Patents

Literature

40results about How to "Improve anti-shrinkage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

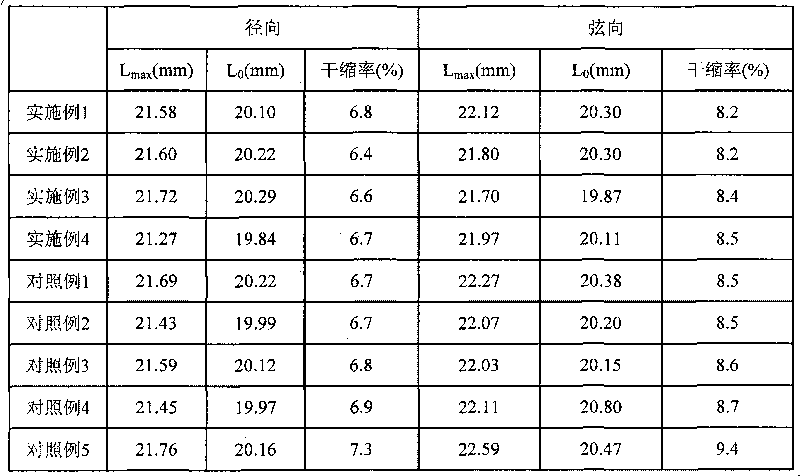

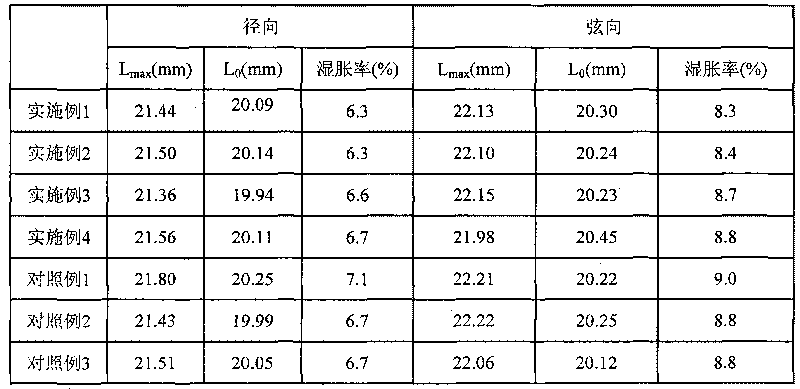

Modified planted forest timber and preparation method thereof

ActiveCN101745951AImproved dimensional stabilityIncreased dry shrinkage and corrosion resistancePressure impregnationWood dampingCorrosion resistantUrea

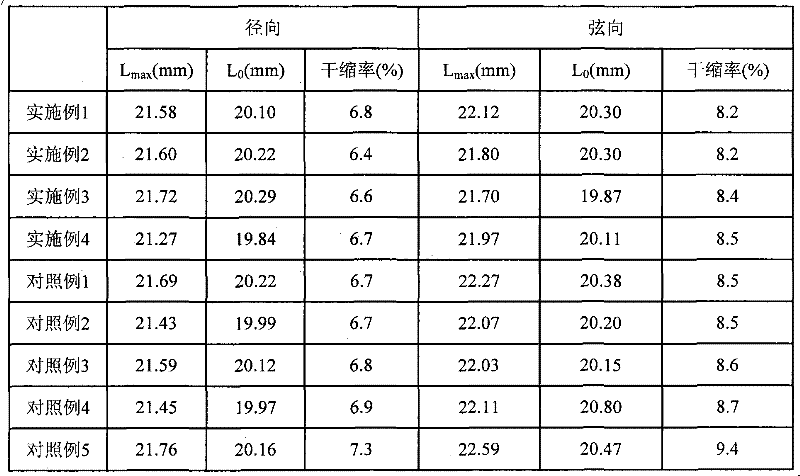

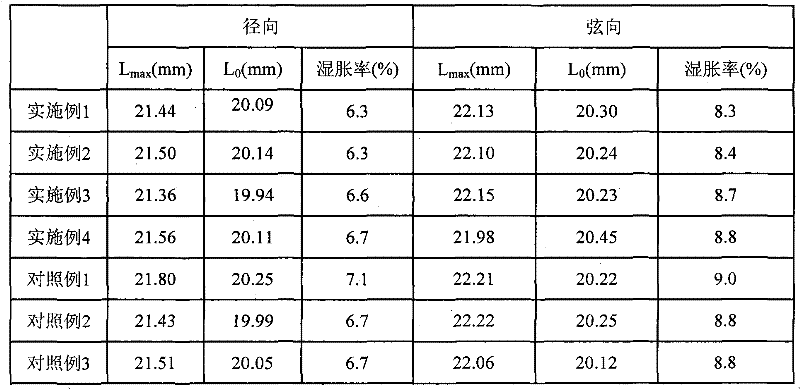

The invention discloses impregnation reinforcement-thermal treatment modifying technology for planted forest timber. The technology comprises the following steps in order: 1) impregnating the timber by adopting impregnation liquid which uses modified urea resin as a main agent of the impregnation liquid; and 2) thermally treating the impregnated timber in vacuum. The timber prepared by the method has high dimensional stability and high strength; the bulking resistance and the corrosion resistance of the timber are improved; the added value of the thermally-treated timber is improved; and the application range of the thermally-treated timber is expanded.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

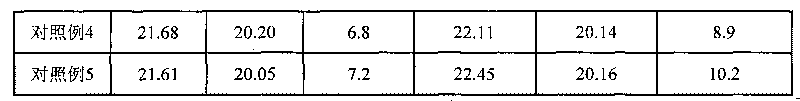

Lead-zinc smelting slag based geopolymer gelling material and preparation method thereof

The invention discloses a lead-zinc smelting slag based geopolymer gelling material and a preparation method thereof and belongs to the technical field of geopolymer. The material is composed of, by mass, 65-72 wt.% of lead-zinc smelting slag, 5-10 wt.% of coal ash, 8-15 wt.% of composite alkali activator, 3-6 wt.% of sulfate activator, 1-3 wt.% of aluminate activator and 10-14 wt.5 of deionized water. The preparation method includes: respectively drying and grinding lead-zinc smelting slag and coal ash, and mixing well with a sulfate activator and an aluminate activator before joint grinding to obtain a ball-milled mixture; adding a composite alkali activator solution into the ball-milled mixture, stirring well, forming, and maintaining to obtain the material. The preparation method is simple, low in energy consumption and free of pollution in the preparation process, and geopolymer has good gelling performance, mechanical performance, corrosion resistance, wear resistance and dry shrinkage resistance.

Owner:燕京理工学院

Method for preparing geopolymers by taking stone coal vanadium extraction tailings as main raw materials

ActiveCN103482890AFavorable strength developmentHigh compressive strengthCement productionSlagMetakaolin

The invention relates to a method for preparing geopolymers by taking stone coal vanadium extraction tailings as main raw materials. The technical scheme is as follows: the method adopts the following raw materials in percentage by weight: 55-76% of stone coal vanadium extraction tailings, 1-5% of hydrated lime, 0.3-2% of anhydrous sodium sulfate, 10-16% of metakaolin, 6-10% of sodium hydroxide and 6-13% of silica fume. The preparation method disclosed by the invention comprises the steps of firstly, uniformly mixing the stone coal vanadium extraction tailings and an activating agent, standing, calcining, and performing mechanical vibration milling to obtain activated slag; then, adding metakaolin and sand, and stirring; finally, adding a liquid alkali activator prepared from sodium hydroxide, silica fume and water, stirring, forming, aging and curing to prepare the stone coal vanadium extraction tailing geopolymers. The method disclosed by the invention is simple in process, low in cost, relatively small in energy consumption, high in tailing utilization ratio and environment-friendly; the prepared geopolymers are relatively high in compression strength, strong in dry shrinkage resistance, good in permeability resistance and high in durability, and have a good curing effect on heavy metal ions.

