Patents

Literature

118 results about "Vinyl halide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

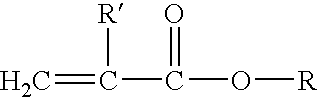

In organic chemistry, a vinyl halide is a compound with the formula CH₂=CHX (X = halide). The term vinyl is often used to describe any alkenyl group. For this reason, alkenyl halides with the formula RCH=CHX are sometimes called vinyl halides. From the perspective of applications, the dominant member of this class of compounds is vinyl chloride, which is produced on the scale of millions of tons per year as a precursor to polyvinyl chloride. Polyvinyl fluoride is another commercial product. Related compounds include vinylidene chloride and vinylidene fluoride.

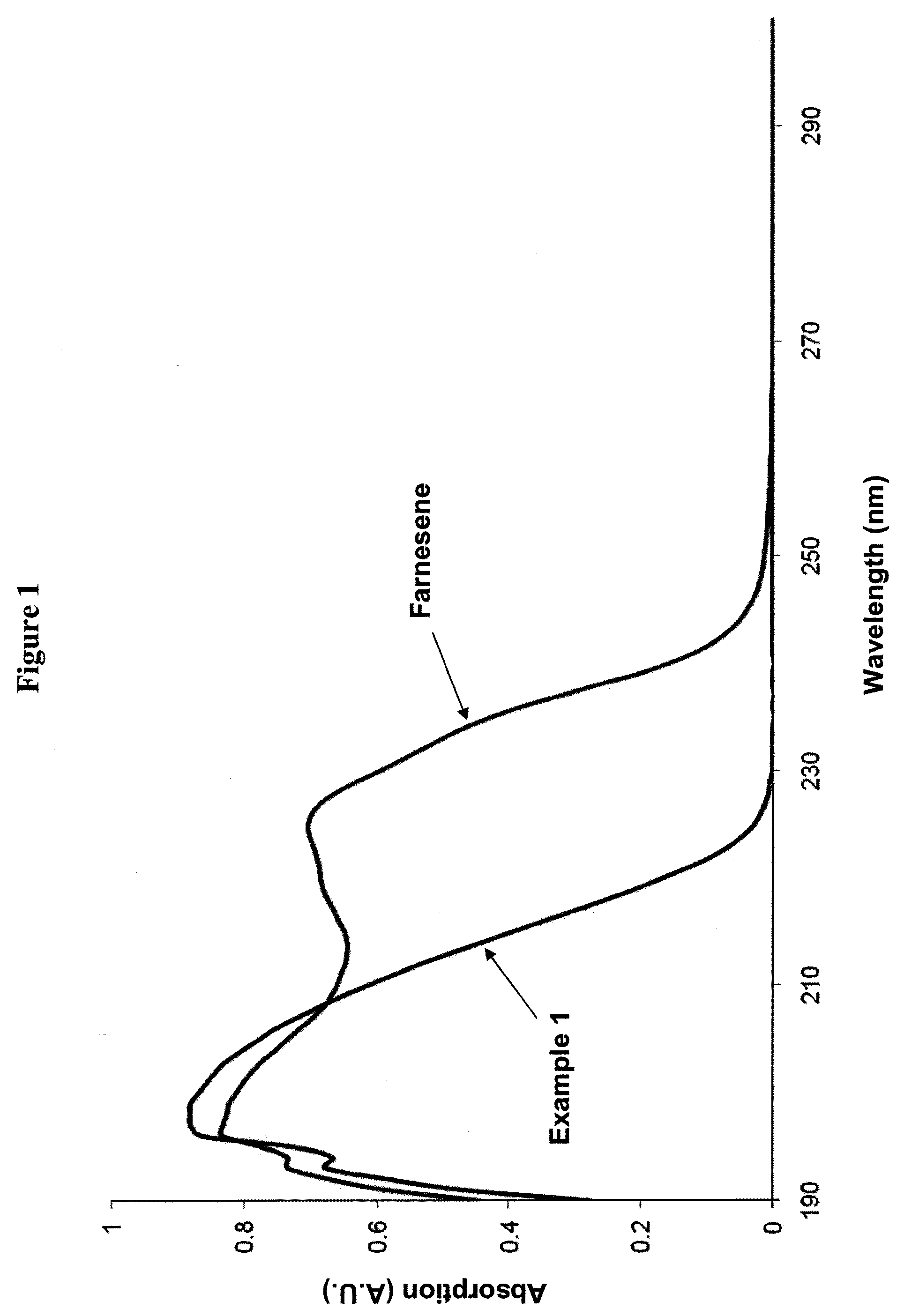

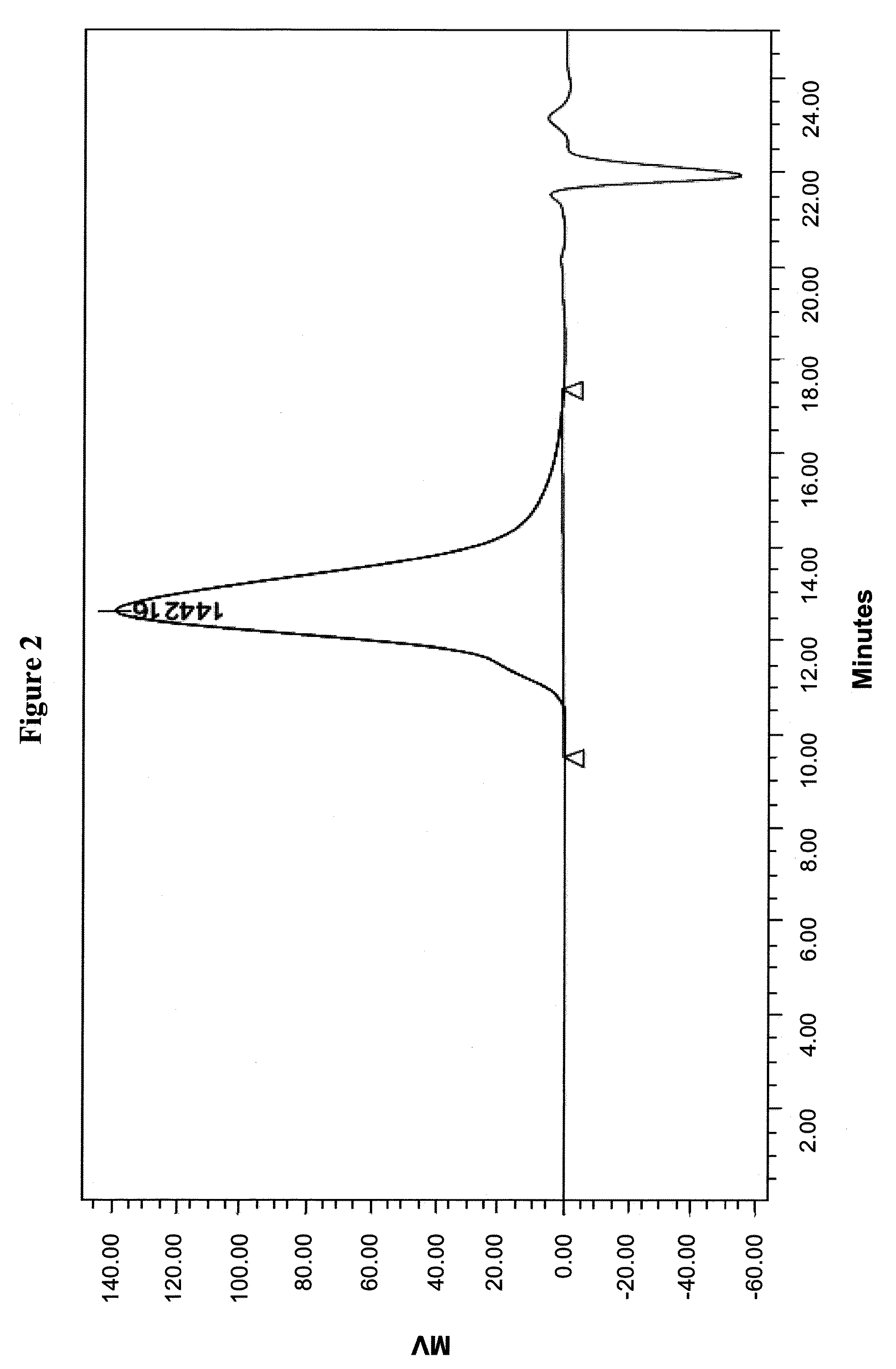

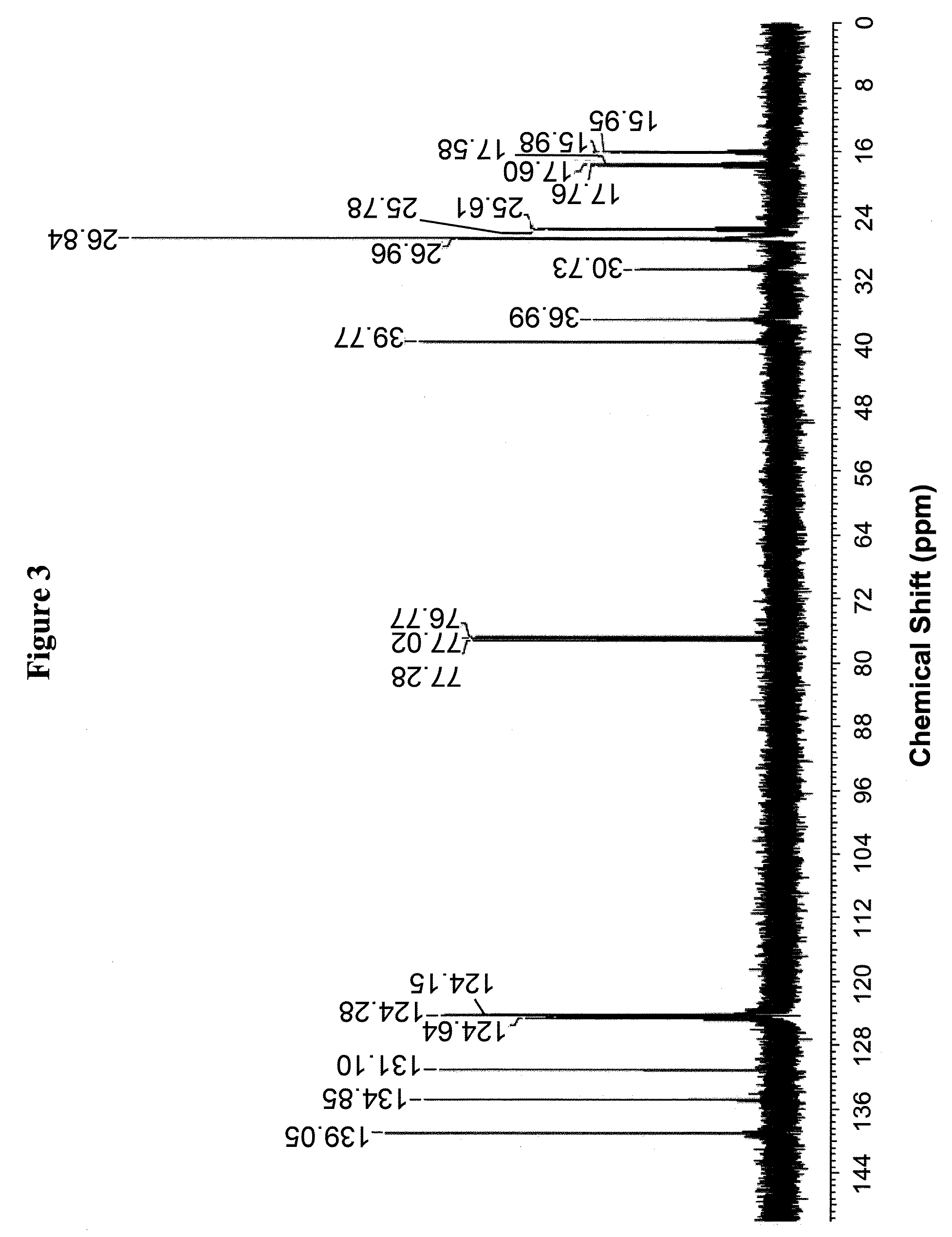

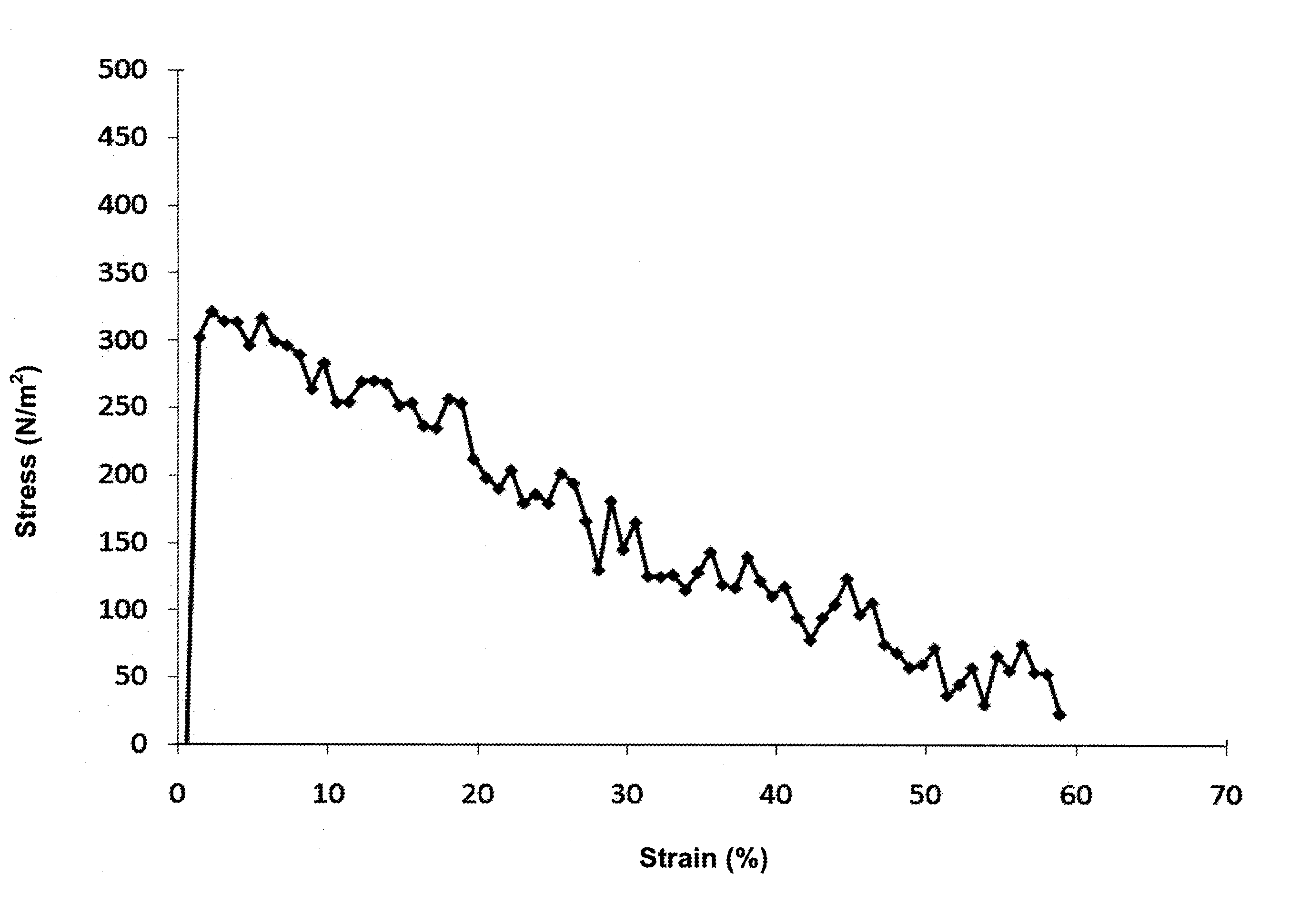

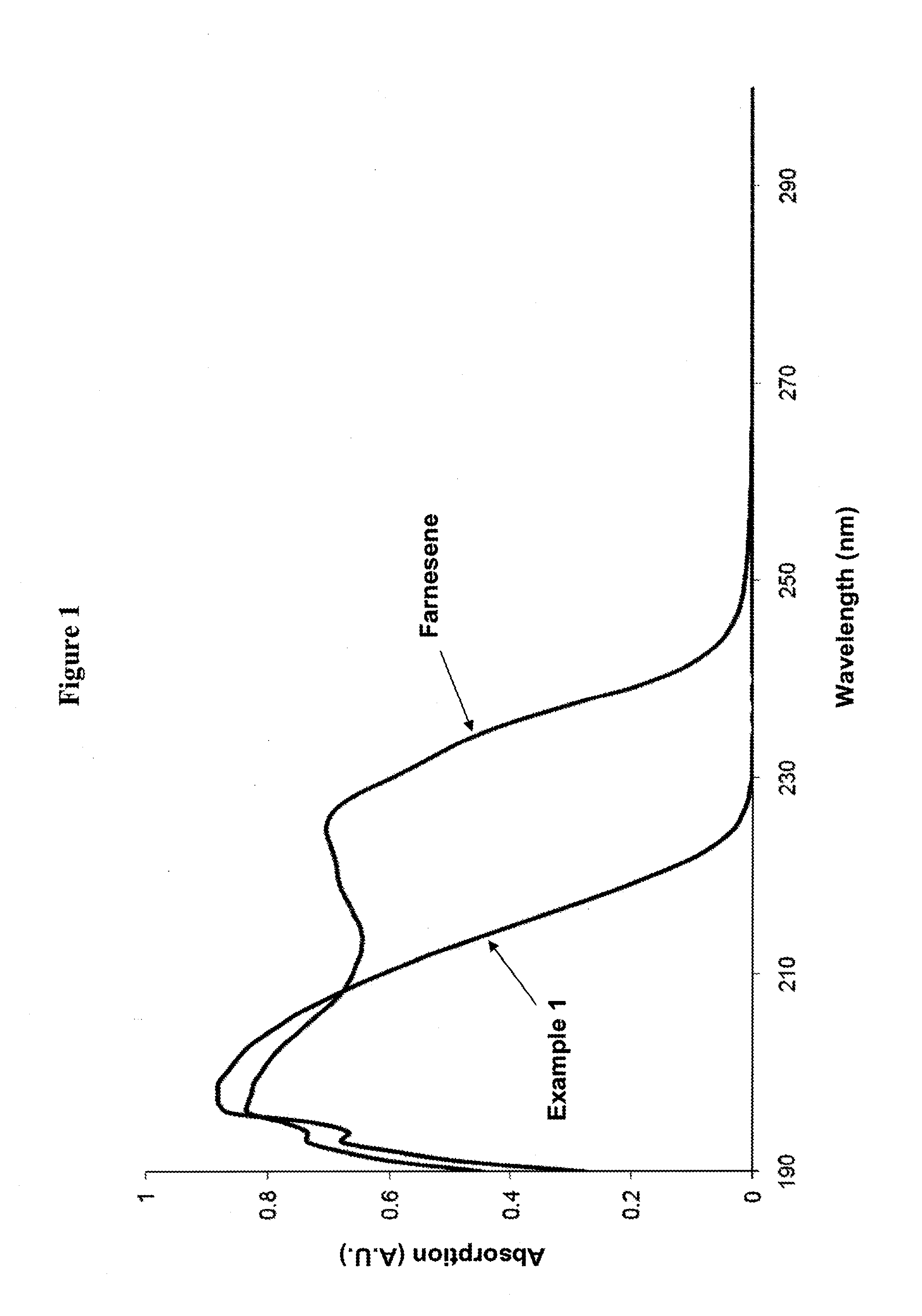

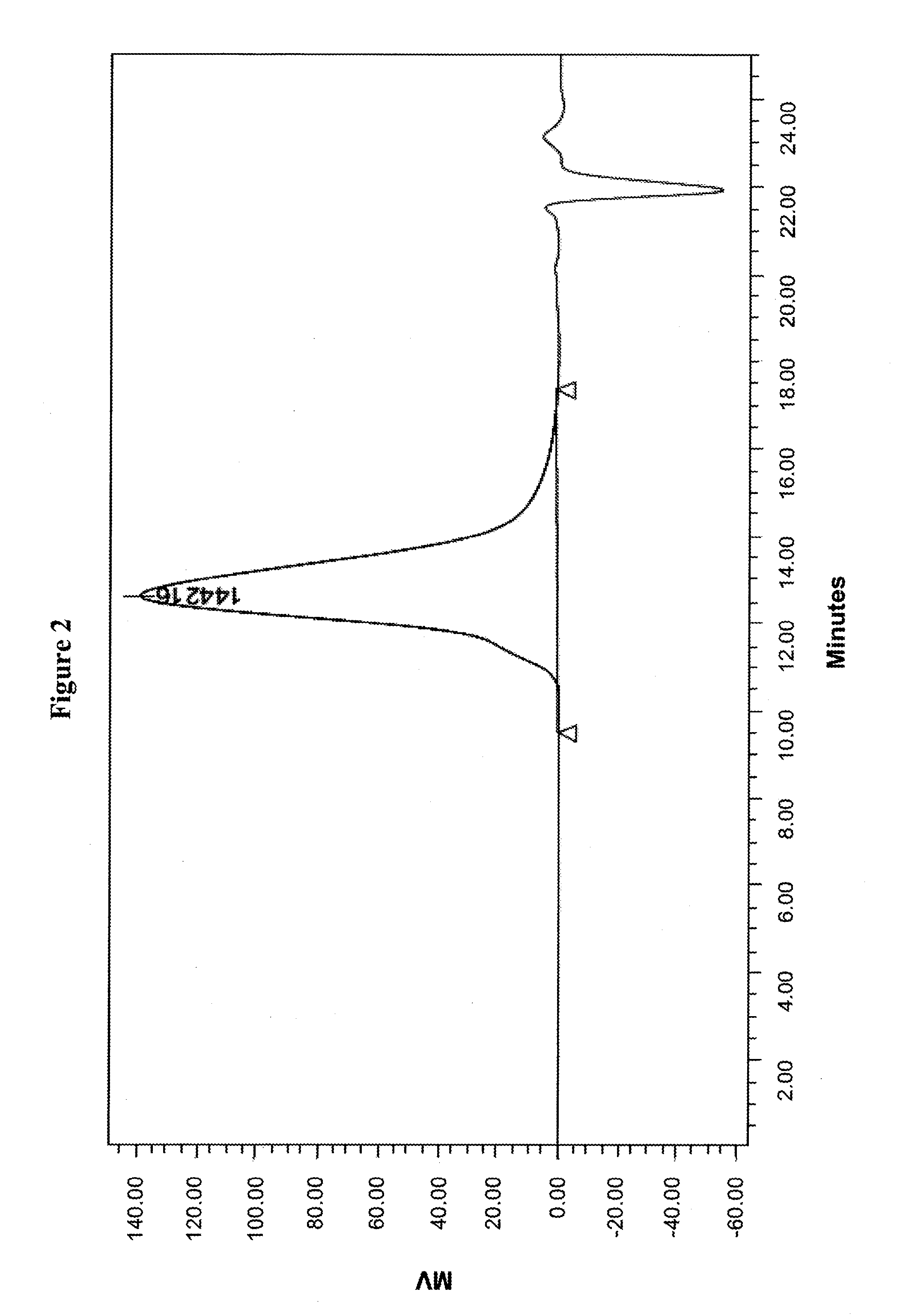

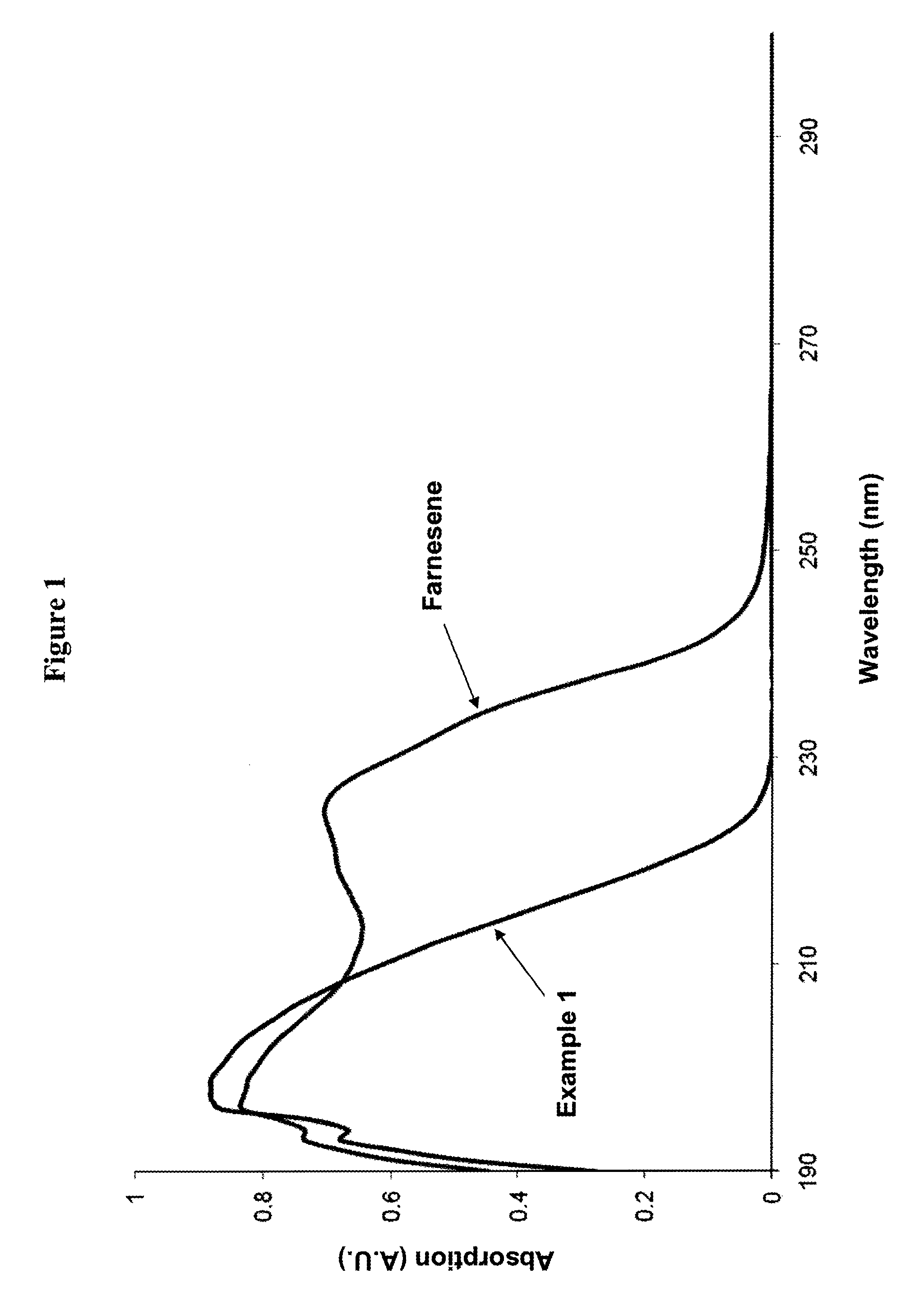

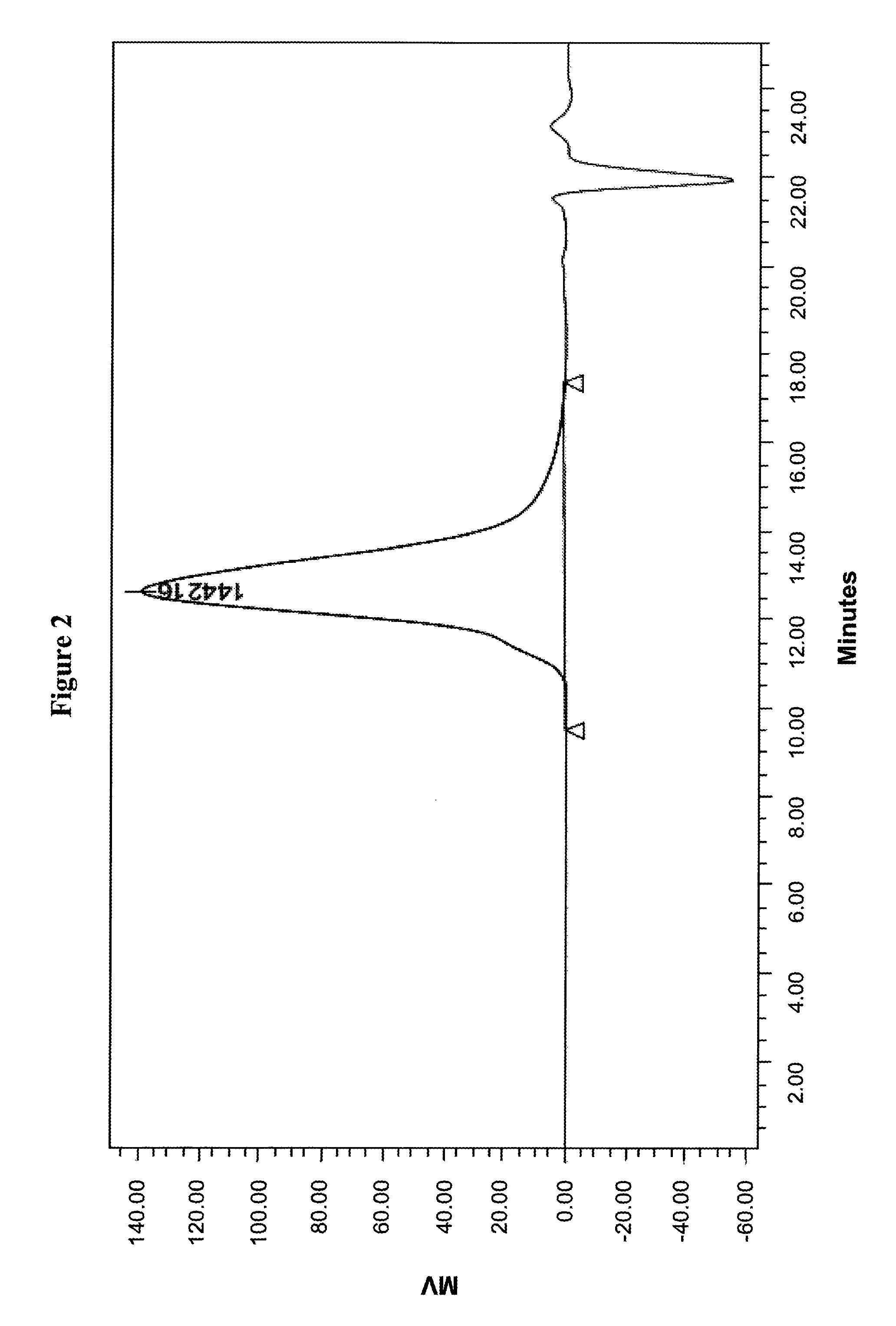

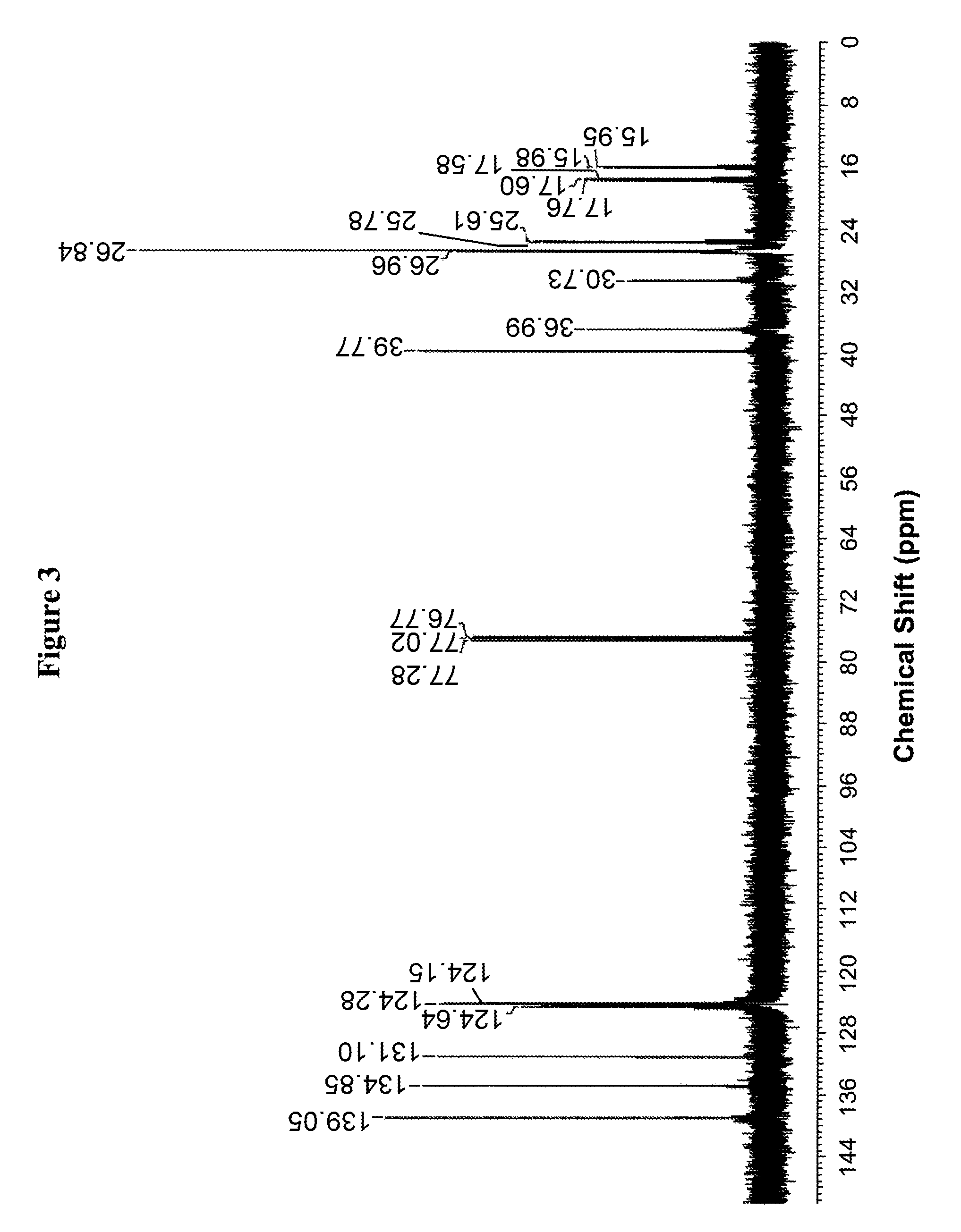

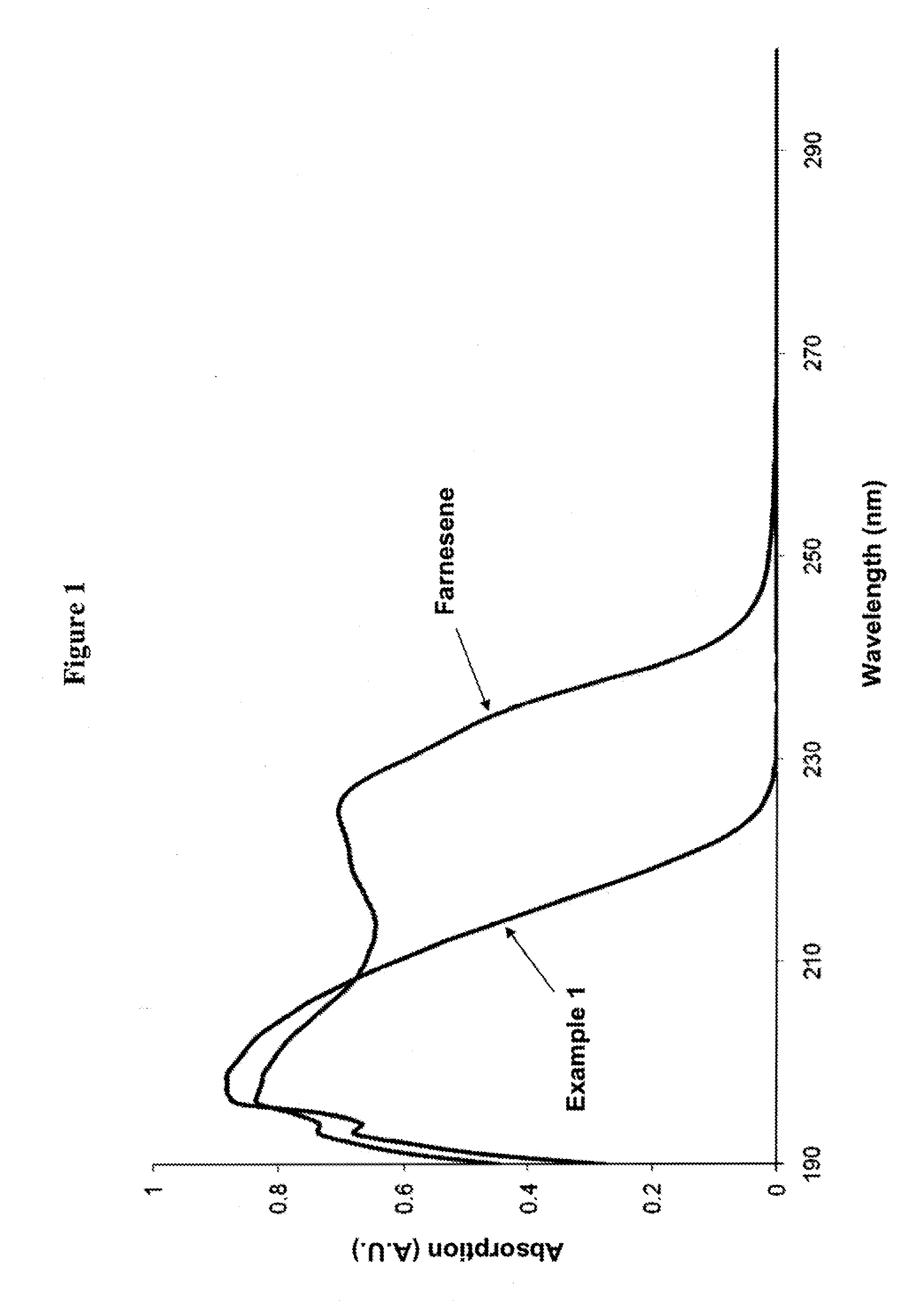

Farnesene interpolymers

Farnesene interpolymer comprises units derived from a farnesene (e.g., α-farnesene or β-farnesene) and units derived from at least one vinyl monomer. The farnesene interpolymer can be prepared by copolymerizing the farnesene and at least one vinyl monomer in the presence of a catalyst. In some embodiments, the farnesene is prepared from a sugar by using a microorganism. In other embodiments, the at least one vinyl monomer is ethylene, an α-olefin, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof.

Owner:AMYRIS INC

Adhesive compositions comprising a polyfarnesene

Adhesive composition comprises a polyfarnesene and a tackifier. The polyfarnesene can be a farnesene homopolymer derived from a farnesene (e.g., α-farnesene or β-farnesene) or a farnesene interpolymer derived from a farnesene and at least a vinyl monomer. In some embodiments, the at least one vinyl monomer is ethylene, an α-olefin such as styrene, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof. The composition disclosed herein can be used as a hot melt adhesive, a pressure sensitive adhesive or the like.

