Patents

Literature

51results about How to "Not easy to polymerize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling low-melting-point inclusion in high-strength low-alloy steel

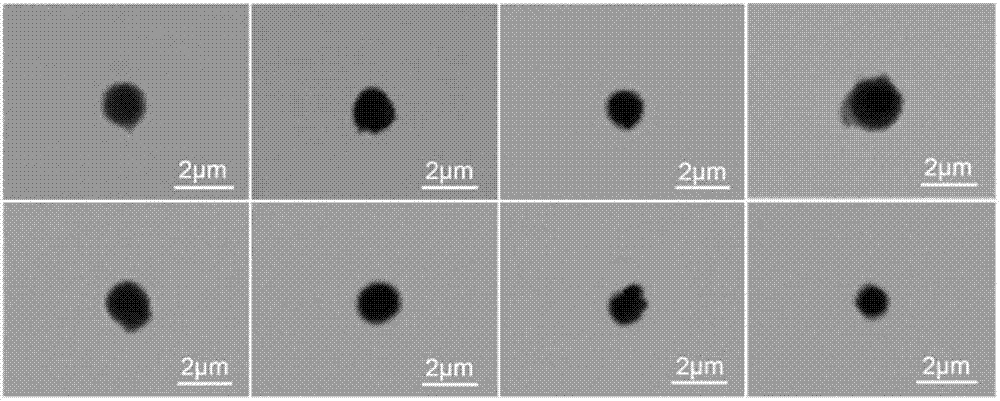

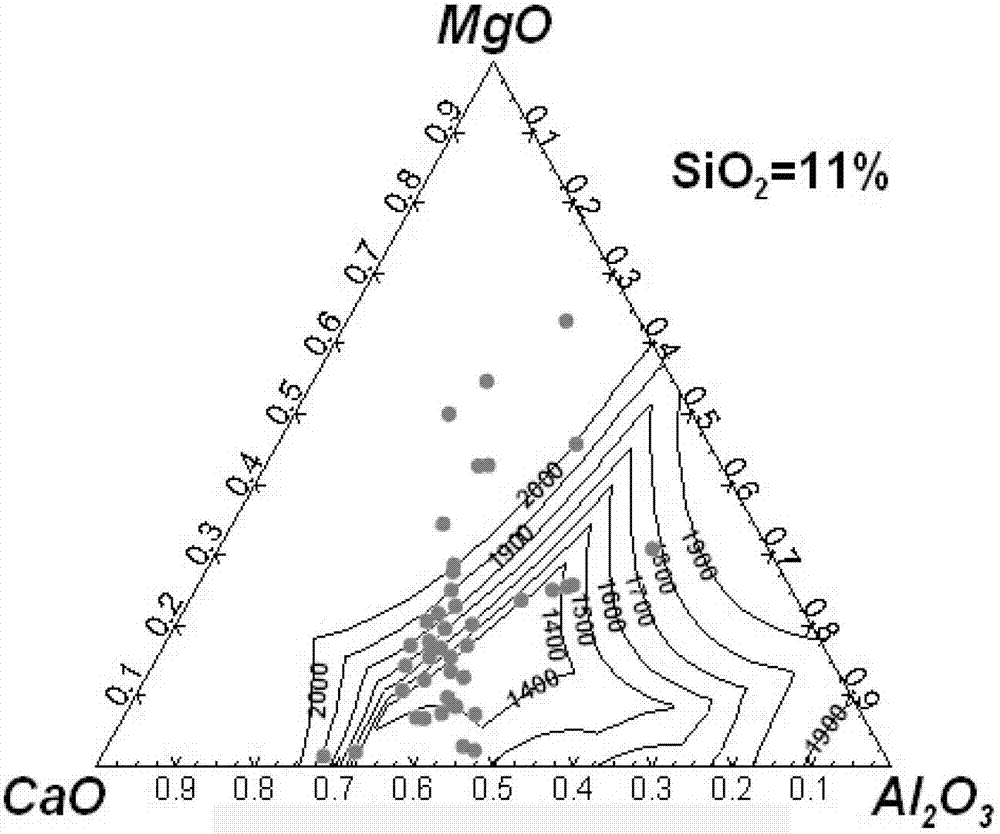

InactiveCN103045806ANot easy to polymerizeReduce distortionProcess efficiency improvementNon-metallic inclusionsMaterials science

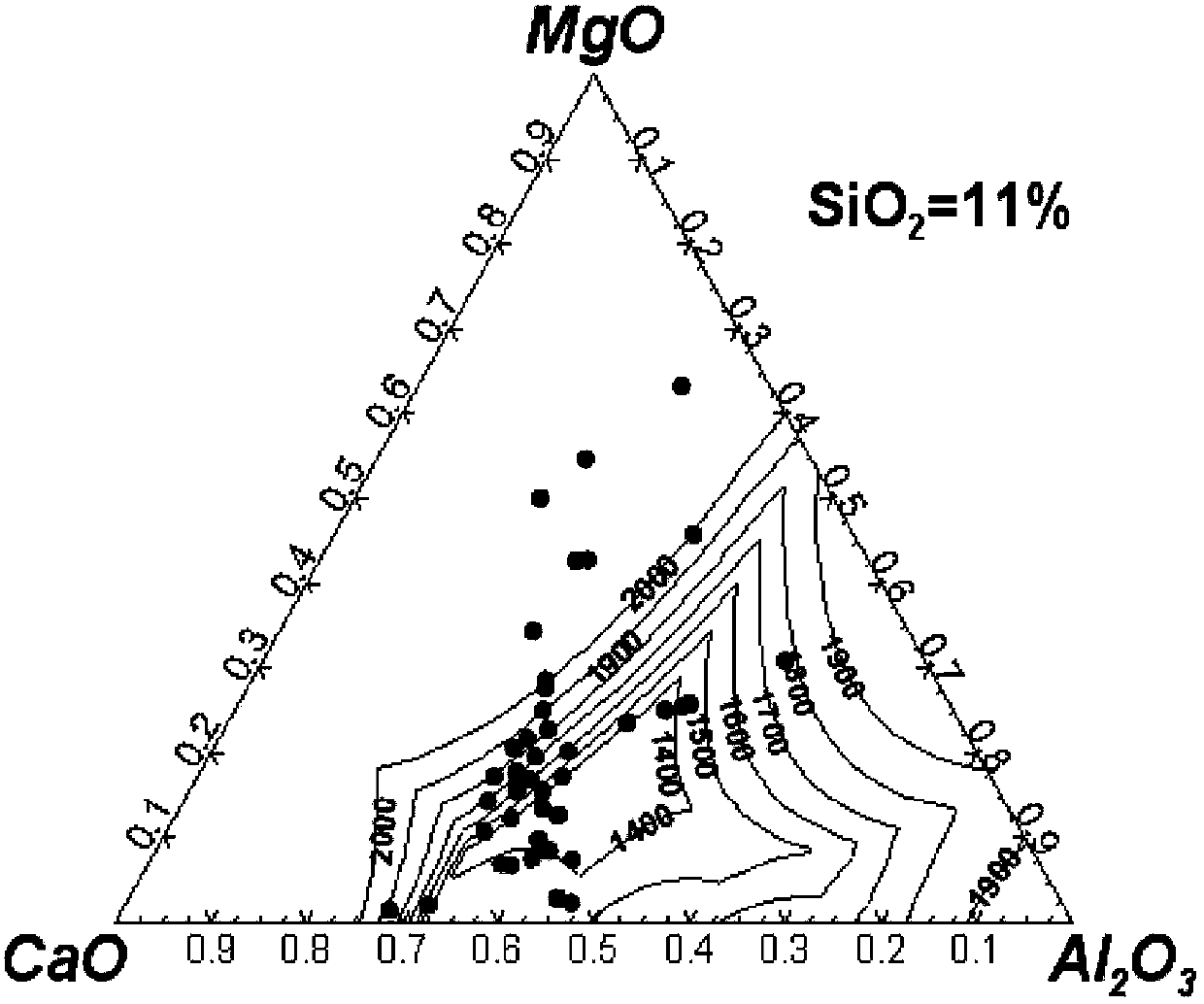

The invention provides a method for controlling a low-melting-point inclusion in high-strength low-alloy steel, which comprises the following steps: 1, tapping into a ladle, and adding additives into molten steel in the ladle after the start of tapping, wherein the additives include an iron alloy, aluminum deoxidizer, slow release deoxidizer and lime; 2, performing LF (ladle furnace) refinement in the ladle, wherein the basicity range of slag in the refinement process is 3-6; the refining slag subjected to LF slagging comprises the following components in percentage by mass: 50-65% of CaO, 6-12% of MgO, 13-26% of Al2O3, 9-19% of SiO2 and less than 0.5% of (FeO+MnO); 3, after slagging, blowing Ar gas from the bottom of the ladle, and desulfurizing while strongly stirring; and 4, in the strongly stirring process and the subsequent process, reacting the slag, the molten steel and an inclusion. The invention has the following advantages: favorable deoxidization and desulfurization effect is achieved, and simultaneously, the composition of the non-metallic inclusion in the steel is controlled to be in a high-melting-point region of a CaO-MgO-Al2O3(-SiO2) phase diagram, so that the inclusion is less prone to polymerization, and less deformation is caused in the subsequent rolling process, thereby achieving the purpose of controlling the large strip-shaped inclusion in a high-strength low-alloy steel plate.

Owner:UNIV OF SCI & TECH BEIJING

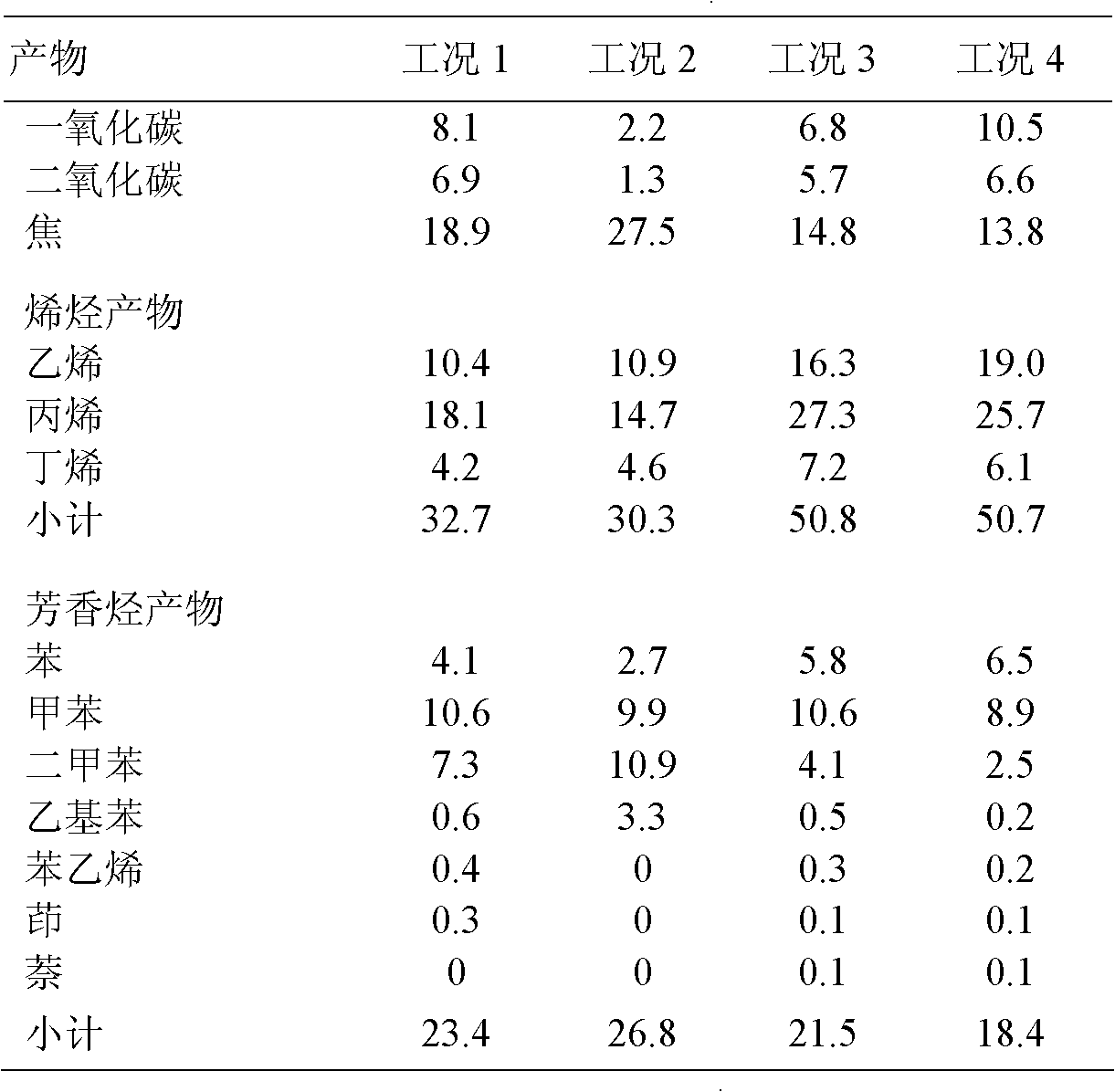

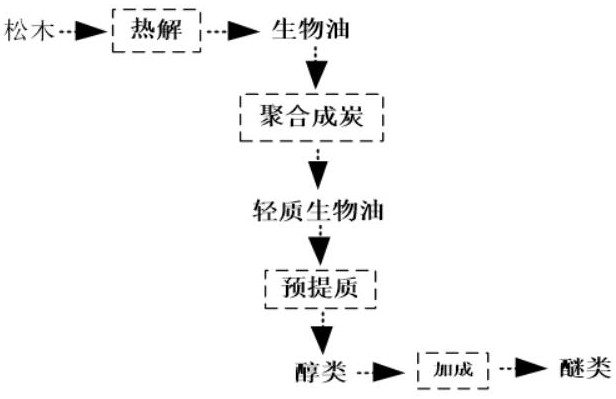

Two-step method for preparing olefin and aromatic hydrocarbon by catalyzing and upgrading bio-oil

InactiveCN102070386ANot easy to polymerizeHigh carbon yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrogenNitrogen

The invention discloses a two-step method for preparing olefin and aromatic hydrocarbon by catalyzing and upgrading bio-oil. Aqueous-phase bio-oil serves as a raw material, and the method comprises the following steps of: performing selective hydrogenation the aqueous-phase bio-oil, converting into stable compounds, and performing zeolite catalytic conversion on the stable compounds to obtain hydrocarbon compounds, wherein the selective hydrogenation is performed in a pressurized reactor, and the reaction conditions are that: the reaction atmosphere is hydrogen, a Ru / C and a Pt / C are catalysts, the temperature is between 100 and 300 DEG C, the mass space velocity is 1 to 5h<-1>, and the pressure is 5 to 15 MPa; the zeolite catalysis is performed in a normal pressure reactor, and the reaction conditions are that: the reaction atmosphere is hydrogen or nitrogen, the catalyst is HZSM-5, the temperature is between 350 and 650 DEG C, and the mass space velocity is 5 to 50h<-1>. The obtained olefin and aromatic hydrocarbon have the carbon yield of 30.3 to 50.8 percent and 18.4 to 26.8 percent respectively, and the catalysts for hydrogenation and zeolite catalysis have high stability.

