Method for extracting fault features of rolling bearing based on equal-angle double sampling

A fault feature, rolling bearing technology, applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc. The effect of feature enhancement, overcoming frequency aliasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

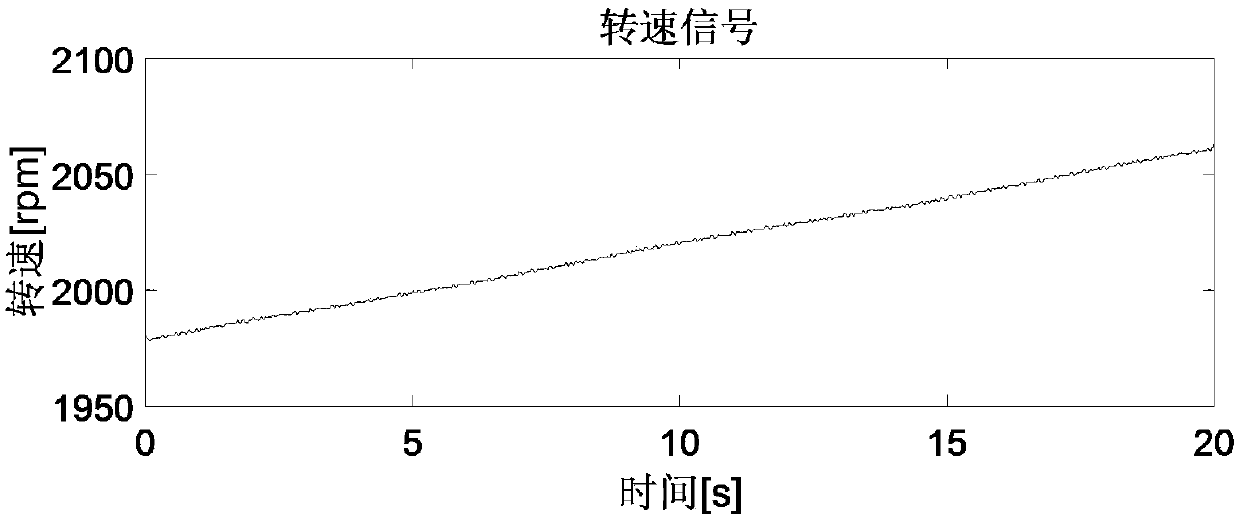

[0035] Taking the locomotive rolling bearing fault detection test bench in a depot as an example, the bearing fault location is at the outer ring / roller, and the fault type is manual peeling / indentation. Specific parameters of the bearing: a certain type of angular contact ball bearing, the pitch diameter of the bearing is 183.929mm, the number of bearing rollers is 19, the radius of the bearing rollers is 26mm, and the contact angle is 10°.

