Patents

Literature

396results about How to "Achieve aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method, device and system for self-adaptation multiple-link aggregation

InactiveCN103618678AHigh speedQuality improvementError preventionNetworks interconnectionData streamTelecommunications link

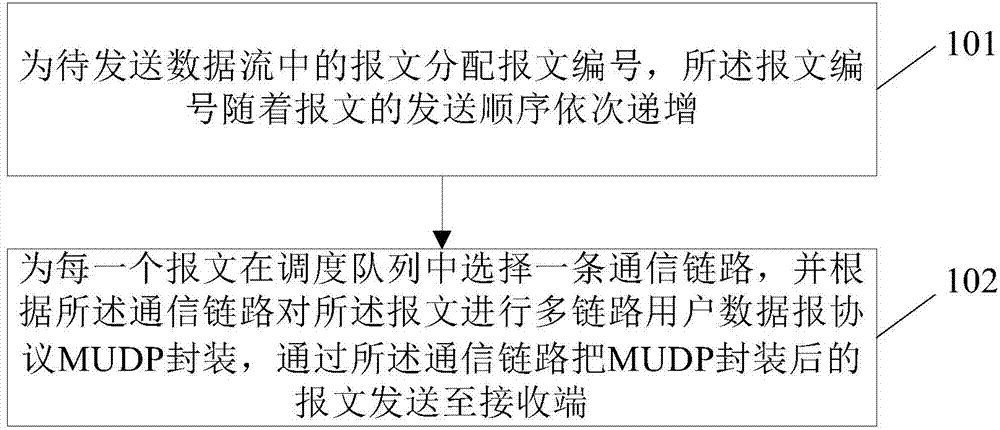

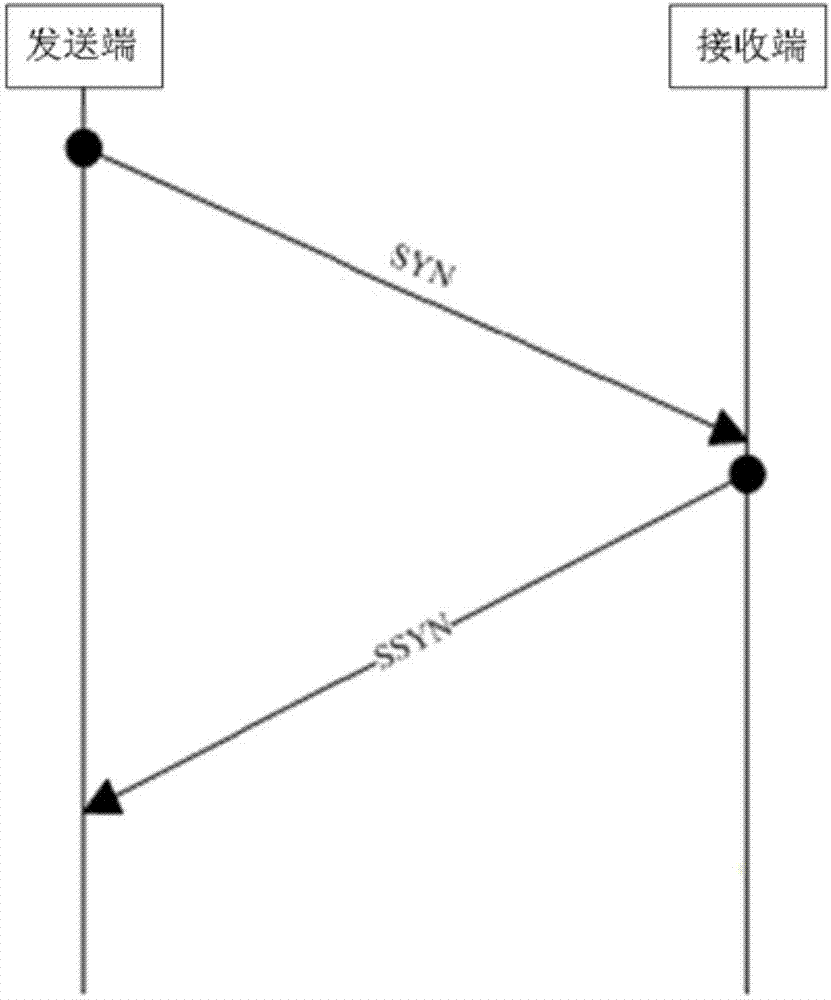

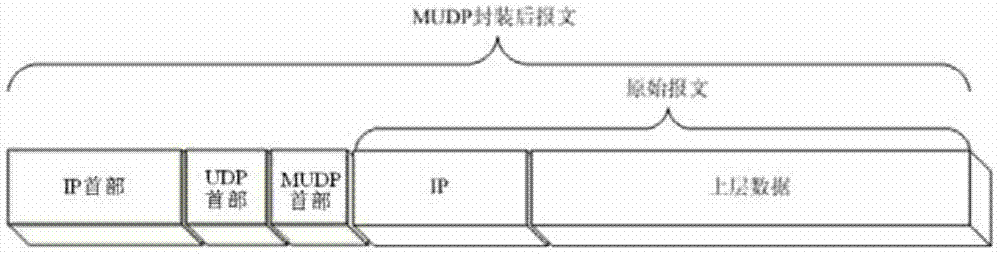

The invention provides a method, device and system for self-adaptation multiple-link aggregation. The method includes the steps of the step 1, distributing message numbers to messages in a dataflow to be sent, wherein the message numbers are increased sequentially along with the sending sequence of the messages, and the step 2, selecting one communication link for each message in a scheduling queue, carrying out MUDP packaging on the messages according to the communication links, and sending the messages subjected to the MUDP packaging to a receiving end through the communication links. According to the technical scheme, a single message serves as a triggering object for communication link selection, the defect that data transmission is carried out only through single dataflow in the prior art is overcome, the single dataflow can be transmitted through different communication links, the upper limit of available bandwidth of one dataflow is no longer limited by bandwidth of a single link, and therefore the multiple-link aggregation is achieved and communication speed and quality are improved; meanwhile, load balance of the multiple communication links is achieved.

Owner:BEIJING XINWANG RUIJIE NETWORK TECH CO LTD

Power equipment fault knowledge graph construction method

PendingCN111737496AImprove accuracyImprove the level of intelligenceData processing applicationsNatural language data processingPower equipmentKnowledge visualization

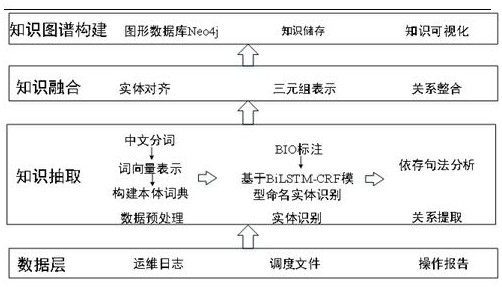

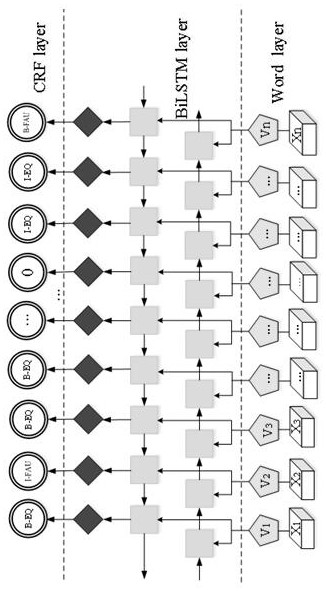

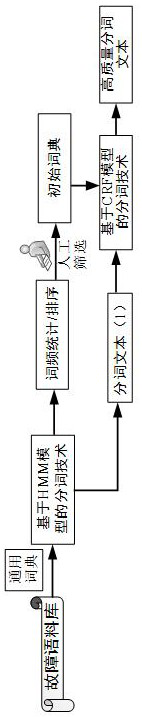

The invention discloses a power equipment fault knowledge graph construction method. The method comprises the steps of power text preprocessing; named entity identification: identifying and extractingpower domain entities, obtaining local features on global features through a CRF model, and accurately obtaining optimal sequence annotations of the text; relationship identification: analyzing sentence structures by analyzing dependency relationships among components of sentences, and analyzing sentence dependency relationships by identifying and positioning grammatical relationships in the sentences; and knowledge storage and visualization: carrying out knowledge aggregation on the identified entities and relationships to form an RDF ternary form, and importing knowledge into a graphic database Neo4j to carry out knowledge storage and knowledge visualization. The method can achieve the extraction and aggregation of the power equipment fault knowledge, facilitates the quick and comprehensive construction of a power equipment fault knowledge graph, and facilitates the improvement of the intelligent level of power equipment fault diagnosis.

Owner:NORTHEAST DIANLI UNIVERSITY

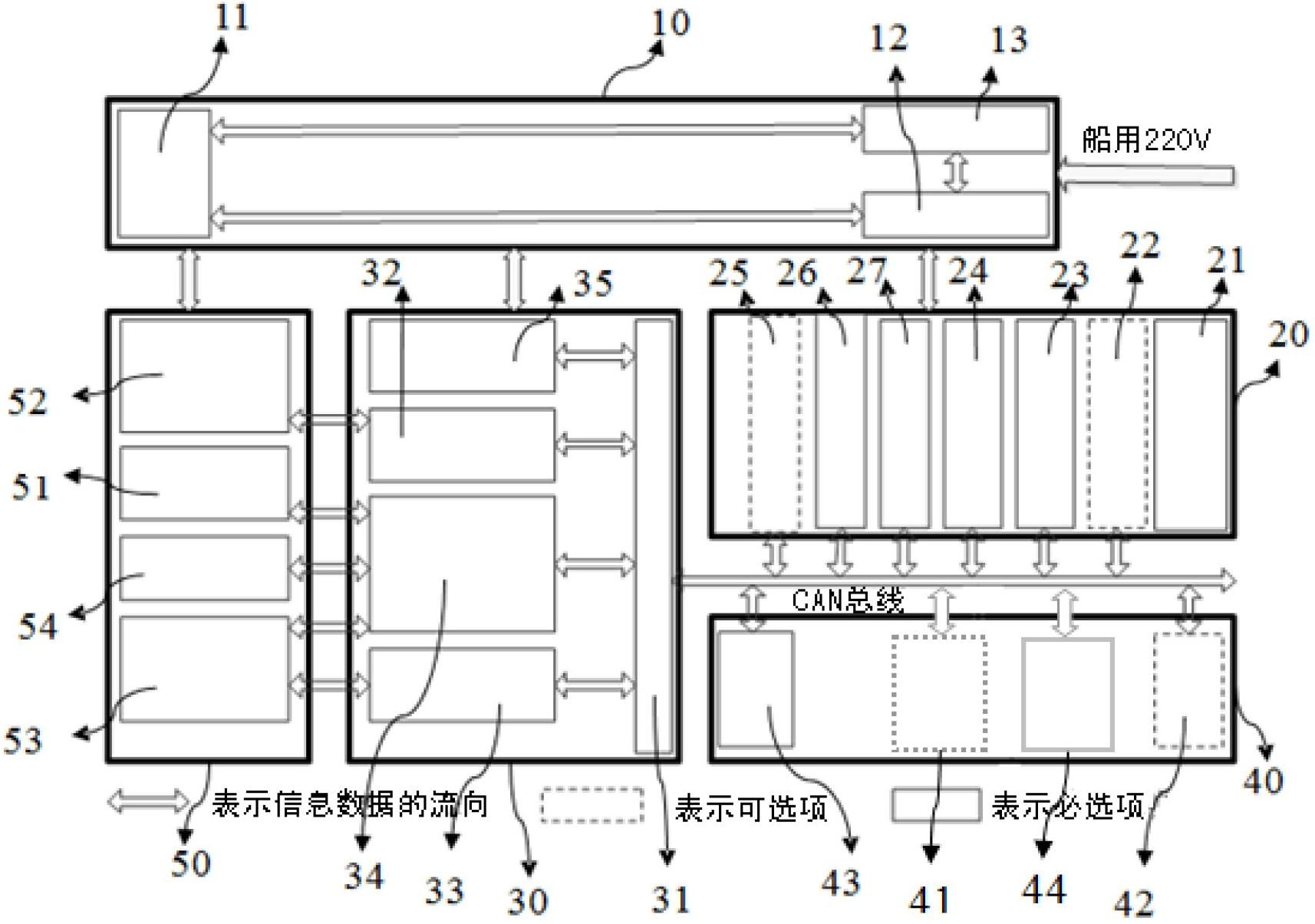

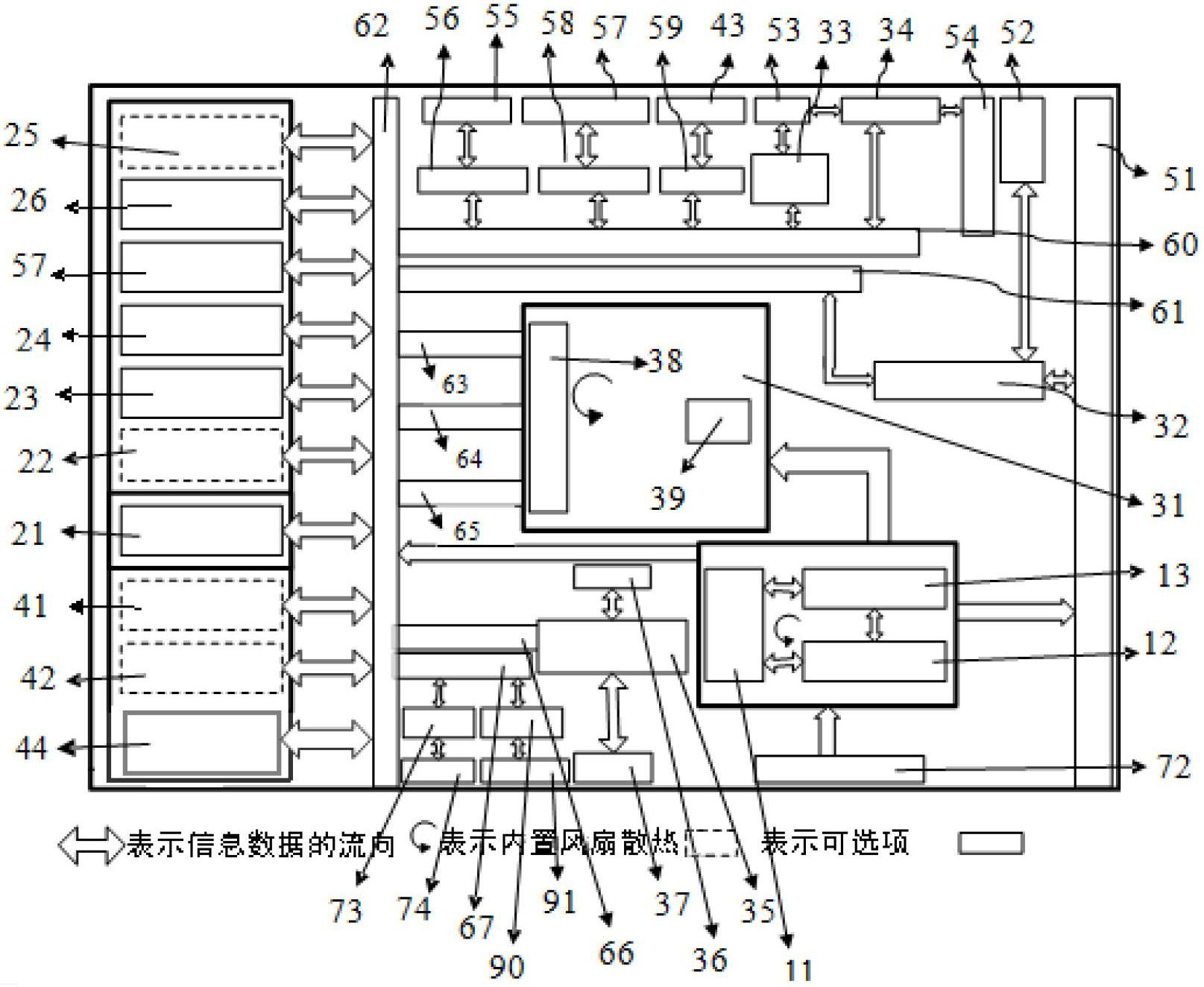

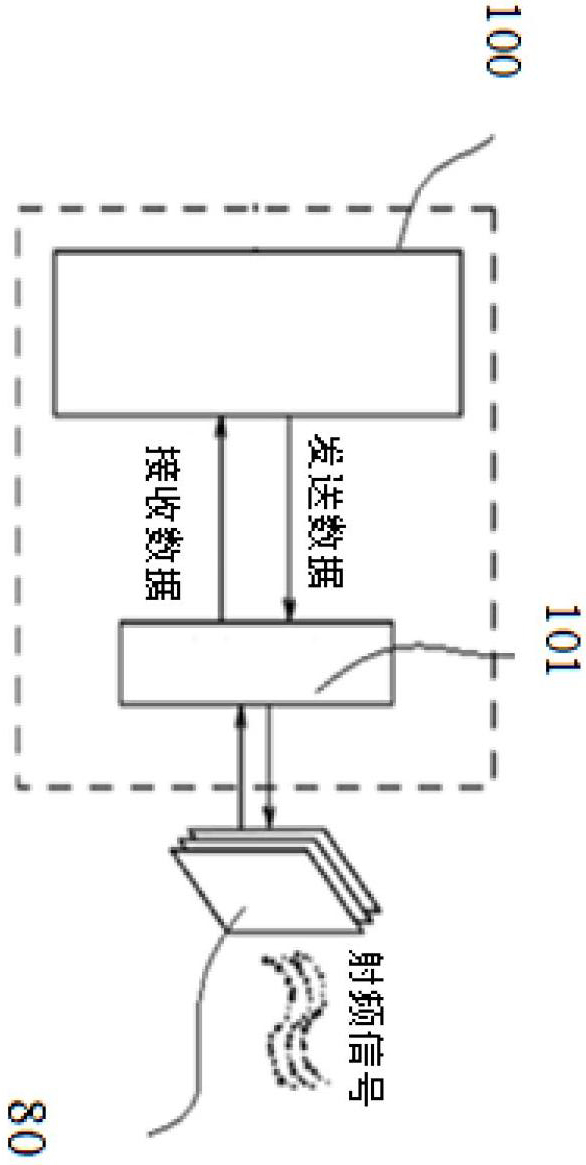

Intelligent ship-borne terminal device for inland waterway intelligent shipping information service

InactiveCN102663899AImplement IntelliSenseAchieve aggregationNavigational aid arrangementsMarine craft traffic controlThe InternetGlobal Positioning System

The invention discloses an intelligent ship-borne terminal device for inland waterway intelligent shipping information service. The ship-borne terminal device consists of a power supply module, a data collection module, a main control module, a communication module and a human-computer interaction module; and an online analysis processing technology, multiple sensing technologies (global positioning system (GPS), automatic identification system (AIS), wireless frequency identification devices (RFID), sensors and videos) and a communication technology are utilized by the invention to realize the automatic identification of a ship identity and the perception of a running status of the ship by aggregating, rebuilding and interacting polymorphic heterogeneous data under the sailing status of the inland waterway ship, so that solid guarantee can be provided for the ship data perception of an inland waterway intelligent shipping information service system, the realization of ship-ship interconnection, ship-bank interconnection and ship-cargo interconnection and for the safe sailing and high efficient transportation of inland waterway ships in China, and the rapid development of the inland waterway intelligent shipping information service (internet of ships) can be promoted.