Owner:WUHAN UNIV OF TECH

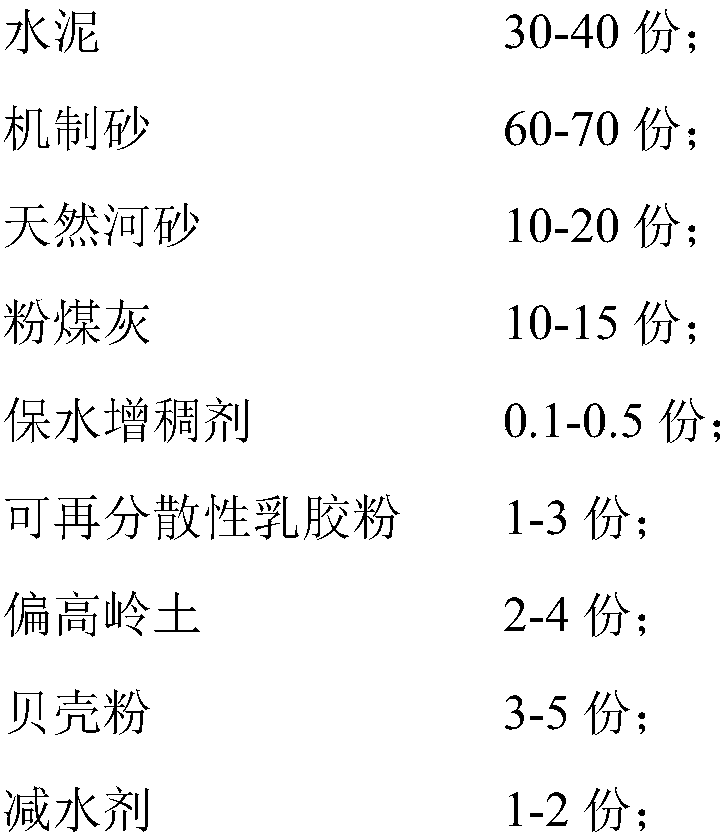

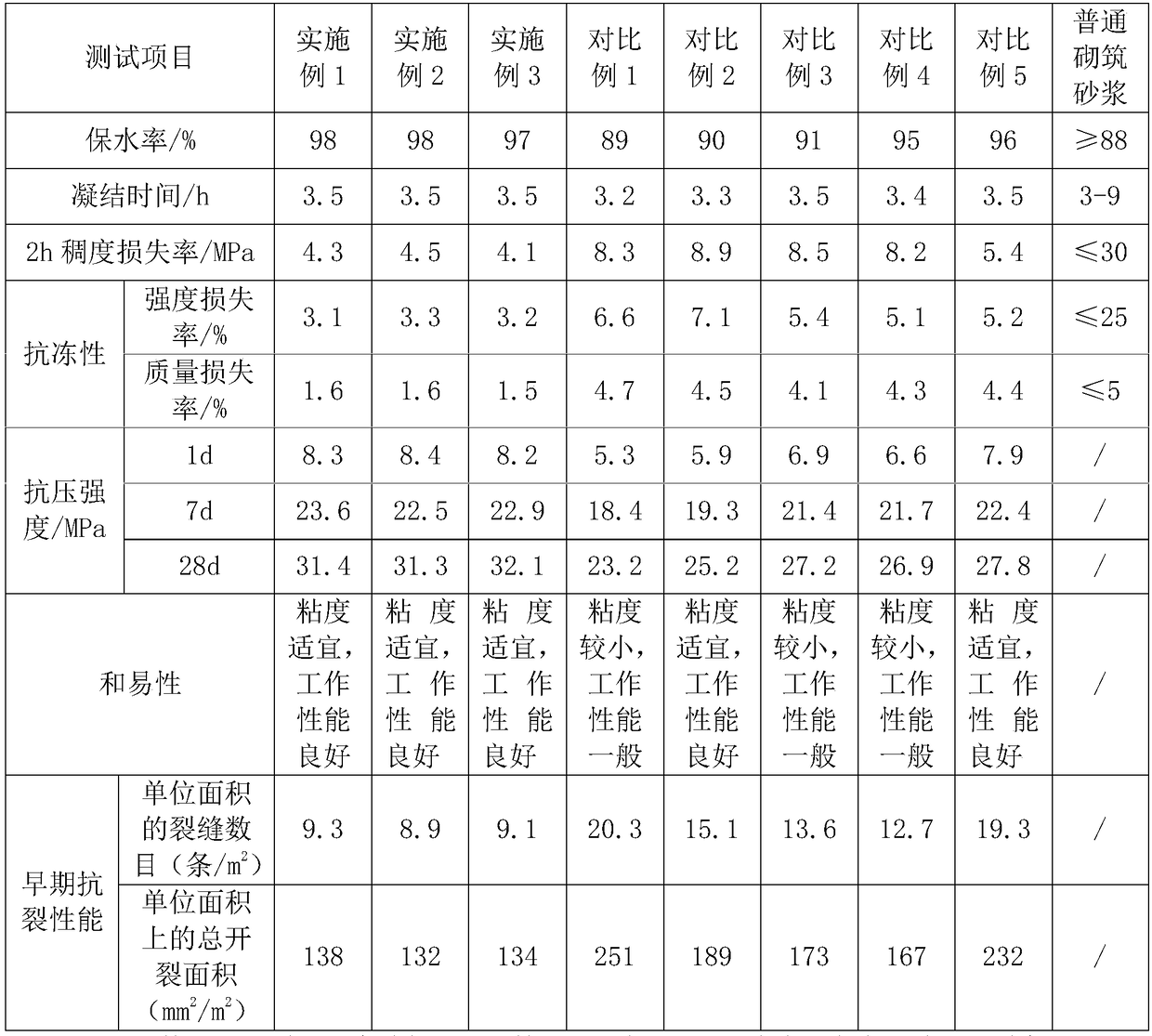

Mechanism sand dry-mixed mortar and preparation method thereof

The invention discloses a mechanism sand dry-mixed mortar and a preparation method thereof, belonging to the technical field of building materials. According main points in a technical scheme of the invention, the mechanism sand dry-mixed mortar comprises the following components: cement, tailing sand, natural river sand, fly ash, a water-retaining thickener, redispersible latex powder, metakaolin, shell powder and a polycarboxylic acid water reducer. According to the invention, the tailing sand widely available is used as a main fine aggregate, and the compounding of the natural river sand and mechanism sand can make up for the problems of poor grading characteristics and grain shape defects of the mechanism sand; by strictly controlling the content of stone powder in the tailing sand, the processing properties of drying and grading of the tailing sand are improved; gaps in the dry-mixed mortar are filled in by the metakaolin and shell powder, so the compactness and impermeability ofthe hardened mortar are enhanced; the water-retaining and thickening properties of the dry-mixed mortar is improved through the water-retaining thickener; and the raw materials of the dry-mixed mortarare improved in dispersion uniformity and workability is improved, and the adhesion between the raw materials of the dry-mixed mortar is enhanced.

Owner:北京建工新型建材有限责任公司

Special cement and its production process

The specific cement is produced with cement clinker, mineral slag, flyash and gypsum in certain weight proportion, and the cement clinker is produced with limestone, loess, silica and iron ore in certain weight proportion and through calcination. The production process of the specific cement includes high temperature calcination of raw material at 1400-1500 deg.c to produce cement clinker while controlling exhaust temperature not lower than 900 deg.c for exhausting alkali to alkali content not more than 0.4 %; and pulverizing cement clinker, mineral slag, flyash and gypsum while controlling specific surface area not smaller than 350 sq m / Kg to obtain the specific cement. The specific cement has low alkali content, high wear resistance, high strength, fast coagulation and other advantages.