Owner:SOUTHEAST UNIV

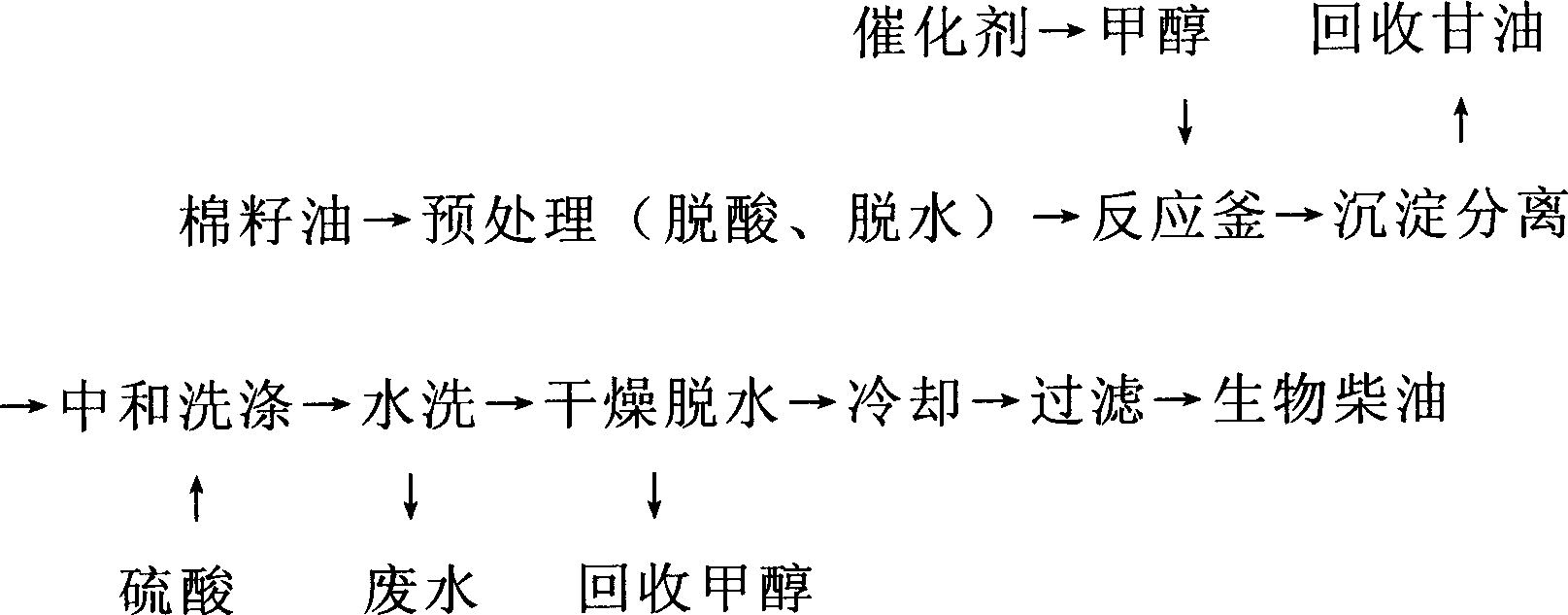

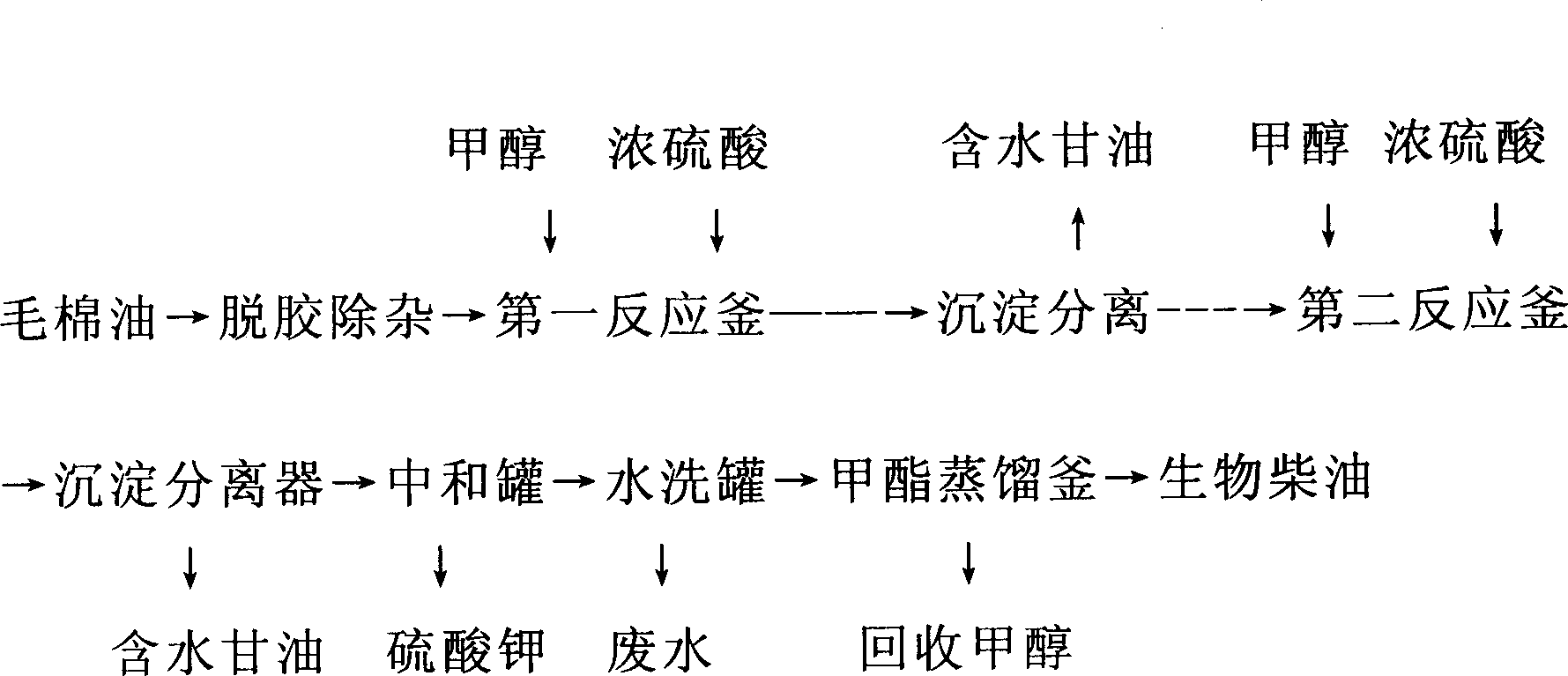

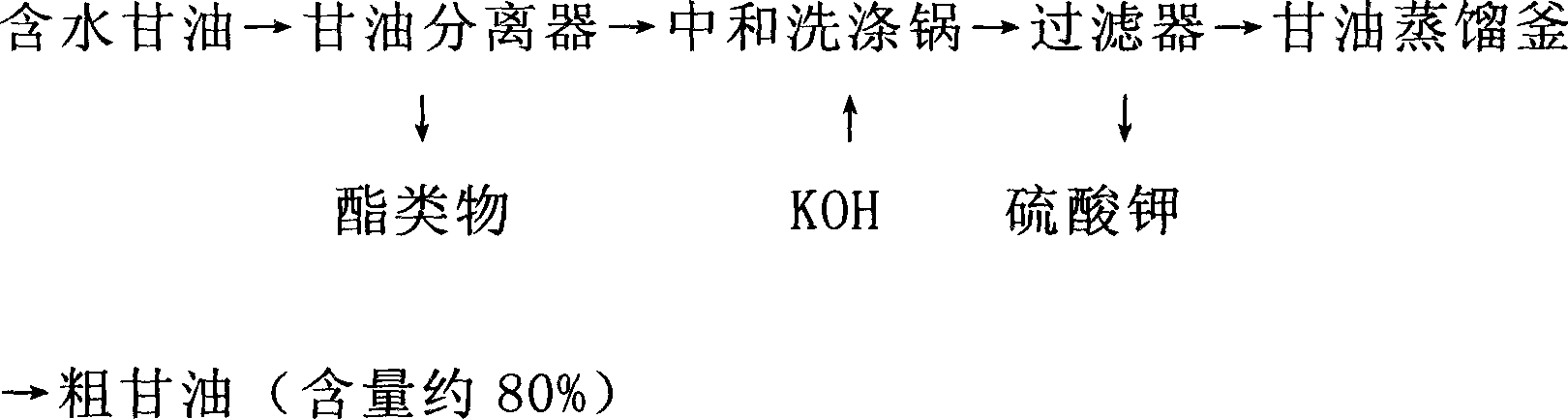

Method for preparing biological diesel oil using high acid value cottonseed oil

InactiveCN1865401AAvoid processing risksReduce pollutionBiofuelsLiquid hydrocarbon mixture productionChemical reactionBiodiesel

The invention discloses a biological diesel preparing method from high-acid value cotton seed oil, which comprises the following steps: the first step: adopting concentrated sulfuric acid as catalyst under normal pressure and temperature; injecting certain quantity of carbinol; reacting most of glyceride and a little of aliphatic acid with carbinol; sedimenting and separating glycerin and water; the second step: adopting concentrated sulfuric acid as catalyst under normal pressure and temperature; injecting excessive carbinol; lengthening reacting time to react glyceride and aliphatic acid with carbinol. The invention can utilize cotton oil reasonably, which reduces the environmental pollution in the refinery course.

Owner:菏泽华瑞油脂有限责任公司

Aromatic hydrocarbon liquid phase alkylation method

ActiveCN103539600AImprove stabilityReduce olefin contentHydrocarbonsBulk chemical productionAlkaneAlkylation unit

The invention relates to an aromatic hydrocarbon liquid phase alkylation method, for mainly solving the problem that a catalyst is easily inactivated and poor in stability in the prior art. According to the technical scheme, a mixture containing saturated alkane, aromatic hydrocarbon and olefin is taken as a raw material, silicon-aluminum crystal zeolite is taken as a catalyst, and the raw material comes into contact with the catalyst to react to generate an alkylation liquid containing alkylbenzene and polyalkylbenzene under the conditions that the reaction temperature is 100-210 DEG C, the reaction pressure is 1.5-5.0MPa, the mole ratio of aromatic hydrocarbon to olefin is 1:10 and the weight space velocity of olefin is 0.1-1.0 hour<-1>, wherein the saturated alkane is at least one of ethane, propane, n-butane, iso-butane, pentane, cyclopentane, methylcyclopentane, hexane or cyclohexane, and the content of the saturated alkane is 1-80% of the weight of the reaction mixture. Due to adoption of the technical scheme, the problem in the prior art is well solved. The aromatic hydrocarbon liquid phase alkylation method can be applied to industrial production of aromatic hydrocarbon liquid phase alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

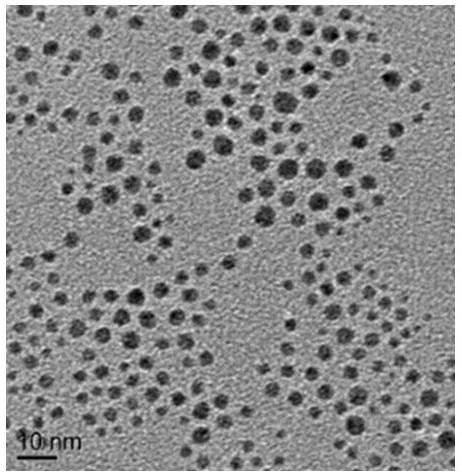

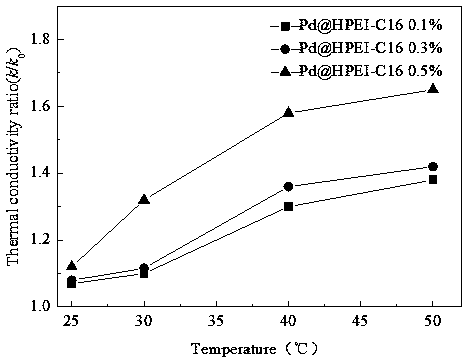

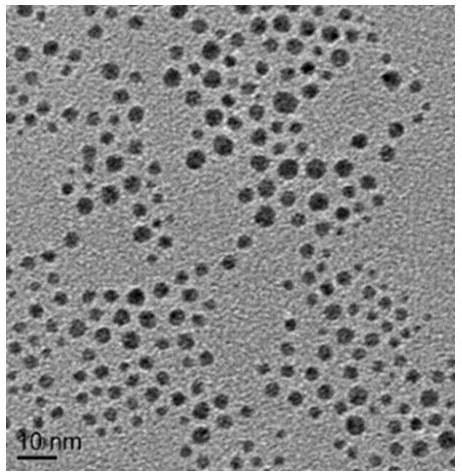

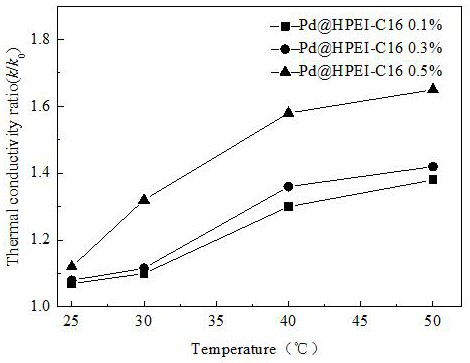

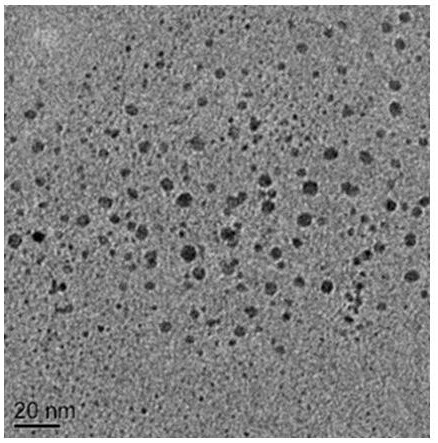

Preparation method of lipophilic hyperbranched molecule modified nanofluid

ActiveCN111087979AEvenly dispersedInhibition of agglomerationHeat-exchange elementsPolymer scienceLiquid medium

The invention discloses a preparation method of lipophilic hyperbranched molecule modified nanofluid, wherein the nanofluid is composed of a liquid medium and nanoparticles dispersed in the liquid medium. The preparation method comprises the main steps of preparation and dispersion of the nanoparticles. The surface of the nano material is modified by lipophilic hyperbranched molecules. Compared with the prior art, the preparation method has the advantages that the nano particles are dispersed stably without agglomeration, the nano particles are loaded by utilizing the specific dendritic macromolecular structure of the hyperbranched polyethyleneimine grafted by long-chain alkyl acyl chloride, the number-average molecular weight of hyperbranched molecules is distributed between 1000 and 36000. The prepared nano particles are relatively small in particle size, not easy to agglomerate and good in stability. By the addition amount of 0.01%-5%, the nano fluid with good stability and excellent heat-conducting property can be obtained; and the preparation process is controllable, good in repeatability and easy to popularize.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

