device with good efficiency.

Owner:SOKEN CHEM & ENG CO LTD

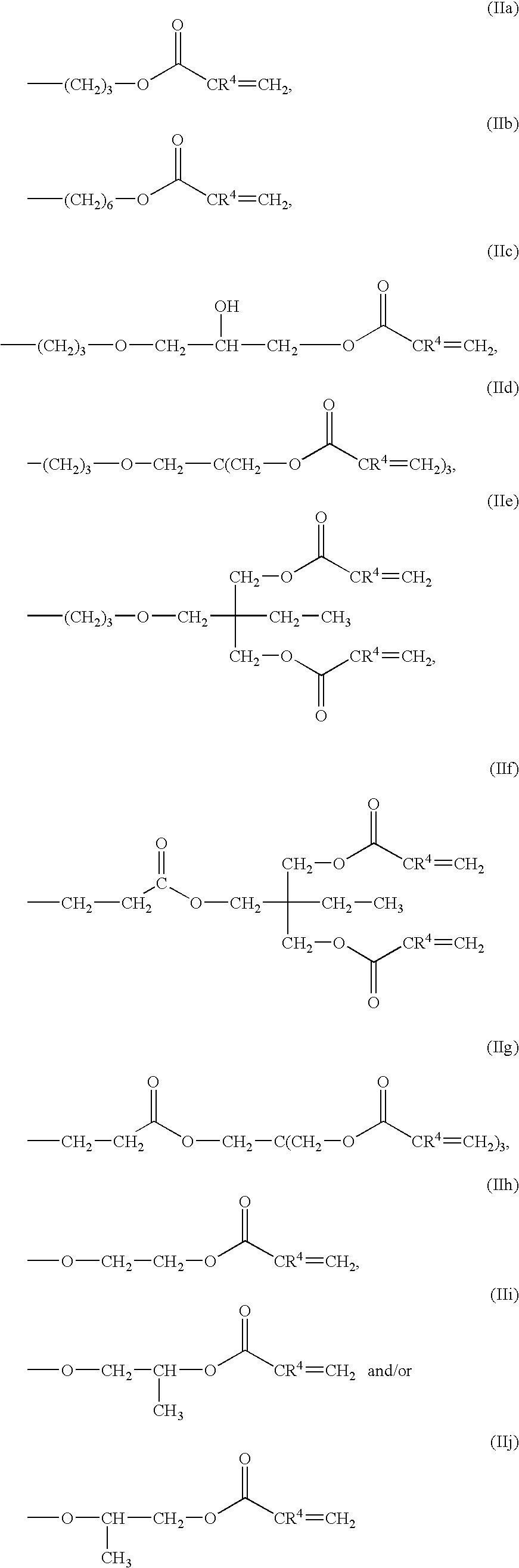

Silicone (METH)acrylate particles, process for preparation thereof and use thereof

InactiveUS20090149573A1Broaden applicationPromote free movementCosmetic preparationsMake-upMeth-Sealant

The present invention relates to silicone (meth)acrylate particles, to a process for preparing such silicone (meth)acrylate particles including the steps of:a) obtaining an emulsion composed of water and an organic phase comprising organopolysiloxanes modified terminally and / or laterally with acrylate groups, andb) polymerizing the inner phase to completion by means of a free-radical initiator, the free-radical initiator being added to the outer phase (aqueous phase) in a concentration of 0.1 to 40% by weight based on the inner phase, and to the use of the particles alone or in a mixture with further particles, pigments and / or further customary additives in the form of powders or dispersions in coating, adhesive or sealant materials, in polymers, in defoamers, in wetting and levelling aids, in cosmetic or pharmaceutical formulations and care products, in cleaning and detergent compositions, or in applications for modifying the interface properties of solid and liquid substrates, for example tactile properties, hydrophobization, or sliding and / or release properties.