Owner:SHANGHAI MARITIME UNIVERSITY

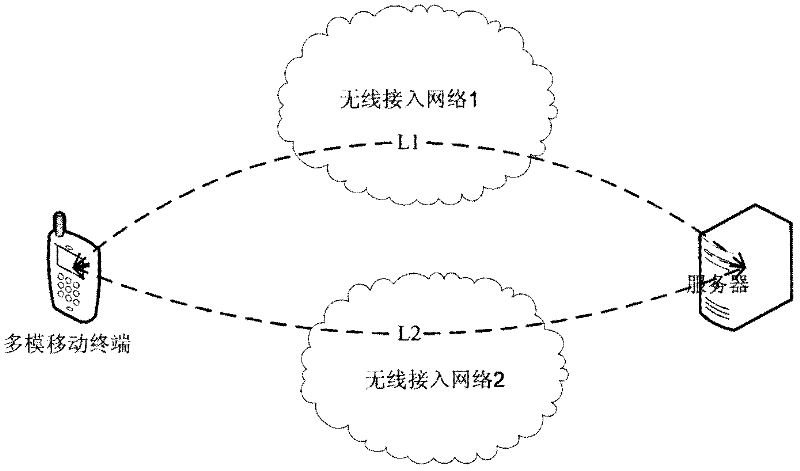

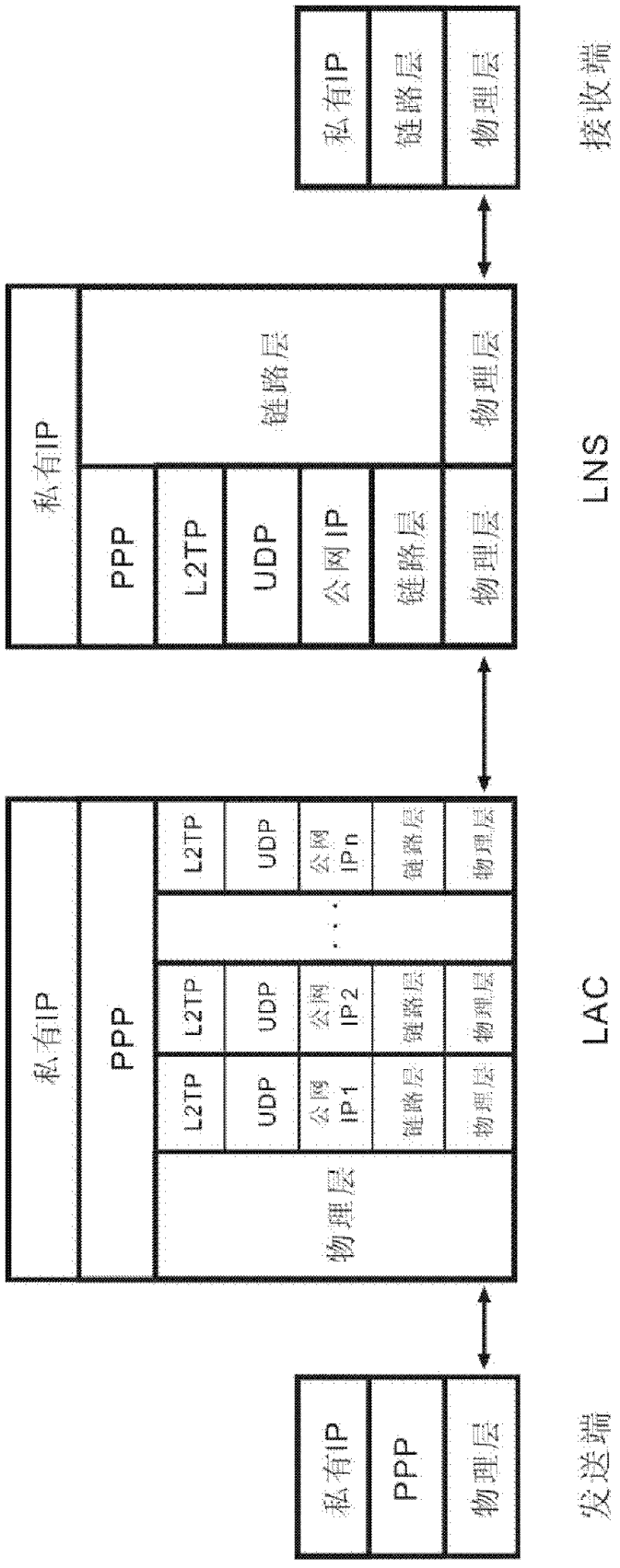

Multi-link aggregated data transmitting method and system

InactiveCN102404221AHigh bandwidthSolve the problem of limited data transmission bandwidthData switching networksTerminal equipmentThe Internet

The invention discloses a multi-link aggregated data transmitting method and a system, which is applied to systems comprising L2TP VPN of LAC and LNS. The method comprises the following steps: building a plurality of L2TP tunnels on a plurality of links between the LAC and the LNS; receiving the IP message coming from a piece of transmitting terminal equipment by the LAC, and executing the PPP encapsulation; transmitting the PPP frames to the LNS through the multiple L2TP tunnels built on the VPN; decapsulating the received PPP frames by the LNS as the original IP message transmitted by the transmitting terminal equipment, and transmitting to a piece of receiver terminal equipment. The multiple links can be aggregated as one logic link based on un-changing the source address and the destination address of the service and un-changing the original port, so seamless connection with the current internet can be realized. The method and system can be applied to communications of various service application types and have good university.

Owner:廖小明

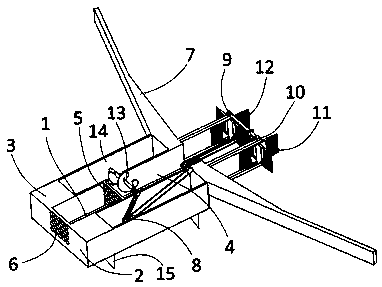

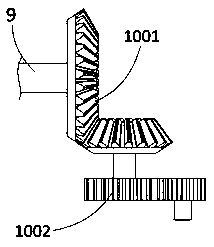

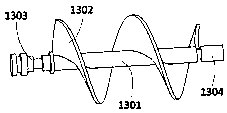

Floating object on water cleaning device and cleaning method thereof

ActiveCN109853500AAchieve aggregationRealize automatic recyclingWater cleaningWaterborne vesselsReciprocating motionWater flow

The invention discloses a floating object on water cleaning device and a cleaning method thereof, and belongs to environmental protection devices. The floating object on water cleaning devicecomprisesabasic assembly, a collection assembly, a cleaning assembly, and a fixingassembly;the base assembly comprises a water flow passage between hulls, a filter screen arranged on the water flow passage, and floating fencesarranged on the outer sides of the hulls; the collecting assembly comprises a first servo motor, rotating bladesconnected with the first servo motor through a transmission assembly; the cleaning assembly comprises a threaded rollerconnected with the first servo motor; and the fixing assembly comprises a plurality of retractable anchors at the bottoms of the hulls. According to thefloating object on water cleaning device and the cleaning method thereof,a cleaning device is fixed in a narrow water area by the retractable anchors and a fixing cable, garbage is gathered and collected by utilizing the fluidity of the water flow in the water area; or the collecting device is driven by a tractor boat to be inan S-shaped reciprocating motionina contaminated area, the gathering and collection of the garbage are achieved,and the problem of floating garbage cleaning in small water areas is solved.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

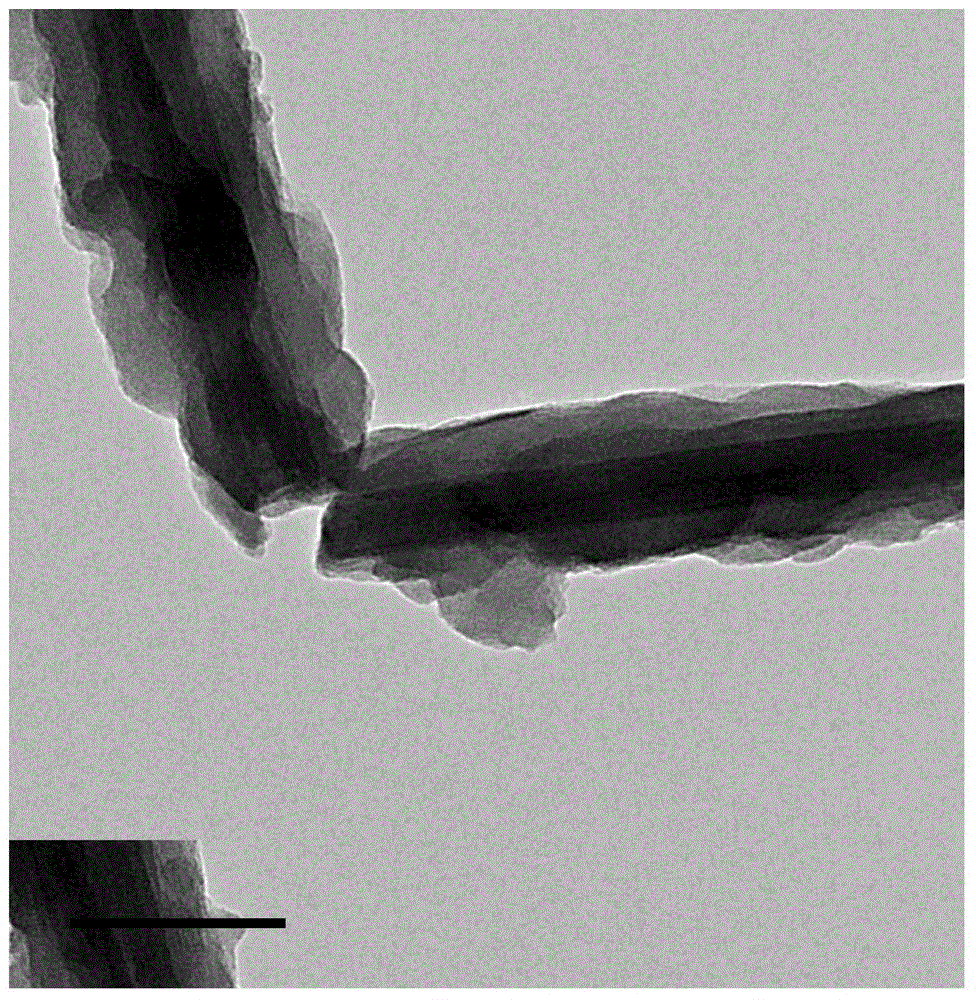

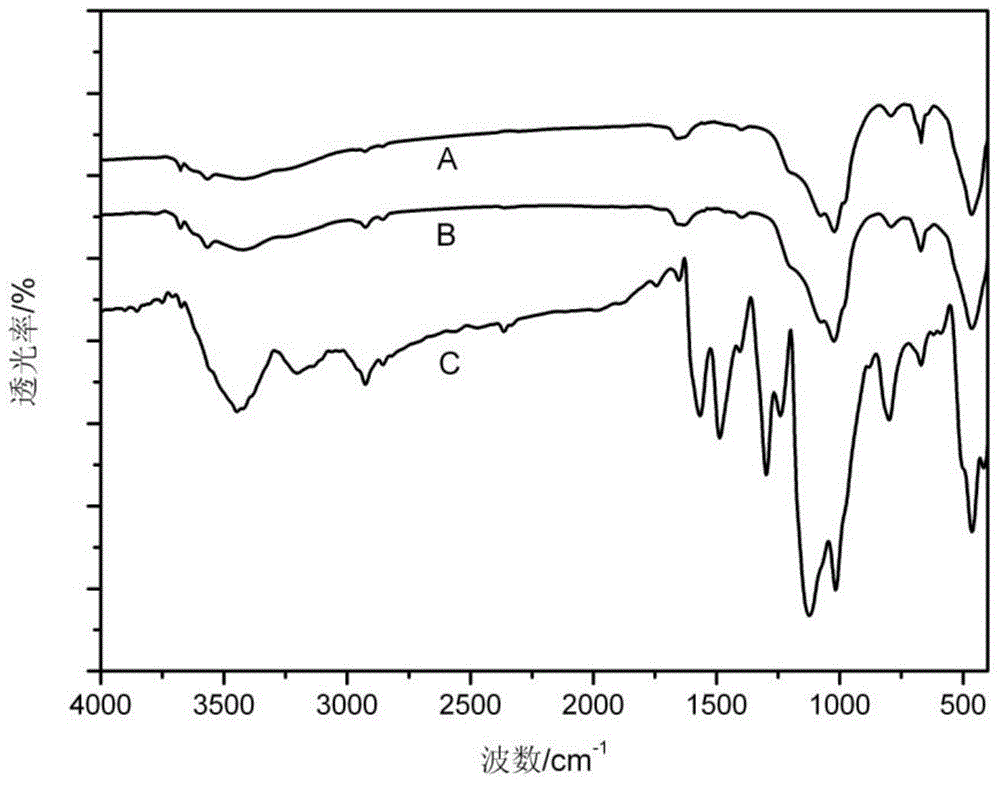

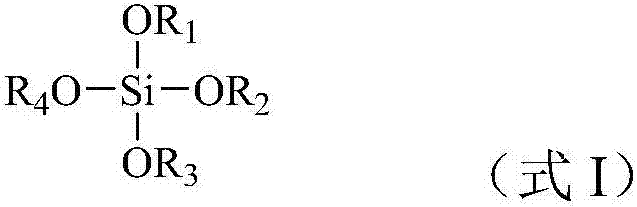

Preparation method of sepiolite/polyaniline nanocomposite material

The invention discloses a preparation method of a sepiolite / polyaniline nanocomposite material. The preparation method is characterized by comprising the following steps: mixing sepiolite with water, standing, filtering an upper-layer sepiolite suspension liquid, washing with water, and drying to obtain washed sepiolite; mixing the washed sepiolite with hydrochloric acid, stirring in a water bath, filtering, washing solids with water, and drying to obtain acid activated sepiolite; mixing the acid activated sepiolite with an organic solvent, adding amino-carrying silane coupling agent, mixing, stirring in the water bath, filtering, washing, and drying to obtain organized modified sepiolite; mixing the organized modified sepiolite with water into a dispersion liquid; adding a dopant and phenylamine while stirring, cooling, adding an oxidant for stirring, reacting and then washing and drying materials, to obtain a product sepiolite / polyaniline nanocomposite material. The prepared composite material has high electric conductivity and high specific capacitance, and is applicable to the fields of a supercapacitor electrode material, a secondary material, an electromagnetic shielding material and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

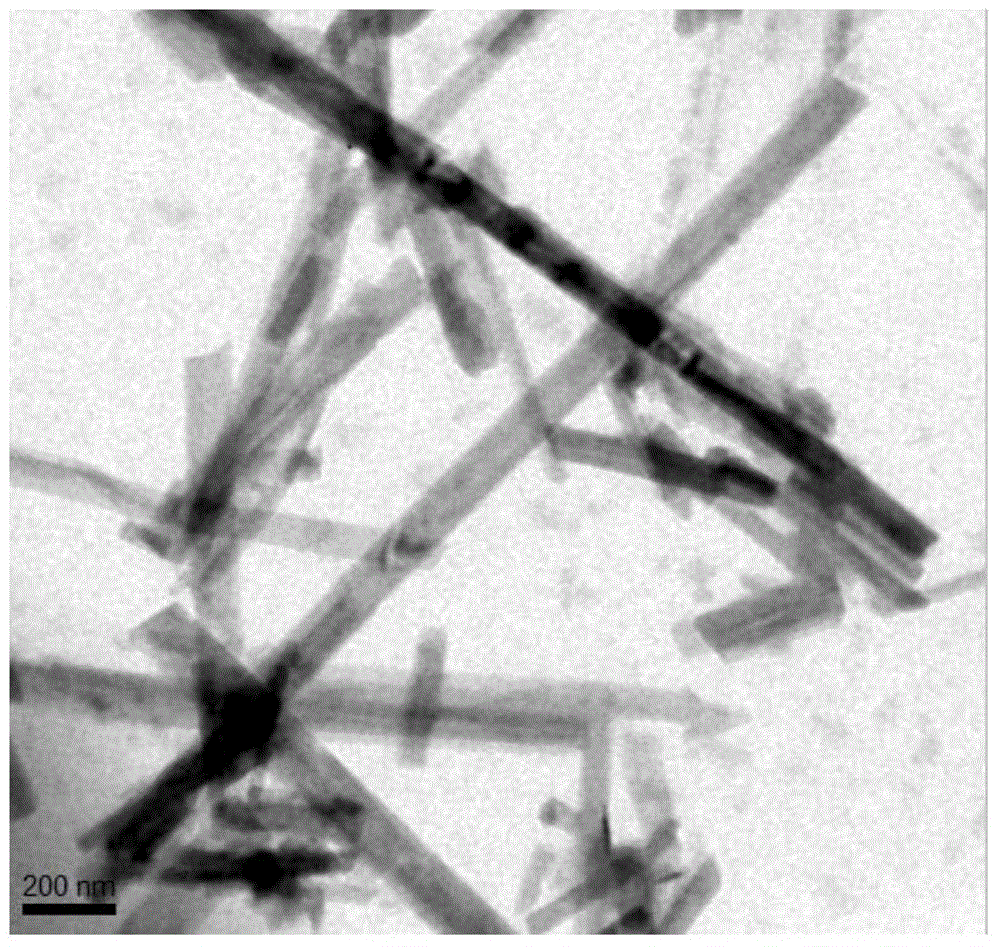

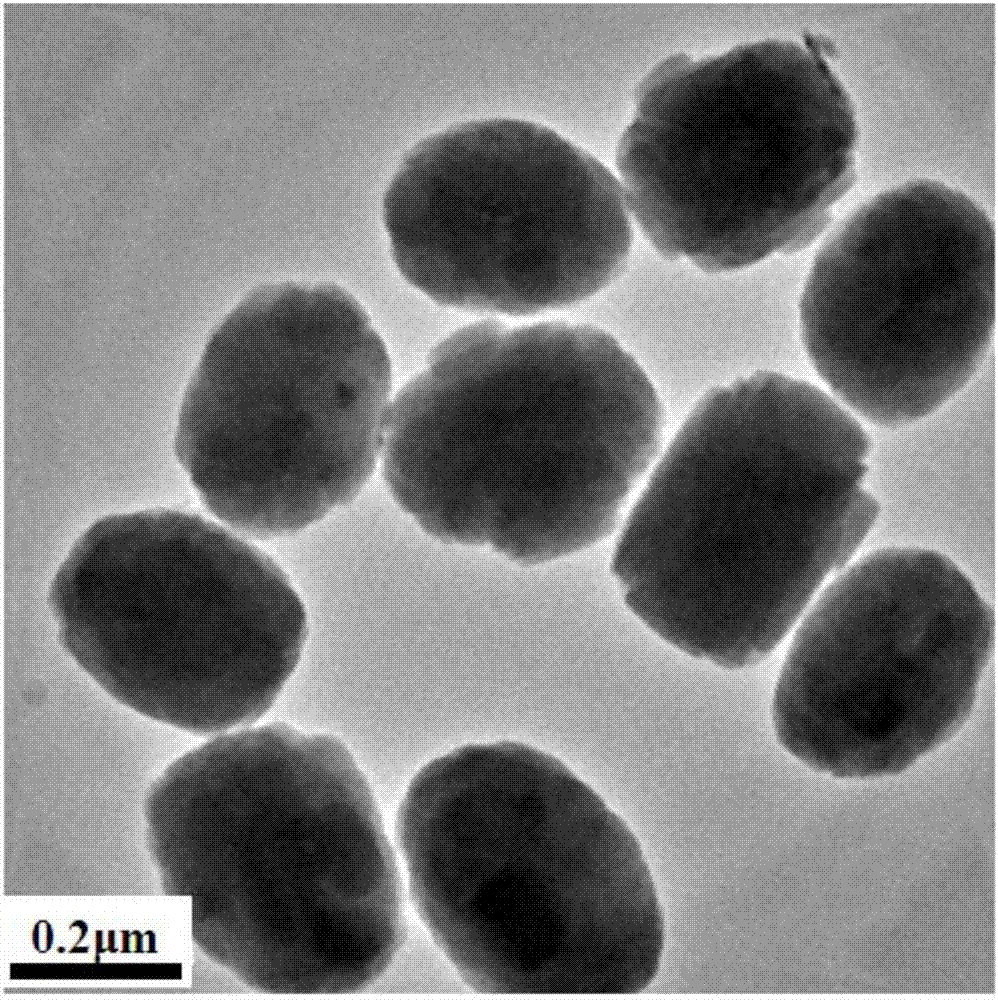

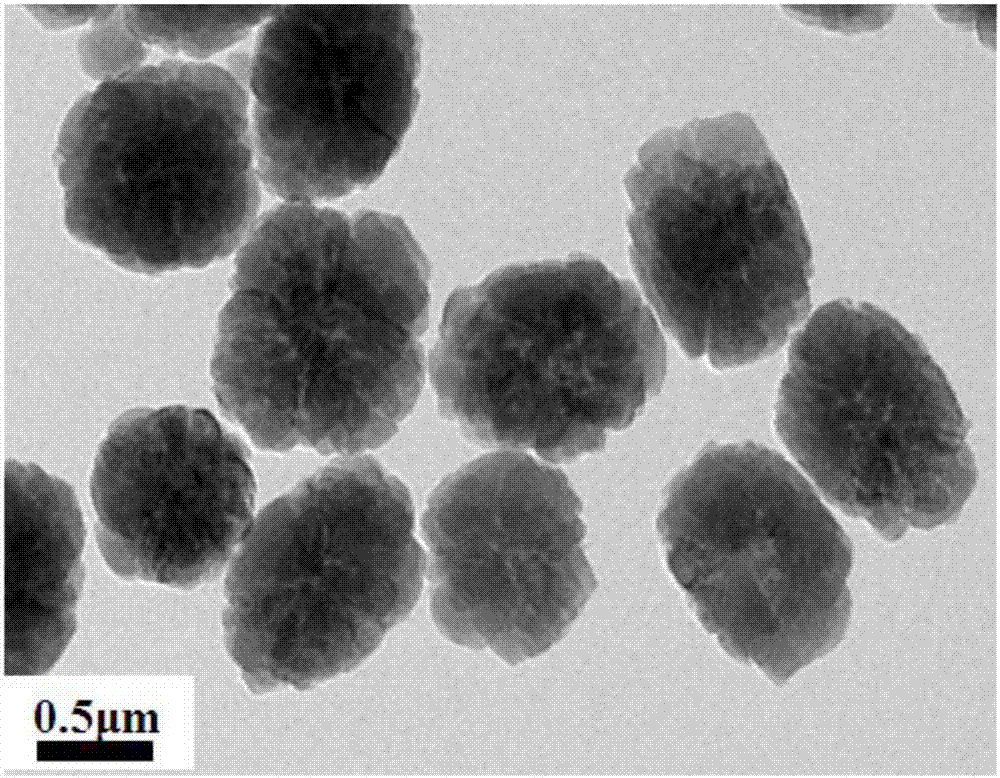

Titanium silicon molecular sieve, synthetic method and applications thereof, and cyclic ketone oxidation method

ActiveCN107539998AImprove stabilityFacilitated DiffusionMaterial nanotechnologyMolecular sieve catalystsMolecular sieveSynthesis methods