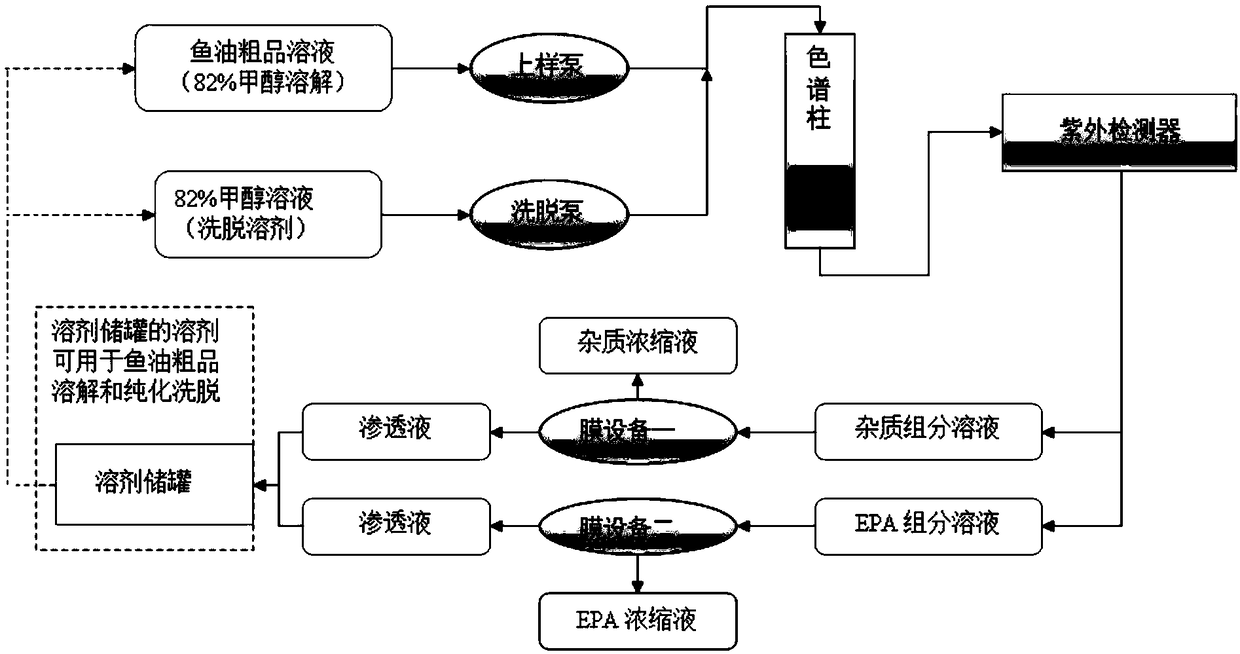

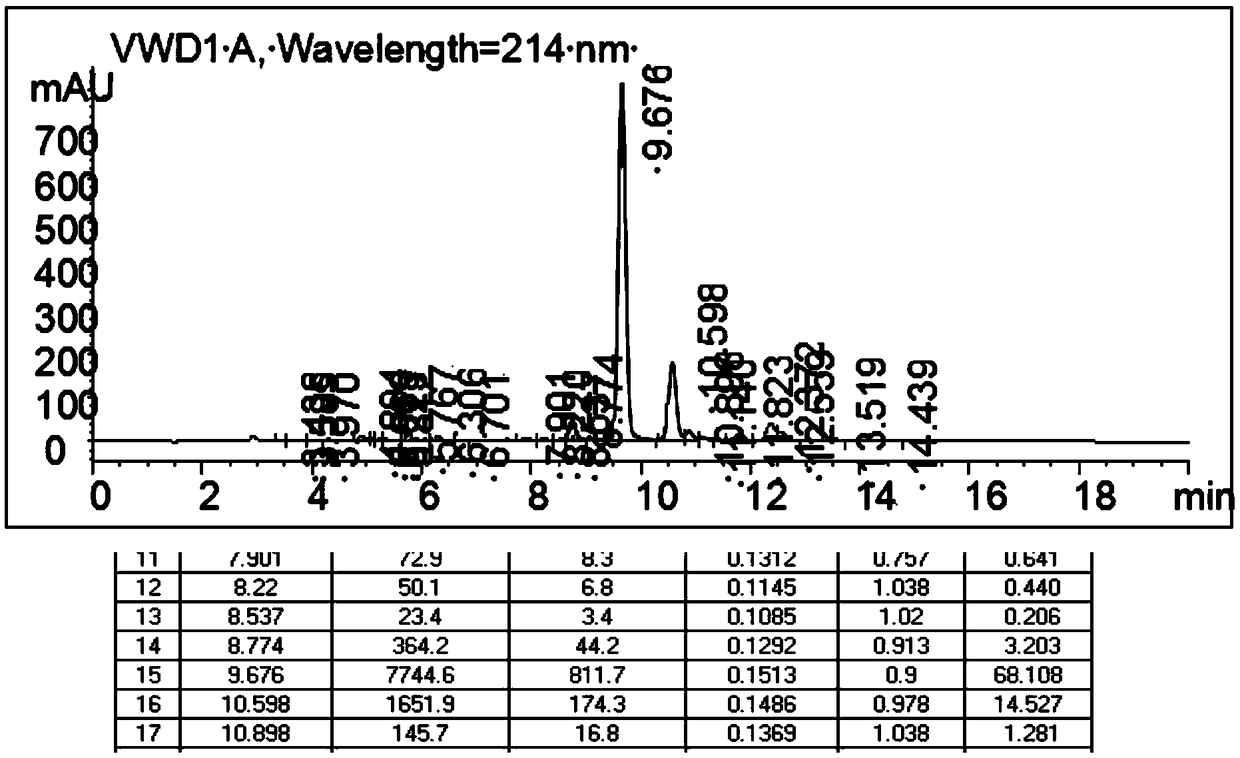

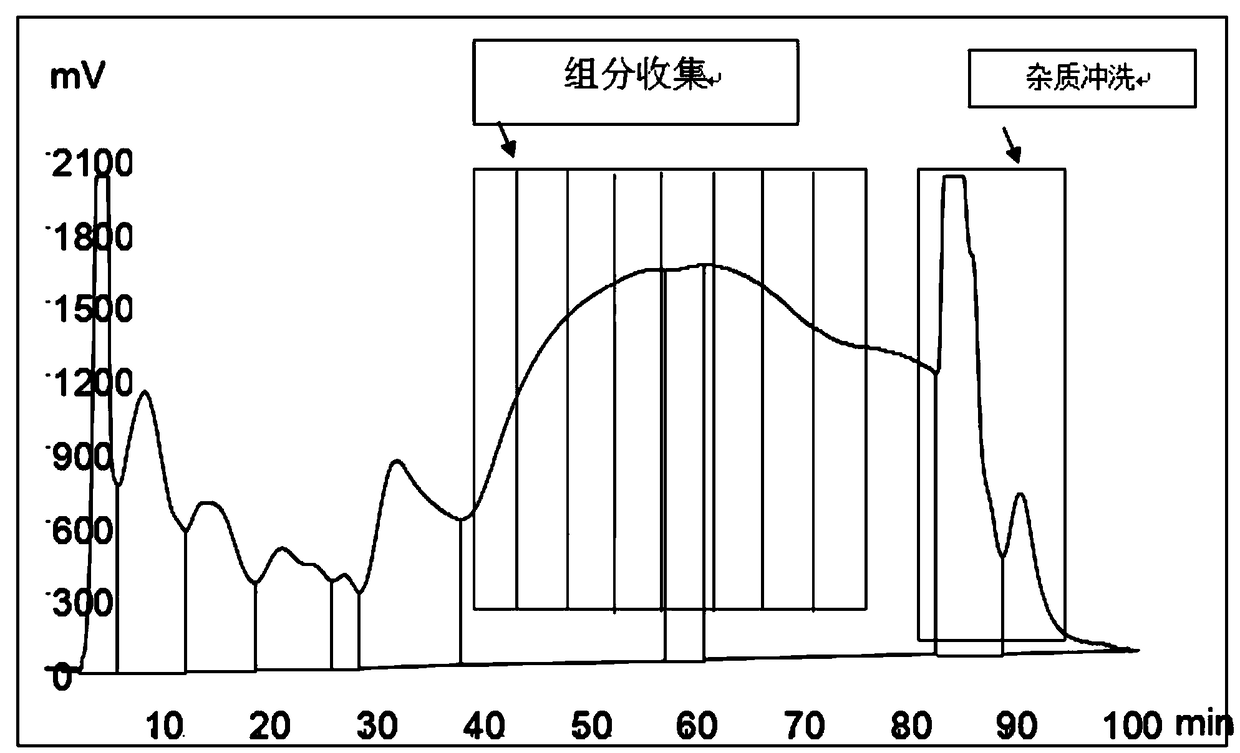

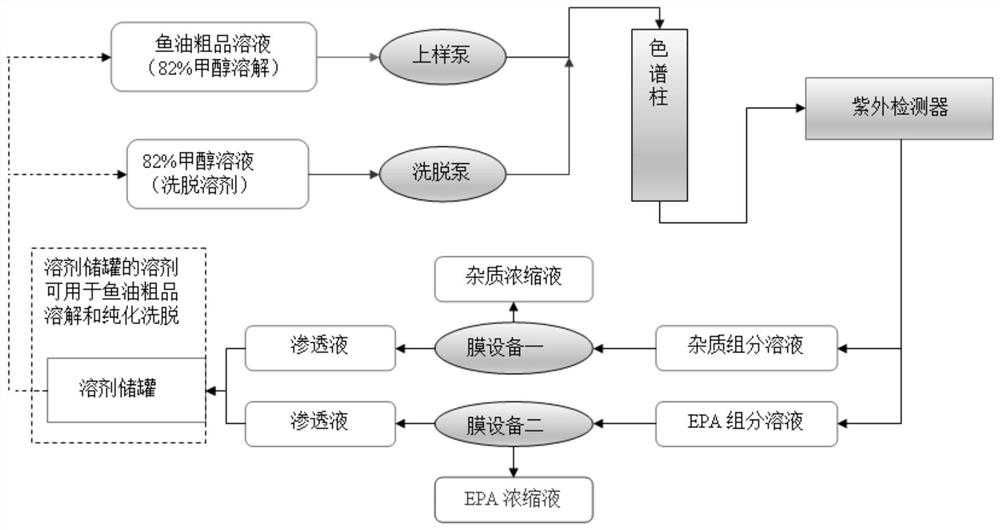

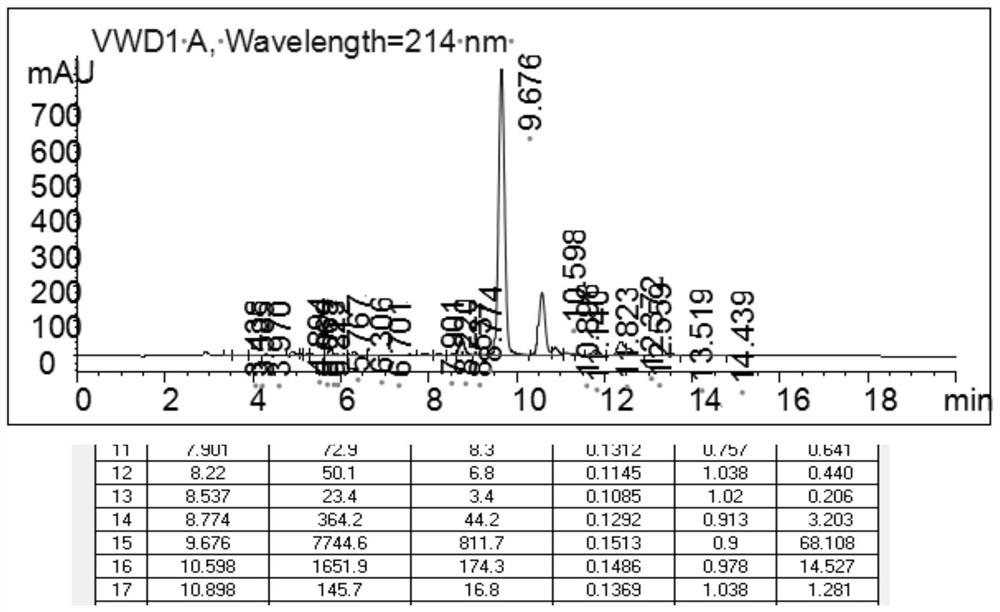

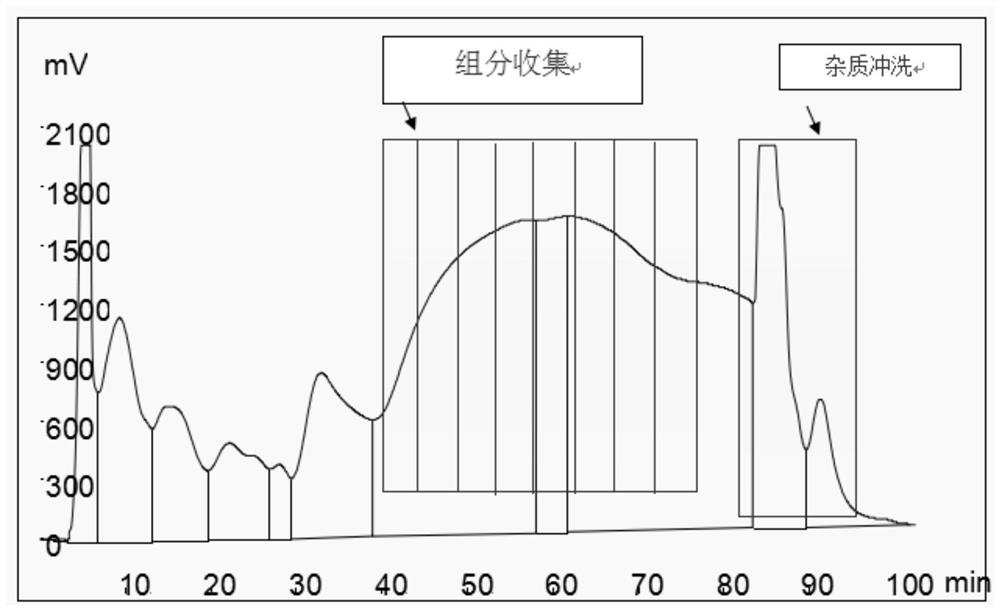

Method for purifying EPA (eicosapentaenoic acid) from fish oil

ActiveCN109438220AGuaranteed feasibilityHigh recovery rateCarboxylic compound separation/purificationOrganic solventEicosapentaenoic acid

The invention relates to the field of analysis, in particular to a method for purifying EPA (eicosapentaenoic acid) from fish oil. The method has high selectivity and separation efficiency, EPA, DHA and other impurities can be effectively separated, unsaturated fatty acid and impurities in the fish oil are selectively adsorbed, sample loads are high, a moving phase of an organic solvent or organicsolvent / water system is used, the solvent can be recycled, and industrialization cost is reduced.