Owner:EVONIK DEGUSSA GMBH

Water adhesive for lithium ion battery, preparation method thereof and lithium ion battery positive plate

ActiveCN101260282AIncrease volumetric energy densityEasy to manufactureSecondary cellsActive material electrodesAdhesiveElectrical battery

The invention relates to aqueous bonding agent for lithium ion batteries, a preparation method and a positive plate for the lithium ion batteries, belonging to the energy storage device such as battery manufacturing field. The aqueous bonding agent for the lithium ion batteries provided by the invention is aqueous polymer emulsion formed after polyvinyl alcohol or ethylidene ether derivatives thereof is taken as a main polymer and two or more than two monomers with different polarities are taken as a graft comonomer to undergo a graft modification in water medium, the solid content of the emulsion is between 5 and 40 percent, and the viscosity is between 200 and 20000 centipoise (40 DEG C). The positive electrode prepared by the aqueous bonding agent for the lithium ion batteries of the invention has higher compacted density, so the volume energy density of the lithium ion batteries is improved; at the same time, the positive plate has good flexibleness after the drying, which contributes to the production of the batteries, improves the finished product rate of battery production, and solves the problems that the positive electrode of the lithium batteries has lower compacted density and the positive plate is brittle and has bad flexibleness after the drying.

Owner:SICHUAN INDIGO TECH CO LTD

High-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and preparation method thereof

ActiveCN103205210AHigh bonding strengthImprove heat resistanceFilm/foil adhesivesPolyureas/polyurethane adhesivesElastomerPolyester

The invention discloses a high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and a preparation method thereof. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards is made from, by weight percent, 30-50% of polyester elastomer with above 180 DEG C of melting point, 10-40% of polyolefin copolymer modified by maleic anhydride, 0-40% of polyolefin copolymer, 10-30% of tackifying resin, 0-15% of filler, and 1-3% of functional aid. The components add up to 100%. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards has the advantages of high adhesion strength, instantaneous resistance to the temperature up to 170-190 DEG C, and long-term resistance to the temperature up to 130 DEG C.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