The invention belongs to the field of titanium silicon molecular sieve, and more specifically provides a titanium silicon molecular sieve, and a synthetic method and applications thereof. The titaniumsilicon molecular sieve is composed of crystal particles with a particle size ranging from 5 to 200nm via aggregation; the particle size of the titanium silicon molecular sieve ranges from 0.3 to 5<mu>m; the I960 / I550 value ranges from 0.7 to 0.85. The invention also provides a cyclic ketone oxidation method. The cyclic ketone oxidation method comprises a step of contact of cyclic ketone, and anoxidizing agent with a catalyst. The catalyst contains the titanium silicon molecular sieve. The crystal of the titanium silicon molecular sieve is high in I960 / I550 value, and is large in effective framework ti content. When the titanium silicon molecular sieve is used in oxidation reaction, the catalytic oxidation activity, and the reaction product selectivity are increased obviously, and excellent catalytic stability is achieved. The titanium silicon molecular sieve is capable of realizing aggregation of small crystal particles in crystallization growth process instead of simple physical aggregation of the small crystal particles, and micron order is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

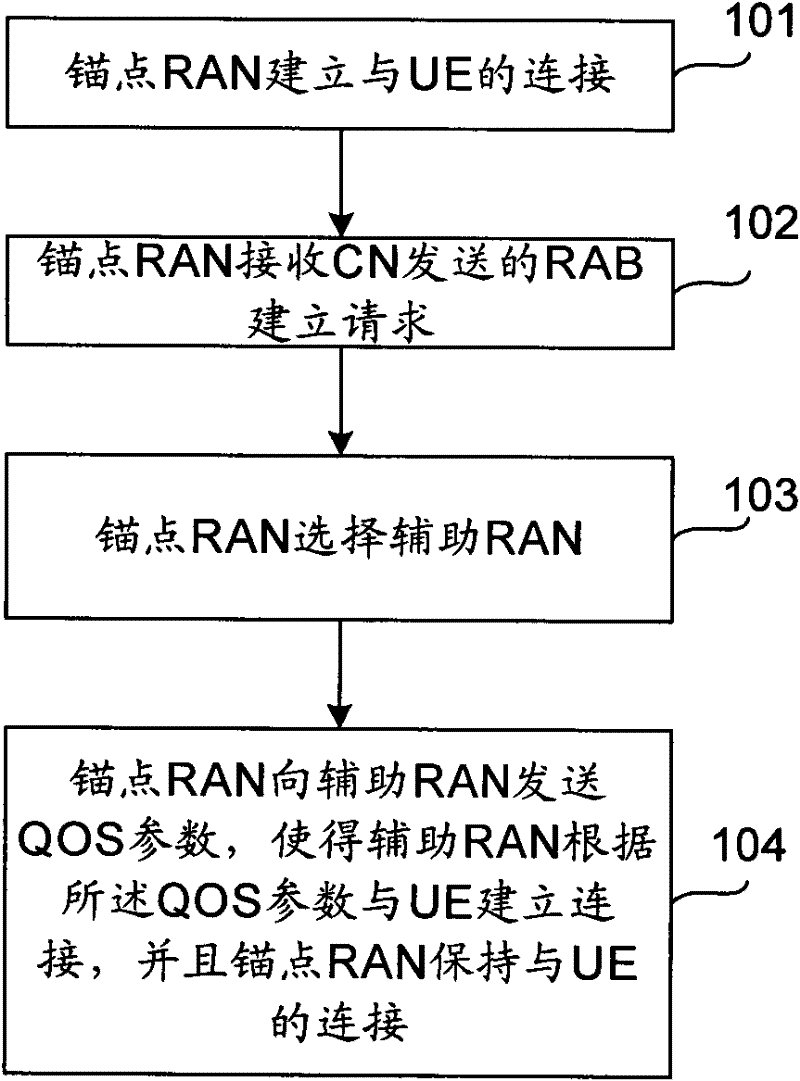

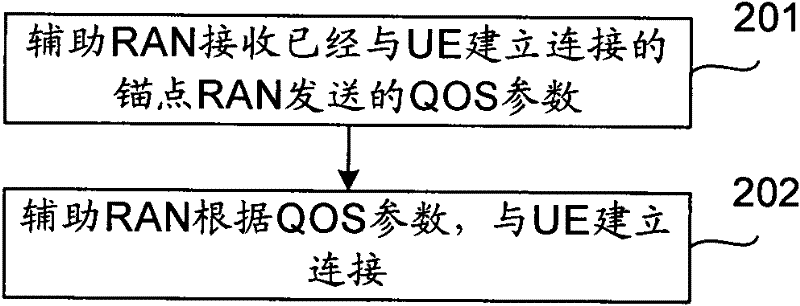

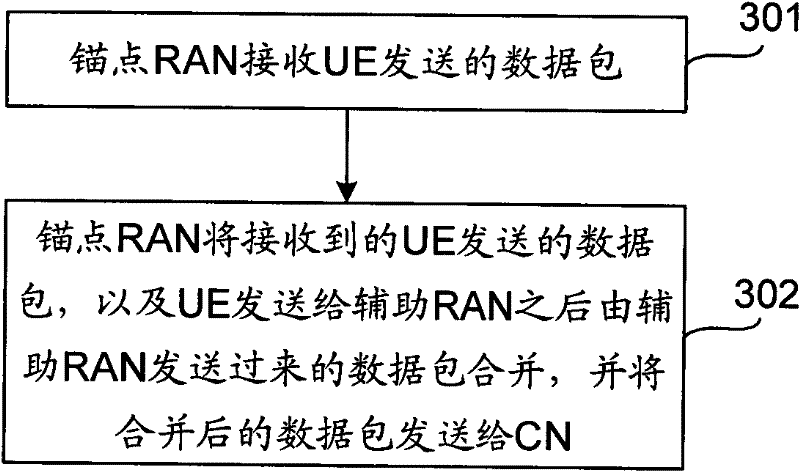

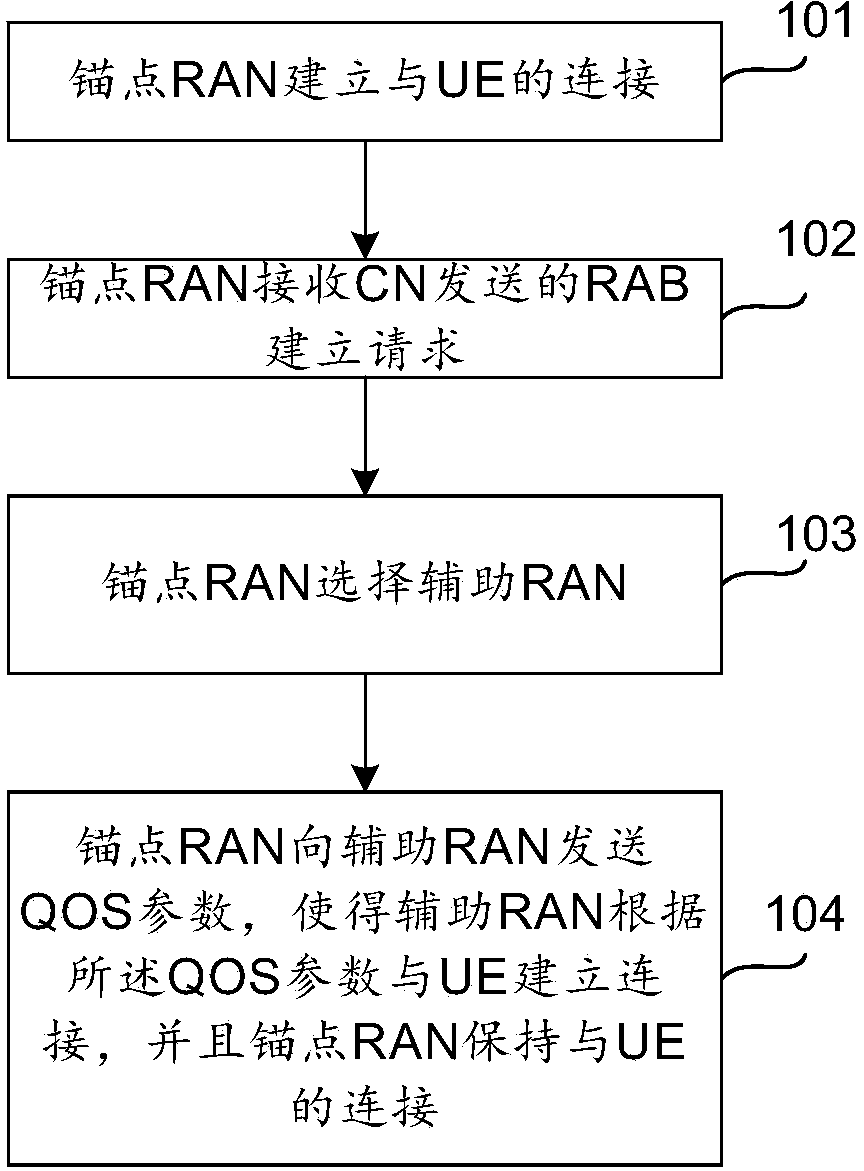

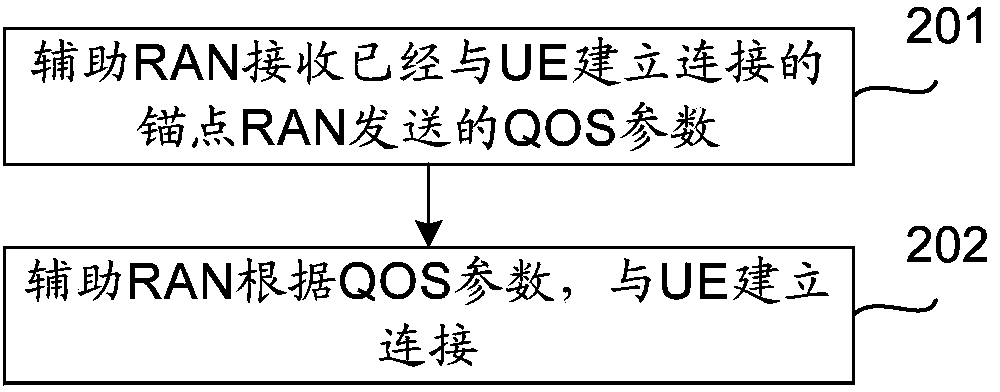

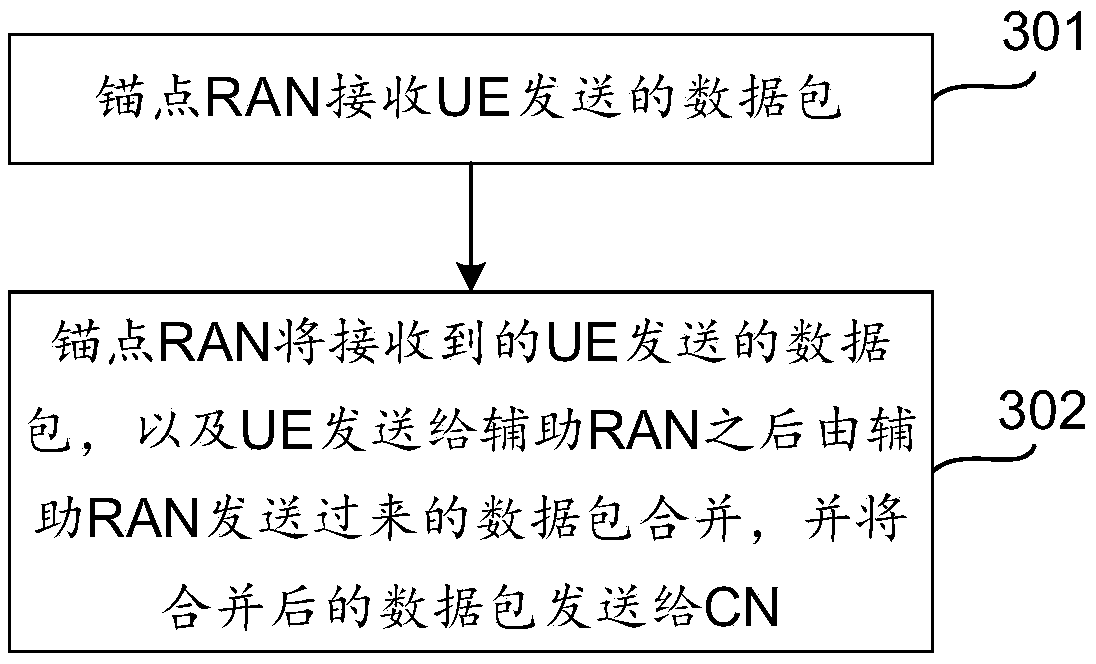

Multi-radio access network aggregation system, implementation method and network element of access network

ActiveCN102348256AAchieve aggregationIncrease peak rateNetwork traffic/resource managementAssess restrictionQuality of serviceAccess network

The invention provides a multi-radio access network aggregation system, an implementation method and a network element of an access network. The method comprises that: an anchor radio access network (RAN) establishes connection with user equipment (UE); the anchor RAN receives a radio access bearer (RAB) establishment request from a core network (CN); the anchor RAN selects secondary RANs; and the anchor RAN transmits a quality of service (QOS) parameter to the secondary RANs, so that the secondary RANs establish connection with the UE according to the QOS parameter, and the anchor RAN keeps the connection with the UE. By the method provided by the embodiment of the invention, the aggregation of a plurality of RANs is realized; and the UE can establish the connection with the anchor RAN and the secondary RANs at the same time, so the peak rate of the UE can be increased.

Owner:HUAWEI TECH CO LTD

Method for smelting reduction production of zinc smelting slag

InactiveCN107699699ASolve the accumulationTake advantage ofProcess efficiency improvementIndiumBismuth

The invention discloses a method for smelting reduction production of zinc smelting slag. The method for smelting reduction production of the zinc smelting slag comprises the following steps that S1,the zinc smelting slag is added into an insulation device or a smelting reaction device allowing slag to flow out, calcium minerals and additives are added, all the components are heated to be in themolten state, one or more of copper oxide minerals, copper sulfide minerals and copper-containing materials are added into the insulation device or the smelting reaction device at the moment, reactionslag is monitored in real time, and molten slag is obtained by regulating and controlling the temperature and the CaO / SiO2 basicity ratio of the reaction slag; and S2, the molten slag is obtained, aferrum-containing silicate mineral phase, a copper-rich phase, a ferrum-rich phase and dust containing zinc, lead, bismuth and smoke are obtained through settlement separation, gold and silver are migrated and enriched to enter the copper-rich phase, and all the phases are separated. According to the method for smelting reduction production of the zinc smelting slag, the slag copper content (lowerthan 0.1 wt%) can be decreased, efficient recovery of components such as copper, ferrum, gold, silver, lead, zinc, indium, bismuth, sodium and potassium can be achieved, and low-copper ferrum-containing materials are obtained; and the metal recovery rate is high, the production cost is low, environmental friendliness is achieved, and economic benefits are high.

Owner:NORTHEASTERN UNIV

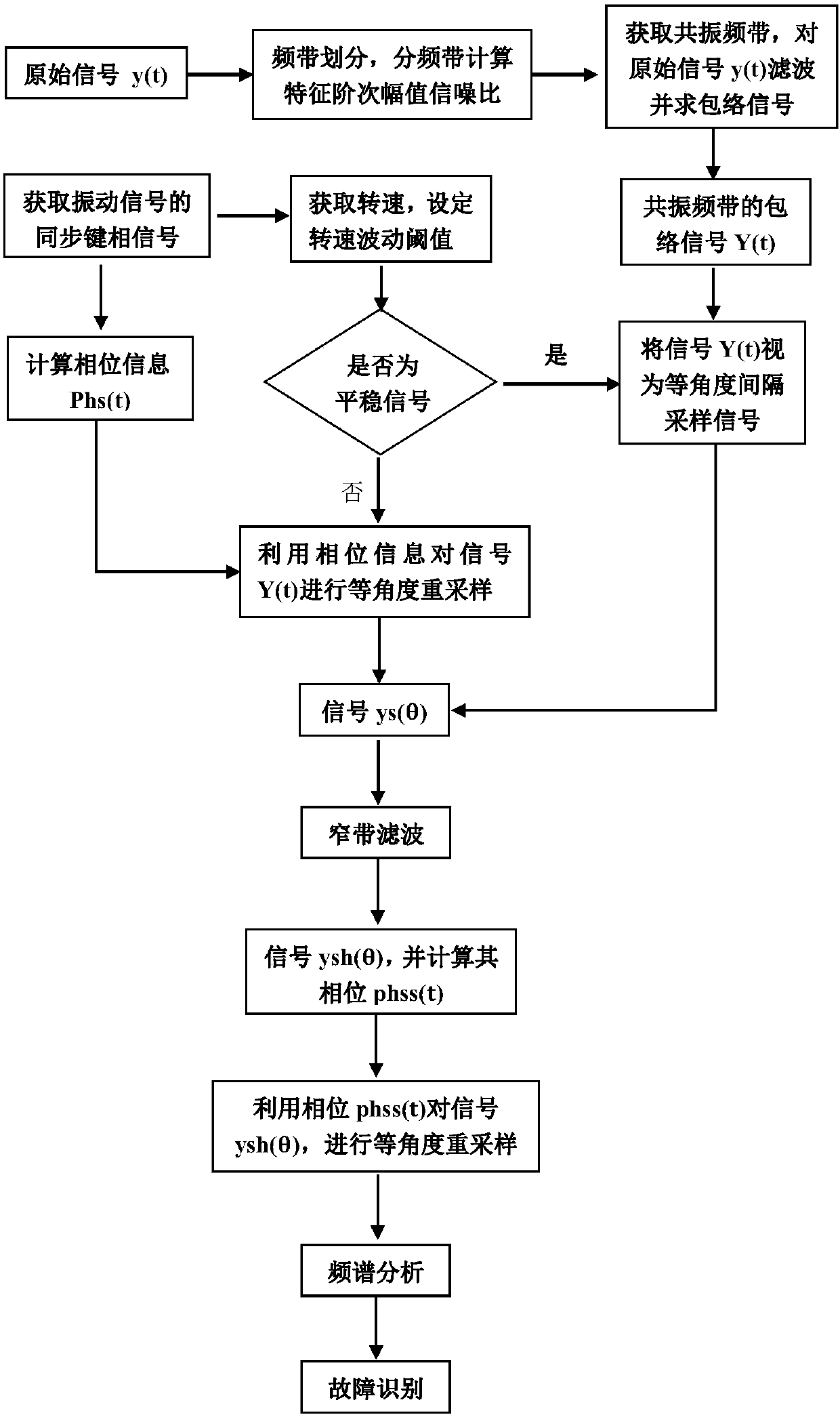

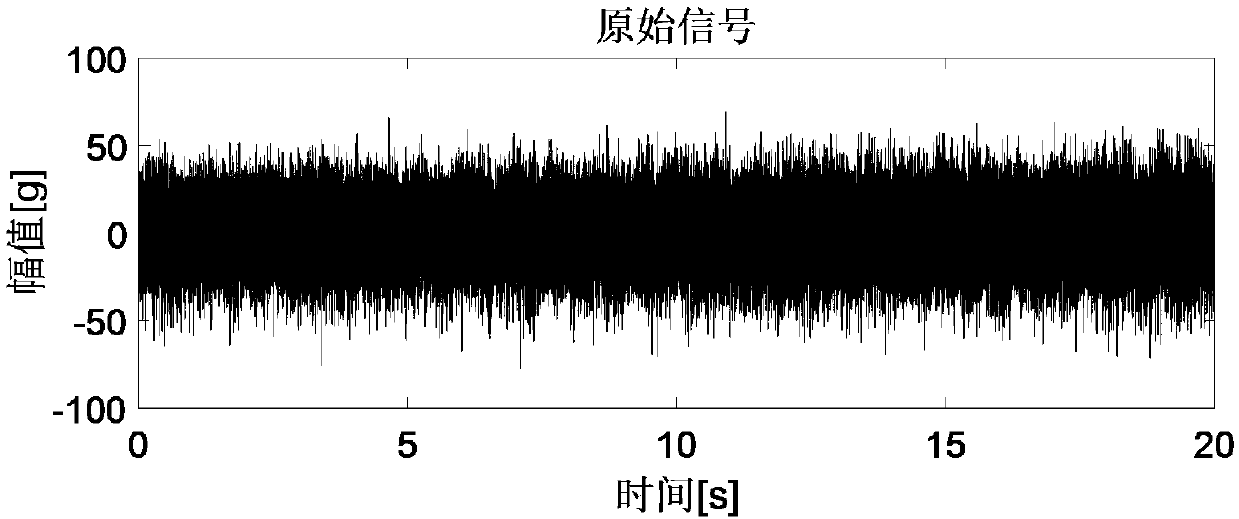

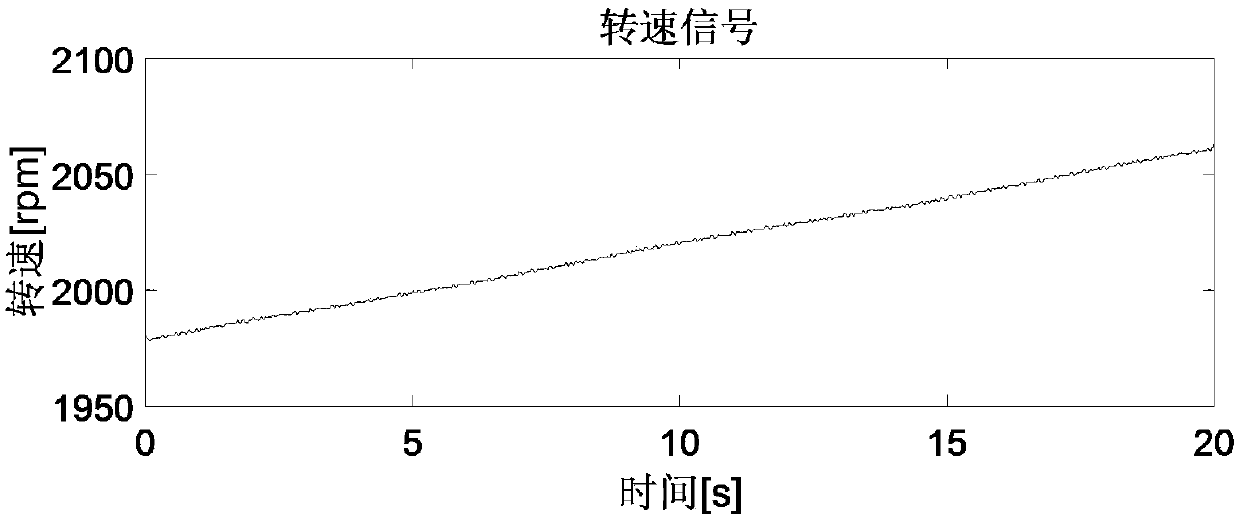

Method for extracting fault features of rolling bearing based on equal-angle double sampling

ActiveCN107941510AEasy to identifyOvercome the problem of frequency aliasingMachine bearings testingResonanceEngineering

The invention discloses a method for extracting fault features of a rolling bearing based on equal-angle double sampling. The method comprises the steps of: acquiring an envelope signal of a resonancefrequency band signal, calculating a rotation speed by using a key-phase signal, determining whether the rotation speed is stable by setting a threshold value, performing primary equal-angle re-sampling on an envelope signal of a resonance frequency band of a variable rotation speed signal exceeding a threshold value range by utilizing phase information, regarding the envelope signal of the resonance frequency band as an equal-angle re-sampling signal of the resonance frequency band when fluctuations of the rotation speed do not exceed the threshold value, and calculating an envelope signal of the equal-angle re-sampling signal; and performing secondary narrow-band filtering on the equal-angle re-sampling signal while only reserving feature orders of interest, calculating phases of a narrow-band signal, performing secondary re-sampling on the narrow-band signal by utilizing the calculated phases, and realizing extraction of the fault features of the rolling bearing by means of an envelope order spectra of a double sampling signal. The method can obviously suppress the aliasing phenomenon of feature orders caused by random sliding of a rolling body, realize the aggregation of the fault feature order energy, and enhance the fault features.

