A method for purifying epa from fish oil

A technology of EPA-C18 and fish oil, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of slow hydrolysis speed, inability to separate EPA and DHA, and inability to effectively separate EPA and DHA, and achieve recovery High efficiency, not easy to oxidize, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

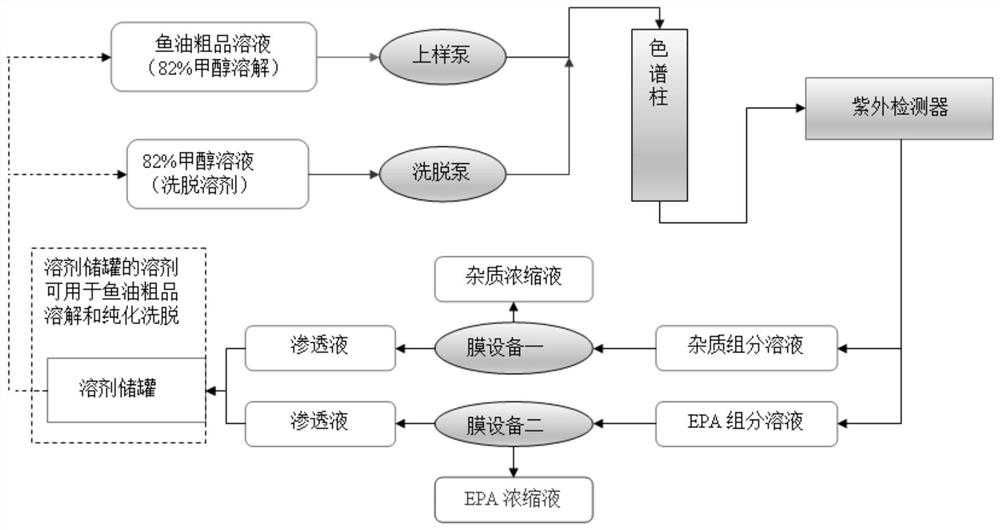

Method used

Image

Examples

Embodiment 1

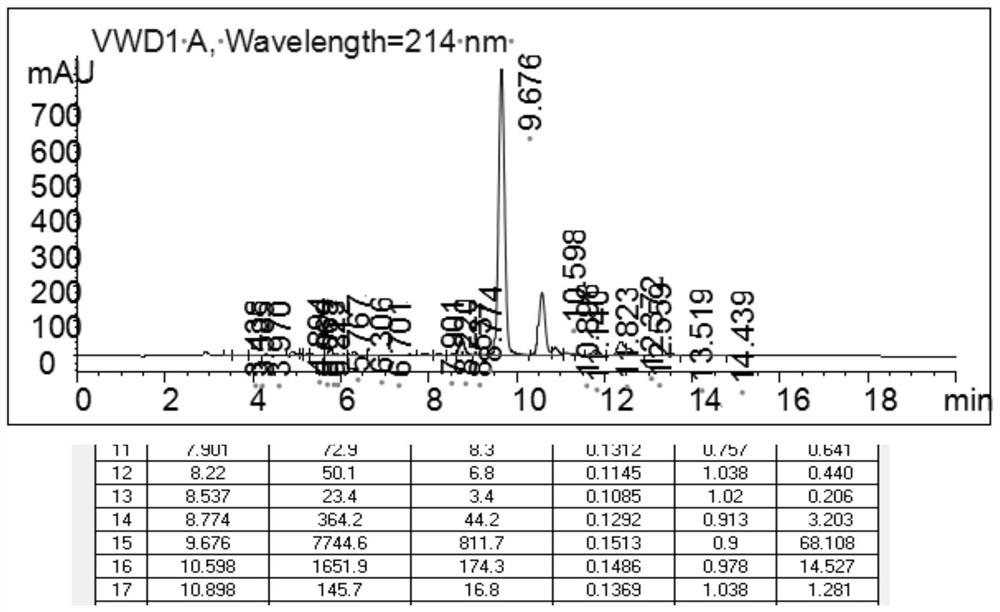

[0099] Example 1 Analysis of fish oil crude product before purification

[0100] The crude fish oil is 70 % pure.

