Heating system for caprolactam polymerization reaction apparatus

A technology of caprolactam and polymerization reaction, applied in lighting and heating equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of low freezing point, low production efficiency, high production cost, etc., to reduce production cost and maintenance times , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

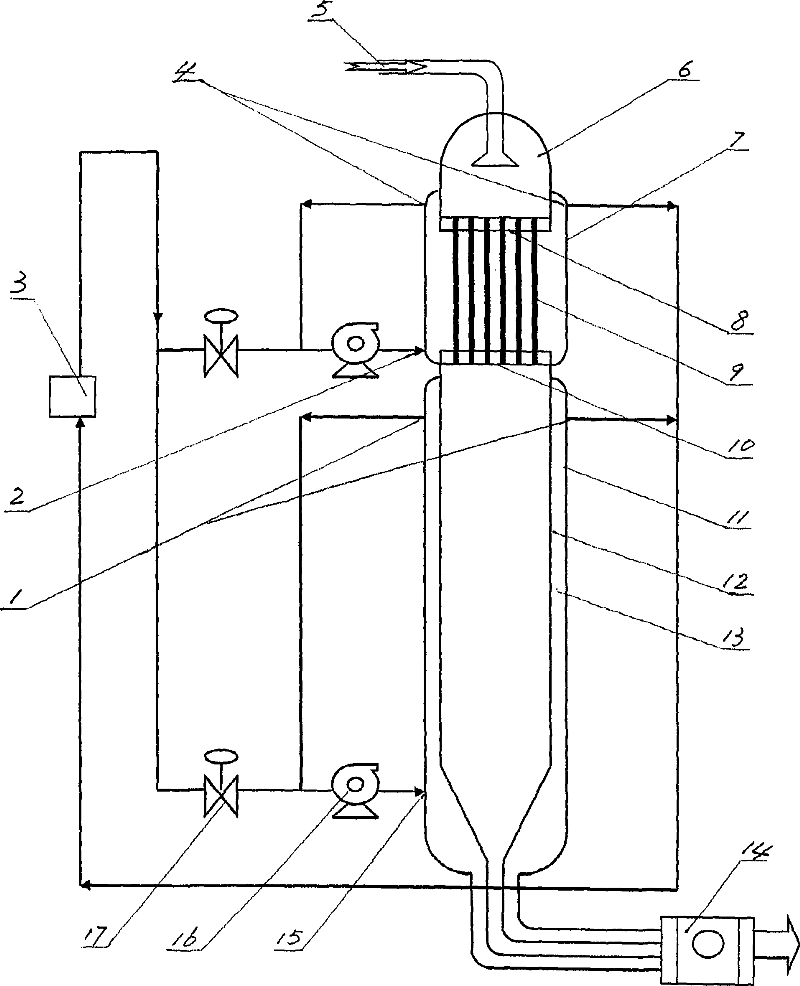

[0012] As shown in the accompanying drawings, the heating system for the caprolactam polymerization reaction device of the present invention includes a reaction cylinder and a heat transfer oil source 3 . The reaction cylinder is cylindrical and consists of an upper cylinder and a lower cylinder. An upper supporting plate 8 is arranged in the upper cylinder, and the surroundings of the upper supporting plate 8 are connected with the inner wall of the upper cylinder in a sealed shape. Both the upper support plate 8 and the bottom plate 10 of the upper cylinder are processed with through holes, and the through holes on the upper support plate 8 correspond to the through holes on the bottom plate 10 one by one. There are steel pipes 9 between the corresponding pair of through holes between the upper support plate 8 and the base plate 10. The steel pipes are stainless steel pipes, and the outer sides of the upper and lower ends are sealed with the corresponding through holes on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com