Owner:XI AN JIAOTONG UNIV

Method for recycling valuable components from copper-containing slag

InactiveCN107699702ARealize comprehensive utilizationTake advantage ofProcess efficiency improvementHeavy metalsCalcium

The invention relates to a method for recycling valuable components from copper-containing slag. The method includes the steps that S1, clinker is mixed, wherein copper slag is added in a smelting reaction device, calcium-series mineral and an additive are added, mixed slag is formed, the mixed slag is heated to the molten state to be used as reaction slag and is evenly mixed, the reaction slag ismonitored in real time, the mixed reaction slag is made to meet the condition a and the condition b at the same time through regulation and control, and slag subjected to reaction is obtained; and S2, separation and recycling are conducted. By means of the method, hot-state slag can be processed, molten copper slag physical heat resources and hot-state metallurgy flux are sufficiently utilized, cold-state clinker can also be processed; by adjusting the physicochemical property of the slag and using the mature physicochemical property of the copper-containing slag, the copper-containing slag metallurgy process is achieved, and the problem that because a large amount of clinker is stacked at present, environment pollution is caused and the problem of heavy metal element pollution are solved.

Owner:NORTHEASTERN UNIV

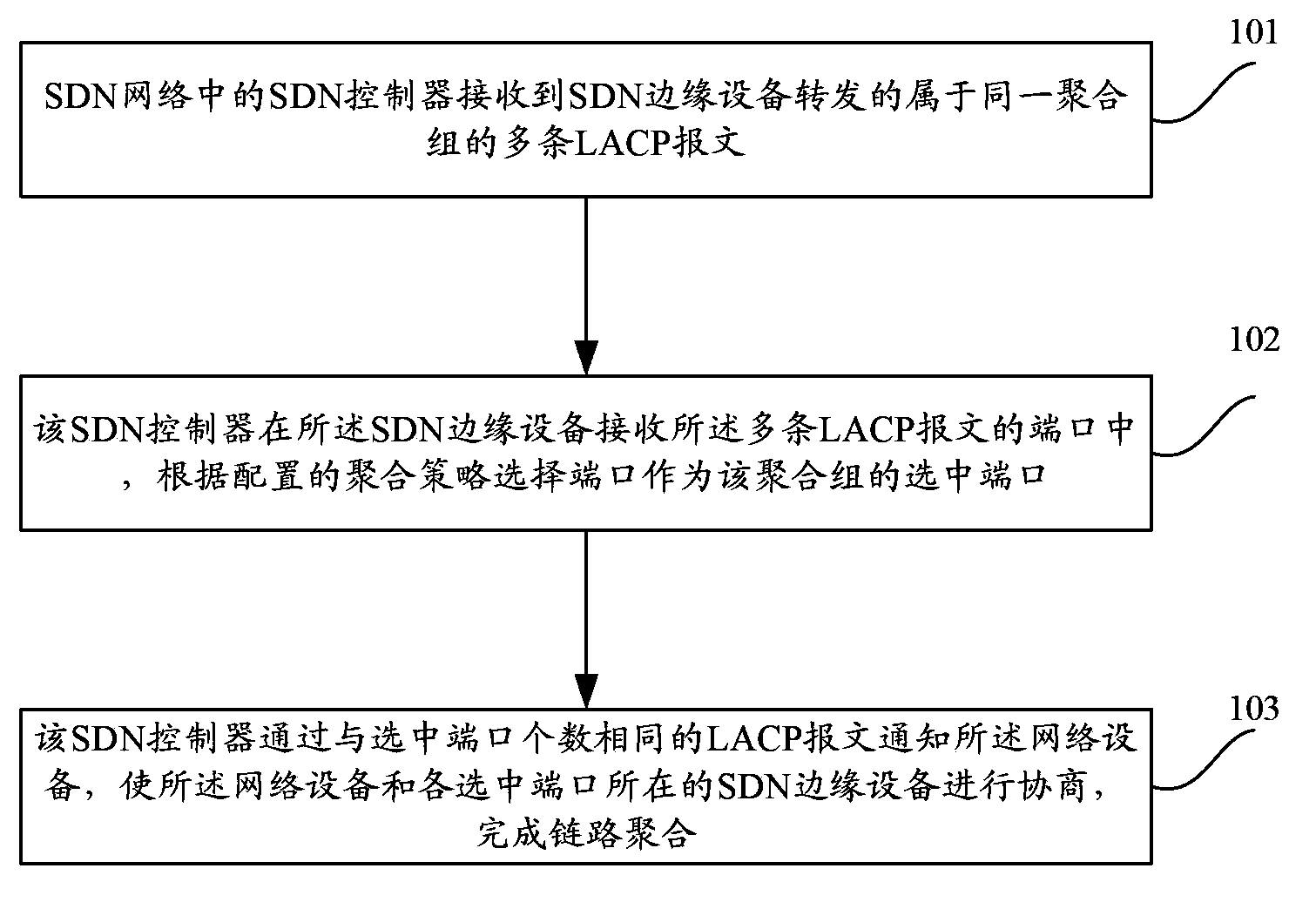

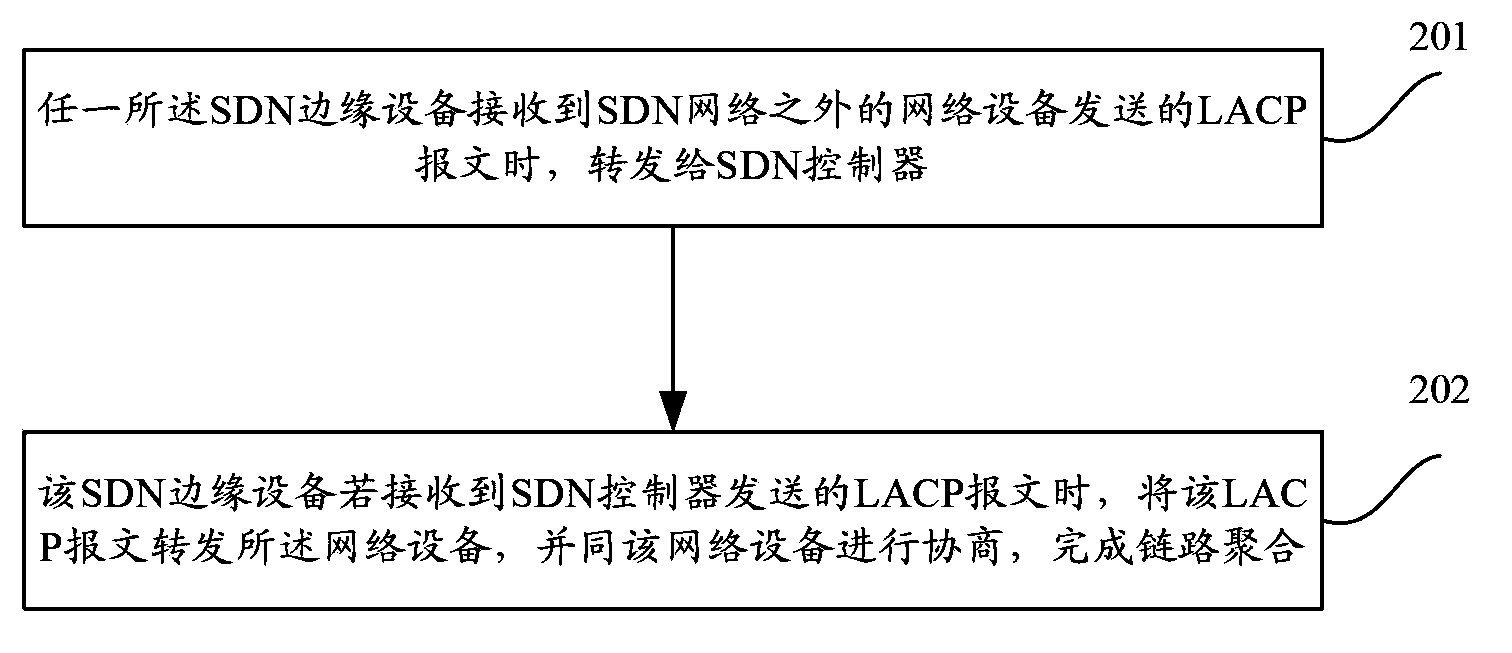

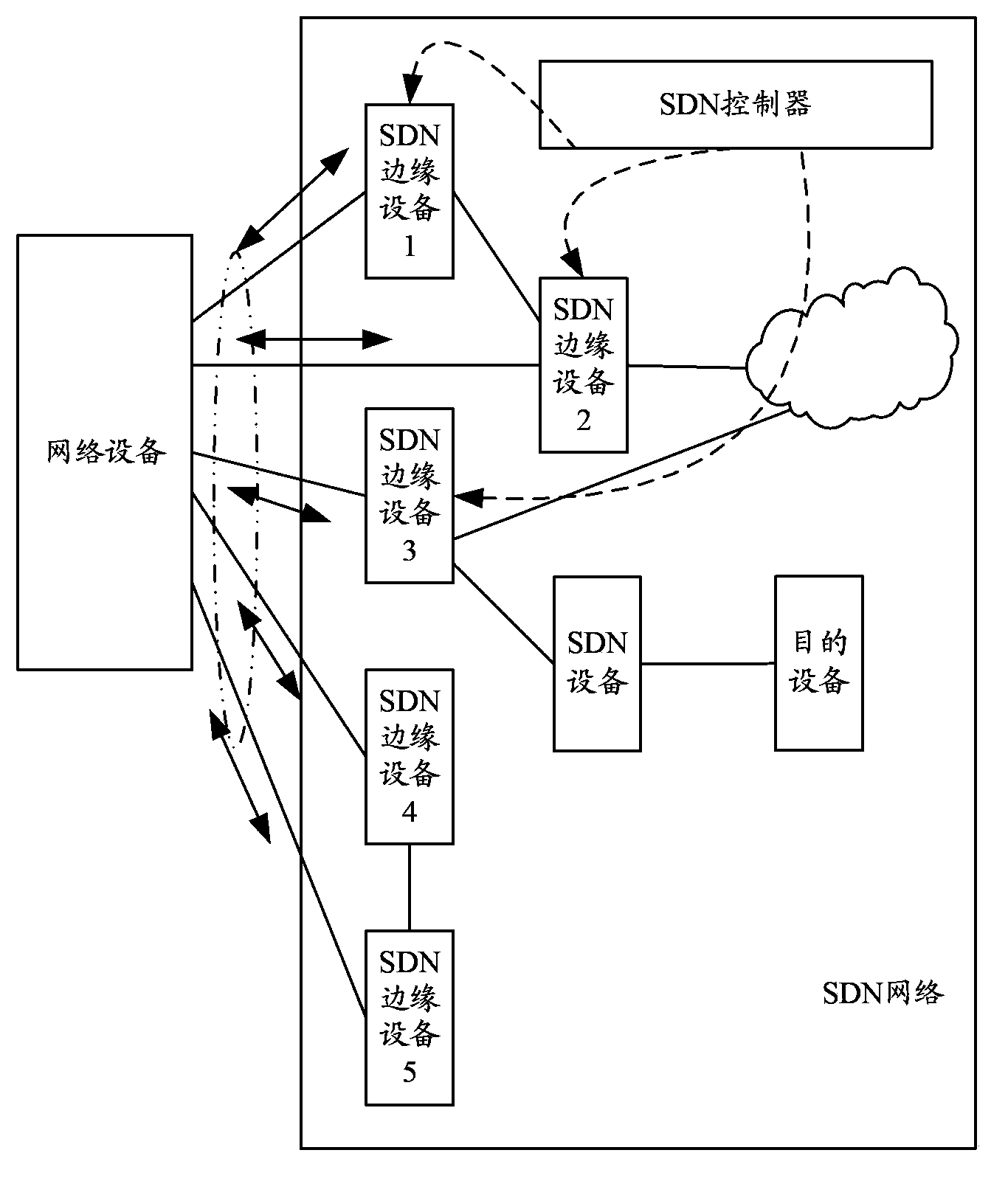

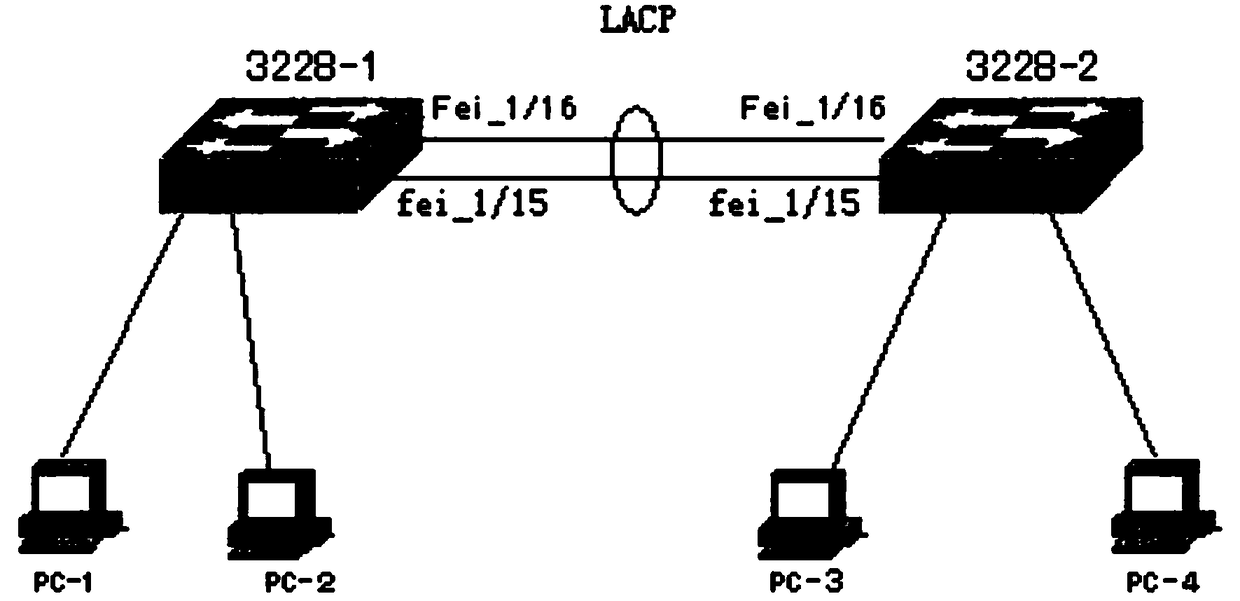

Link aggregation method and device

The invention discloses a link aggregation method. The link aggregation method includes that an SDN (software defined networking) controller selects some ports as selected ports of an aggregation group from ports receiving the LACP messages on an SDN edge device via configured aggregation strategies according to LACP (link aggregation control protocol) messages transferred by the SDN edge device, and the LACP messages in the number identical with the selected ports are transmitted to notify a network device, so that the network device negotiates with the SDN edge device where the selected ports are located to complete link aggregation. On the basis of the same above idea, the invention further provides a link aggregation device through which the link aggregation of the SDN edge device and the network device outside the SDN network is realized.