Owner:SEPAX TECH

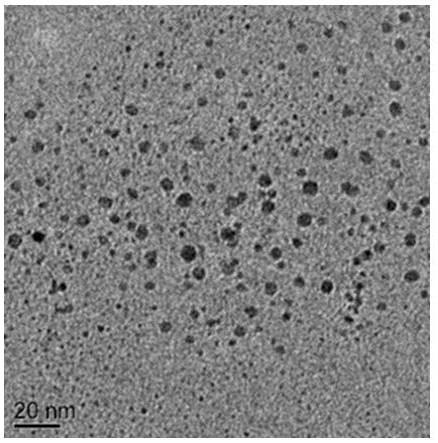

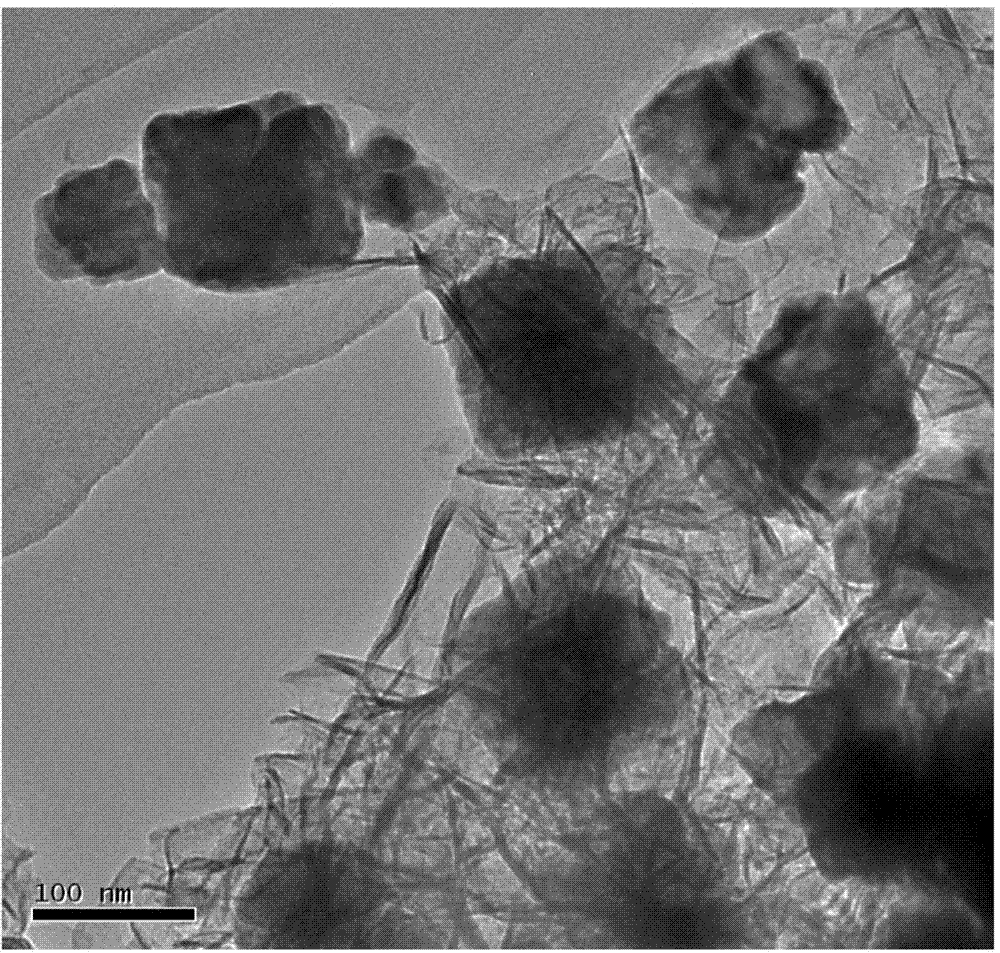

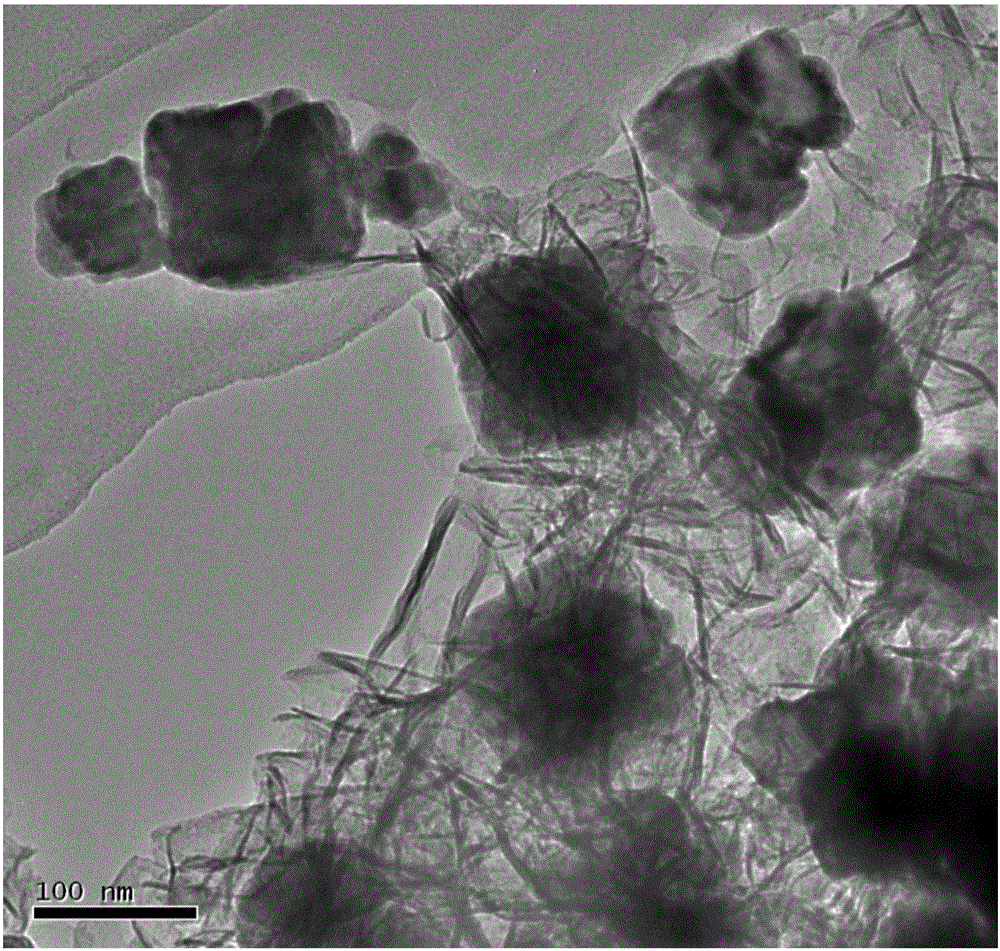

Ni/Fe double-metal face-centered cubic crystal nano-particles and preparing method and application thereof

InactiveCN103894619AHigh dechlorination efficiencyEasy to operateWater contaminantsWater/sewage treatment by reductionPolychlorinated biphenylControllability

The invention discloses Ni / Fe double-metal face-centered cubic crystal nano-particles and a preparing method and application thereof. The liquid phase reduction method is adopted, PVP is used as a stabilizer, NaBH4 is used as a reducing agent, ferrous ions and nickle ions are added step by step for reduction, prepared Ni / Fe double-metal nano-particles are of a regular face-centered cubic structure, particle size distribution is even, particle size is large than the surface area, stability is good, and the polymerism can not easily happen. The prepared nano-particles can effectively catalyze and degrade polychlorinated biphenyl. Needed reaction equipment of the nano-particles is simple, equipment cost is low, the preparation process is high in controllability and simple in operation, the reaction condition is mild, and further industrial production is possible.

