Patents

Literature

125results about How to "Improve polymerization stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

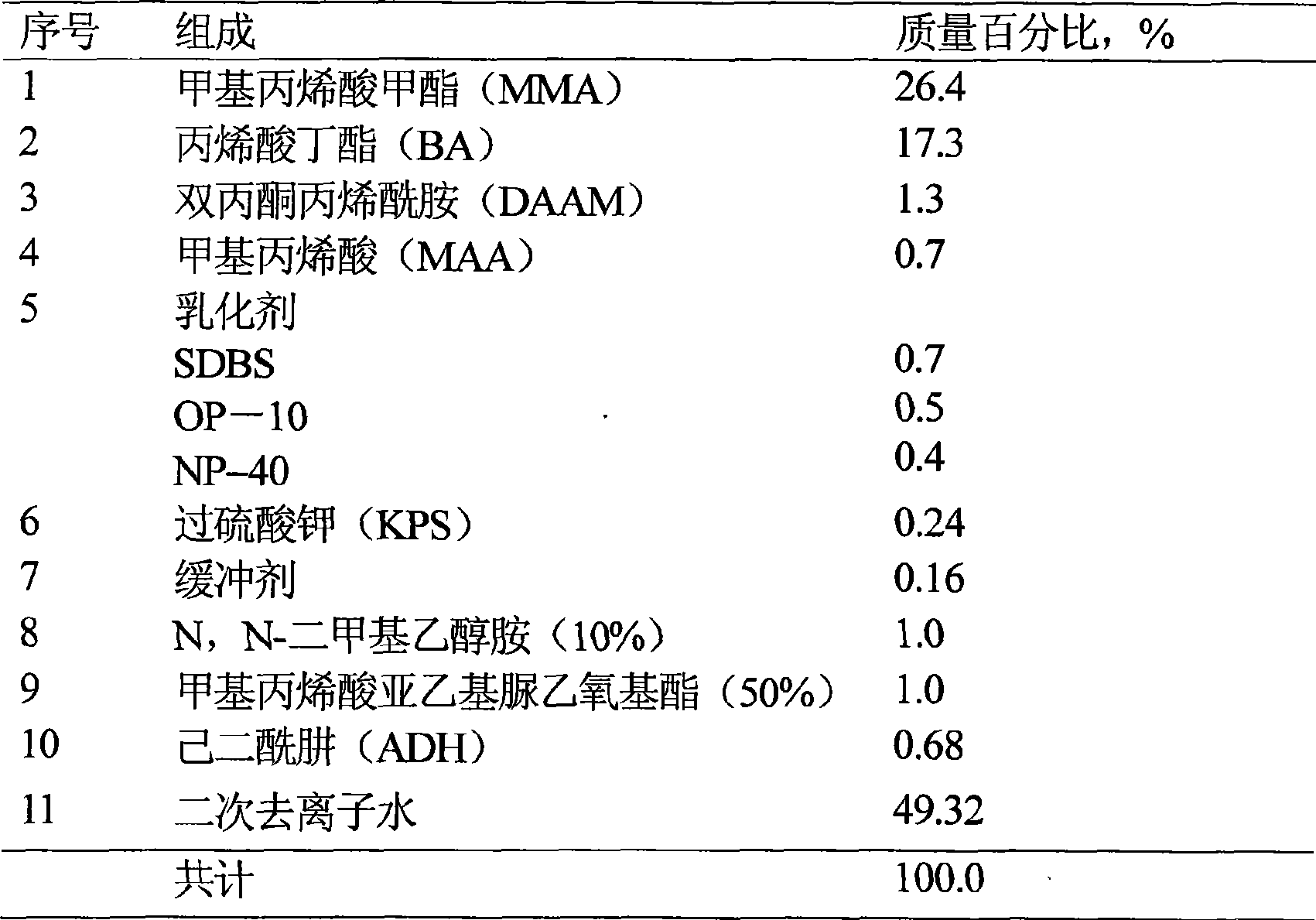

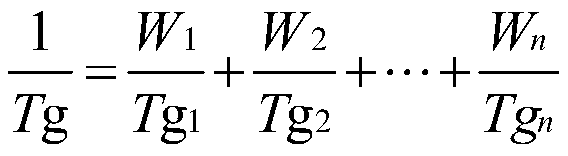

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

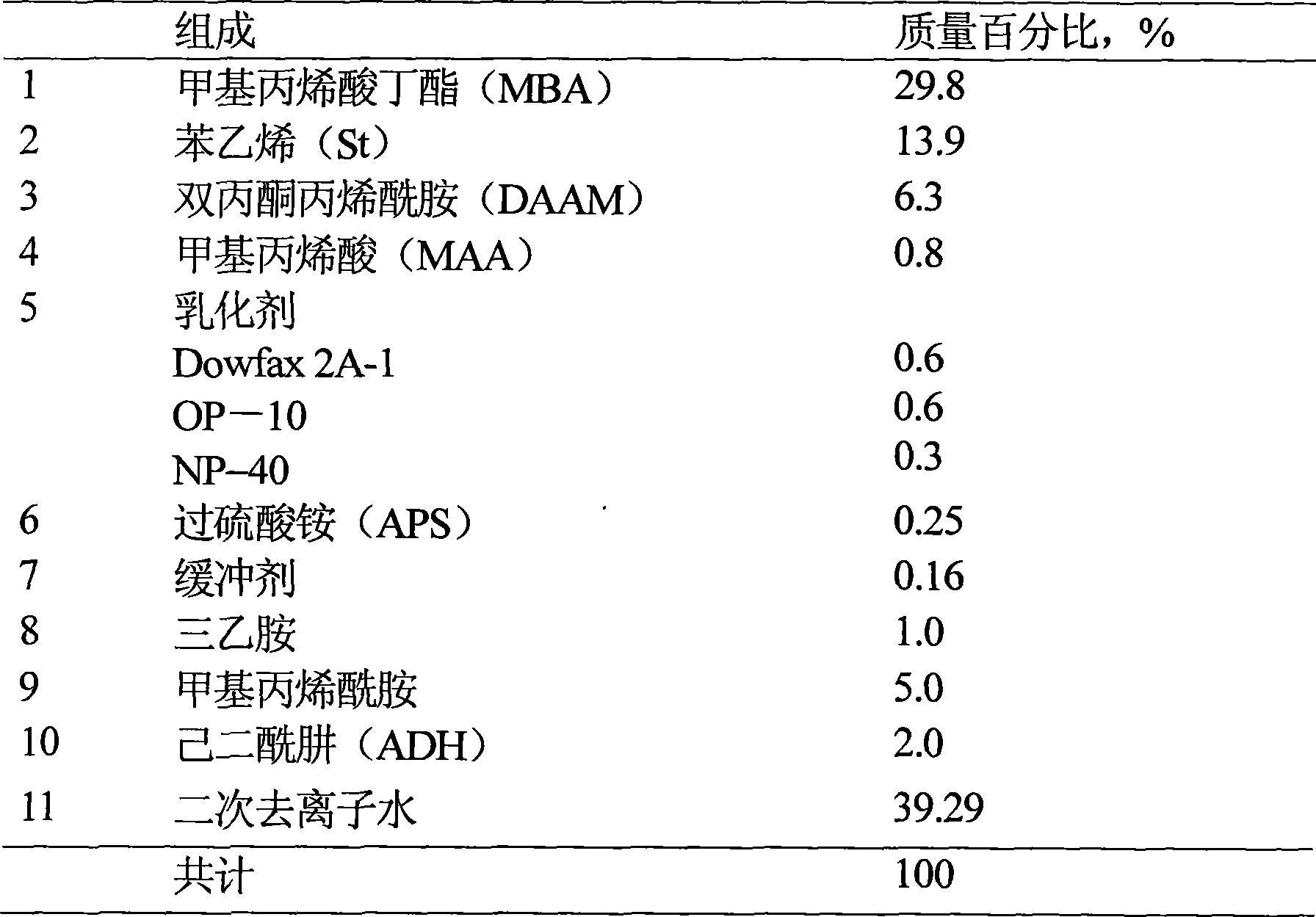

Preparation method of styrene-acrylate copolymer emulsion used in antirust paint

InactiveCN102199240AGood stabilityEmulsion particle size is smallAnti-corrosive paintsFunctional monomerIon

The invention relates to a novel method for preparing a styrene-acrylate copolymer emulsion used in antirust primer paint. The method comprises steps that: (1) phosphate ester functional monomers are subject to a polymerization reaction; two hydroxyl groups of each phosphate ester group are subject to a chelation reaction on the metal surface, such that a dense phosphate ester (salt) protective film is formed on the metal surface, and water molecules and other salt ions are prevented from contacting the metal; the introduced phosphate ester group assists in improving the adhesion of painted coatings on metal surfaces, and in improving the antirust capacity of the painted coatings; (2) diacetone acrylamide (DAAM) and adipic dihydrazide (ADH) form a cross-linking system of the antirust emulsion; hydrazine groups in hydrazino-(NH2-NH2) and ketone groups in the DAAM (C=O) are subject to a dehydration condensation reaction, wherein the ketone groups are copolymerized on the copolymer; through outer cross-linking, a emulsion film with a three-dimensional reticular structure is obtained; (3) an emulsifying system is formed by combining a reactive anion emulsifier and a non-ion emulsifier, such that problems of emulsion deposition and gelling are solved. With the method provided by the invention, an aqueous emulsion with a high solid content is prepared, and water resistance and weathering resistance of the antirust paint is improved.