Owner:AMYRIS INC

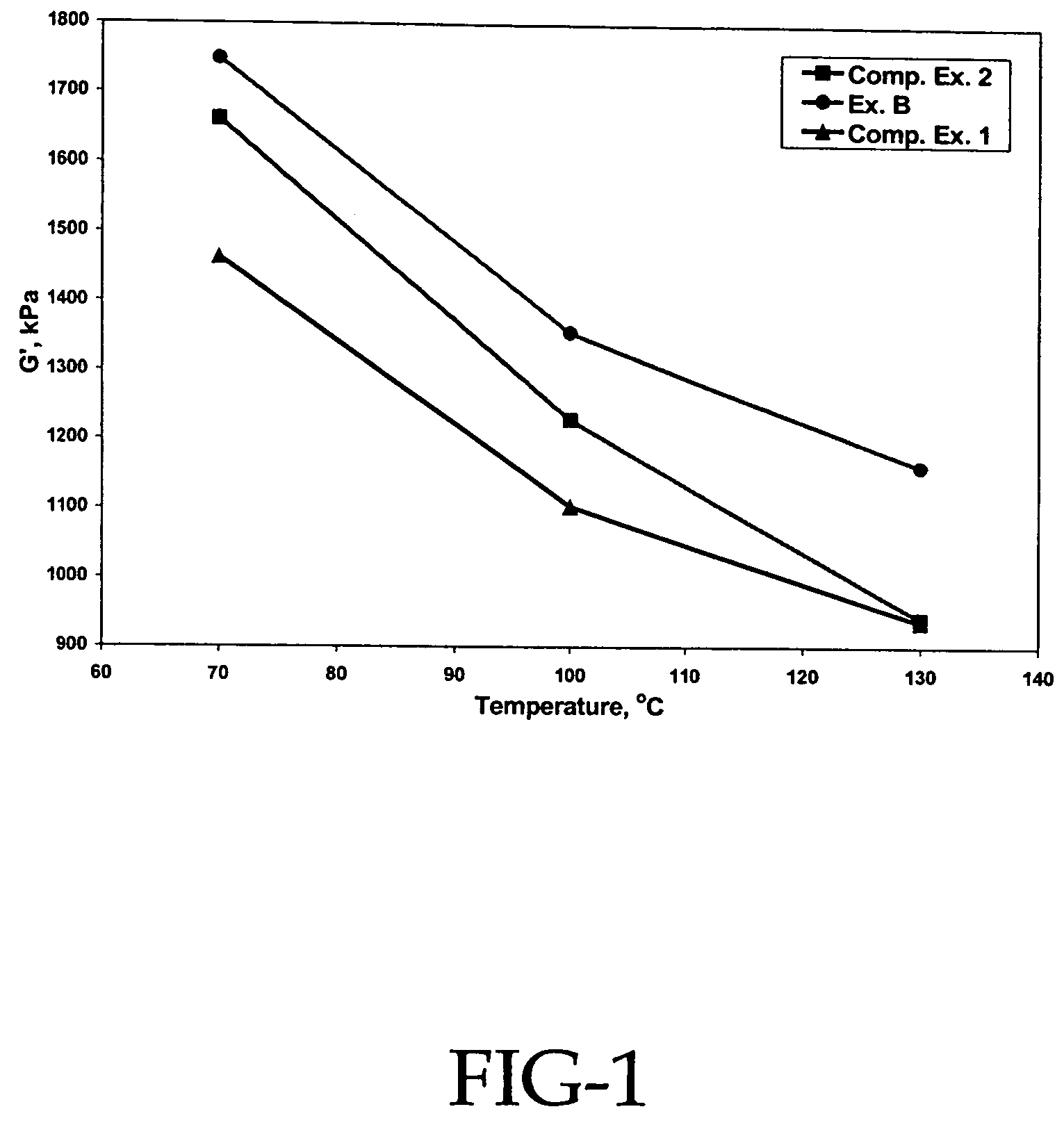

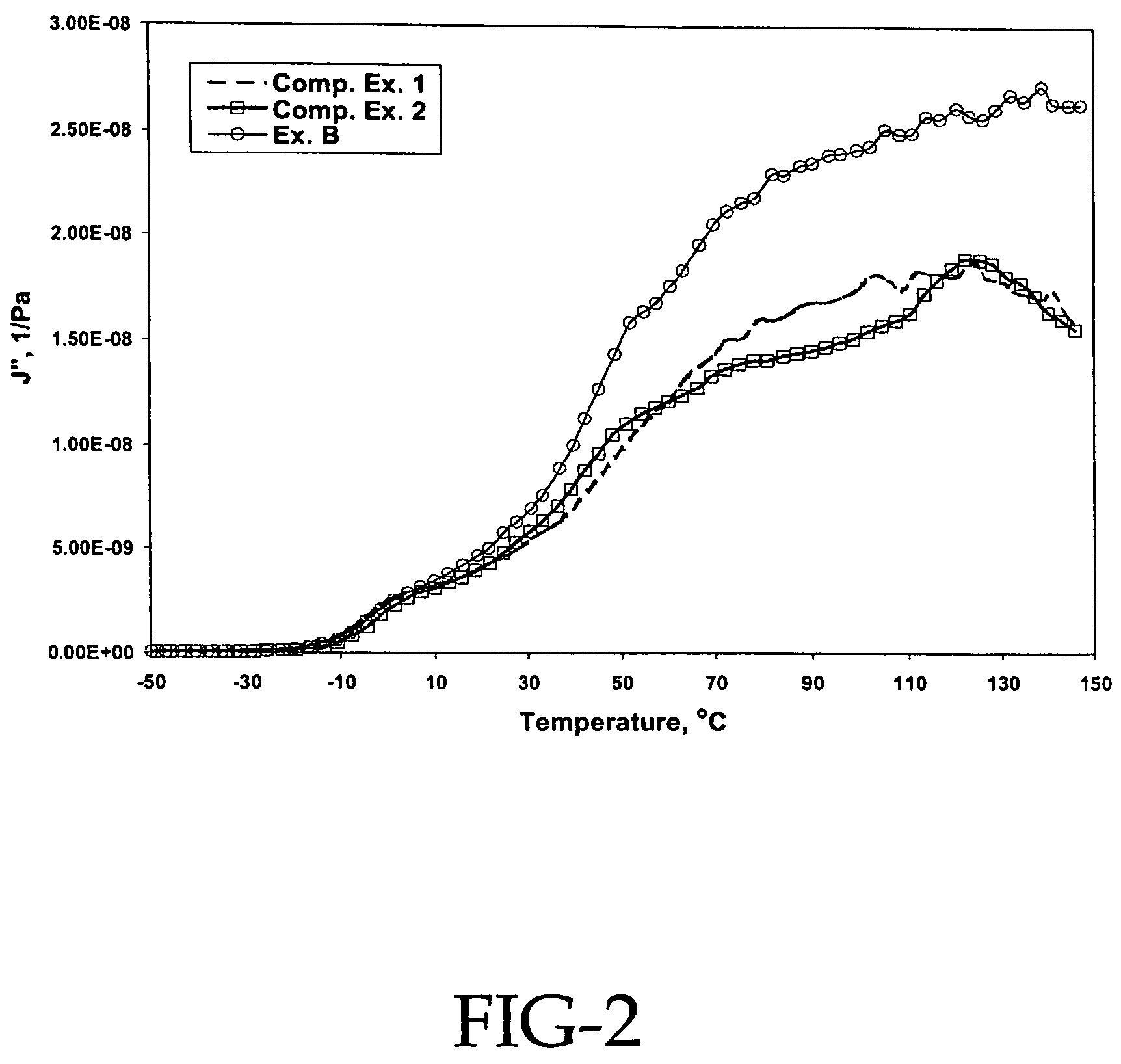

Rubber composition containing resinous nanoparticle

InactiveUS7347237B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresInflatable tyresElastomerEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

Process for producing fast curing molding compounds bonded with phenolic resin

A process is provided for producing fast curing bonded with phenolic resin, which comprises pulverulent phenolic resins mixed with or applied to the substrate to be adhered together with pulverulent addition polymers selected from the group consisting of polyvinyl alcohols and addition polymers, stabilized by hydroxyl-containing protective colloids of at least one monomer selected from the group consisting of the vinyl esters of branched or unbranched carboxylic acids of 1 to 12 carbon atoms, the esters of acrylic acid and methacrylic acid with branched or unbranched alcohols of 1 to 12 carbon atoms, vinylaromatics, vinyl halides, olefins and dienes, and subsequently, by the employment of elevated temperature and optionally elevated pressure, cured and processed into a shaped article.