Owner:NEW H3C TECH CO LTD

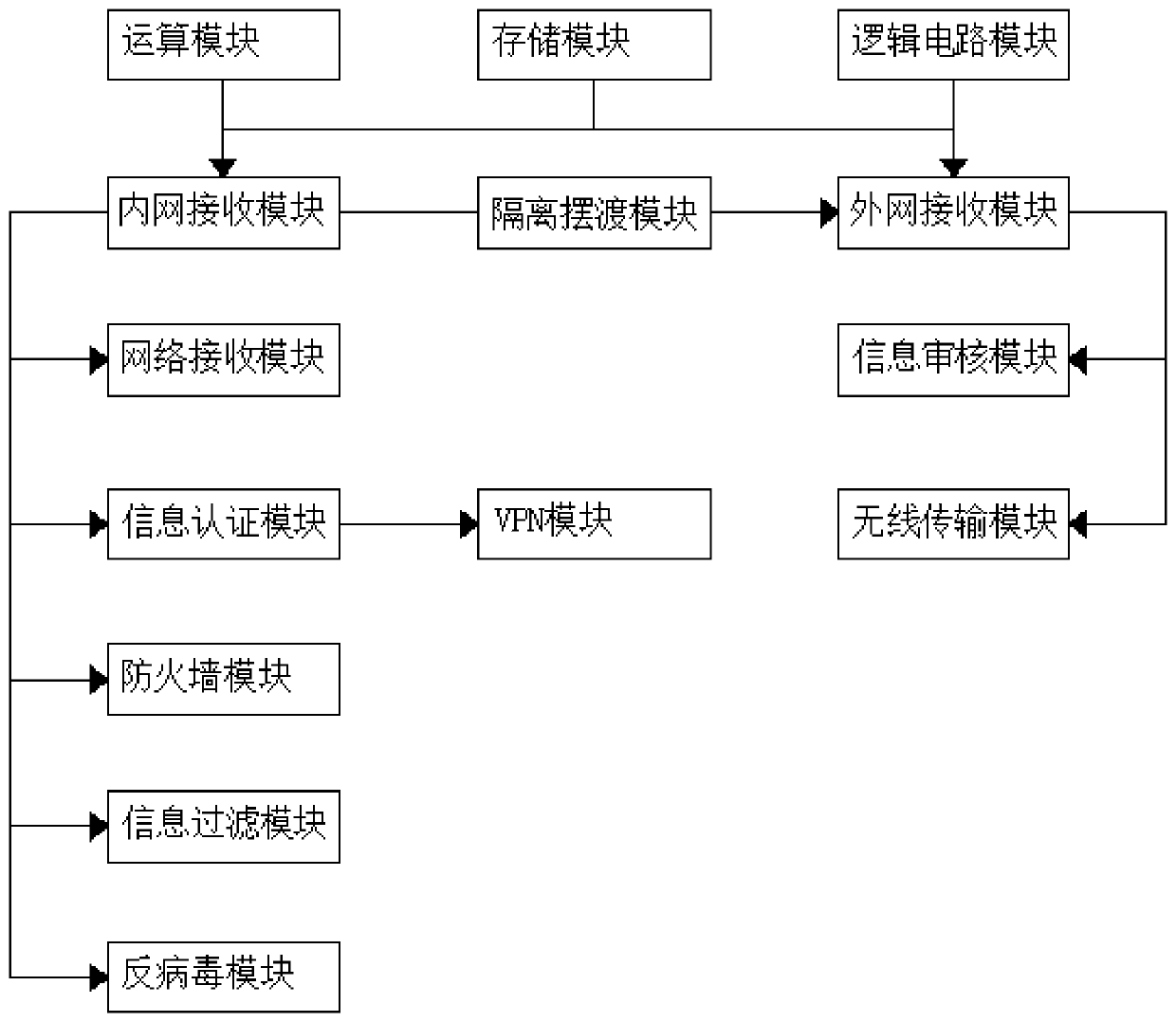

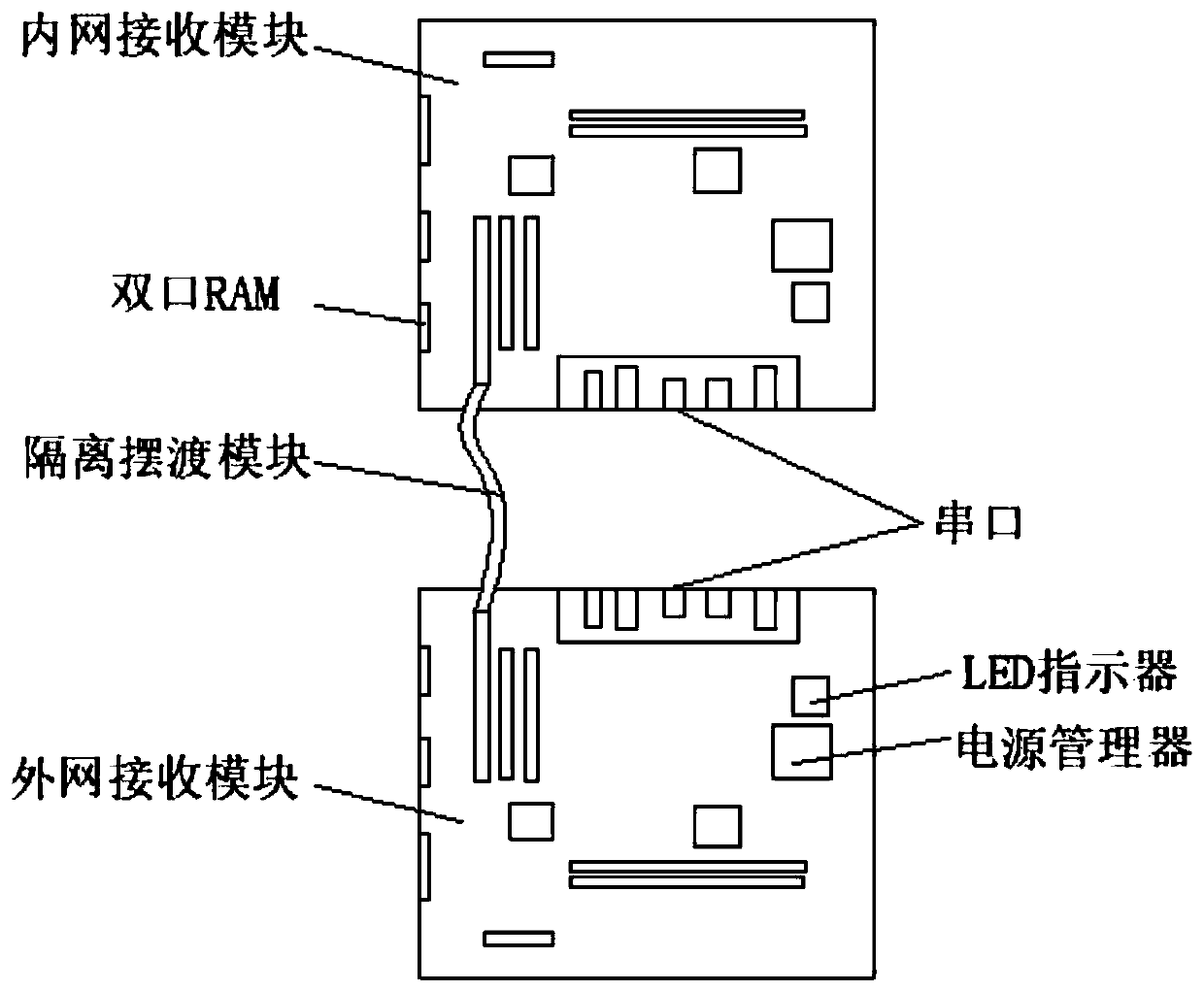

Industrial security isolation gateway

InactiveCN110943913ASafe and stable operationImprove reliabilityNetwork connectionsAnti virusInformation networks

The invention discloses an industrial security isolation gateway. The gateway comprises an external network receiving module, an internal network receiving module and an isolation ferry module. The external network receiving module and the internal network receiving module are two independent control systems. Each of the modules comprises an operation module, a storage module and a logic circuit module. Data transmission is carried out between the external network receiving module and the internal network receiving module through the isolation ferry module. The transmission process comprises protocol stripping, verification, encryption, decryption and storage processes, and the external network receiving module comprises a network receiving module, an information authentication module, a firewall module, an information filtering module and an anti-virus module. According to the invention, data security isolation between an industrial network and an information network can be realized,the reliability is improved by combining physical isolation and logic isolation, the functions of data encryption, virus prevention, network firewall, user authentication, intrusion prevention and thelike are supported, and the safe and stable operation of an industrial control system can be ensured.

Owner:广东互动电子有限公司

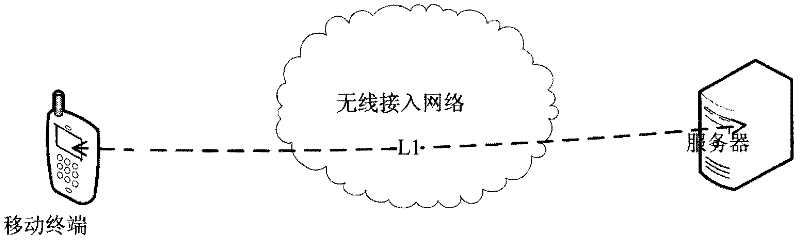

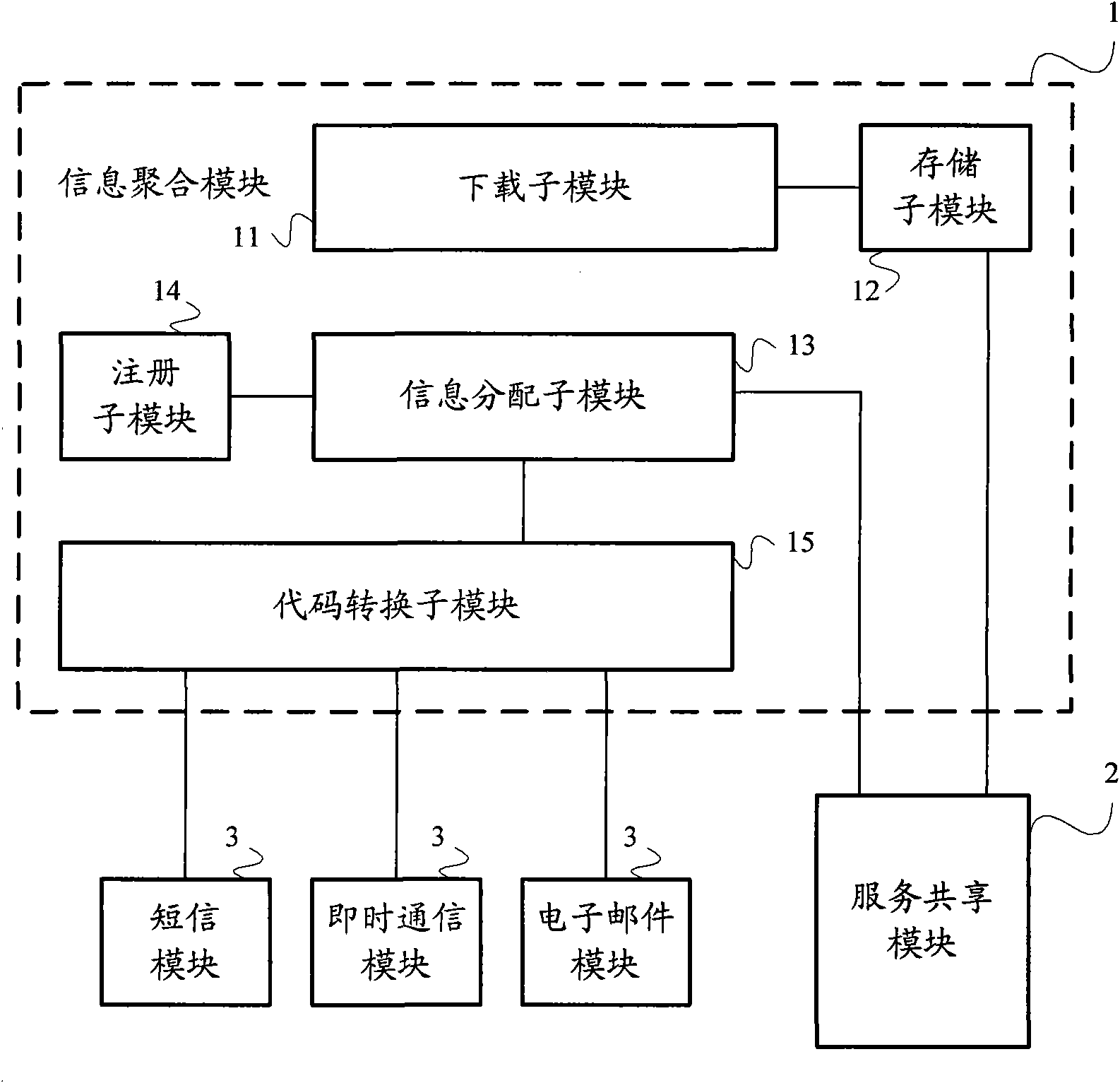

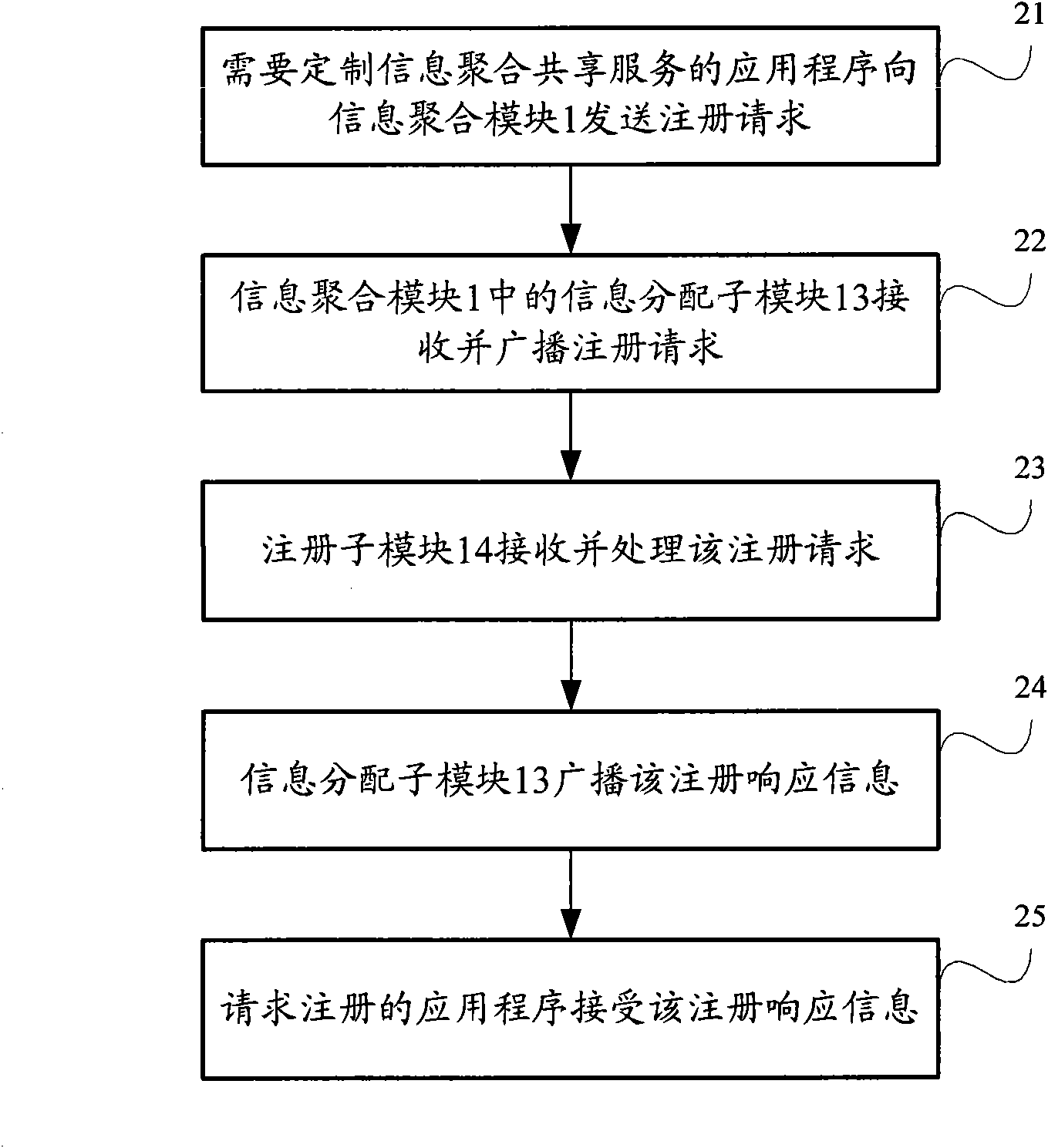

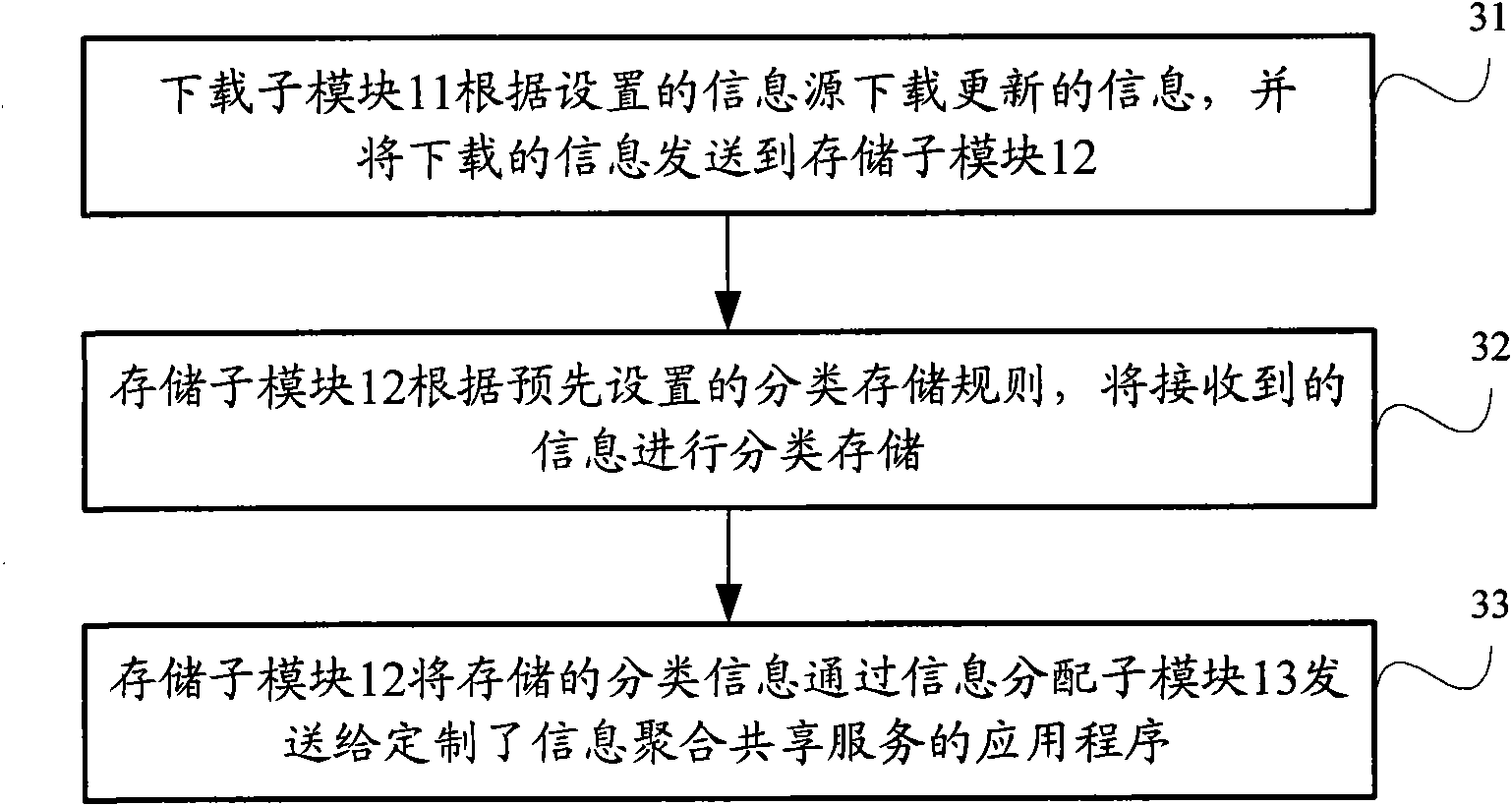

Method for realizing information aggregation share through terminal device and terminal device

ActiveCN101783733AAchieve aggregationMeet individual requirementsSpecial service provision for substationTerminal equipmentClassification rule

The invention discloses a method for realizing information aggregation share and a terminal device. The terminal device comprises an information aggregation module, a service share module and a communication module, wherein the information aggregation module is used for obtaining the released updating information of the information source from the network according to the setup information source and classifies the released updating information to store according to the setup classification rule; the service share module is used for transmitting the information which is stored in classification by the information aggregation module to the communication module through the information aggregation module; and the communication module is used for transmitting the received information to other devices. By adopting the method, the information aggregation share expenditure of the terminal device can be reduced, and the problem that the share information is limited is solved.