Owner:BEIJING UNIV OF CHEM TECH

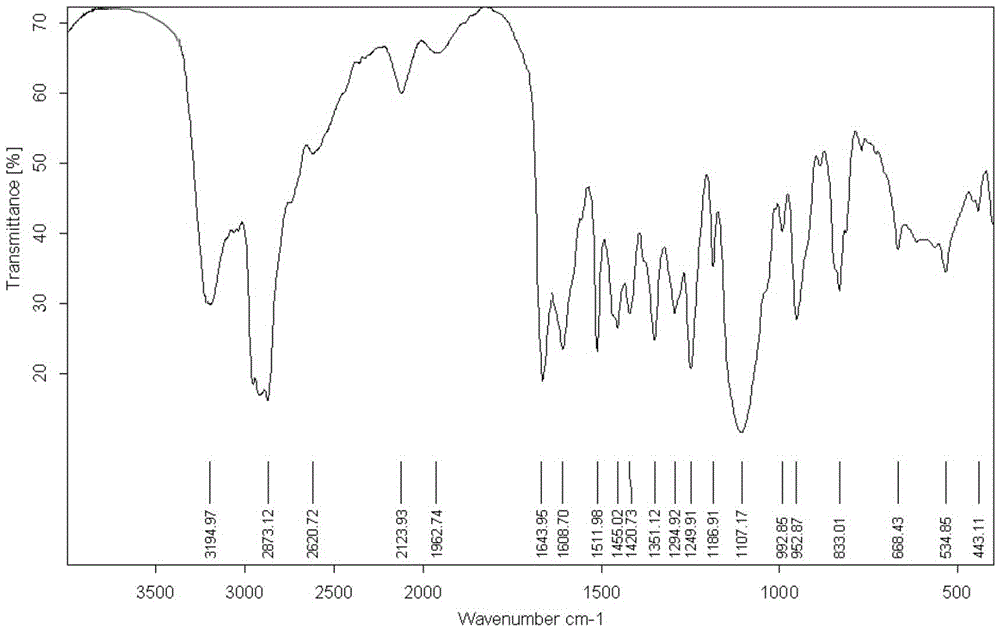

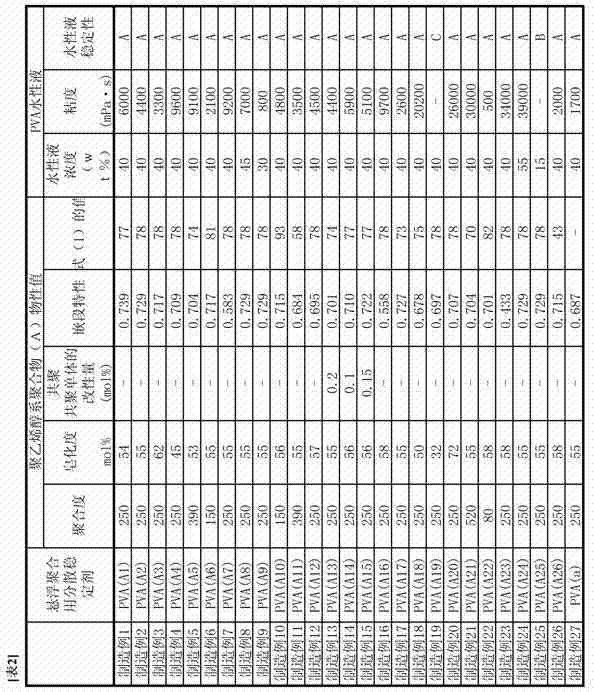

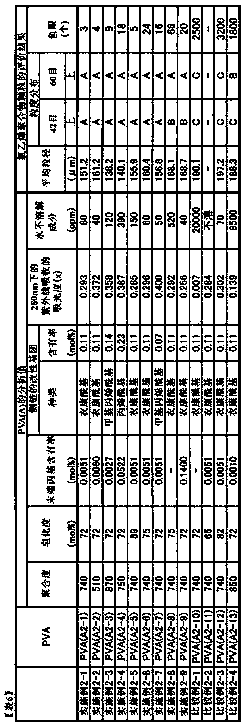

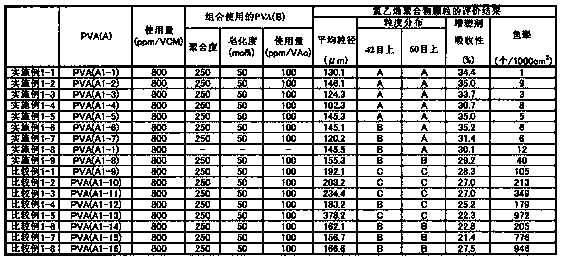

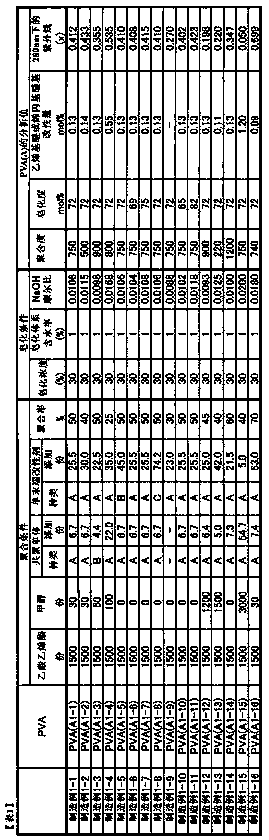

Dispersion stabilizer

ActiveUS20090111940A1Improve polymerization stabilityThe polymerization process is stableTransportation and packagingMixingPolymer scienceSide chain

The aforementioned problems can be solved by a dispersion stabilizer composed of a polyvinyl alcohol polymer (B) having a double bond in its side chain. The polyvinyl alcohol polymer (B) is obtained by esterifying a polyvinyl alcohol polymer (A) with a carboxylic acid having an unsaturated double bond or a salt thereof. Furthermore, the aforementioned problems can be solved with a dispersion stabilizer composed of a carboxylic acid-modified polyvinyl alcohol polymer (C) that is obtained by esterifying a polyvinyl alcohol polymer (A) with aliphatic carboxylic acid and / or aromatic carboxylic acid containing no olefinically unsaturated bond in the molecule or a salt thereof.

Owner:KURARAY CO LTD

Method for preparing temperature-resistant anti-salt amphoteric polymer filtrate reducer

The invention relates to a method for preparing a temperature-resistant anti-salt amphoteric polymer filtrate reducer used for drilling fluid. In the filtrate reducer, C6 to C10 paraffin hydrocarbons are used as a continuous phase; Span and Tween are used as a compound non-ionic surface active agent, wherein the mass ratio of the Span to the Tween is 2-4:1-3; three monomers, namely acrylamide(AM), acrylic acid(AA) and styrene sulfonic sodium(SSS), are used as raw materials in a mass ratio of 10:3-6:1-4; and an initiator of ammonium persulphate or redox initiator of ammonium persulphate-sodium bisulphite is added for copolymerization by adopting an opposite micro-emulsion polymerization method to obtain the filtrate reducer. The filtrate reducer provided by the invention has the advantages of higher temperature resistance, salt resistance and filtrate-reducing property, simple preparation method, mild and controllable reaction conditions, high polymerization stability, high reaction speed and high conversion rate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

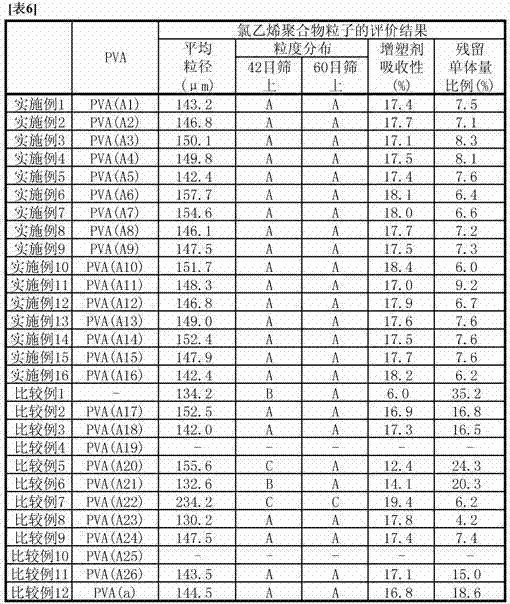

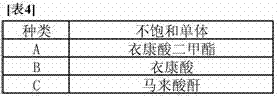

Dispersion stabilizer for suspension polymerization

The present invention provides a dispersion stabilizer having an excellent polymerization stability. When used for suspension polymerization of vinyl compounds even in small amounts, the dispersion stabilizer according to the present invention attains the effects that: with respect to vinyl polymer particles to be obtained, the plasticizer absorptivity is high, leading to easy processing; residual monomer components such as a vinyl compound can be removed easily; the number of coarse particles is small; the obtained particles are as uniform as possible in particle size so that formation of fish-eyes can be prevented. The present invention provides a dispersion stabilizer for suspension polymerization including a polyvinyl alcohol polymer (A) having a saponification degree of 60 mol % or more and a polymerization degree of 200 or more, and a polyvinyl alcohol polymer (C) obtained by esterifying a polyvinyl alcohol polymer (B) having a saponification degree of less than 60 mol % with a carboxylic acid compound.

Owner:KURARAY CO LTD

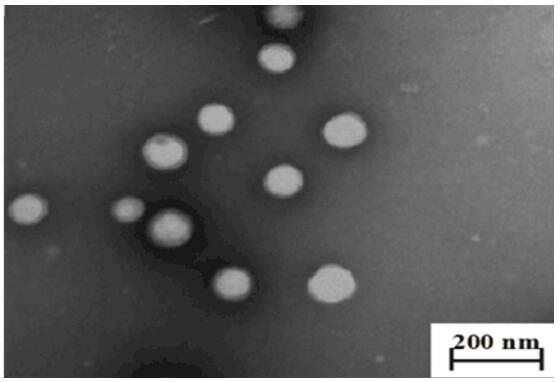

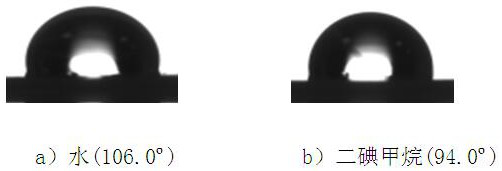

Preparation method of fluorine-containing polyacrylate soap-free emulsion

InactiveCN102585086AOvercome the defect of easy migrationImprove polymerization stabilityCoatingsEnd-groupSolvent

The invention relates to a preparation method of a fluorine-containing polyacrylate soap-free emulsion. According to the invention, the fluorine-containing polyacrylate soap-free emulsion is prepared by adopting an amphiphilic segmented copolymer polyacrylic acid-b-polyhexafluorobutyl acrylate (PAA-b-PHFBA) to substitute a routine emulsifier, and carrying out soap-free emulsion copolymerization on acrylate monomers, and can be applied to the leather field, the textile field, the coating field, the papermaking field, the adhesive field and the like. The compatibility of the hydrophobic segment of the used PAA-b-PHFBA and above prepolymerization monomers is good, so a problem of bad compatibility of fluorine-containing monomers is solved, thereby the stability of the emulsion polymerization process is substantially improved. Additionally, the PAA-b-PHFBA is anchored to emulsion particles in the emulsion polymerization, and the hydrophilic segment stretches into a water phase to stabilize the emulsion particles through an electrostatic effect and a steric hindrance effect, so the storage stability and the freeze-thaw resistance stability of the emulsion are improved, disadvantages of bad adhesion, bad water resistance and bad solvent resistance of films of common emulsions are overcome, and the mechanical properties, the adhesion and the abrasive resistance of the film of the emulsion are improved.