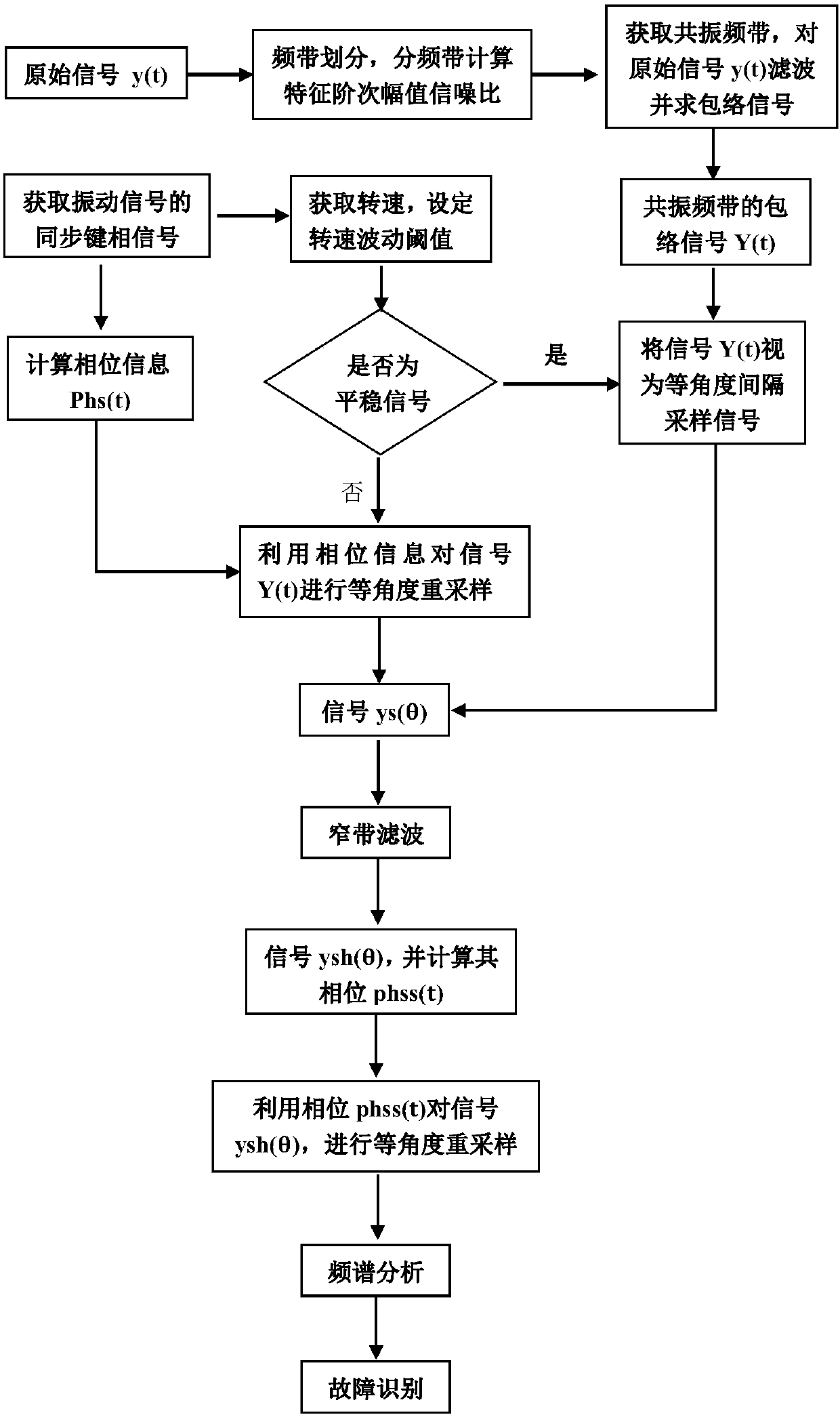

[0036] Such as figure 1 As shown, the extraction method of rolling bearing fault features based on equal-angle double sampling includes the following steps:

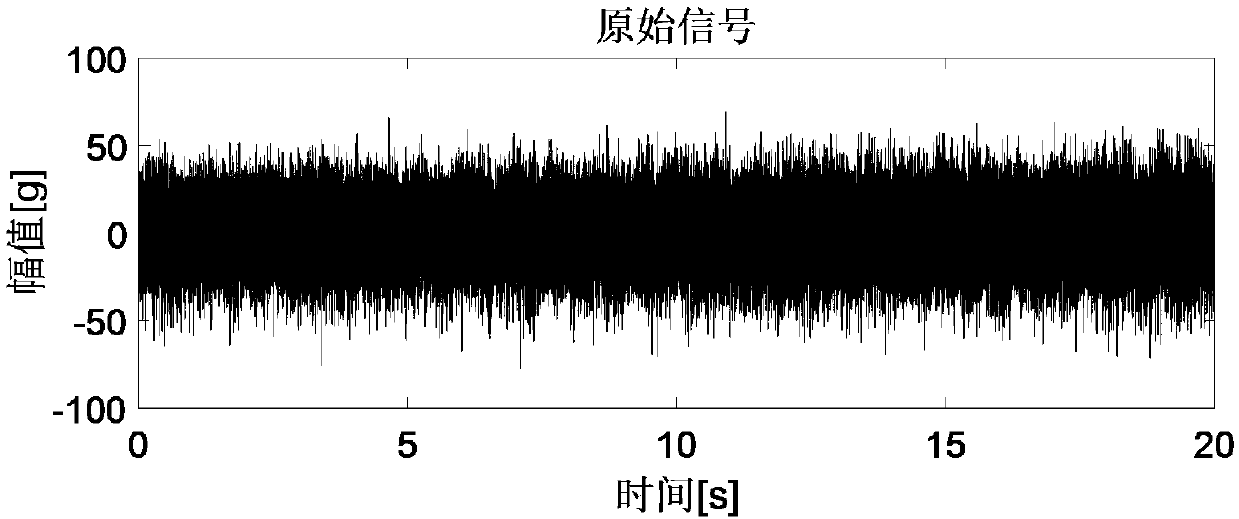

[0037] Step 1: Adsorb the vibration acceleration sensor on the bearing seat of the rolling bearing to be tested, perform high-frequency sampling to obtain the vibration signal, and use the key phase sensor to synchronously collect the key phase signal; ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com