Owner:TONGHUA SPECIAL CEMENT GROUP JILIN PROV

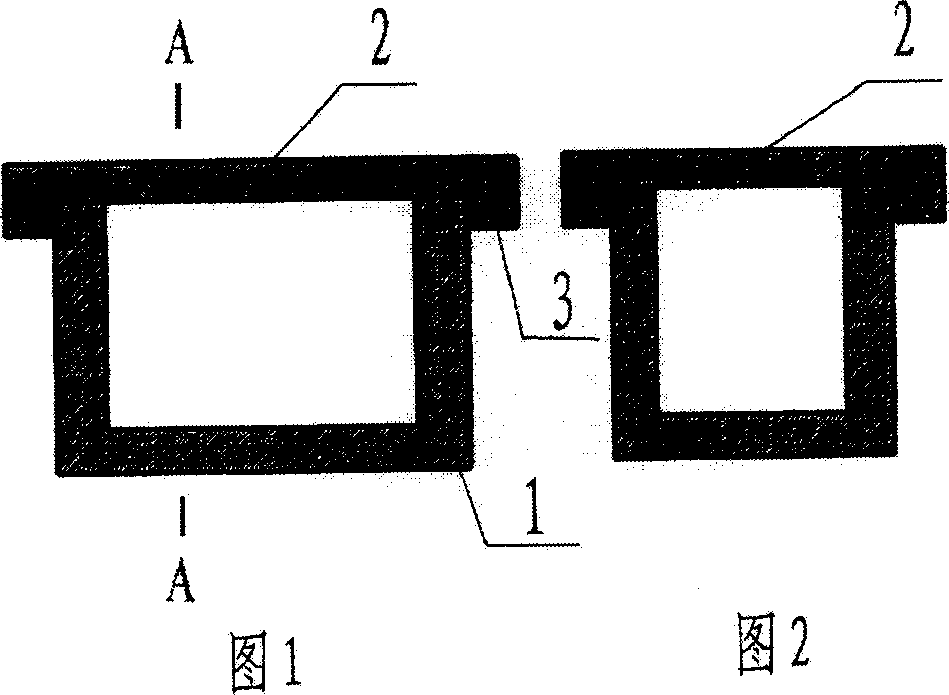

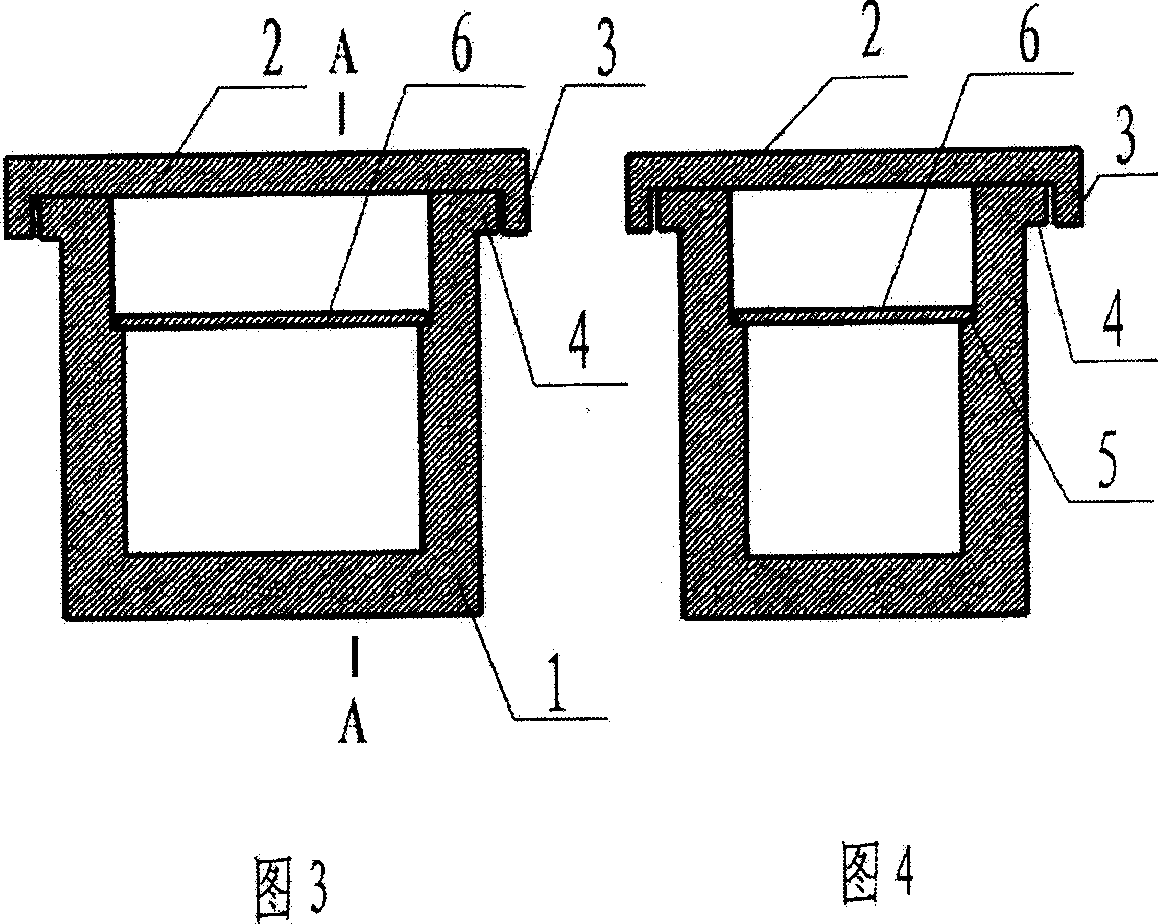

Fiber reinforced artificial stone tomb box and its manufacturing method

InactiveCN1776163AWide variety of sourcesImpact resistantUrnsCeramic shaping apparatusSuperplasticizerSlurry

This invention relates to a fiber reinforced artificial stone tomb box and making method, which contains fiber reinforced artificial stone made box unit with cavity and box cover with lower convex edge engaged with upper edge of box unit. The method contains mixing and agitating raw material into slurry, laying fiber net fabric in mold, putting slurry in mold, by molding, maintenance, stripping, repairing, finishing, spraying surface treating liquid to get products, raw material ratio is 30-60 part of cement, 40-65 part of fine aggregate, 1-4 part fiber filament, 1-8 part of anti-cracking permeability-reducing admixture, 0.2-1 part of superplasticizer, 1-5 part of silicate intensifier, 0-4 part of surface treating liquid, 0-0.5 part antifoaming agent and 0-0.5 part of paint. Said invention has advantages of fine anti-impact ability and impermeability, high strength, fine outline and low cost.

Owner:张正锋

Modification technology capable of improving strength and tenacity of wood

InactiveCN104802262AHigh strengthImprove toughnessWood treatment detailsWood impregnation detailsVacuum pressureThermal treatment

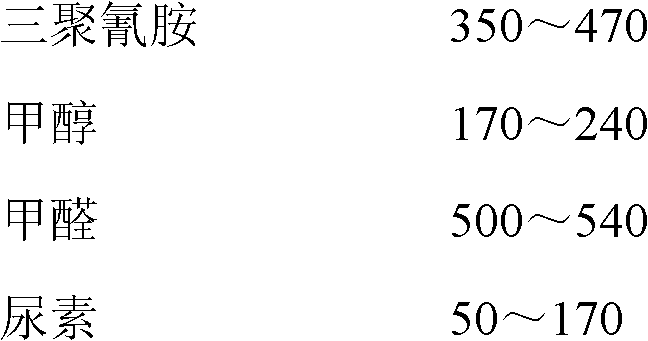

The invention relates to the technical field of wood modification, in particular to a modification technology capable of improving strength and tenacity of wood. The modification technology comprises the following steps: A. preparation of impregnation liquid which is prepared from the following raw materials in parts by weight: 10-30 parts of melamine modified urea resin, 6-10 parts of dextrin, 1-5 parts of a nanometer modifying agent, 1-3 parts of a flexibilizer, 1-5 parts of auxiliaries and 60-100 parts of water, weighing the raw materials according to the weight proportion and uniformly mixing to obtain the impregnation liquid; B. impregnating: performing vacuum-pressure impregnation treatment on the wood, and enabling the wood to adsorb the impregnation liquid; C. drying: drying the impregnated wood; D. thermal treatment: conducting thermal treatment on the dried wood under a vacuum state. The modification technology disclosed by the invention can obviously improve the strength and the tenacity of the wood, is simple in steps, convenient to operate and control, stable in quality, high in production efficiency and capable of realizing large-scale industrial production.