Owner:TIANJIN UNIV

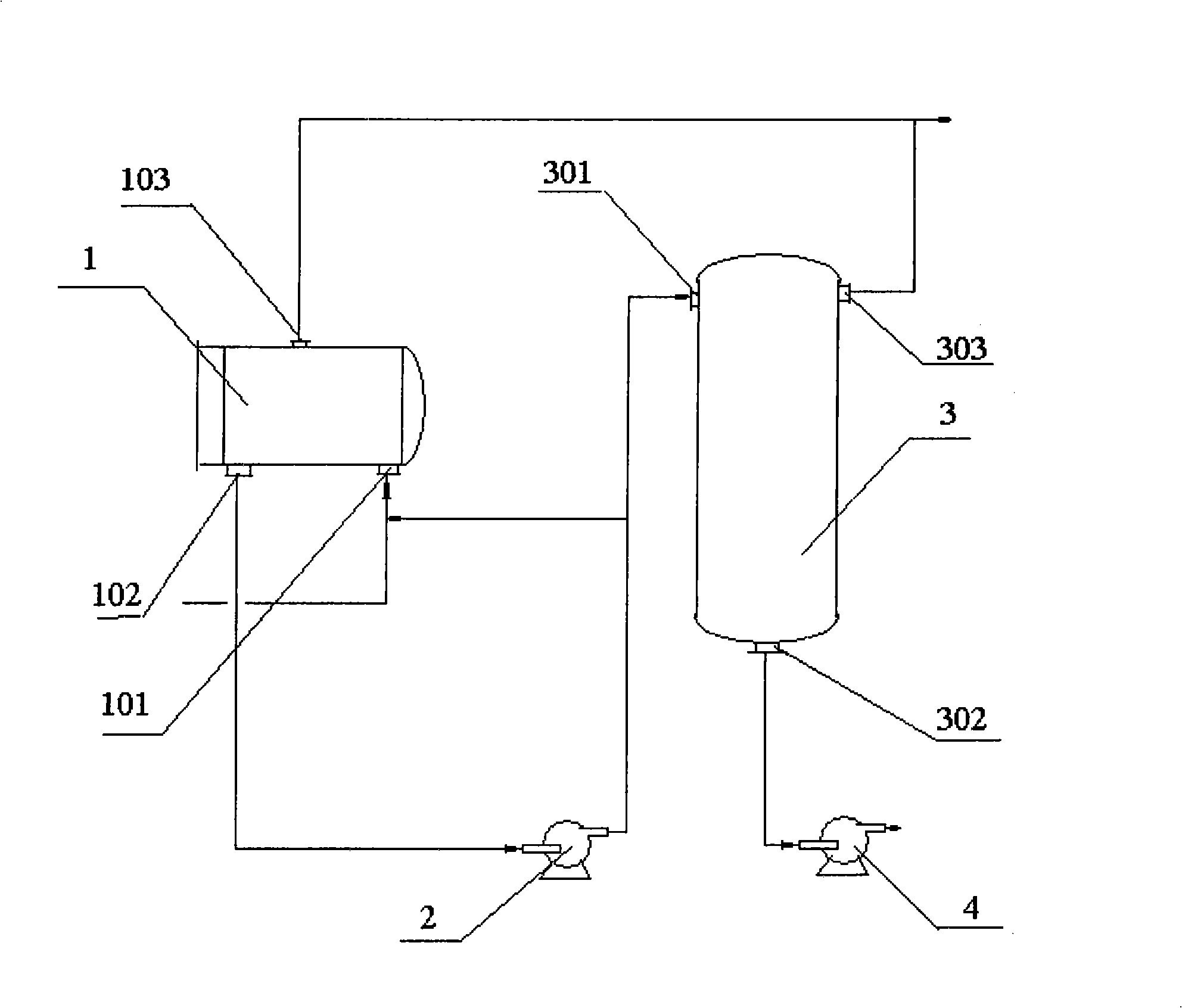

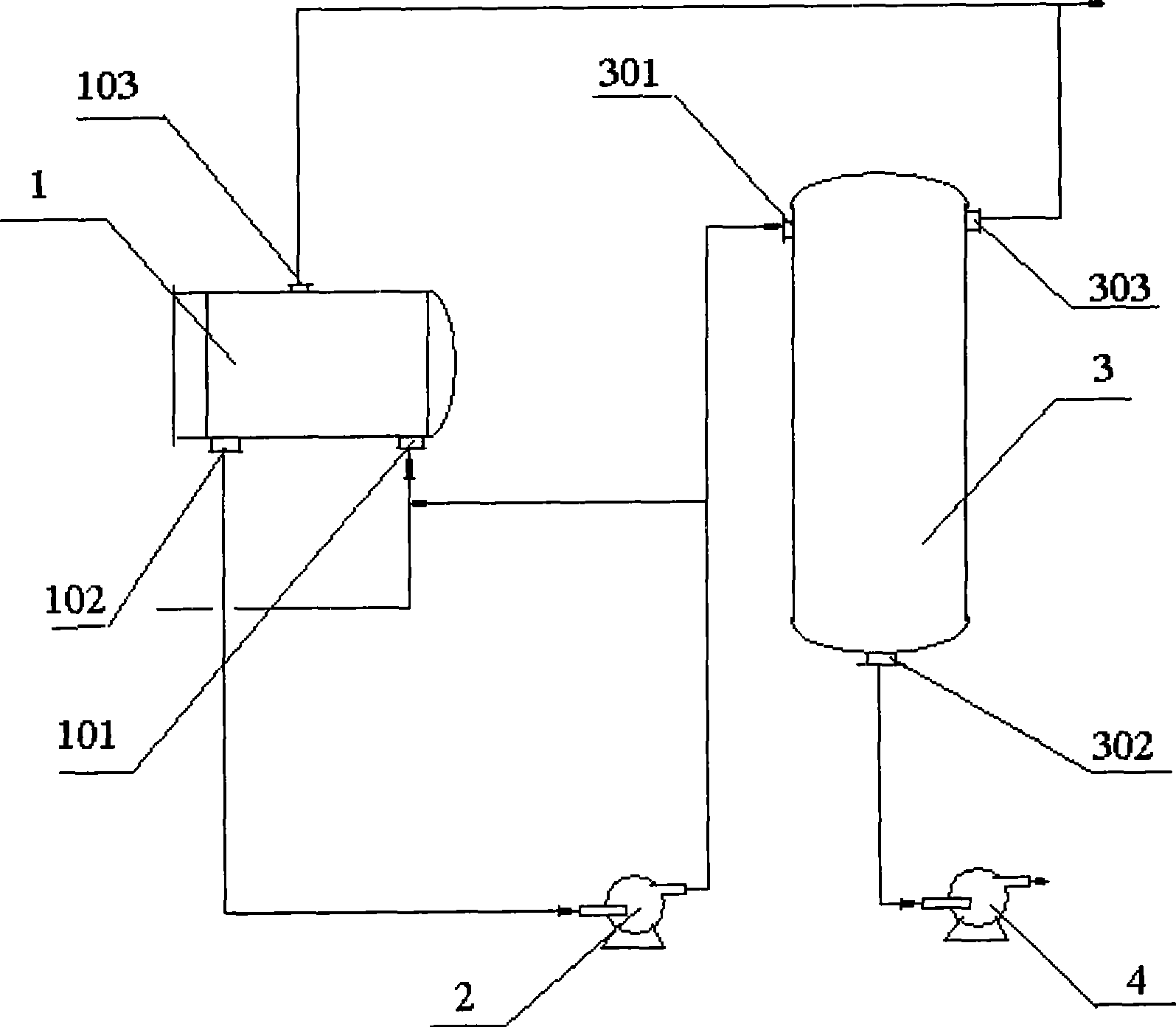

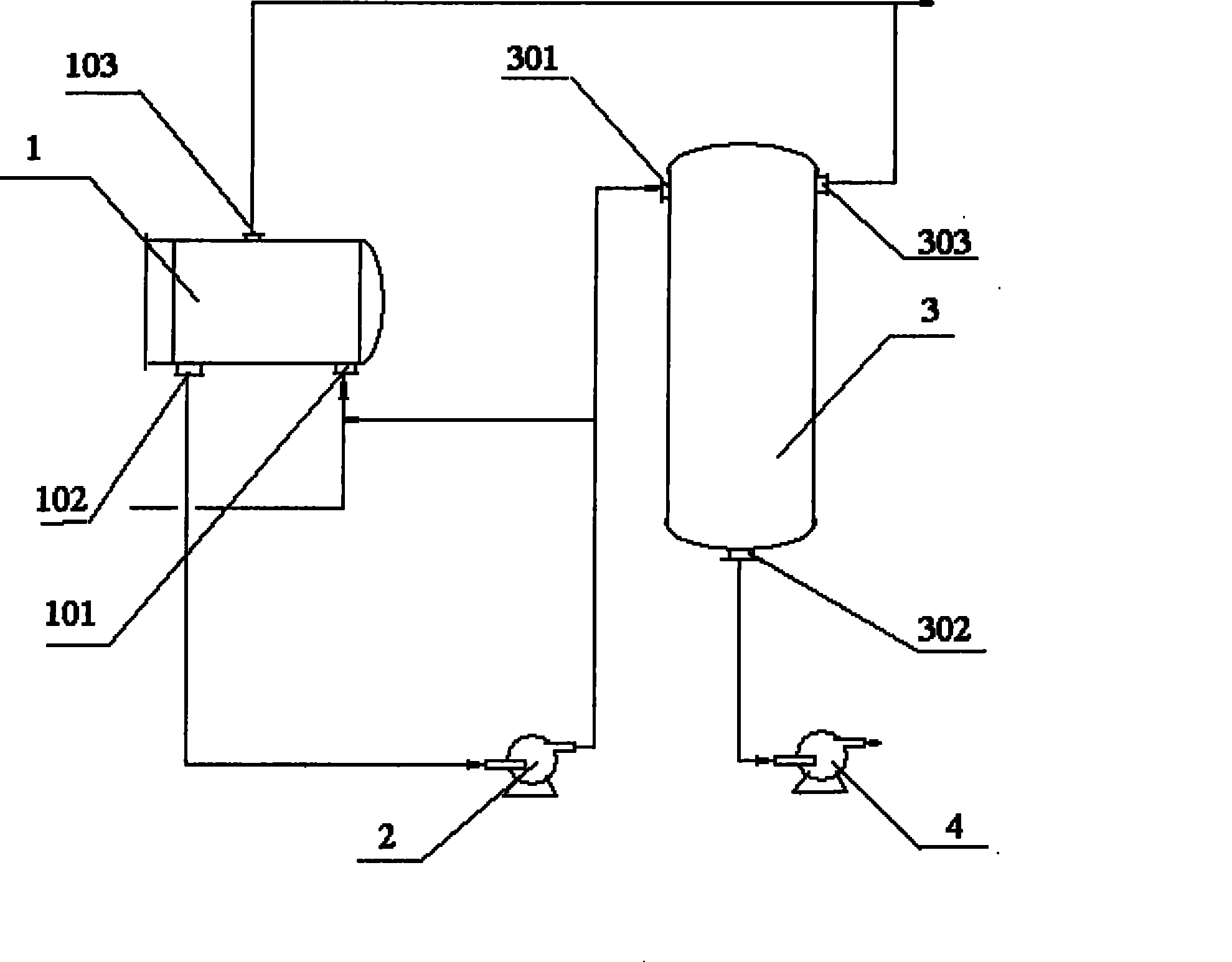

Evaporation method and device easy for polymerizing hydrocarbon solution

ActiveCN101337131AGuaranteed uptimeEasy to updateDistillation purification/separationEvaporationPolymer scienceCirculator pump

The present invention provides an evaporation method and apparatus for an easily polymerizing hydrocarbon solution, said evaporation method includes processes that: the easily polymerizing hydrocarbon solution is fed into a main evaporator(1),the evaporated hydrocarbon gas is discharged from the top of the main evaporator(1), the evaporated liquid components are drawn out via a cycle pump(2) from the bottom of the main evaporator(1), part of them being circularly fed into the main evaporator(1) and part of them being fed into a film evaporator(3). The evaporated hydrocarbon gas is then discharged from the top of the film evaporator(3) and the remnant liquid after evaporation is forced to be discharged from the film evaporator(3). The forced circulation evaporator and the film evaporator in this invention combines to realize the evaporation process, the polymeric monomer in the easily polymerizing hydrocarbon solution is not subject to polymerization, thereby improving the evaporation efficiency, maintaining the steady operation, lowering the consume of source and energy.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

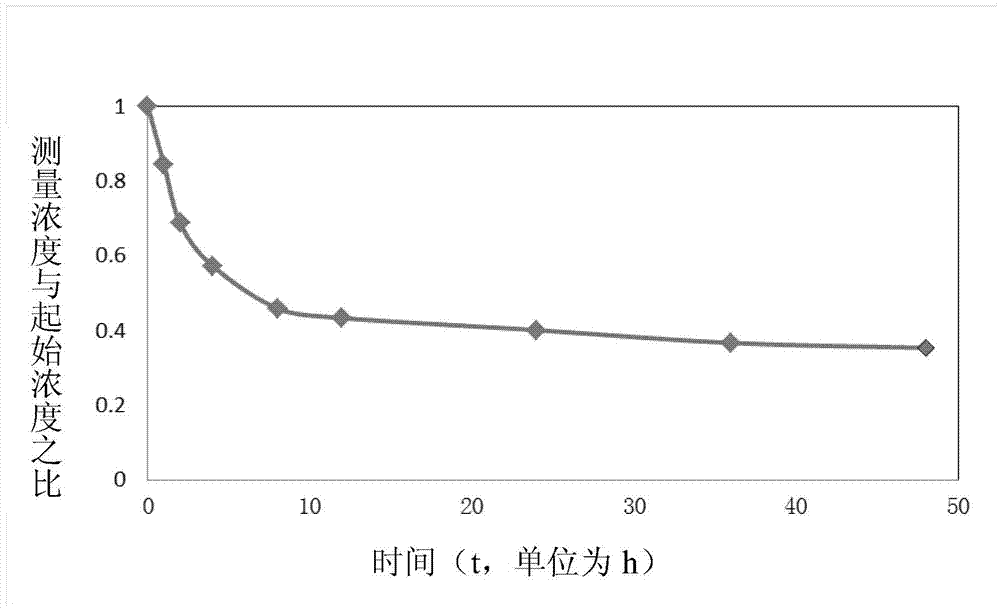

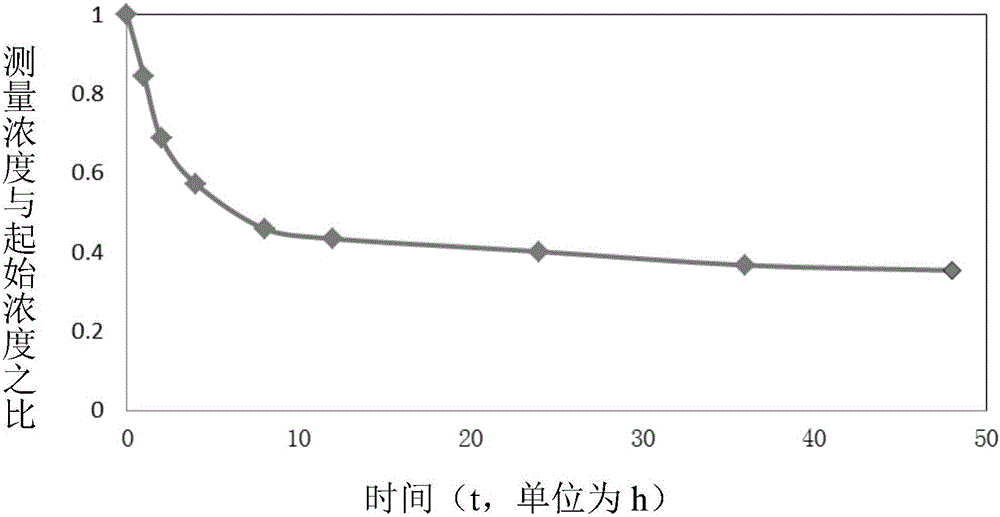

Method for preparing precoating ultrafiltration membrane based on micro-emulsion modified nano-zero-valent iron and application method of precoating ultrafiltration membrane

InactiveCN106474940ANot easy to polymerizeImprove polymerization stabilitySemi-permeable membranesMembranesPolyethylene glycolTyrosine

The invention belongs to the technical field of novel water treatment materials or functional environmental materials, and particularly relates to a method for preparing precoating ultrafiltration membrane based on micro-emulsion modified nano-zero-valent iron (nano-ZVI) and an application method of the precoating ultrafiltration membrane. According to the method for preparing the preparing precoating ultrafiltration membrane, a turbid liquid of the micro-emulsion modified nano-zero-valent iron in methoxy polyethylene glycol amino (MPEG-NH2), coating 3-hydroxy-L-tyrosine (L-DOPA) on the surface of an ultrafiltration membrane, and grafting the nano-ZVI, combined with the MPEG-NH2, on the surface of the ultrafiltration membrane under a covalent combining action of amidogen in the MPEG-NH2 and the L-DOPA. The method has the advantages that the prepared precoating ultrafiltration membrane is high in anti-pollution capacity and capable of effectively removing pollutants including heavy metal like chromium, arsenic, antimony and the like and organic halides in the water.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Water purification method of ultrafiltration membrane based on microemulsion-modified nano-zero-valent iron-carbon material precoated layer

ActiveCN106492644AImprove utilization efficiencyNot easy to polymerizeSemi-permeable membranesWater contaminantsPurification methodsNitrobenzene

The invention belongs to the technical field of water treatment novel materials or environmental functional materials and particularly relates to a preparation method and application method of an ultrafiltration membrane based on a microemulsion-modified nano-zero-valent iron-carbon material precoated layer. The preparation method comprises the following steps: firstly preparing microemulsion-modified nano-zero-valent iron, then preparing turbid liquid of the microemulsion-modified nano-zero-valent iron and carbon material in amino polyethylene glycol monomethyl ether (MPEG-NH2), and coating the surface of the ultrafiltration membrane with 3-hydroxyl-L tyrosine (L-DOPA); and grafting nano-ZVI and carbon material bonded with MPEG-NH2 to the surface of the ultrafiltration membrane by virtue of a covalent binding action between amino in the MPEG-NH2 and L-DOPA. The material prepared by virtue of the preparation method has very strong anti-pollution capacity and is capable of effectively removing heavy metals, such as chromium, arsenic and antimony, and organic pollutants, such as nitrobenzene and organic halide, in water.

Owner:恩科水环科技(北京)有限公司

Modified molecular sieve catalyst, preparation method thereof and styrene oxide preparation method

ActiveCN111318299AExtend your lifeEasy to recycleOrganic chemistryMolecular sieve catalystsMolecular sieveStyrene oxide

The invention discloses a modified molecular sieve catalyst and a preparation method thereof. The modified molecular sieve catalyst is MCM-41 / M-N, MCM-41 is a molecular sieve, M is a rare earth metal,N is a polymerization inhibition factor, based on the total mass of the catalyst, the content of M is 1-5%, and the content of N is 1-10%. The catalyst is obtained through multi-step modification such as rare earth metal modification, pore-enlarging modification, polymerization inhibition factor coordination modification, and the like. The invention mainly solves the defects of low catalyst stability, unsatisfactory product selectivity and yield and unsatisfactory process safety in the prior art. The catalyst is used for preparing styrene oxide, the reaction activity and selectivity are improved, the styrene polymerization degree is reduced, the intrinsic safety of the process is improved, the production cost is reduced, various defects in the prior art are overcome, and the catalyst canbe used for industrial production.