Owner:山西佳宇丰化工科技有限公司

Large-sized vinyl chloride seed, method of preparing the seed, vinyl chloride resin prepared using the seed, and method of preparing the vinyl chloride resin

InactiveUS20090311531A1Improve polymerization stabilityHigh viscositySynthetic resin layered productsCellulosic plastic layered productsAqueous mediumViscosity

The present invention relates to a large-sized vinyl chloride seed with an average particle size of 0.65 to 1.5 μm, a vinyl chloride resin with improved low-viscosity properties, and preparation methods thereof. The preparation of the large-sized vinyl chloride seed includes adding a vinyl chloride monomer, an emulsifier, and a polymerization initiator to an aqueous medium; homogenizing the mixed solution using a rotor-stator type homogenizer; and subjecting the resultant monomer droplets to a polymerization reaction.

Owner:LG CHEM LTD

Preparation method of high temperature resistant film-forming styrene-acrylic emulsion for paper product printing

PendingCN110591006AImprove high temperature resistanceHigh strengthFireproof paintsInksFunctional monomerEmulsion

The invention relates to a preparation method of a high temperature resistant film-forming styrene-acrylic emulsion for paper product printing. The method includes the steps of: S1. adding alkali-soluble resin with an acid value of 150-500, ammonia water and deionized water into a reaction kettle respectively, conducting stirring heating to 70-85DEG C, and regulating the pH value to 8.0-9.0 with ammonia water so as to obtain a resin solution for standby use; S2. adding an emulsifier into water, and performing stirring to obtain an emulsifier aqueous solution; S3. mixing a polymerizable monomer, a functional monomer and a molecular weight regulator uniformly, adding the mixture into the emulsifier aqueous solution, and performing stirring and emulsifying to obtain a pre-emulsified solution;S4. adding the resin solution and 10% of the pre-emulsified solution into a reaction kettle, conducting stirring heating to 70-85DEG C, and then adding an initiator; S5. starting dropwise adding of the residual pre-emulsified solution, at the end of the adding, raising the temperature to 85-90DEG C, carrying out heat preservation reaction for 0.5-1.5h; S6. carrying out heat preservation reactionfor 0.5-1.5h, then performing cooling to 65DEG C, then starting dropwise adding of an oxidizing agent and a reducing agent simultaneously; and S7. further performing cooling to 40DEG C, adding amino resin, stirring the substances uniformly, and then performing filtering and discharging. The film-forming styrene-acrylic emulsion provided by the invention has a low film-forming temperature, and at the same time has high temperature resistance.

Owner:WUHAN DESYTEK ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

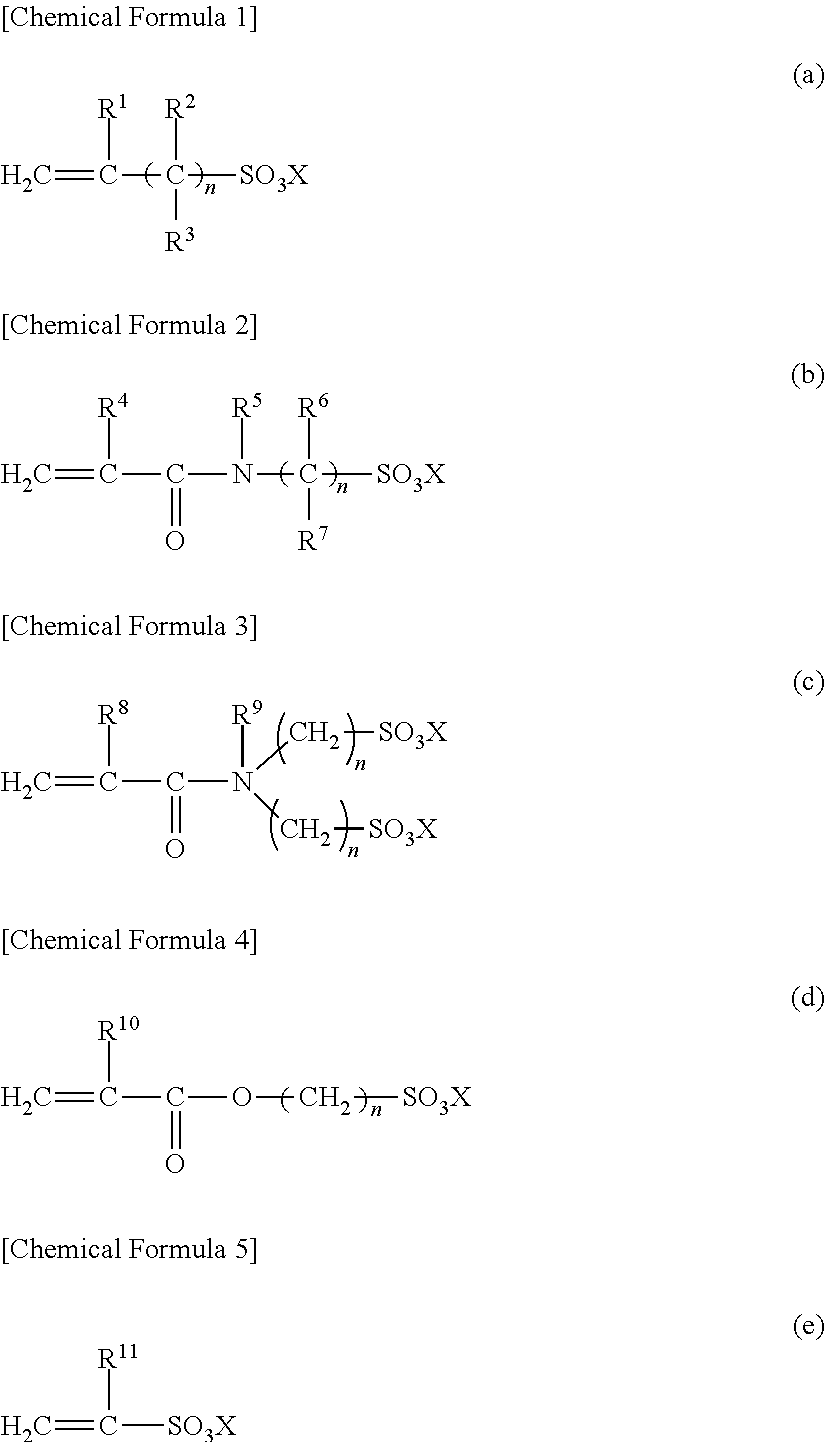

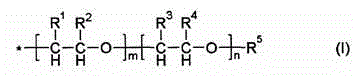

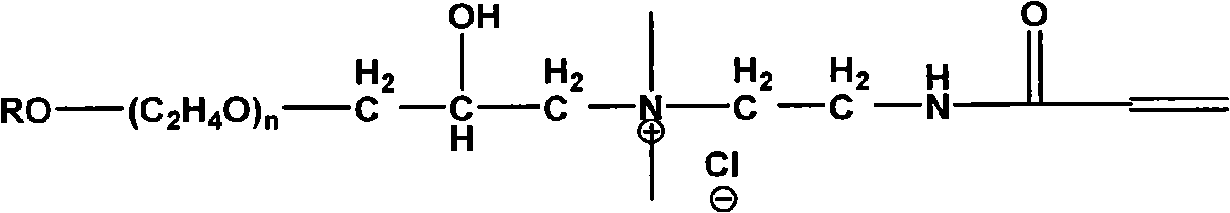

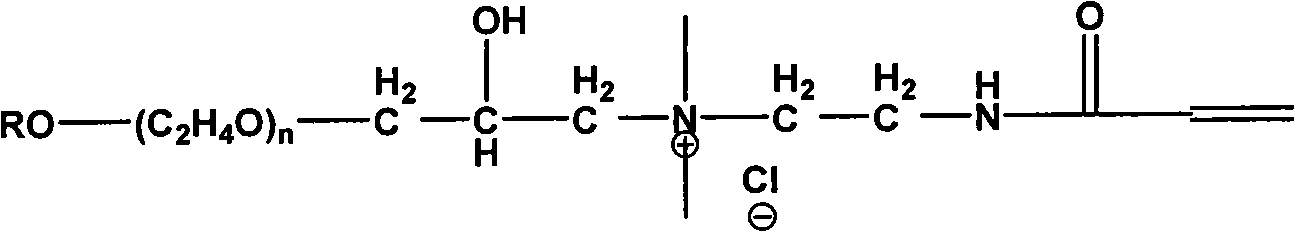

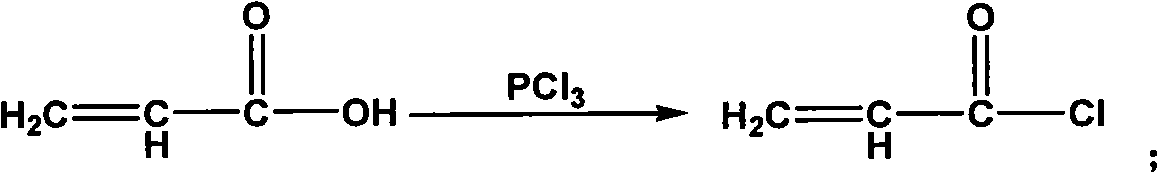

N-acrylyl amino acid polymerizable emulsifier and preparation method thereof

ActiveCN104368271AEfficient polymerization performanceGood emulsifying effectOrganic compound preparationTransportation and packagingEmulsion polymerizationCombinatorial chemistry

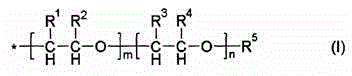

The invention relates to an N-acrylyl amino acid polymerizable emulsifier and a preparation method thereof. The N-acrylyl amino acid polymerizable emulsifier is characterized in that the N-acrylyl amino acid polymerizable emulsifier is shown in the formula I. The preparation method comprises the following steps: (1) synthesizing acryloyl chloride; (2) synthesizing N-acrylyl amino acid; and (3) synthesizing the polymerizable emulsifier. The prepared N-acrylyl amino acid polymerizable emulsifier belongs to a high-efficiency reactive type surface active agent, has a good emulsifying property and good polymerization stability, and can be used for emulsion polymerization, inverse emulsion polymerization, microemulsion polymerization and reversed-phase microemulsion polymerization.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Dispersion stabilizer for suspension polymerization and method for producing vinyl resin

The present invention provides a highly water-soluble and easy-to-handle dispersion stabilizer for suspension polymerization that meets the following requirements: even if the amount of the dispersion stabilizer for suspension polymerization used for suspension polymerization of a vinyl compound is small, the resulting vinyl resin has high plasticizer absorptivity and is easy to work with; it is easy to remove residual monomer components from the resulting vinyl resin; and the resulting vinyl resin contains fewer coarse particles. The present invention relates to a dispersion stabilizer for suspension polymerization of a vinyl compound. This dispersion stabilizer contains a vinyl alcohol polymer (A) having a degree of saponification of 20 mol % or more and less than 65 mol %, a viscosity average degree of polymerization (P) of 100 or more and less than 600, an aliphatic hydrocarbon group having 6 to 18 carbon atoms at its terminal, and an anionic group in its side chain.

