Patents

Literature

340 results about "Post polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Post-polymerization modification of incorporated monomer units focus on two types of reaction. One is the removal of protecting groups where monomers with the desired functionality are incompatible with one or more components of the selected polymerization process.

Production Process of Polyacrylic Acid (Salt) Water-Absorbent Resin

ActiveUS20080161512A1Improve relationshipPromote absorptionAbsorbent padsBandagesPolymer scienceALLYL SUCROSE

An embodiment of the present invention allows for production, with a high productivity, of a water-absorbent resin including an improved relationship between absorption capacity and water-soluble polymer which are conflicting properties of the water-absorbent resin, being easily controlled for polymerization reaction, being of no odor, being less colored, and being of high absorption properties. In one embodiment of the present invention, acrylic acid composition is neutralized with a basic composition including an iron content of 0.2 to 5 ppm by weight (relative to a basic compound exclusive of a solvent); and then polymerizing a resultant neutralized product, the acrylic acid composition including: (i) a methoxyphenol content of 10 to 200 ppm by weight relative to the weight of acrylic acid; and (ii) at least one compound content of which is 0 to 10 ppm by weight relative to the weight of acrylic acid, the compound being selected from the group consisting of protoanemonin and furfural.

Owner:NIPPON SHOKUBAI CO LTD

Thermoset nanocomposite particles, processing for their production, and their use in oil and natural gas drilling applications

ActiveUS20070066491A1Improve curingImprove heat transfer performanceMaterial nanotechnologySynthetic resin layered productsEnvironmental resistanceBall bearing

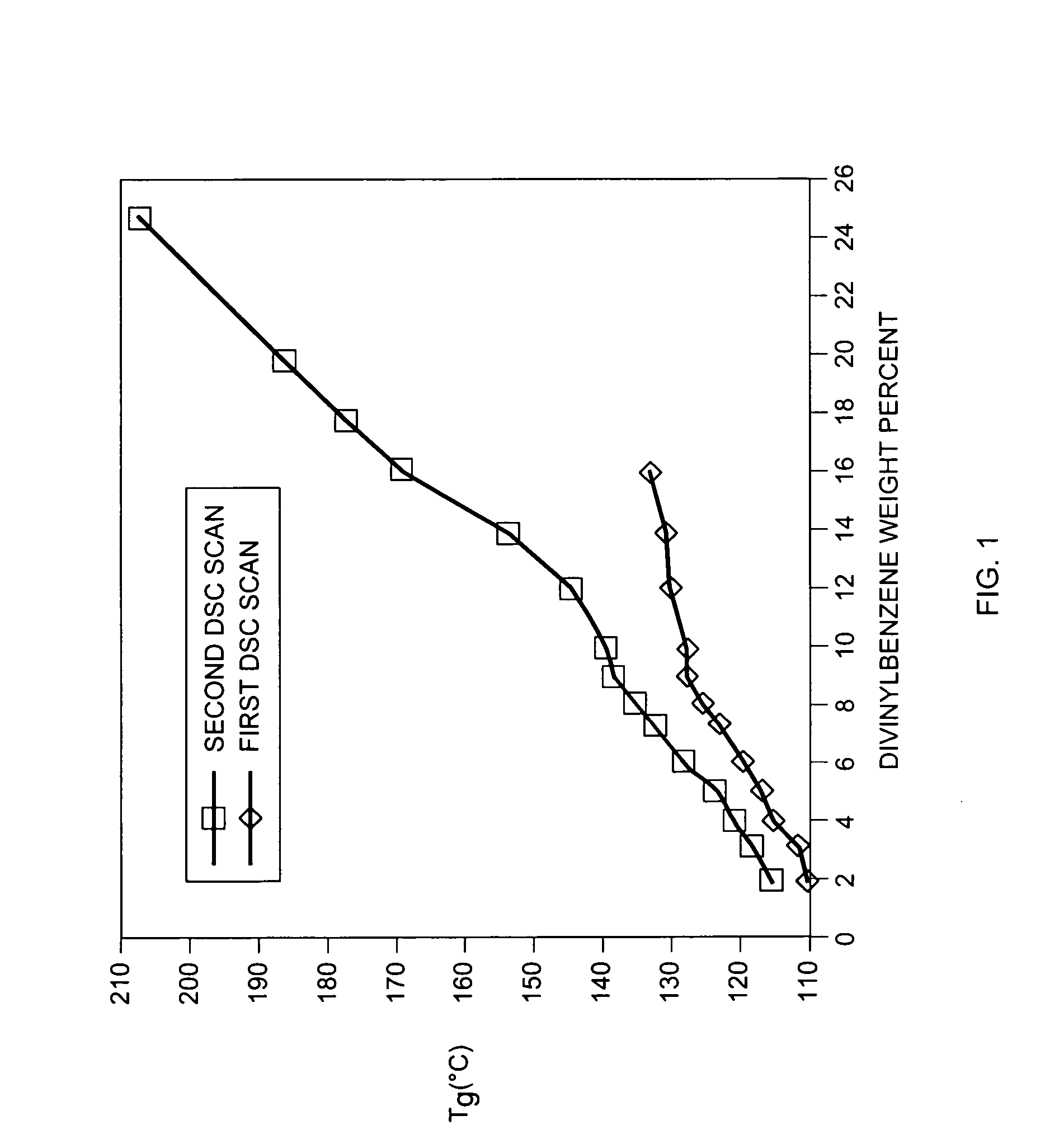

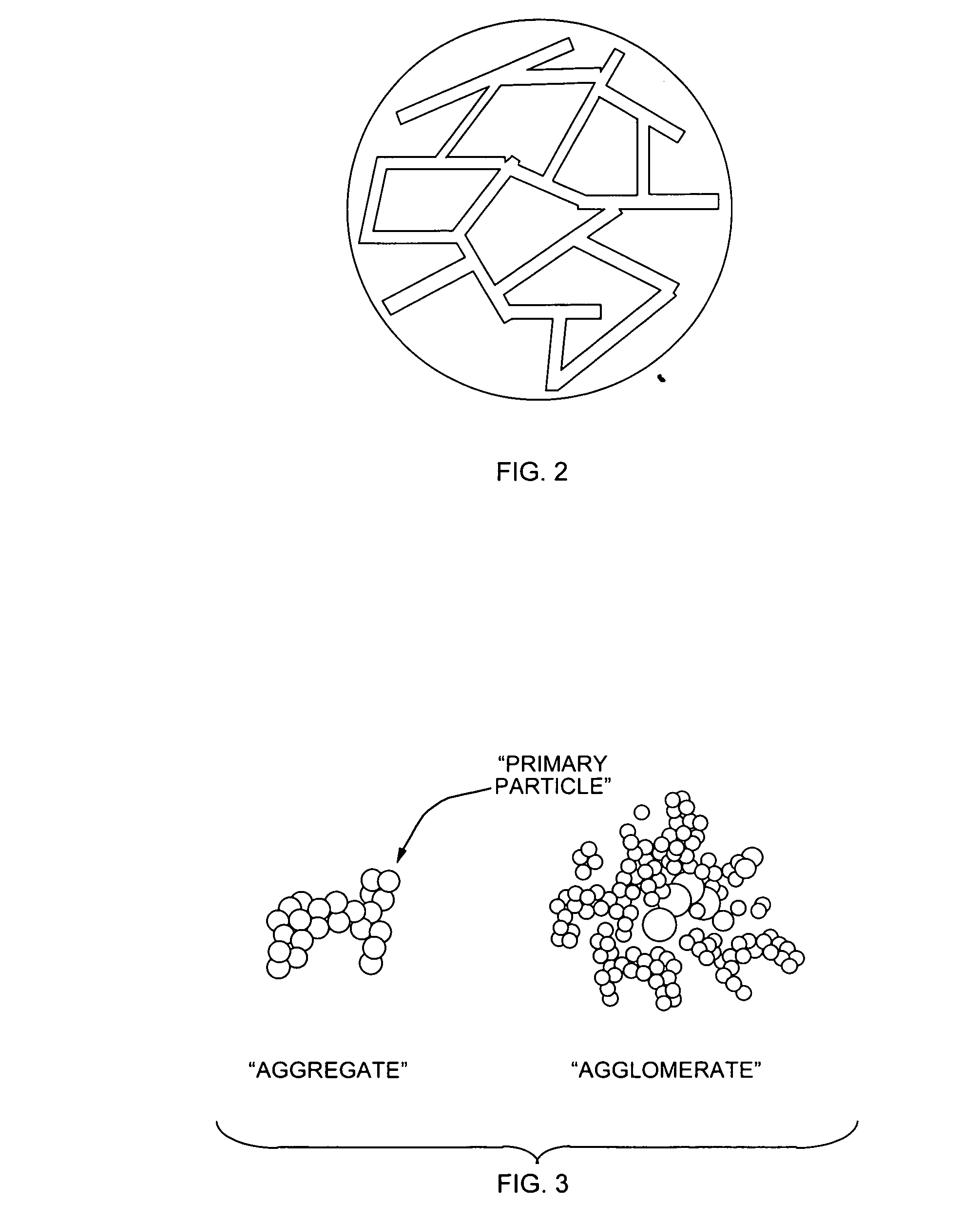

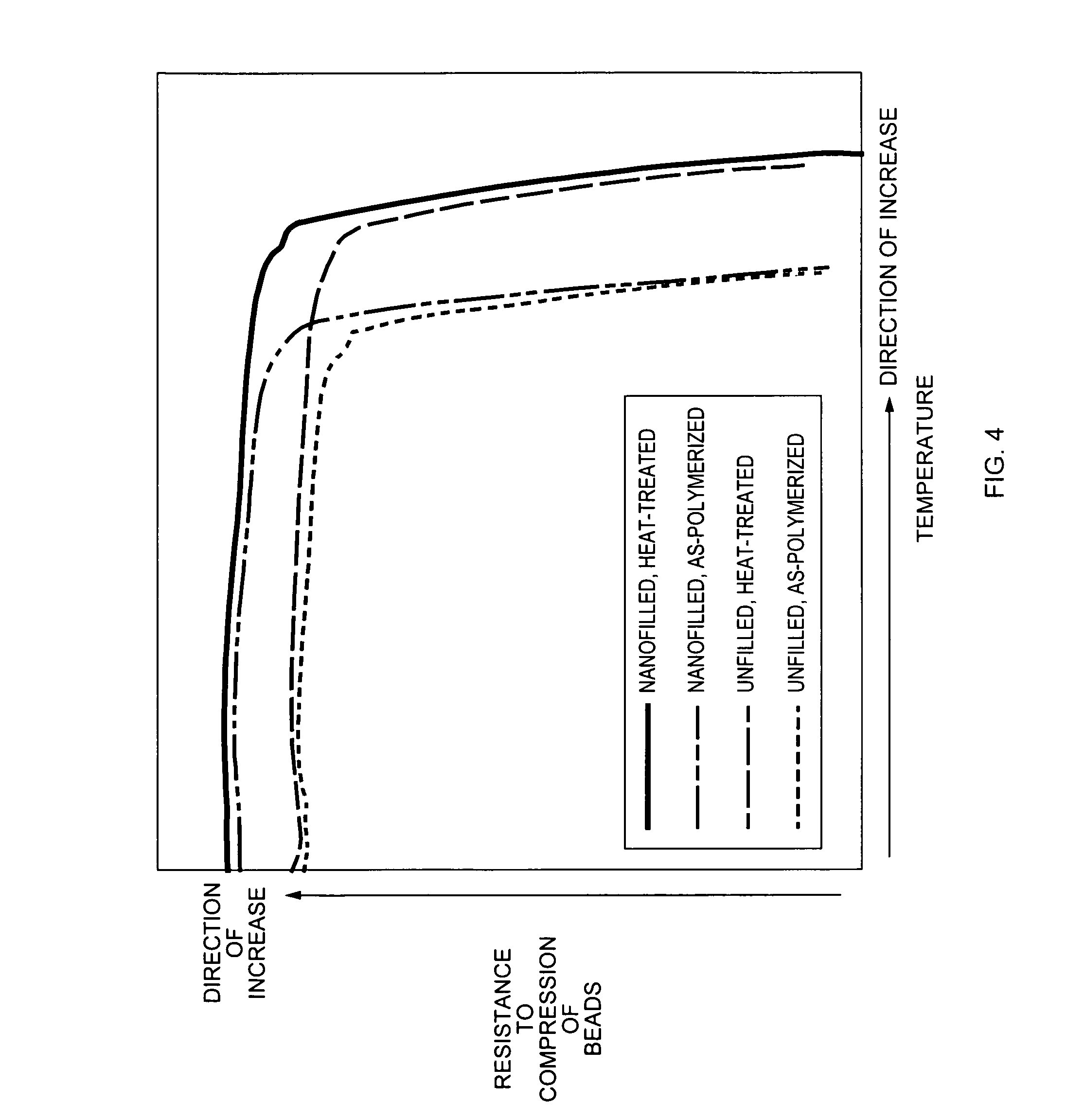

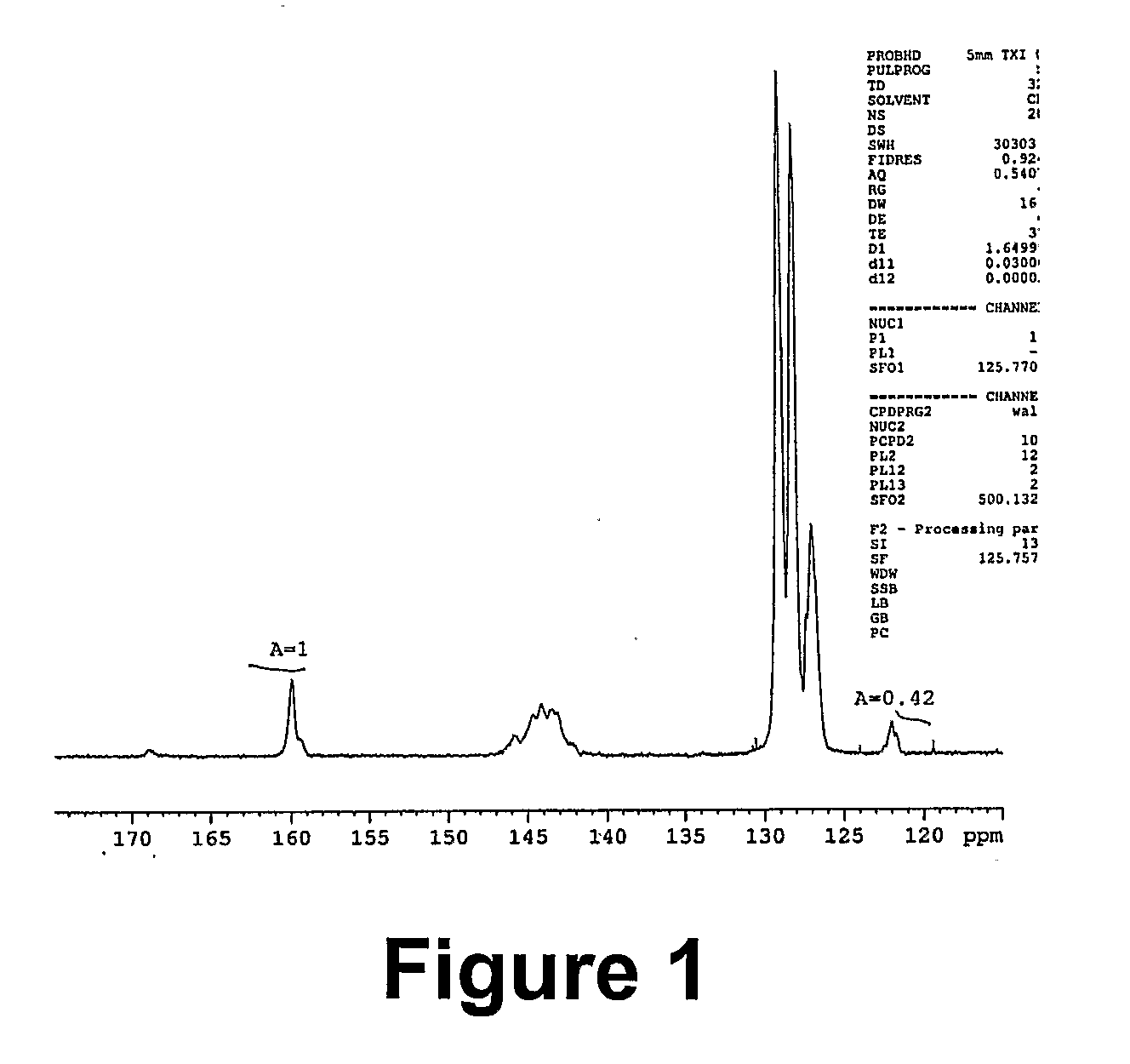

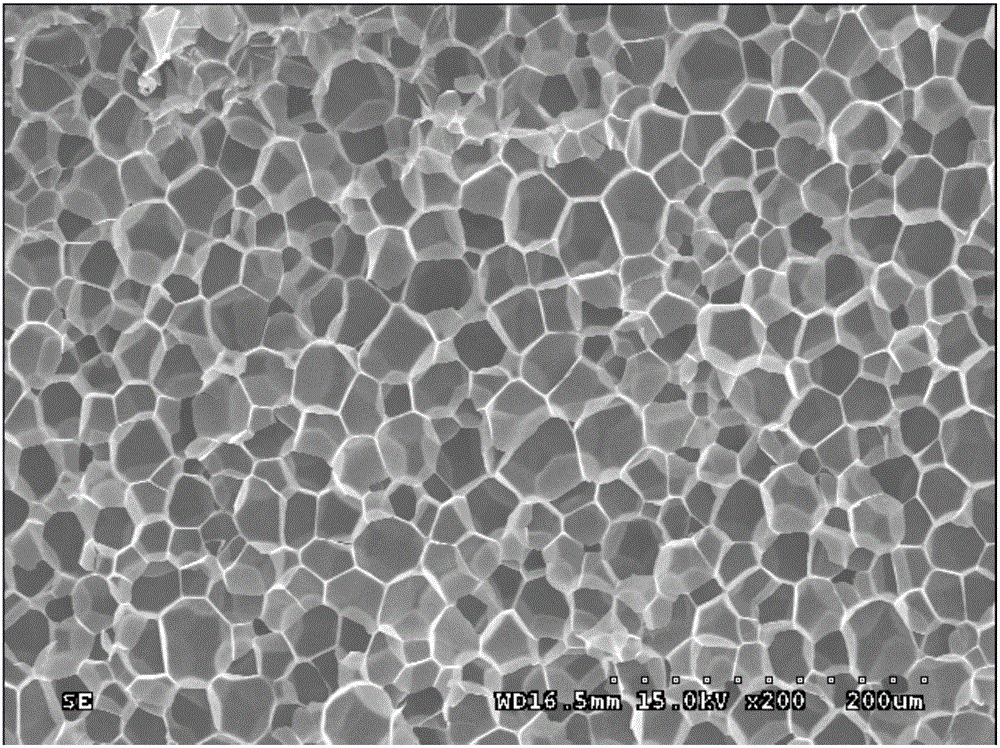

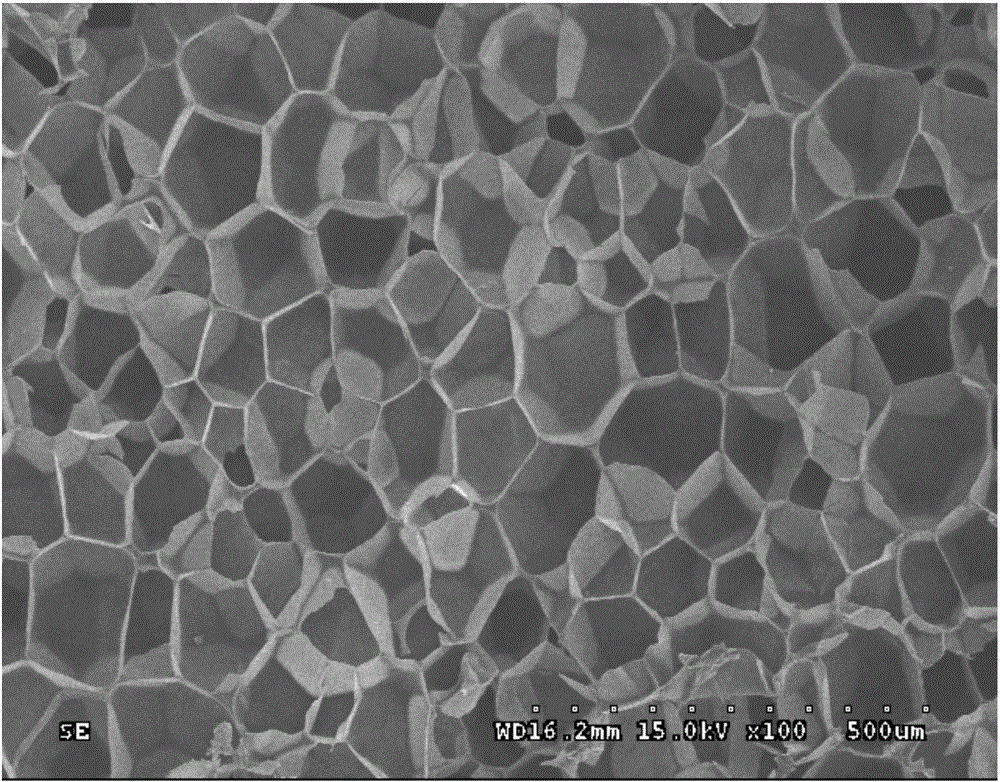

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of two different methods, either each by itself or in combination, to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method is the application of post-polymerization process steps (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. In general, its main benefits are the enhancement of the maximum possible use temperature and the environmental resistance. The other method is the incorporation of nanofillers, resulting in a heterogeneous “nanocomposite” morphology. In general, its main benefits are increased stiffness and strength. Nanofiller incorporation and post-polymerization heat treatment can also be combined to obtain the benefits of both methods simultaneously. The present invention relates to the development of thermoset nanocomposite particles. It also relates to the optional further improvement of the heat resistance and environmental resistance of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

Preparation of Functional Polymers

The process of the present invention is directed toward conducting highly selective, high yield post polymerization reactions on polymers to prepare functionalized polymers. An embodiment of the present invention comprises conducting click chemistry reactions on polymers. Preferably, the polymers were prepared by controlled polymerization processes. Therefore, embodiments of the present invention comprise processes for the preparation of polymers comprising conducting a click chemistry reaction on a functional group attached to a polymer, wherein the polymer has a molecular weight distribution of less than 2.0. The functional polymers may be prepared by converting an attached functional unit on the polymer thereby providing site specific functional materials, site specific functional materials comprising additional functionality, or chain extended functional materials. Embodiments of the process of the present invention include functionalization reactions, chain extensions reactions, to form mock copolymer linking reactions, and attaching side chains to form graft copolymers, for example.