Owner:WANHUA CHEM GRP

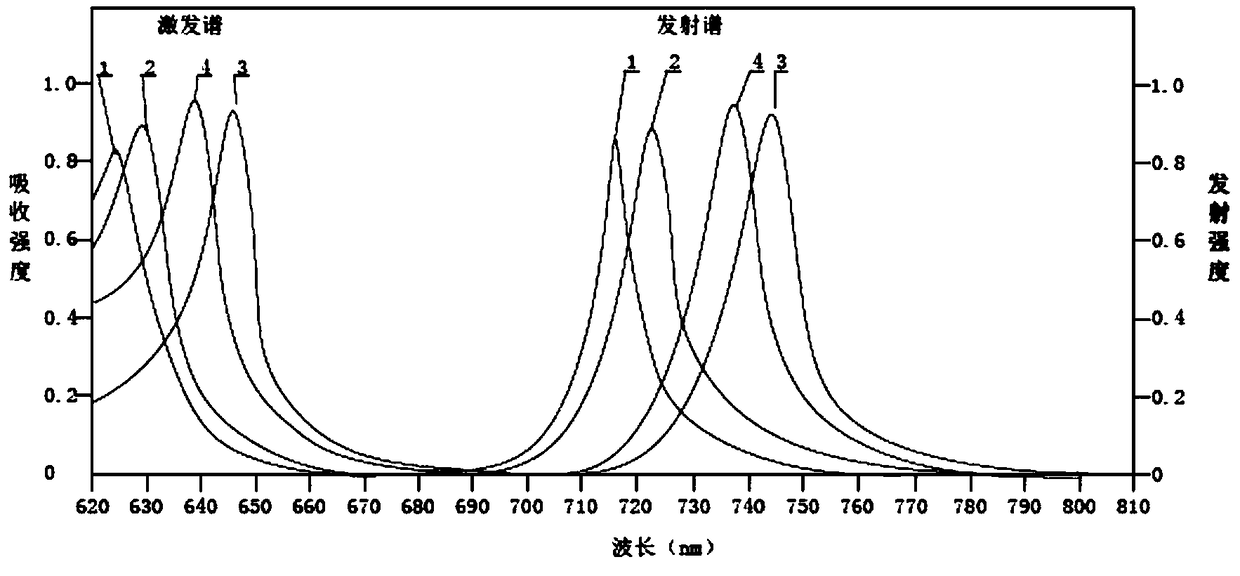

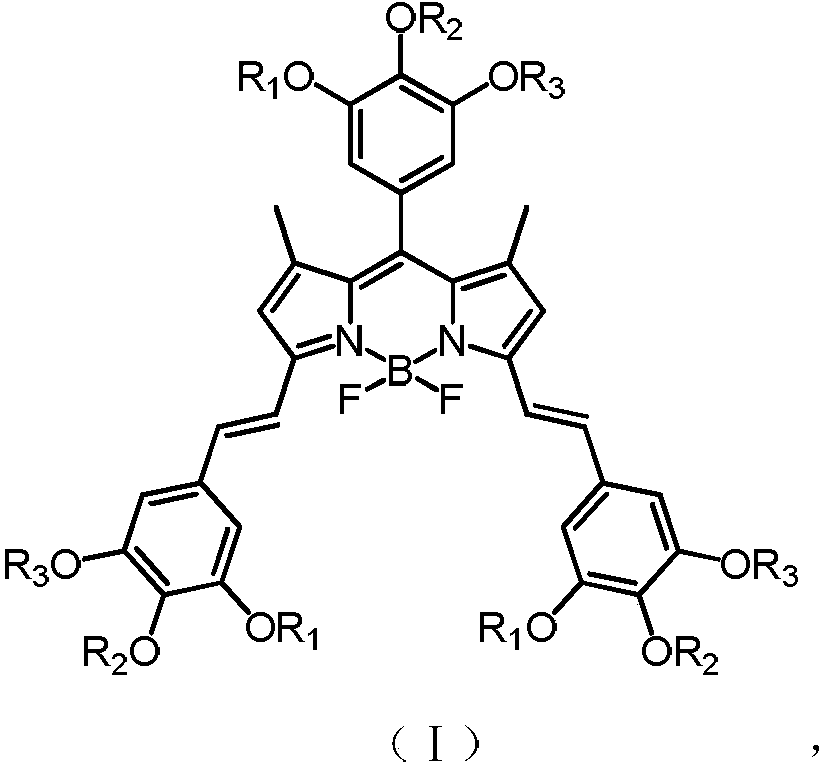

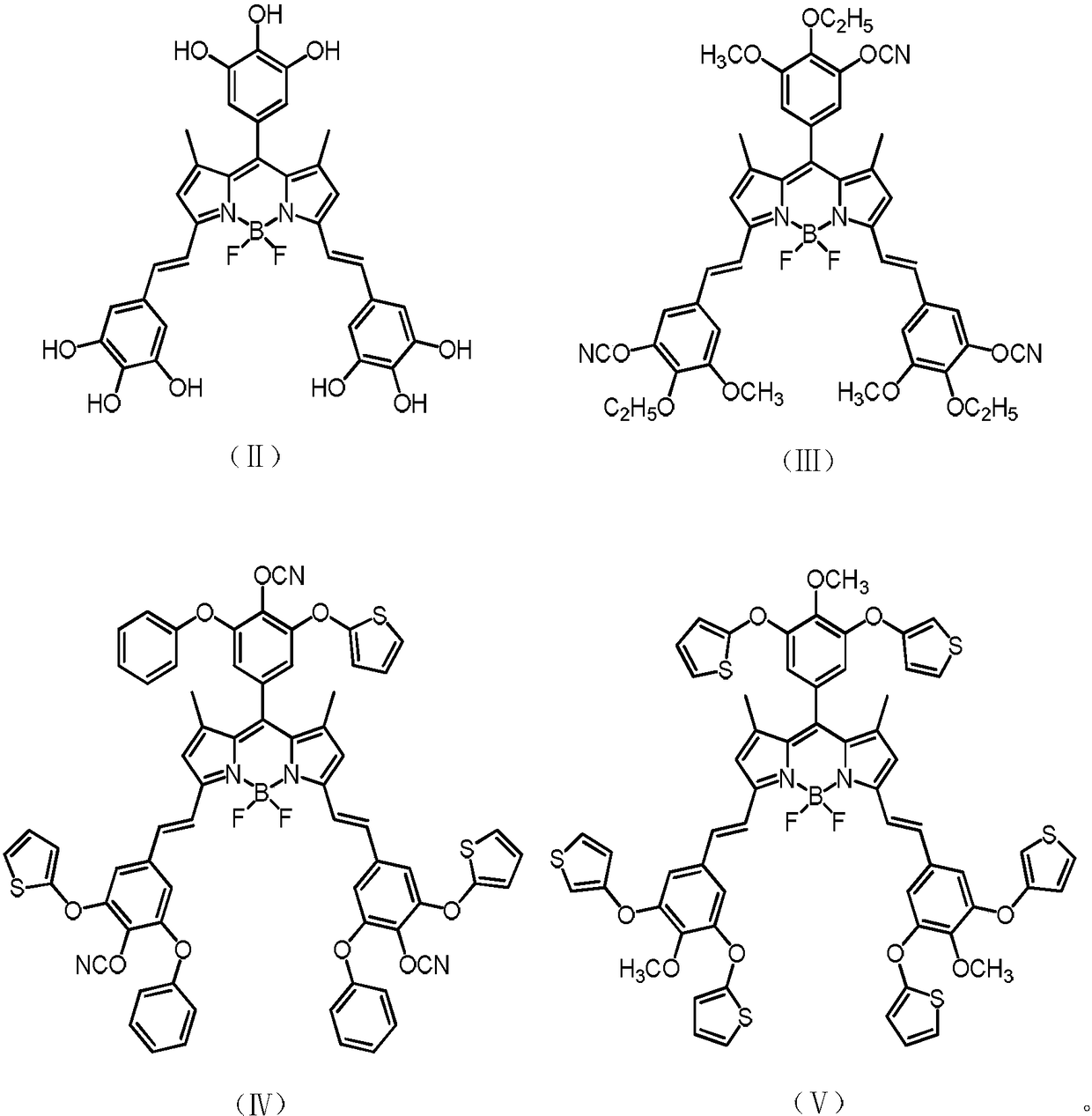

Red light excited fluorescent dye as well as preparation method and application thereof

PendingCN108130070AEnlarging the large π bondIncreased conjugated systemSolid-state devicesAzo dyesLaser dyeApplication areas

The invention relates to the field of photo-functional materials, in particular to a red light excited fluorescent dye. The red light excited fluorescent dye has a structure shown as the formula (I) in the description. The red light excited fluorescent dye has quite wide excitation spectrum, is good in photostability and high in sensitivity, realizes trace detection, can be used in different application fields such as cell imaging, fluorescence probes, laser dyes, fluorescence sensors and the like, and shows good practicability. According to the preparation method, raw material cost is low, nopollution is produced, the process is simple, and yield is high; the prepared fluorescent dye is novel in structure, good in performance and suitable for being widely applied in the fields of biology, environment and the like.

Owner:SUZHOU BAIYUAN GENT CO LTD

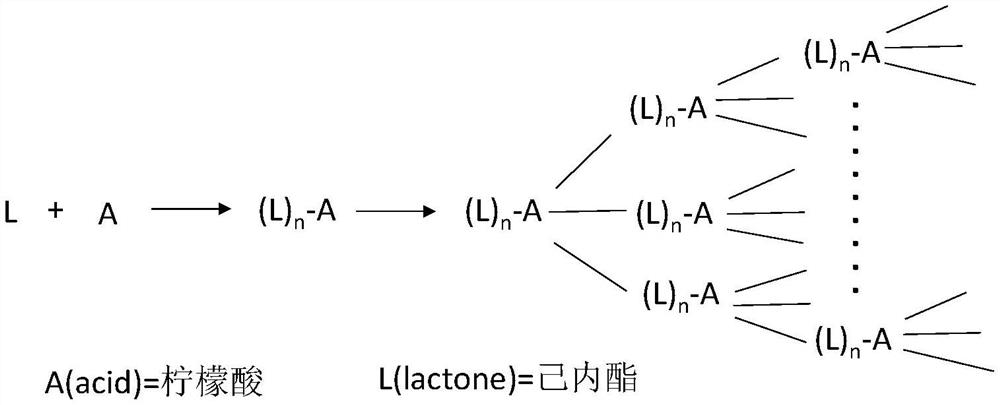

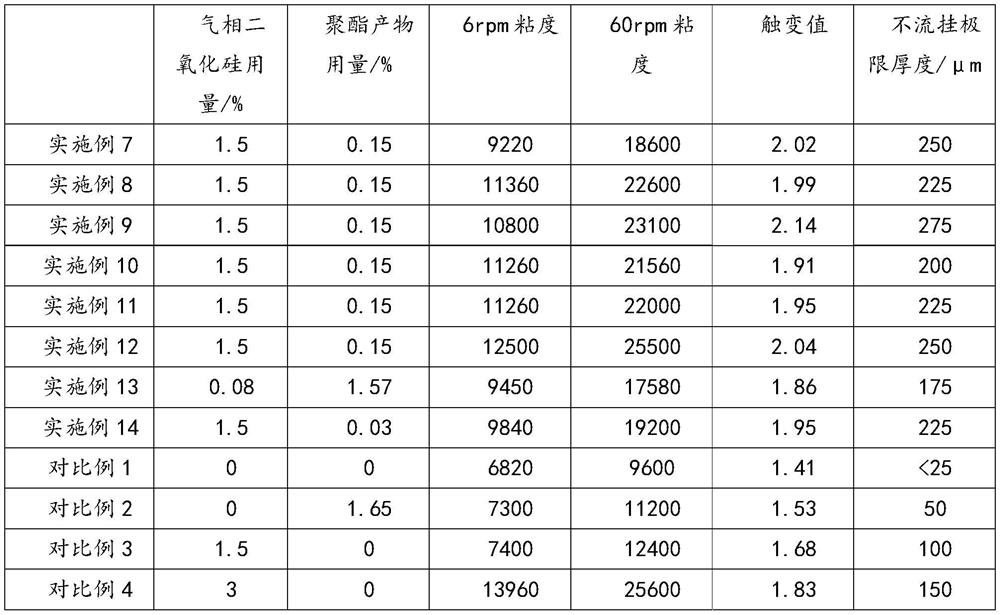

Highly branched polyester product, thixotropic compound and coating

The invention relates to the field of coating performance improvement, in particular to a highly branched polyester product, a thixotropic compound and a coating. According to the highly branched polyester product, esterification polymerization components comprise carboxylic acid and lactone; wherein the carboxylic acid is polyhydroxy acid at least containing two carboxyl groups and one hydroxyl group at the same time and / or polybasic carboxylic acid containing at least three carboxyl groups. The highly branched polyester provided by the invention is polymerized by using carboxylic acid and lactone as monomers, and the highly branched polyester and fumed silica form a more stable space structure, so that the highly branched polyester has remarkable thixotropic enhancement performance; meanwhile, the dosage range is large, synthesis is simple and convenient, raw materials are rich and easy to obtain, and good application and popularization value is achieved.

Owner:优卡化学(上海)有限公司

Wood-plastic floor for bathroom

InactiveCN105566932ASmall specific heat capacityIncrease relative volatilityFlooringLinear low-density polyethylenePolyethylene glycol

A wood-plastic floor for a bathroom is prepared from, by weight, 60-70 parts of wood powder, 22-32 parts of PVC resin, 7-11 parts of zinc stearate, 13-22 parts of n-amyl-4-hydroxybenzoate, 15-24 parts of sodium dehydroacetate, 17-25 parts of phenolic resin, 17-25 parts of polypropylene, 17-25 parts of linear low-density polyethylene, 1-3 parts of walnut shells, 0.2-0.4 part of chestnut shells, 8-13 parts of vermiculite, 6-12 parts of kaolin, 5-9 parts of dioctyl phthalate, 1-2 parts of polyacrylamide, 6-13 parts of polyoxyethylene bis(stearate), 12-15 parts of polymethyl sorbate, 7-11 parts of snakegourd fruit vines, 3-7 parts of polyethylene wax, 1-2 parts of activated carbon, 2-3 parts of dandelions, 0.1-0.2 part of wheat germ oil, 0.1-0.2 part of sunflower seed oil and 0.1-0.2 part of edible vinegar. The wood-plastic floor is waterproof and anti-skid, water is not likely to gather on the surface of the floor, components are dispersed, moisture volatility is accelerated, dryness of the surface of the floor is kept, and the floor is resistant to bacterium erosion and worm damage. Besides, the wood-plastic floor is small in specific heat capacity, is warm in winter and cool in summer when people step on the floor, and is particularly suitable for the bathroom to use and wide in application prospect.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

Method for controlling low-melting-point inclusion in high-strength low-alloy steel

InactiveCN103045806BNot easy to polymerizeReduce distortionProcess efficiency improvementNon-metallic inclusionsDeoxidization

The invention provides a method for controlling a low-melting-point inclusion in high-strength low-alloy steel, which comprises the following steps: 1, tapping into a ladle, and adding additives into molten steel in the ladle after the start of tapping, wherein the additives include an iron alloy, aluminum deoxidizer, slow release deoxidizer and lime; 2, performing LF (ladle furnace) refinement in the ladle, wherein the basicity range of slag in the refinement process is 3-6; the refining slag subjected to LF slagging comprises the following components in percentage by mass: 50-65% of CaO, 6-12% of MgO, 13-26% of Al2O3, 9-19% of SiO2 and less than 0.5% of (FeO+MnO); 3, after slagging, blowing Ar gas from the bottom of the ladle, and desulfurizing while strongly stirring; and 4, in the strongly stirring process and the subsequent process, reacting the slag, the molten steel and an inclusion. The invention has the following advantages: favorable deoxidization and desulfurization effect is achieved, and simultaneously, the composition of the non-metallic inclusion in the steel is controlled to be in a high-melting-point region of a CaO-MgO-Al2O3(-SiO2) phase diagram, so that the inclusion is less prone to polymerization, and less deformation is caused in the subsequent rolling process, thereby achieving the purpose of controlling the large strip-shaped inclusion in a high-strength low-alloy steel plate.

Owner:UNIV OF SCI & TECH BEIJING

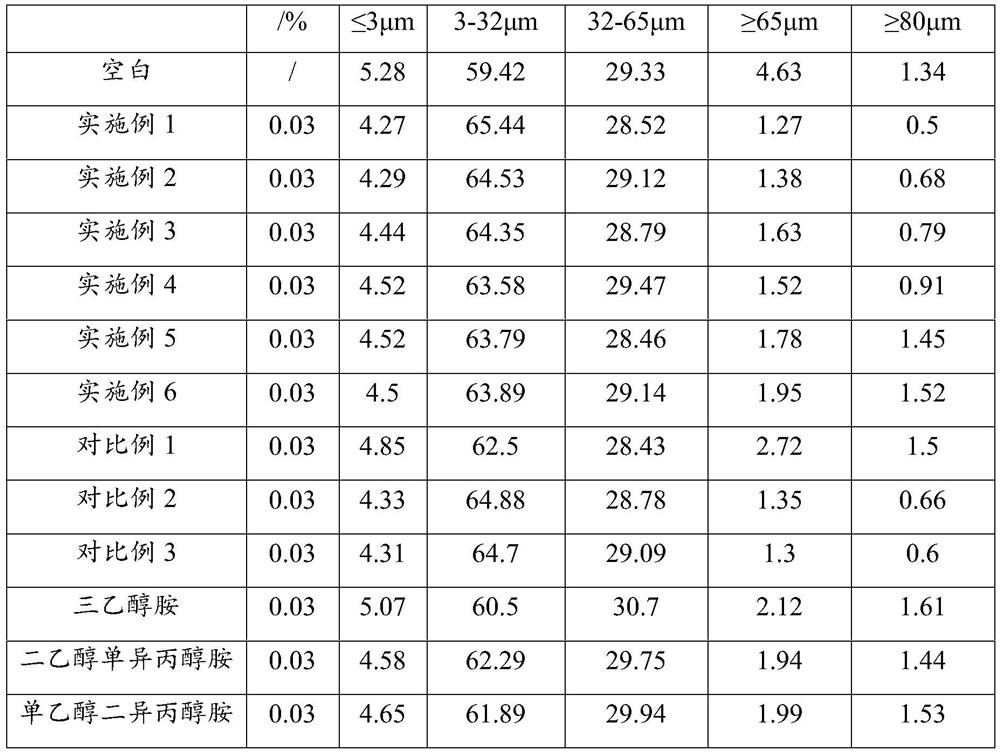

HDPE pipe and preparation method thereof

InactiveCN111675848ADoes not affect other mechanical strength indicatorsGood flexibilityPolymer sciencePtru catalyst

The invention provides an HDPE pipe and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing and reacting a vanadium-modified SBA-15 molecular sieve withtitanium tetrachloride and butyl titanate to prepare a catalyst; grafting graphene with polyglutamic acid to obtain a filler; then, under the action of a catalyst, carrying out a polymerization reaction on vinyl fluoride, 1-octene, hydrogen, ethylene and the like used as raw materials to obtain a resin matrix; and finally, carrying out melt blending on the resin matrix and filler to obtain the HDPE resin. On the premise that other mechanical strength indexes are not affected, the flexibility of the HDPE resin can be greatly improved, market vacancy is made up, and the HDPE resin has good market prospects.