Owner:CHINA MOBILE COMM GRP CO LTD

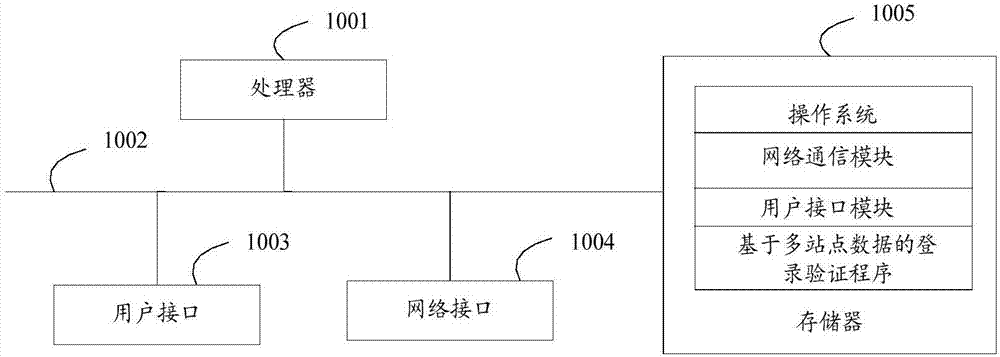

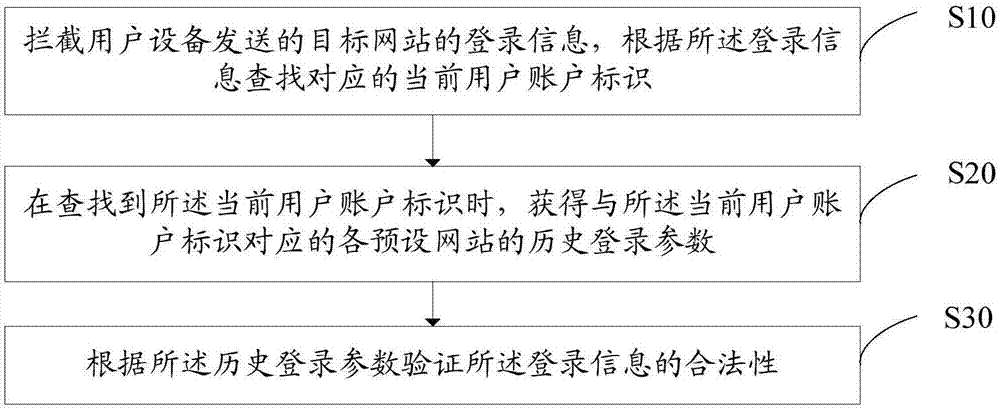

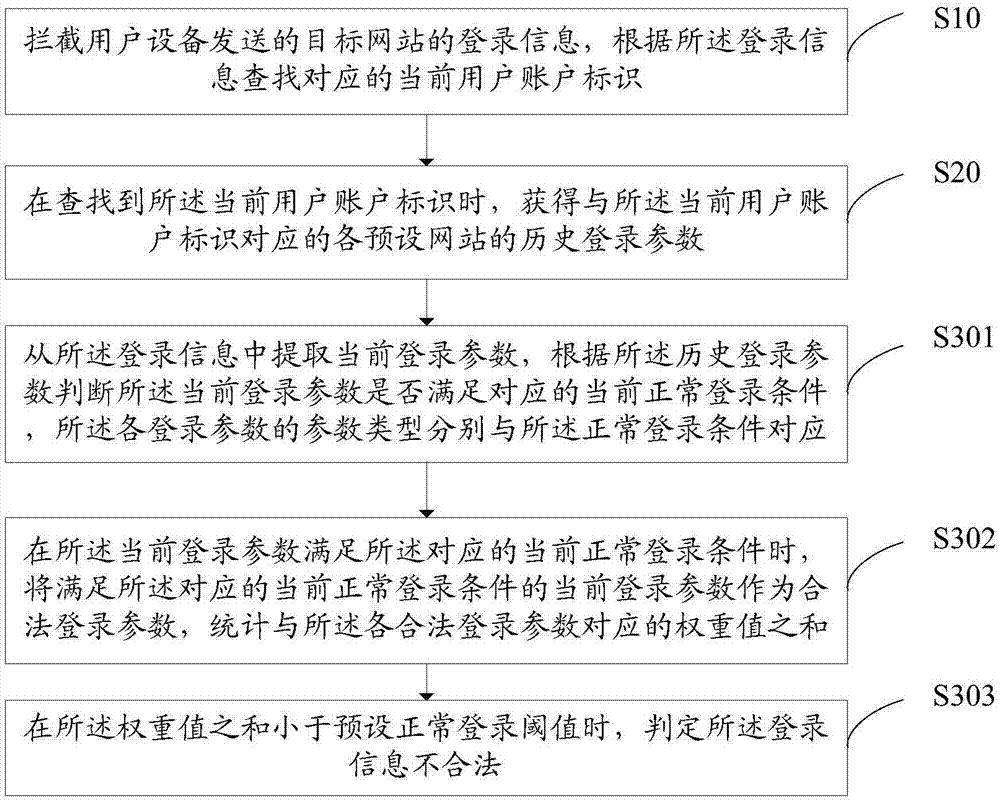

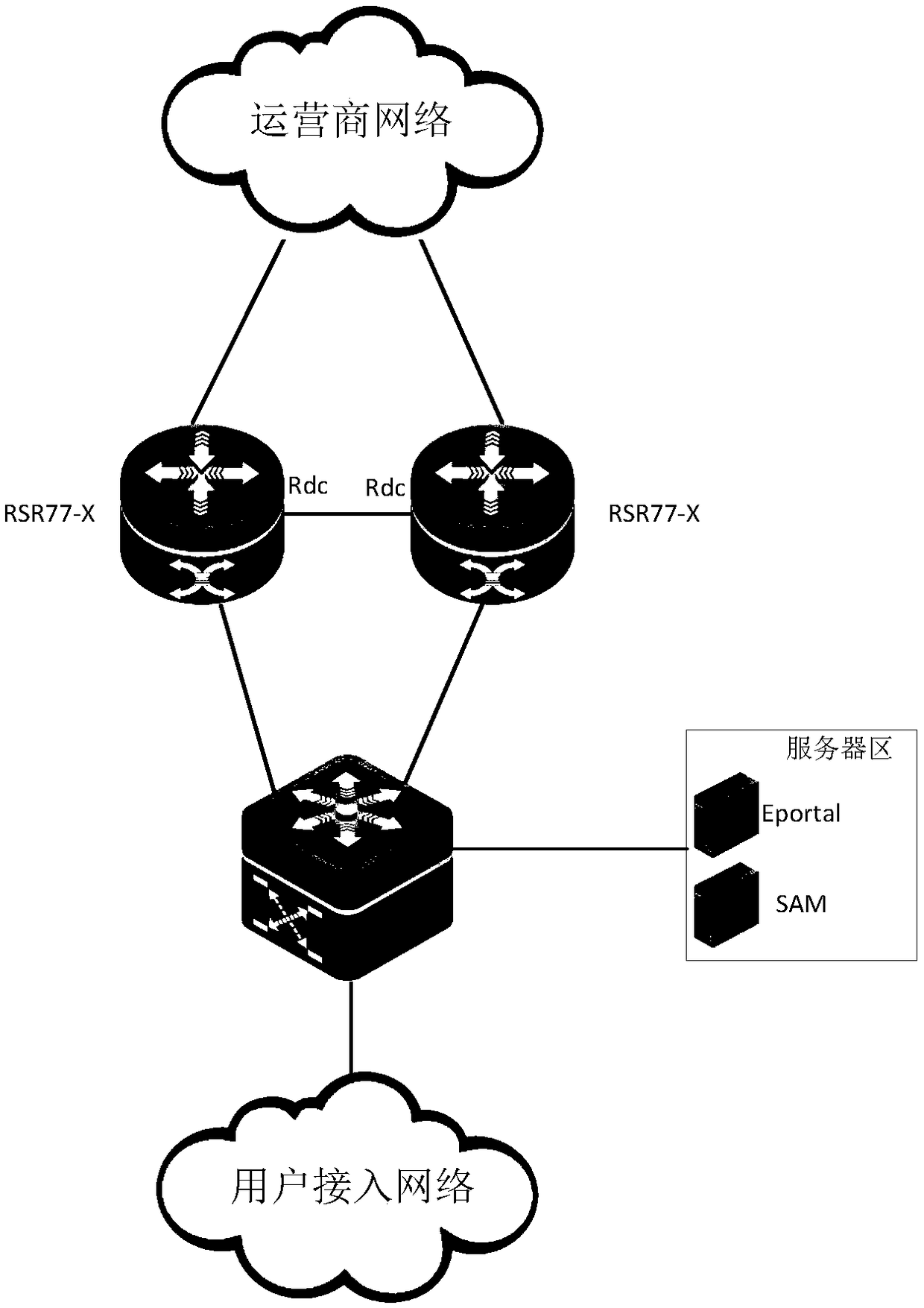

Login verification method based on multi-station data, verification device and memory medium

ActiveCN107277036AAchieve aggregationAccurate discriminationTransmissionValidation methodsUser equipment

The invention discloses a login verification method based on multi-station data, a verification device and a memory medium. According to the method, the device and the memory medium, login information of a target website sent by user equipment is intercepted; a corresponding current user account identifier is searched according to the login information; when the current user account identifier is searched, history login parameters of each preset website corresponding to the current user account identifier are obtained; and the legality of the login information is verified according to the history login parameters. Through setting of one user account identifier capable of identifying a user identity across a plurality of websites, the corresponding history login parameters of each preset website can be obtained, namely, the history login parameters of each preset website are gathered. Compared with the login data of the single website, the login verification method has the advantage that whether a current login behavior is legal or not can be identified accurately according to the gathered history login parameters, and the technical problem that a library hit behavior cannot be solved well is solved.

Owner:贝硕科技(云南)有限公司

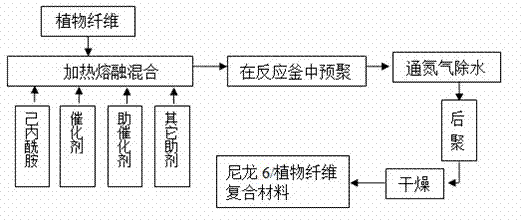

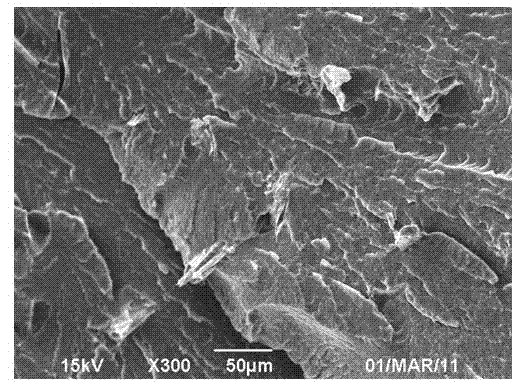

Nylon 6/plant fiber composite material and preparation method thereof

InactiveCN103044911APreparation Recipe ImprovementsImproved Polymerization ProcessFiberIn situ polymerization

The invention discloses a nylon 6 / plant fiber composite material and a preparation method thereof. The composite material is prepared and obtained by in-situ polymerization of the following components in part by weight: 100 parts of Epsilon-caprolactam, 0.2-1.5 parts of plant fibers, 0.3-0.8 part of catalyst, 0.3-1 part of cocatalyst, 0.5-3 parts of activators and 2-10 parts of water. The preparation method of the nylon 6 / plant fiber composite material comprises the following steps: melting the monomer Epsilon-caprolactam, uniformly agitating and mixing with the plant fiber, the catalysts, the cocatalyst, the activator and the water and singly dispersing the plant fibers in the molten Epsilon-caprolactam, adding into a reaction vessel for reaction and preparing the nylon 6 / plant fiber composite material with excellent performance through the processes of prepolymeriazation, nitrogen introduction, water removal and post polymerization.

Owner:HUBEI UNIV OF TECH

Method for recycling valuable components from mixed slag containing nickel and iron

InactiveCN107663589ASolve pollutionAchieve recyclingProcess efficiency improvementLead smeltingIron alloys

The invention relates to a method for recycling valuable components from mixed slag containing nickel and iron. The method comprises the following steps: S1, mixing slag, namely adding nickel smeltingslag into a smelting reaction device, and adding one or more of lead smelting slag, blast furnace slag, steel slag and iron alloy slag, thus forming mixed slag; heating the mixed slag to be in a smelting state to be taken as reaction slag, mixing uniformly, monitoring the reaction slag in real time, and meanwhile, regulating to enable the mixed slag containing nickel and iron to meet conditions aand b simultaneously, thus obtaining the reacted slag; and S2, separating for recycling. According to the method, the mixed slag containing nickel and iron can be treated efficiently, so that the problems that a great amount of slag is accumulated to result in environment pollution and heavy metal pollution are solved, and the heavy metal components can be recycled.

Owner:NORTHEASTERN UNIV

Method for recovering valuable components from zinc smelting slag

InactiveCN107674985ASolve pollutionRealize comprehensive utilizationProcess efficiency improvementMolten stateIndium

The invention discloses a method for recovering valuable components from zinc smelting slag. The method comprises the following steps that S1, the zinc smelting slag is added to a heat insulating device or a smelting reaction device in which slag can flow out, calcium-based minerals and additives are added, and mixed slag is formed; the mixed slag is heated to a molten state, reaction slag is formed, the reaction slag is monitored in real time, and by regulating and controlling the temperature of the reaction slag and the specific value of alkalinity CaO / SiO2, the slag obtained after a reaction is completed is obtained; and S2, the obtained slag is subjected to sedimentation separation, smoke dust containing a ferrous silicate mineral phase, a copper-rich phase and an iron-rich phase and smoke dust containing zinc, lead, bismuth and indium are obtained, and gold and silver components are migrated and enriched and enter the copper-rich phase; and all the phases are recovered. By the adoption of the method, the copper-containing slag (copper-containing slag smaller than 0.1wt%) can be lowered, besides efficient recovery of the components of copper, iron, gold, silver, lead, zinc, indium, bismuth, sodium, potassium and the like can be achieved, low-copper materials containing iron are obtained, the metal recovery rate is high, the production cost is low, environmental friendlinessis achieved, and the economic returns are high.

Owner:NORTHEASTERN UNIV

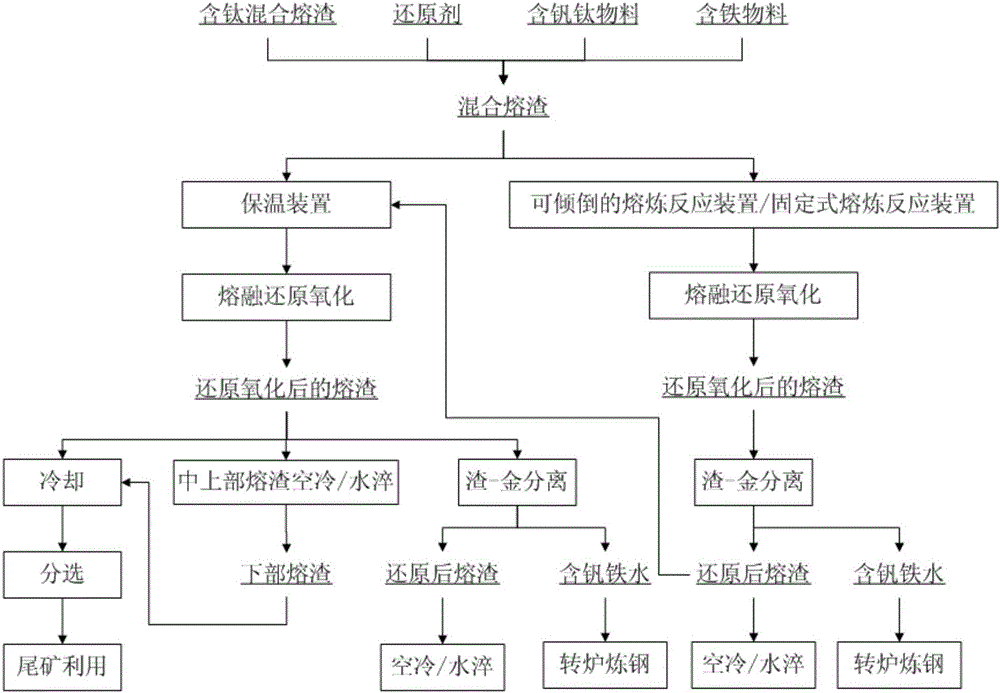

Smelting reduction production and thermal refining method for titanium-containing slag mixture

ActiveCN106048107AAchieve growthAchieve settlementRecycling and recovery technologiesProcess efficiency improvementMolten stateMaterials science

The invention provides a smelting reduction production and thermal refining method for a titanium-containing slag mixture. The smelting reduction production and thermal refining method for the titanium-containing slag mixture comprises the following steps of (1) adding a reduction agent, a vanadium-titanium-containing mineral and / or an iron-containing material into the titanium-containing slag mixture and performing heating to a set temperature to enable the slag mixture to be in a molten condition, and then injecting oxidative gas for smelting reduction and oxidation, and controlling the temperature range of the slag mixture and the alkalinity ratio range of CaO / SiO<2>; and (2) performing separation and recovery according to different reaction devices. According to the method, the titanium component, the iron component, the vanadium component, the phosphorus component and the free calcium oxide component in the slag mixture can be recycled efficiently; solid-state materials containing vanadium, titanium and iron can be processed massively by using a smelting reduction ironmaking technology for the production of high-grade titanium slag and vanadium-enriched slag, and at the same time the method is the novel smelting reduction ironmaking technology which is capable of realizing thermal refining of the slag and efficient and comprehensive utilization of resources. The method is short in reaction time, high in metal recovery rate, low in production cost, strong in raw material adaptability, large in processing capacity and capable of solving the problem of efficient recovery and use of multi-metal complex ore metallurgical resources and heat energy effectively.

Owner:NORTHEASTERN UNIV

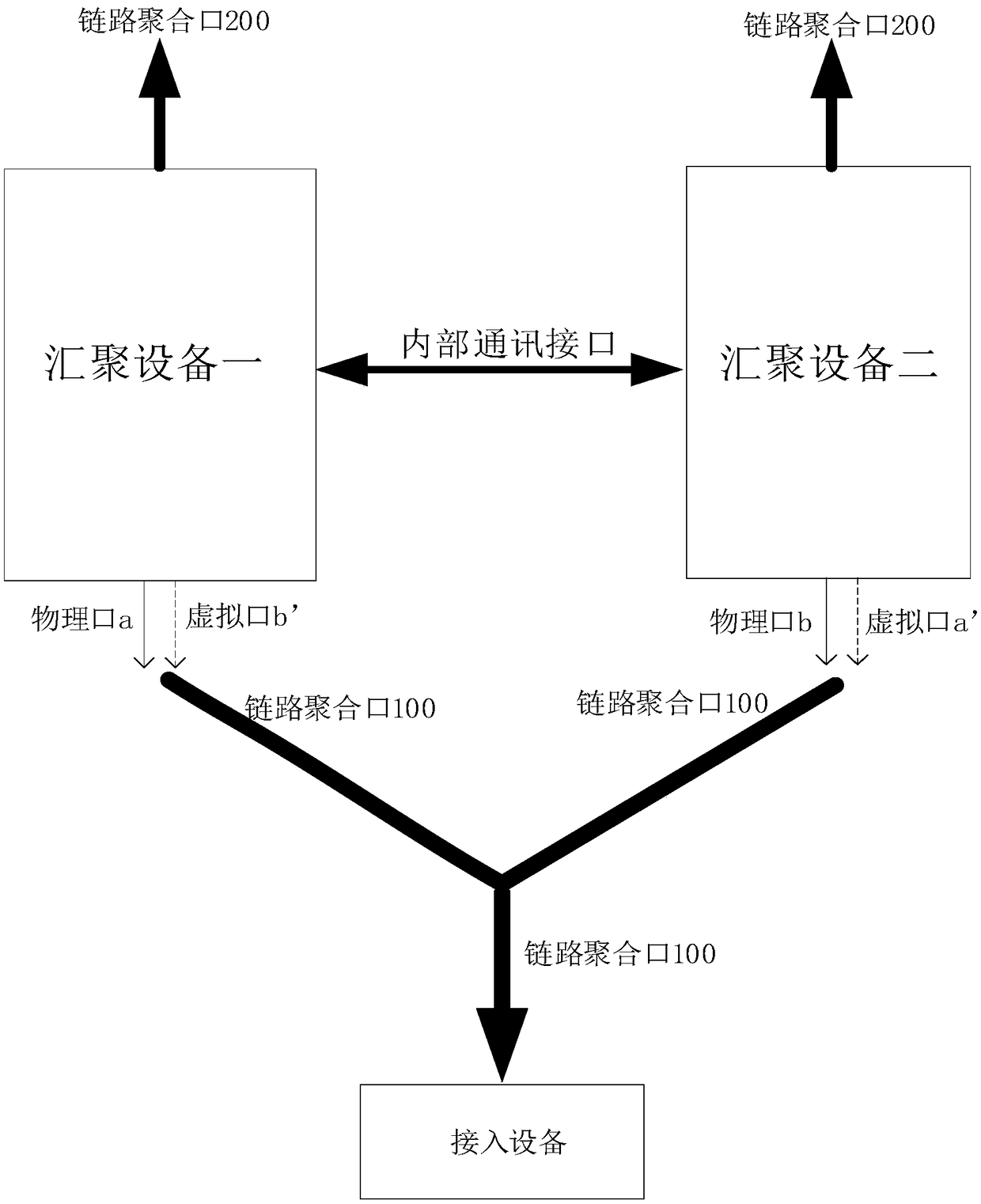

Cross-device link aggregation method, apparatus, computing device and storage medium

ActiveCN109088820AEasy to implementReduce couplingData switching networksCommunication interfacePhysical interface

A method, apparatus, computing device and storage medium for cross-device link aggregation relate to the field of data communication and is used to solve the problem of cross-device link aggregation.In the method, the aggregation device is connected through an internal communication interface, and the cross-device link aggregation is realized according to the corresponding relationship between the interface identifier of the physical interface and the interface identifier of the virtual interface, so that the realization is simpler. At the same time, because the convergence equipment is independent of each other software system, coupling is less.

Owner:RUIJIE NETWORKS CO LTD

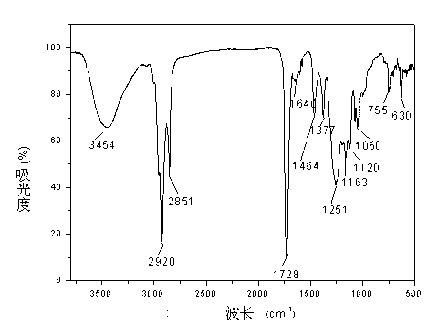

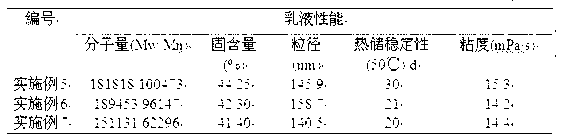

Preparation method of acrylic-modified water-based tall oil alkyd resin emulsion

ActiveCN102796228AEasy to reuseIn line with the national policy of developing circular economyPolyesterPolymer science

The invention relates to a preparation method of an acrylic-modified water-based tall oil alkyd resin emulsion, which comprises the following steps: (1) reacting dibasic acid with -SO3M group with dibasic alcohol to prepare a polyester intermediate; (2) reacting the polyester intermediate, vegetable oil fatty acid, polybasic alcohol and polybasic acid, and dispersing with deionized water to prepare an alkyd resin water dispersion; and (3) reacting an acrylic monomer and the alkyd resin water dispersion to prepare the acrylic-modified water-based tall oil alkyd resin. The acrylic-modified water-based tall oil alkyd resin prepared by the method has the advantages of no emulsifier, almost zero VOC (volatile organic compound) content, low viscosity, high storage stability, high solid content, high drying and curing rate and high hardness, does not need an amine neutralizer for neutralization, and can be used in metal anticorrosive paint, woodware paint and the like. The coated film has the advantages of quick drying, high hardness, favorable mechanical properties and high corrosion resistance.