Owner:CARNEGIE MELLON UNIV

Reagent and method for providing coatings on surfaces

InactiveUS20030165613A1Easy to controlImprove coating efficiencyMaterial nanotechnologySurgeryPorosityBiological activation

A grafting reagent and related method of using the reagent to form a polymeric layer on a support surface, and particularly a porous support surface, in a manner that provides and / or preserves desired properties (such as porosity) of the surface. The reagent and method can be used to provide a thin, conformable, uniform, uncrosslinked coating having desired properties onto the surface of a preformed, and particularly a porous, polymeric substrate. The method includes the steps of a) providing a porous support surface, b) providing a nonpolymeric grafting reagent comprising a photoinitator group, c) providing one or more polymerizable monomers adapted to be contacted with the surface, in the presence of the grafting reagent, and to be polymerized upon activation of the photoinitiator; and d) applying the grafting reagent and monomer(s) to the surface in a manner, and under conditions, suitable to coat the surface with the grafting reagent and to cause the polymerization of monomers to the surface upon activation of the grafting reagent.

Owner:SURMODICS INC

Preparation of functional polymers

Owner:CARNEGIE MELLON UNIV

Microspheres as a delivery vehicle for bio-active agents useful in agricultural applications

A plurality of releasably loaded elastomeric microspheres comprising a plurality of elastomeric microspheres loaded with at least one releasable agriculturally active agent within the optical boundaries of the elastomeric microspheres and post-polymerization addition and in-situ polymerization processes for preparing the releasably loaded elastomeric microspheres are also provided.

Owner:3M INNOVATIVE PROPERTIES CO

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Bio-polymer and scaffold-sheet method for tissue engineering

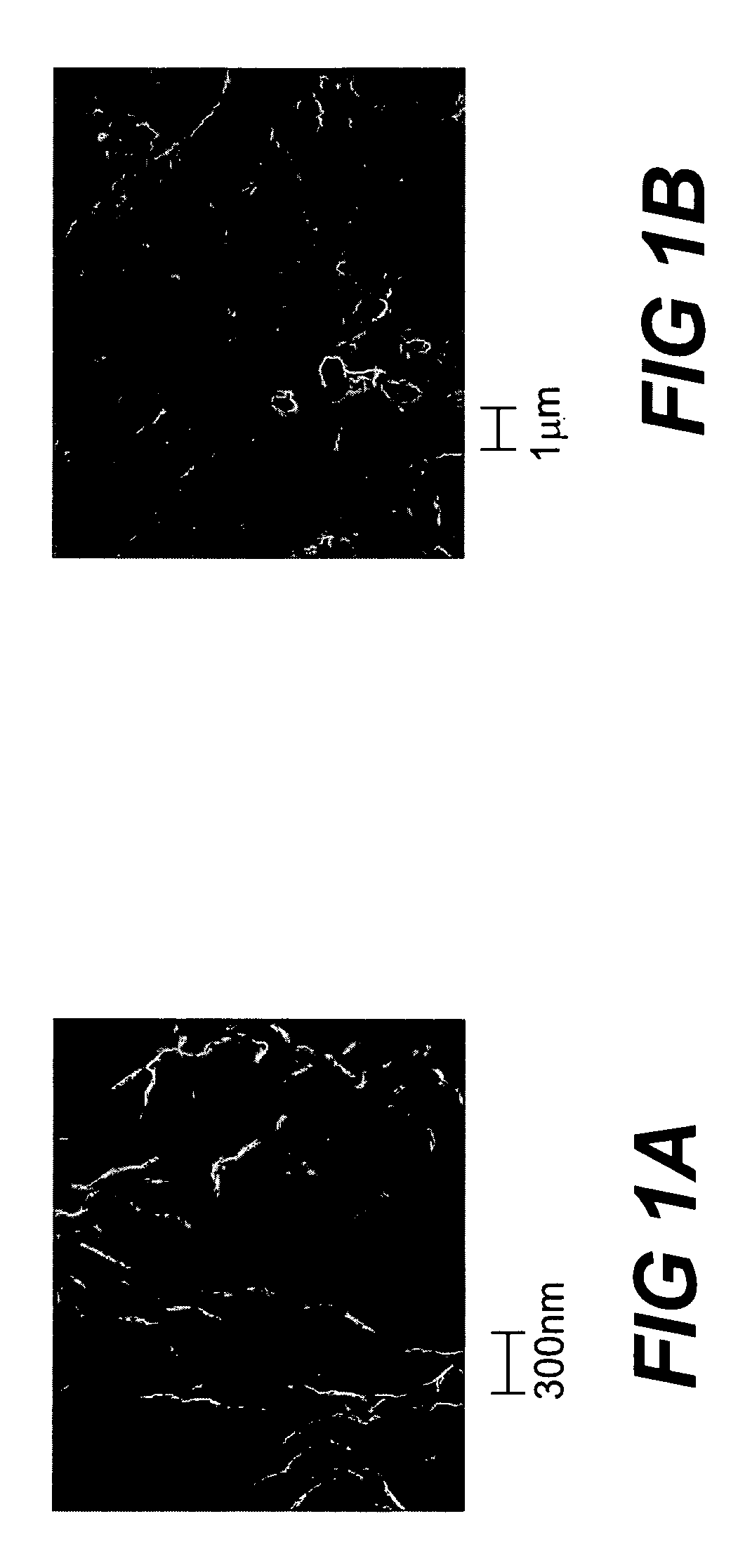

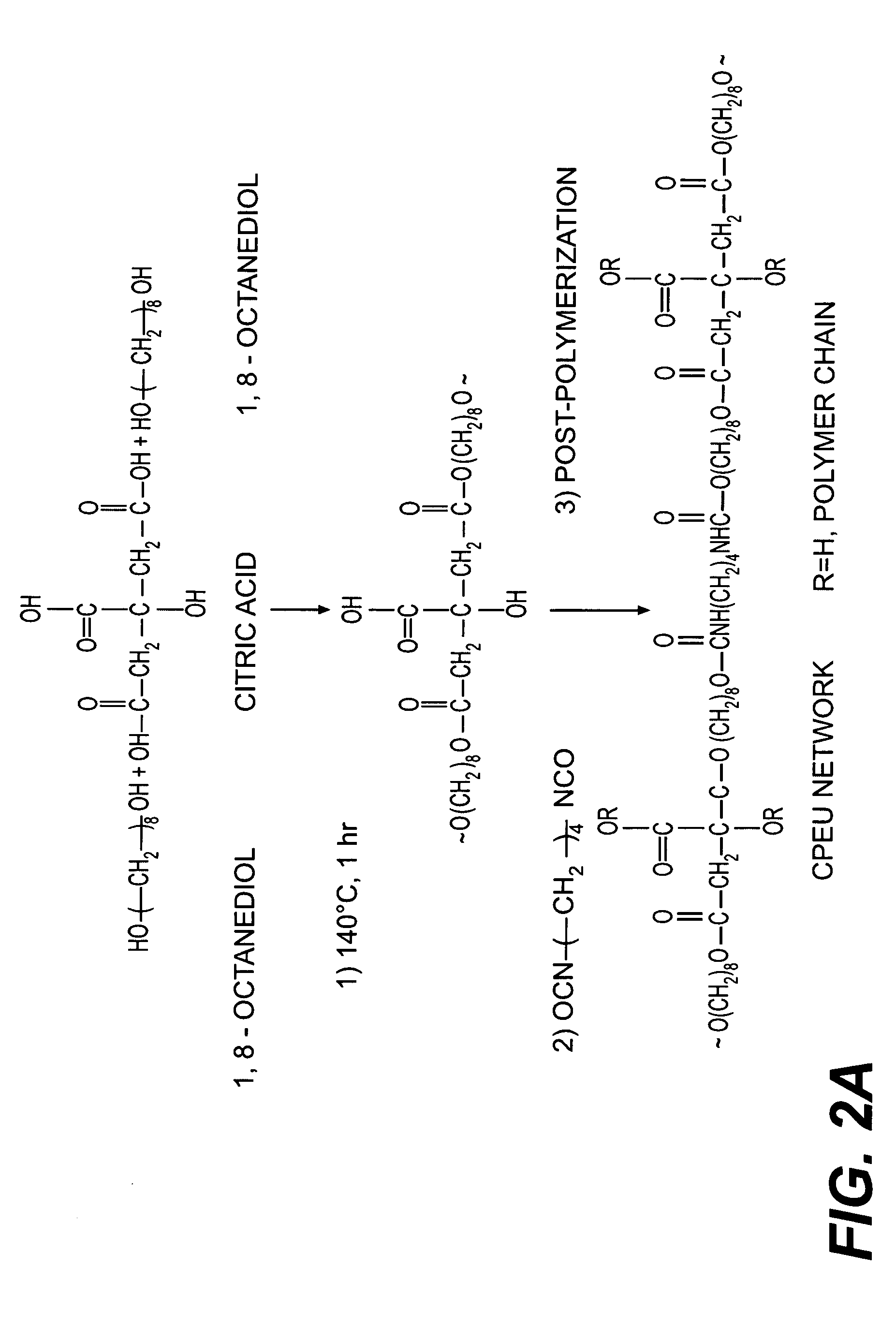

ActiveUS20090093565A1Easy to divideAvoid communicationAdditive manufacturing apparatusSurgical adhesivesElastomerPolyester