Owner:长沙三思新材料科技有限公司

Preparation method of sodium p-styrenesulfonate

ActiveCN109836359AReduce unit consumptionLow costSulfonic acids salts preparationBenzeneOrganic synthesis

The invention belongs to the field of organic synthesis and specifically relates to a preparation method of sodium p-styrenesulfonate. The preparation method comprises the following steps: (1) (2-chloroethyl)benzene and SO3 react to generate p-sulfonic acid-(2-chloroethyl)benzene; and (2) the p-sulfonic acid-(2-chloroethyl)benzene prepared in the step (1) reacts with NaOH to generate sodium p-styrenesulfonate. The invention has the following advantages: (2-chloroethyl)benzene adopted in the invention is cheap and easily available and its unit consumption and cost are lower. In addition, motherliquor produced by the method can be subjected to centrifugal separation to obtain pure sodium p-styrenesulfonate. Part of sodium p-styrenesulfonate dissolved in the primary mother liquor can be recovered to obtain a recycled product. Recovered secondary mother liquor almost contains no sodium p-styrenesulfonate, and concentrated secondary mother liquor can recover industrial sodium chloride. Thereby, the pollution of ''three wastes (waste gas, waste water and industrial residue)'' to the environment is reduced. In addition, the sodium p-styrenesulfonate prepared by the method is not easy topolymerize. The prepared product is not easy to polymerize when being placed or dissolved for use, and the property is stable.

Owner:XZL BIO TECHNOLOGY CO LTD

Polycarboxylic acid polymer, preparation method and application thereof

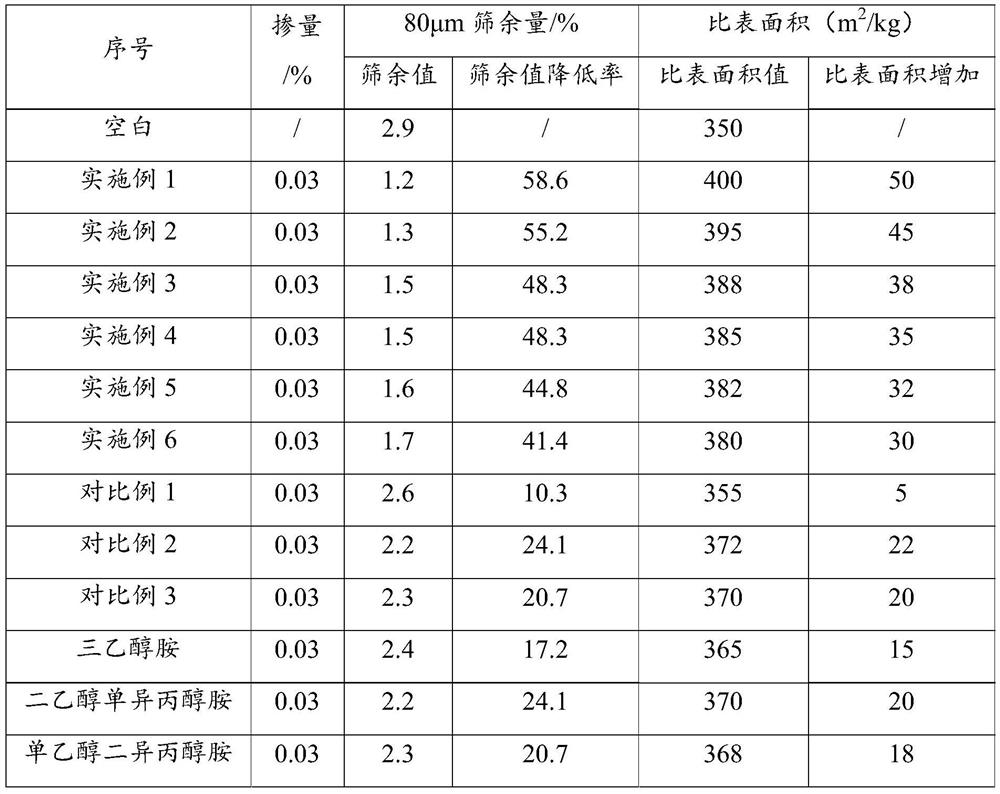

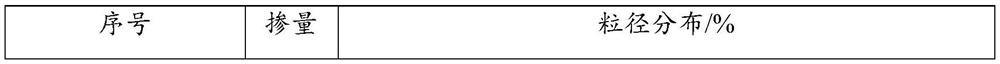

The invention belongs to the technical field of building material preparation, and particularly relates to a polycarboxylic acid polymer, a preparation method and application thereof. The method comprises the following steps: (1) adding a polymerization inhibitor and part of unsaturated carboxylic acid into molten unsaturated polyether to form a mixed solution A; (2) preparing a mixed solution B from an esterification monomer and the residual unsaturated carboxylic acid; and (3) adding the mixed solution B into the mixed solution A, and performing bulk polymerization under the action of an initiator to obtain a polycarboxylic acid polymer, wherein in the step (3), inert gas is introduced in the early stage of the reaction, oxygen is introduced in the middle stage of the reaction, and inert gas is introduced in the later stage of the reaction. According to the invention, when the method is used for preparing the polycarboxylic acid polymer, the viscosity of a reaction system can be well controlled, the reaction rate is improved, the whole reaction process is stable, the molecular weight of the obtained polymer is narrow, and the effective content is increased; and the polycarboxylic acid polymer is used as a cement grinding aid, so that the grinding aid has good grinding aiding effect, water-reducing rate and early strength performance, and a solvent does not need to be added in the use process.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

Preparation method of anti-wear agent

InactiveCN110484330AWith surface modificationWith anti-friction and anti-wear effectAdditivesMicrobial oilCalcite

The invention belongs to the technical field of preparation of lubricating materials, and particularly relates to a preparation method of an anti-wear agent. The preparation method comprises the following steps: preparing anti-wear suspension by taking multi-walled carbon nanotubes as a raw material; mixing and heating microbial oil, ethyl palmitate, lithium amide and the like to obtain an esterification product; finally, distilling an antioxidant lubricating grease crude product to obtain antioxidant lubricating grease; subjecting rapeseed oleic acid, azelaic acid and neopentyl glycol which are used as raw materials to esterification to obtain mixed ester; adding the mixed ester into the anti-wear suspension to obtain the anti-wear agent. Aluminum in the anti-wear suspension in the anti-wear agent participates in a local metallurgical reaction to achieve surface modification so that the anti-friction and anti-wear effects are achieved; an aluminum oxide passivation film can be formedto improve extreme pressure lubricating and antioxidant performance. Through the high polarity of the antioxidant lubricating grease, the conversion rate of the calcite crystal form formed by calciumlignosulphonate is improved, and the high-temperature resistance and the self-repairing performance of a lubricant are improved, such that the prepared anti-wear agent has broad application prospects.

Owner:刘群艳

Broad-spectrum antibacterial nano-silver finishing agent and preparation method thereof

InactiveCN107173397AHigh antibacterial activityHas a broad-spectrum antibacterial effectBiocideDead animal preservationAntibacterial activityAndrographis

The invention provides a broad-spectrum bacterial nano-silver finishing agent and a preparation method thereof. The finishing agent is prepared from the following components in parts by weight: 10 to 12 parts of common andrographis herb ethanol extract, 15 to 26 parts of herba houttuyniae ethanol extract, 4 to 6 parts of nanosilver and 0.1 to 0.3 part of bonding agent. The common andrographis herb ethanol extract and the herba houttuyniae ethanol extract have broad-spectrum antibacterial functions, and the antibacterial activities of the extracts are increased after ultrasonic treatment; the antibacterial function of the nanosilver is enhanced further in cooperation with the nanosilver. A silver nitrate solution is difficult to polymerize after infrared and ultrasonic treatment, a dispersing agent does not need to be added, and the prepared nanosilver has high stability.

Owner:山东森凌环保科技有限公司

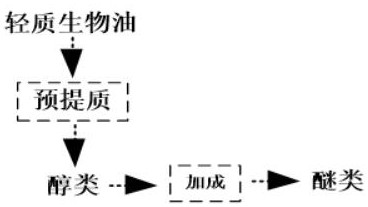

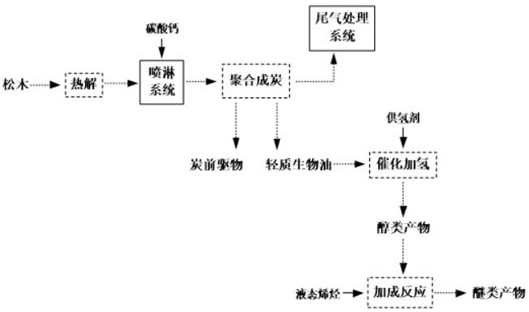

Method for preparing fuel from light bio-oil

InactiveCN112920861AIncrease oxygen contentHigh molecular weightLiquid carbonaceous fuelsCombustionEther

The invention discloses a method for preparing fuel from light bio-oil, which is characterized by comprising the following steps of 1, changing the light bio-oil into an alcohol substance, and 2, converting the obtained alcohol substance into an ether substance. In the step 2, a method for changing the changed alcohol substance into the ether substance is as follows: liquid olefin containing double bonds is added into the changed alcohol substance, and the high-quality ether substance is generated through an addition reaction. The bio-oil is subjected to an addition reaction to generate a high-quality ether substance which is used as an oxygen-containing additive. According to the method, the molecular weight of each component in the light bio-oil can be improved, and the combustion performance of the light bio-oil is improved, so that the utilization value of the light bio-oil is improved; and the problems of low efficiency and poor product selectivity caused by direct catalytic upgrading due to complex light bio-oil components can be well solved.

Owner:SOUTHEAST UNIV

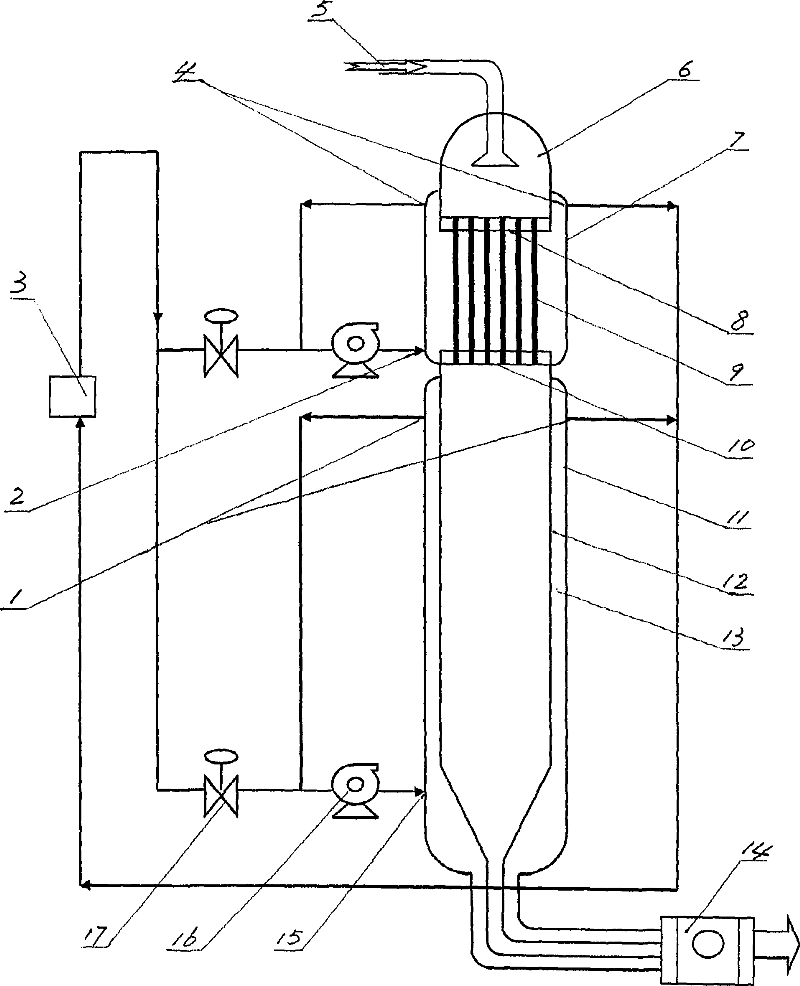

Heating system for caprolactam polymerization reaction apparatus

InactiveCN101037502AAchieve aggregationNot easy to polymerizeStationary tubular conduit assembliesEngineeringHeating system

The invention discloses a heating system for caprolactam polymerization reaction device, which includes a reaction cartridge constituted of an upper cartridge and a lower cartridge. A upper supporting plate is disposed in the upper cartridge, through-holes are arranged at both the upper supporting plate and the upper cartridge, and steel pipes are connected to a pair of corresponding through-hole. A distribution cavity is remained at top of the upper supporting plate and the upper cartridge, and caprolactam inlet is arranged at top of the distribution cavity. The lower cartridge is constituted of inner cartridge and outer cartridge to form jacket. Upper end of the inner cartridge is connected with bottom plate of the upper cartridge, a caprolactam outlet is disposed at bottom of the lower cartridge, and heat conductivity oil source is also included in bottom of the lower cartridge. Oil inlet and outlet are both disposed at upper cartridge and lower cartridge, the oil outlets are connected with inlet of the heat conductivity oil source by oil pipe, and the oil inlets are connected with outlet of the heat conductivity oil source by oil pump and valve. Advantages of the heating system are: fire hazard and explosion accident can be avoided, production efficiency is high, cost is low, and the heating system is adapt for heating polymerization reaction device for producing nylon section with caprolactam as raw material.

