Dispersion stabilizer for suspension polymerization

A technology of dispersion stabilizer and suspension polymerization, used in transportation and packaging, dissolution, chemical instruments and methods, etc., can solve the problems of low solubility and insufficient handling, and achieve uniform particle size, plasticizer absorption and desorption. Excellent monomer properties and high polymerization stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Hereinafter, the present invention will be described in further detail using examples. In the following examples and comparative examples, unless otherwise specified, "parts" and "%" represent parts by mass and % by mass, respectively.

[0076] The POA-modified PVA (A) obtained by the following production example was evaluated by the following method.

[0077] [Viscosity-average degree of polymerization and degree of saponification of PVA]

[0078] The viscosity average polymerization degree and saponification degree of PVA were calculated|required by the method described in JISK6726.

[0079] [POA-based modification rate of PVA]

[0080] The POA group modification rate of PVA was calculated|required by the method using the above-mentioned proton NMR. In addition, JEOL GX-500 of 500 MHz was used for proton NMR.

manufacture example 1

[0081] [Manufacturing example 1: Manufacture of PVA (A1)]

[0082] In the 3L reactor that has agitator, reflux condenser, nitrogen introduction pipe, comonomer drop-in port and the addition port of initiator, the structure shown in 690g vinyl acetate, 2310g methyl alcohol, 7.1g table 2 is charged Nitrogen substitution was performed in the system for 30 minutes while nitrogen gas bubbling was performed for the monomer (monomer A) containing a POA group for block copolymerization. Also, as a delay solution, a comonomer solution having a concentration of 20% by dissolving a POA group-containing monomer (monomer A) in methanol was prepared, and nitrogen replacement was performed by bubbling nitrogen gas. The temperature of the reactor was started to rise, and when the internal temperature reached 60°C, 1.6 g of 2,2'-azobisisobutyronitrile (AIBN) was added to start polymerization. Polymerization was carried out at 60° C. for 6 hours while the delay solution was added dropwise so t...

manufacture example 2~16

[0083] [Manufacturing Examples 2-16: Manufacture of PVA (A2-16)]

[0084] Change the loading amount of vinyl acetate and methanol, the type and amount of unsaturated monomer with POA group used in polymerization, the polymerization rate and other polymerization conditions, the concentration of POA-modified PVAc in saponification, sodium hydroxide Except for the saponification conditions such as the molar ratio of vinyl acetate units, POA-modified PVA (A2-16) was produced in the same manner as in Example 1. The production conditions are shown in Table 1, and the structure of the unsaturated monomer having a POA group used is shown in Table 2.

[0085]

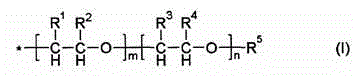

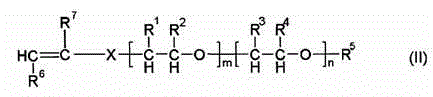

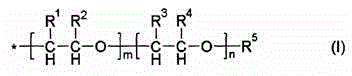

[0086] [Table 2]

[0087]

[0088] 1) * indicates the basal side of POA

[0089] 2) m and n are block-like respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com