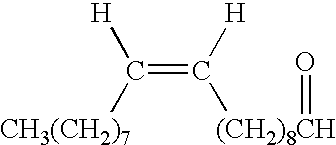

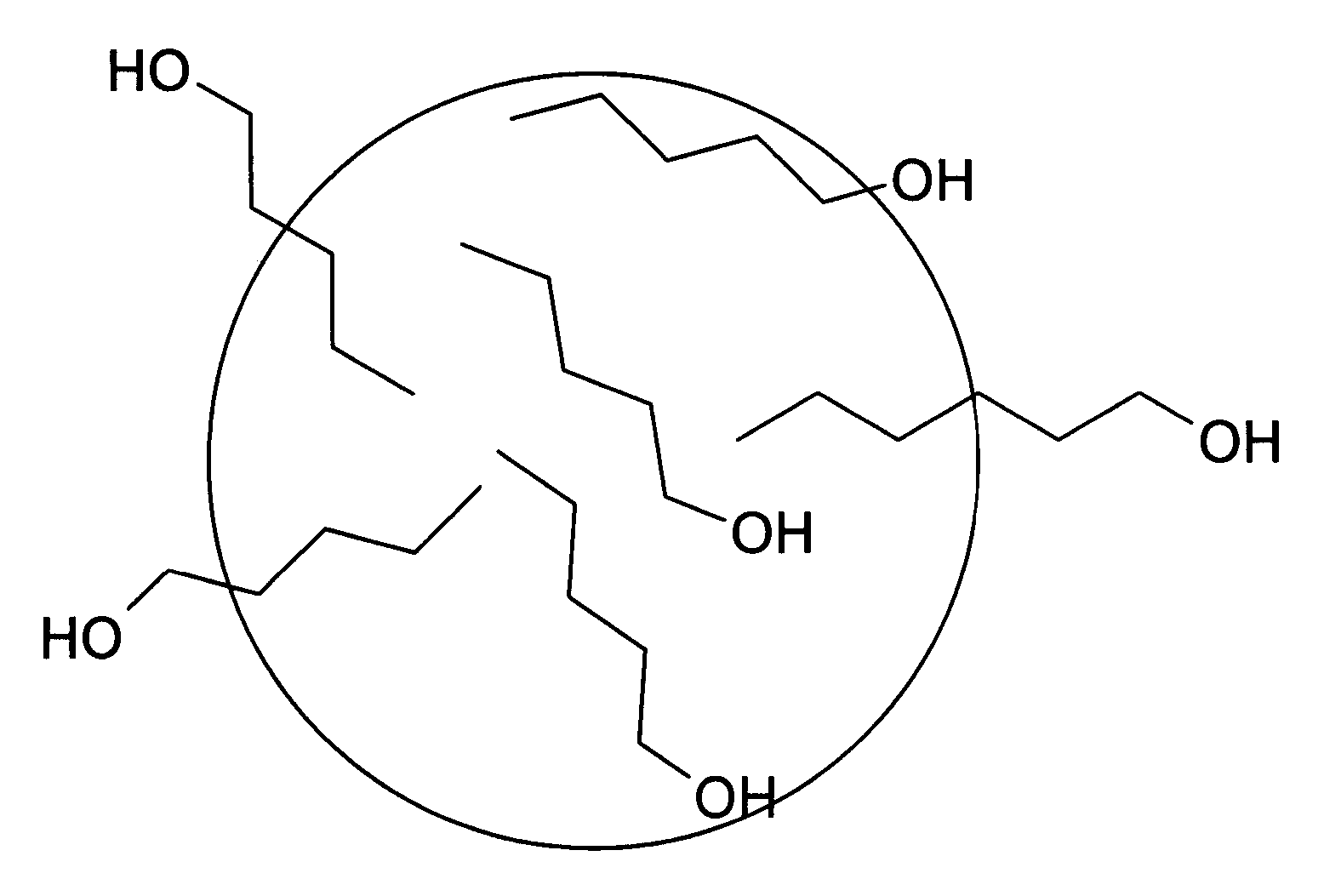

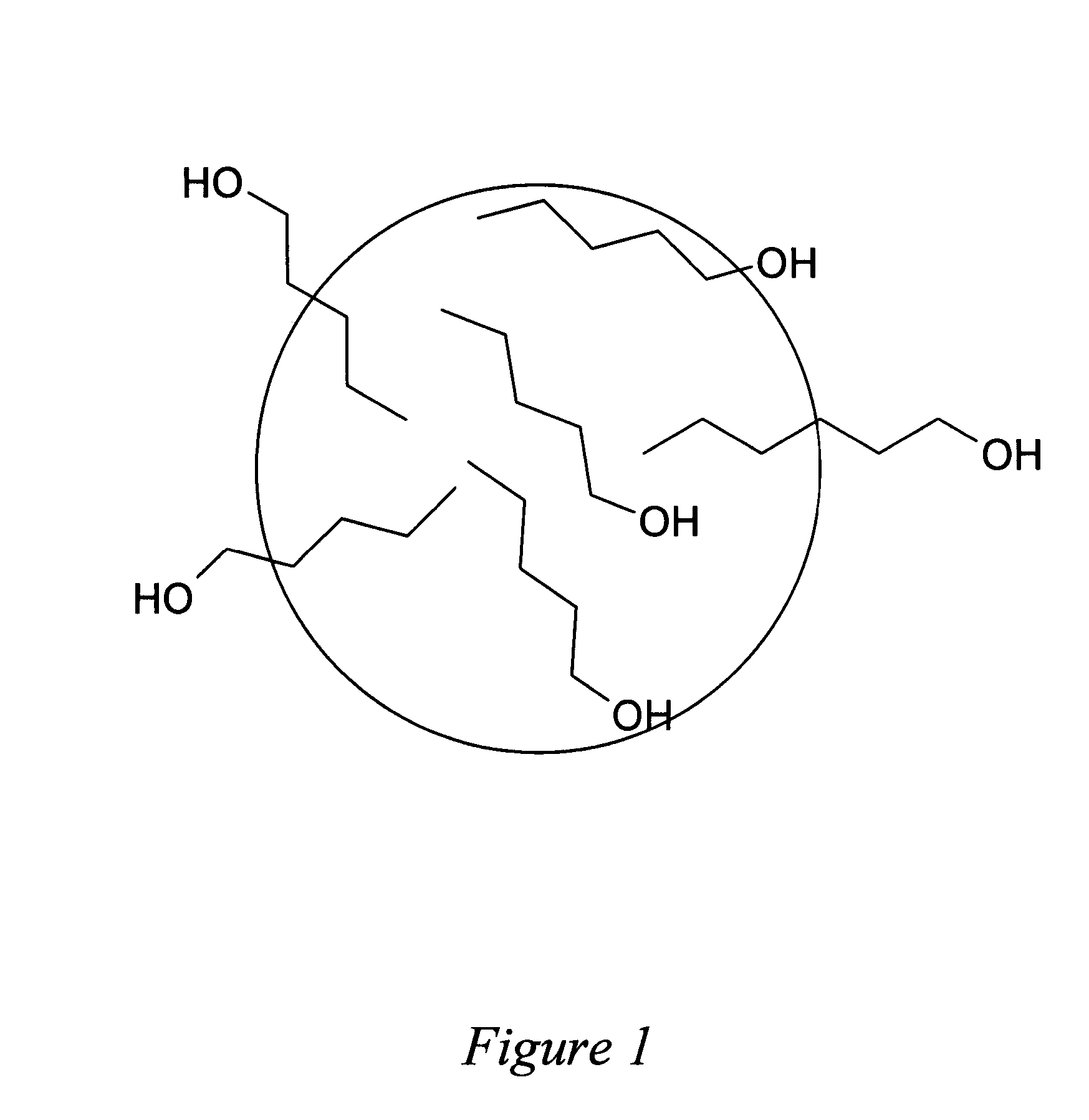

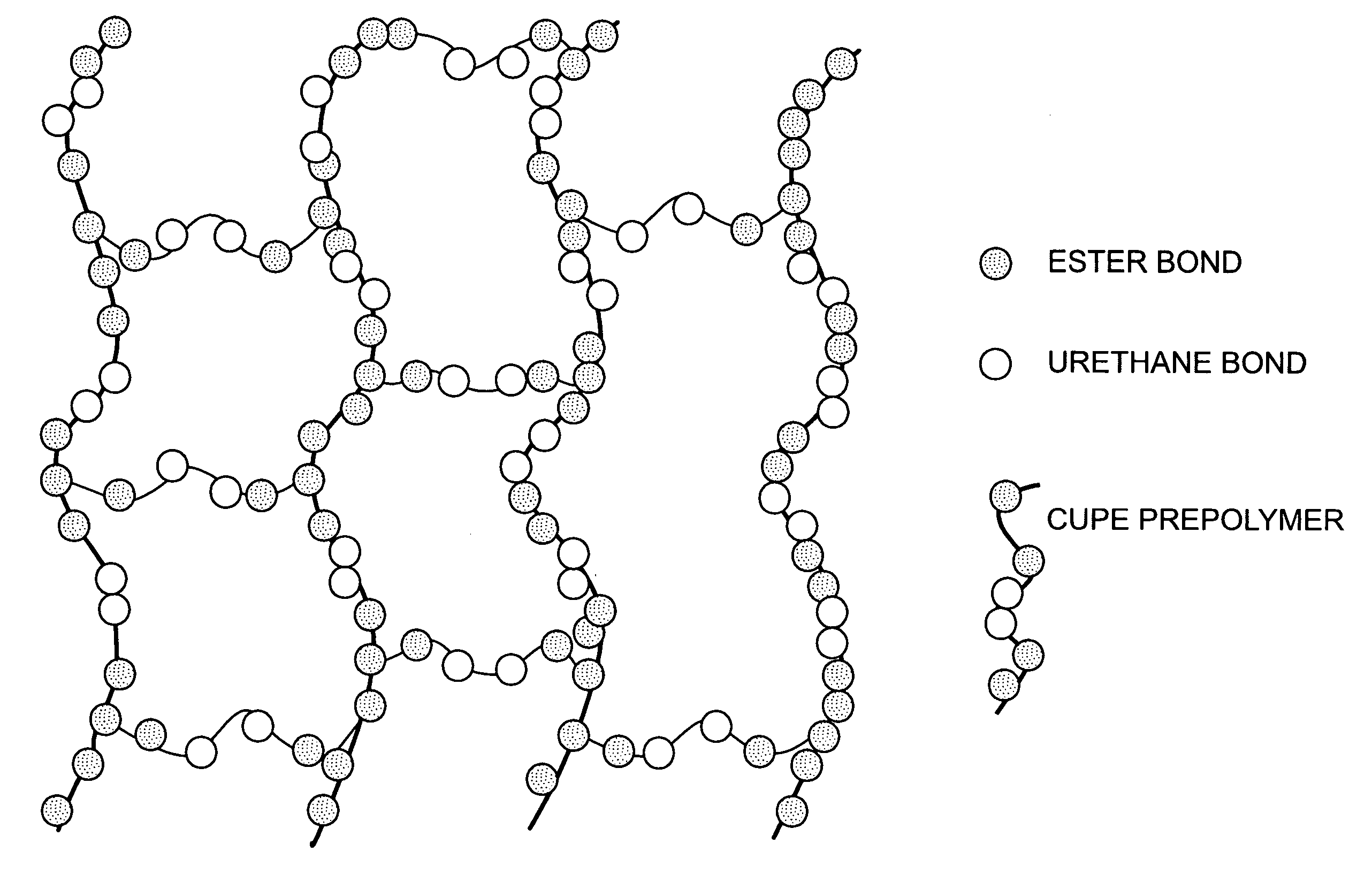

A method of making a new type of biomaterials, biodegrable crosslinked urethane-containing polyester (CUPE) elastomers and a scaffold-sheet engineering method for tissue engineering applications is provided. CUPEs can be synthesized by forming a linear pre-polymer, which is a polyester, introducing the urethane bonds into polyester using a diisocyanate as a linker, and crosslinking the resulting urethane containing linear polymers to form CUPEs via post-polymerization. This family of polymers, CUPEs, exhibit excellent biocompatibility with desired degradation. Tissue engineering scaffolds made of CUPEs are soft and elastic, and have good mechanical strength. Complex tissue grafts can be constructed by a novel layer-by-layer (LBL) scaffold-sheet engineering design using CUPE sheets. CUPE scaffolds can provide openings for cell to cell communication across scaffold layers and angiogenesis into the depth of the construct. Biomolecules, such as anticoagulants, can be incorporated into the CUPE polymers, increasing their viability as vascular graft scaffolds.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

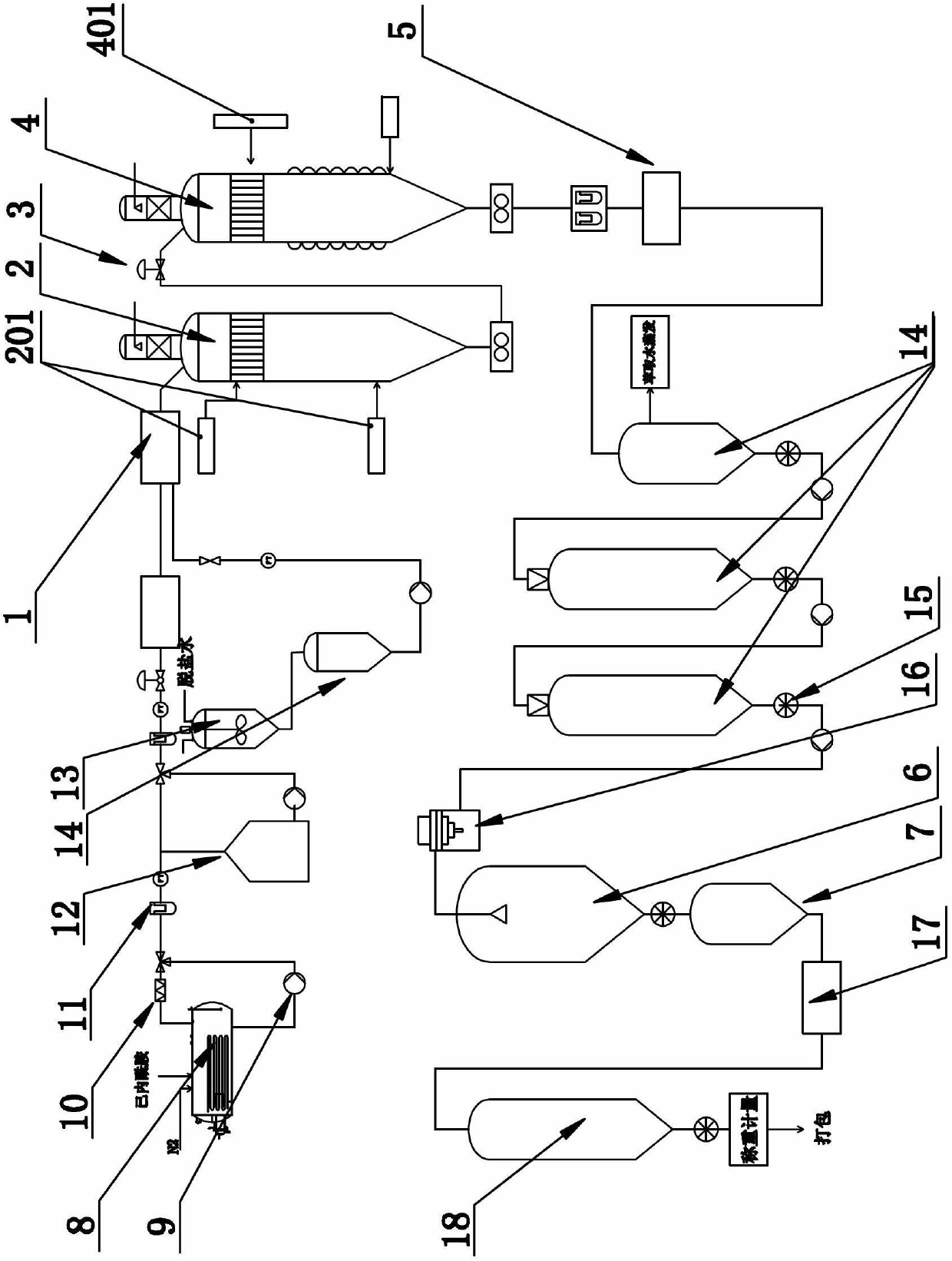

Technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers

ActiveCN102943316AEfficient transferAchieving Scale AggregationWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers, and belongs to the field of high performance fiber production. The technology comprises the steps: A, degassing, pre-polymerizing and defoaming; B, post-polymerizing and defoaming; C, spinning and solidifying; D, post-treating; and E, heat-treating and the like. Through optimizing equipment and controlling parameters, a plurality of problems of the prior art are solved. The technological process, equipment cooperation and parameter control of the basic technical scheme are taken as an integral system, are cooperated with each other and are dispensable, materials can be effectively transferred, the scale polymerizing and subsequent scale spinning of the PBO polymer are realized, and a high-quality PBO fiber product is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Anti-microbial agent delivery system

A delivery system for delivering an anti-microbial agent to a surface in a time release manner. The delivery system includes one or more polymeric particles (e.g., microspheres, core / shell particles, latexes, porogens, cryogenically ground beads, condensation polymer particles, flakes, etc.) and at least anti-microbial agent attached thereto. The anti-microbial agents may or may not be soluble in the polymeric particle or in the monomeric precursor used to make the polymeric particle. The anti-microbial agent can be incorporated into the microsphere using either a post polymerization addition process or an in situ addition process. The delivery system can be fashioned to provide characteristics that are application specific. Examples of such delivery systems include but are not limited to substrates (such as tapes, sheets of material and the like) coated with the releasably loaded polymeric particles, sprayable dispersions or suspensions of these polymeric particles and the like.

Owner:3M INNOVATIVE PROPERTIES CO

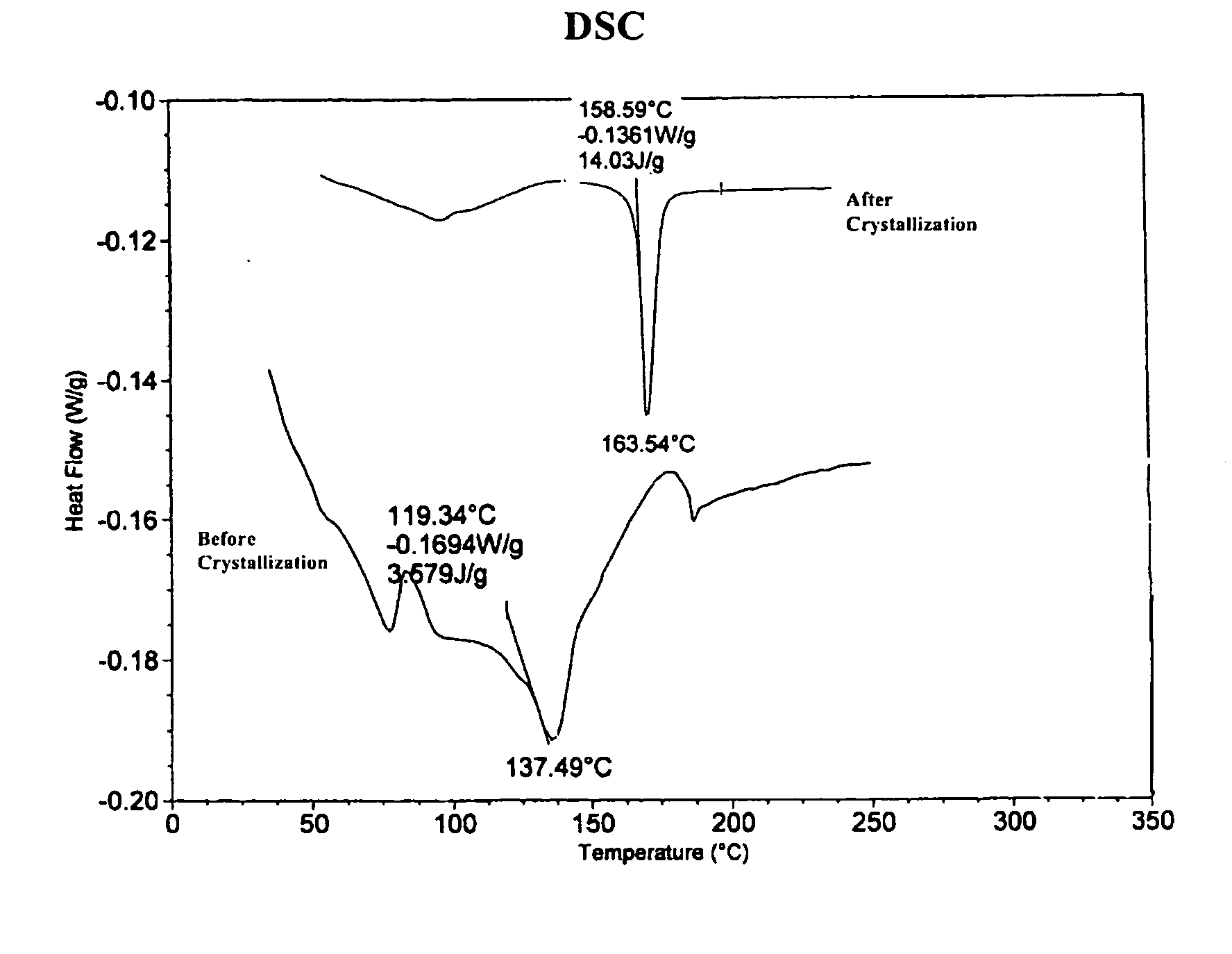

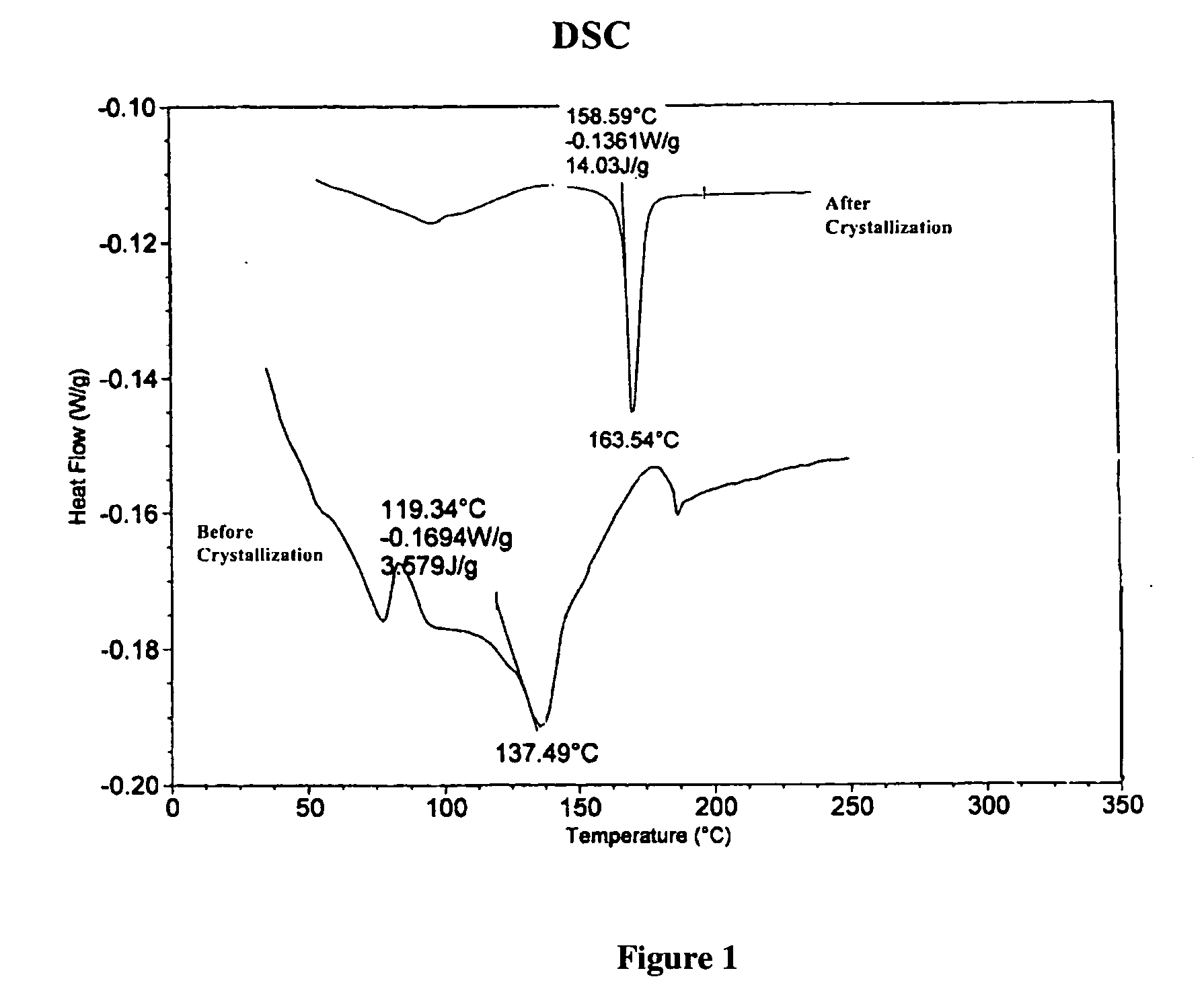

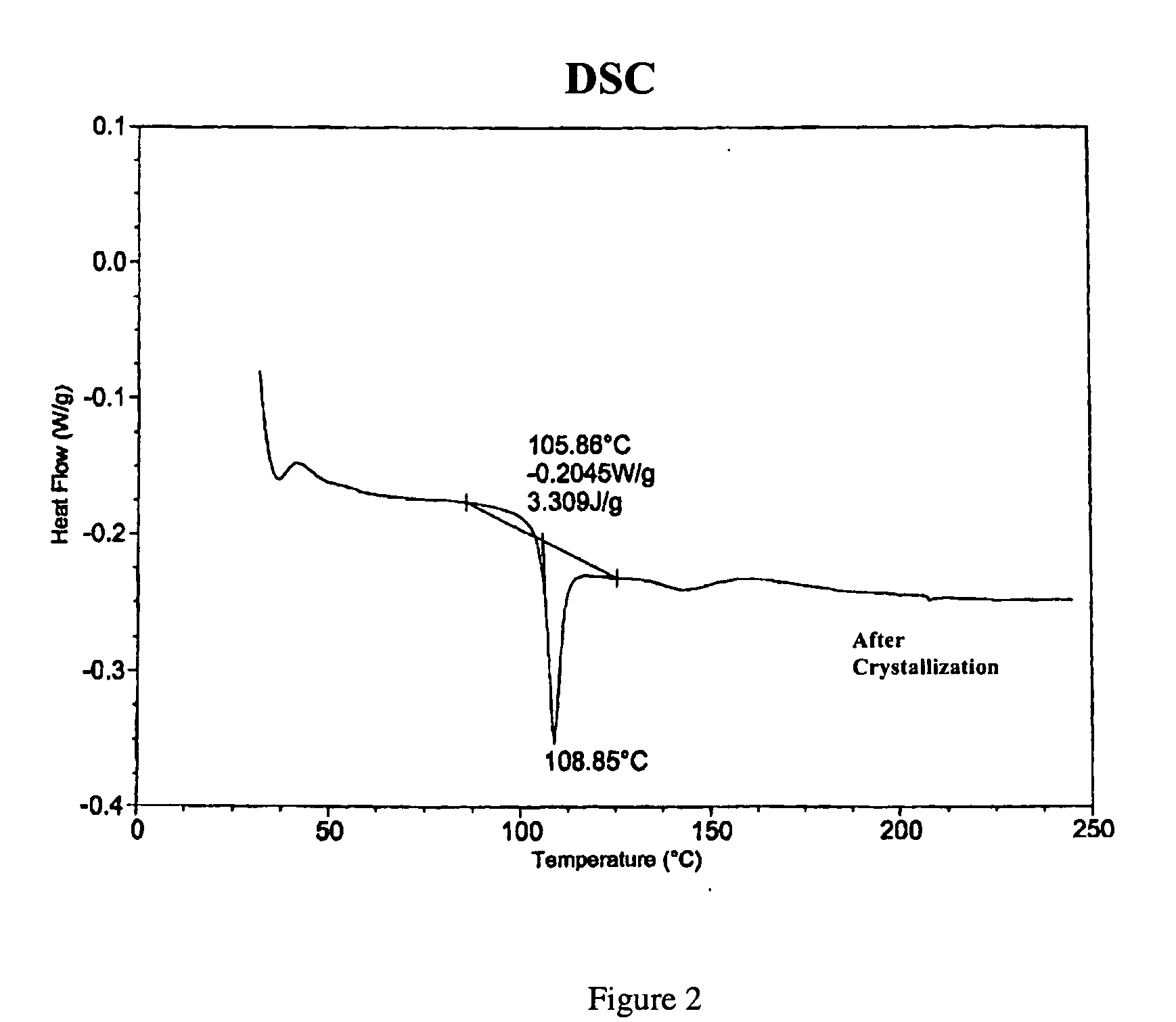

Crystalline polyphosphonates and methods related thereto

InactiveUS20050222370A1High molecular weightExcellent combination of fire resistanceFiberPolymer science

Disclosed are crystalline polyphosphonates and a method to induce crystallization. These crystalline polyphosphonates exhibit a unique and advantageous combination of properties, allowing for solid state post polymerization reactions and solid state dry mixing with other polymers. Also disclosed are polymer compositions that comprise these polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these crystalline polyphosphonates and polymer compositions, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof.