Owner:WACKER CHEM GMBH

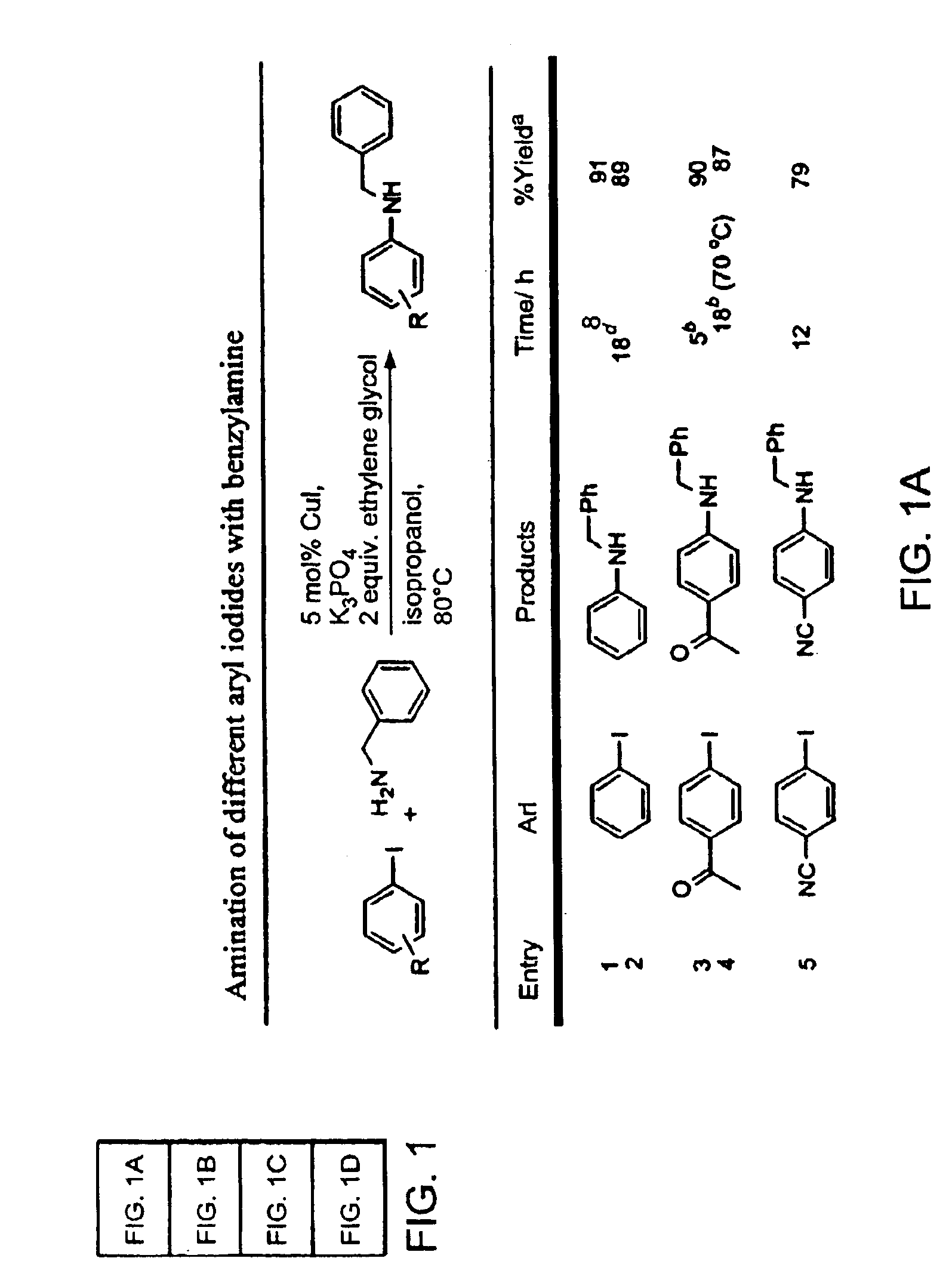

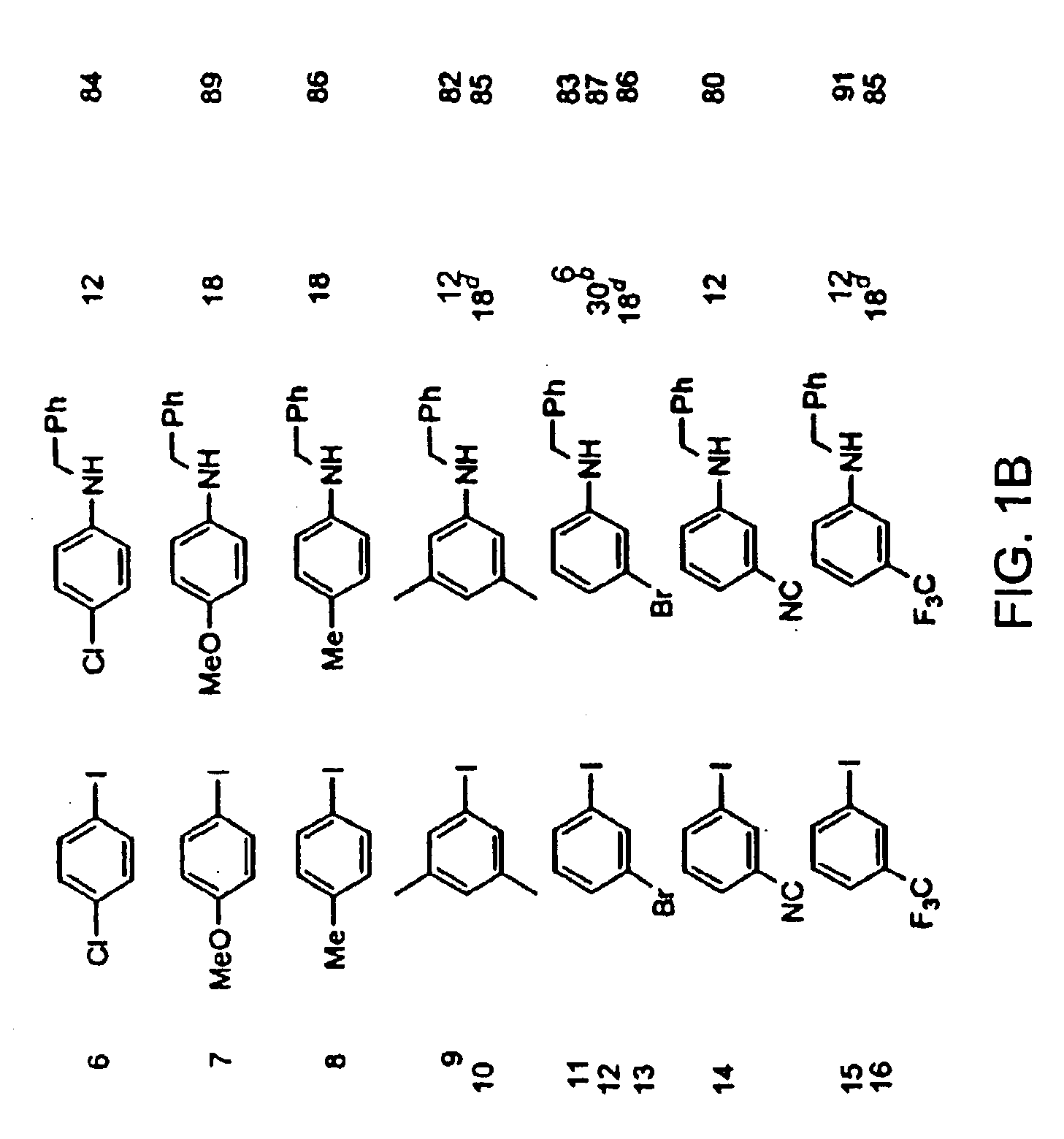

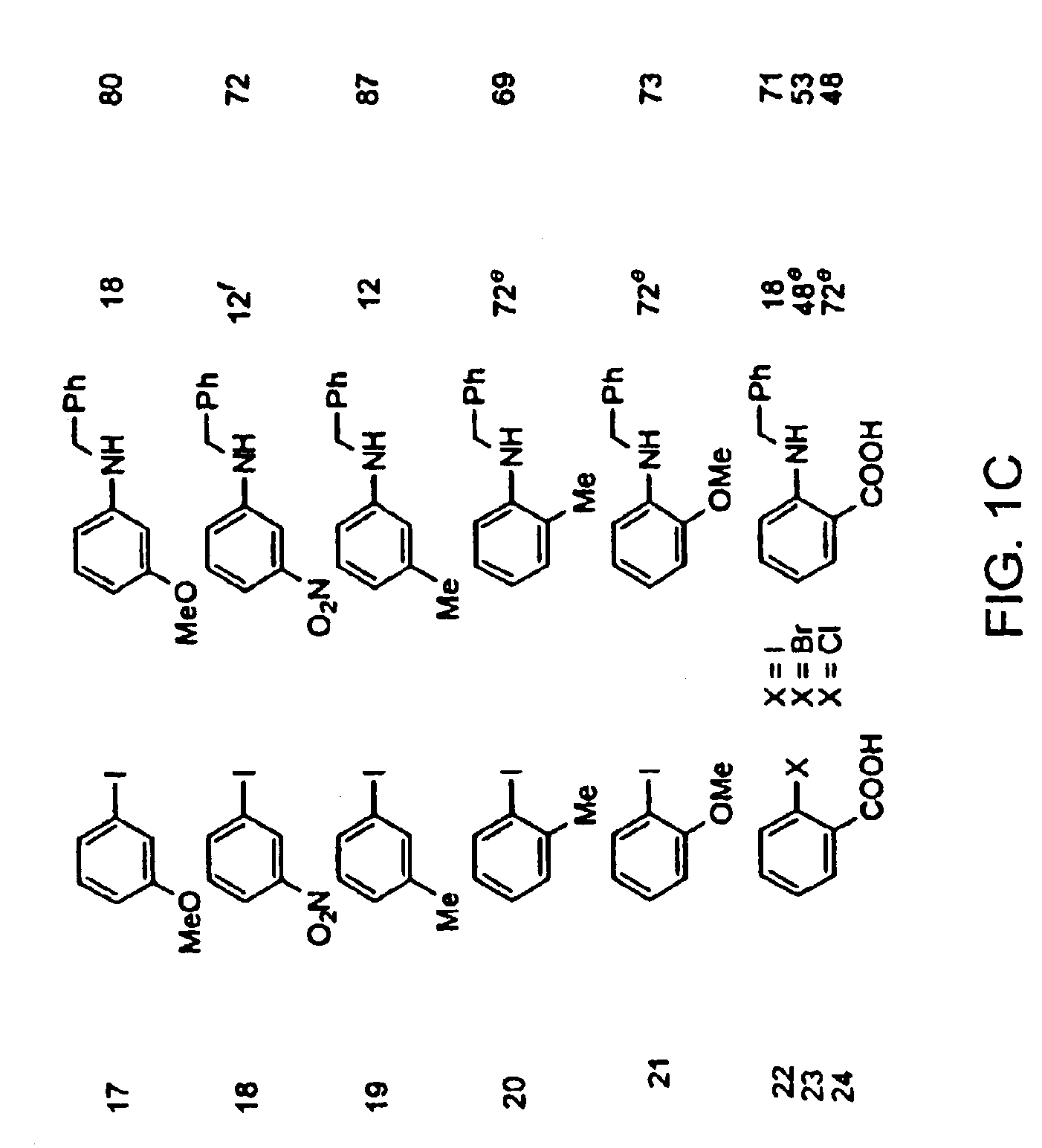

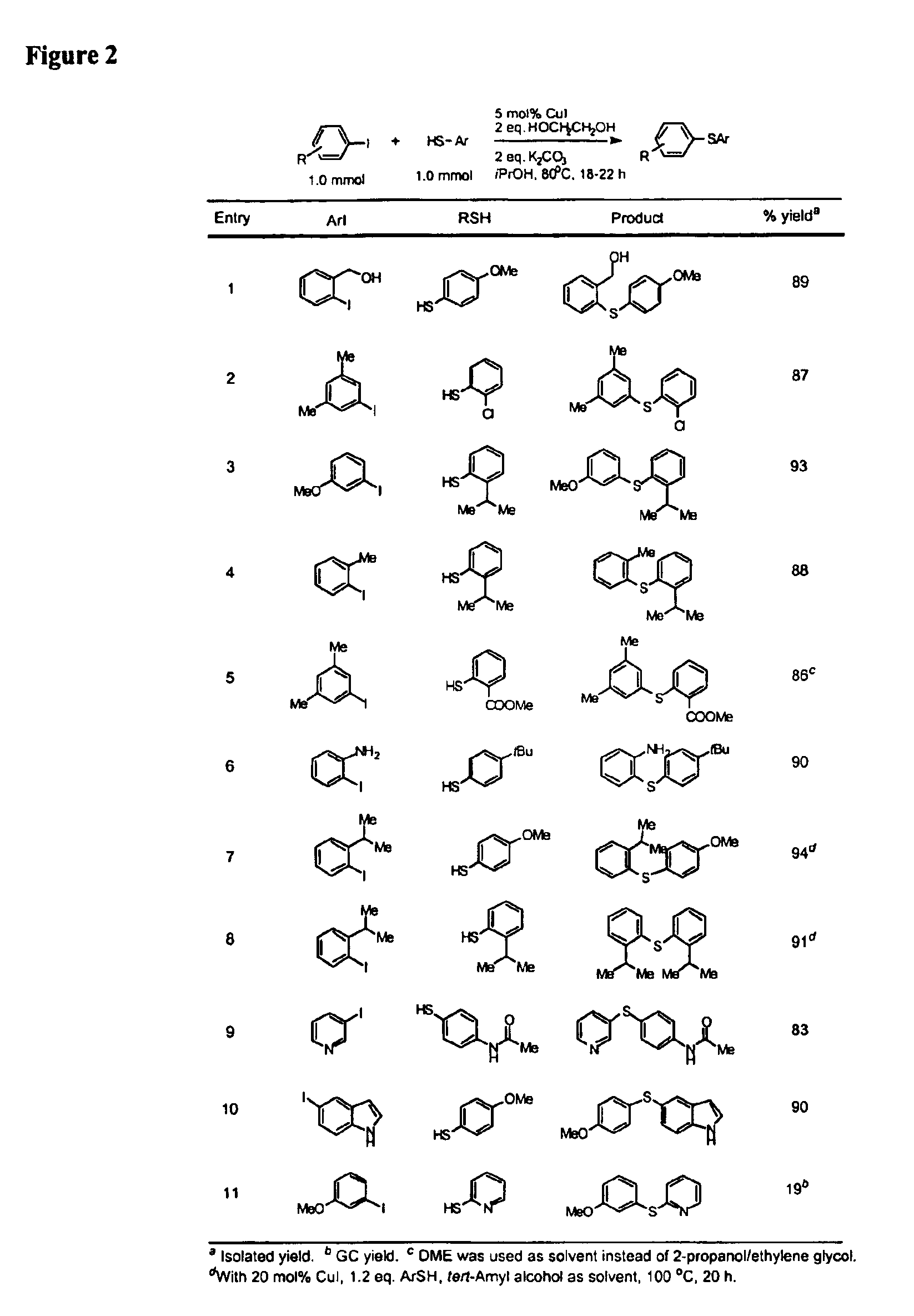

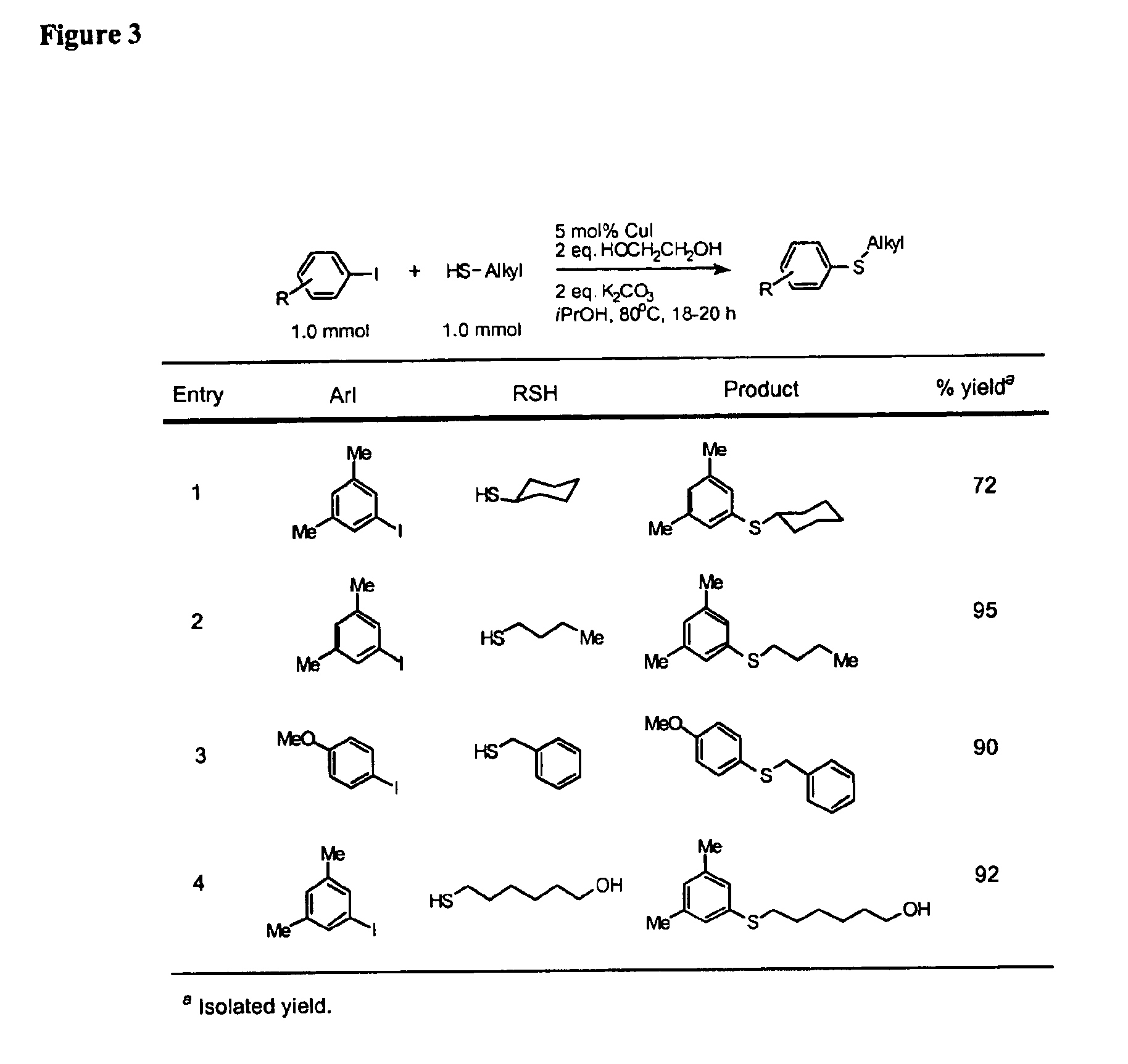

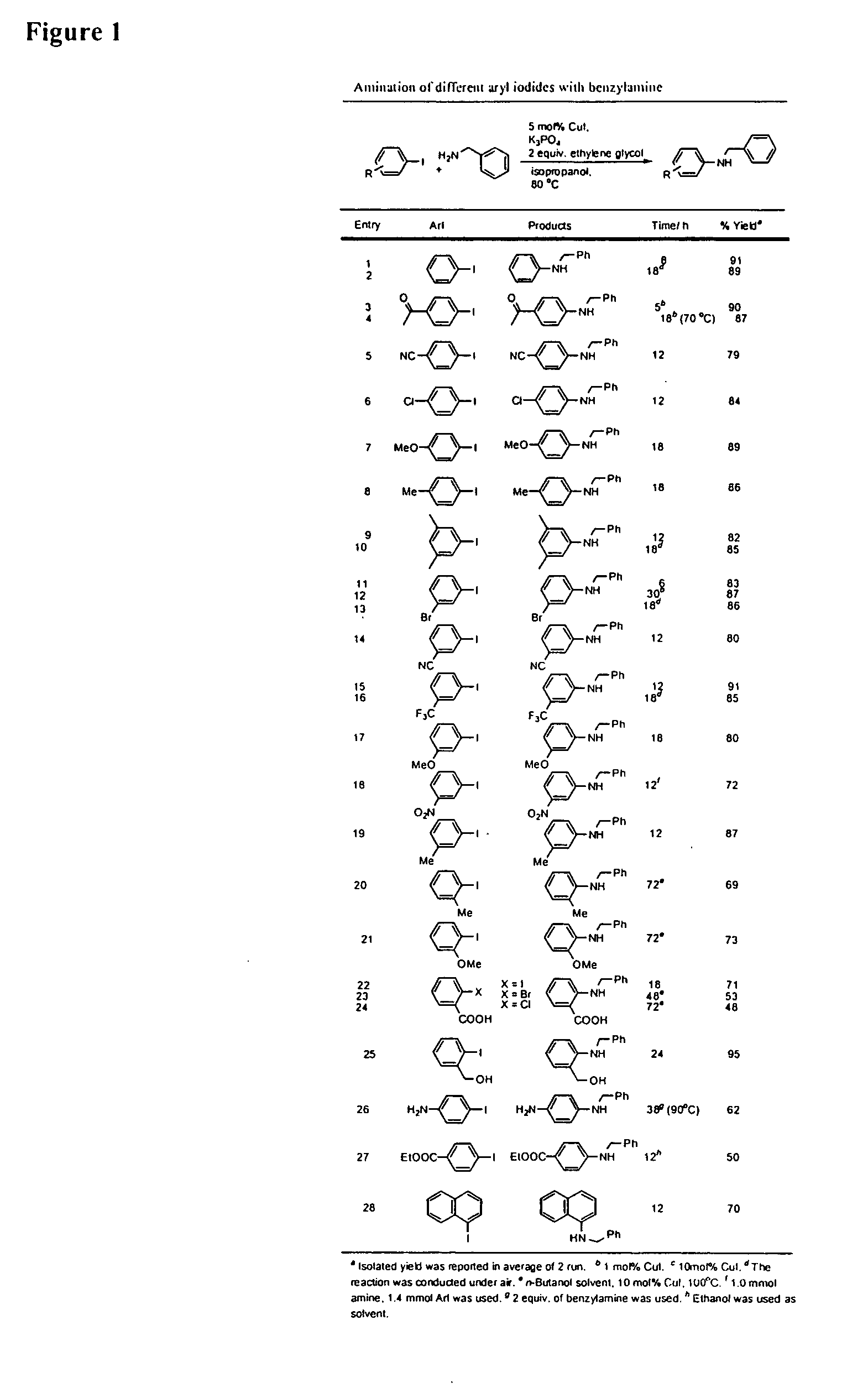

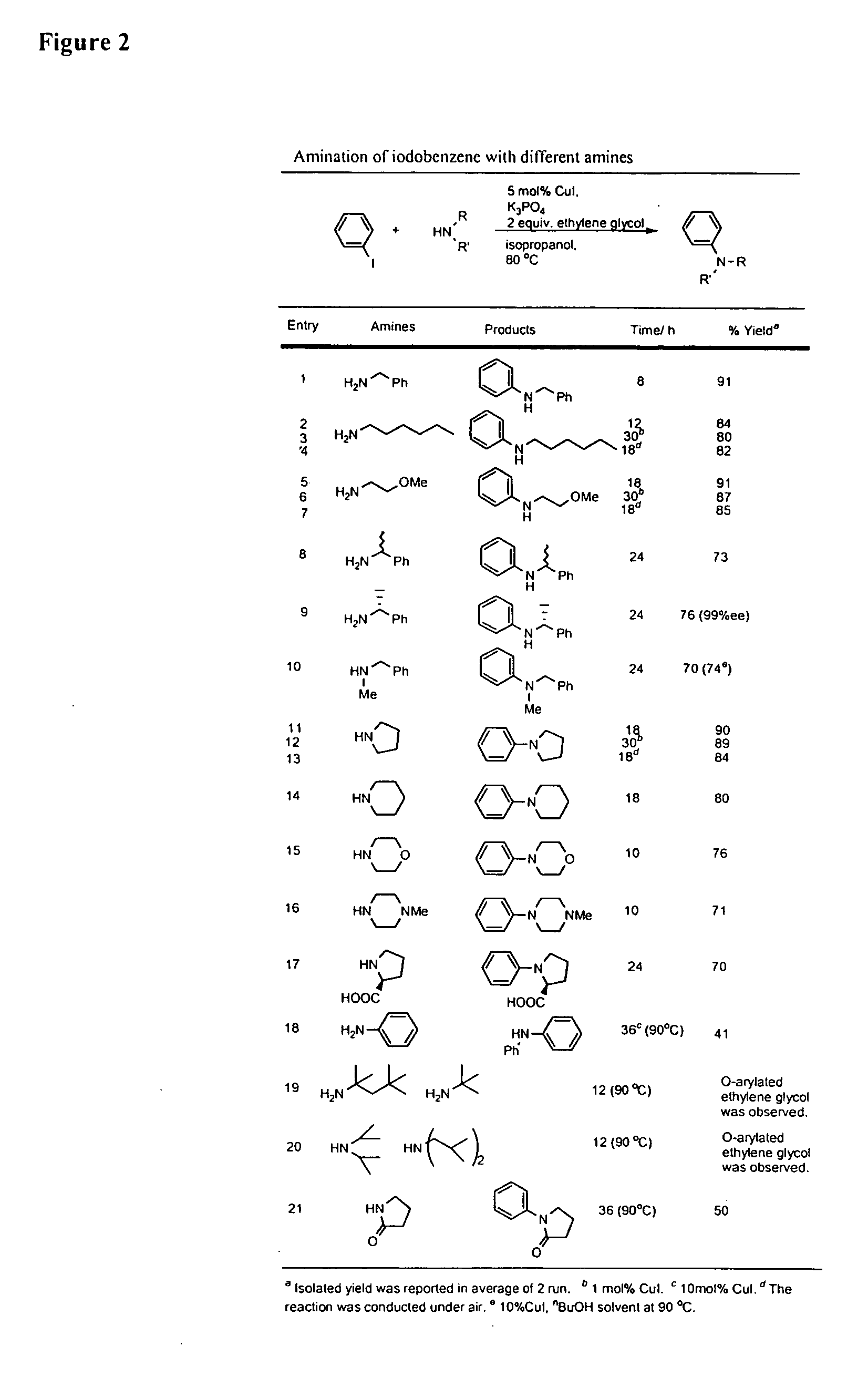

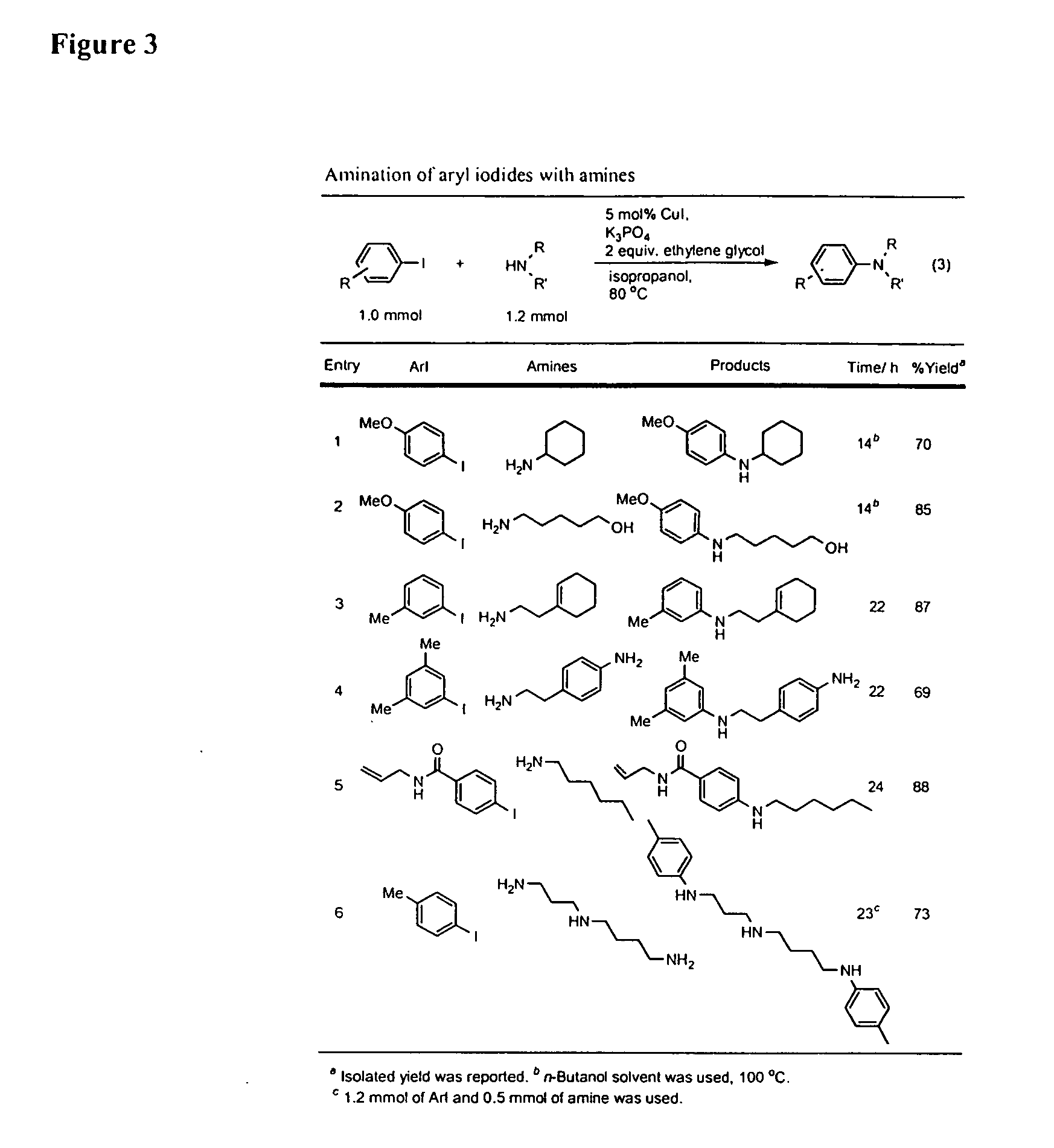

Copper-catalyzed formation of carbon-heteroatom and carbon-carbon bonds

InactiveUS6867298B2Cheap and practicalLow costUrea derivatives preparationCarbamic acid derivatives preparationCarbon–oxygen bondHydrazine compound

The present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide or amine moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In additional embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between a nitrogen atom of an acyl hydrazine and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of a nitrogen-containing heteroaromatic, e.g., indole, pyrazole, and indazole, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-oxygen bond between the oxygen atom of an alcohol and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. The present invention also relates to copper-catalyzed methods of forming a carbon-carbon bond between a reactant comprising a nucleophilic carbon atom, e.g., an enolate or malonate anion, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. Importantly, all the methods of the present invention are relatively inexpensive to practice due to the low cost of the copper comprised by the catalysts.

Owner:MASSACHUSETTS INST OF TECH

Rubber composition containing resinous nanopractice

InactiveUS7071246B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresCoatingsElastomerPolymer science

