Application of temperature-sensitive hydrogel in improvement of anti-dry-shrinkage cracking property of concrete

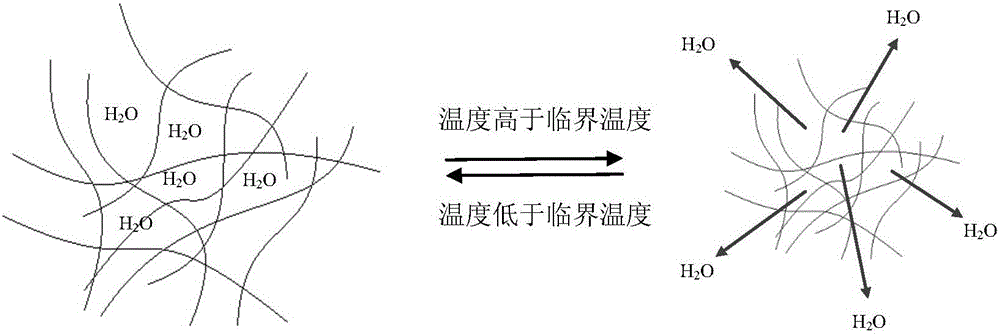

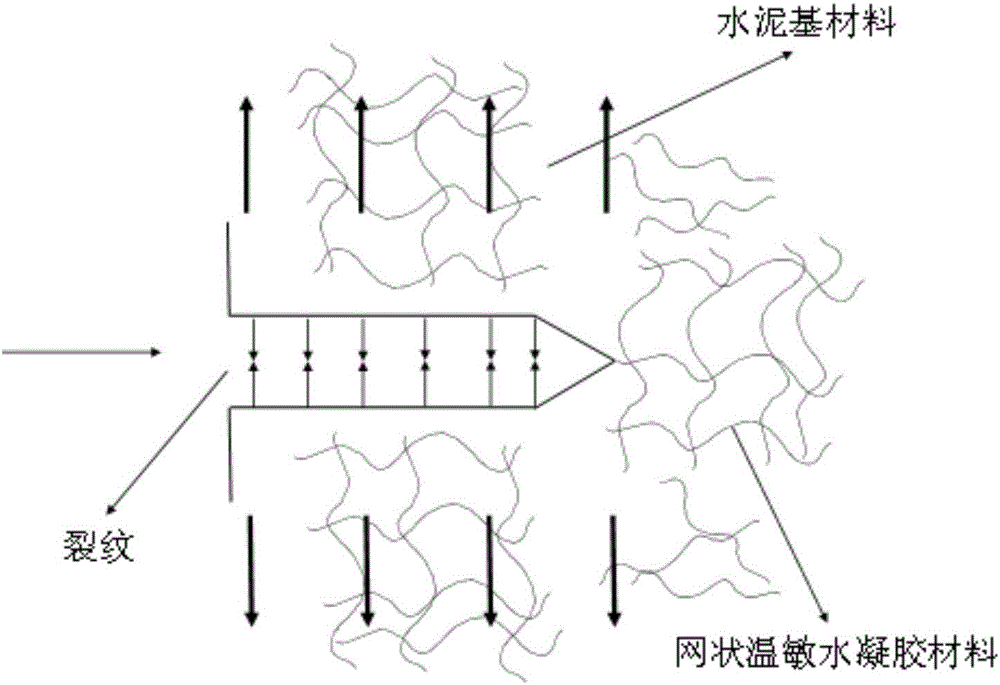

A temperature-sensitive hydrogel and concrete technology, applied in the field of road materials, can solve the problems of affecting the mechanical properties of cement concrete and the poor anti-drying shrinkage cracking effect, so as to improve the anti-drying shrinkage performance, improve the anti-cracking performance and reduce the shrinkage rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