Owner:KURARAY CO LTD

Dispersion stabilizer for suspension polymerization

ActiveCN104066753AReduce formationUniform particle sizeTransportation and packagingMixingSide chainPolymer chemistry

The purpose of the present invention is to provide a dispersion stabilizer for suspension polymerization, whereby polymer particles of uniform diameter can be manufactured with minimal formation of coarse particles, and whereby polymer particles can be obtained having reduced blocking and scaling, as well as extremely superior plasticizer absorption properties and monomer removal properties. [Solution] A dispersion stabilizer for suspension polymerization, containing a polyoxyalkylene-modified vinyl alcohol-based polymer (A) having a polyoxyalkylene group with 2 to 100 repeating units and 2-4 carbon atoms in an alkylene group in a side chain, the polyoxyalkylene-modified vinyl alcohol-based polymer (A) having a viscosity average degree of polymerization of less than 500 and a degree of saponification greater than 70 mol%, and the denaturation rate of the polyoxyalkylene group being 0.1 mol% to 10 mol%.

Owner:KURARAY CO LTD

Preparation method of butyronitrile latex with high nitrile group content

The invention provides butyronitrile latex with high nitrile group content for manufacturing asbestos or a non-asbestus sheet. The butyronitrile latex is prepared by taking butadiene and acrylonitrileas monomers and adopting a compound emulsifying system formed by an anionic emulsifier and a non-ionic emulsifier and a redox initiation system formed by persulfate and mercaptan. An intermediate-temperate emulsion polymerization technology of a three-stage stepped temperature control process that the monomers, an emulsifying agent, an initiating agent, a reducing agent, an auxiliary reducing agent, and the like are added in batches is adopted so as to ensure that the polymerization stability of the latex is greatly improved, prevent the generation of gel and improve the mechanical stabilityof the latex. The content of the acrylonitrile combined by the latex is 28-33 percent, and the strength in each aspect of the nitrile latex exceeds the strength of the prior nitrile latex product. Particularly, the butyronitrile latex has good oil resistivity and low loss ratio in a solvent, thus the nitrile latex has excellent performance when used for manufacturing the asbestos or the non-asbestes sheet.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Impact strength modifier for chlorine-containing resin, chlorine-containing resin composition and molded body of chlorine-containing resin composition

ActiveUS20160039963A1Improve polymerization stabilityPolymerization speed fasterSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceMeth-

Disclosed is an impact strength modifier (α) for a chlorine-containing resin, comprising a powder of a graft copolymer (A) obtained by graft polymerizing one or more kinds of vinyl monomers (b1) onto a polyorganosiloxane rubber (A1) or a composite rubber (A2) containing a polyorganosiloxane rubber and a polyalkyl(meth)acrylate rubber, wherein the specific surface area of the powder of the graft copolymer (A) measured by a nitrogen gas adsorption method is from 0.6 to 30 m2 / g, and the pH of water used for extraction under conditions, in which (1) in an oven at 180° C., 5.0 g of the powder of the graft copolymer (A) is left to stand still and heated for 15 minutes, and (2) after the heating, the powder is dispersed in 100 ml of heated pure water and extracted for 1 hour at 70° C. while stirring, is from 4 to 11.

Owner:MITSUBISHI CHEM CORP

Vinyl alcohol copolymer and method for producing same

ActiveUS20160083490A1Easily produceHigh polymerization stabilityTransportation and packagingMixingDouble bondChemistry

Provided is a vinyl alcohol-based copolymer, obtained by saponifying a copolymer of vinyl acetate and a polyfunctional monomer, wherein the polyfunctional monomer contains two or more ethylenic double bonds in its molecule, the vinyl alcohol-based copolymer has a side chain containing an ethylenic double bond and a molar ratio (d) of the ethylenic double bond to a total of vinyl alcohol units and vinyl acetate units is from 0.05 / 100 to 2 / 100, and the vinyl alcohol-based copolymer is water soluble.

Owner:KURARAY CO LTD

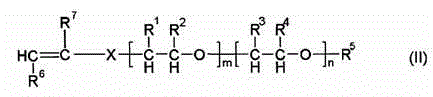

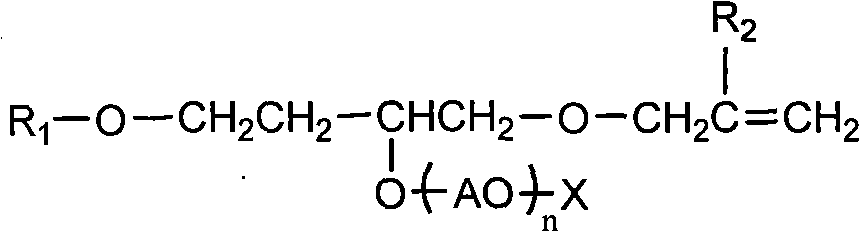

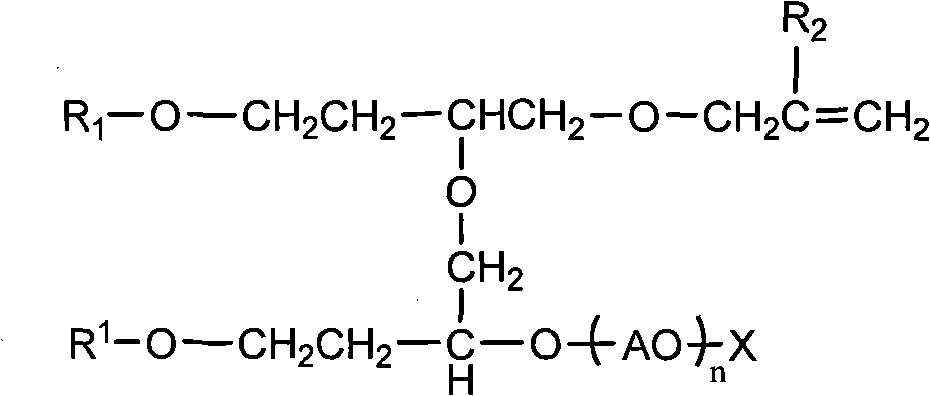

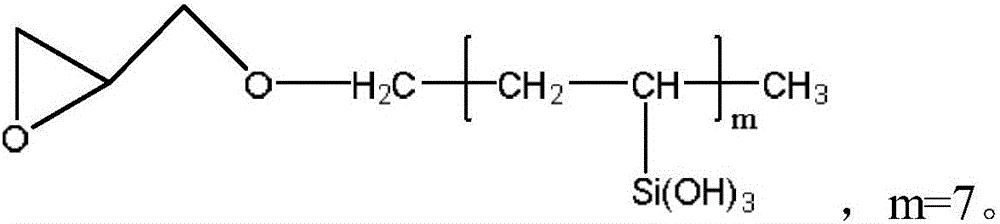

Polymerizable surfactant

InactiveCN101982224AImprove mechanical stabilityImprove polymerization stabilityTransportation and packagingMixingEmulsionChemistry

The invention relates to a polymerizable surfactant which is prepared by the following steps: carrying out etherification reaction between a glycidyl ether compound and allyl alcohol or methallyl alcohol; and carrying out epoxy addition reaction on the product of the etherification reaction to obtain a nonionic surfactant with allyl or methyl allyl groups and an anion polymerizable surfactant derived from the nonionic surfactant. The polymerizable surfactant comprises two structures as shown in the formula (I) and the formula (II). In the formulas, R1 in the formula (I) and R1 in the formula (II) are alkyl, alkenyl, phenyl, alkyl phenyl, diphenyl and the like with 3-30 atoms, the R1 in the formula (I) and R1 in the formula (II) can be the same or not the same; R2 is hydrogen or methyl; A is alkylene with 2-4 carbon atoms; n is an integral number between 1 and 90; X is hydrogen or sulfate radical, phosphate radical and succinic acid radical; the polymerizable surfactant provided by the invention can provide excellent polymerization stability and mechanical stability and endows the emulsion film with excellent water resistence, cohesiveness and other properties. The formula (I) and the formula (II) are shown in the specification.