Owner:FRX POLYMERS LLC

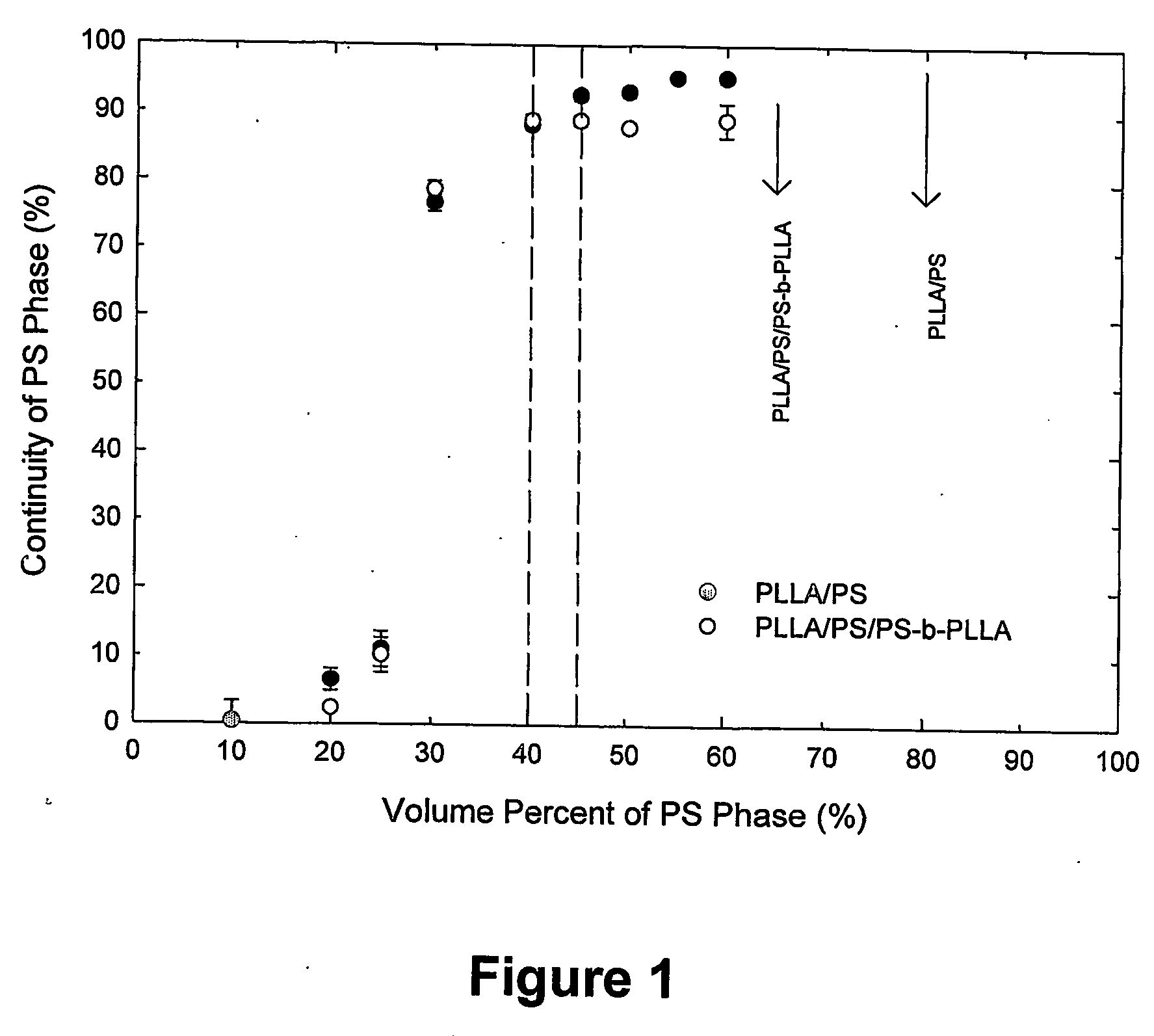

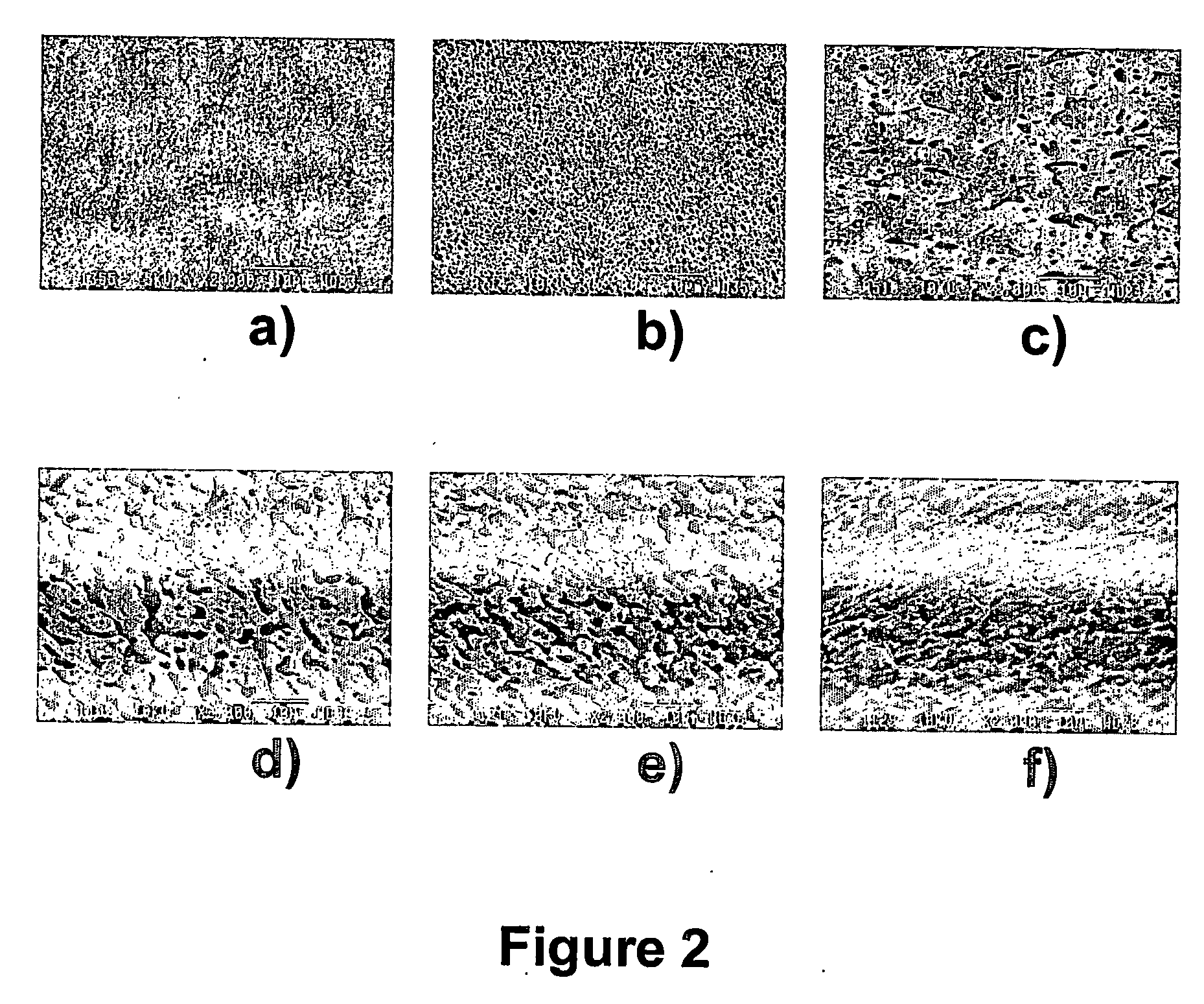

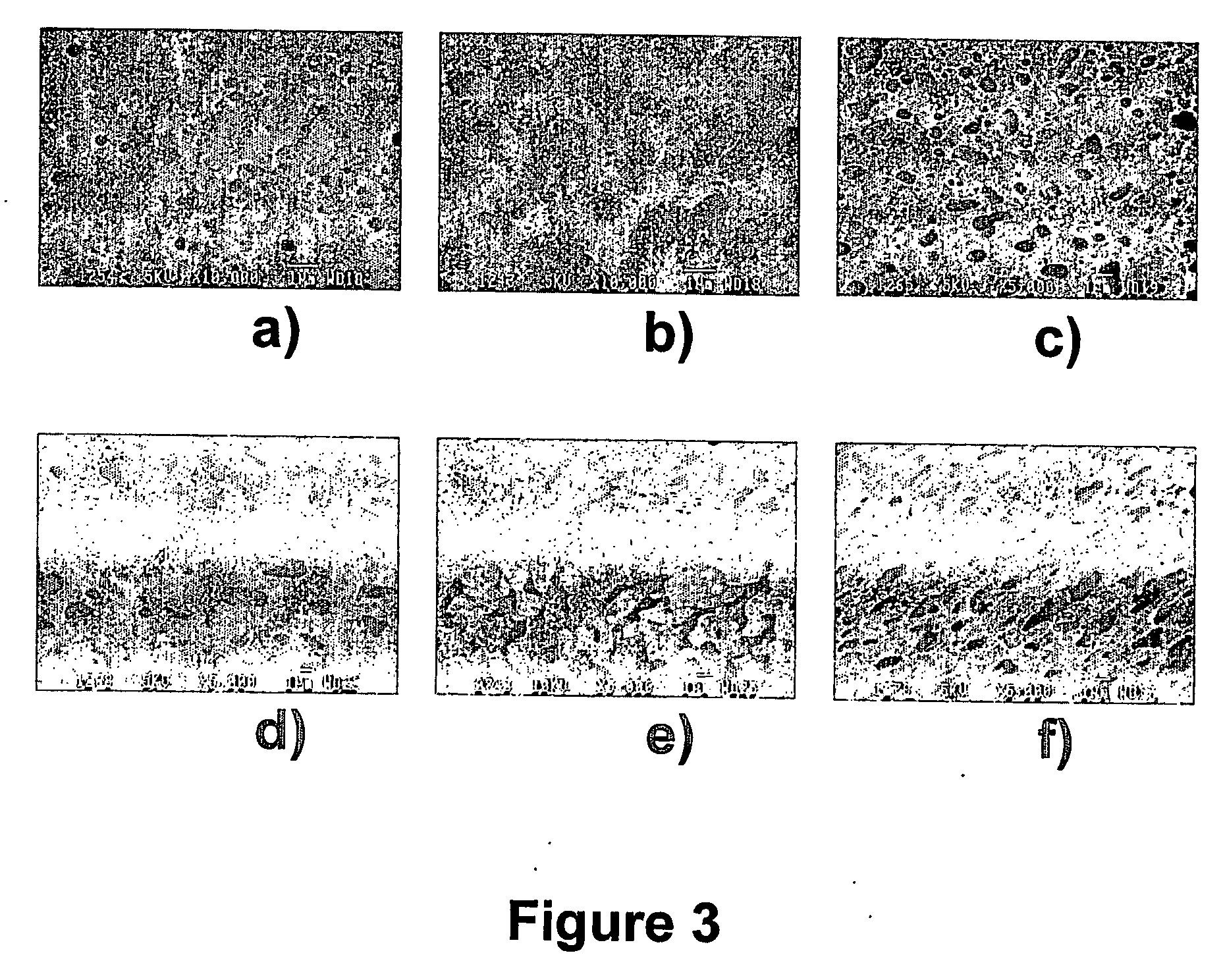

Microporous articles comprising biodegradable medical polymers, method of preparation thereof and method of use thereof

The present invention relates to a highly controlled method of preparation of a microporous biodegradable polymeric article. Firstly, at least one biodegradable polymer A, one polymer B, biodegradable or not, partially or totally immiscible with A, and a compatibilizer C for A and B are selected. Secondly, the selected polymers are melt-blended, thereby preparing a polymer blend; wherein said polymers A and B have an essentially continuous morphology. Thirdly, after cooling, polymer B and compatibilizer C are selectively extracted from the polymer blend by dissolution in a solvent that is a non-solvent of polymer A. The resulting polymeric article has an essentially continuous porosity with a void volume between 10 and 90% and a unimodal diameter distribution set to a predefined unimodal peak location. It can be used in tissue engineering, for controlled release applications or as an implantable medical device.

Owner:CORP DE LECOLE POLYTECHNIQUE DE MONTREAL

Sterilizable Photopolymer Serum Separator

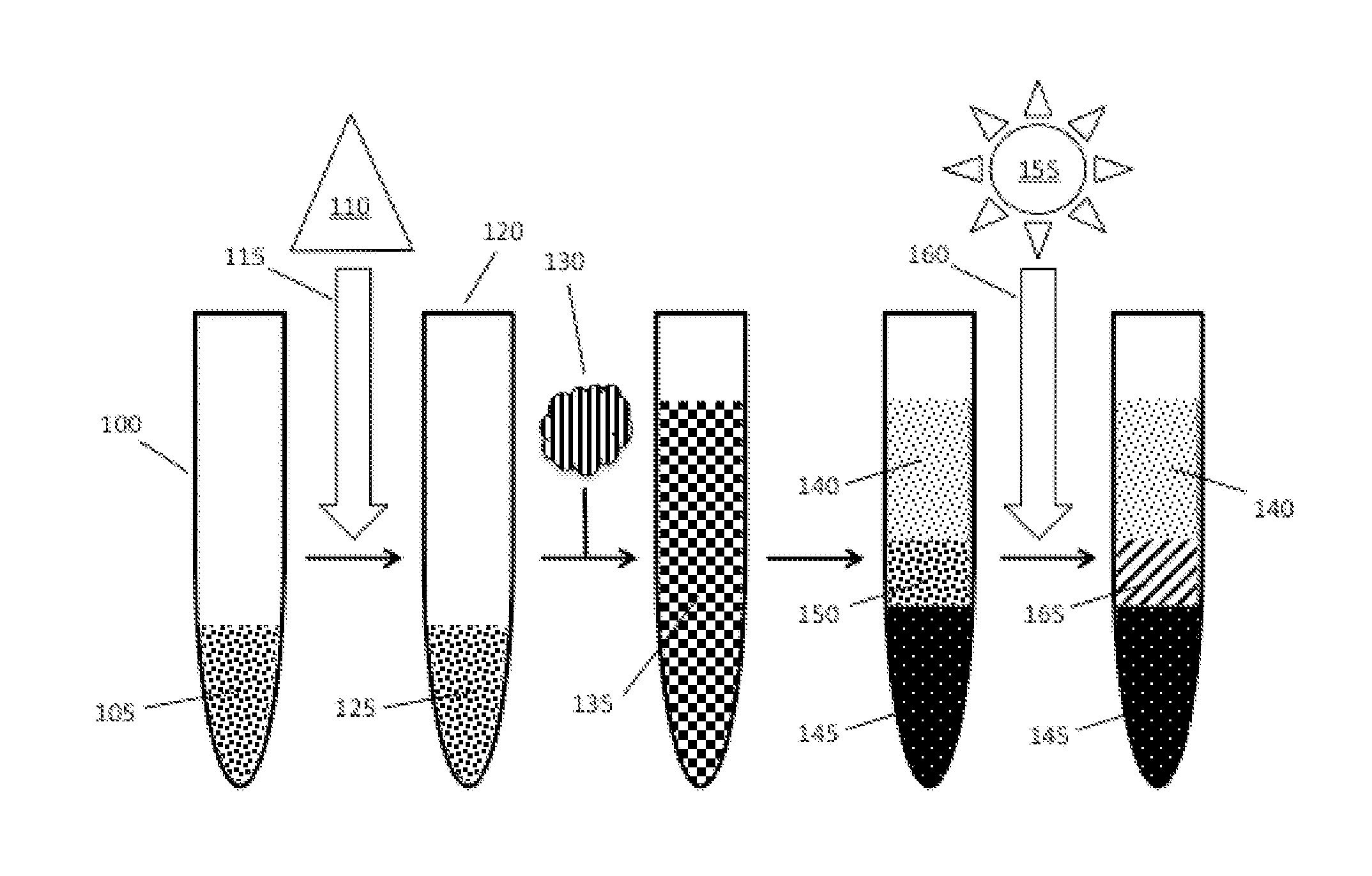

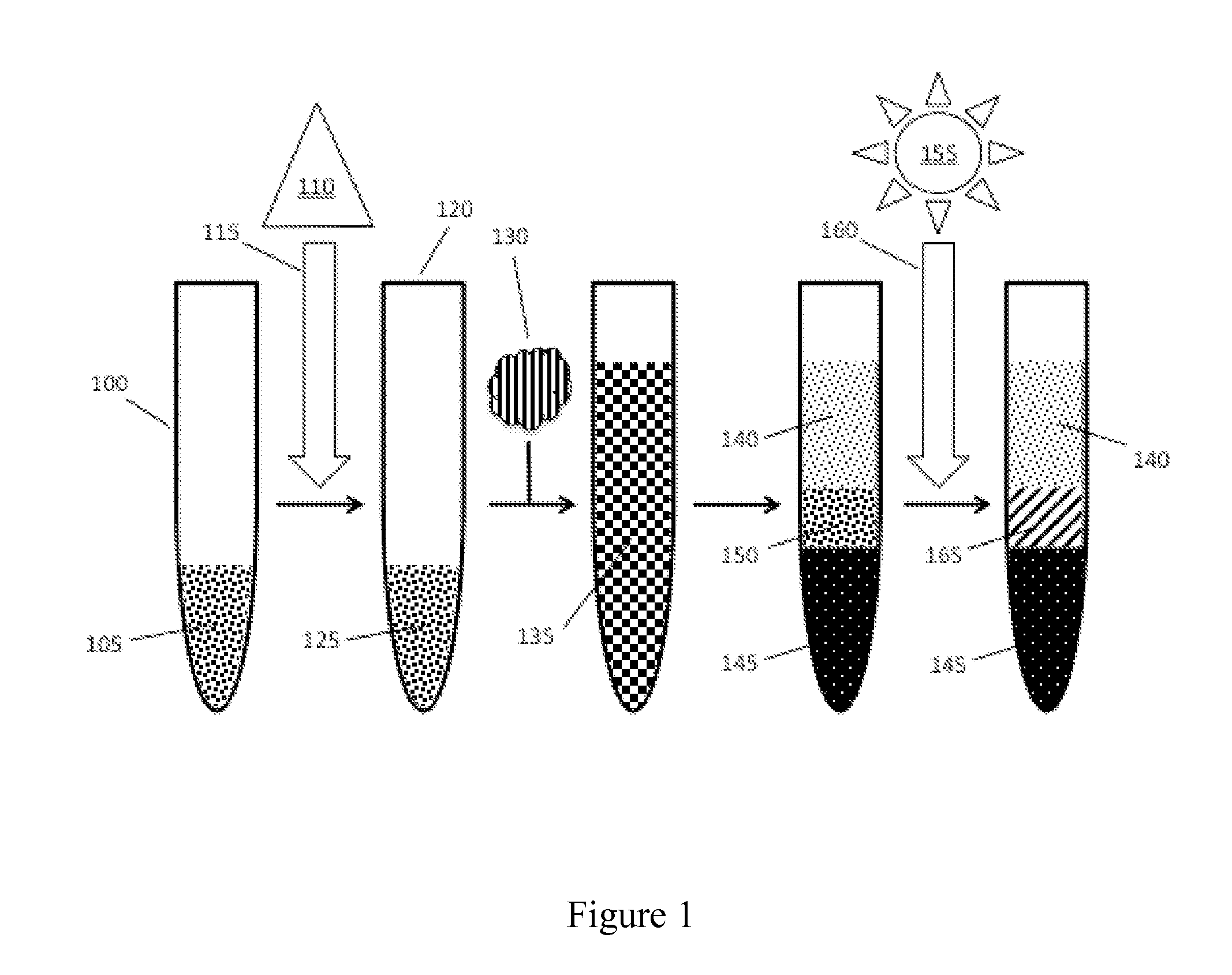

ActiveUS20140113795A1Dispersed particle separationCentrifugal force sediment separationCentrifugationPhysical chemistry

