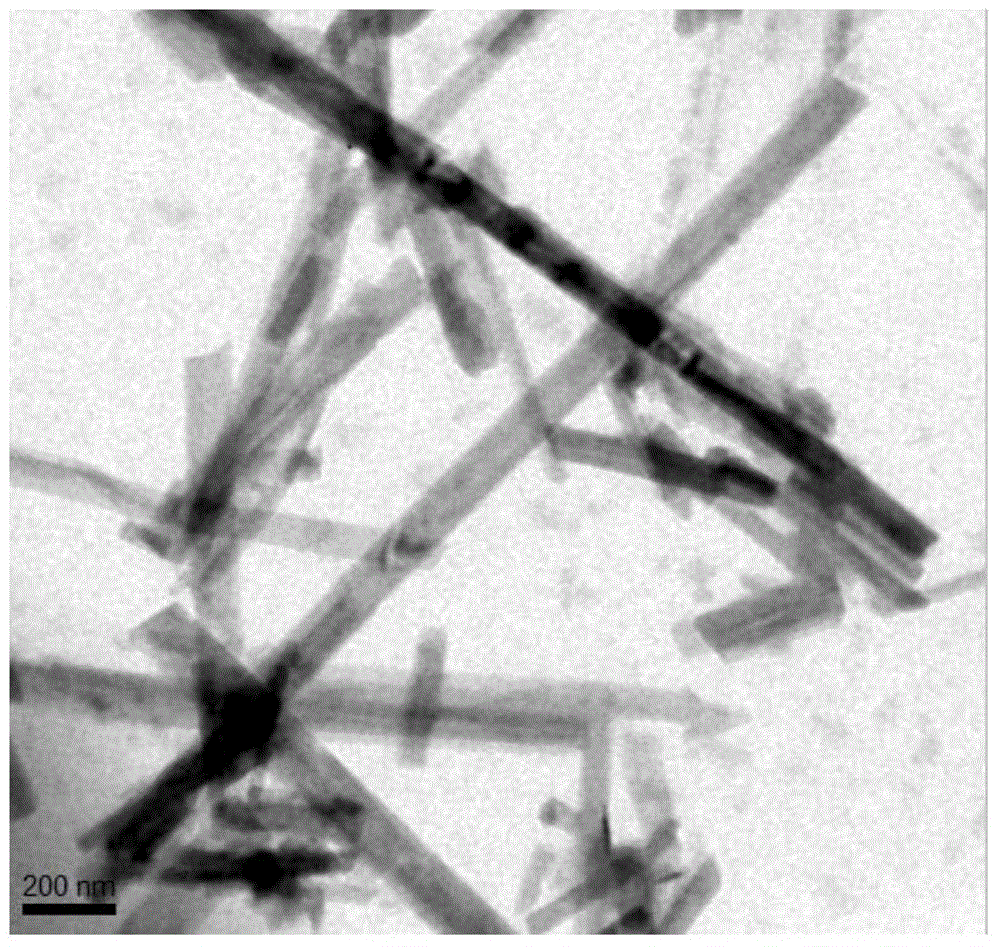

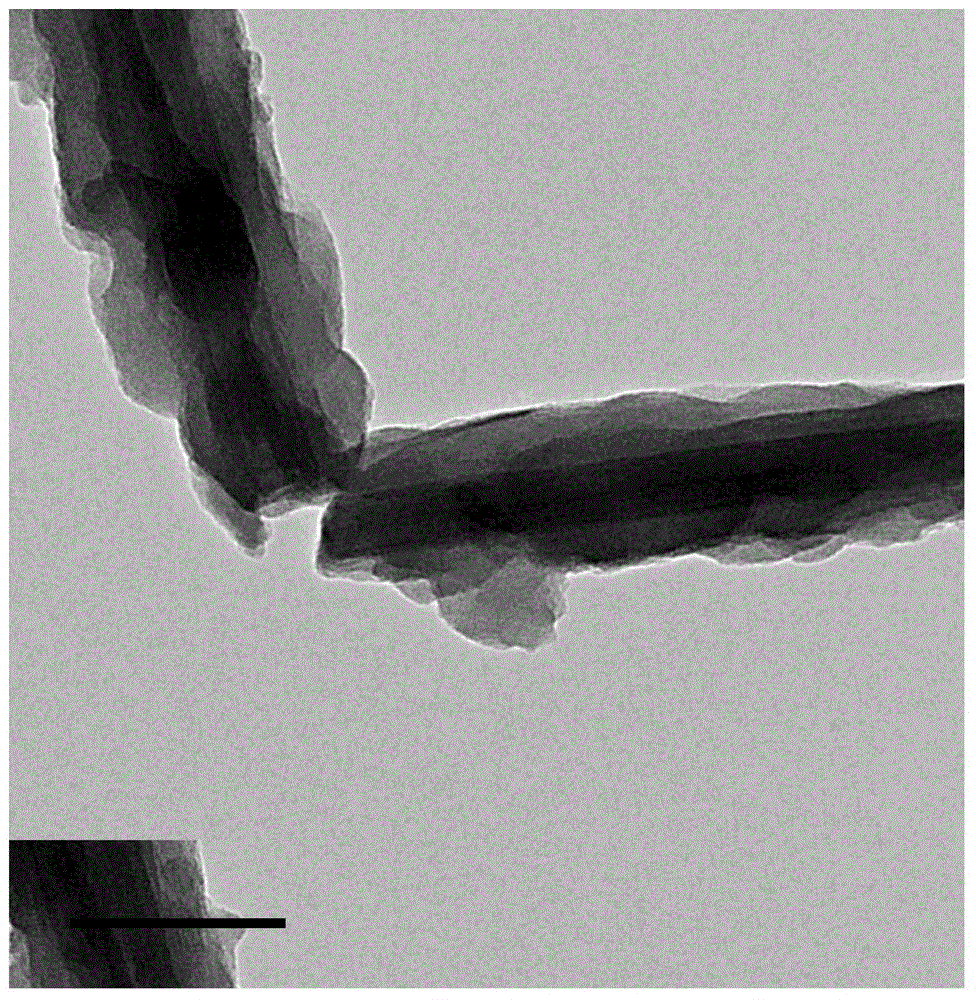

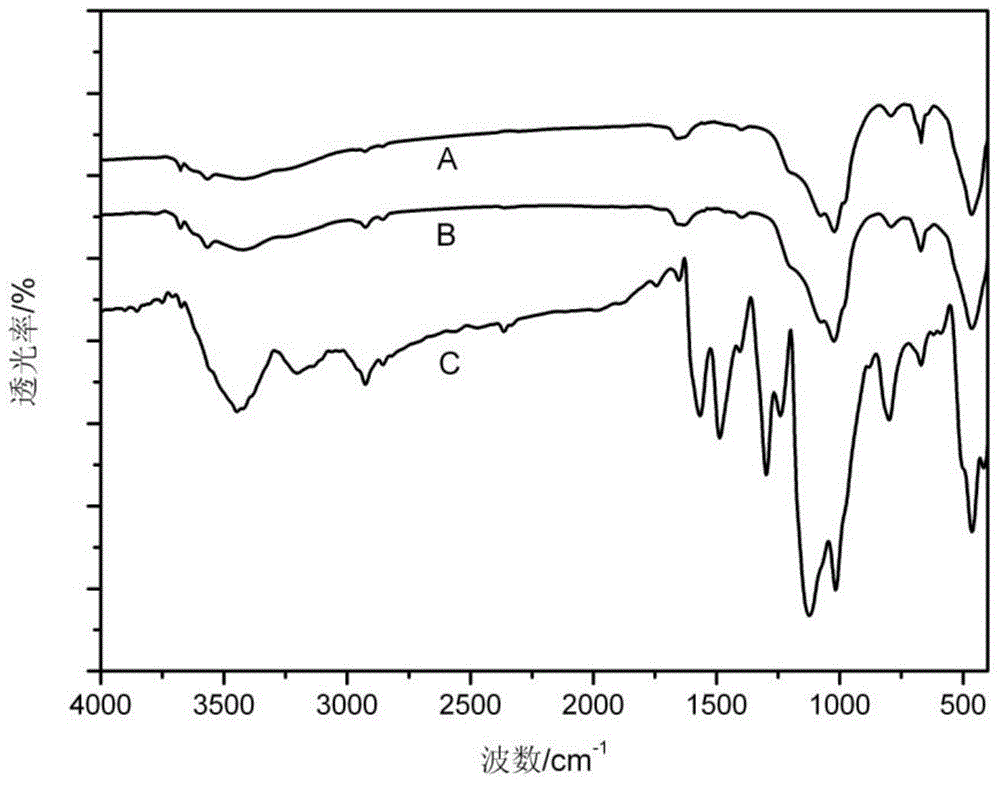

Preparation method of sepiolite/polyaniline nanocomposite material

A technology of nanocomposite materials and sepiolite, which is applied in the field of preparation of sepiolite/polyaniline nanocomposite materials, can solve problems such as low specific surface area, low specific capacitance, and poor material performance, and achieve large specific surface area and high The effect of specific capacitance and structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of sepiolite / polyaniline nanocomposite material, the preparation steps are as follows:

[0037] 1) Mix the sepiolite raw material and distilled water passing through the 80 mesh sieve in a weight ratio of 1:30, stir and mix vigorously for 6 hours, then let it stand for 24 hours, take the upper layer of sepiolite suspension, suction filter, wash with distilled water, and vacuum at 60°C Dry for 24h to obtain washed sepiolite;

[0038] 2) Mix the washed sepiolite passed through a 200-mesh sieve with a hydrochloric acid solution with a concentration of 3mol / L at a weight ratio of 1:20, then stir at 25°C for 16 hours, filter, wash with distilled water until neutral, and vacuum at 60°C Dry for 24 hours to obtain acid-activated sepiolite;