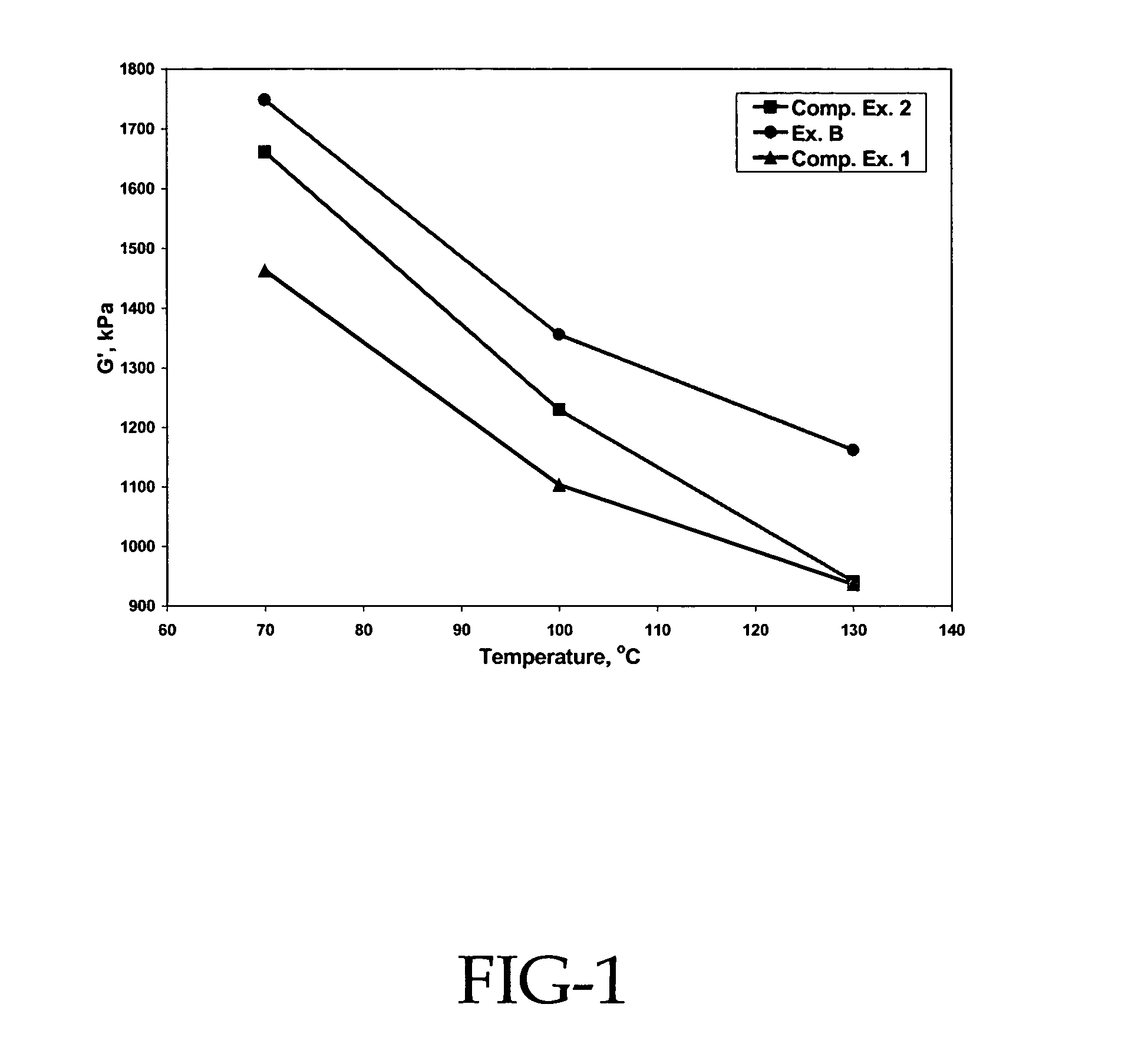

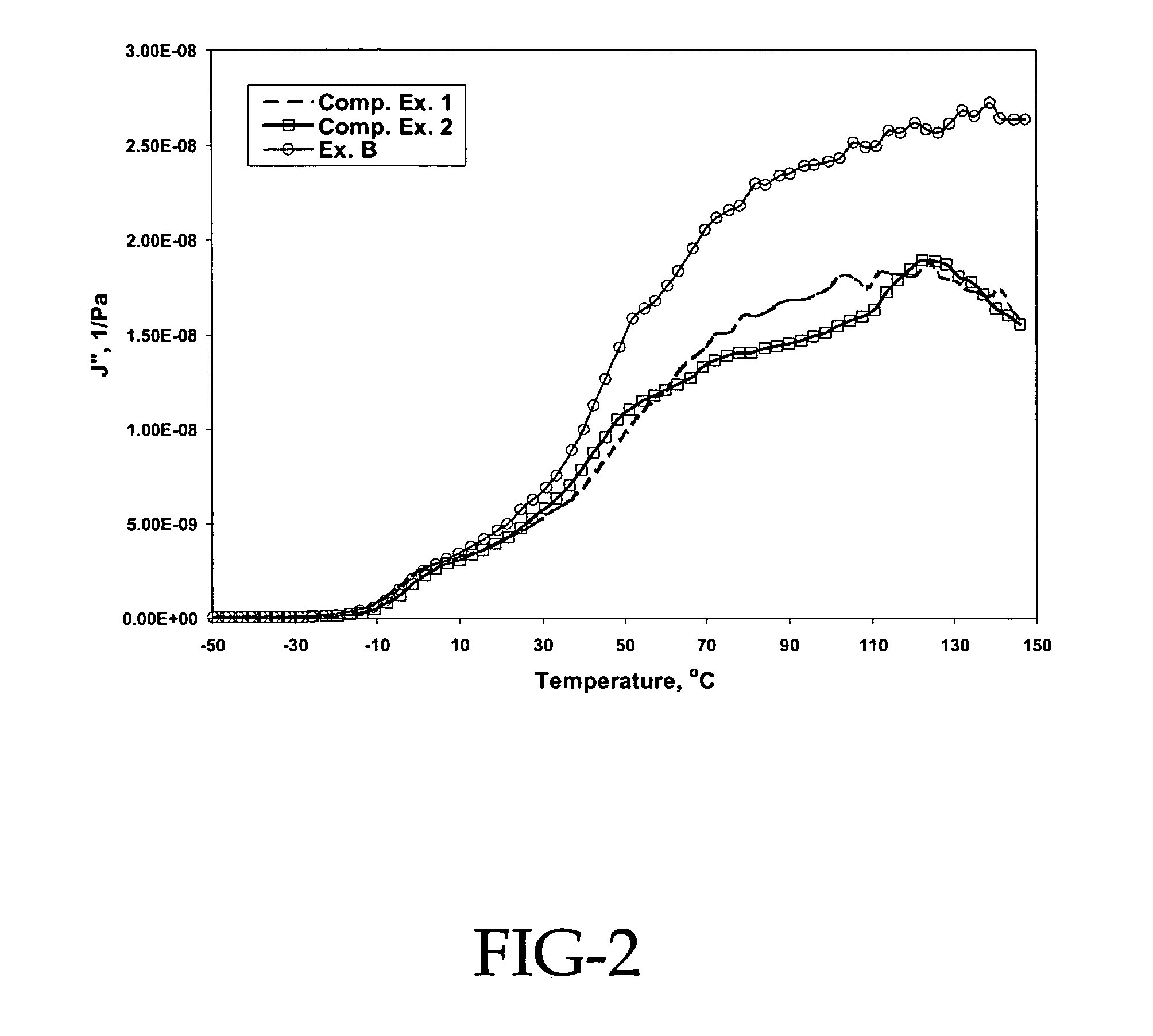

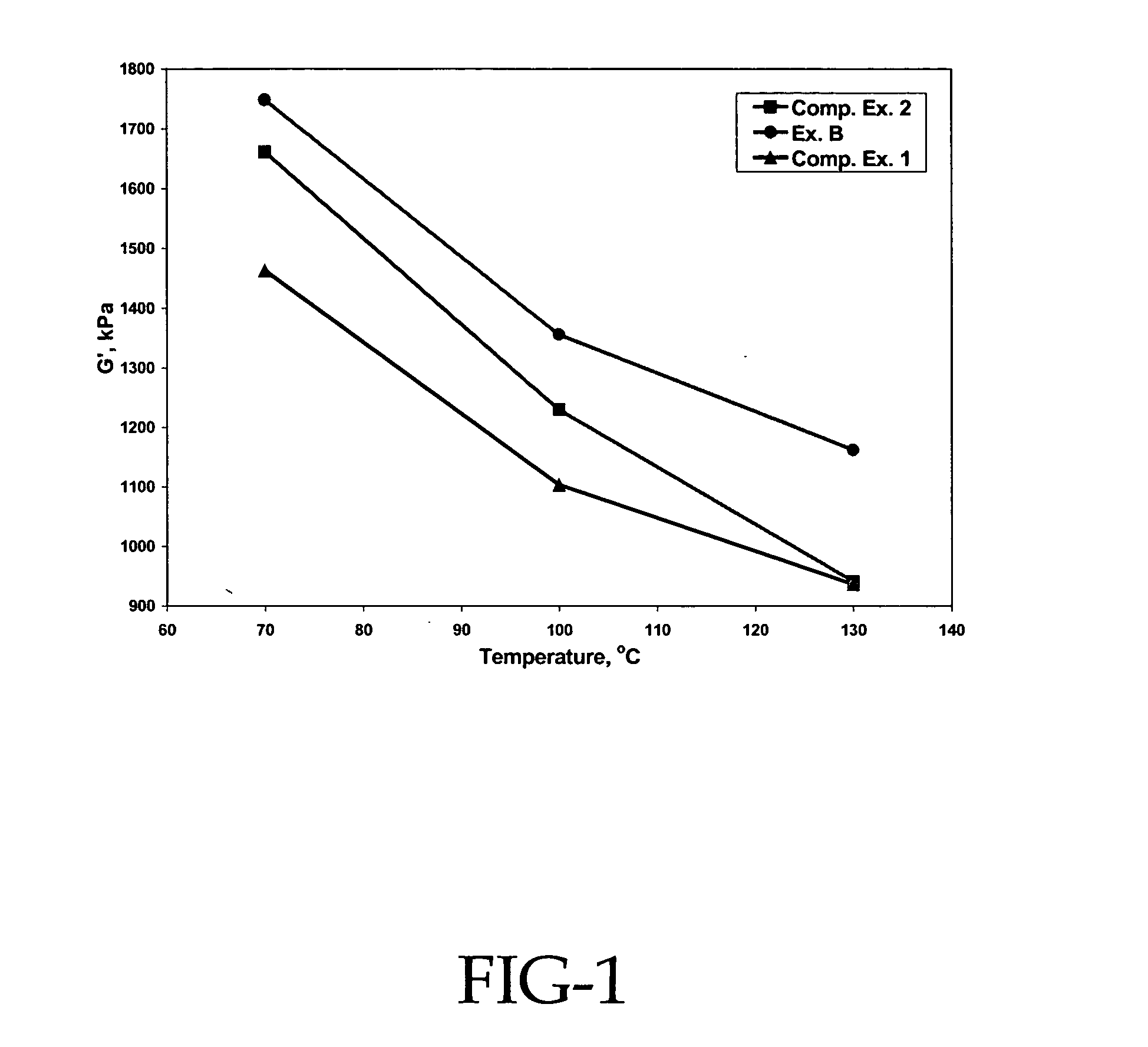

This invention relates to a tread rubber composition for tires with the addition of crosslinked resinous nanoparticles having a high glass transition temperature (Tg) into elastomeric base polymers. The invention demonstrates greatly improved handling performance without deteriorating controllability and stability during high-speed running. The present invention discloses a rubber composition comprising: (1) a rubbery polymer and (2) from 1 to 30 parts per hundred parts of rubber by weight (phr) of pre-crosslinked polymer particles, wherein the pre-crosslinked polymer particles have a particle size which is within the range of 30 nm to 500 nm, wherein the pre-crosslinked polymer is comprised of repeat units that are derived from at least one monomer selected from the group consisting of acrylate monomers, vinyl aromatic monomers, acrylonitrile monomer, and vinyl halide monomers, and wherein the pre-crosslinked polymer has a glass transition temperature which is within the range of 30° C. to 200° C.

Owner:THE GOODYEAR TIRE & RUBBER CO

Copper-catalyzed formation of carbon-heteroatom and carbon-carbon bonds

InactiveUS6888032B2Cheap and practicalLow costOrganic compound preparationThiol preparationCarbon–carbon bondSulfide

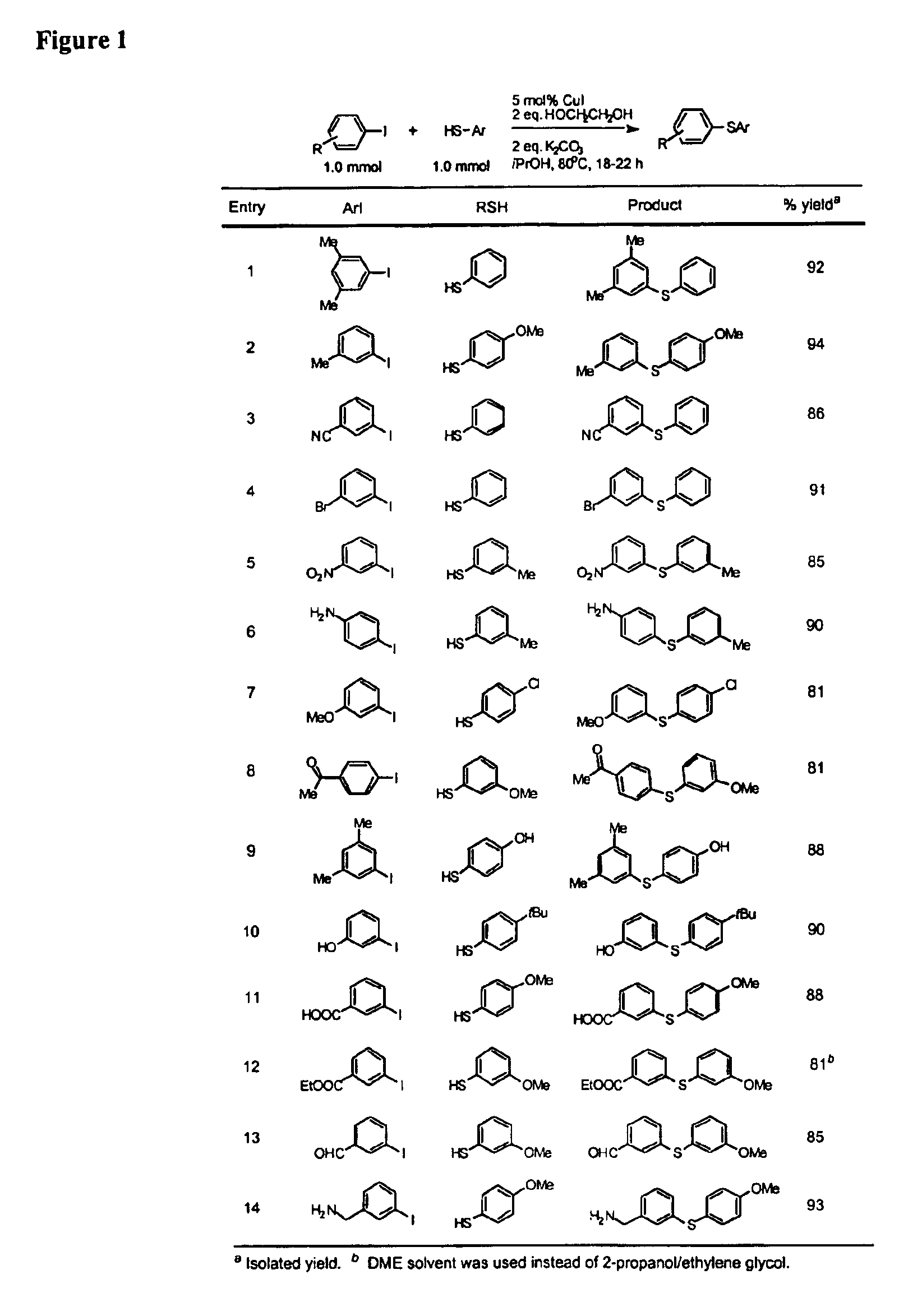

One aspect of the present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-sulfur bond between the sulfur atom of a thiol moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper(II)-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-carbon bond between the carbon atom of cyanide ion and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In another embodiment, the present invention relates to a copper-catalyzed method of transforming an aryl, heteroaryl, or vinyl chloride or bromide into the corresponding aryl, heteroaryl, or vinyl iodide. Yet another embodient of the present invention relates to a tandem method, which may be practiced in a single reaction vessel, wherein the first step of the method involves the copper-catalyzed formation of an aryl, heteroaryl, or vinyl iodide from the corresponding aryl, heteroaryl, or vinyl chloride or bromide; and the second step of the method involves the copper-catalyzed formation of an aryl, heteroaryl, or vinyl nitrile, amide or sulfide from the aryl, heteroaryl, or vinyl iodide formed in the first step.