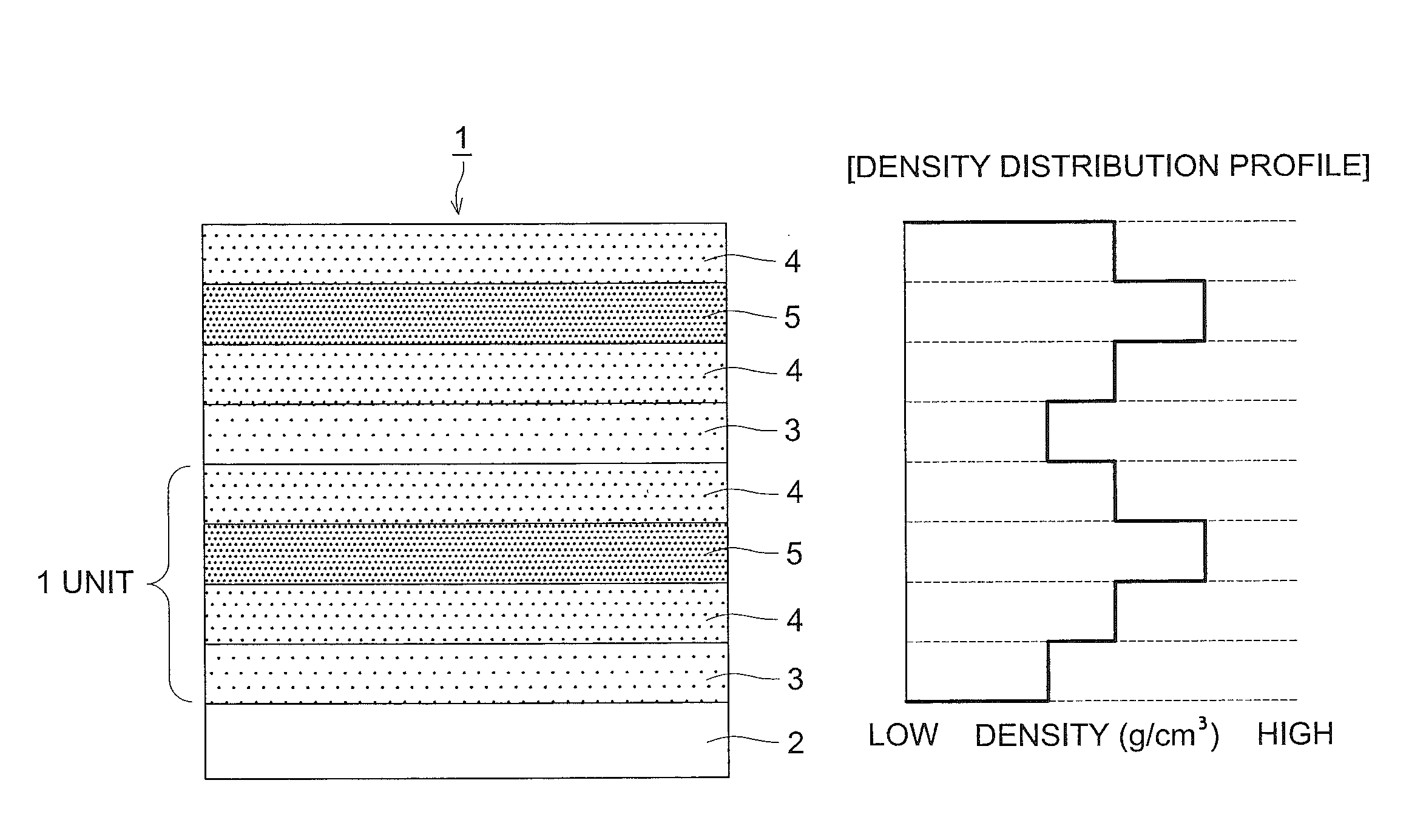

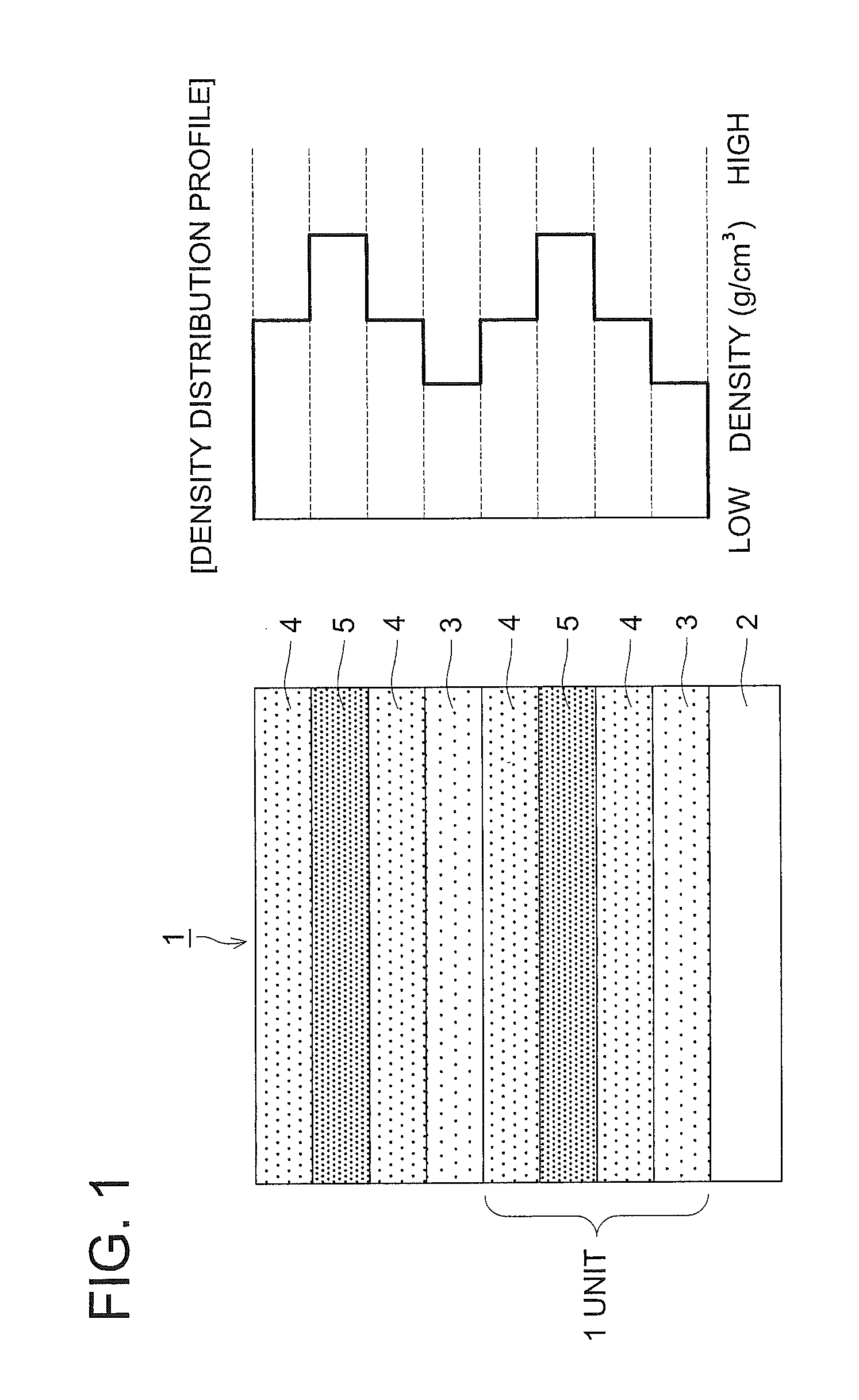

Sterilizable separator tubes and methods of utilization of same are presented. Methods include providing a separator tube containing a separator substance that can be polymerized to a desired hardness following sterilization using radical generating radiation. The separator substance is formulated to have a density between that of the average densities of separable fractions derived from a sample fluid such as blood, and to be flowable. Upon centrifugation of a separator tube containing a fluid sample, the separator substance forms a barrier between the fractions. The barrier subsequently hardens to form a solid barrier when triggered by a suitable energy source.

Owner:UNIV OF MARYLAND +1

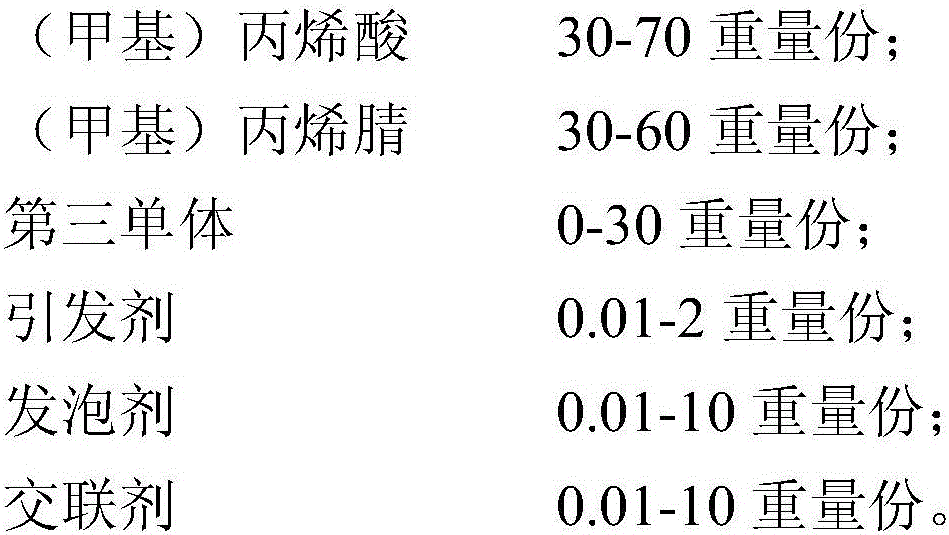

Preparation method of microporous PMI (polymethacrylimide) foam and PMI foam prepared by method

The invention discloses a preparation method of microporous PMI (polymethacrylimide) foam and PMI foam prepared by the method. The method comprises the following steps: (1) uniformly mixing reaction monomers, a third monomer, an initiator, a foaming agent and a crosslinking agent according to the proportion to obtain a mixed solution; (2) injecting the obtained mixed solution into a closed vessel, carrying out prepolymerization to obtain a transparent prepolymerization plate body, and carrying out post polymerization on the transparent prepolymerization plate body; and (3) putting the transparent prepolymerization plate body subjected to post polymerization in a drying oven provided with an ultrasonic generator, carrying out ultrasonic nucleation, and foaming at constant temperature. No nucleation substance, such as the white carbon black, foaming agent, toughening monomer or the like, is added, so the cost is low; and the strength is not lowered, but the toughness is enhanced. The pore size of the foam can be freely regulated within the range of 10-100 mu m; and the technique is simple, and only needs to regulate the ultrasonic frequency.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

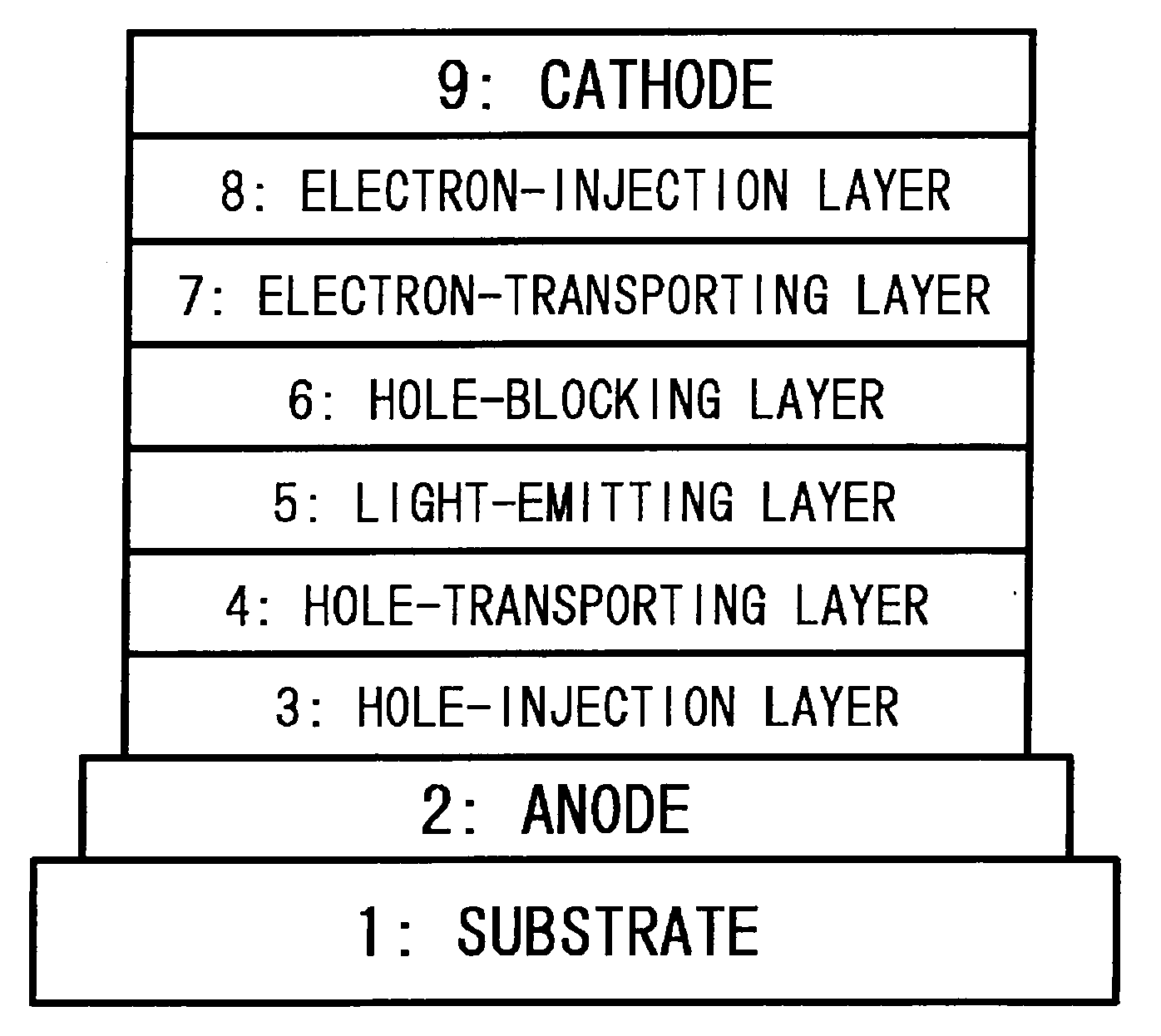

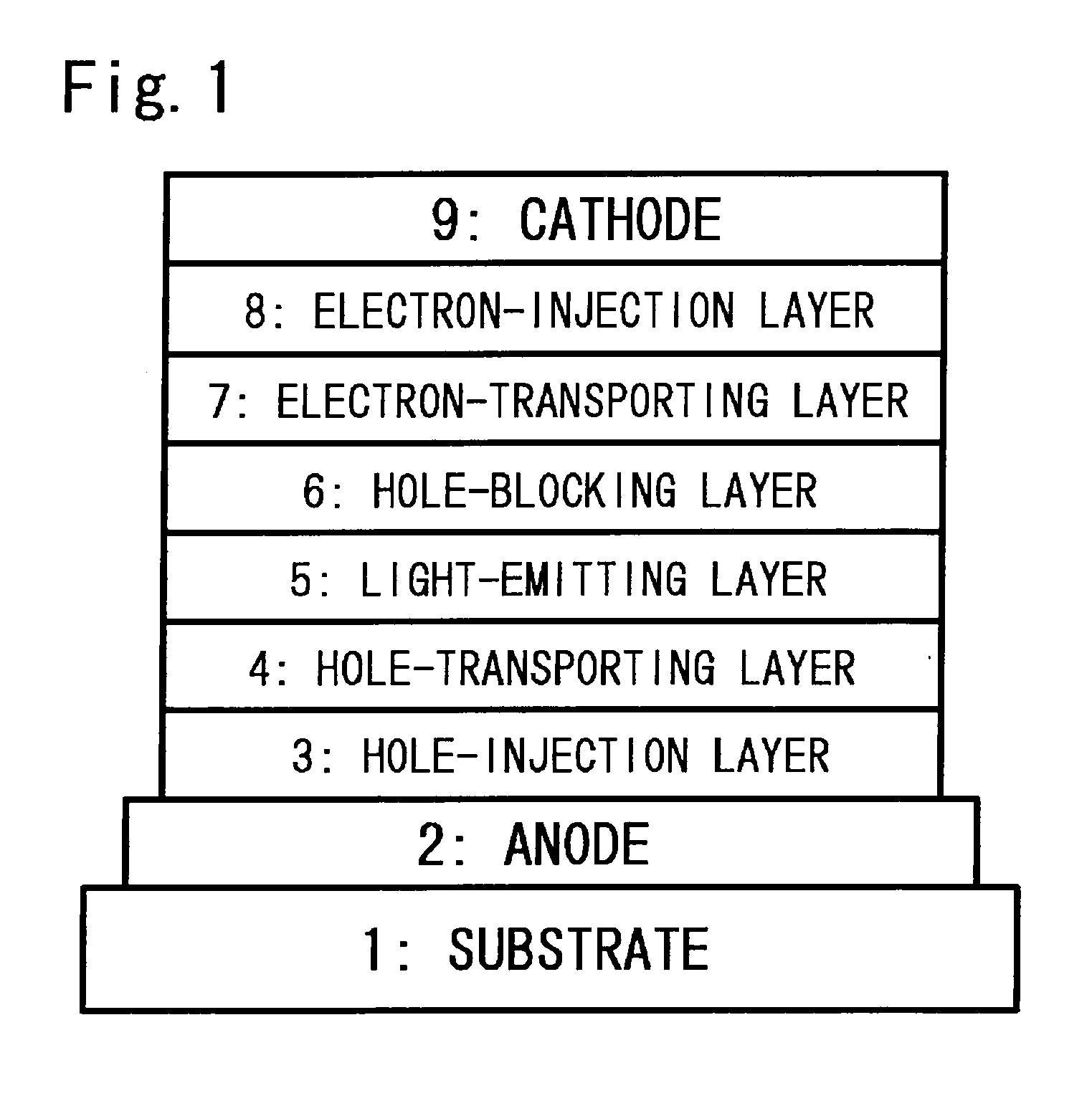

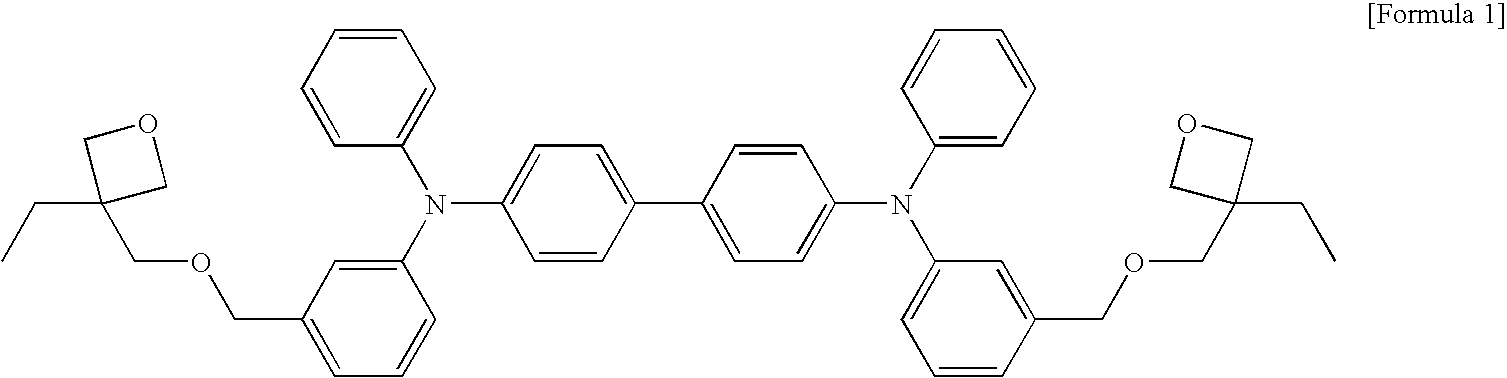

Composition for use in organic device, polymer film, and organic electroluminescent element

InactiveUS20100045174A1High operating requirementsGreat technical valueDischarge tube luminescnet screensElectroluminescent light sourcesOrganic devicesOrganic layer

A composition for use in an organic device, useful in producing an organic device, such as an organic electroluminescent element, having high operation stability, is a composition for use in an organic device that contains at least two cross-linking compounds, at least two of the cross-linking compounds having different numbers of cross-linking groups. A polymer film produced by forming a film of the composition for use in an organic device and then polymerizing the cross-linking compounds. An organic electroluminescent element that includes an anode and a cathode on a substrate and at least one organic layer disposed between the anode and the cathode, wherein at least one of the at least one organic layer is a layer that is produced by forming a film of the composition for use in an organic device and then polymerizing the cross-linking compounds.