Owner:HUNAN UNIV

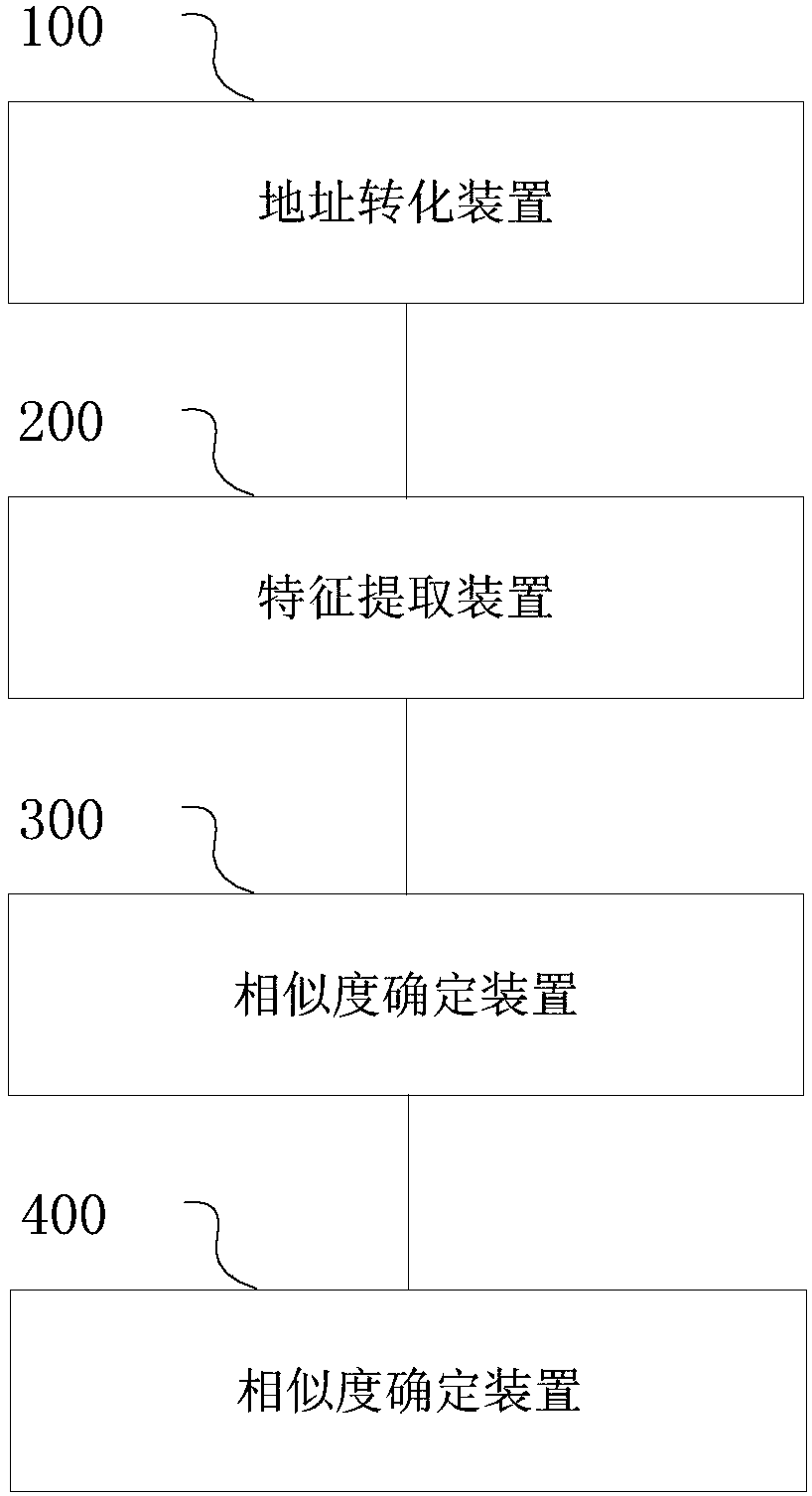

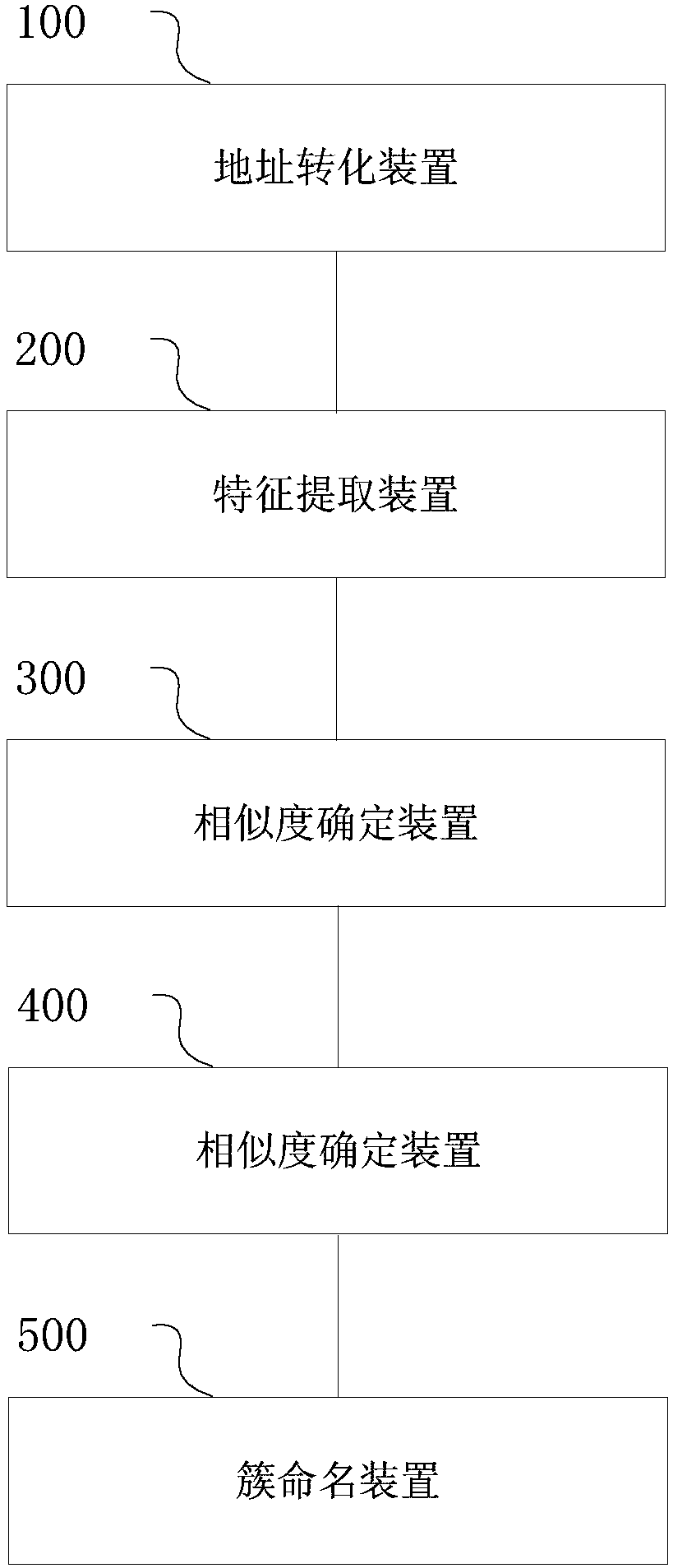

Address aggregation method and device

InactiveCN108460046AAchieve aggregationGeographical information databasesLogisticsFeature setData processing

Embodiments of the invention disclose an address aggregation method and device, and relate to the technical field of data processing. The device comprises an address conversion apparatus used for converting multiple communication addresses into multiple structured addresses, a feature extraction apparatus used for performing feature extraction on the structured addresses to obtain multiple featuresets corresponding to the communication addresses, a similarity determination apparatus used for determining the similarity between any two communication addresses in the communication addresses according to the feature sets corresponding to the communication addresses, and an address aggregation apparatus used for aggregating the communication addresses according to the similarity to obtain multiple clusters, wherein the feature sets at least comprise road and road number information and / or region names of regions. By utilizing the method and the device, different communication addresses belonging to the same region can be aggregated in the same cluster.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

Converging system for a plurality of wireless access networks and access network element

ActiveCN104023376AAchieve aggregationIncrease peak rateAssess restrictionConnection managementAccess networkPeak value

The invention provides a converging system for a plurality of wireless access networks, a realizing method and an access network element thereof. The method comprises the steps of: establishing a connection with UE by an anchor RAN; receiving a RAB establishing request transmitted from a CN by the anchor; selecting an auxiliary RAN by the anchor RAN; and transmitting a QOS parameter by the anchor RAN to the auxiliary RAN so that the auxiliary RAN establishes connection with the UE according to the QOS parameter, and the anchor RAN keeps connection with the UE. The method provided by the embodiment of the invention realizes convergence of a plurality of RANs. The UE is simultaneously connected with the anchor RAN and the auxiliary RAN, and peak speed of the UE can be improved.

Owner:HUAWEI TECH CO LTD

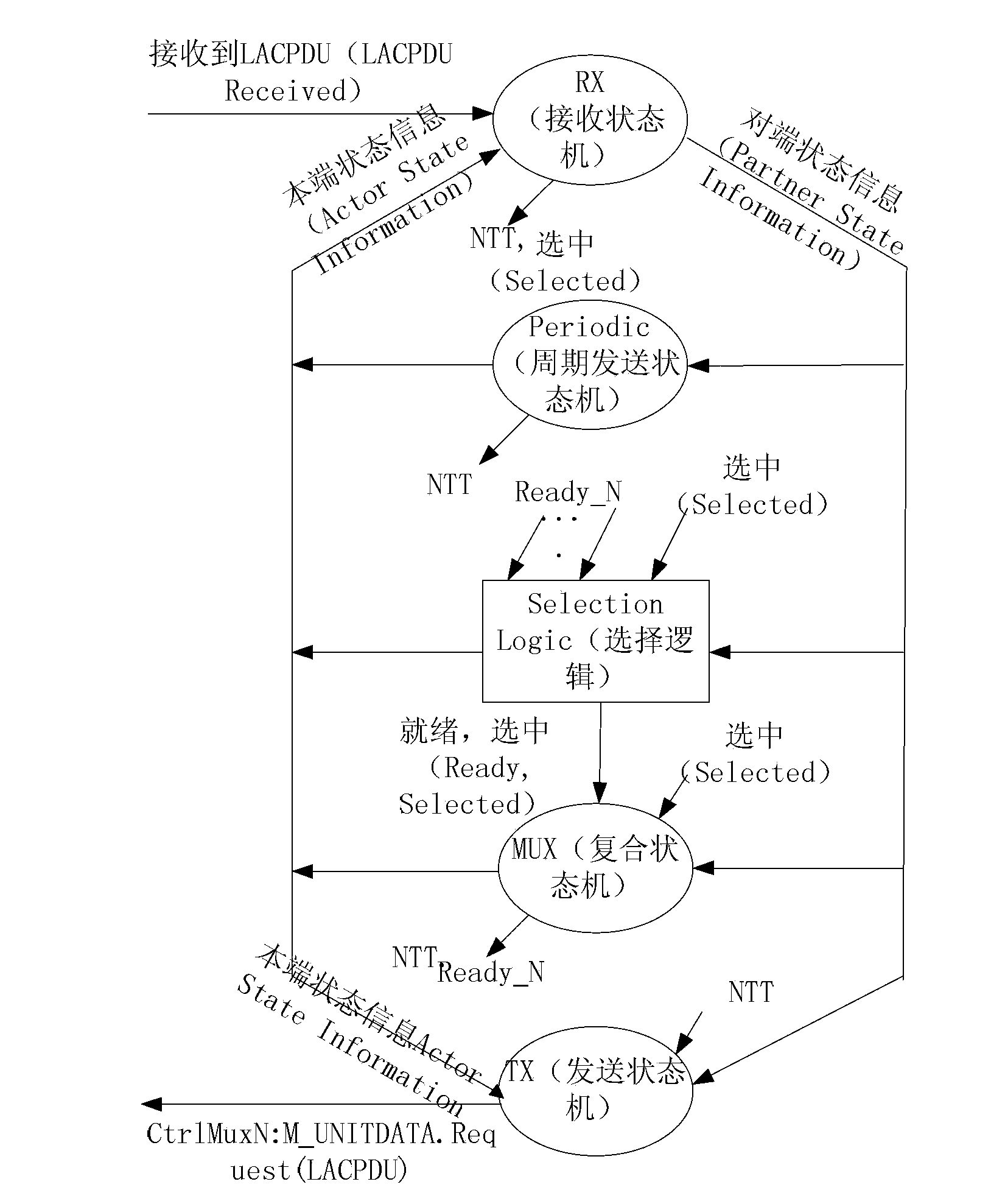

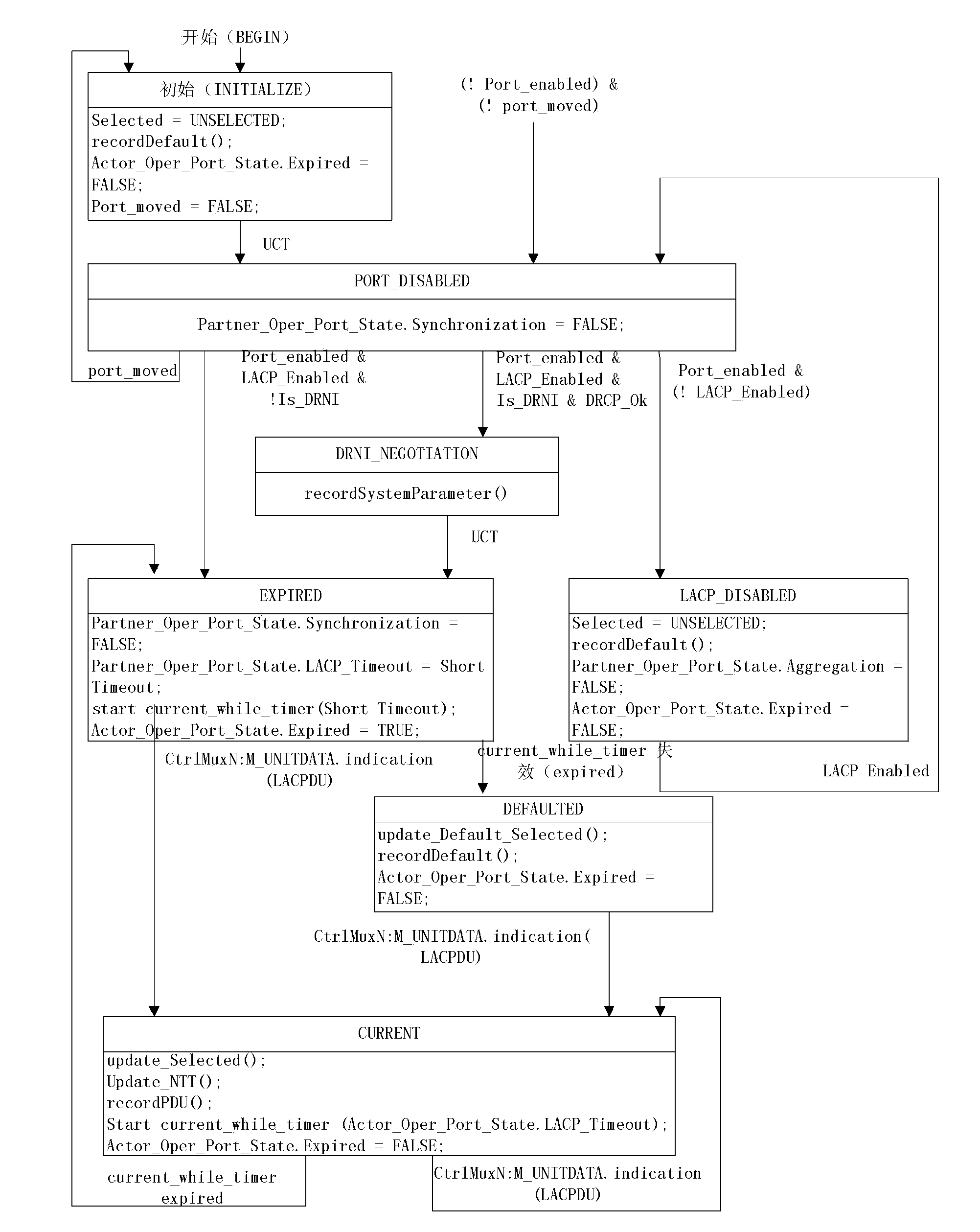

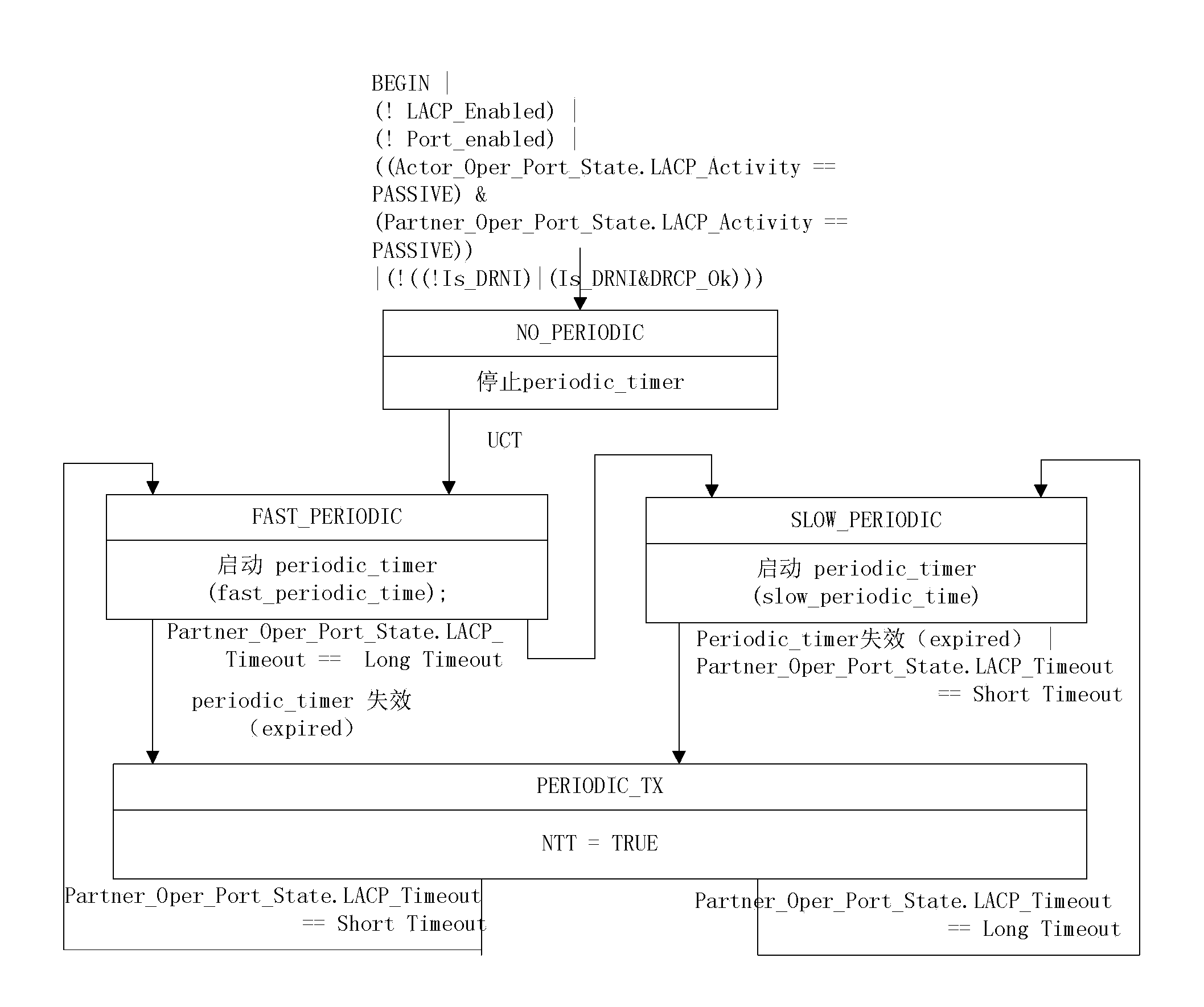

Method and system for cooperation of distributed elastic network interconnection systems

InactiveCN104243259AAchieve protectionAchieve aggregationNetworks interconnectionHigh level techniquesElastic networkLink aggregation

The invention provides a method for cooperation of distributed elastic network interconnection systems. The method comprises the step that after an LACP system receives systemic parameters announced by a distributed relay control protocol (DRCP) system, the systemic parameters of the DRCP system are used as system negotiation parameters of the LACP system. The invention further provides an LACP system which comprises a receiving module and a control module. The receiving module receives the systemic parameters announced by the DRCP system, and the control module regards the systemic parameters of the DRCP system as the system negotiation parameters of the LACP system. By means of the method, cooperation of the LACP system and the DRCP system is achieved.