[0039] 3) Mix the acid-activated sepiolite passed through a 200-mesh sieve with absolute ethanol in a ratio of 1:20 by weight, add 3-aminopropyltriethoxysilane, 3-aminopropyltriethoxysilane and The weight ratio of aci...

Embodiment 2

[0043] A preparation method of sepiolite / polyaniline nanocomposite material, the preparation steps are as follows:

[0044] 1) Mix the sepiolite raw material passed through a 80-mesh sieve with distilled water at a weight ratio of 1:40, stir and mix vigorously for 3 hours, then let it stand for 16 hours, take the upper layer of sepiolite suspension, suction filter, wash with distilled water, and vacuum at 60°C Dry for 24h to obtain washed sepiolite;

[0045] 2) Mix the washed sepiolite passed through a 200-mesh sieve with an aqueous hydrochloric acid solution with a concentration of 1mol / L at a weight ratio of 1:10, then stir at 40°C for 24 hours, filter, wash with distilled water until neutral, and vacuum at 60°C Dry for 24 hours to obtain acid-activated sepiolite;

[0046] 3) Mix the acid-activated sepiolite passed through a 200-mesh sieve with absolute ethanol at a weight ratio of 1:30, add 3-aminopropyltrimethoxysilane, 3-aminopropyltrimethoxysilane and acid-activated Th...

Embodiment 3

[0050] A preparation method of sepiolite / polyaniline nanocomposite material, the preparation steps are as follows:

[0051] 1) Add the raw material of sepiolite passing through 80 mesh sieve and distilled water to mix in a weight ratio of 1:60, stir and mix vigorously for 1 hour, then let it stand for 12 hours, take the upper layer of sepiolite suspension, suction filter, wash with distilled water, and store at 60°C Vacuum drying for 24h to obtain washed sepiolite;

[0052] 2) Mix the washed sepiolite passed through a 200-mesh sieve with an aqueous hydrochloric acid solution with a concentration of 2mol / L at a weight ratio of 1:30, then stir at 60°C for 8 hours, filter, wash with distilled water until neutral, and vacuum at 60°C Dry for 24 hours to obtain acid-activated sepiolite;

[0053] 3) Mix the acid-activated sepiolite and anhydrous toluene passing through a 200-mesh sieve in a ratio of 1:40 by weight, add diaminodiethoxysilane, diaminodiethoxysilane and acid-activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com