Owner:MASSACHUSETTS INST OF TECH

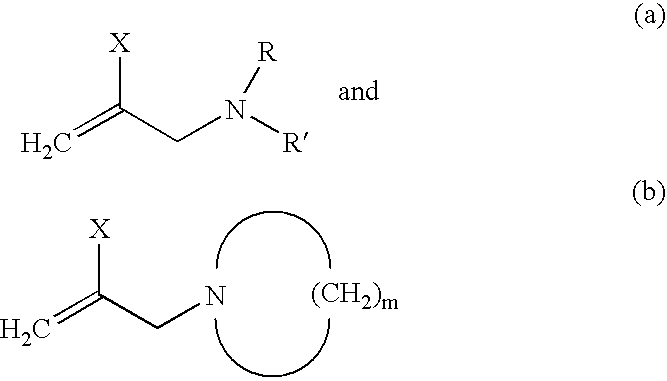

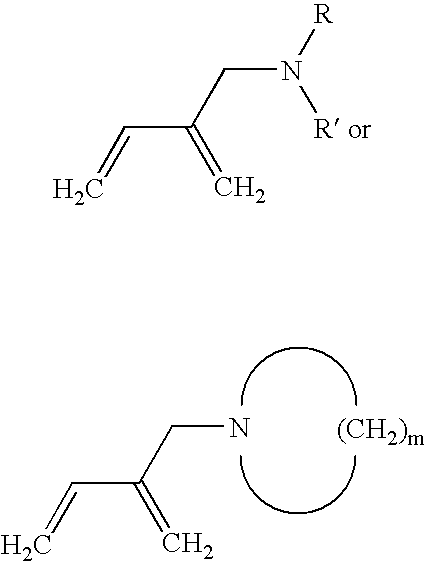

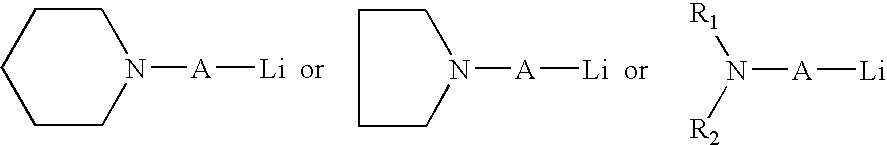

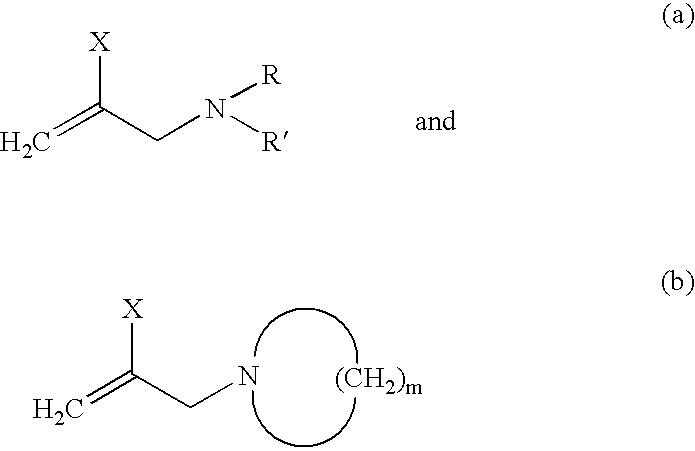

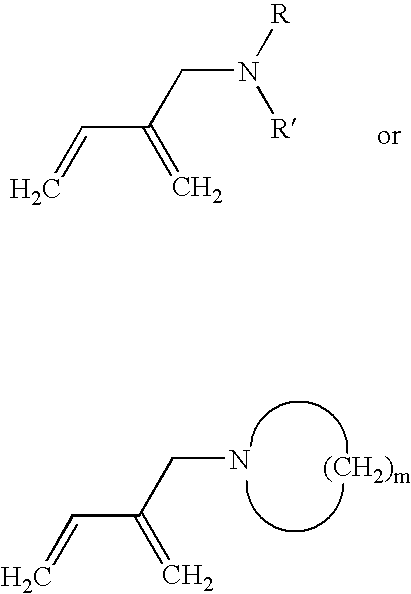

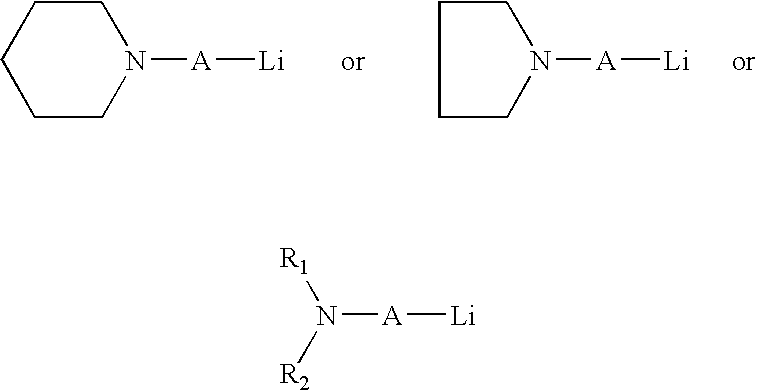

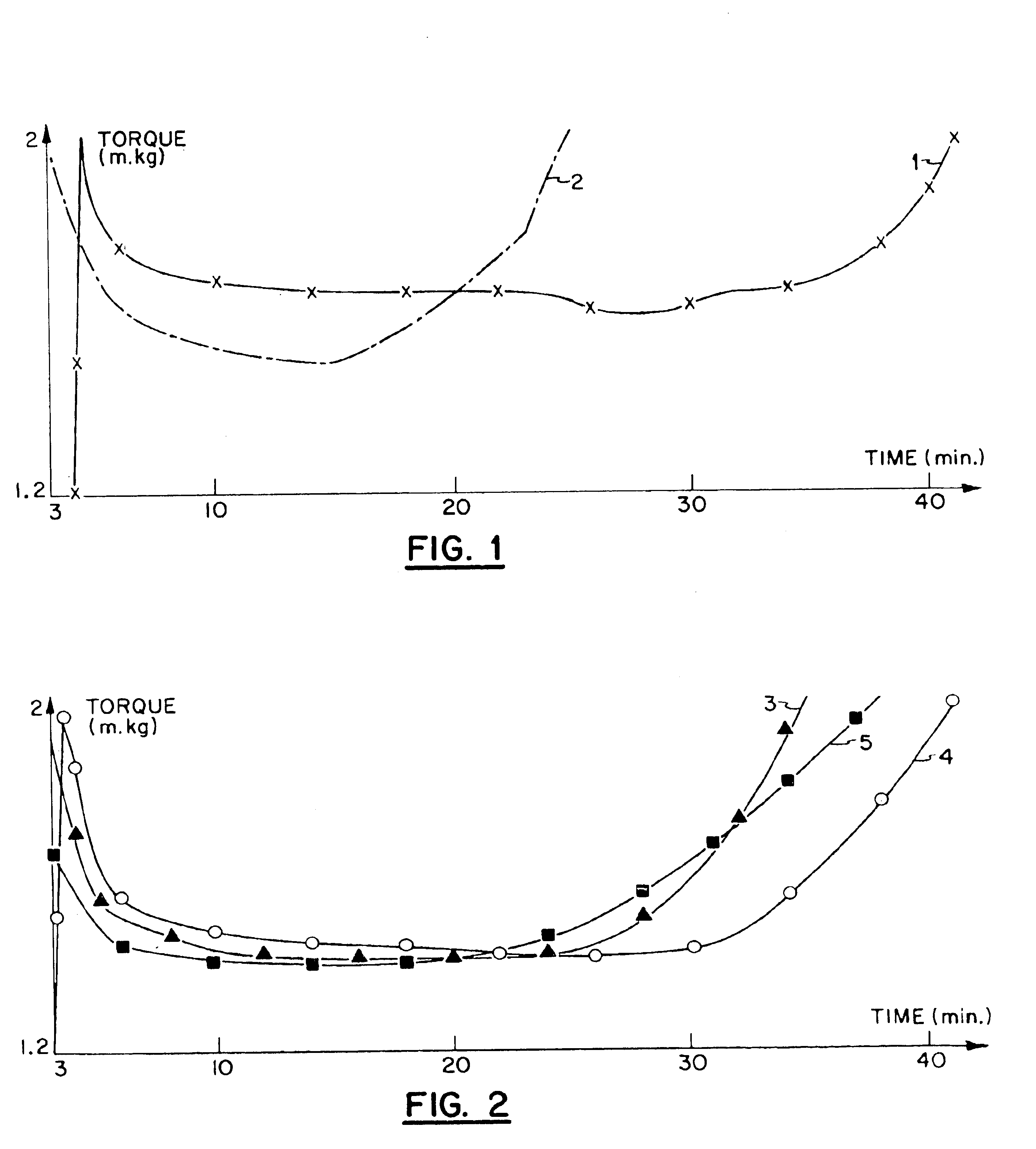

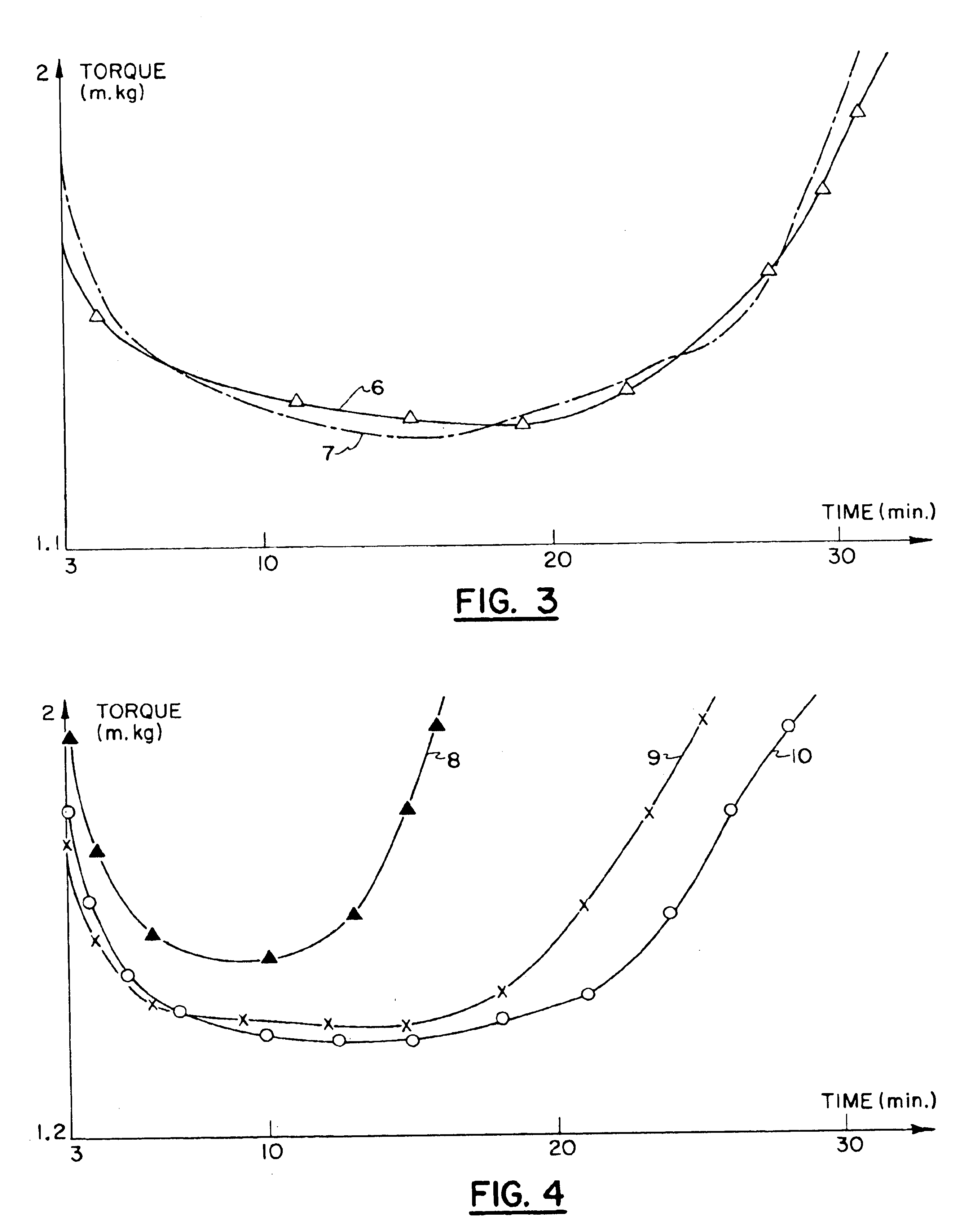

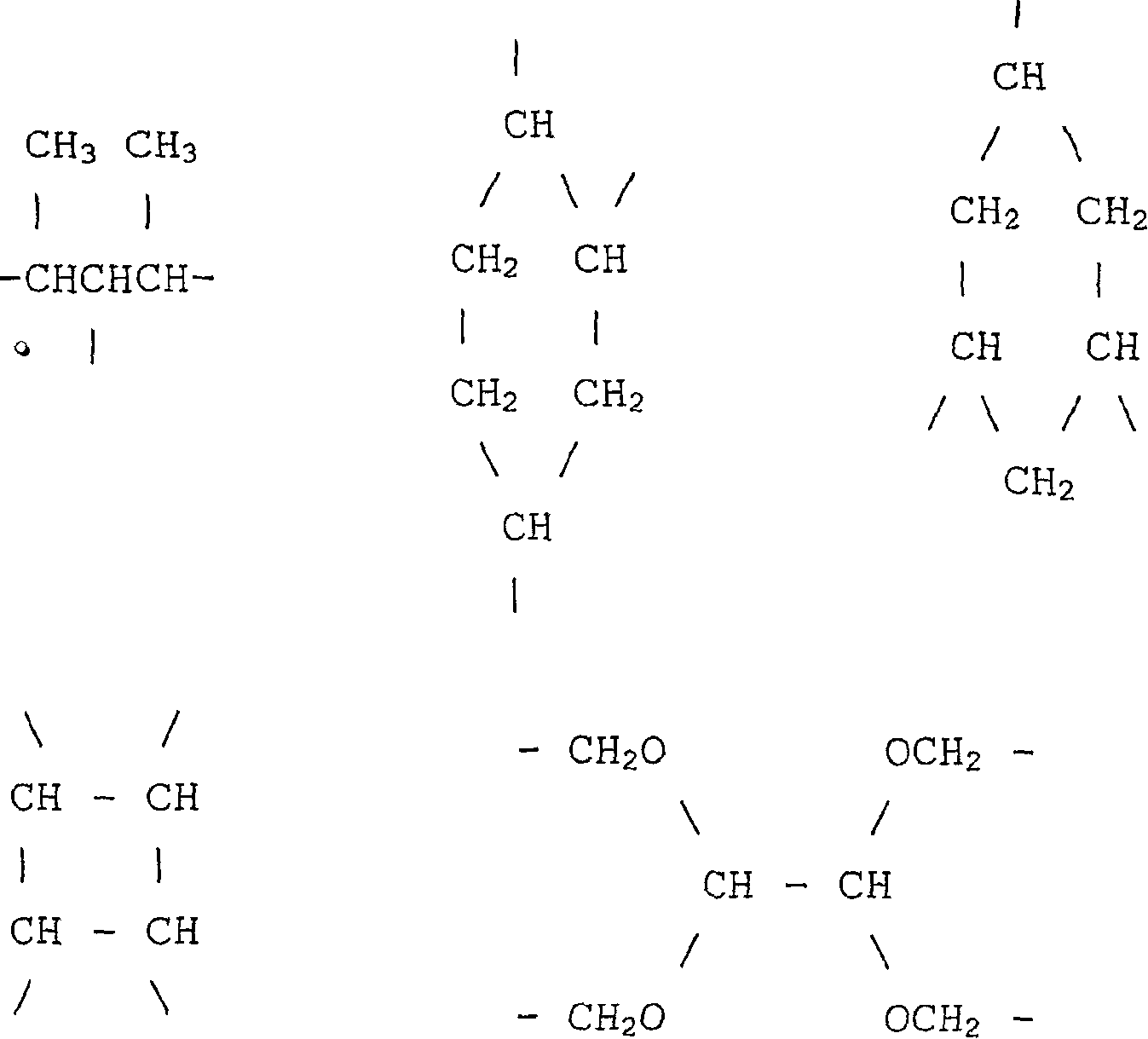

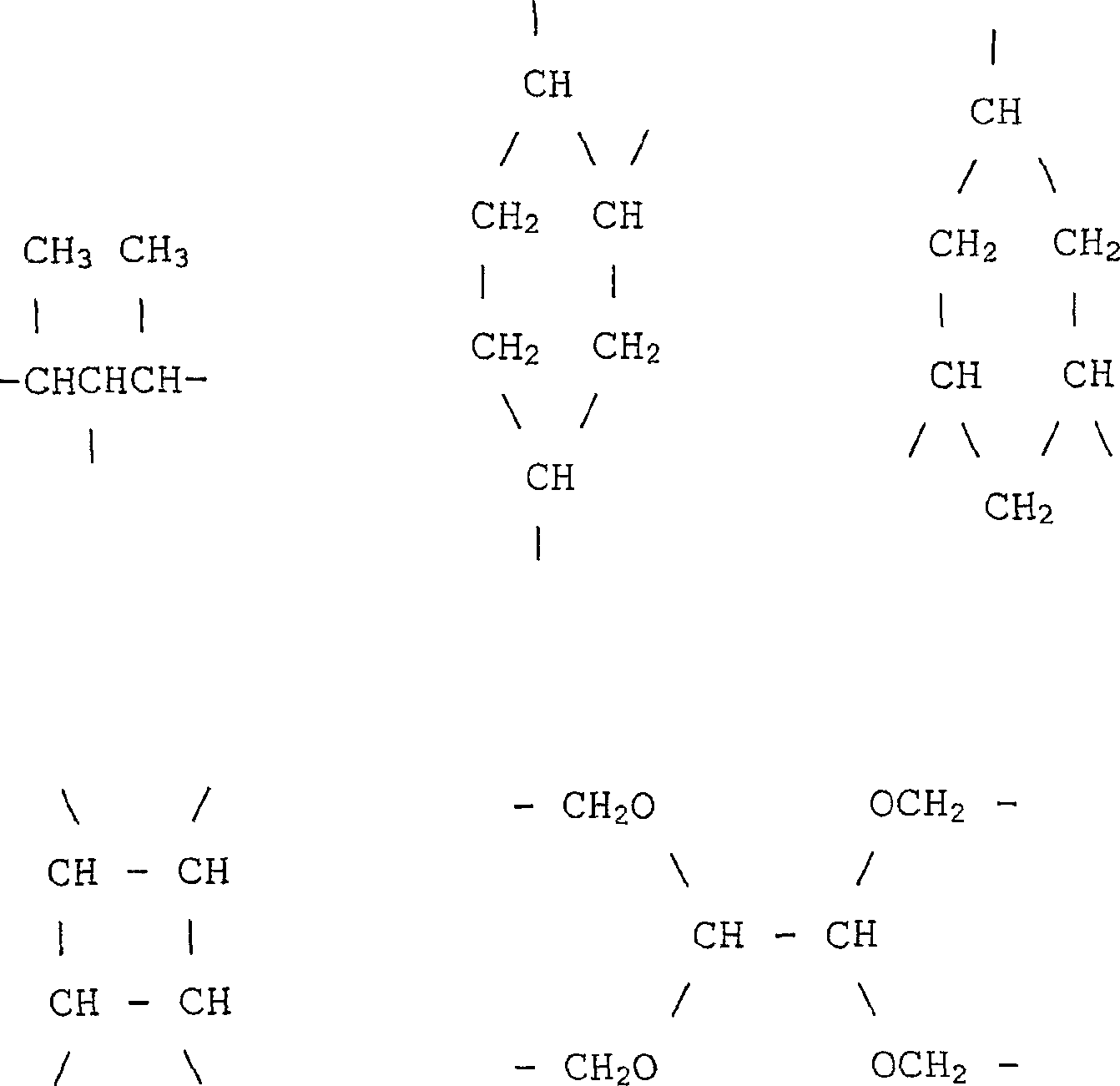

Functionalized monomers for synthesis of rubbery polymers

This invention discloses a process for synthesizing an amine functionalized monomer that comprises (1) reacting a secondary amine with a 2,3-dihalopropene to produce a vinyl halide containing secondary amine having a structural formula selected from the group consisting of wherein R and R′ can be the same or different and represent allyl, alkoxyl or alkyl groups containing from 1 to about 10 carbon atoms, and wherein X represents a halogen atom, and wherein m represents an integer from 4 to about 10, and wherein X represents a halogen atom; and (2) reacting the vinyl halide containing secondary amine with a vinyl magnesium halide to produce the monomer having a structural formula wherein R and R′ can be the same or different and represent alkyl, allyl or alkoxyl groups containing from 1 to about 10 carbon atoms, and wherein m represents an integer from about 4 to about 10.

Owner:THE GOODYEAR TIRE & RUBBER CO

Compositions comprising a polyfarnesene

Provided herein are compositions comprising a polyfarnesene. The polyfarnesene can be a farnesene homopolymer derived from a farnesene (e.g., α-farnesene or β-farnesene) or a farnesene interpolymer derived from a farnesene and at least a vinyl monomer. In some embodiments, the at least one vinyl monomer is ethylene, an α-olefin such as styrene, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof.

Owner:AMYRIS INC

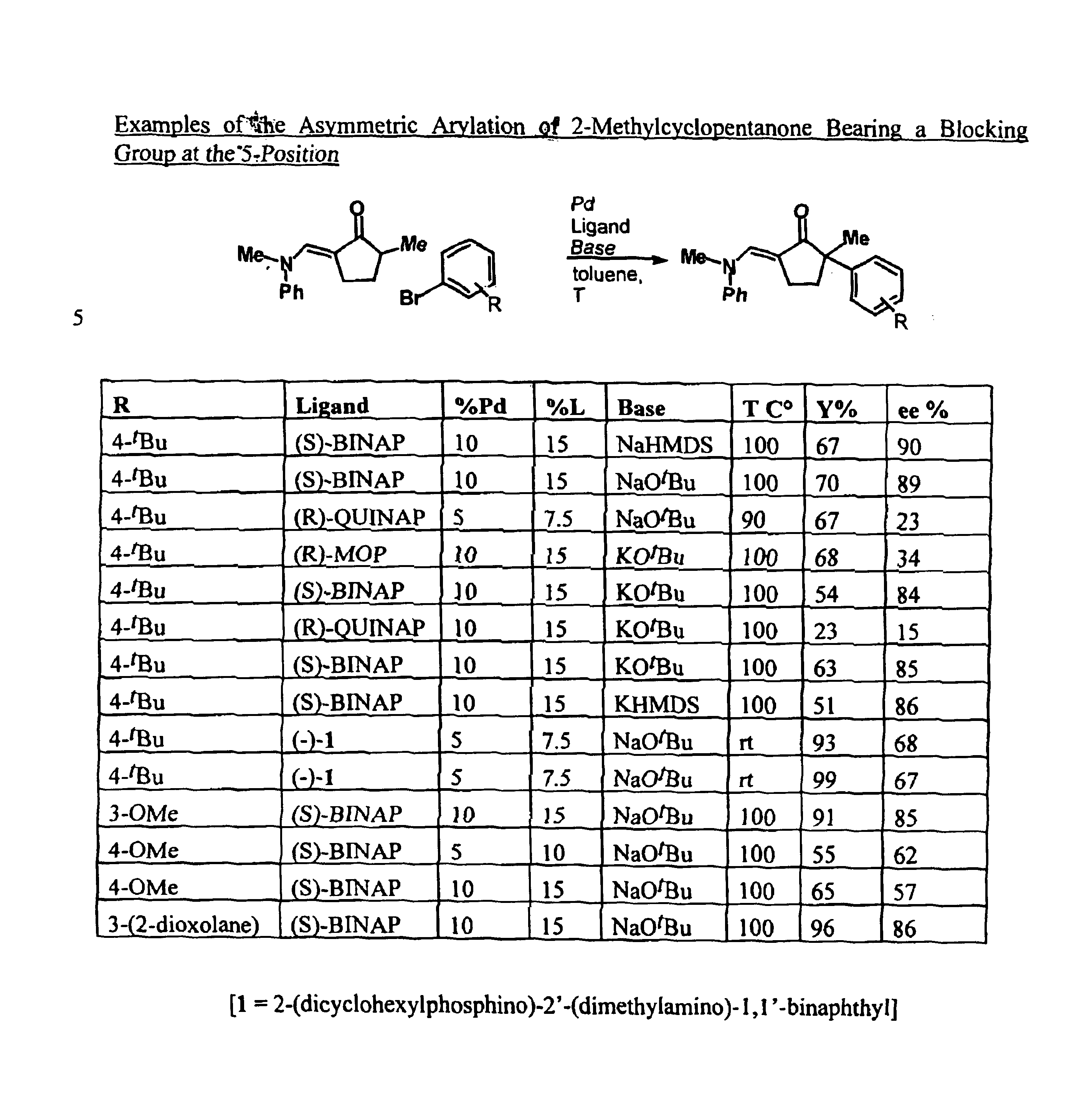

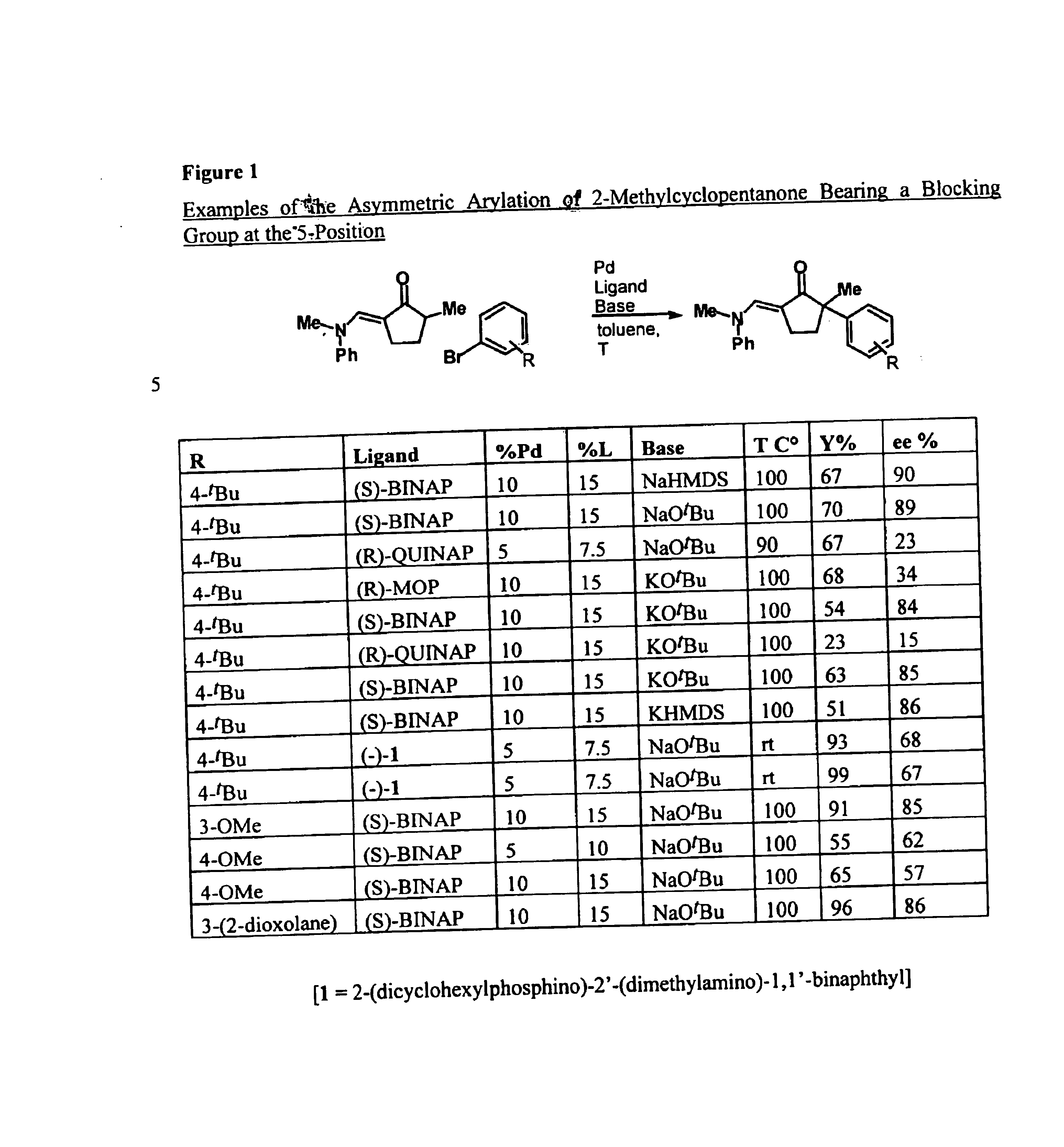

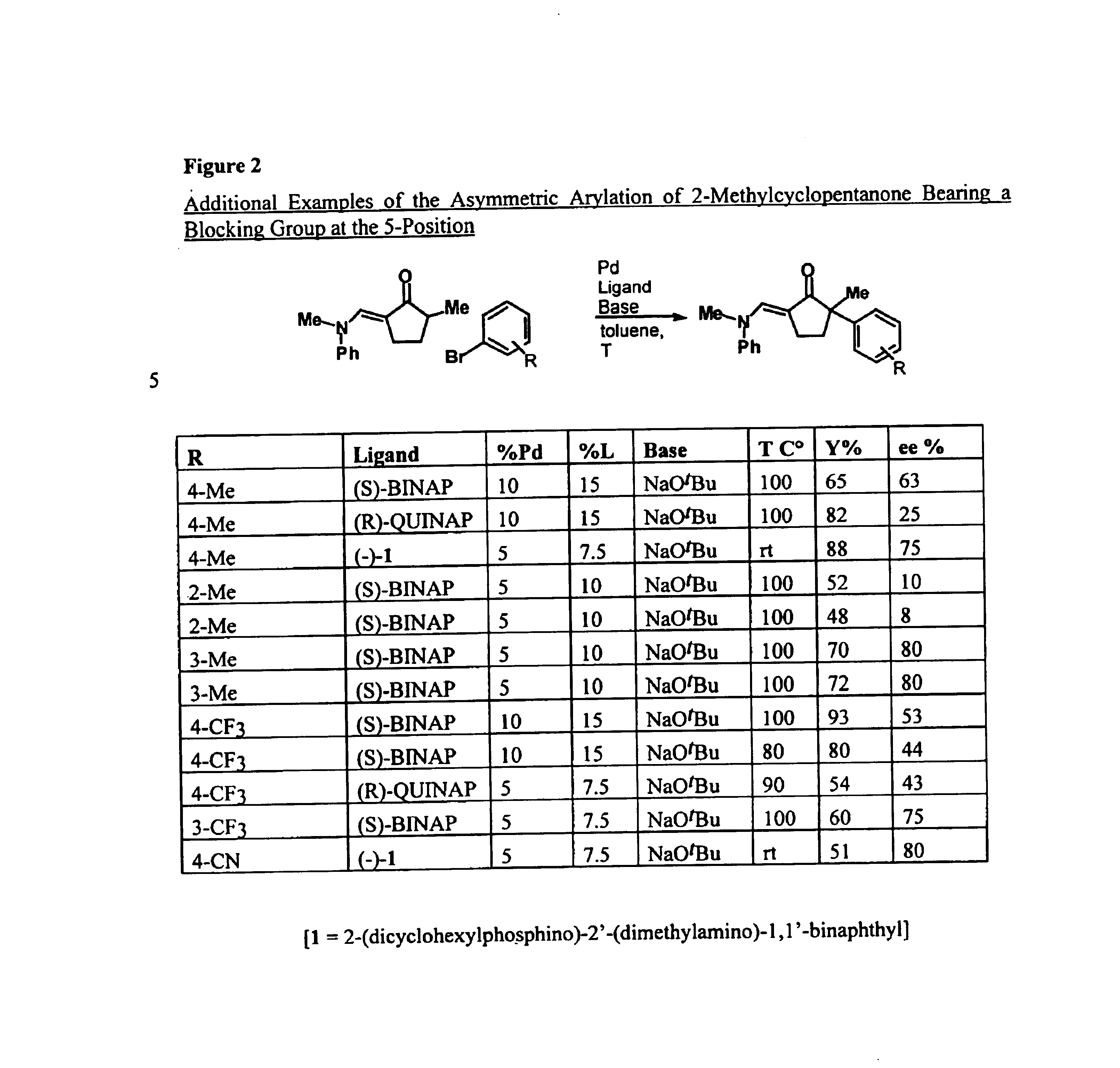

Arylation and vinylation of activated carbons

InactiveUS6867310B1Carboxylic acid nitrile preparationGroup 5/15 element organic compoundsActivated carbonHydrazone

The present invention provides transition-metal-catalyst-based methods for the arylation and vinylation of activated methyl, methylene, and methine carbons with aryl halides, vinyl halides, and the like. The methods of the invention provide several improvements over existing methods, including the ability to synthesize efficiently and under mild conditions α-aryl and α-vinyl products from a wide range of starting materials, including ketones, esters, hydrazones, and imines. Furthermore, the methods of the invention may be used in an asymmetric sense, i.e. to produce enantiomerically-enriched chiral α-aryl and α-vinyl products.