Owner:李雪松

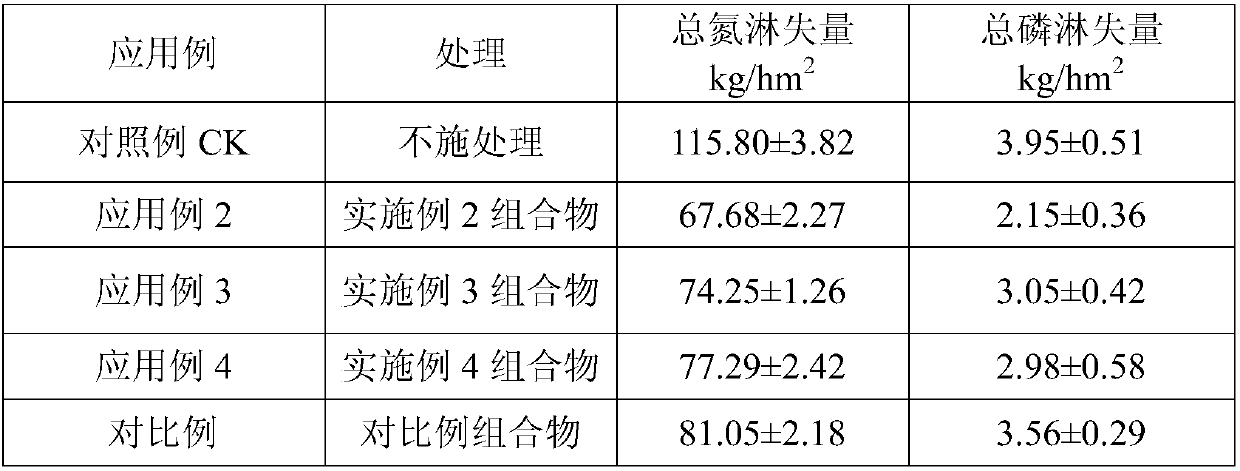

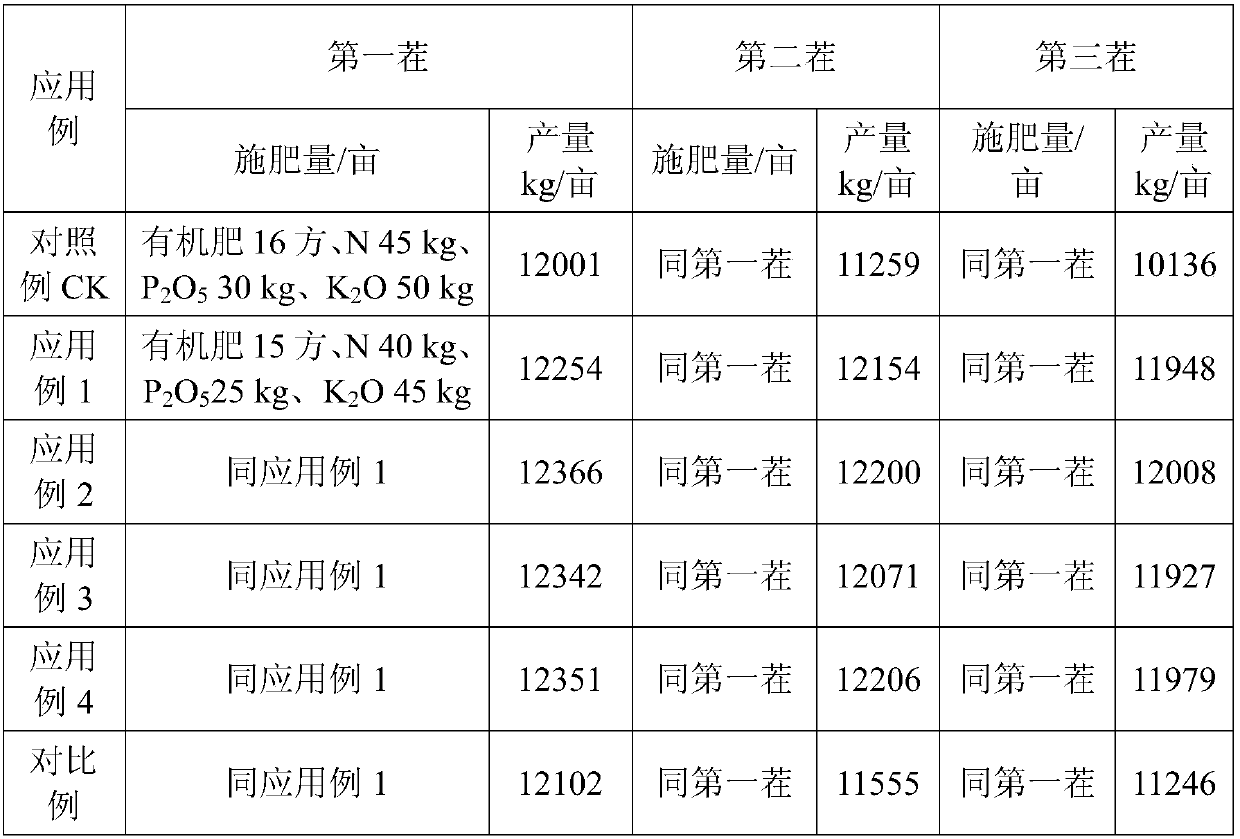

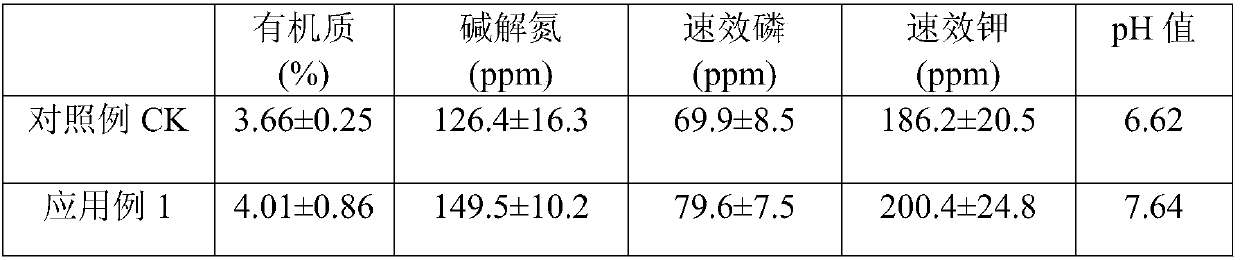

Composition with functions of resistance and control of nitrogen and phosphorus loss of protected horticultural vegetable fields and improvement of soil fertility

InactiveCN107628863AStrong retention and adsorptionReduce leachingFertilizer mixturesSodium BentoniteHigh carbon

The invention provides a composition with functions of resistance and control of a nitrogen and phosphorus loss of protected horticultural vegetable fields and improvement of soil fertility. The composition comprises 30 to 50 parts of modified straw powder, 20 to 30 parts of biocoke, 15 to 25 parts of shell powder, 10 to 15 parts of bentonite, 5 to 10 parts of chitooligosaccharides and 10 to 15 parts of edible mushroom residues. Through use of strong adsorption of modified straw powder, chemical fixing action of shell powder to phosphorus, fixing action of bentonite to ammonium nitrogen, and denitrification transformation and microbial conversion of nitrate nitrogen based on denitrification bacteria in soil at a high carbon-nitrogen ratio, nitrogen and phosphorus effective use is improvedand the nitrogen and phosphorus loss can be effectively inhibited and controlled under synergism. The composition improves physico-chemical properties of soil and soil fertility, activates soil microbial activity, improves nitrogen and phosphorus availability of soil, reduces fertilizer application and saves a cost.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Antibacterial cationic waterborne polyurethane resin and preparation method thereof

ActiveCN108299614AIncrease the degree of cross-linkingImprove water resistanceAntifouling/underwater paintsPaints with biocidesIsocyanateChemistry

The invention provides an antibacterial cationic waterborne polyurethane resin and a preparation method thereof. The preparation method comprises the steps of: reacting macromolecular polyol with polyisocyanate at 80-95DEG C for 2-4h; then adding a small molecular alcohol chain extender and chlorogenic acid for reaction at 75-85DEG C for 1-3h; then adding a catalyst for reaction at 55-65DEG C for2-4h; adding a hydrophilic chain extender by starved charging technique, carrying out reaction at 35-45DEG C for 0.5-1.5h, performing cooling to a temperature ranging from -5DEG C to 5DEG C, adding aneutralizer for neutralizing, adding deionized emulsified water and dispersing the substances uniformly, and then conducting reduced pressure distillation so as to obtain the cationic waterborne polyurethane resin. According to the invention, chlorogenic acid is introduced to a cationic waterborne polyurethane molecular chain by chemical bonding, the influence of functional additives to the mechanical properties of waterborne polyurethane can be avoided, and also a good antibacterial effect can be realized.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Acrylic acid ester copolymer composition and redispersible powders

InactiveUS20100160496A1Improve polymerization stabilityGood fluidityNon-fibrous pulp additionPaper coatingSolubilityAdhesive

The present invention provides an acrylic acid ester copolymer emulsion composition, and redispersible powders made therefrom. The acrylic acid ester copolymer emulsion composition comprises polyvinyl alcohol having a degree of saponification of 85 mol % or more, and an average degree of polymerization of 300 to 1400; hydrophilic ethylenic unsaturated monomers having a water solubility of 1% or more; hydrophobic ethylenic unsaturated monomers having a water solubility of less than 1%; and a lipophilic initiator. The acrylic acid ester copolymer composition according to the present invention has excellent polymerization stability, and improved water resistance, alkali resistance, and fluidity, and the redispersible powders prepared by a spray-dry of the acrylic acid ester copolymer composition have improved water redispersibility, and thus, can be used in various fields such as an additive to a hydraulic material, a powder paint, and an adhesive.

Owner:YOUNGWOO CHEMTECH

Acrylamide polymerizable emulsifier with cations and non-ions and preparation method thereof

InactiveCN101628214AAdjust lipophilicityAchieve synergyTransportation and packagingMixingNon ionicPOLYOXYETHYLENE ETHER

The invention relates to an acrylamide polymerizable emulsifier with cations and non-ions and a preparation method thereof, belonging to the field of polymerizable emulsifier of the surfactant and a preparation thereof. The polymerizable emulsifier has not only cationic groups but also non-ion groups in structure so that the synergy of the two kinds of groups can be realized without combination. The specific solution is to adopt acrylic acid as starting material to perform chlorination reaction, acylation reaction, epichlorohydrin addition reaction and quaternization reaction to prepare the acrylamide cationic polymerizable emulsifier. The method has simple operation so that products with good application effectiveness can be obtained without purification. The product with the structure can control the HLB value of the synthesized surfactant by adjusting the epoxide addition number of polyoxyethylene ether, has good emulsifying performance and stability of polymerization and when using in emulsion polymerization, can be used to prepare a polymer emulsion with good performance. When the polymer emulsion is applied in coating, the coating can have antibacterial property without other added antimicrobial additives.