[0101] Chromatographic column: Sepax GP-C18 ( 5um, 4.6 x 250 mm )

[0102] mobile phase:

[0103] A: water

[0104] B: Acetonitrile

[0105] Flow rate: 1ml / min Injection volume: 5ul Column temperature: RT

[0106] Sample: 1mg / ml (dissolved in 82% methanol) Pressure: 78bar

[0107] Instrument: Agilent 1260

[0108] Detection wavelength: UV @ 214nm

[0109] Elution was performed according to the following gradient:

[0110] Table 2

[0111] Time min) A% B% 0 5 95 20 0 100

[0112] The crude product analysis diagram is as follows figure 2 shown.

Embodiment 2

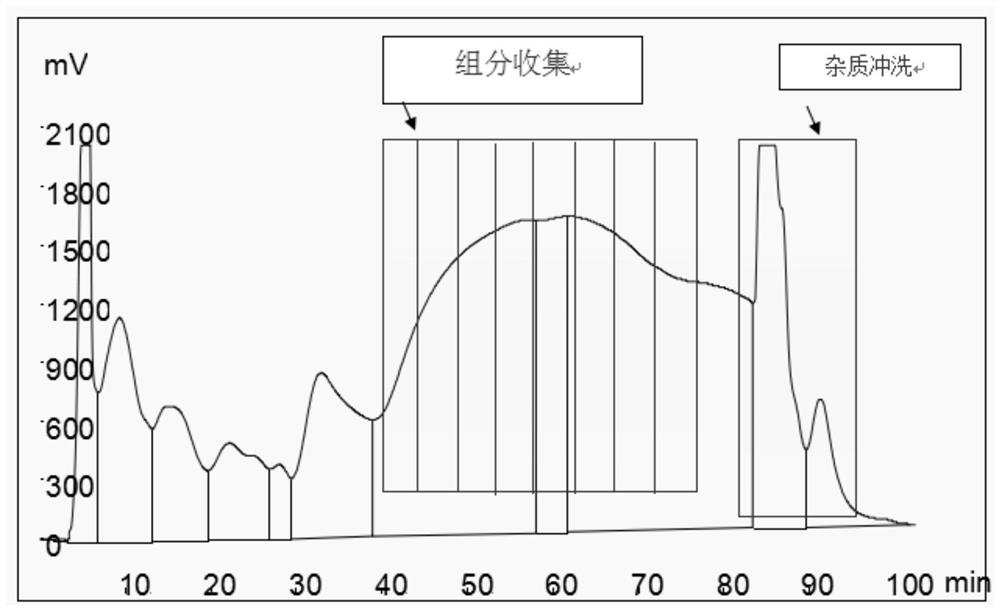

[0113] Example 2 Purification of Crude Fish Oil

[0114] The crude fish oil has a purity of 20%.

[0115] Chromatographic column: EPA-C18 ( 1000 x 250 mm )

[0116] mobile phase:

[0117] A: water

[0118] B: Methanol

[0119] Flow rate: 400ml / min Injection volume: 400ml Column temperature: RT

[0120] Sample: 100mg / ml Pressure: 1.2M Pa

[0121] Instrument: Sepax preparative chromatograph

[0122] Detection wavelength: UV @ 214nm

[0123] Gradient: 82%B

[0124] The specific method is as follows:

[0125] (1) Sample weighing: weigh 40g of crude fish oil on an analytical balance;

[0126] (2) Solvent preparation: prepare 400ml of 82% methanol, take 328ml of methanol, and 72ml of purified water, mix the two together, stir evenly, prepare two parts, and set aside;

[0127] (3) Sample dissolution: add one portion of the solvent prepared in (2) to (1) 40g of crude fish oil, seal it with plastic wrap, add a stirrer, and keep stirring on a magnetic stirrer to fully dissolve...

Embodiment 3

[0135] Take 40g of crude fish oil, in which the EPA content is 70% (m / m), add 400ml of 82% methanol (V / V), stir to fully dissolve; put on the chromatographic column EPA-C18 (100mm×250mm , with a packing mass of about 1.18kg), the sample loading flow rate is 200ml / min, after loading the sample is eluted with 82% methanol, the elution flow rate is 400ml / min, and the total elution is 100min, the EPA component solution is collected by HPLC detection, the membrane is concentrated, and the used Nanofiltration membrane area 2.54m 2 , molecular weight cut off 150~300, membrane flux 20L / (m 2 h), the temperature was controlled at 0-50°C, and the concentrated component solutions were dried to obtain 26.2 g of EPA product, with a purity of 97.3% and a recovery rate of 91.1% by HPLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com