Owner:沈有清

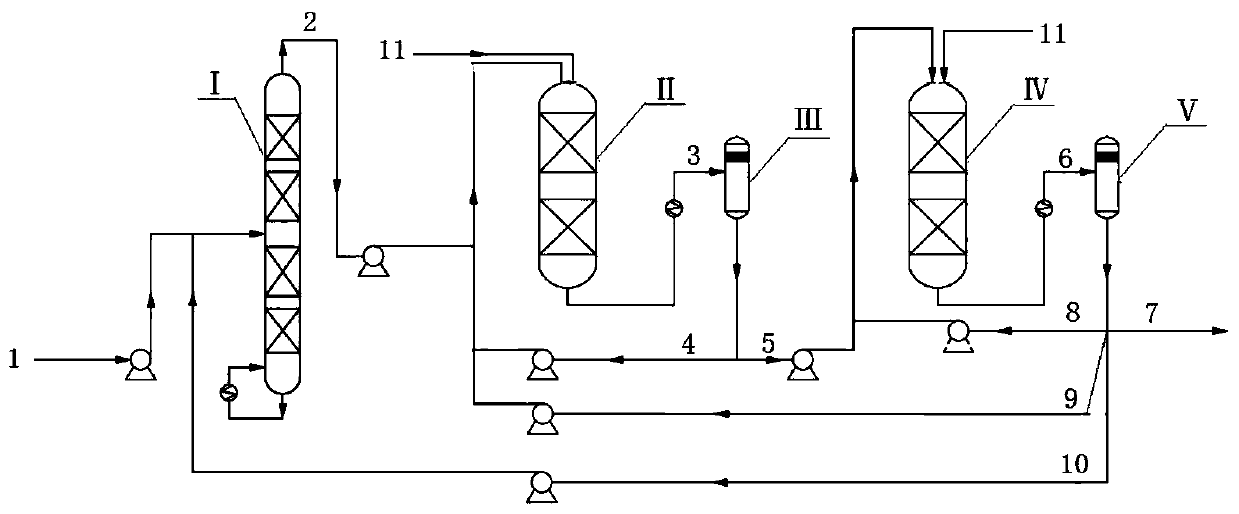

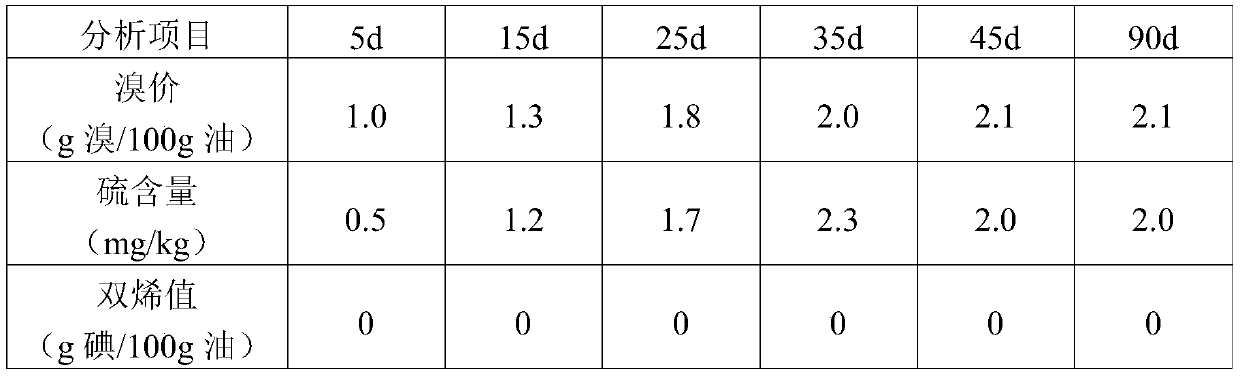

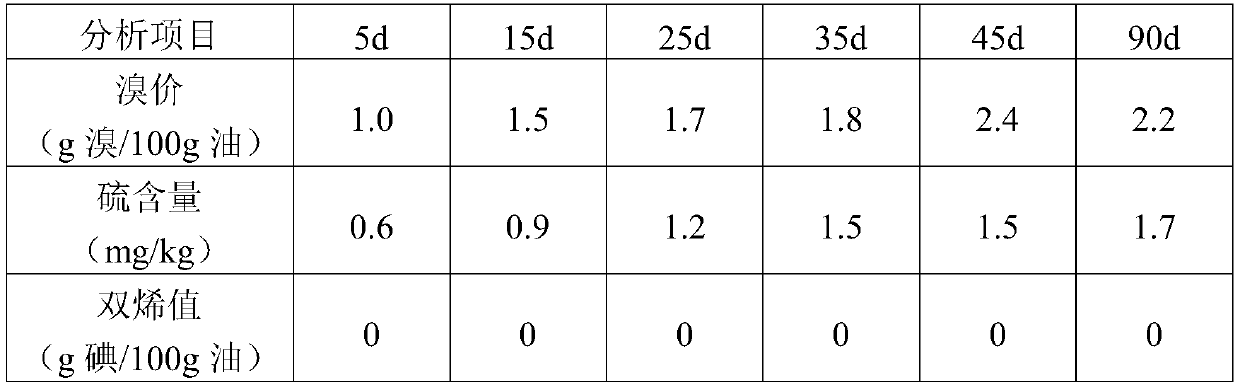

Hydrogenation method of C9 < + > fraction for pyrolysis gasoline

ActiveCN111234869AAchieve separationReduce difficultyTreatment with hydrotreatment processesBromine numberPtru catalyst

The invention discloses a hydrogenation method of a C9 < + > fraction for pyrolysis gasoline. By utilizing a hydrogenation process of carrying out staged hydrogenation and enabling one part of a firstproduct flow to be recycled back to a first reactor and one part of a second product flow to be respectively recycled back to a colloid separation tower, a first reactor and a second reactor, and cooperatively using a catalyst with high low-temperature activity, the operation stability of the device and the hydrogenation activity of the catalyst are improved. According to the method, the export bromine value of the finally prepared hydrogenation product can be reduced to below 3g bromine / 100g oil, the export diene value reaches 0g iodine / 100g oil, and the sulfur content is reduced to below 3mg / kg.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for purifying epa from fish oil

ActiveCN109438220BDurableReduce manufacturing costCarboxylic compound separation/purificationOrganic solventFishery

Owner:SEPAX TECH

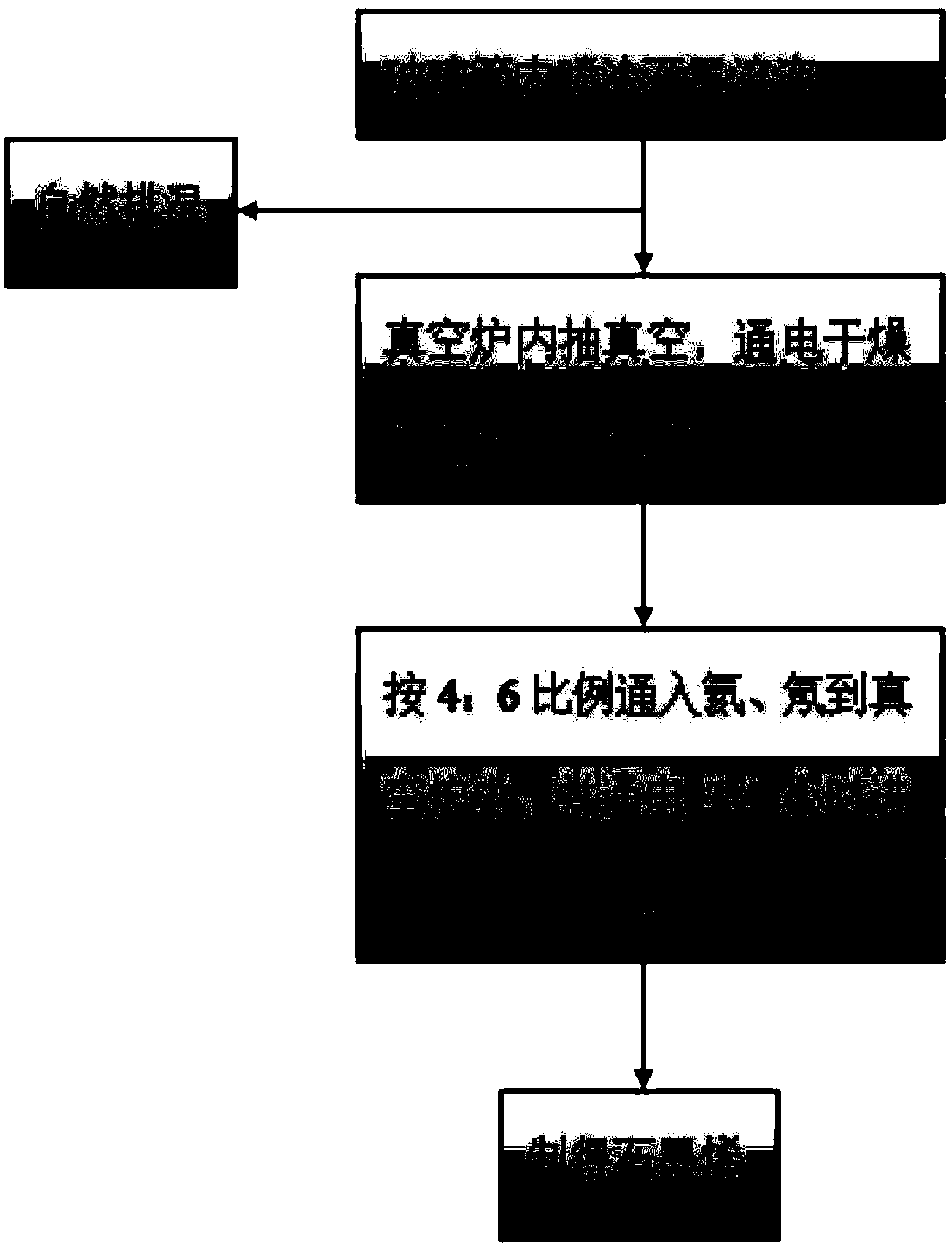

A method for producing graphene using vacuum photoelectric reaction

The invention discloses a method for producing graphene through vacuum photoelectric reaction. The method comprises the following steps: mixing graphite of 1000 meshes with ionized water, and spraying to the inner side of a glass tube; putting the glass tube into a vacuum furnace, vacuumizing, setting electrodes before and after the vacuum furnace, and electrifying the electrodes for photoelectric hating so as to dry and dehumidify the glass tube; and continuously heating, ensuring that the glass tube is completely vacuumized inside, adding helium and neon simultaneously according to a ratio of 4:6, keeping the glass tube being in a vacuum state, continuously electrifying for oxidation reduction for 3-4 hours, and discharging, thereby obtaining the graphene. As graphene is produced in a novel photoelectric reaction mode, and energy transition of photoelectric atoms is utilized, multi-layer graphene can be reduced; meanwhile, as the reaction does not involve multiple oxidation reductants, the production is clean and non-toxic; and furthermore, multiple glass tubes can be placed into the vacuum furnace for carrying out sufficient and uniform reaction simultaneously in uniform contact, so that the capacity and quality can be greatly improved.

Owner:东莞市悉达纳米科技有限公司

A kind of preparation method of lipophilic hyperbranched molecular modification nanofluid

ActiveCN111087979BEvenly dispersedInhibition of agglomerationHeat-exchange elementsPolymer scienceLiquid medium

The invention discloses a preparation method of lipophilic hyperbranched molecule modified nanofluid, wherein the nanofluid is composed of a liquid medium and nanoparticles dispersed in the liquid medium. The preparation method comprises the main steps of preparation and dispersion of the nanoparticles. The surface of the nano material is modified by lipophilic hyperbranched molecules. Compared with the prior art, the preparation method has the advantages that the nano particles are dispersed stably without agglomeration, the nano particles are loaded by utilizing the specific dendritic macromolecular structure of the hyperbranched polyethyleneimine grafted by long-chain alkyl acyl chloride, the number-average molecular weight of hyperbranched molecules is distributed between 1000 and 36000. The prepared nano particles are relatively small in particle size, not easy to agglomerate and good in stability. By the addition amount of 0.01%-5%, the nano fluid with good stability and excellent heat-conducting property can be obtained; and the preparation process is controllable, good in repeatability and easy to popularize.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

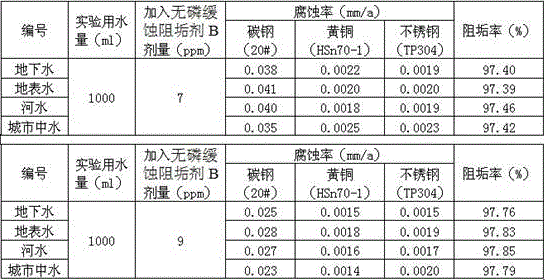

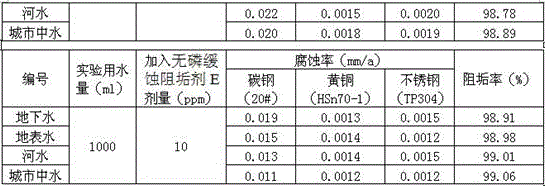

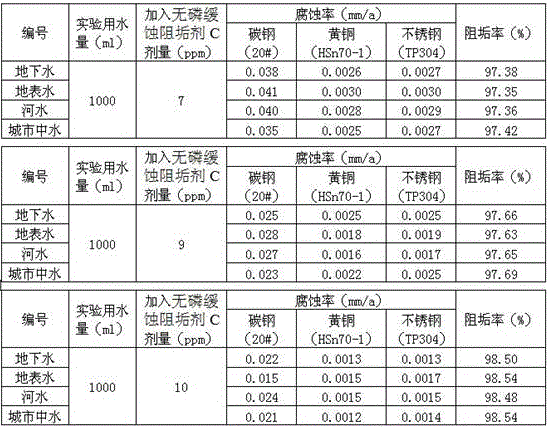

Phosphorus-free scale and corrosion inhibitor containing fulvic acid and preparation method thereof

ActiveCN105084561BEliminate external supplyInhibit rapid reproductionScale removal and water softeningBiopolymerPOLYOXYETHYLENE ETHER

Owner:陕西安得科技实业有限公司

Pretreating agent for treating polymerization and crystallization of tower bottom liquid waste of CTEG rectifying tower

InactiveCN106946367ANot easy to polymerizeSolve the blockageDistillation regulation/controlSpecific water treatment objectivesSulfonateLiquid waste

The invention discloses a pretreating agent for treating polymerization and crystallization of a tower bottom liquid waste of a CTEG rectifying tower. The pretreating agent is prepared from dodecylbenzene sulfonic acid, dodecyl sulfonate, hydroxyethyl diphosphate and ethylene glycol at the mass ratio of (0-2) to (0-2) to (0-2) to (1-2). The pretreating agent is added to the liquid waste at the mass ratio of 0.1-1.8% to be fully mixed, and a stable CTEG liquid waste can be obtained for separation and recovery in the next step, so that polymerization blockage of a pipeline, a pump and the rectifying tower in the separation and recovery processes of the CTEG liquid waste is avoided, and the recovery system can continuously and stable run.

Owner:HENAN CHEM IND RES INST

Evaporation method and device easy for polymerizing hydrocarbon solution

ActiveCN101337131BGuaranteed uptimeEasy to updateDistillation purification/separationEvaporationPolymer scienceProduct gas

The present invention provides an evaporation method and apparatus for an easily polymerizing hydrocarbon solution, said evaporation method includes processes that: the easily polymerizing hydrocarbon solution is fed into a main evaporator(1),the evaporated hydrocarbon gas is discharged from the top of the main evaporator(1), the evaporated liquid components are drawn out via a cycle pump(2) fromthe bottom of the main evaporator(1), part of them being circularly fed into the main evaporator(1) and part of them being fed into a film evaporator(3). The evaporated hydrocarbon gas is then discharged from the top of the film evaporator(3) and the remnant liquid after evaporation is forced to be discharged from the film evaporator(3). The forced circulation evaporator and the film evaporator in this invention combines to realize the evaporation process, the polymeric monomer in the easily polymerizing hydrocarbon solution is not subject to polymerization, thereby improving the evaporation efficiency, maintaining the steady operation, lowering the consume of source and energy.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com