Owner:DALIAN UNIV OF TECH

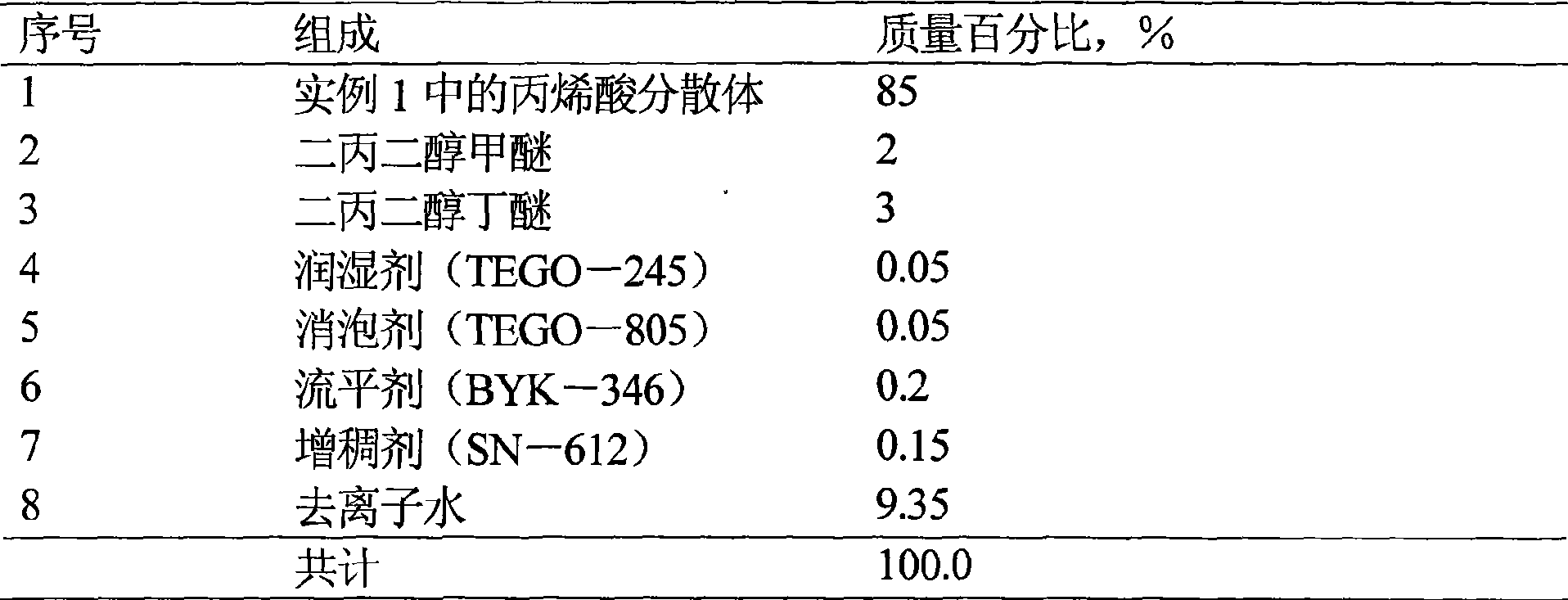

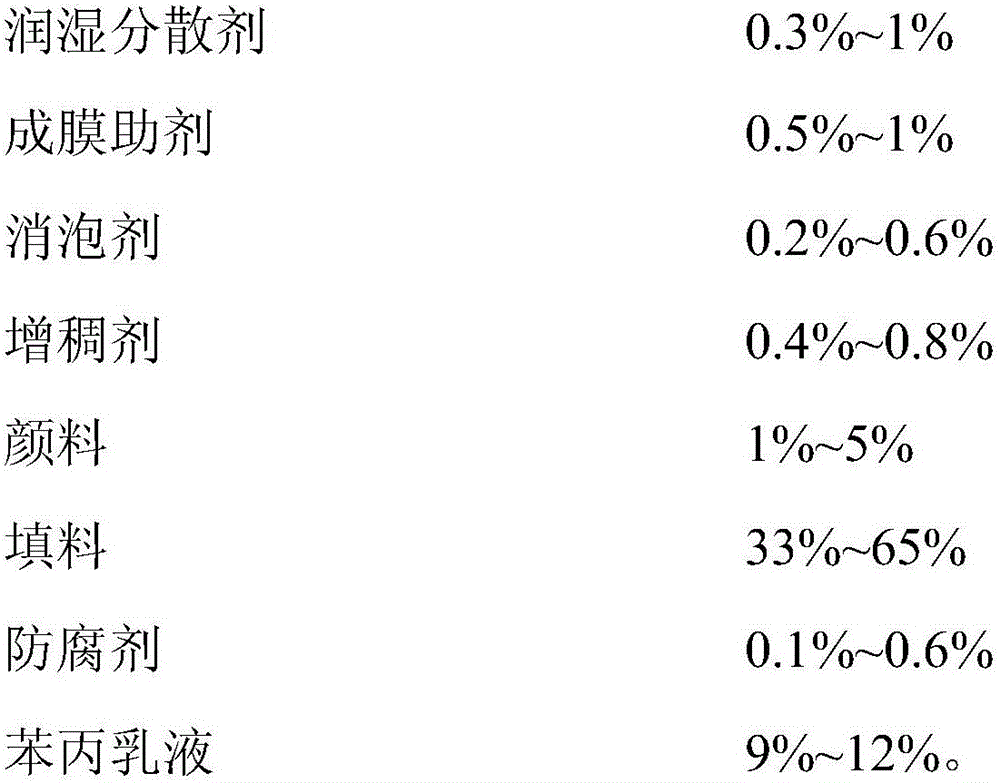

Styrene acrylic emulsion and scrub-resistant high-PVC (pigment volume concentration) interior wall latex paint prepared from same

InactiveCN105801739AWide variety of sourcesLow costEmulsion paintsVolatile organic compoundWeather resistance

The invention belongs to the technical field of paint and discloses styrene acrylic emulsion and scrub-resistant high-PVC (pigment volume concentration) interior wall latex paint prepared from the same. According to the styrene acrylic emulsion, a semi-continuous seed emulsion polymerization method is adopted, a specific kind of crosslinking monomer is enabled to have a synergistic effect with an anionic / nonionic emulsifier and a functional polymeric monomer through controlling of the adding amount and the adding manner of the crosslinking monomer, and the emulsion polymerization stability and the compatibility of the emulsion with the components in the paint preparation formula are improved. The latex paint prepared from the styrene acrylic emulsion adopts a specific kind of anionic / nonionic composite thickener in combination with a specific paint preparation process, the obtained high-PVC interior wall latex paint has low content of VOC (volatile organic compound) and free formaldehyde and good alkali resistance and weather resistance, especially the scrub resistance times is 2-4 times of the scrub resistance times of the latex paint on the same grade, and good application prospect is realized.

Owner:SOUTH CHINA UNIV OF TECH

Dispersion stabilizer for suspension polymerization, and manufacturing method for vinyl resin

ActiveCN105452308APromote absorptionHigh removal ratioTransportation and packagingMixingWater basedHigh absorption

Provided is a dispersion stabilizer for suspension polymerization having outstanding handling properties, and when said dispersion stabilizer for suspension polymerization is used in the suspension polymerization of a vinyl compound, even when used in small quantities it is possible to obtain a vinyl resin which has a high absorption of a plasticizer and which is easy to work, the residual monomer component can be removed easily from the resultant vinyl resin, and there is minimal formation of large rough particles in the vinyl resin obtained. The present invention is a water-based dispersion stabilizer for suspension polymerization, containing 20mass% to 50mass% of a PVA having a degree of saponification of 35mol% to 65mol%, a viscosity-average degree of polymerization of 100 to 480, a C6-C12 aliphatic hydrocarbon group on the terminal, and a block character of the residual ester group of at least 0.5. The values for P (viscosity average degree of polymerization of PVA) and S (amount of denaturation of the aliphatic hydrocarbon group) satisfy the following formula: 50 <= S x P / 1.880 <= 100.