Owner:MITSUBISHI CHEM CORP

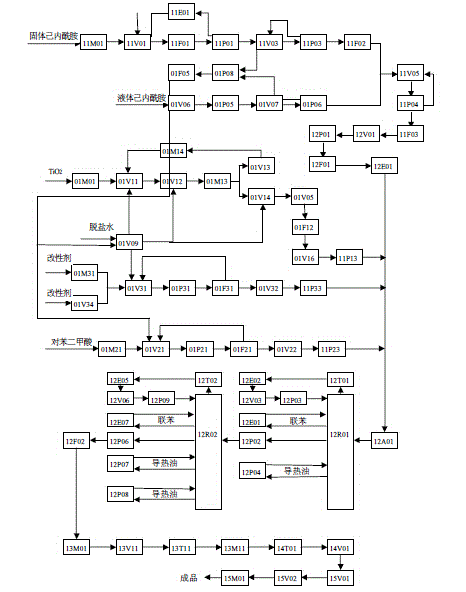

Process for producing caprolactam and nylon 66 salt copolymer slice

The invention relates to a process for producing a caprolactam and nylon 66 salt copolymer slice. The process comprises the following steps of: 1) preparing raw materials, namely respectively preparing caprolactam melt, a nylon 66 salt aqueous solution and an additive; 2) mixing the raw materials prepared in the step 1) in a mixer; 3) reacting the raw materials mixed in the step 2) in a pre-polymerization tower; 4) reacting the materials treated in the step 3) in a post-polymerization tower for reaction; 5) slicing the materials prepared in the step 4); 6) extracting the slices prepared in the step 5); 7) drying the extracted slices in the step 6); and 8) cooling the slices dried in the step 7), thus obtaining the caprolactam and nylon 66 salt copolymer slice finished product. According to the technical scheme, the caprolactam and nylon 66 salt copolymer slice has the characteristics of outstanding tensile strength, anti-impact strength and anti-puncturing strength, high gas isolation performance, high heat resistance, high mist degree, high glossiness, low temperature performance, flexibility, high transparency, high printablility and the like.

Owner:浙江华建尼龙有限公司

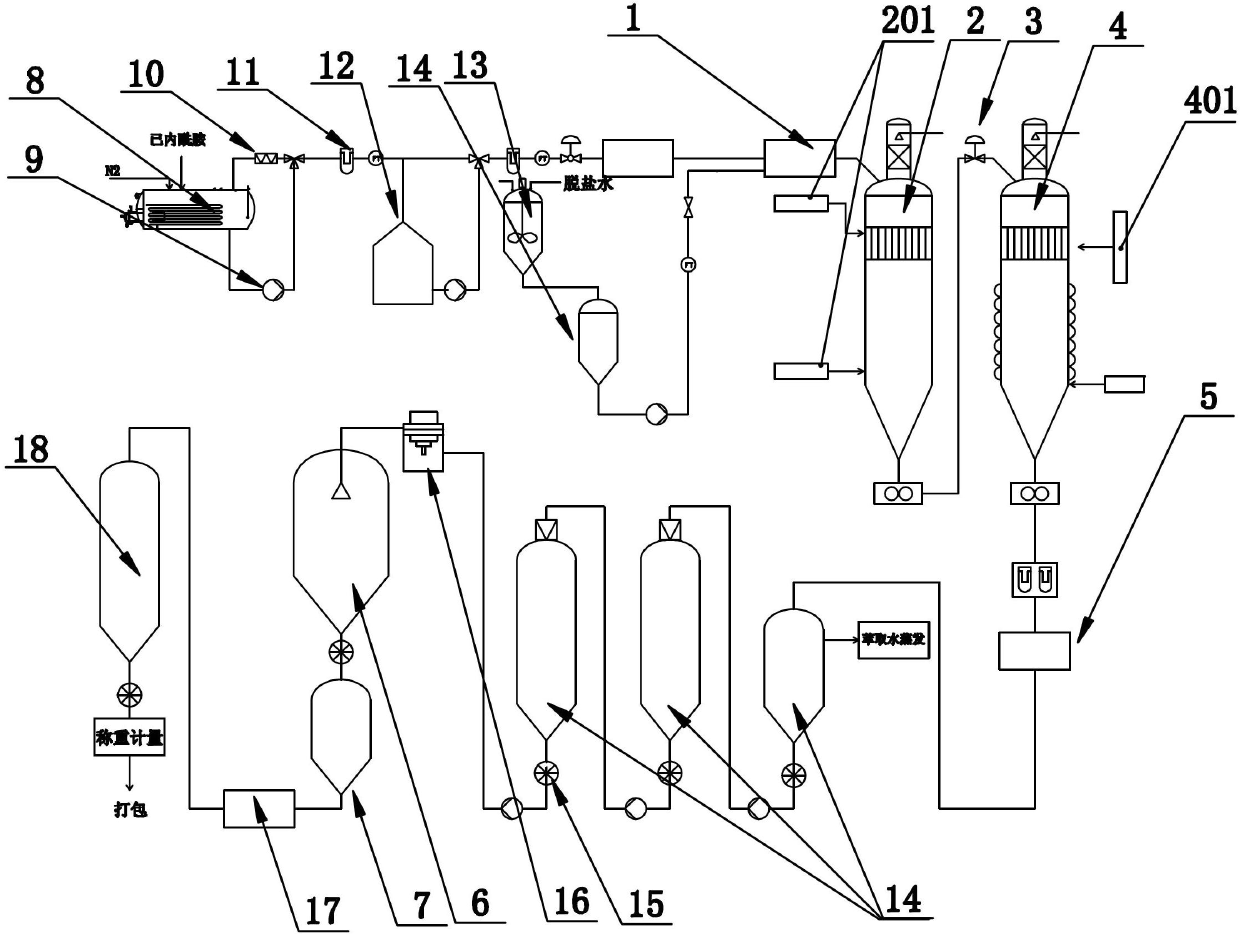

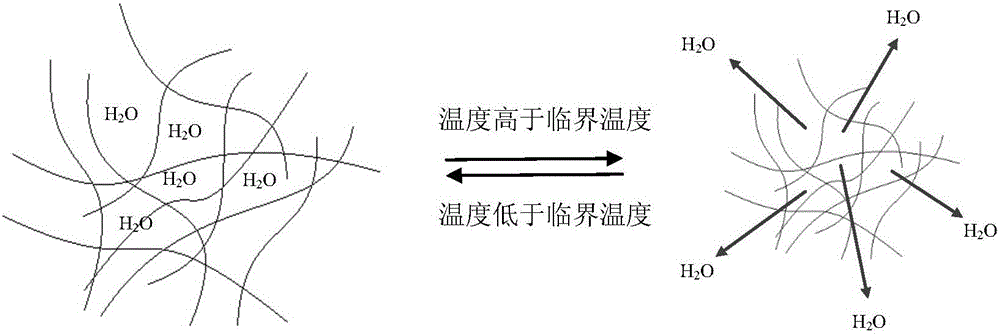

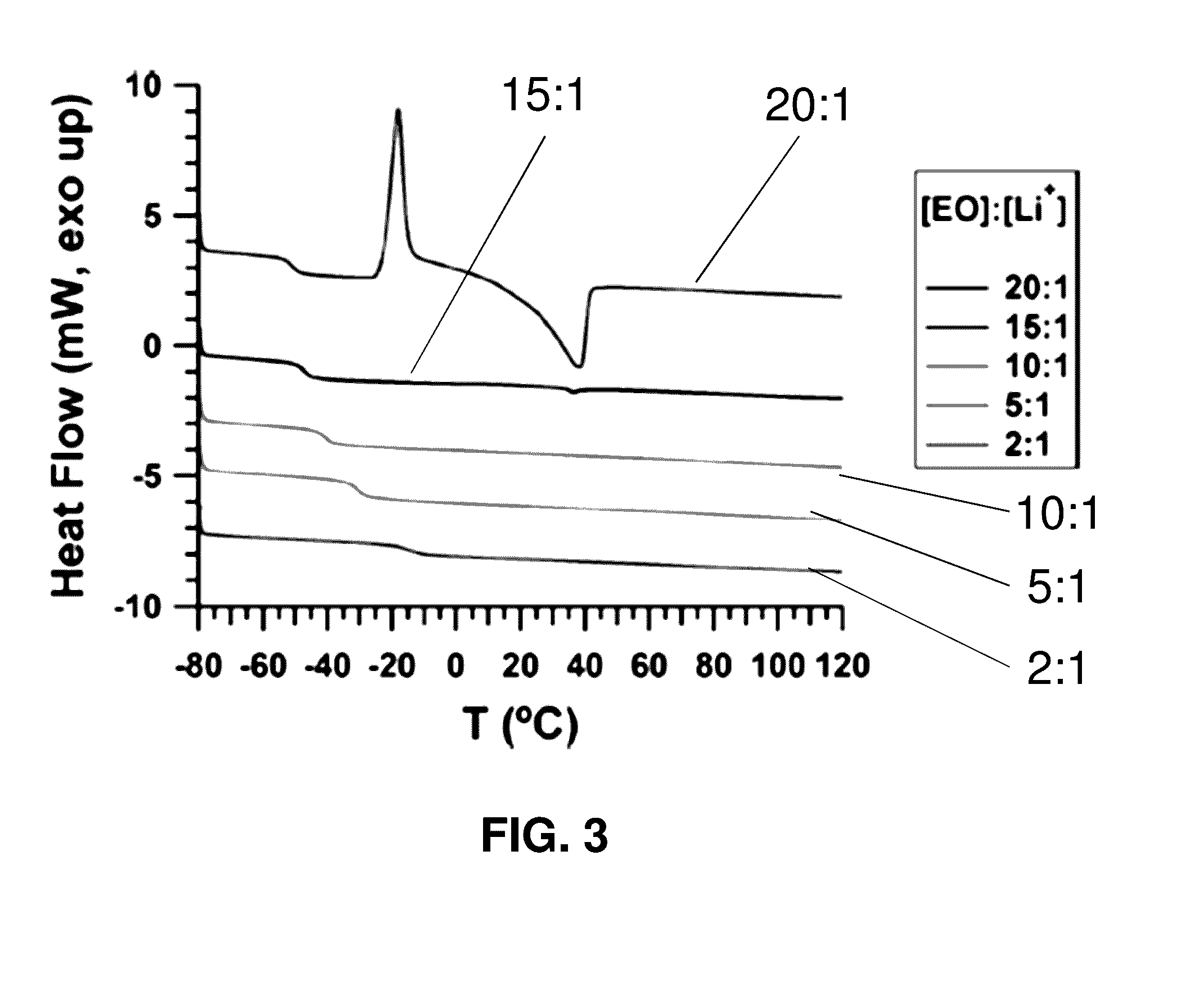

Application of temperature-sensitive hydrogel in improvement of anti-dry-shrinkage cracking property of concrete

The invention provides application of temperature-sensitive hydrogel in improvement of the anti-dry-shrinkage cracking property of concrete. The concrete is prepared from the temperature-sensitive hydrogel, cement, aggregates and water. A preparation method of the concrete comprises the steps that firstly, the temperature-sensitive hydrogel is prepared; secondly, the aggregates and the water are blended to be uniform; lastly, the temperature-sensitive hydrogel and the water are added, the materials are blended to be uniform, and then the concrete can be prepared. The adopted homemade temperature-sensitive hydrogel is lightly-crosslinked macromolecules which can be polymerized to form a film after releasing water, no hole can be reserved in the cement concrete, and other properties of the cement concrete are not affected while the anti-cracking property of the concrete is improved. The initial volume water content of the concrete is increased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the water storage capacity of the concrete is enhanced by mixing the temperature-sensitive hydrogel; the water absorption rate of the concrete is decreased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the connectivity of capillary pores in the concrete is reduced by mixing the temperature-sensitive hydrogel.