Owner:HUNAN DONGLIANG WOOD IND

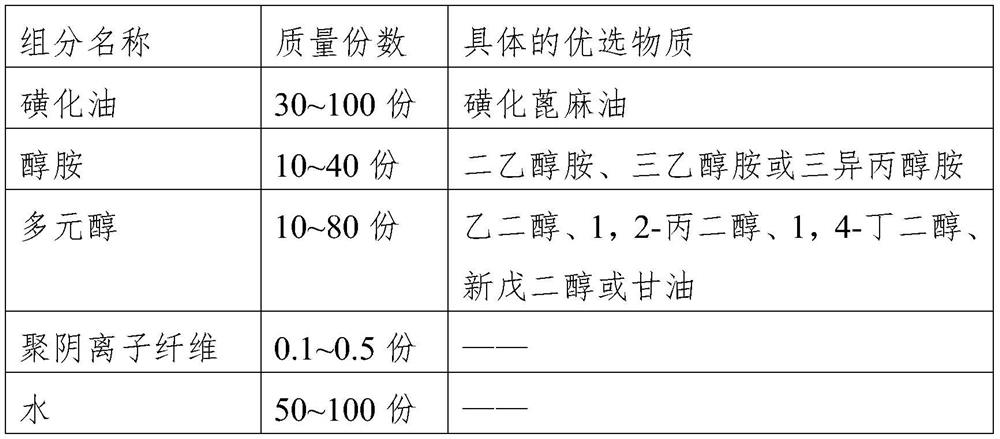

Red mud curing agent for paving road and preparation method of red mud curing agent

InactiveCN102584128ANo extravasationIncrease work intensityHydration reactionTetrahydrophthalamic acid

The invention relates to a red mud curing agent for paving a road and a preparation method of the red mud curing agent. The red mud curing agent is made of silicon oxide, aluminum oxide, calcium oxide, industrial byproduct alkali residue, tetrahydrophthalic anhydride and ethylene glycol double trimellitic anhydride ester. According to the preparation method, the active matters, such as silicon oxide, aluminum oxide and calcium oxide, are mixed; the active constituents of the matters are matched with one another, thereby obtaining curing agent and red mud; after being stirred, the curing agent and the red mud are subjected to ion exchange under the catalysis of concentrated material, thereby boosting the coagulation of red mud particles; and meanwhile, the red mud is coagulated and hardened, under the hydration reaction of a gelled material in the curing agent; the red mud has higher working strength within a short period of time; and the exosmose of heavy metal, radioactive elements and the like, is avoided. The red mud curing agent prepared by the preparation method disclosed by the invention is used together with red mud for paving the road. Compared with the prior art, the red mud curing agent has the advantages of high strength, excellent plate property, high durability, excellent water stability, excellent frost and melt resistance, excellent air shrinkage resistance, and the like.