Owner:MASSACHUSETTS INST OF TECH

Wet-rub resistant ink compositions

Owner:FUNAI ELECTRIC CO LTD

Copolymers containing nanoparticles

The invention provides copolymers of ethylenically unsaturated monomers and of ethylenically functionalized nanoparticles in the form of their aqueous polymer dispersions or water-redispersible polymer powders, obtainable by means of free-radically initiated polymerization in an aqueous medium and, if desired, subsequent drying of the resultant polymer dispersion, ofA) one or more monomers from the group consisting of vinyl esters, (meth)acrylic esters, vinylaromatics, olef ins, 1,3-dienes, vinyl ethers and vinyl halides and, if desired, further monomers copolymerizable therewith, in the presence ofB) at least one particle P having an average diameter of ≦1000 nm, which is functionalized with ethylenically unsaturated, free-radically polymerizable groups, characterized in thatB2) particles P used are one or more from the group of metal oxides and semimetal oxides, and / orB2) particles P used are silicone resins composed of repeating units of the general formula [R4(p+Z)SiO(4−p−Z) / 2] (II), where for at least 20 mol % of the respective silicone resin p+z=0, 1 or 3,and where B1) and B2) are each functionalized with one or more α-organosilanes of the general formula (R1O)3−(R2)nSi—(CR32)—X (I), where X is a radical having 2 to 20 hydrocarbon atoms and containing an ethylenically unsaturated group.

Owner:WACKER CHEM GMBH

Gypsum plaster compositions with improved adhesion to plastic surfaces and metal surfaces

InactiveUS20020121326A1Improve adhesionLaminationLamination apparatusPolymer scienceAlkaline earth metal

Gypsum plaster compositions with improved adhesion to plastic surfaces and metal surfaces comprise from 10 to 90% by weight of gypsum plaster, based on the total weight of the composition, and also, where appropriate, other additives, and a combination of: a) one or more water-redispersible polymer powders based on one or more vinyl ester, (meth)acrylate, vinylaromatic, olefin, 1,3-diene, or vinyl halides monomers, and optionally other monomers copolymerizable therewith; and b) one or more alkali metal and / or alkaline earth metal salts of short-chain fatty acids having from 1 to 4 carbon atoms in the hydrocarbon skeleton and from 1 to 4 carboxy groups, and which contain no OH groups.

Owner:WACKER CHEM GMBH

Functionalized monomers for synthesis of rubbery polymers

This invention discloses a process for synthesizing an amine functionalized monomer that comprises (1) reacting a secondary amine with a 2,3-dihalopropene to produce a vinyl halide containing secondary amine having a structural formula selected from the group consisting of wherein R and R′ can be the same or different and represent allyl, alkoxyl or alkyl groups containing from 1 to about 10 carbon atoms, and wherein X represents a halogen atom, and wherein m represents an integer from 4 to about 10, and wherein X represents a halogen atom; and (2) reacting the vinyl halide containing secondary amine with a vinyl magnesium halide to produce the monomer having a structural formula wherein R and R′ can be the same or different and represent alkyl, allyl or alkoxyl groups containing from 1 to about 10 carbon atoms, and wherein m represents an integer from about 4 to about 10.

Owner:THE GOODYEAR TIRE & RUBBER CO

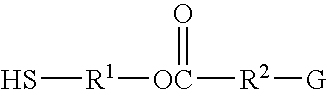

Stabilization of vinyl halide polymers

The heat and light stability imparted to vinyl halide polymers by metal compounds conventionally employed for this purpose is considerably improved by the presence of a mercapto ester such as 2-mercaptoethyl stearate. The esters can replace a substantial portion of the metal compound with no significant reduction in stability.

Owner:PMC ORGANOMETALLIX INC

Laminar articles with good hydrocarbon barrier

Disclosed is a laminar shaped article comprising a heterogeneous blend of (a) a composition comprising a vinyl halide or vinylidene halide polymer and optionally an ethylene copolymer containing carboxyl and / or carbon monoxide moieties, and (b) a polyolefin functionalized with a comonomer selected from the group consisting of maleic anhydride, maleic acid diesters, maleic acid monoesters, itaconic anhydride, itaconic acid diesters, itaconic acid monoesters, fumaric acid diesters, fumaric acid monoesters, or combinations thereof as a compatibilizer; and (c) a polyamide wherein the polyamide is present in the vinyl halide or vinylidene halide polymer as a multitude of overlapping layers.

Owner:DOW GLOBAL TECH LLC

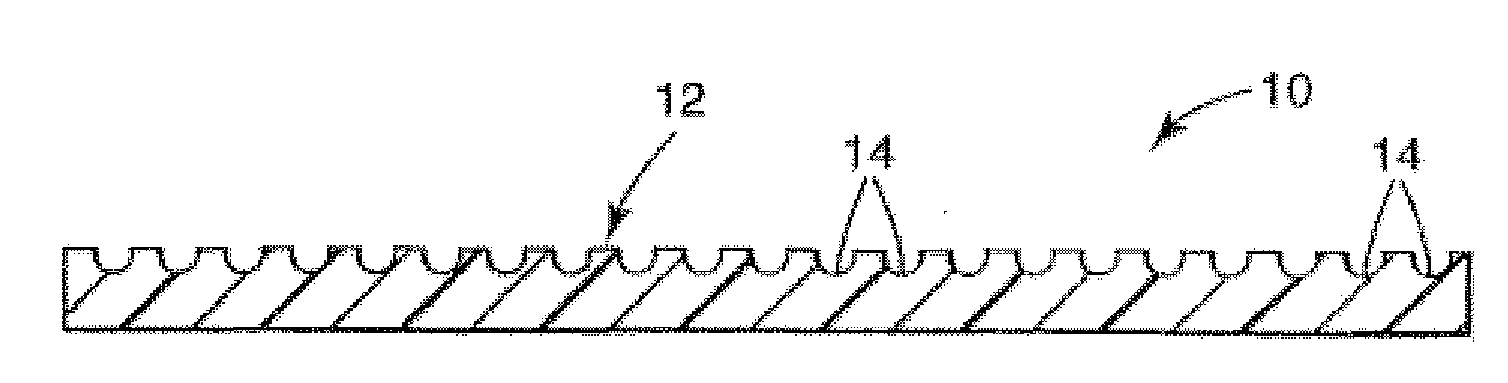

Method of making molded articles

ActiveUS20100112288A1Made rapidly and accuratelyRoof covering using tiles/slatesSynthetic resin layered productsPolymer scienceShell molding

A method of making a finely textured molded article is disclosed. The method utilizes properties of the compound being molded, such as impact toughness and melt flow index. Poly(vinyl halide), particularly poly(vinyl chloride), articles an be compound-injection-molded using the method, in order to simulate the appearance of original metal, glass, or wood articles. Consumer, transportation, building construction, and other industries can benefit from durable plastic articles that simulate the more fragile articles.

Owner:GEON PERFORMANCE SOLUTIONS LLC

Compositions comprising a farnesene interpolymer

Provided herein are composition comprising a farnesene interpolymer. The farnesene interpolymer can be derived from a farnesene and at least one vinyl monomer. In some embodiments, the mole percent ratio of the farnesene to the at least one vinyl monomer is from about 1:4 to about 100:1. In certain embodiments, the farnesene is α-farnesene, β-farnesene or a combination thereof. In some embodiments, the at least one vinyl monomer is ethylene, an α-olefin such as styrene, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof.

Owner:AMYRIS INC

Aqueous film-forming mixtures and conformable films and articles made therefrom

This invention relates to an aqueous film-forming mixture which does not contain a vinyl halide and which can be utilized to prepare conformable films which are useful in various applications such as adhesive tapes, labels and decorative sheets. The aqueous film-forming mixtures generally comprise, based on the weight of the solids in the aqueous mixture, (A) from about 50% to about 80% by weight of an acrylic-urethane copolymer which forms a film having an elongation at break of at least about 300%, and (B) from about 5% to about 25% by weight of an acrylic polymer or copolymer having a Tg of less than about 55° C., wherein the acrylic polymer or copolymer (B) is different from the acrylic-urethane copolymer (A). The aqueous mixtures also may contain up to about 40% by weight of a pigment. These aqueous film-forming mixtures are useful in preparing conformable films and other articles such as adhesive articles which comprise an adhesive layer and a layer of the conformable film of this invention which is adhered to the adhesive layer. The conformable films of the present invention may be printed with various graphics, and the films are die-cuttable.

Owner:AVERY DENNISON CORP

Rubber composition containing resinous nanopractice

InactiveUS20050228134A1Deteriorate controllabilityDeteriorate stabilitySpecial tyresCoatingsElastomerPolymer science

This invention relates to a tread rubber composition for tires with the addition of crosslinked resinous nanoparticles having a high glass transition temperature (Tg) into elastomeric base polymers. The invention demonstrates greatly improved handling performance without deteriorating controllability and stability during high-speed running. The present invention discloses a rubber composition comprising: (1) a rubbery polymer and (2) from 1 phr to 30 phr of pre-crosslinked polymer particles, wherein the pre-crosslinked polymer particles have a particle size which is within the range of 30 nm to 500 nm, wherein the pre-crosslinked polymer is comprised of repeat units that are derived from at least one monomer selected from the group consisting of acrylate monomers, vinyl aromatic monomers, acrylonitrile monomer, and vinyl halide monomers, and wherein the pre-crosslinked polymer has a glass transition temperature which is within the range of 30° C. to 200° C.

Owner:THE GOODYEAR TIRE & RUBBER CO

Nanoparticulate silicone organo copolymers and use thereof in coating means

The object of the invention is nanoparticulate silicone organo copolymers in the form of aqueous polymer dispersions thereof or polymer powders that can be redispersed in water, whereupon the polymer dispersion obtained can optionally dried, said copolymers being obtainable through the radically-initiated polymerization, in an aqueous medium, of A) one or more monomers selected from the group consisting of vinyl esters, (meth)acrylic acid esters, vinyl aromatics, olefins, 1,3- dienes, vinyl ethers and vinyl halogenides and optionally other monomers copolymerizable therewith in the presence of B) at least one particle P having an average diameter of < 1000 nm and being functionalized with ethylenically unsaturated, radically polymerizable groups, wherein Bl) particles P can be selected from one or more members of the group of metal oxides and semimetal oxides, and / or B2 ) silicone resins of the general formula [R4 (p+z) SiO(4-.p-z) / 2] m (II) can be used as particles P, wherein the individual radicals R4 can be hydrogen, hydroxy, alkyl, cycloalkyl, aryl, alkoxy or aryloxy radicals independent of one another, each of said radicals having up to 18 C atoms and being optionally substituted, where m stands for a whole number = 30, and where p + z = 0, 1 or 3 for at least 20 mol-% of the respective silicone resin, said silicone organo copolymers being characterized in that C) one or more linear polydiorganosiloxanes of the general formula R93Si0- [R82Si02 / 2] n-SiR9 3 (III) are copolymerized.