Owner:CHANGAN UNIV

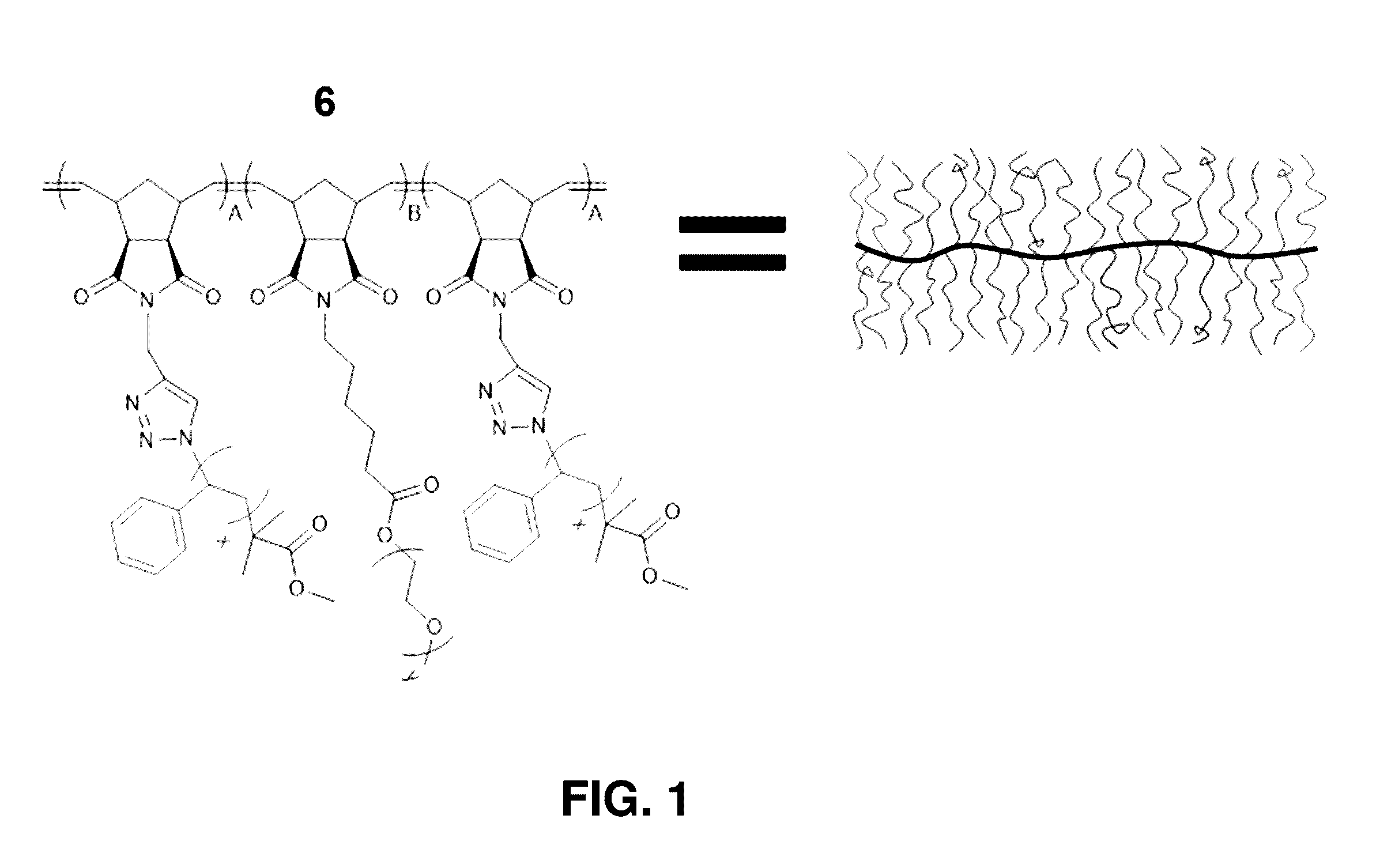

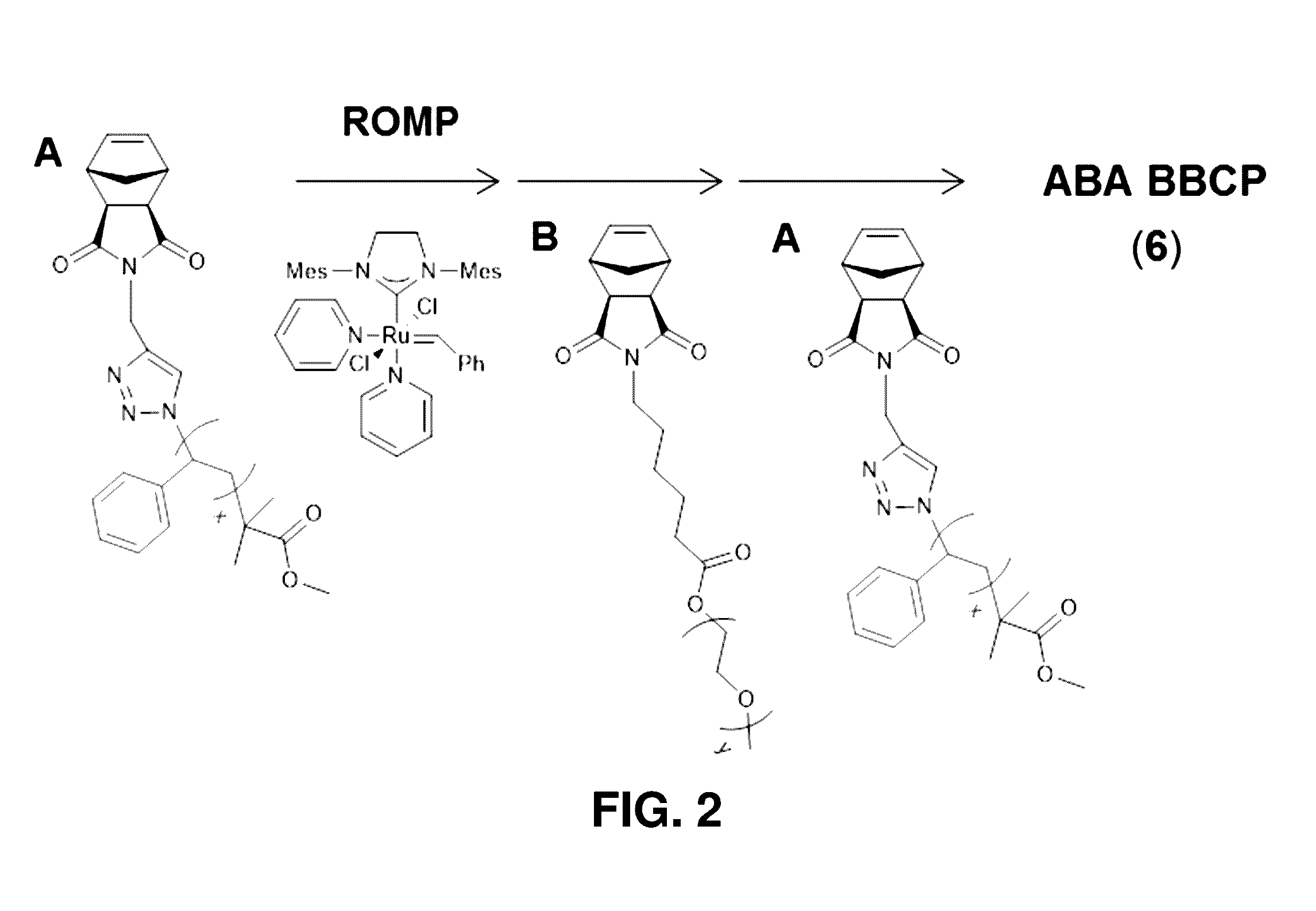

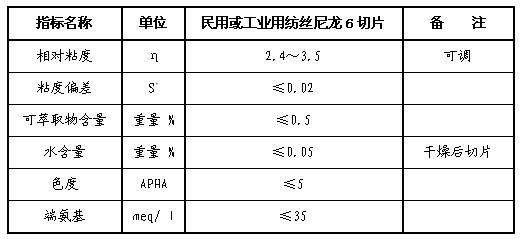

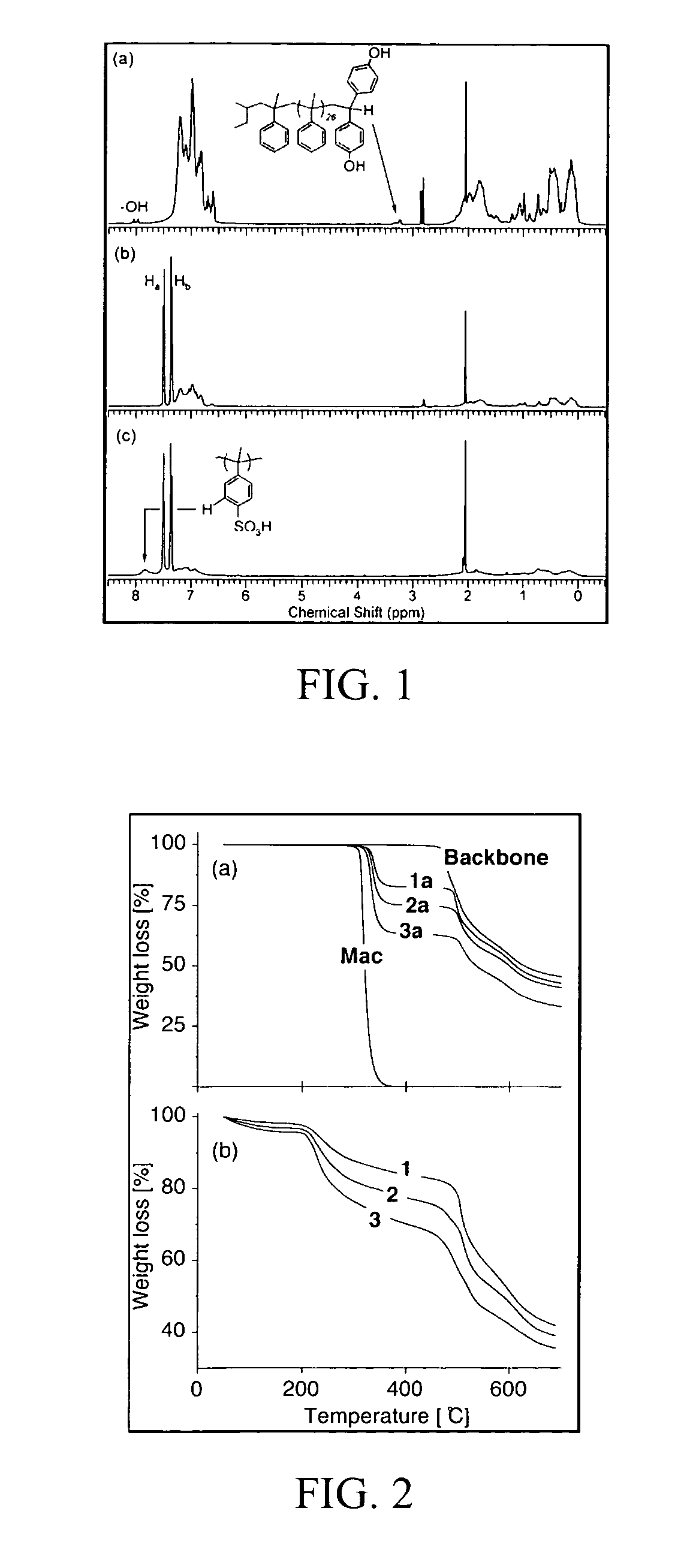

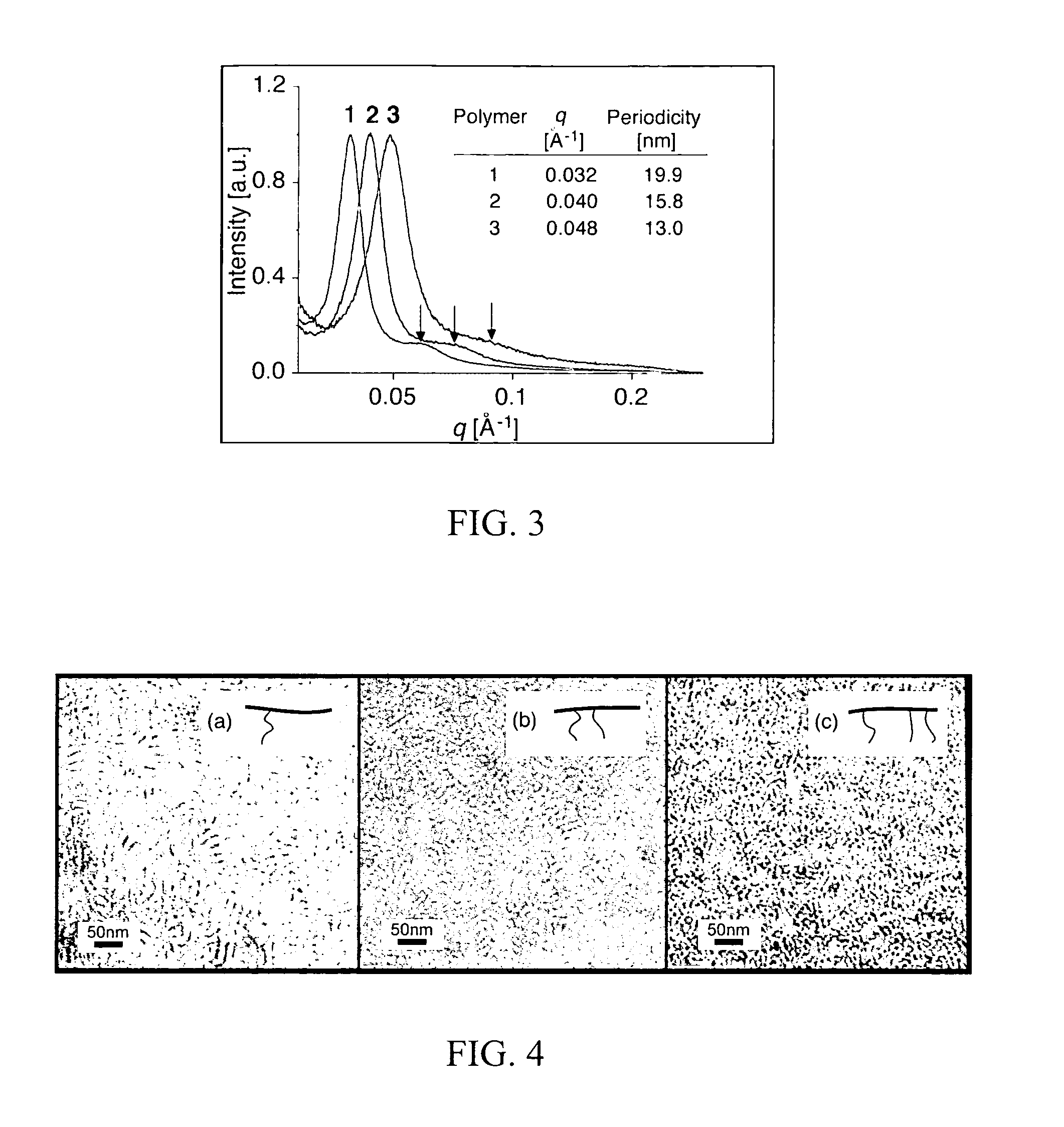

Brush block copolymer electrolytes and electrocatalyst compositions

ActiveUS20170018801A1Improve electrochemical performanceEffective compositionSolid electrolytesSecondary cellsDispersityCross-link

Provided herein are copolymer electrolytes and electrocatalyst platforms, including brush block copolymers, triblock brush copolymers and pentablock brush copolymers. The copolymers described have beneficial chemical, physical and electrical properties including high ionic conductivity and mechanical strength. In embodiments, for example, the provided copolymer electrolytes and electrocatalyst platforms are doped with lithium salts or mixed with ionic liquids to form ion gels. In some embodiments, the copolymers provided herein self-assemble into physically cross-linked polymer networks with additional useful properties. The provided copolymers have low dispersity in the polymer side chains and do not require post-polymerization modifications.

Owner:CALIFORNIA INST OF TECH

Catalyst for ternary polymerization of norbornene, maleic anhydride and pentene, and ternary polymerization method

InactiveCN103396514AHigh catalytic efficiencyEasy to wash and separateWater bathsReaction temperature

The invention relates to a catalyst for ternary polymerization of norbornene, maleic anhydride and pentene, and a ternary polymerization method. The catalyst is prepared by following steps: dissolving bis(cyclopentadienyl) zirconium dichloride, a ligand and an alkyl metal compound to a first solvent in a dry single-opening glass bottle in which inert gas is filled; sealing the bottle opening by an emulsion tube, keeping the bottle at a constant temperature for 5 to 15min in a water bath of 40 to 50 DEC C; and cooling so as to obtain the zirconium complex catalyst. Preparation method of the catalyst is simple. The catalyst can produce catalytic activity under a certain pressure, at a temperature and in nitrogen protection system; the norbornene, maleic anhydride and pentene are catalyzed and are subjected to ternary polymerization; and products are easy to wash and separate after being soaked by methanol. The yield of copolymer is high; the reaction temperature is low; the catalyst is low in cost and is easy to obtain; and the catalytic efficiency is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Transparent pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet thereof

InactiveUS20030102081A1Improve balanceNon-macromolecular adhesive additivesLaminationPressure sensitiveSolvent

A transparent acrylic pressure-sensitive adhesive composition which combines transparency and high-temperature adhesive properties. The transparent pressure-sensitive adhesive composition contains a polymer of one or more acrylic-based monomers and an organophilic layered clay mineral dispersed therein, wherein part of the polymer has been intercalated between layers of the clay mineral to cause interlayer separation and the clay mineral has a layer-to-layer distance of 100 Å or longer. It is produced by a process which includes: mixing 100 parts by weight of the monomers with 10 to 150 parts by weight of an organophilic layered clay mineral and 0.005 to 5 parts by weight of a polymerization initiator together with an organic solvent; exerting an external action on this mixture to thereby intercalate part of the monomers, polymerization initiator, and organic solvent into interstices of the organophilic layered clay mineral; subsequently removing the solvent; and then polymerizing the monomers.

Owner:NITTO DENKO CORP

Organic electroluminescence element, display device and lighting device

ActiveUS20110095278A1Light emission efficiencyMinimized dark spotElectroluminescent light sourcesSolid-state devicesDisplay deviceOrganic layer

In an organic electroluminescence element which incorporates a substrate having thereon an anode and a cathode and which incorporates a plurality of organic layers between the aforesaid anode and cathode, wherein at least one of the aforesaid organic layers is a first organic layer incorporating a compound having at most 10 repeating units, the first organic layer being prepared by coating the compound having at least one polymerizable group, followed by polymerization.

Owner:MERCK PATENT GMBH

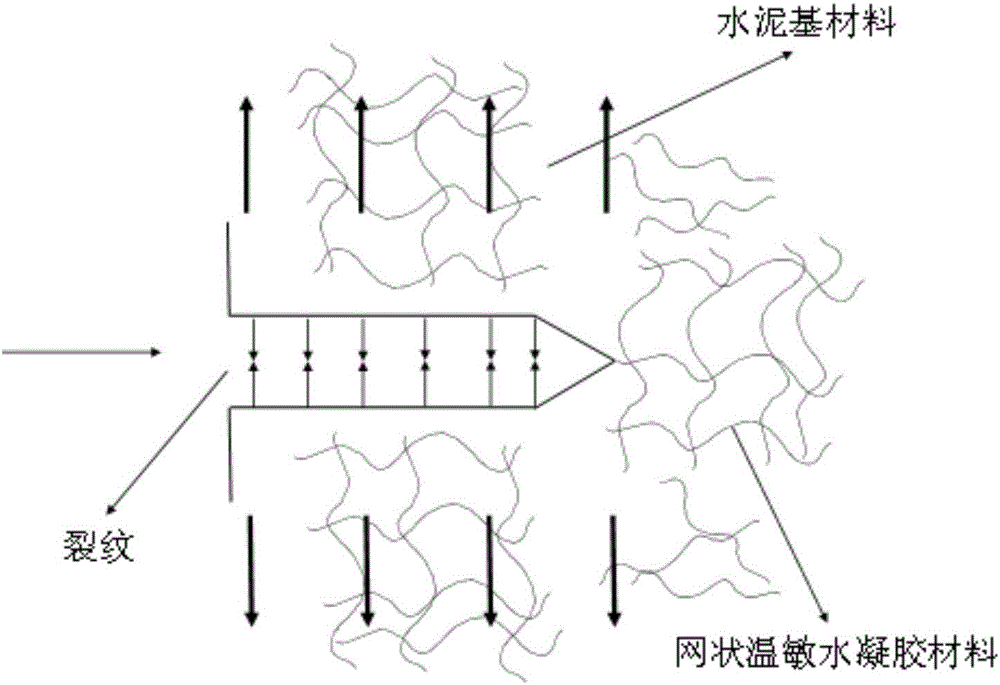

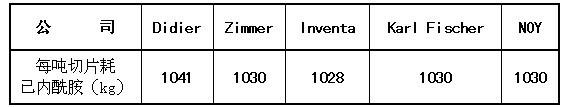

Continuous polymerization production process of high-viscosity polyamide 6

The invention relates to a continuous polymerization process of high-viscosity polyamide 6, comprising the following steps of: preparing caprolactam with de-ionized water; pre-heating the mixed caprolactam to a temperature in a range of 220+ / -30 DEG C by a pre-heater and conveying the mixed caprolactam into a pre-polymerizer by a feeding pump to carry out hydrolyzed ring opening and pre-polymerization on the caprolactam, wherein the pressure of the ring opening and the pre-polymerization is 2.50+ / -0.50 bar, the temperature is in a range of 270+ / -15 DEG C and the flow of the caprolactam is 2200+ / -500 kg / h; then, discharging materials into a post-polymerizer to carry out post-polymerization to obtain a polymer melt, wherein the pressure of the post-polymerization is 0.35+ / -0.25 bar and the temperature is 250+ / -30 DEG C; treating the polymer melt by a polymer filter, a casting strip head, an underwater granulator and a vibrating screen to obtain slices; adding the slices into a pre-extracting water pot to carry out pre-extraction with hot water at the temperature in a range of 115+ / -10 DEG C; then, conveying the treated slices into an extracting tower and extracting with the hot water at the temperature in a range of 100+ / -20 DEG C; conveying the extracted slices into a drying tower and carrying out counter-current drying by nitrogen gas; drying at the temperature in a range of 120+ / -30 DEG C and discharging the dried slices into a slice cooling bin; and conveying the cooled slices into a slice storage bin and a slice packaging bin by the nitrogen gas and packaging to obtain the high-viscosity polyamide 6 slices with the relative viscosity of 3.4-4.0.

Owner:湖南岳化化工股份有限公司

Production process for preparing fiber-grade nylon 6 chips with extracted aqueous concentrated solution and apparatus thereof

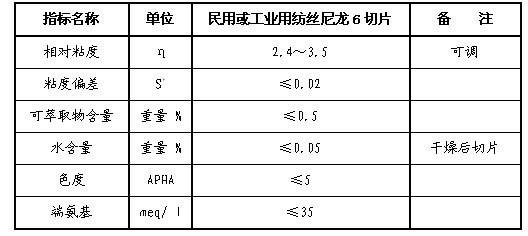

ActiveCN102382296AImprove slice qualityQuality improvementMonocomponent polyamides artificial filamentMaterial consumptionPolymerization reactor

The invention relates to a production process for preparing fiber-grade nylon 6 chips with extracted aqueous concentrated solution, which includes the following steps: filter pressing: the extracted aqueous concentrated solution is filter-pressed by a high-temperature filter press; preparation: the extracted aqueous concentrated solution is first added into a melting kettle, solid caprolactam andmolecular weight stabilizer are then added into a melting kettle, and after heating, caprolactam melt is obtained; prepolymerization: the caprolactam melt is heated by an energy saver, and then enters a prepolymerization reactor, and the prepolymerization reactor is heated and pressurized, so that prepolymerized material is obtained; postpolymerization: the prepolymerized material is sent into a postpolymerization reactor, and the postpolymerization reactor is depressurized to remove residual moisture, removes reaction heat, and keeps the temperature, so that the prepolymerized material carries out polycondensation reaction; dicing; chip extraction; chip drying; and packaging. The technical scheme of the invention can effectively reduce material consumption, energy consumption and pollution, the quality of the nylon 6 chips is high, and moreover, the invention can create high economic and social benefits.

Owner:浙江华建尼龙有限公司

Process for the application of a metal film on a polymer surface of a subject

InactiveUS6506293B1Insulating substrate metal adhesion improvementLiquid/solution decomposition chemical coatingChemistryPolymeric surface

A process for the application of a metal film on a polymer surface of a subject, to which, after nucleation with a catalytically active platinum metal and / or a platinum metal compound, a coating metal is precipitated autocatalytically from an aqueous solution without any external current supply, before at least another layer is applied, preferably electrolytically under external current supply, to this preliminary coating. To achieve favorable construction features, it is suggested that centers of a Lewis acid or Lewis base are enriched first on the polymer surface to be coated by a vacuum plasma treatment via a plasma gas adapted to the polymer used, before the polymer surface is nucleated under vacuum with the platinum metal and / or the platinum metal compound by another plasma gas containing an evaporated platinum metal and / or a platinum metal compound for nucleophilic and / or electrophilic reaction on the Lewis acids and / or Lewis bases.