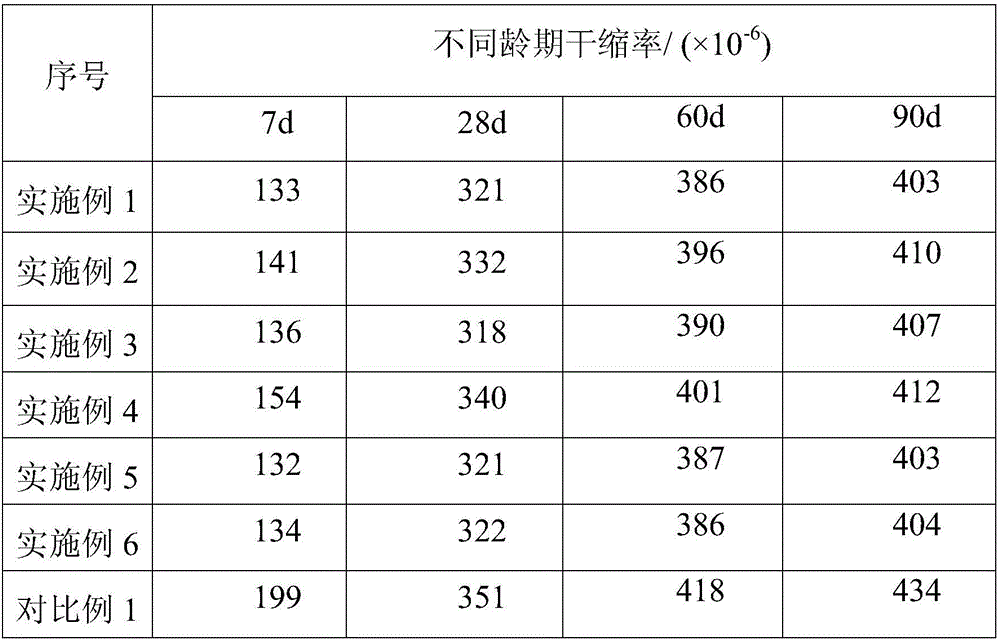

[0027] The present embodiment provides a kind of concrete, which is composed of the following raw materials in terms of mass percentage: 4% of thermosensitive hydrogel, 15% of cement, 74% of aggregate, and 7% of water; wherein fine aggregate is 25%, Coarse aggregate is 49%.

[0028] Wherein: the lower critical solution temperature of the temperature-sensitive hydrogel involved is 32°C.

[0029] The fineness modulus of the fine aggregate is 2.8, the mud content is 2.5%, and the apparent density is 2650kg / m 3 , bulk density is 1420kg / m 3 . The particle size distribution of the coarse aggregate is 10-31.5mm, the crushing index is 7.5%, and the apparent density is 2690kg / m 3 , the mud content is 0.5%. The total volume occupied by aggregates in concrete is very high, but in most cases, it is difficult to reach the critical saturation inside the aggregates, so the concrete performance changes caused by aggregates are small, so this application uses different particle sizes aggr...

Embodiment 2

[0037] This embodiment provides a kind of concrete, which is composed of the following raw materials in terms of mass percentage: 3% of temperature-sensitive hydrogel, 16% of cement, 73% of aggregate, and 8% of water.

[0038] In this embodiment, the requirements for raw materials and the preparation method of concrete are the same as in Example 1, the difference is that the additions of N-isopropylacrylamide monomer, deionized water, initiator and crosslinking agent are respectively : 6g, 54g, 0.0024g, 0.0033g.

[0039] The performance test results of this embodiment are shown in Tables 1-4.

Embodiment 3

[0041] This embodiment provides a kind of concrete, which is composed of the following raw materials in terms of mass percentage: 5% of thermosensitive hydrogel, 14.2% of cement, 74% of aggregate, and 6.8% of water.

[0042]In this embodiment, the requirements for raw materials and the preparation method of concrete are the same as in Example 1, the difference is that the additions of N-isopropylacrylamide monomer, deionized water, initiator and crosslinking agent are respectively : 10g, 90g, 0.0041g, 0.0055g.

[0043] The performance test results of this embodiment are shown in Tables 1-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com