Owner:ZTE CORP

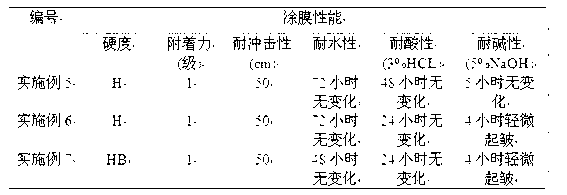

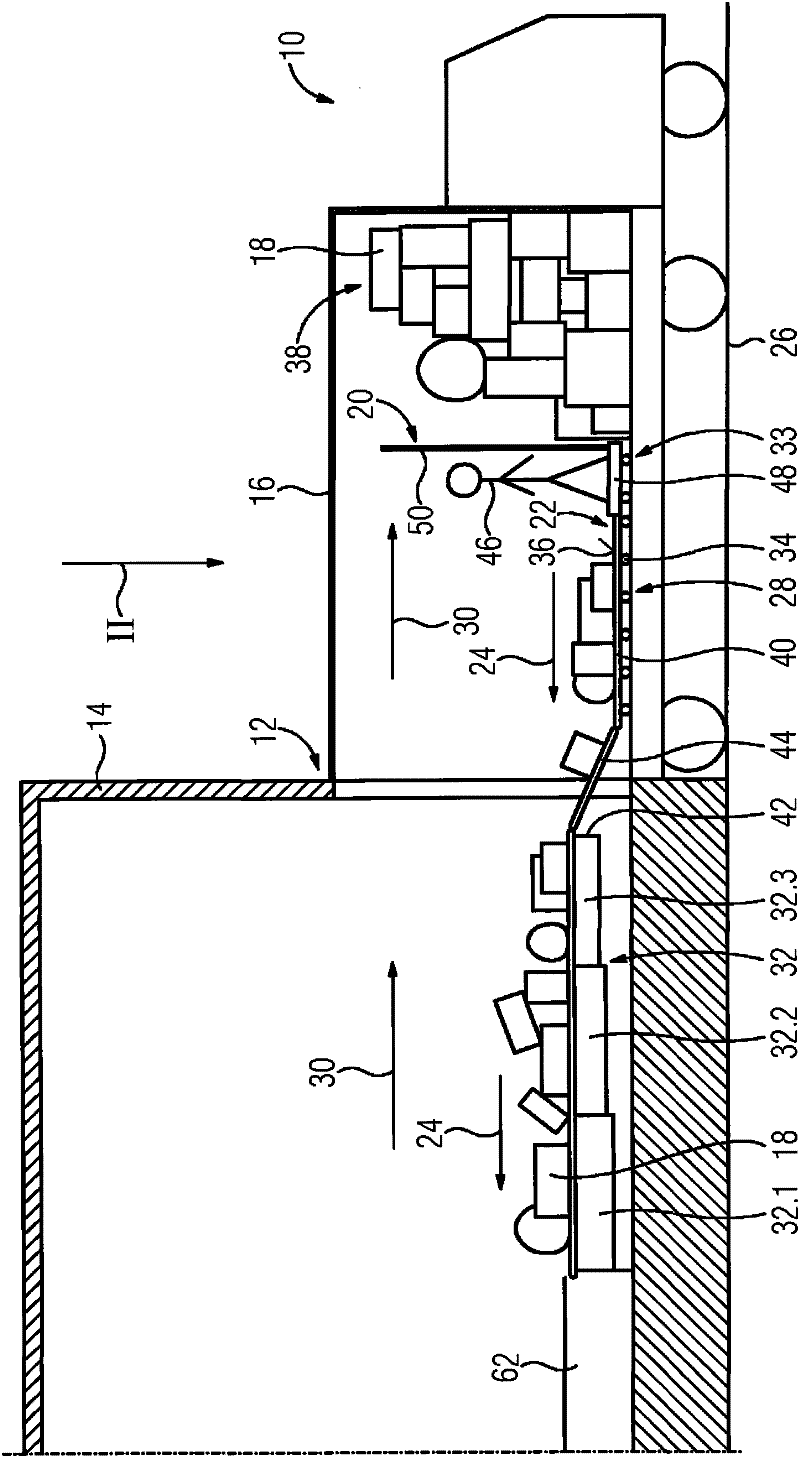

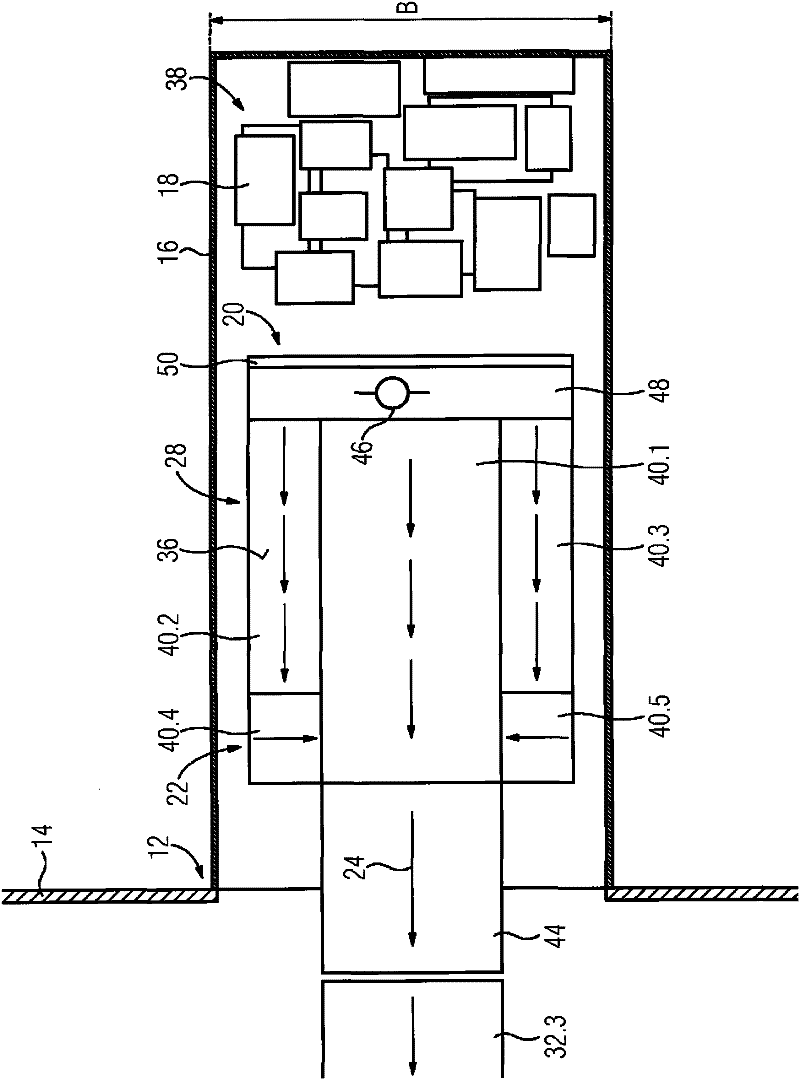

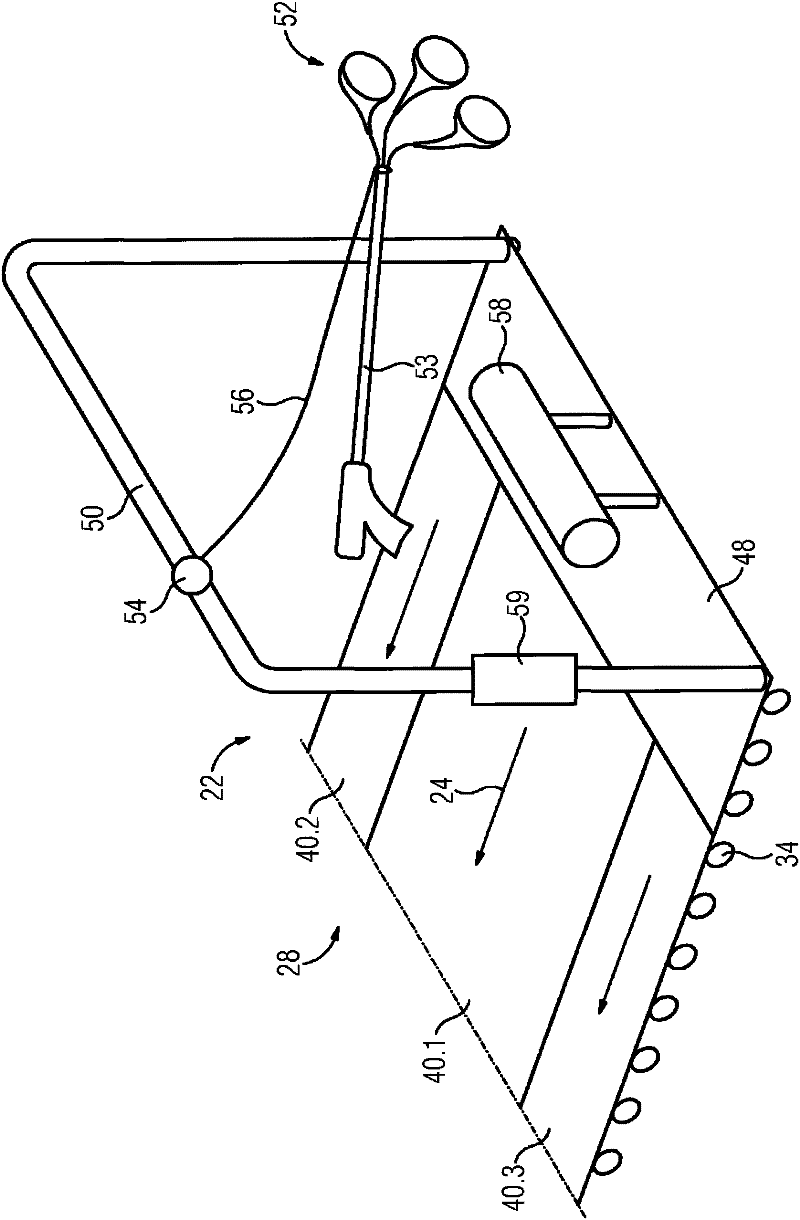

Device for treating piece goods of a transport unit, particularly a swappable container and unloading device

ActiveCN102556688APrevent tippingEliminate height differenceLoading/unloadingExternal fittingsOperational costsMechanical engineering

The invention relates to a device for treating piece goods (18) of a transport unit (16), particularly a swappable container and unloading device. The device has a movable conveyor unit (22), driven into the transport unit so as to unloading the transport unit (16). Under control of an operator (46), piece-goods (18) stacked in the transport unit are received and shipped out from the transport unit (16) in a discharge direction (24) for further processing. In order to provide a device capable of shipping out inconsistently or unclassified stacked piece-goods with low operational cost, the invention provides a conveyor unit (22) comprising a bottom conveyor (28) that conveys the piece goods fallen from a piece-goods stack (38) in a loose arrangement.

Owner:KOERBER SUPPLY CHAIN LOGISTICS GMBH

Method for producing copper-containing slag

InactiveCN107641717ARealize comprehensive utilizationSolve the accumulationProcess efficiency improvementThermal stateCopper oxide

The invention relates to a method for producing copper-containing slag. The method comprises the following steps: S1, furnace slag mixing: adding copper slag into a reaction device, and adding a calcium-system mineral and an additive; heating the slag into a molten state, and adding one or more of a copper oxide mineral, a copper sulphide mineral and a copper-containing material; uniformly mixingthe materials to obtain reaction slag, monitoring the reaction slag in real time, and treating the mixed reaction slag through regulation and control to enable the mixed reaction slag to simulatenously meet conditions a and b, thus obtaining reacted slag; S2, separation and recycling. According to the method, both thermal-state slag and cold-state furnace slag can be treated; by full use of moltencopper slag physical thermal resources and a thermal-state metallurgical flux, treatment of copper-containing furnace slag and treatment of the copper oxide mineral are realized; the problem of bulkdeposition of furnace slag at present is solved; simultaneous production of copper and iron is realized; two world problems that the copper oxide mineral is difficult to treat and an iron component isdifficult to recycle are solved; meanwhile, the problems of environmental pollution and heavy metal pollution are solved.

Owner:NORTHEASTERN UNIV

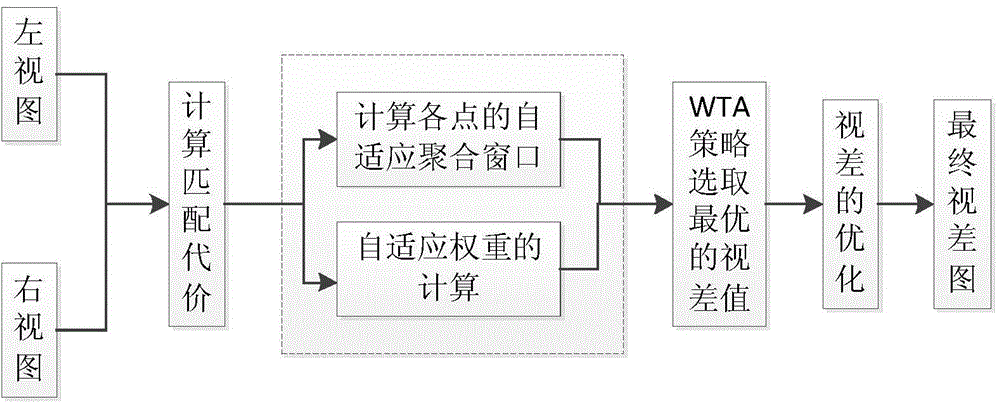

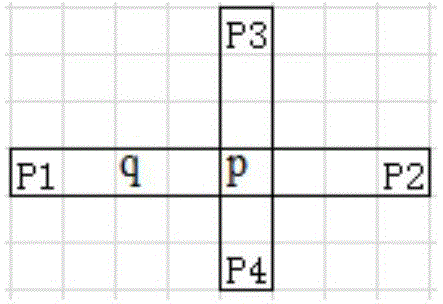

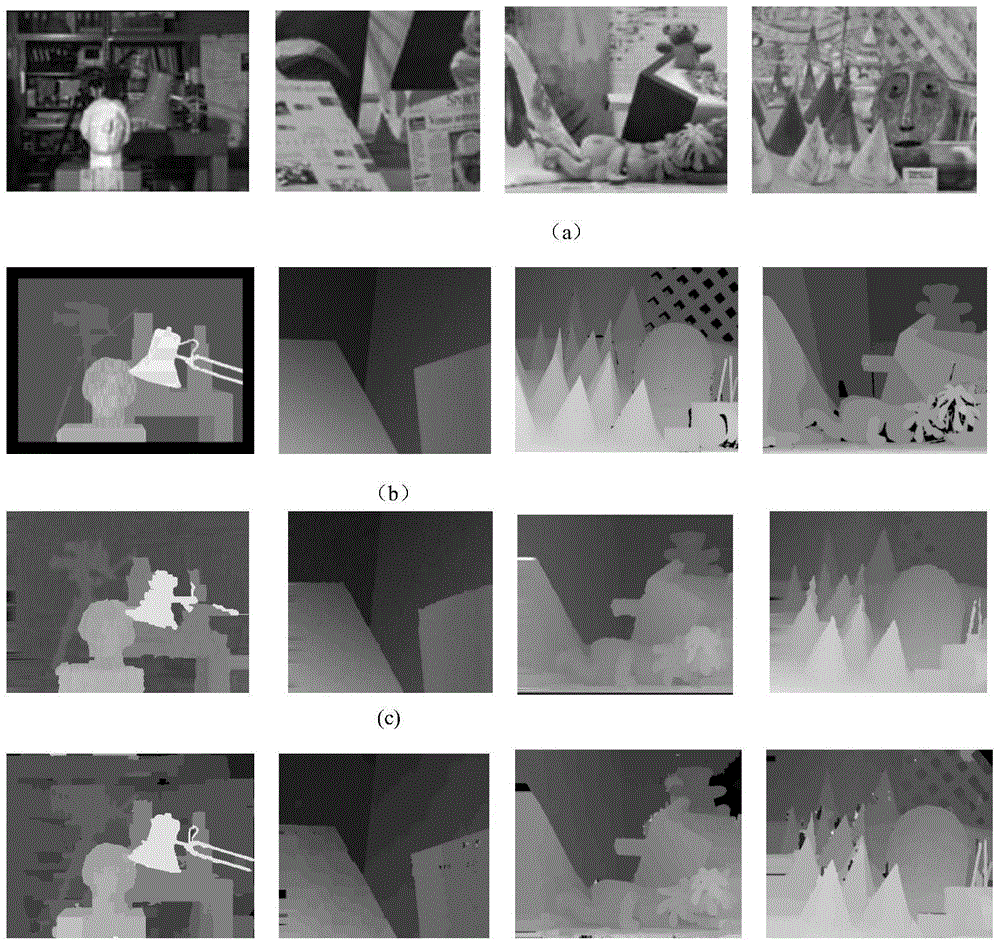

Self-adaptive weight three-dimensional matching method based on SIFT descriptor

ActiveCN104966290AAchieve aggregationHigh precisionImage enhancementImage analysisPattern recognitionParallax

The present invention discloses a self-adaptive weight three-dimensional matching method based on an SIFT descriptor. The self-adaptive weight three-dimensional matching method comprises the following steps: obtaining a self-adaptive aggregation window of each center point through a similarity area decision criterion; performing self-adaptive weight calculation through an L1 norm of an SIFT descriptor of each point, and optimizing a matching cost according to an initial combined matching cost and the self-adaptive aggregation window; for the optimized matching cost, selecting the optimal parallax value of each point through a WTA strategy, then detecting the optimal parallax value by adopting a left-right consistency detection method, and filling detected mismatching points by using a background filling method to obtain a final parallax image. The self-adaptive weight three-dimensional matching method of the present invention realizes aggregation of the matching costs in a three-dimensional matching process, can obtain a parallax image with high accuracy, overcomes the problems that a traditional algorithm has low matching accuracy in a depth discontinuous area and a low texture area, and has wide application prospect.

Owner:天津渤化南港码头仓储有限公司

Method for conducting production through nickel smelting slag

InactiveCN107699703ASolve the accumulationSolve the two major worldwide problems that are not easy to recycleProcess efficiency improvementSmelting processCopper sulfide

The invention relates to a method for conducting production through nickel smelting slag. The method includes the following steps that S1, clinker is mixed, wherein the nickel smelting slag is added in a smelting reaction device, calcium-series mineral and an additive are added; stirring is conducted, the slag is heated to the molten state, and one or more of copper oxide ore mineral, nickel oxidemineral, copper sulfide mineral, nickel sulfide mineral and a copper-containing material are added; the mixture is evenly mixed to be used as reaction slag, monitoring is conducted in real time, andmeanwhile the mixed copper-containing slag can meet the condition a and the condition b at the same time through regulation and control and slag subjected to reaction is obtained; and S2, separation and recycling are conducted. By means of the method, the hot-state slag can be processed, and the cold-state clinker can also be processed; molten nickel smelting slag physical thermal resources and hot-state metallurgy flux are sufficiently utilized, copper-containing clinker can be processed, the copper oxide mineral and / or the nickel sulfide mineral can also be processed, the method is a new copper smelting process, and simultaneous production of copper and iron is achieved.

Owner:NORTHEASTERN UNIV

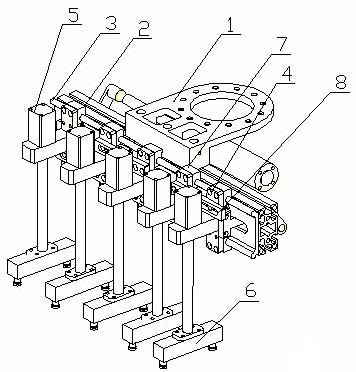

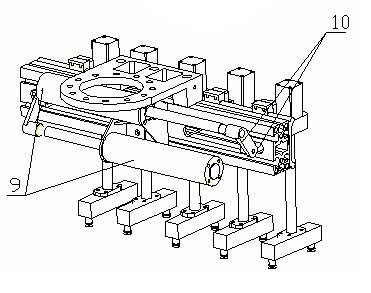

Robot hand grip for packaging and conveying dispersed materials

InactiveCN102249087AImplement one-time fetchingAdjustable spacingConveyor partsRobot handEngineering

The invention relates to a robot hand grip for packaging and conveying dispersed materials. The hand grip comprises a platform (1), a support frame (2), a sliding rail (3), N groups of fingers, a sliding block (7), a first connecting member (8) with a limit groove, air cylinders (9) and a second connecting member (10). The support frame (2) is fixed on the platform (1). The sliding rail (3) is fixed at the front side of the support frame (2). Each group of fingers comprises a small air cylinder base (4) with columnar embossments, a small air cylinder (5) and an executing part (6). The sliding block (7) is connected to the sliding rail (3) in a sliding manner. The adjacent N groups of fingers are connected by means of the first connecting member (8) with the limit groove. Columnar embossments on the small air cylinder base (4) having the columnar embossments of the N groups of fingers are spliced and matched with the limit groove of the first connecting member (8) having the limit groove. Two air cylinders (9) are fixed at the back side of the support frame (2) reversely. The invention can meet the need of grasping a plurality of dispersed materials once and can be used for adjusting space between the materials.

Owner:江阴纳尔捷机器人有限公司

Method for recovering valuable components in mixed slag containing copper and iron

InactiveCN107699704AAchieve recyclingSolve pollutionRecycling and recovery technologiesProcess efficiency improvementLead smeltingZinc

The invention relates to a method for recovering valuable components in mixed slag containing copper and iron. The method for recovering the valuable components in the mixed slag containing copper andiron comprises the steps of S1, slag mixing, specifically, copper slag is added into a smelting reaction device, and one or more of lead smelting slag, blast furnace slag, steel slag and iron alloy slag are added at the same time so as to form mixed slag, the slag is heated to be in a molten state to form reaction slag, the reaction slag is evenly mixed and monitored in real time, the mixed reaction slag is regulated and controlled to meet a condition a and a condition b, and thus reacted slag is obtained; and S2, separation and recovery. By adoption of the method for recovering the valuablecomponents in the mixed slag containing copper and iron, copper, iron, zinc, lead, gold, silver, phosphorus, calcium and silicon in non-ferrous metallurgical slag and ferrous metallurgical slag are comprehensively utilized, and the problems of accumulation of a large quantity of slag and environmental pollution in the prior art are solved.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com