Owner:ATOTECH DEUT GMBH

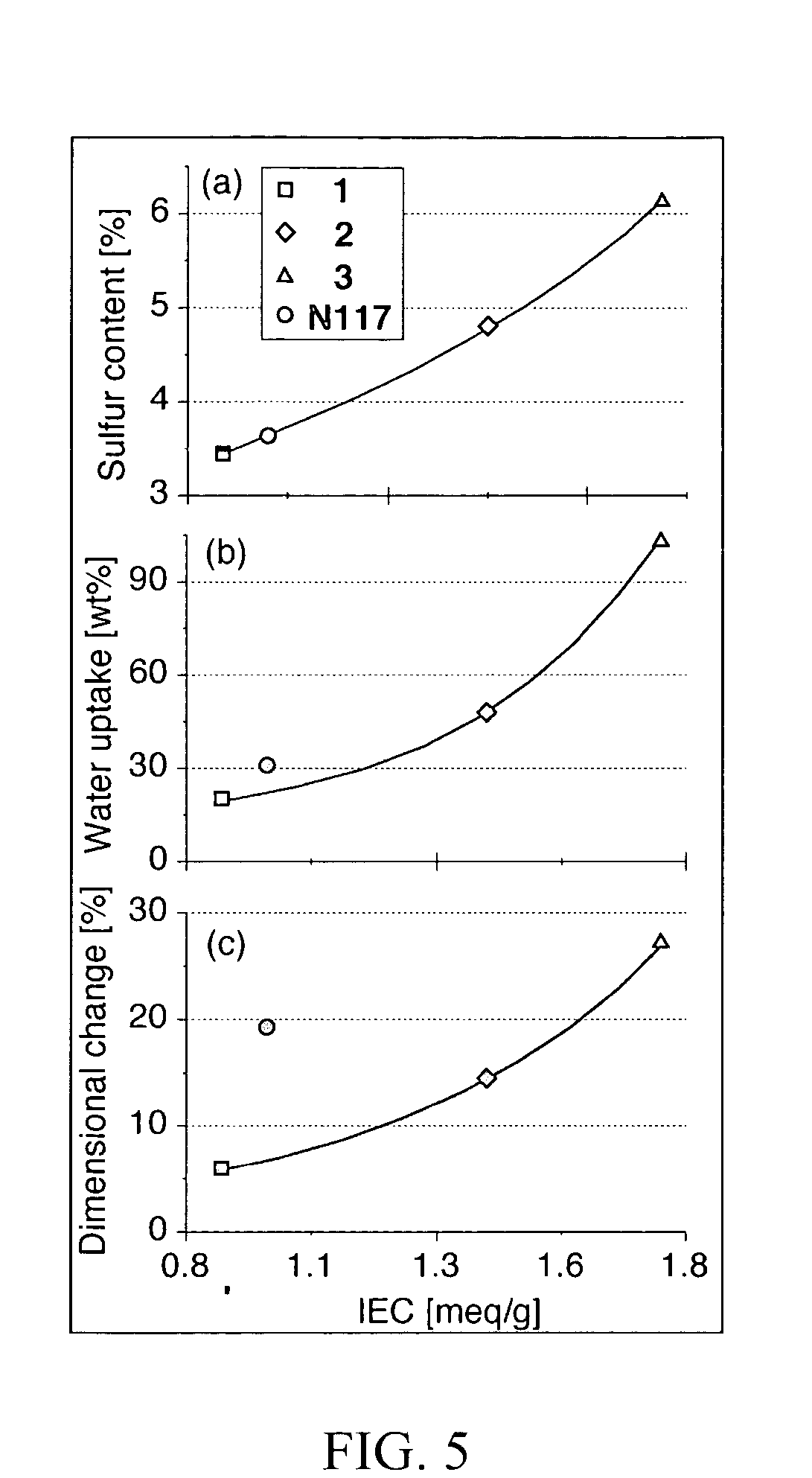

Fluorinated comb-shaped polymers

Fluorinated comb co-polymers have a main chain including a semi-rigid hydrophobic fluorinated poly(ether) backbone and comb segments in the form of flexible and monodisperse side chains that are more hydrophilic than the backbone. The side chains may be hydrophilic polymeric chains obtained from “living-type” polymerization, for example polymethacrylates, polyethylene oxides, polystyrenes. Hydrophilic functionality, for example, ionic groups may be selectively introduced onto the side chain post polymerization. The side chain may be sulfonated α-methyl polystyrene. Such polymers are useful in proton exchange membranes.

Owner:NAT RES COUNCIL OF CANADA

Nylon-6 slice production method capable of improving polymerization conversion rate

The invention discloses a nylon-6 slice production method capable of improving a polymerization conversion rate. The method comprises the following steps: fusing and storing raw materials, preparing an additive, performing pre-polymerization, performing post polymerization, performing casting strip slicing, performing multistage extraction, performing continuous drying, conveying the slices, metering and packaging. The method disclosed by the invention has the beneficial effects that a two-stage polymerization process, namely pressurized pre-polymerization and normal pressure post polymerization, is adopted, a polymerization tower is subjected to sectional heat supply by utilizing different heat transfer media, and different requirements on reaction conditions at different reaction stages are met by using a flash technology, so that the polymerization conversion rate of caprolactam is improved from the conventional 90 percent to over 92 percent. Therefore, the raw material utilization rate is improved, the pressure at the extraction and recovery section is alleviated, the product cost is reduced, and the economic benefits are improved.

Owner:HUNAN JINBO CHEM FIBER

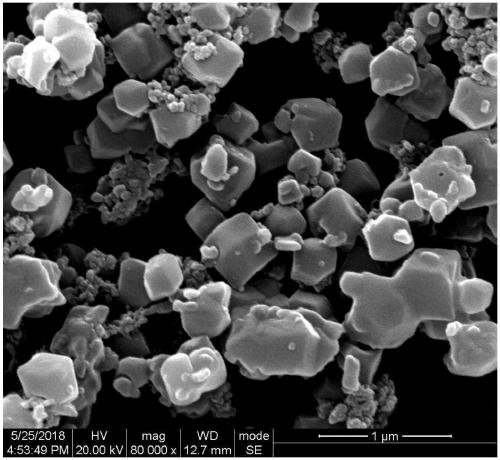

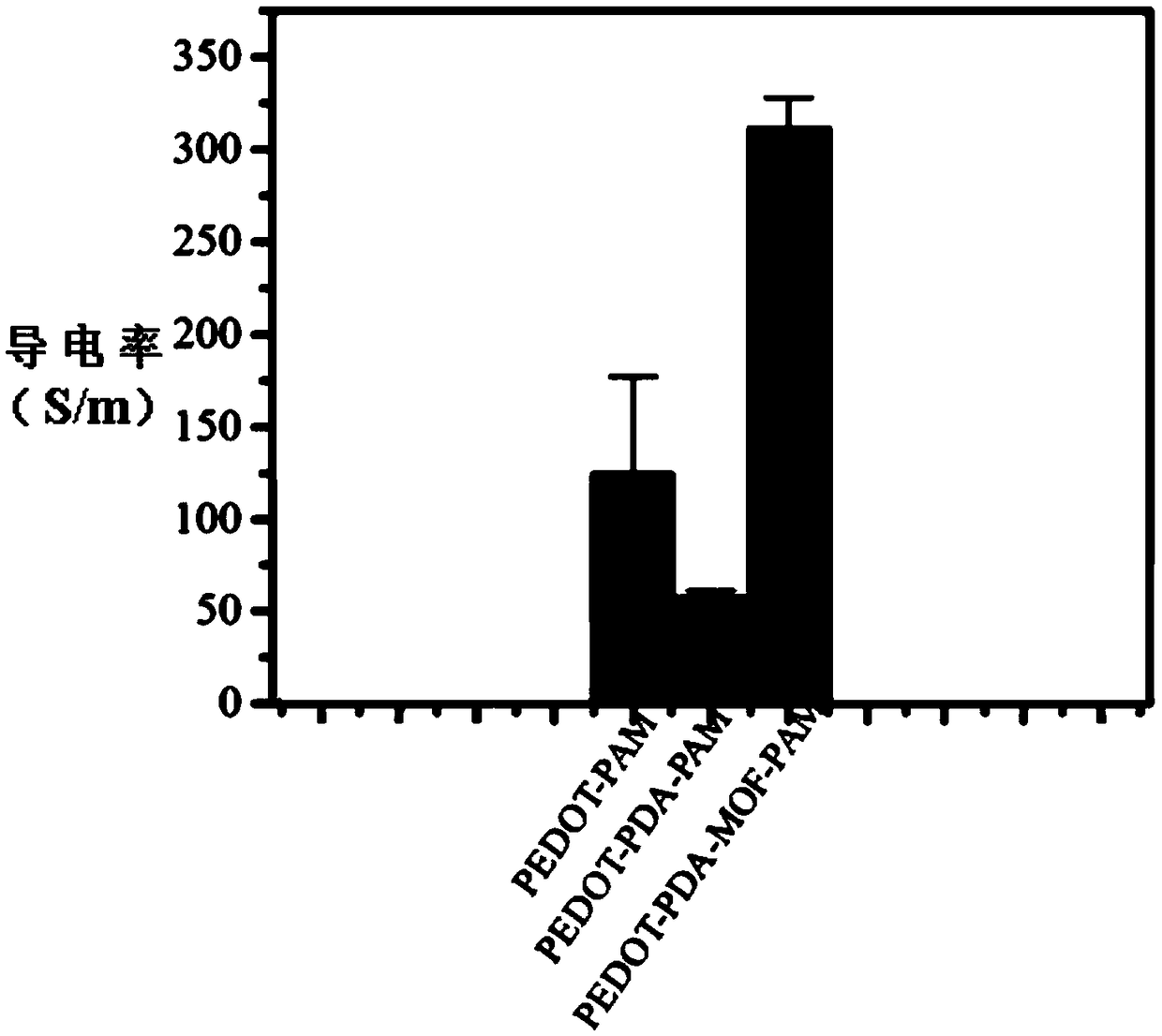

Preparation method and application of conductive hydrogel capable of slowly releasing drugs and factors

InactiveCN109265709AImprove conductivityImprove electrochemical activityPeptide/protein ingredientsAerosol deliveryDrug carrierDopamine

The invention discloses a preparation method and application of a conductive hydrogel capable of slowly releasing drugs and factors. The preparation method comprises the following steps: step 1, a conductive macromolecular monomer solution is prepared, an oxidant is added, and after sufficient reaction, a conductive macromolecular polymer is obtained; step 2, a concentrated aqueous dopamine solution is prepared, the conductive macromolecular polymer obtained in step 1 is added, and after sufficient reaction, a polydopamine / conductive macromolecular polymer compound is obtained; step 3, a metalion salt solution and an organic ligand solution are prepared; step 4, the polydopamine / conductive macromolecular polymer compound is added into the metal ion salt solution, and after uniform mixing,the organic ligand solution is added; and reaction is sufficiently carried out; step 5, the metal-organic framework / polydopamine / conductive macromolecular polymer compound is added into a monomer ordouble-bond biomacromolecular solution; and after additive is added, the needed hydrogel is formed by polymerization. The conductive hydrogel has excellent conductivity and electrochemical activity, and can be used in the preparation of drug carriers and biological electrodes.

Owner:SOUTHWEST JIAOTONG UNIV

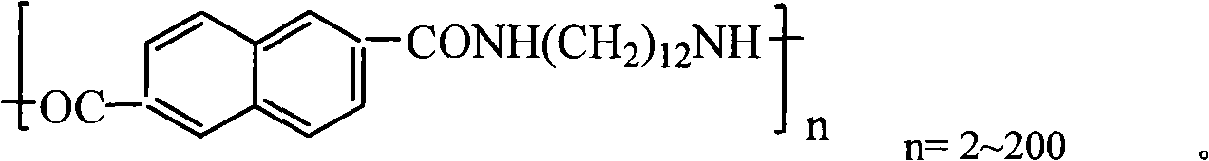

Long carbon chain condensed ring semi-aromatic nylon and synthetic process thereof

The invention discloses a novel long carbon chain fused ring semi-aromatic nylon PA12N and a method for synthesizing the same. The structural formula is as shown, wherein, n is equal to 2 to 200. The novel long carbon chain fused ring semi-aromatic nylon PA12N takes the long carbon chain aliphatic diamine 1, 12-twelve carbon diamine and fused ring aromatic serials dibasic acid 2,6-naphthalenedicarboxylic acid as raw materials and is made by the processes of salifying, prepolymerizing and polymerizing after solid phase. The technique has low energy consumption and protects the environment; the PA12N produced by the technique has good performance and is easy to process to form; and the technique has good market potential particularly in the industries such as electronics, appliances and automobiles.

Owner:ZHENGZHOU UNIV

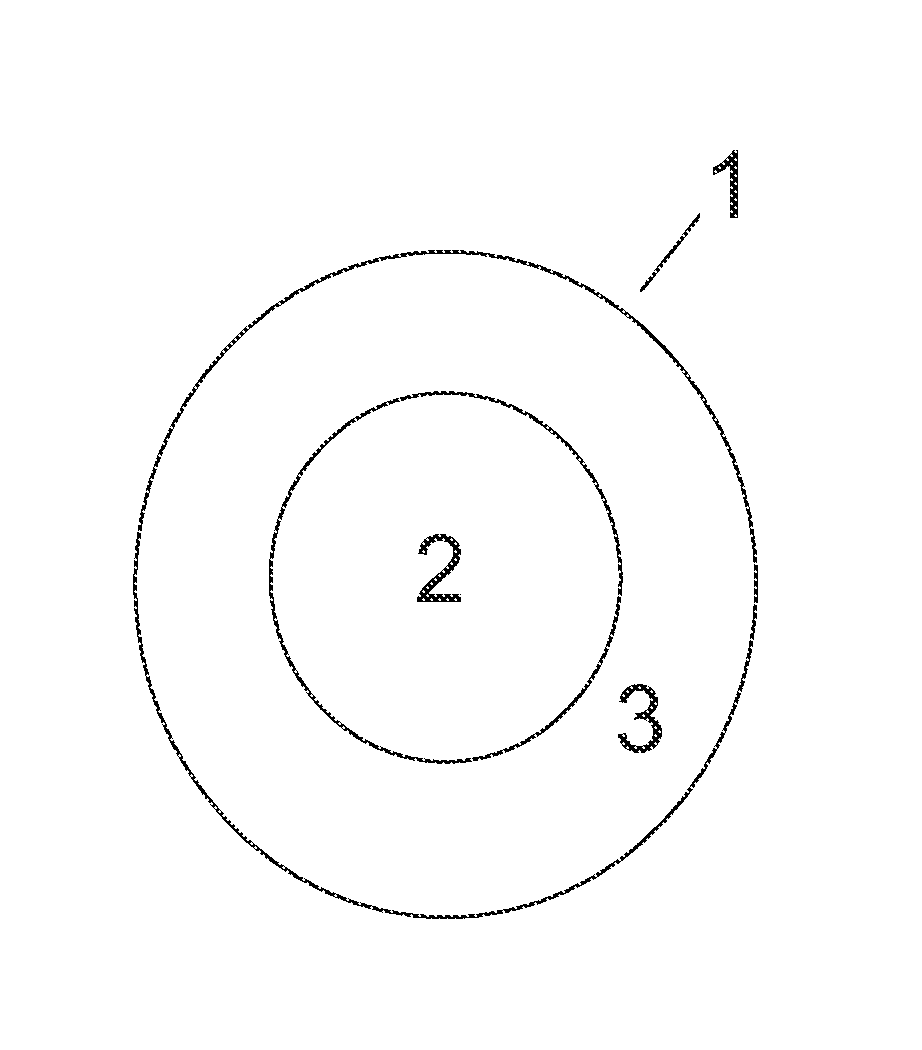

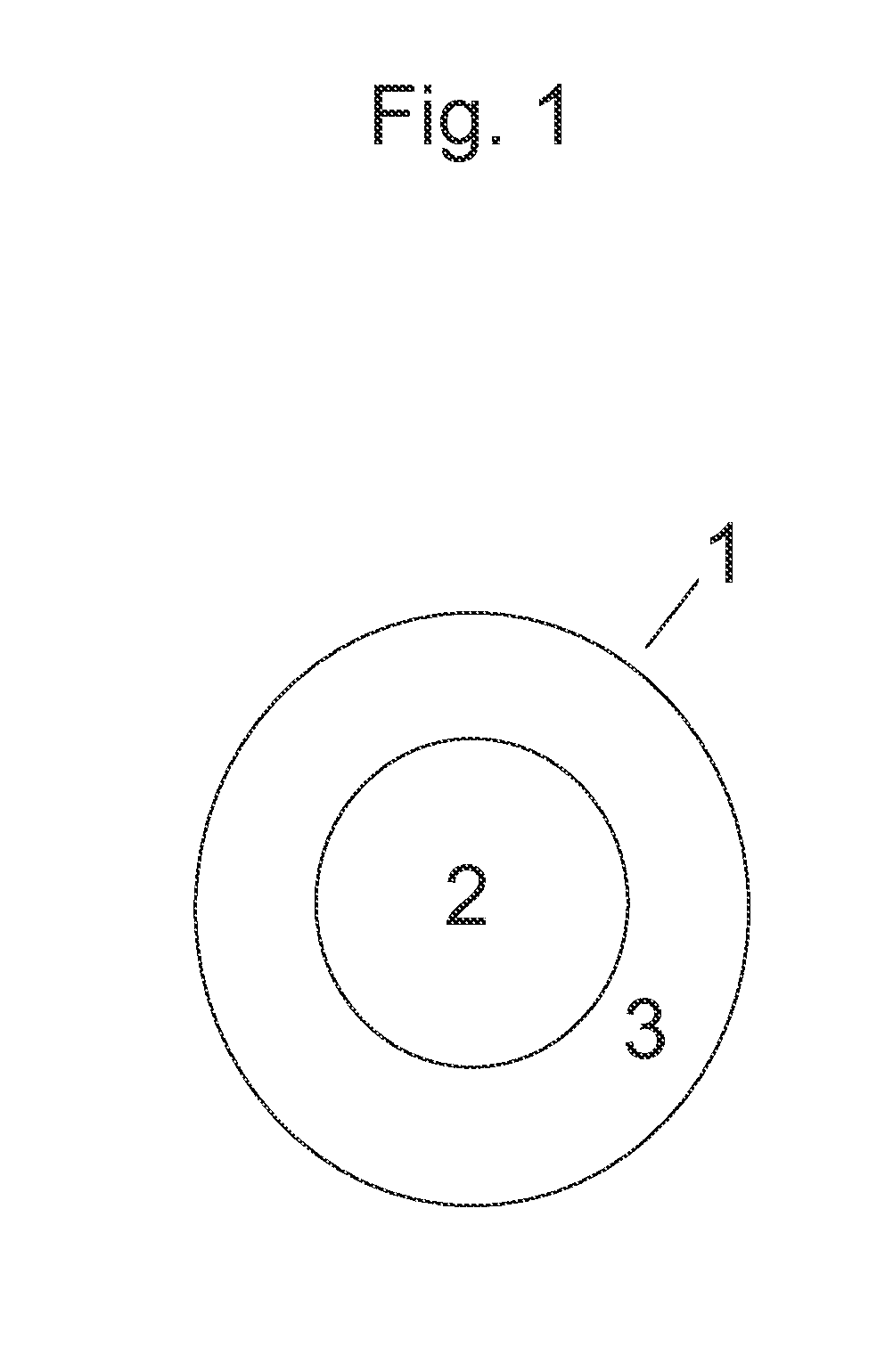

Structured acrylate copolymer for use in multi-phase systems

InactiveUS20130183361A1Good rheological and clarity propertyImprove clarityCosmetic preparationsLiquid surface applicatorsPersonal careCLARITY

Disclosed are multi-staged acrylic based core-shell polymers comprising a linear core polymer and at least one subsequently polymerized shell polymer. At least one of the subsequently polymerized shell polymers is crosslinked. The core-shell polymers surprisingly provide desirable rheological, clarity, and aesthetic properties in aqueous surfactant containing compositions, particularly at low pH. The multi-staged acrylic base core-shell polymers can be included in at least one phase of a multi-phase personal care, home care, health care, and institutional and industrial care composition to impart phase stability thereto.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Norbornene, maleic anhydride and vinyl acetate ternary polymerization catalyst and ternary polymerization method

InactiveCN103626919AHigh catalytic efficiencyEasy to wash and separateReaction temperatureCarvacryl acetate

The invention relates to a catalyst for ternary polymerization of norbornene, maleic anhydride and vinyl acetate and a ternary polymerization method. The catalyst is characterized by being prepared by a method comprising the following steps: dissolving tri(cyclopentadienyl) neodymium, titanium tetrachloride and a ligand compound in a solvent in a dry single-opening glass bottle in an inert gas atmosphere, and sealing the opening of the bottle by using a latex tube, so as to obtain a titanium complex catalyst. Compared with the prior art, the invention provides a novel titanium complex catalyst and a ternary polymerization method using the same, the preparation method is simple, the titanium complex catalyst can generate catalytic activity in a nitrogen protection system at 40-90 DEG C to catalyze ternary polymerization of norbornene, maleic anhydride and vinyl acetate, and after being soaked in methanol, a polymerization product can be easily washed and separated; the catalyst has the characteristics of high yield, low reaction temperature, low price, availability, high catalytic efficiency and the like.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com