Modified-starch-based wood adhesive and preparation method thereof

A wood adhesive, starch-based technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., to achieve the effects of wide source, long storage period and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

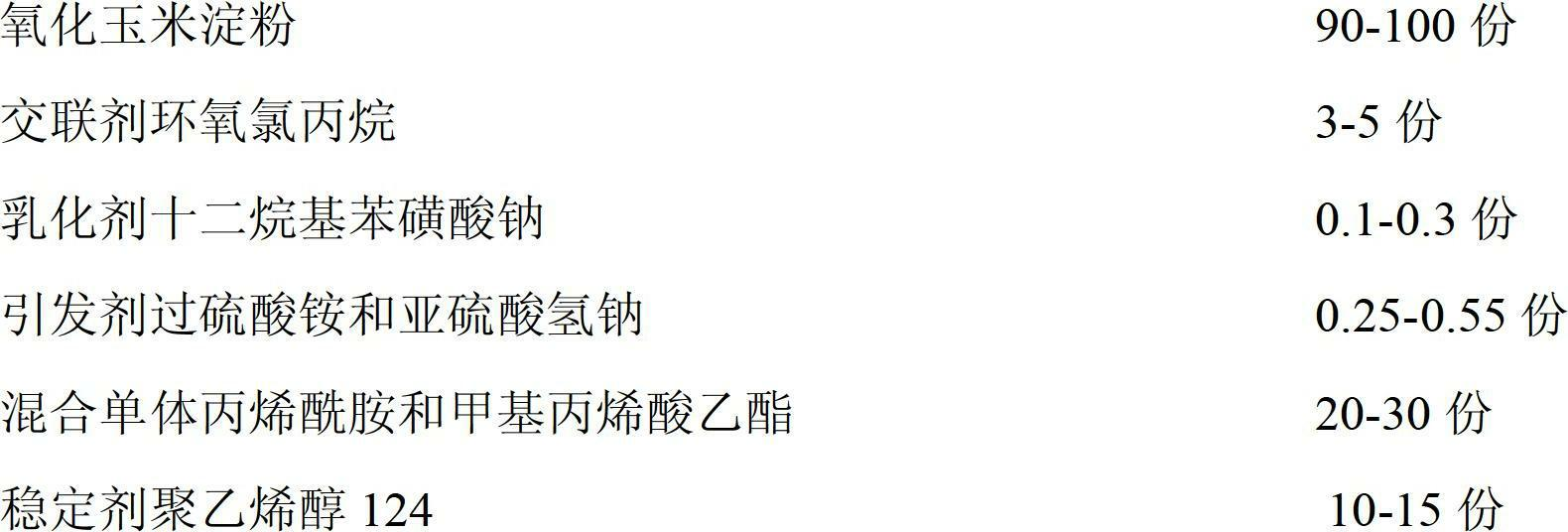

[0022] 1. Formula (parts by mass):

[0023] 100 parts of oxidized corn starch, 100 parts of deionized water, 0.3 parts of sodium hydroxide, 3.0 parts of epichlorohydrin, 0.1 parts of sodium dodecylbenzenesulfonate, 0.18 parts of ammonium persulfate, 0.04 parts of sodium bisulfite, propylene 14 parts of amide, 7 parts of ethyl methacrylate, 10 parts of polyvinyl alcohol, 1 part of tributyl phosphate, 2 parts of urea, and 2 parts of glycerin.

[0024] 2. Process:

[0025] Add 80 parts of oxidized cornstarch to 100 parts of deionized water, and configure a starch emulsion with a mass concentration of 44% in a container with a stirring device. After stirring at a speed of 1000 rpm for 20 minutes, add sodium hydroxide to adjust the pH value to 9 -10, the temperature is 50 ° C, slowly drop the cross-linking agent epichlorohydrin to carry out the cross-linking reaction, the reaction time is 2 hours, and then add the remaining 20 parts of oxidized corn starch, the reaction conditions...

Embodiment 2

[0029] 1. Formula (parts by mass):

[0030] 100 parts of oxidized corn starch, 100 parts of deionized water, 0.4 parts of sodium hydroxide, 5.0 parts of epichlorohydrin, 0.3 parts of sodium dodecylbenzenesulfonate, 0.25 parts of ammonium persulfate, 0.06 parts of sodium bisulfite, propylene 19 parts of amide, 10 parts of ethyl methacrylate, 15 parts of polyvinyl alcohol, 1 part of tributyl phosphate, 2 parts of urea, and 2 parts of glycerin.

[0031] 2. Process:

[0032] The preparation method of this example is the same as that of Example 1, and the solid content of the prepared adhesive is 48%.