Owner:HENAN UNIV OF SCI & TECH

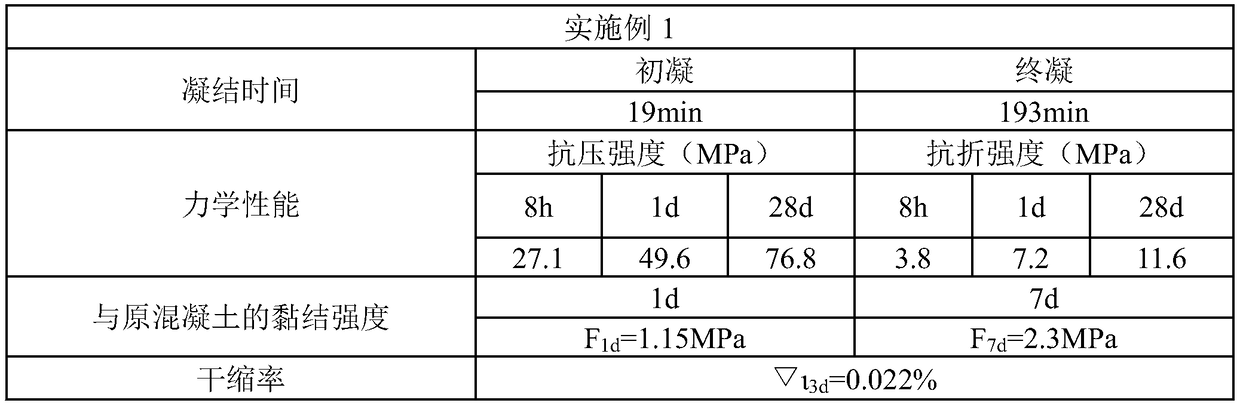

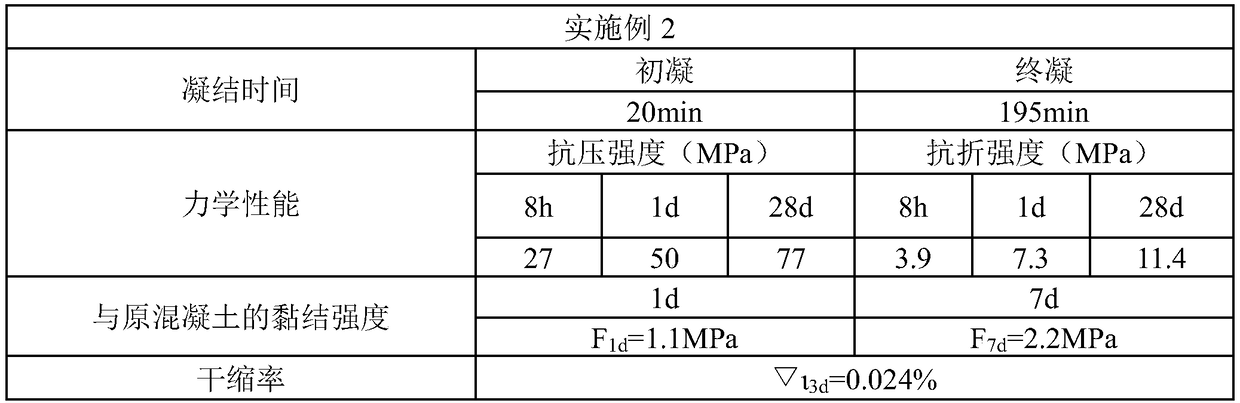

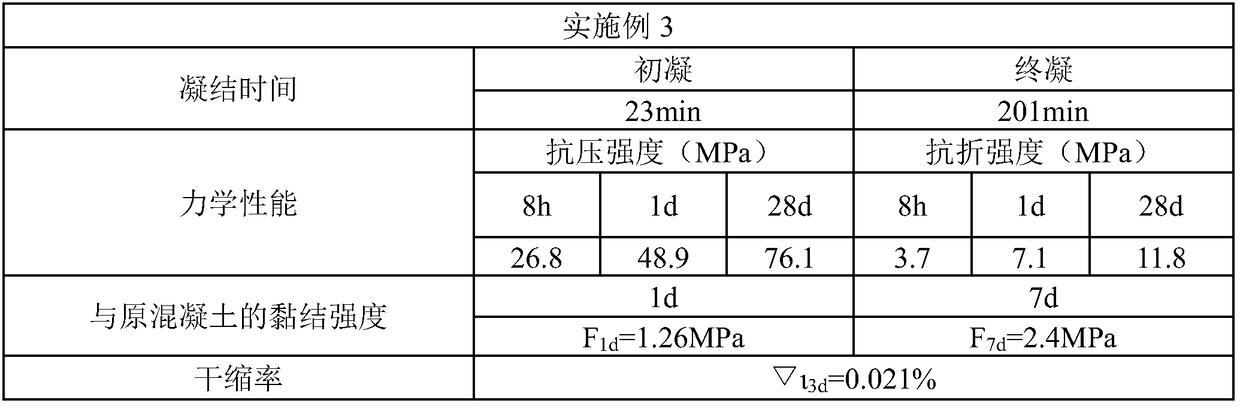

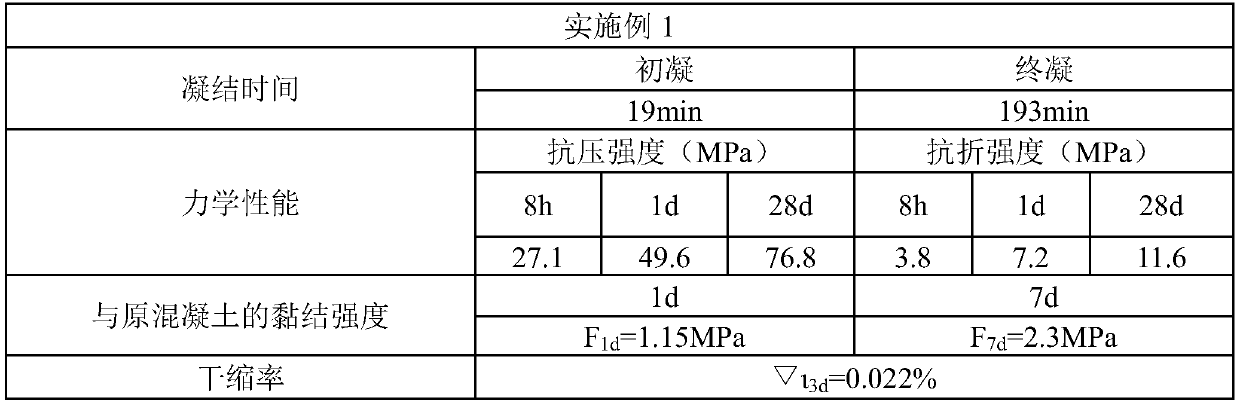

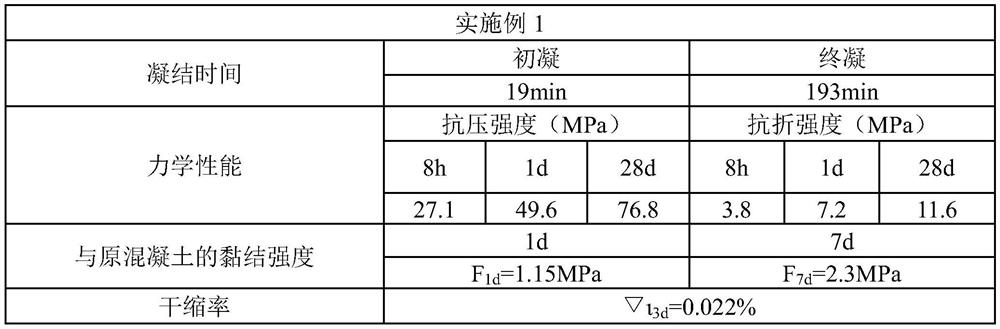

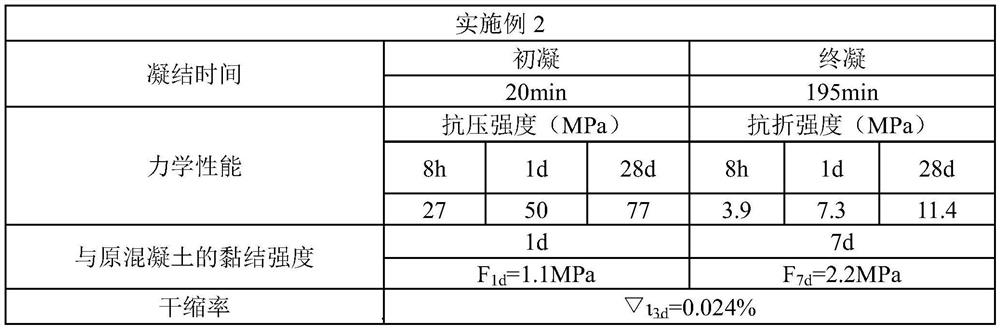

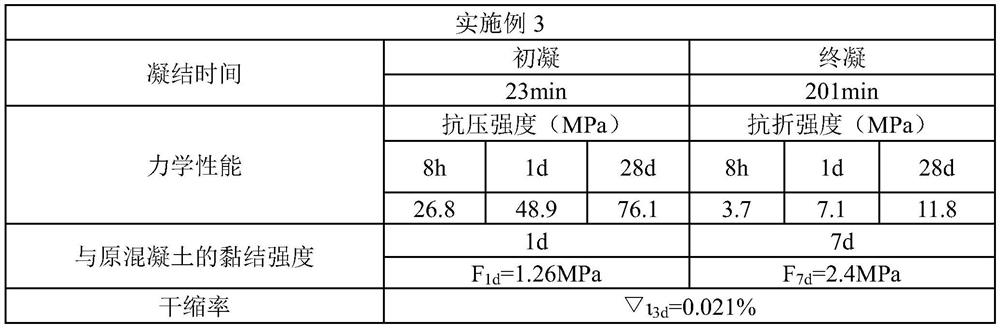

Fast hardening early strength type composite repair mortar

The invention belongs to the technical field of a building material, and provides fast hardening early strength type composite repair mortar. The mortar is prepared from the following ingredients in percentage by weight: 5 to 10 percent of water, 20 to 30 percent of cement, 1 to 5 percent of silicon ash, 1 to 5 percent of fly ash, 50 to 70 percent of quartz sand, 0.4 to 0.5 percent of compound early strength agents, 0.06 to 0.1 percent of water reducing agents, 1 to 5 percent of rubber powder and 0.06 to 0.8 percent of hybrid fiber, wherein the composite early strength agent is prepared from an ingredient A and an ingredient B; the ingredient A is lithium carbonate; the ingredient B is a mixture of triethanolamine and aluminum sulfate; the quartz sand consists of coarse sand, medium sand and fine sand; and the hybrid fiber consists of basalt fiber and polypropylene fiber. The fast hardening early strength type composite repair mortar solves the problems of reduced strength, high dry shrinkage rate and low bonding strength of the repair mortar in the prior art.

Owner:JILIN JIANZHU UNIVERSITY

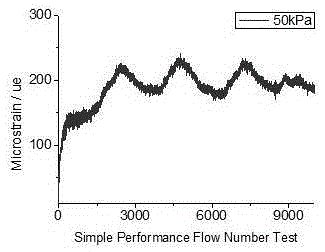

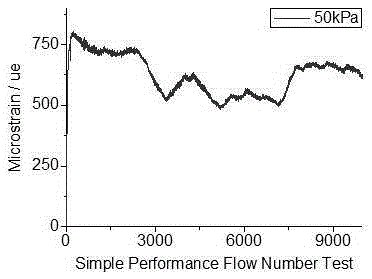

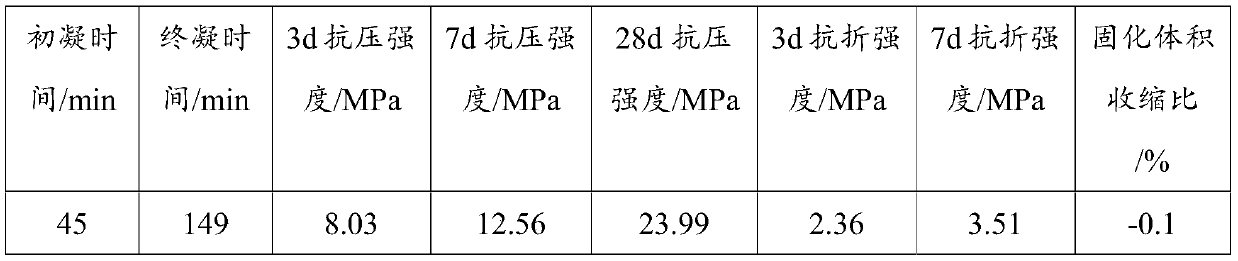

Water-resistant fatigue-resistant subgrade grouting material, and preparation method and applications thereof

InactiveCN105236890AImprove water resistanceGood flexibilityRoadwaysSoil preservationSoil scienceReducing agent

The invention relates to a water-resistant fatigue-resistant subgrade grouting material. The water-resistant fatigue-resistant subgrade grouting material is prepared from following materials by weight at a water / binder ratio of 0.28 to 3.0 via mixing: 90 to 95% of a binding material, 0.13 to 0.44% of an alkali excitation ingredient, 4.18 to 9.5% of a water-resistant latex, 0.2 to 0.5% of a water reducing agent, 0.01 to 0.02% of a stabilizing ingredient, and 0.03 to 0.05% of a delayed coagulation ingredient. The raw materials are easily available; a preparation method is simple; performance is excellent; the water-resistant fatigue-resistant subgrade grouting material can be applied for strengthening spraying of new subgrade and grouting strengthening of sedimentation subgrade, and possesses excellent effects on areas suffered from long-term rain wash and large rain capacity.