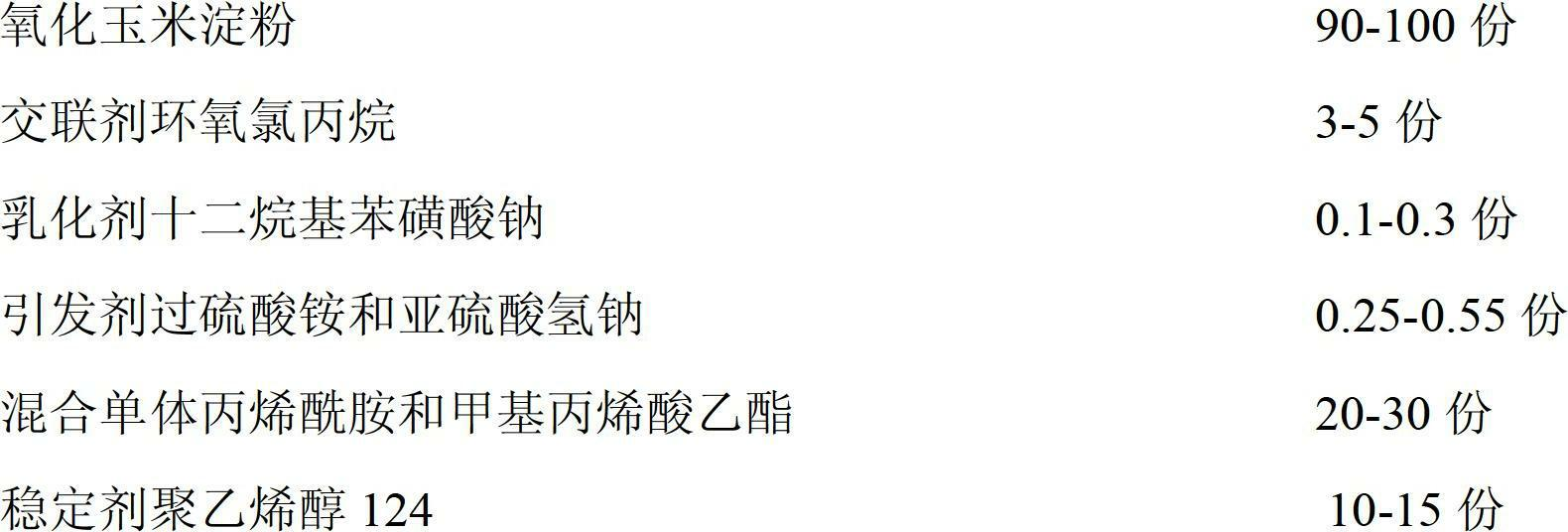

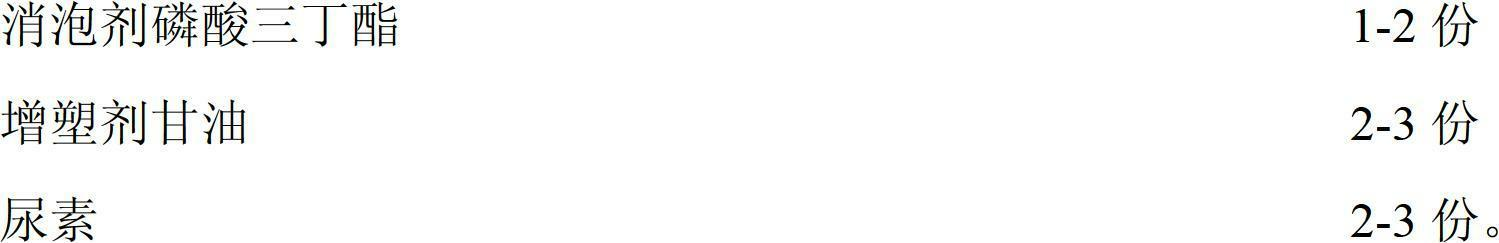

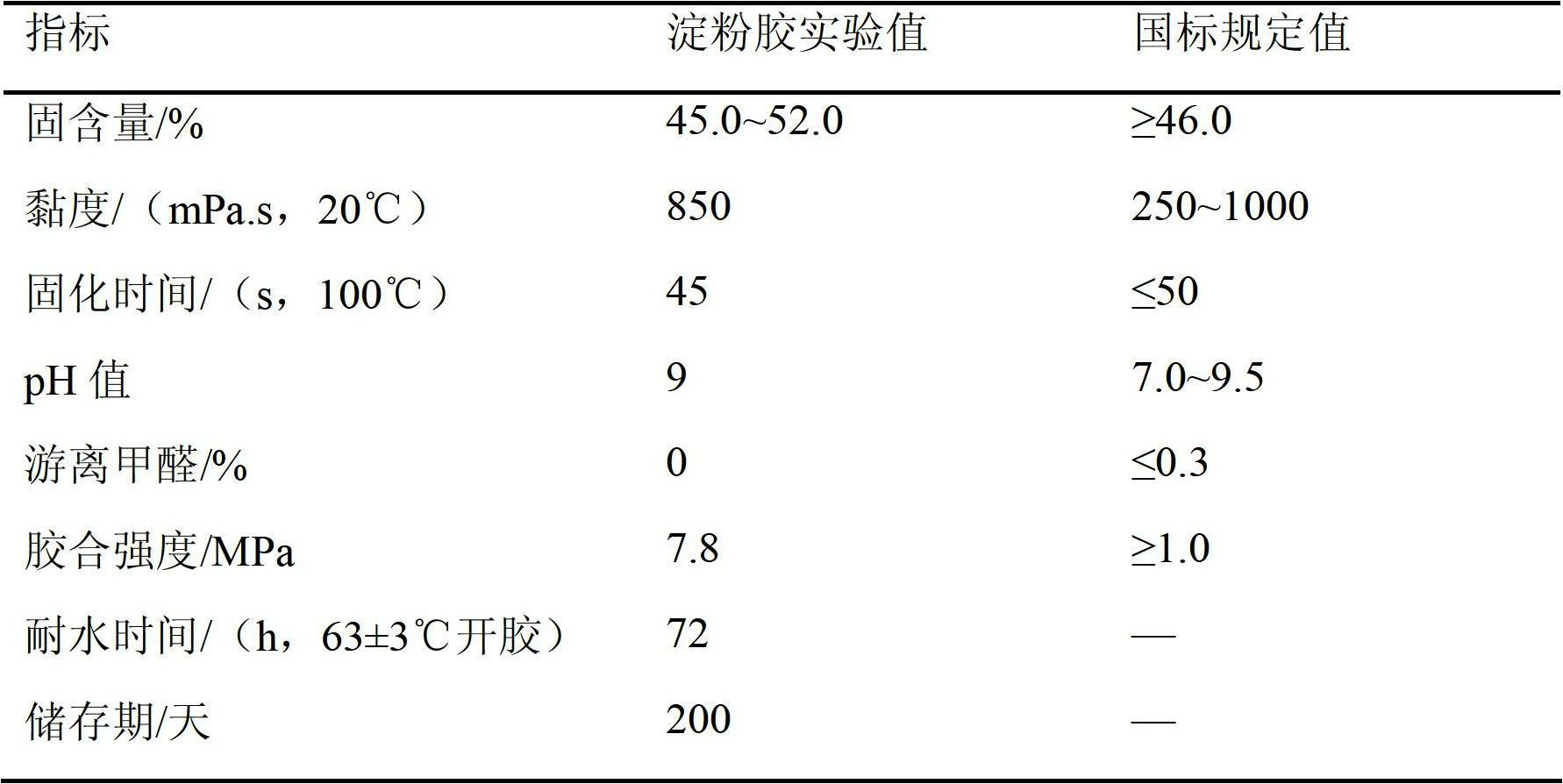

Modified-starch-based wood adhesive and preparation method thereof

InactiveCN102676098AReduce dependenceStrong water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseCross-link

The invention discloses a modified-starch-based wood adhesive and a preparation method thereof. The preparation method comprises the steps that oxidized corn starch is used as a main raw material, a cross-linking agent is added into the oxidized corn starch to conduct crosslinking modification, and then an initiating agent and a high molecular monomer are added to the oxidized corn starch to conduct graft modification, so as to obtain a modified starch emulsion in a complex net structure; and after the modified starch emulsion is warmed up and pasted, modifying agents comprising a stabilizing agent, a defoaming agent, a plasticizing agent and the like are added into the modified starch emulsion, and the high-performance green environment-friendly adhesive is manufactured. Each performance of the adhesive disclosed by the invention can reach or exceed requirements of a GB / T9846-2004 standard, the adhesive has the characteristics of high bonding strength, good water resistance, long storage time, high solid content, low cost, greenness, environment friendliness and wide use range, and can be widely applied to the bonding and the use of wood materials such as artificial boards, plywood and cellulose boards.

Owner:HEFEI UNIV OF TECH

Adhesive tissue repair patch

InactiveUS20050054771A1Composition is easySurgical adhesivesProtein waste adhesivesTissue repairAdhesive tissue

A method of tissue repair is provided using a biocompatible nonimmunogenic adhesive composition. The adhesive composition comprises collagen and a plurality of crosslinkable components having reactive functional groups thereon, with the functional groups selected so as to enable inter-reaction between the components, i.e., crosslinking. Kits for use in carrying out the method of the invention are also provided, as are pretreated surgically acceptable patches that have been coated with the aforementioned adhesive composition.

Owner:ANGIODEVICE INT GMBH

Polyolefin compositions and articles prepared therefrom, and methods for making the same

The invention provides a composition comprising at least the following: an olefin multi-block interpolymer, a functionalized olefin-based polymer, and a thermoplastic polyurethane. The invention also provides for articles prepared from the inventive compositions and for methods for making the same.

Owner:DOW GLOBAL TECH LLC

Silane-Grafted Olefin Polymers, Compositions and Articles Prepared Therefrom, and Methods For Making the Same