Owner:KURARAY CO LTD

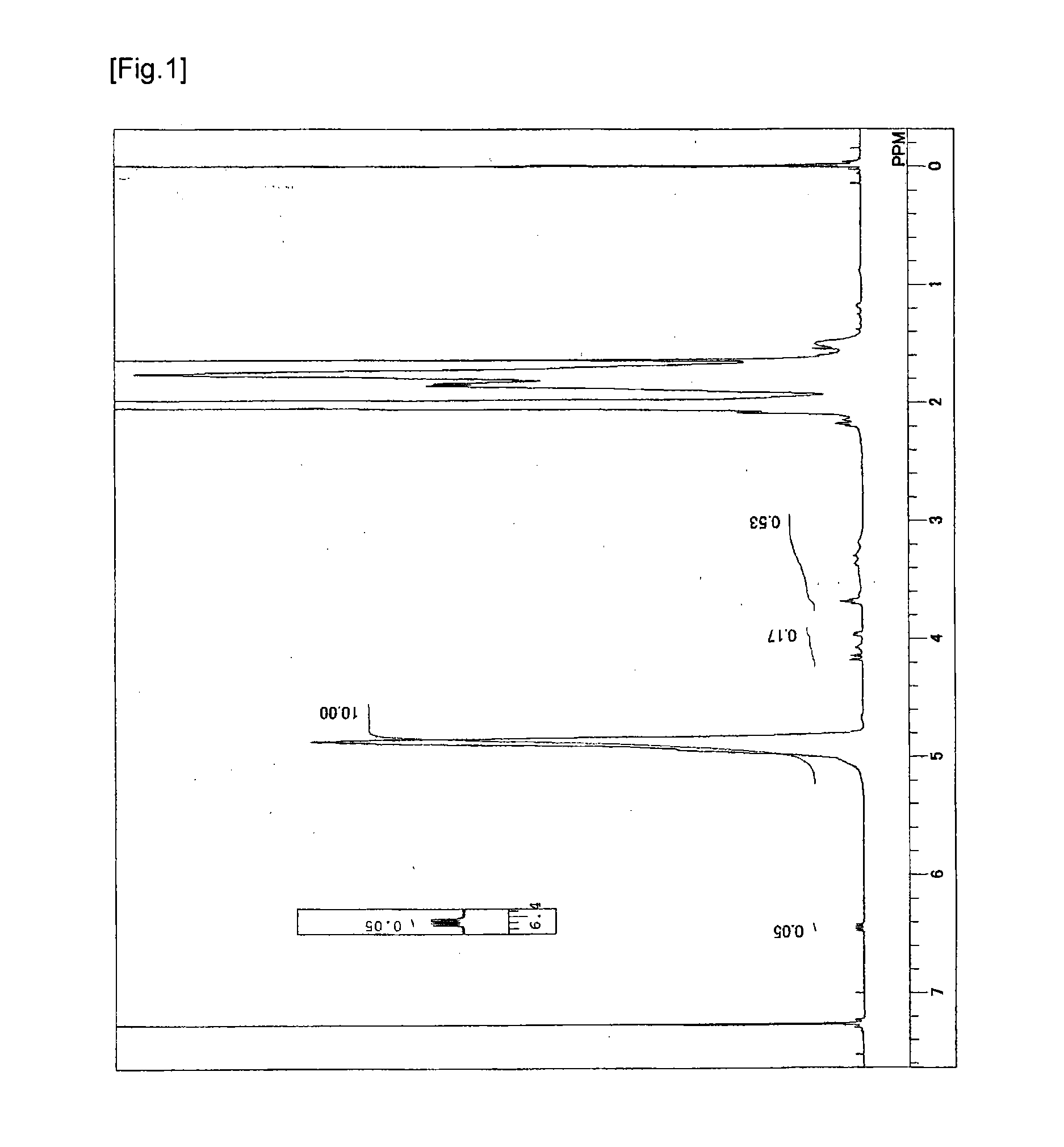

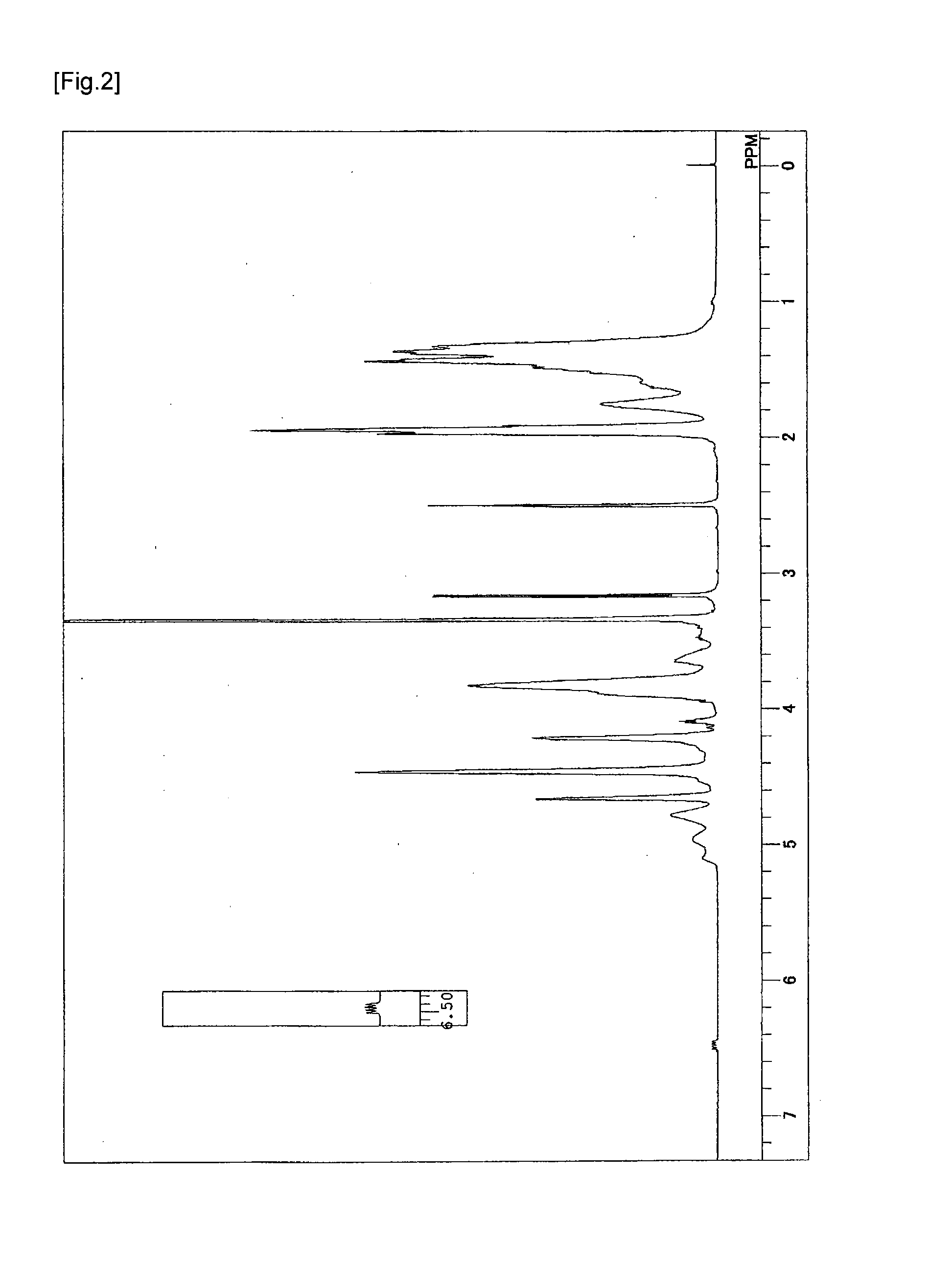

Dispersion stabilizer for suspension polymerization and method for producing vinyl polymer using same

The present invention provides: a dispersion stabilizer for suspension polymerization that is excellent in polymerization stability when subjecting a vinyl compound to suspension polymerization, can provide a vinyl polymer with a smaller number of coarse particles and can reduce fish eyes on a sheet formed from the obtained vinyl polymer; and a method for producing the same. The present inventionpertains to a dispersion stabilizer for suspension polymerization of a vinyl compound, the dispersion stabilizer comprising a vinyl alcohol polymer (A) that has a viscosity average polymerization degree of more than 400 and less than 1000, and a saponification degree of more than 67 mol% and less than 78 mol%, that includes 0.02-1.0 mol% of a group having an ethylenic double bond in a side chain,and that shows an absorbance (x) of more than 0.17 and less than 0.65 at 280 nm in a UV ray absorbing spectrum of a 0.1-mass% aqueous solution.

Owner:KURARAY CO LTD

PROTECTIVE FILM (As Amended)

ActiveUS20150315346A1Improve polymerization stabilityOvercome short pot lifeConductive layers on insulating-supportsLamination ancillary operationsUltimate tensile strengthPolymerization

The present invention relates to a protective film, a conductive laminate including the protective film, and a polarizing plate including the protective film, and provides the protective film which has peel strength controlled to be low, thus allowing for an easy removal of the protective film, which has an excellent polymerization stability and pot life, and may prevent a problem of an additive transfer to an adherend due to the additive.

Owner:LG CHEM LTD

Method for preparing precoating ultrafiltration membrane based on micro-emulsion modified nano-zero-valent iron and application method of precoating ultrafiltration membrane

InactiveCN106474940ANot easy to polymerizeImprove polymerization stabilitySemi-permeable membranesMembranesPolyethylene glycolTyrosine

The invention belongs to the technical field of novel water treatment materials or functional environmental materials, and particularly relates to a method for preparing precoating ultrafiltration membrane based on micro-emulsion modified nano-zero-valent iron (nano-ZVI) and an application method of the precoating ultrafiltration membrane. According to the method for preparing the preparing precoating ultrafiltration membrane, a turbid liquid of the micro-emulsion modified nano-zero-valent iron in methoxy polyethylene glycol amino (MPEG-NH2), coating 3-hydroxy-L-tyrosine (L-DOPA) on the surface of an ultrafiltration membrane, and grafting the nano-ZVI, combined with the MPEG-NH2, on the surface of the ultrafiltration membrane under a covalent combining action of amidogen in the MPEG-NH2 and the L-DOPA. The method has the advantages that the prepared precoating ultrafiltration membrane is high in anti-pollution capacity and capable of effectively removing pollutants including heavy metal like chromium, arsenic, antimony and the like and organic halides in the water.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