Owner:GANSU CHANGLONG HIGHWAY MAINTENANCE TECH RES INST CO LTD

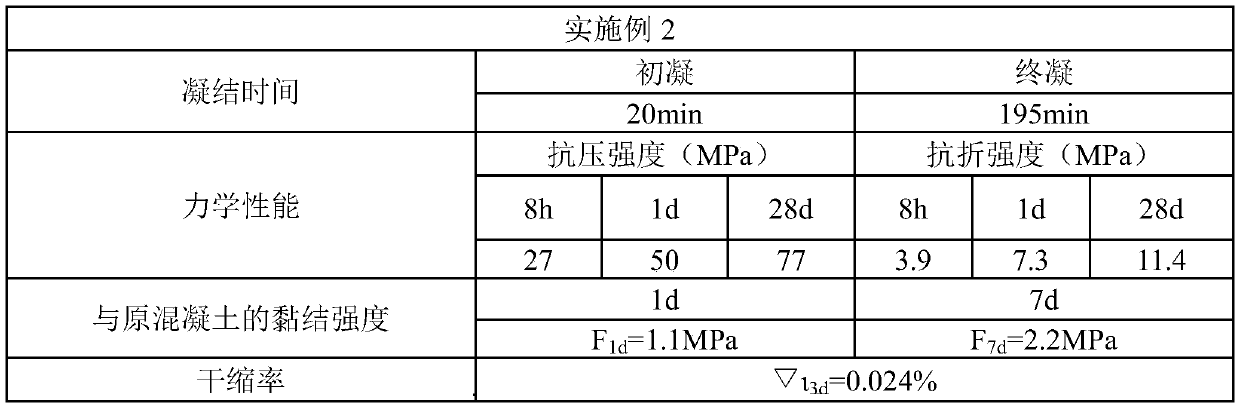

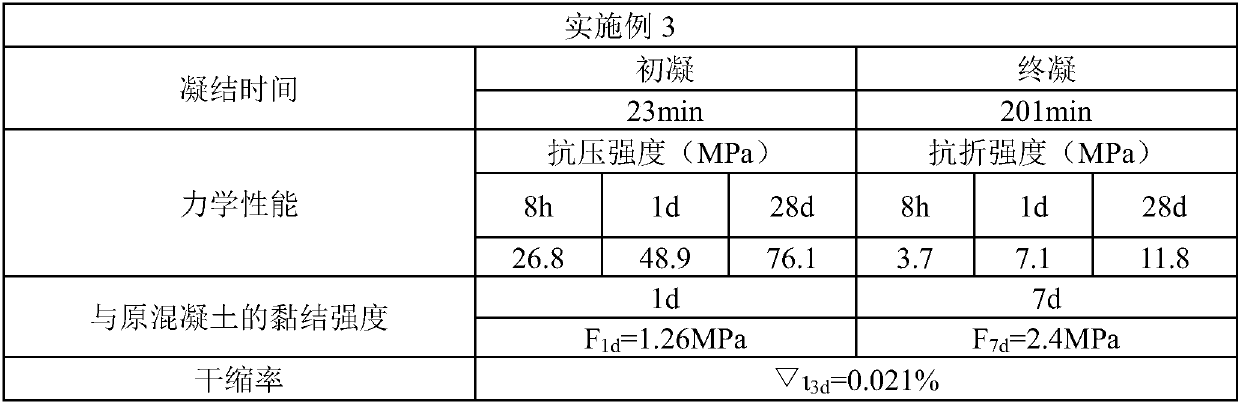

Rapid hardening early strength type composite repair mortar

The invention belongs to the technical field of building materials, and provides rapid hardening early strength type composite repair mortar. The rapid hardening early strength type composite repair mortar comprises, by weight, 5%-10% of water, 20%-30% of cement, 1%-5% of silica fume, 1%-5% of fly ash, 50%-70% of quartz sand, 0.4%-0.5% of composite early strength agents, 0.06%-0.1% of water reducing agents, 1%-5% of gelatin powder and 0.06%-0.8% of hybrid fibers. The composite early strength agents comprise components A and components B, the components A are nanometer calcium carbonate whiskers, the components B are mixtures of triisopropanolamine and aluminum sulfate, the quartz sand comprises coarse sand, medium sand and fine sand, and the hybrid fibers include basalt fibers and polypropylene fibers. The rapid hardening early strength type composite repair mortar has the advantage that the problems of strength decreasing, high dry shrinkage and low bonding strength of repair mortar in the prior art can be solved by the aid of the rapid hardening early strength type composite repair mortar.