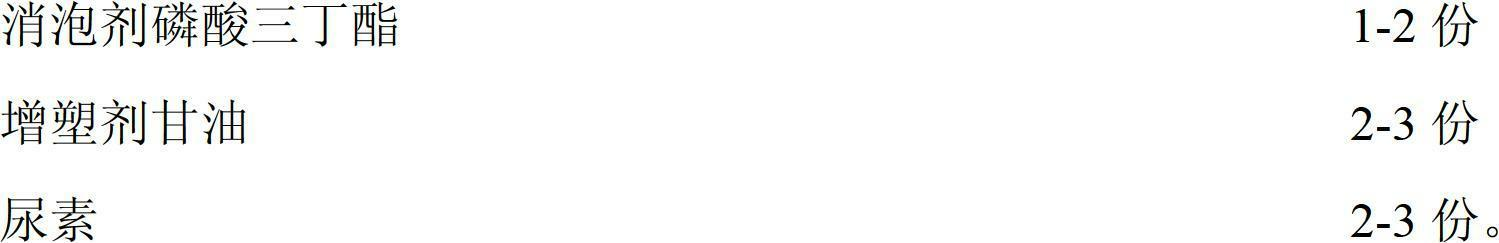

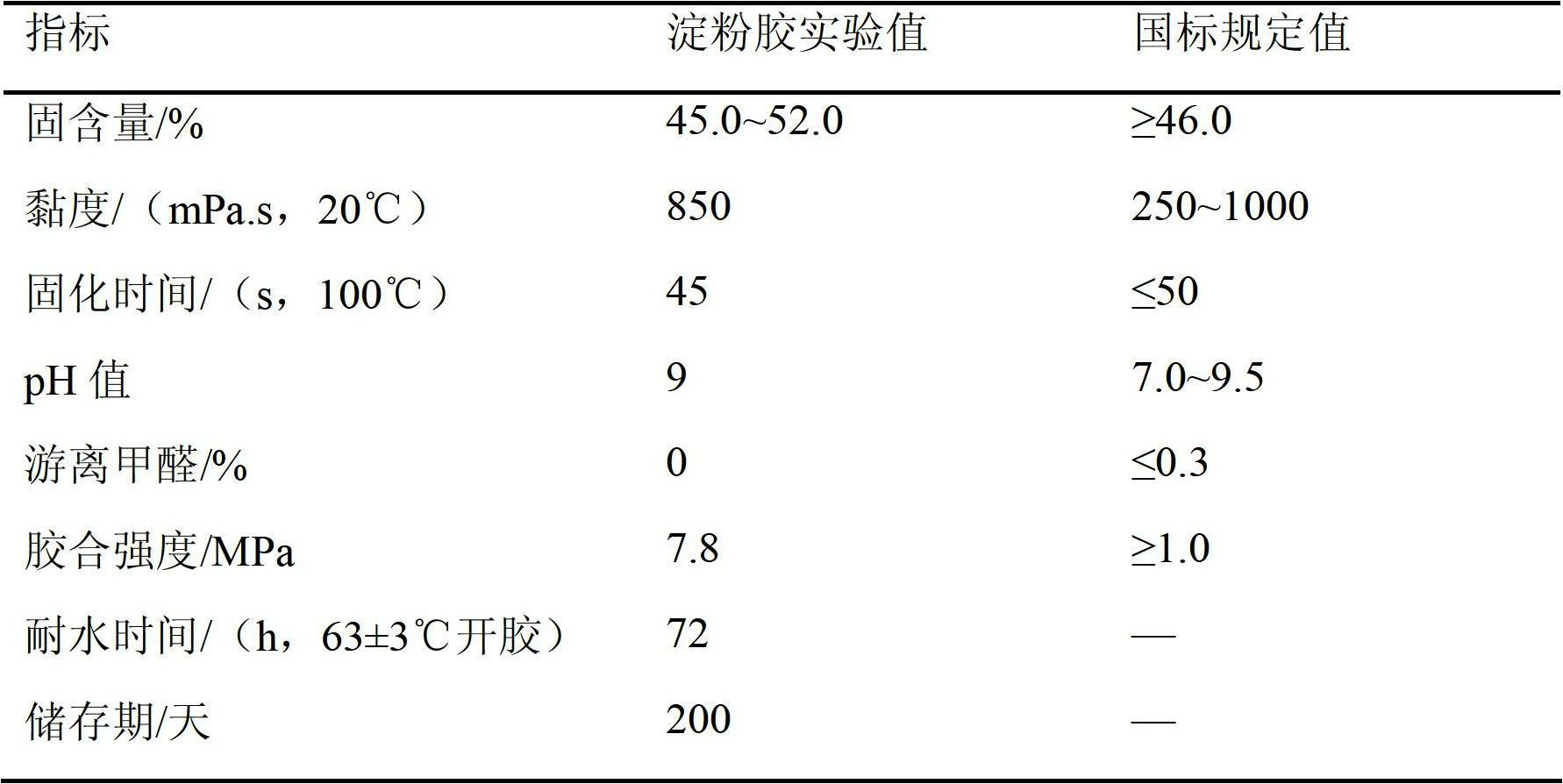

[0033] The adhesive of the invention is used for gluing birch, basswood and poplar plywood, and its dry gluing strength is excellent. Test according to the method specified in GB / T17657-1999, put the test piece in hot water at 63±3°C for 3 hours, then place the test piece flat in an air convection drying oven at 63±3°C for 1 hour, take it out Cool down at room temperature for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com