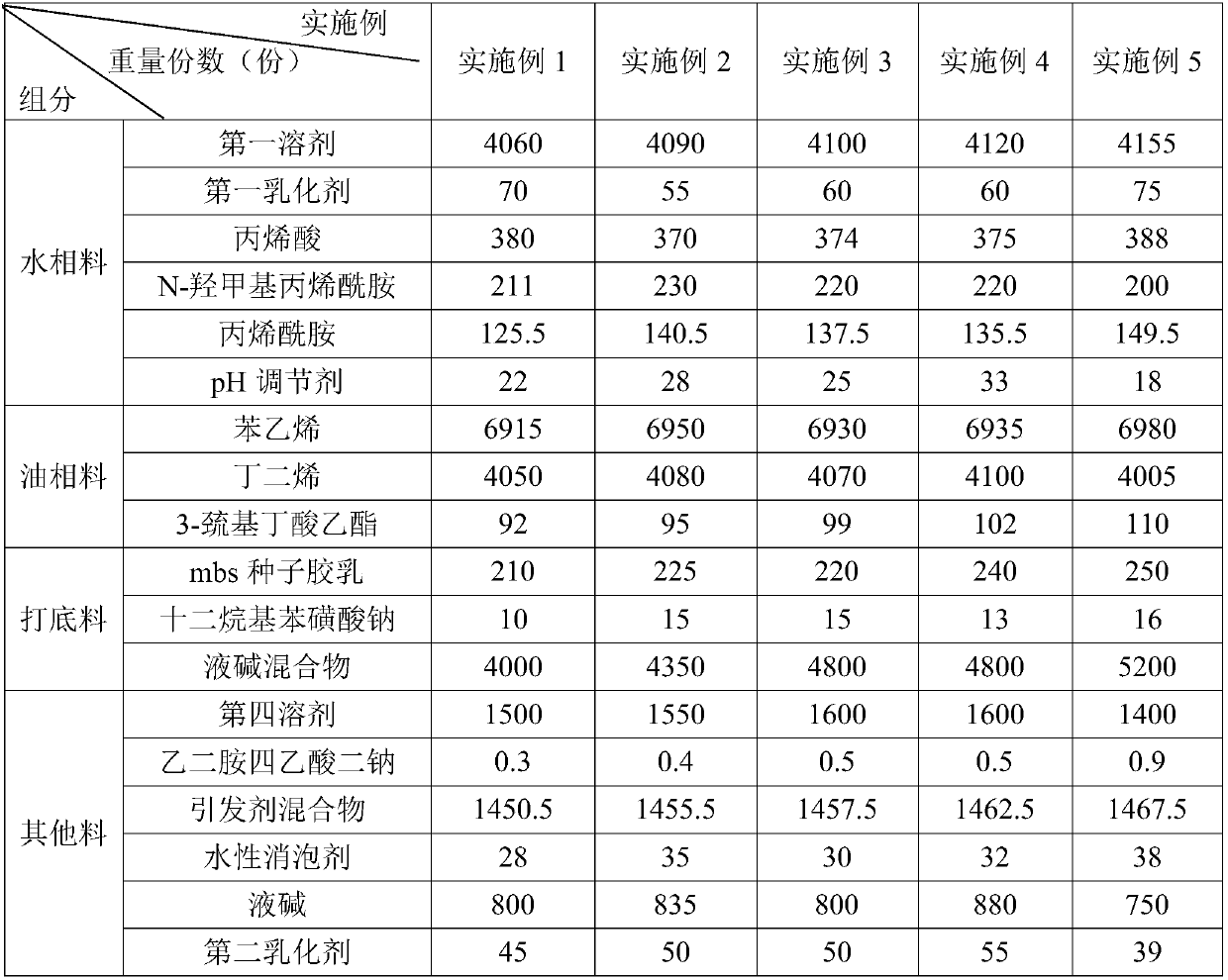

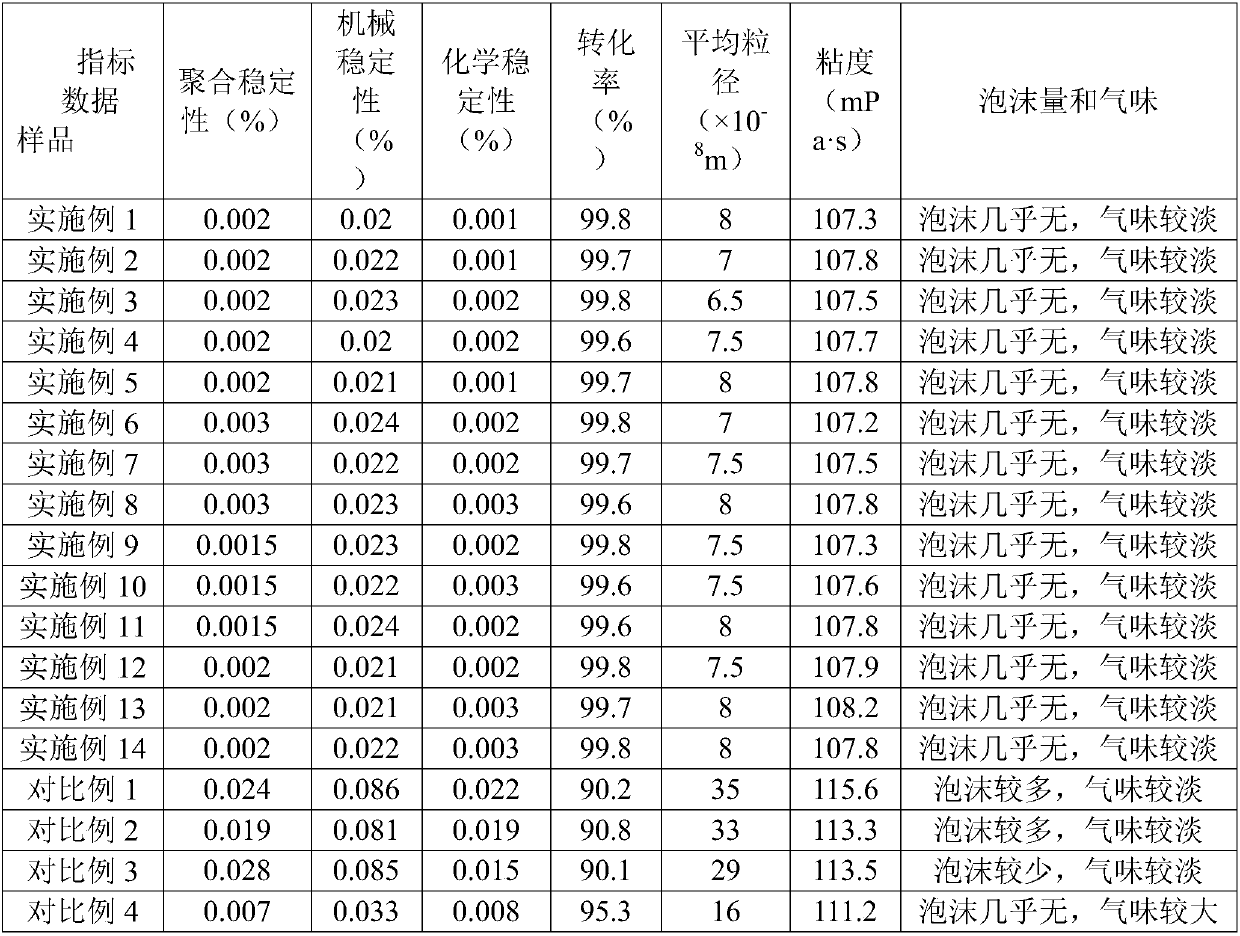

Carboxylic butadiene-styrene latex and preparation technology thereof

InactiveCN107936165AImprove polymerization stabilityImprove mechanical stabilityPolymer scienceMeth-

The invention discloses carboxylic butadiene-styrene latex and a preparation technology thereof. The carboxylic butadiene-styrene latex is prepared from water phase materials, oil phase materials, priming materials, and other materials, wherein the water phase materials comprise a first solvent, a first emulsifier, acrylic acid, N-hydroxymethyl acrylamide, acrylamide and a pH (potential of hydrogen) regulator; the oil phase materials comprise styrene, butadiene and ethyl 3-mercaptobutyrate; the priming materials comprise mbs seed latex, sodium dodecyl benzene sulfonate, and a liquid alkaline mixture; the other materials comprise a fourth solvent, ethylenediaminetetraacetic acid disodium salt, an initiator mixture, a water-based defoamer, liquid alkaline, and a second emulsifier; the firstemulsifier selects an anion emulsifier; the second emulsifier selects a non-ionic emulsifier; the first solvent and the fourth solvent are respectively soft water. The prepared carboxylic butadiene-styrene latex has the advantages that the conversion rate is high, and the polymerizing stability, mechanical stability and chemical stability are good.

Owner:杭州龙驹合成材料有限公司

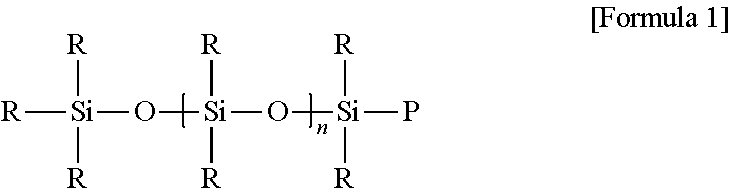

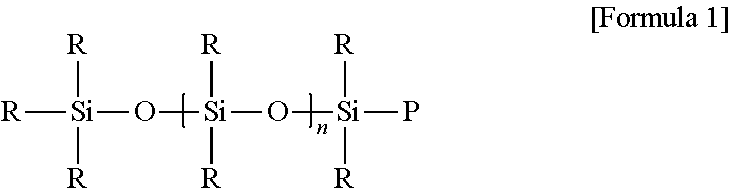

Organosilicone modified copolymer emulsion tipping adhesive and preparation method thereof

InactiveCN109054691AImprove water resistanceHigh bonding strengthMonocarboxylic acid ester polymer adhesivesEmulsionSilanes

The invention provides an organosilicone modified copolymer emulsion tipping adhesive which is prepared from the following materials in parts by weight: 15 to 22 parts of vinyl acetate, 3 to 10 partsof polyvinyl alcohol, 10 to 25 parts of butyl acrylate, 3 to 12 parts of 2-ethylhexyl acrylate, 2 to 4 parts of acrylic acid, 3 to 12 parts of gamma-methylacryloyl oxypropyl trimethoxy silane, 2 to 5parts of vinyl triethoxysilane, 2 to 6 parts of vinyl trimethoxy silane, 4 to 11 parts of deionized water, 1 to 3 parts of a compound emulsifier and 3 to 10 parts of other additives. According to theorganosilicone modified copolymer emulsion tipping adhesive disclosed by the invention and a preparation method thereof, the viscosity and the storage stability are improved, and the rejection rate oftipped cigarettes is reduced.

Owner:CHUZHOU GUANGWEI CHEM

Acrylate emulsion for plastic base materials and method for preparing acrylate emulsion

InactiveCN108570123AIncrease the degree of cross-linkingHigh hardnessCoatingsOrganic acidFunctional monomer

The invention discloses acrylate emulsion for plastic base materials. The acrylate emulsion comprises, by weight, 40-60 parts of deionized water, 10-20 parts of butyl acrylate, 25-35 parts of methyl methacrylate, 5-10 parts of styrene, 2-5 parts of hydrophilic unsaturated organic acid, 1-3 parts of functional monomers, 1-3 parts of surfactants, 0.1-1 part of initiators and 1-3 parts of pH (potential of hydrogen) regulators. The invention further provides a method for preparing the acrylate emulsion. The acrylate emulsion and the method have the advantage that the acrylate emulsion prepared bythe aid of the method is excellent in adhesion, solvent resistance, chemical resistance, water resistance, gloss fullness and paint preparation tolerance.

Owner:佛山市顺德区巴德富实业有限公司

Water purification method of ultrafiltration membrane based on microemulsion-modified nano-zero-valent iron-carbon material precoated layer

ActiveCN106492644AImprove utilization efficiencyNot easy to polymerizeSemi-permeable membranesWater contaminantsPurification methodsNitrobenzene

The invention belongs to the technical field of water treatment novel materials or environmental functional materials and particularly relates to a preparation method and application method of an ultrafiltration membrane based on a microemulsion-modified nano-zero-valent iron-carbon material precoated layer. The preparation method comprises the following steps: firstly preparing microemulsion-modified nano-zero-valent iron, then preparing turbid liquid of the microemulsion-modified nano-zero-valent iron and carbon material in amino polyethylene glycol monomethyl ether (MPEG-NH2), and coating the surface of the ultrafiltration membrane with 3-hydroxyl-L tyrosine (L-DOPA); and grafting nano-ZVI and carbon material bonded with MPEG-NH2 to the surface of the ultrafiltration membrane by virtue of a covalent binding action between amino in the MPEG-NH2 and L-DOPA. The material prepared by virtue of the preparation method has very strong anti-pollution capacity and is capable of effectively removing heavy metals, such as chromium, arsenic and antimony, and organic pollutants, such as nitrobenzene and organic halide, in water.

Owner:恩科水环科技(北京)有限公司

Fluorine-silicon modified styrene-acrylic emulsion with comb-shaped structure and preparation method of fluorine-silicon modified styrene-acrylic emulsion

The invention discloses a comb-shaped fluorine-silicon modified styrene-acrylic emulsion and a preparation method thereof. The method comprises the following steps: 1) dissolving an emulsifier and a reactive emulsifier in water to prepare an aqueous emulsifier solution A; 2) preparing a uniform solution B from a monomer mixture of styrene, acrylate, fluorine-containing acrylate, vinyl organosiloxane and hydroxyl silicone oil as well as a water repellent; 3) dispersing the solution B into the aqueous emulsifier solution A under stirring to obtain a pre-emulsion C; 4) performing fine emulsification on the pre-emulsion C to obtain a miniemulsion D; and 5) adding a water-soluble initiator into the miniemulsion D, and conducting initiating to obtain the fluorine-silicon modified styrene-acrylic emulsion. According to the invention, a miniemulsion polymerization method is adopted, polymerization is carried out in liquid drops, and the prepared product can be used as a functional coating material on the surfaces of paper, fabrics, leather and the like, has good stability, and also has excellent film-forming property, air permeability, brightness, water and oil resistance, heat resistance and chemical reagent resistance.

Owner:濮阳蓝星新材料有限公司

Hydrosol polyacrylate leather filling resin and preparation method thereof

ActiveCN103694402AReduce loose flourEasy to recycleLeather impregnationPolymer scienceAcrylate ester

Owner:SICHUAN DOWELL SCI & TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com