Owner:长春昌驰新材料科技有限公司

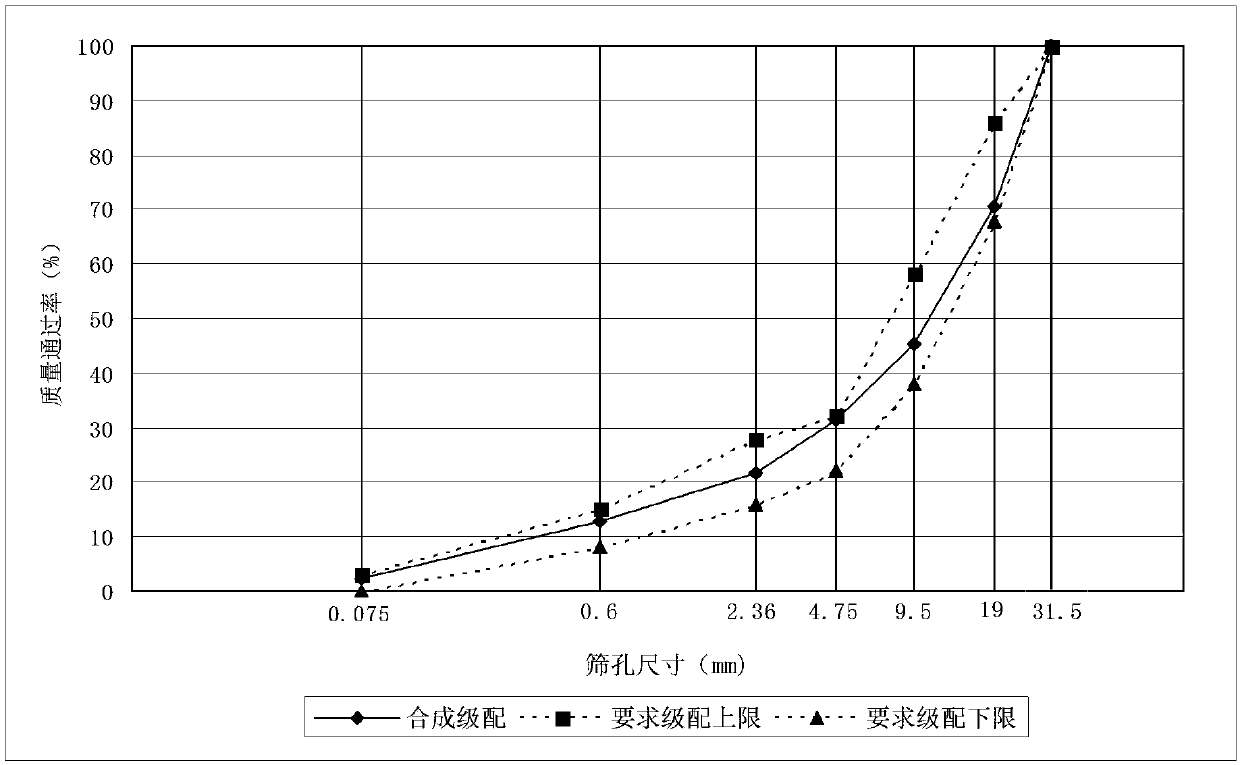

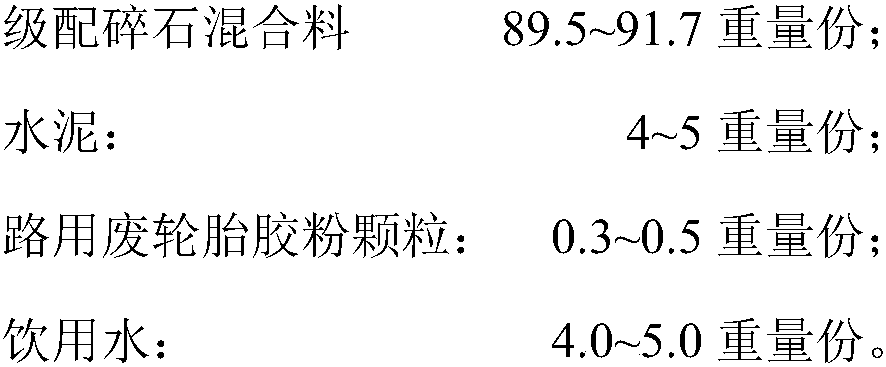

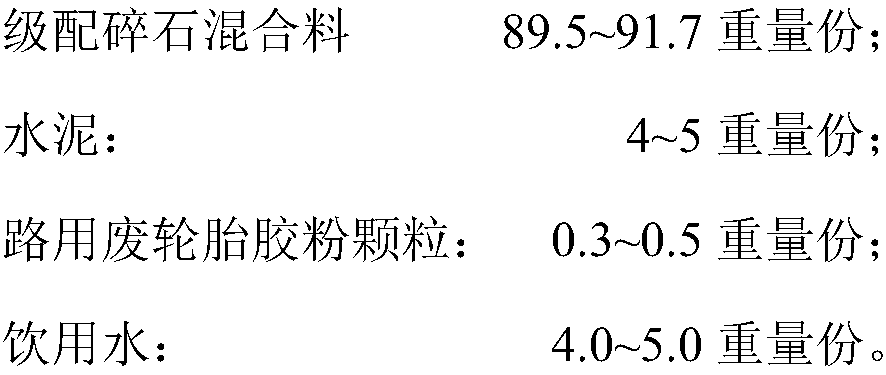

Anti-crack type rubber powder cement stabilized macadam mixture and preparation method thereof

InactiveCN107777967AImprove anti-shrinkage performanceImprove the ability to resist temperature shrinkagePolymer scienceCrushed stone

The invention relates to an anti-crack type rubber powder cement stabilized macadam mixture which comprises the following components in parts by weight: 89.5-91.7 parts of a graded broken stone mixture, 4-5 parts of cement, 0.3-0.5 part of scrap tire rubber powder particles for road and 4.0-5.0 parts of drinking water. The invention further relates to a preparation method of the anti-crack type rubber powder cement stabilized macadam mixture. The preparation method comprises the following steps: (1) preparing a graded broken stone mixture, namely adopting a graded broken stone mixture with thefollowing grading range; (2) mixing, namely uniformly stirring the graded broken stone mixture, namely adding 4-5 parts of cement by weight into 89.5-91.7 parts of the graded broken stone mixture, continuously stirring to a uniform state, adding 0.3-0.5 part of scrap tire rubber powder particles for road, adding drinking water with a weight percentage of 4.0-5.0%, and uniformly stirring. The anti-crack type rubber powder cement stabilized macadam mixture mixed with the scrap tire rubber powder particles for road serves as a semi-flexible asphalt pavement of the base to be reasonably applied to high-grade highways.

Owner:天津市交通科学研究院

Wood enhancement and corrosion prevention modification liquid and preparation method thereof

InactiveCN104802252ASimple processEasy to operate and controlWood treatment detailsWood impregnation detailsPreservativeHardness

The invention relates to the technical field of wood modification, in particular to a wood enhancement and corrosion prevention modification liquid and a preparation method thereof. The wood enhancement and corrosion prevention modification liquid comprises the following raw materials in parts by weight: 10-30 parts of melamine modified urea resin, 4-8 parts of dextrin, 1-5 parts of a nano modifier, 0.5-1.5 parts of a preservative, 1-5 parts of auxiliaries and 60-100 parts of water. According to the wood enhancement and corrosion prevention modification liquid, the intensity and the corrosion resistance of woods can be improved; furthermore, the insect bite, mildewing, water, flame, deformation and cracking prevention performance of the modified woods are greatly improved; the density, the hardness, the anti-bending intensity and the elastic modulus are higher, so that the use performance of the woods can be improved, and the service life of the woods is prolonged. The wood enhancement and corrosion prevention modification liquid has natural properties of heat insulation, temperature adjustment, humidity adjustment and the like, is colorful and bright and is high in physical stripe third dimension; a plate looks transparent and natural.