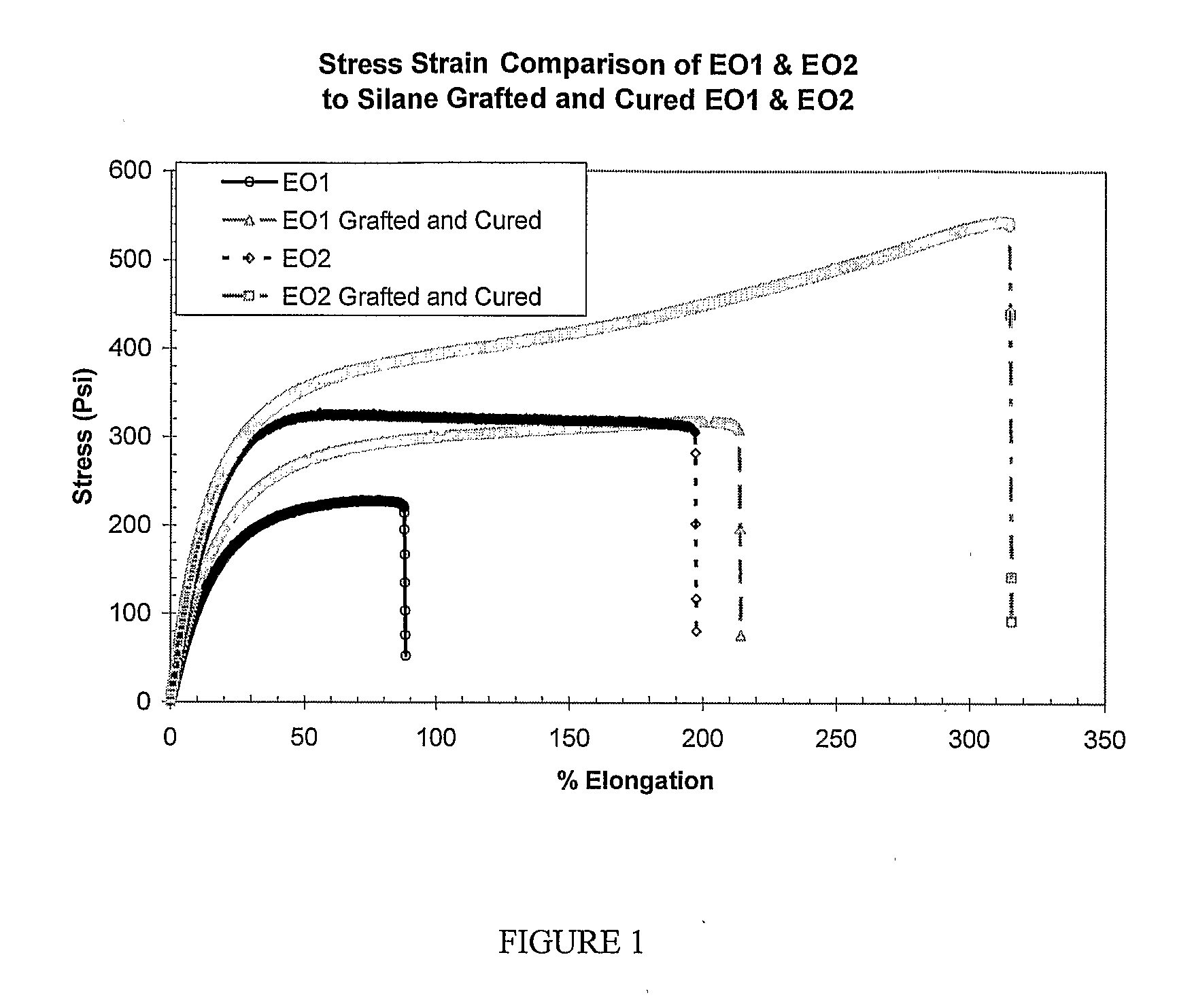

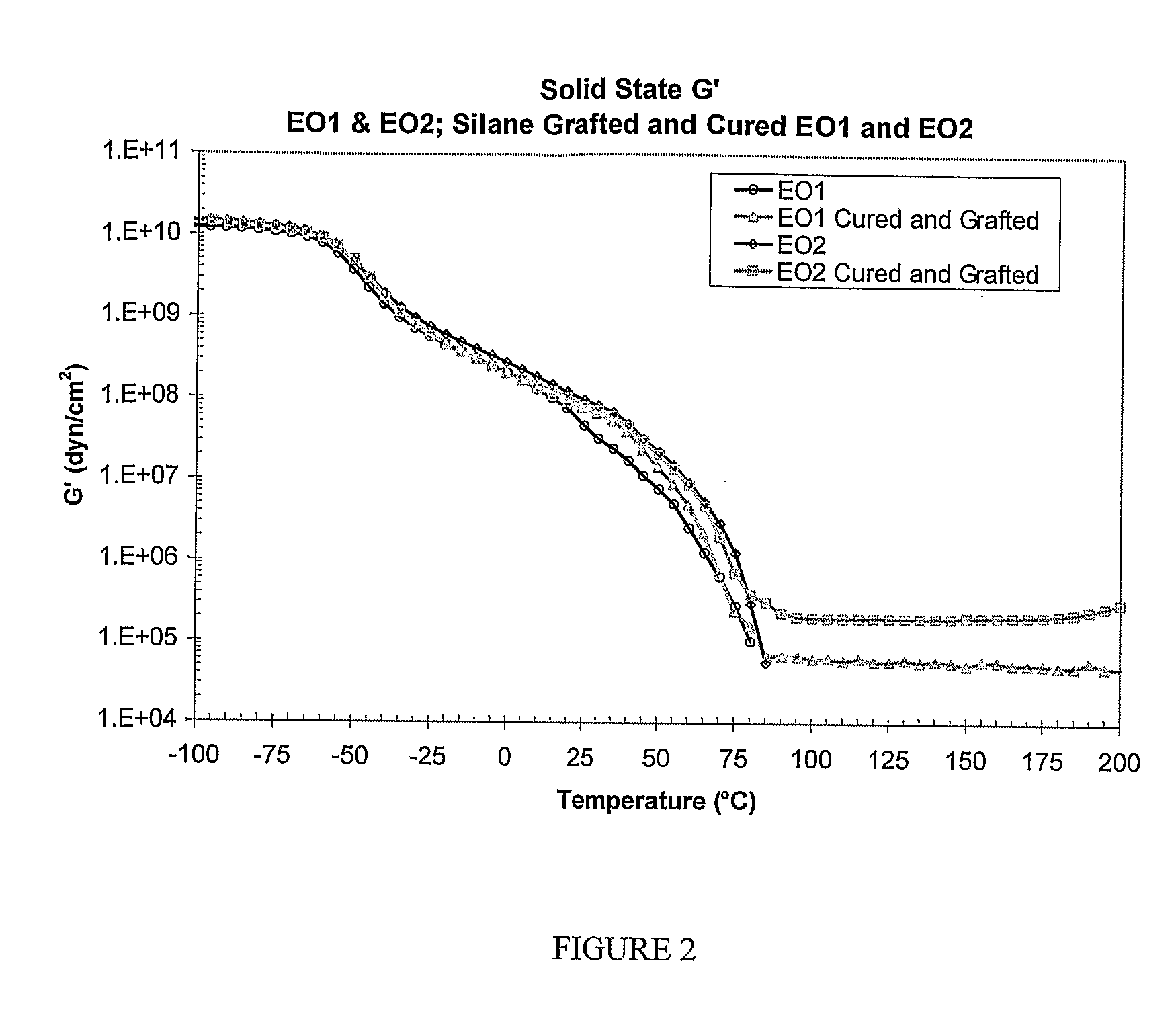

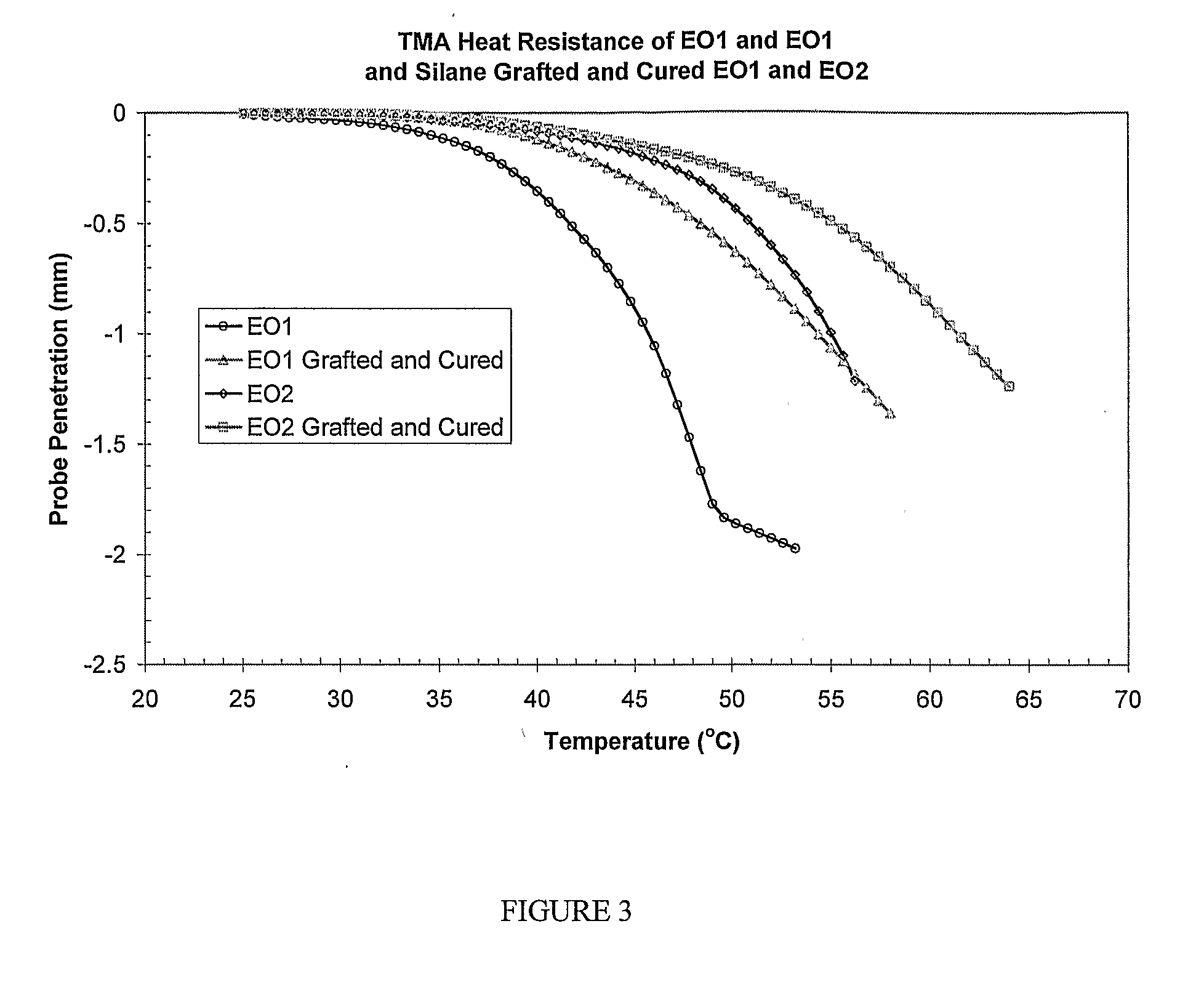

ActiveUS20080167421A1Improve adhesionReduce crystallinitySpecial tyresGraft polymer adhesivesSilane compoundsPolyolefin

The invention relates compositions containing at least one silane-grafted polyolefin, and in particular, to compositions containing at least one silane-grafted ethylene / α-olefin polymer, which has a melt viscosity less than 50,000 cP, and adhesives containing the same. In one embodiment, the at least one silane-grafted ethylene / α-olefin polymer is formed from an ethylene / α-olefin polymer that has a molecular weight distribution from 1 to 3.5. The invention also relates to the preparation of the silane-grafted polymers, by reacting, for example, an ethylene / α-olefin polymer with at least one silane compound and at least one initiator.

Owner:DOW GLOBAL TECH LLC

Rheology-modified grafts and adhesive blends

InactiveUS20090035594A1Shorten the relaxation timeImprove adhesionSynthetic resin layered productsCellulosic plastic layered productsPolyolefinChemistry

Rheologically-modified functionalized polyolefins and tie-layer adhesive blends formulated therewith which exhibit improved adhesion in multi-layer barrier films are provided. Multi-layer barrier shrink films having improved adhesion are also disclosed.

Owner:EQUSR CHEM LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com