Owner:WACKER CHEM GMBH

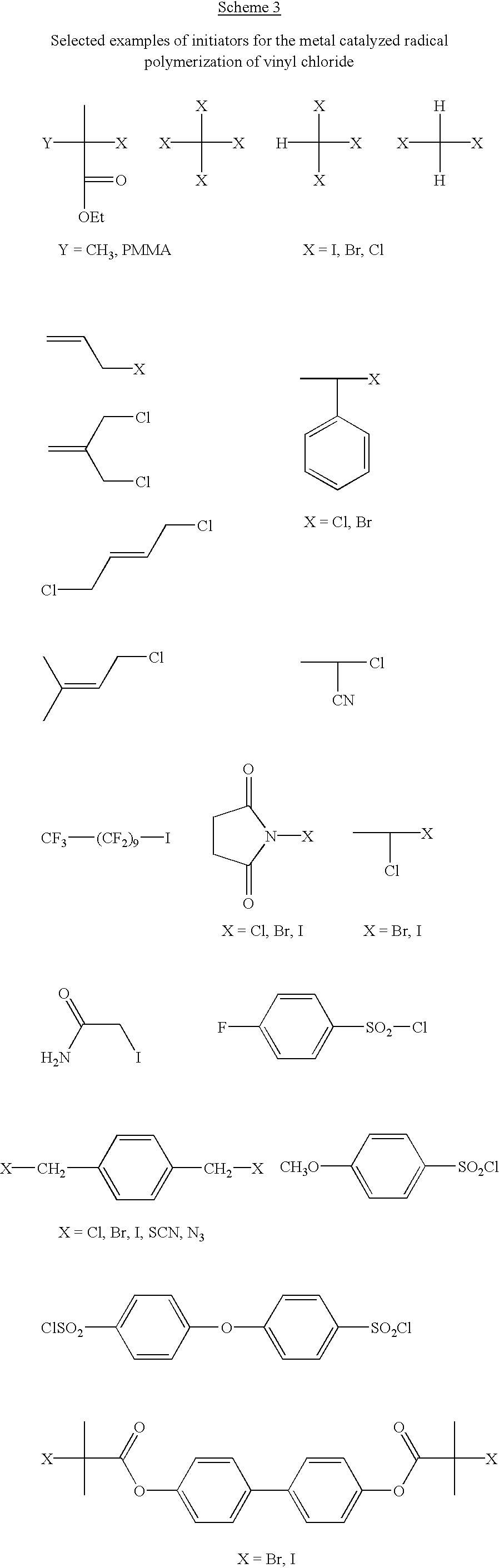

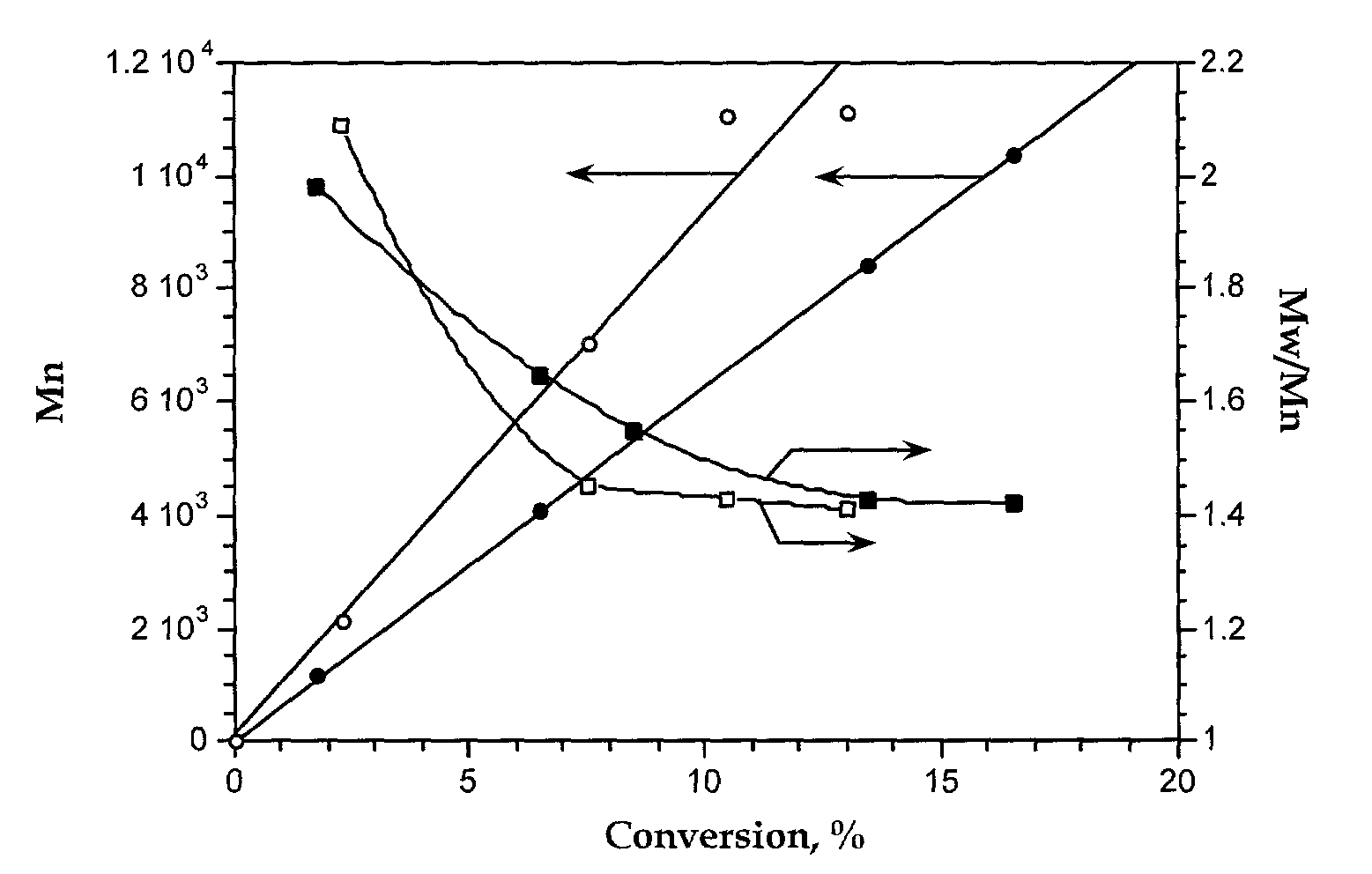

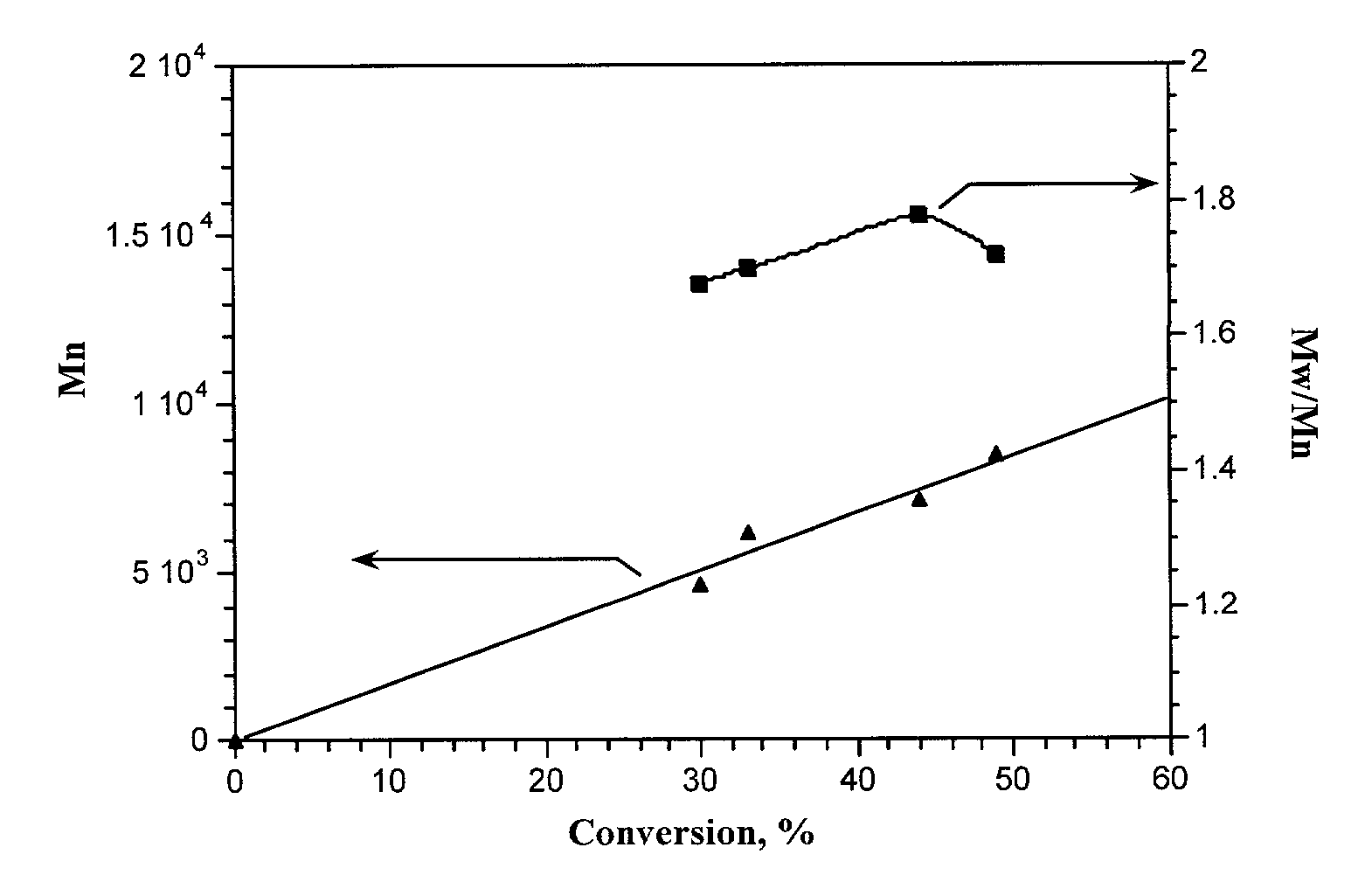

Aqueous room temperature living radical polymerization of vinyl halides

A living polymerization process for preparation of poly(vinyl chloride) (PVC) with controlled molecular weight and molecular weight distribution is described. The polymerization reaction can be initiated by various polyhalocarbon initiators in conjunction with non-metallic reducing single electron transfer reagents as catalysts and accelerated by electron shuttles. The process occurs at room temperature in water or water-organic solvent medium. The polymerization provides PVC with a controlled molecular weight and narrow molecular weight distribution. The halogen containing polymer compositions are useful as, among others, viscosity modifiers, impact modifiers and compatibilizers.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Hydrophobicizing additives

InactiveUS7956113B2Low protective colloid contentSlight propertyNon-fibrous pulp additionFibre treatmentMethacrylateMeth-

Hydrophobicizing additives are water-redispersible powders or aqueous dispersions containing:a) water-insoluble, film-forming base polymer(s) based on homopolymers or copolymers of one or more vinyl esters of optionally branched C1-15 alkylcarboxylic, (meth)acrylic esters of C1-15 alcohols, vinylaromatics, olefins, dienes and vinyl halides,b) one or more hydrophobic organosilicon compounds, fatty acids, or derivatives thereof, or hydrocarbon waxes, andc) one or more protective colloids,wherein the proportion of the component b) based on the total weight of the component a) is more than 30% by weight.

Owner:WACKER CHEM GMBH

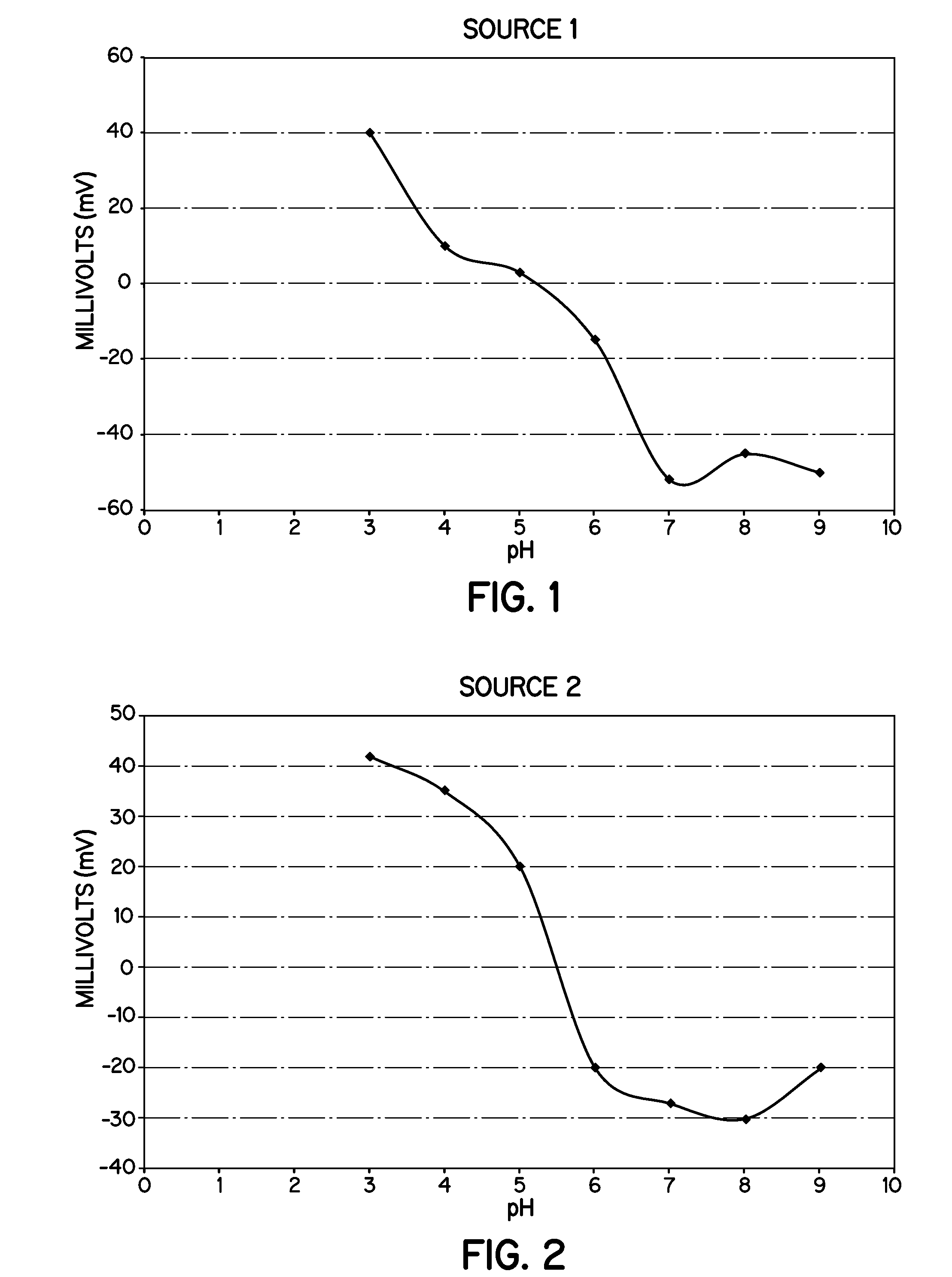

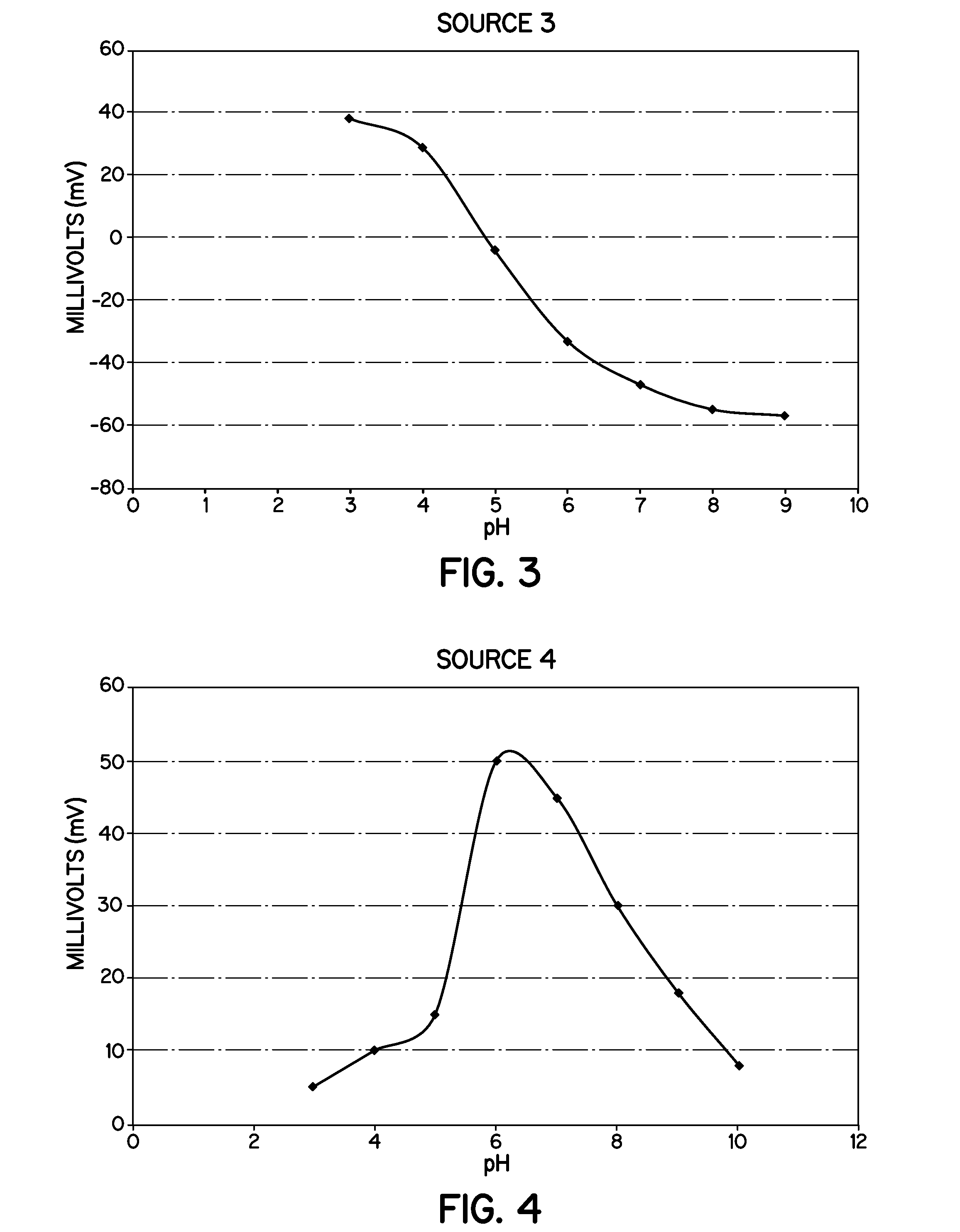

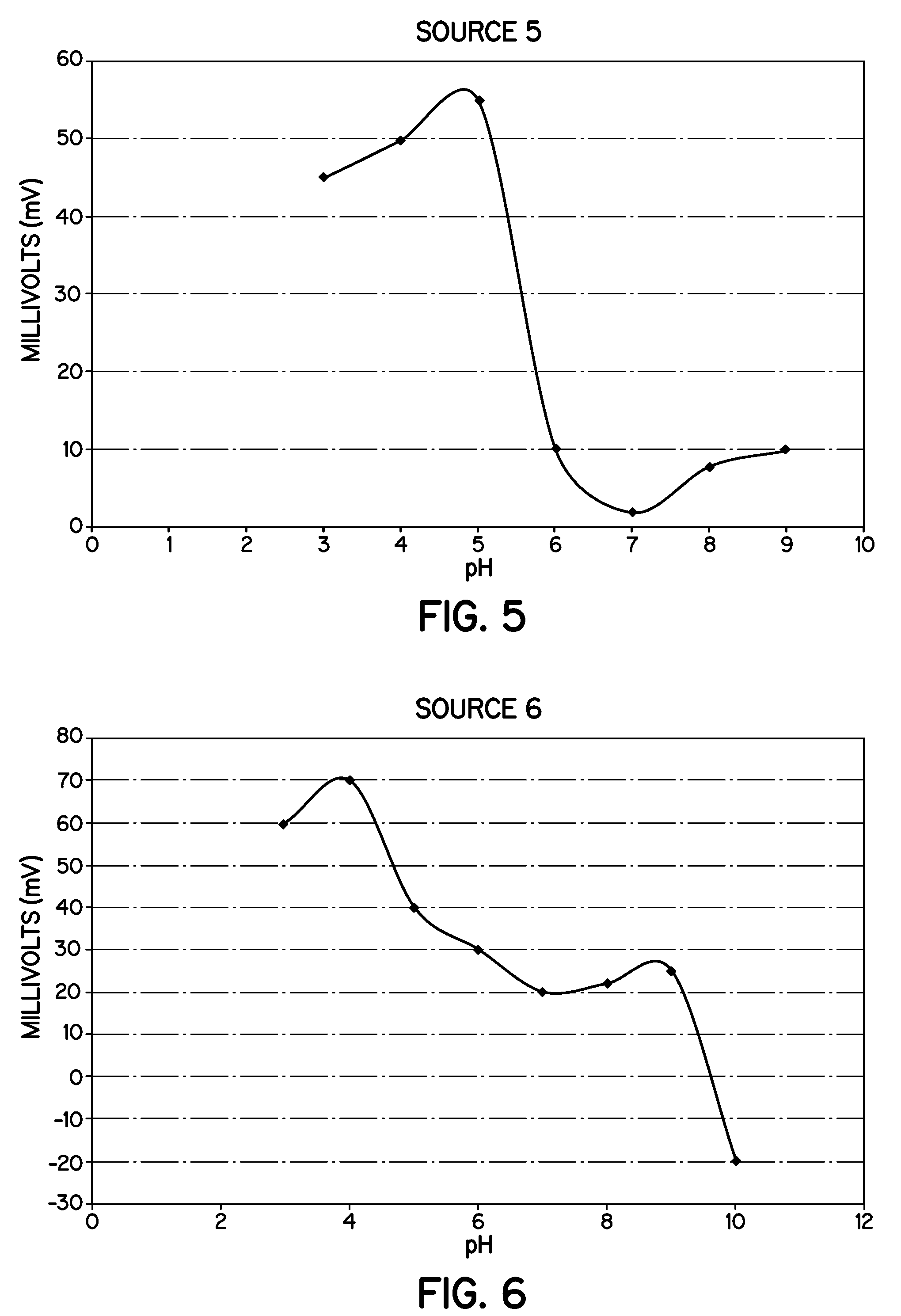

Heat Stabilizers Containing Hydrotalcite Particles With Specific Zeta Potentials That Demonstrate Improved Processing and Performance In Molded Vinyl Compounds

ActiveUS20110127066A1Guaranteed stability and effectivenessStabilizers having high percentages of hydrotalcitePlastic/resin/waxes insulatorsOther chemical processesZeta potentialHydrotalcite

Particulate solid heat stabilizer compositions for vinyl halide polymers are provided having about 30% to 90% by weight hydrotalcite particles represented by a sigmoidal curve on a cartesian coordinate plot of zeta potential (mV) versus pH. The curve has negative zeta potential values balanced against positive zeta potential values over a pH range and an inflection point between a pH of about 3 about 6 representing the isoelectric point (IEP) between said negative and positive zeta potential values. The stabilizer compositions are essentially free flowing, storage stable, and processable upon mixing components of the composition for blending with a vinyl halide polymer in effective amounts to confer heat stabilizing effectiveness upon said polymer.

Owner:CHEMSON POLYMER ADDITIVE AG

Use of a Blend of Phthalate Plasticizers in Poly(Vinyl Halide) Compounds

Use of a blend of phthalate plasticizers is disclosed for flexible polyvinyl chloride compounds. The blend of plasticizers permits the compounds to achieve a 90° C. or higher ratings for usage in wire and cable articles.

Owner:POLYONE CORPORATION

Compostable vinyl halide polymer compositions and composite sheets

Compositions of vinyl halide polymers such as PVC are rendered compostable by a prodegradant system of an organotitanate or zirconate and an organotin. PVC sheets and composites are compostable in landfills.

Owner:BIOTECH PRODS

Polyvinyl-Alcohol-Stabilized Redispersible Powders With Plasticized Properties

InactiveUS20070155862A1Improve liquidityMonocarboxylic acid ester polymer adhesivesSpecial tyresMethacrylatePolymer science

Polyvinyl-alcohol-stabilized redispersible powders which have plasticizing properties are obtained by drying polyvinyl-alcohol-stabilized aqueous dispersions of polymers of one or more monomers from the group of vinyl esters of optionally branched C1-18 alkylcarboxylic acids, (meth)acrylic esters of optionally branched C1-15 alcohols, dienes, olefins, vinylaromatics and vinylhalides, in the presence of a copolymer formed from a) one or more monomers from the group of ethylenically unsaturated monocarboxylic acids, ethylenically unsaturated dicarboxylic acids and their anhydrides, each having 4 to 8 carbon atoms, and salts thereof, b) one or more ethylenically unsaturated compounds containing sulfonic, sulfuric, and / or phosphonic acid groups, and salts thereof, and c) one or more monomers from the group consisting of vinyl esters of optionally branched C1-18 alkylcarboxylic acids and (meth)acrylic esters of optionally branched C1-15 alcohols.

Owner:WACKER CHEM GMBH

Silicone polymerisates

The invention relates to silicone polymerisates produced by radical polymerisation of ethylenically non-saturated monomers in the presence of polysiloxane. The inventive polymerisates are characterised in polymerisation of a) 60-99.99 mass % one or several monomers of a group comprising vinyl esters of linear or branched alkylcarboxylic acids having 1-15 C atoms, alcohol methacrylates and acrylates having 1-15 C atoms, aromatic vinyl compounds, olefins, dienes and vinyl halides in the presence of b) 0.01-40 mass % at least one type of branched polysiloxane whose lipophilic siloxane part contains branched structures and whose hydrophilic polymer organic part can be linear or branched, the mass percentage values relate to the total mass of a) and b).

Owner:WACKER CHEM GMBH

Copper-catalyzed formation of carbon heteroatom and carbon-carbon bonds

InactiveUS20050215794A1Cheap and practicalLow costUrea derivatives preparationCarbamic acid derivatives preparationCarbon–oxygen bondHydrazine compound

The present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide or amine moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In additional embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between a nitrogen atom of an acyl hydrazine and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of a nitrogen-containing heteroaromatic, e.g., indole, pyrazole, and indazole, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-oxygen bond between the oxygen atom of an alcohol and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. The present invention also relates to copper-catalyzed methods of forming a carbon-carbon bond between a reactant comprising a nucleophilic carbon atom, e.g., an enolate or malonate anion, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. Importantly, all the methods of the present invention are relatively inexpensive to practice due to the low cost of the copper comprised by the catalysts.

Owner:MASSACHUSETTS INST OF TECH

Rubber composition containing resinous nanoparticle

InactiveUS20060148931A1Improve handlingHigh glass transition temperatureSpecial tyresInflatable tyresTire beadPolymer science

This invention relates to a tread rubber composition for tires with the addition of crosslinked resinous nanoparticles having a high glass transition temperature (Tg) into elastomeric base polymers. The invention demonstrates greatly improved handling performance without deteriorating controllability and stability during high-speed running. The present invention more specifically discloses a tire which is comprised of a generally toroidal-shaped carcass with an outer circumferential tread, two spaced beads, at least one ply extending from bead to bead and sidewalls extending radially from and connecting said tread to said beads; wherein said tread is adapted to be ground-contacting; and wherein the tread is comprised of a rubber composition comprising: (1) a rubbery polymer; (2) from 1 to 30 parts per hundred parts of rubber by weight of pre-crosslinked polymer particles, wherein the pre-crosslinked polymer particles have a mean number average particle size as determined by light scattering which is within the range of 30 nm to 500 nm, wherein the pre-crosslinked polymer is comprised of repeat units that are derived from at least one monomer selected from the group consisting of acrylate monomers, acrylonitrile monomer, and vinyl halide monomers, wherein the pre-croslinked polymer is in the form of core-shell particles having a core and a shell, and wherein the pre-crosslinked polymer has a glass transition temperature which is within the range of 30° C. to 200° C.; and (3) 10 to 150 parts per hundred parts of rubber by weight of at least one filler selected from the group consisting of carbon black and silica.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com