Preparation method of acrylic-modified water-based tall oil alkyd resin emulsion

An alkyd resin emulsion and alkyd resin technology, applied in the field of chemical materials, can solve problems such as residues, polyxylene, paint amine residues, etc., and achieve the effects of being beneficial to resource reuse, fast drying at room temperature, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

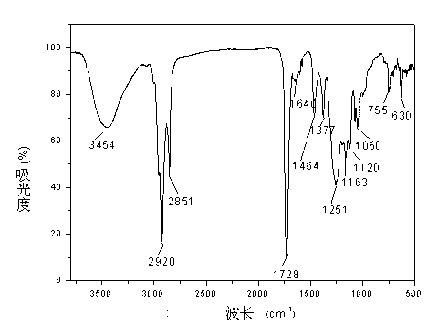

Image

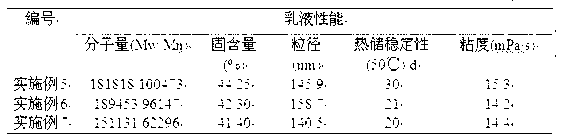

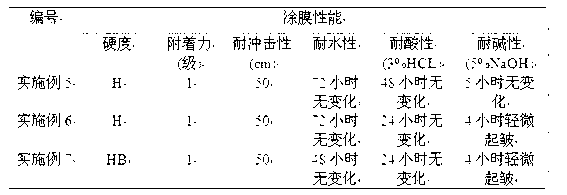

Examples

Embodiment 1

[0035] Example 1:Preparation of polyester intermediate A

[0036] Add 88g of terephthalic acid-5-sodium sulfonate, 119.6g of neopentyl glycol, 36.6g of deionized water and 0.122 g monobutyltin oxide catalyst, pass through nitrogen protection, first raise the temperature to 120°C, then raise the temperature to 150°C after one hour, then raise the temperature to 170°C at a rate of 10°C / 10min for 3 hours, heat at 200°C at constant temperature, and Take a sample to measure the acid value. When the acid value drops below 3 mgKOH / g, stop the reaction, pour the mixed material into the mortar while it is hot, place it in the dry bottle for a period of time, cool it down, grind it to powder, and then dry it stored under conditions.

Embodiment 2

[0037] Example 2 : Preparation of polyester intermediate B

[0038] Add 88g of isophthalic acid-5-sodium sulfonate, 61g of ethylene glycol, 26.5g of deionized water and 0.1g di Butyl tin oxide catalyst, protected by nitrogen gas, firstly heated to 120°C, then raised to 150°C after one hour, then heated to 180°C at a rate of 10°C / 10min for 3 hours, heated at 200°C, and tested regularly When the acid value drops below 3 mgKOH / g, stop the reaction, pour the mixed material into the mortar while it is hot, put it in the dry bottle for a period of time, cool it down, grind it to powder, and then put it under dry conditions store.

Embodiment 3

[0039] Example 3 : Aqueous Alkyd Resin Dispersion A Preparation:

[0040] The polyester intermediate A18g prepared in Example 1, 35.66g of tall oil fatty acid, 10.05g of phthalic anhydride, 8.25g of glycerol, 2.4g of isophthalic acid, and 0.041g of monobutyltin oxide were added to the In the four-necked flask with water separator, condenser, stirrer and nitrogen device, heat the reaction in an oil bath, and at the same time pass nitrogen protection, start the stirrer at the beginning of the reaction, first raise the temperature to 120°C, and then increase the temperature to 10°C / 10min The temperature was increased to 210°C for three hours, and the temperature was kept at 230°C until the acid value was less than 15mgKOH / g to stop the reaction. Cool the alkyd resin to 80°C, slowly add 95g of deionized water, stir at about 2600r / min, stir and disperse for 30 minutes, cool down and discharge. The solid content of the aqueous dispersion is about 48%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com