Owner:HUNAN DONGLIANG WOOD IND

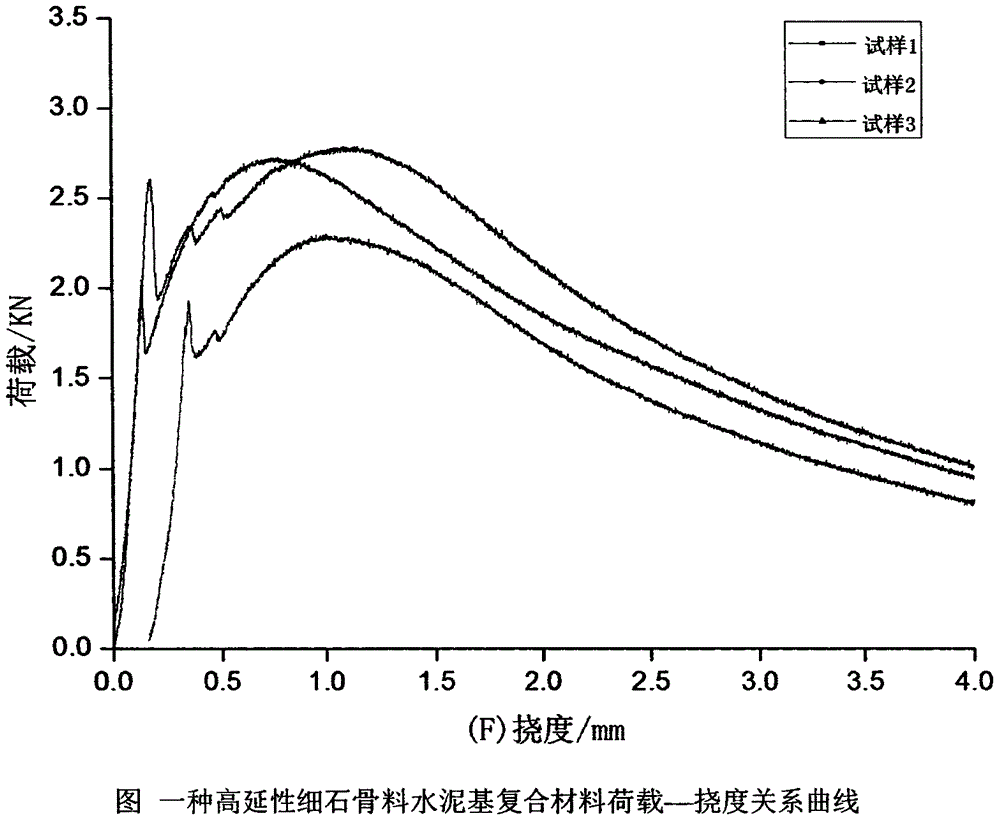

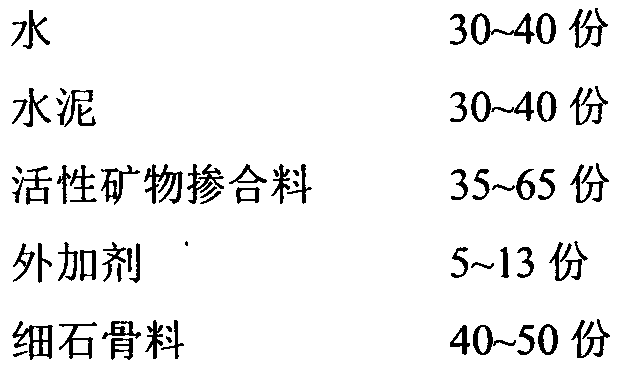

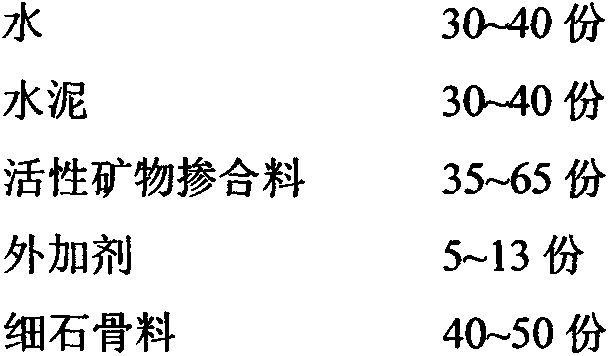

High-ductility cement-based composite material with fine stone aggregate

InactiveCN106478025AImprove carrying capacityHigh strengthClimate change adaptationUltimate tensile strengthMaterials science

The invention relates to a high-ductility cement-based composite material with fine stone aggregate. The high-ductility cement-based composite material is characterized in that the mixing amount of fibers among raw materials is not higher than 3% of the total volume of the composite material; the other materials, except for the fibers, include, by weight, 30-40 parts of water, 30-40 parts of cement, 35-65 parts of active mineral admixtures, 5-13 parts of admixtures and 40-50 parts of fine stone aggregate. The raw materials for the high-ductility cement-based composite material with the fine stone aggregate can be weighed according to proportions and then can be mixed and stirred in fields, or dry mixtures can be preliminarily prepared from the raw materials. The high-ductility cement-based composite material with the fine stone aggregate has the advantages that the high-ductility cement-based composite material is high in strength, impact resistance and abrasion resistance, stable in performance, low in dry shrinkage and obvious in ductile failure capacity and can be widely popularized in the field of civil and traffic engineering.

Owner:黄志义

Environment-friendly stabilizer for CA mortar and preparation method thereof

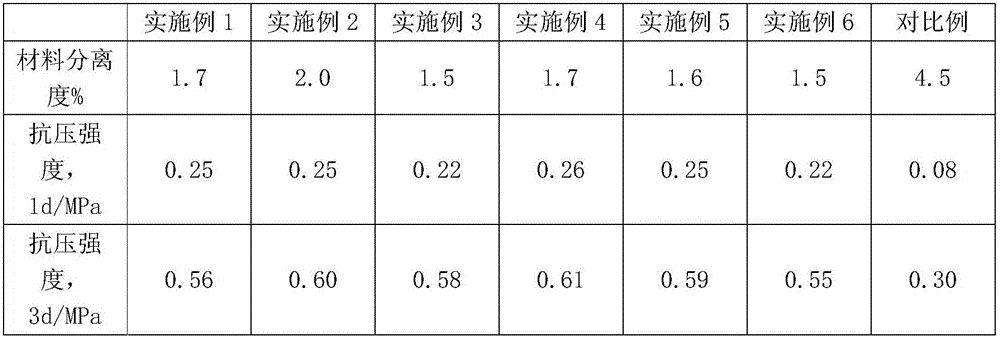

The invention discloses an environment-friendly stabilizer for CA mortar, which comprises the following components, by weight, 3-5 parts of a water-soluble polymer monomer, 20-50 parts of polymer latex, 2-4 parts of a cationic emulsifier, 0.8-1.2 parts of cellulose ether, 1-1.5 parts of metakaolin, 1-2 parts of dextrin, 0.5-0.8 parts of a dispersing agent, and 50-60 parts of deionized water. The invention also discloses a preparation method of the stabilizer of the CA mortar. The stabilizer can improve compatibility of components in the CA mortar and effectively reduce separation degree of CA mortar, thereby greatly improving the stability and mechanical performance of the CA mortar. The stabilizer is toxic-free and environment-friendly and is simple in preparation method.

Owner:宁波森泰新材料有限公司

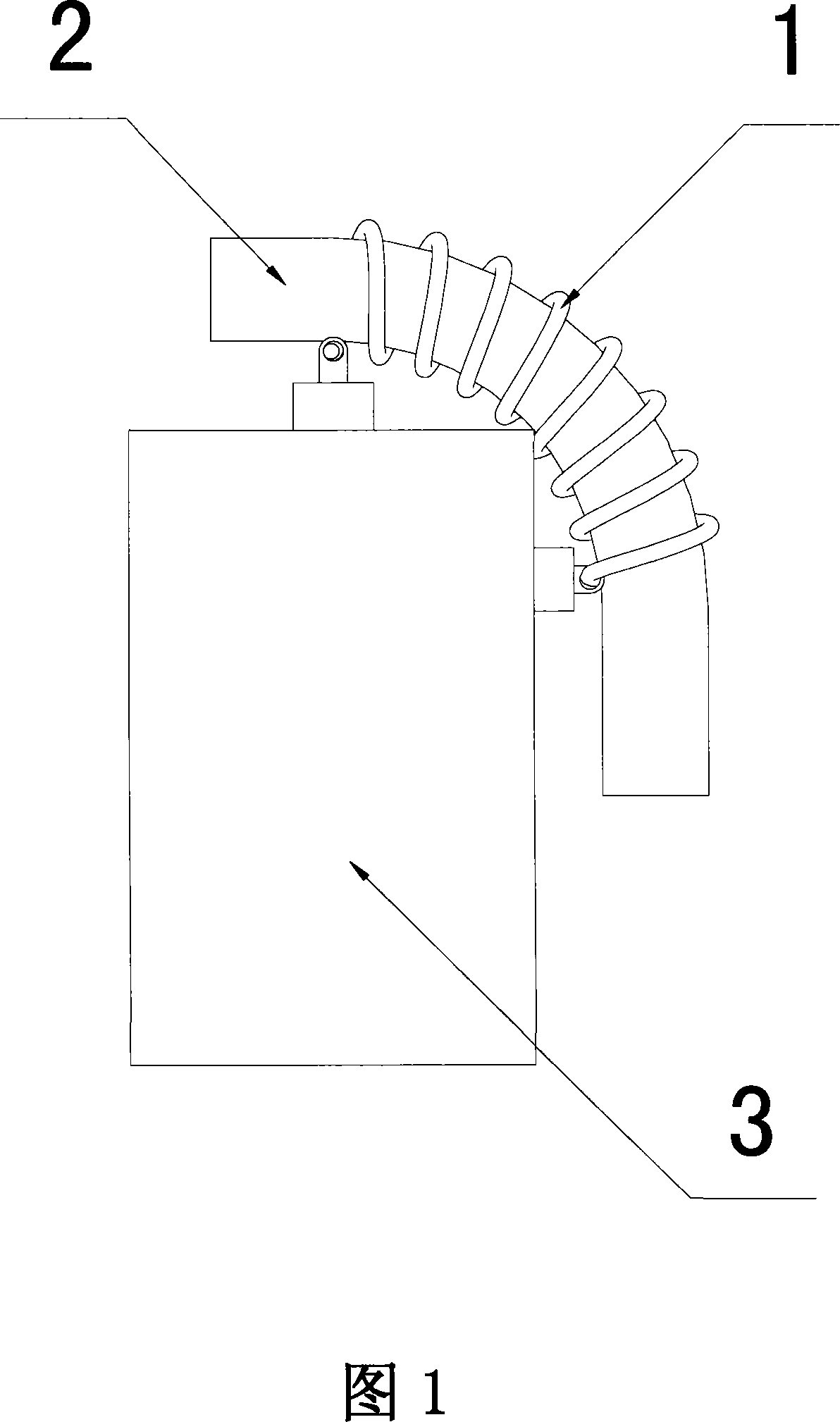

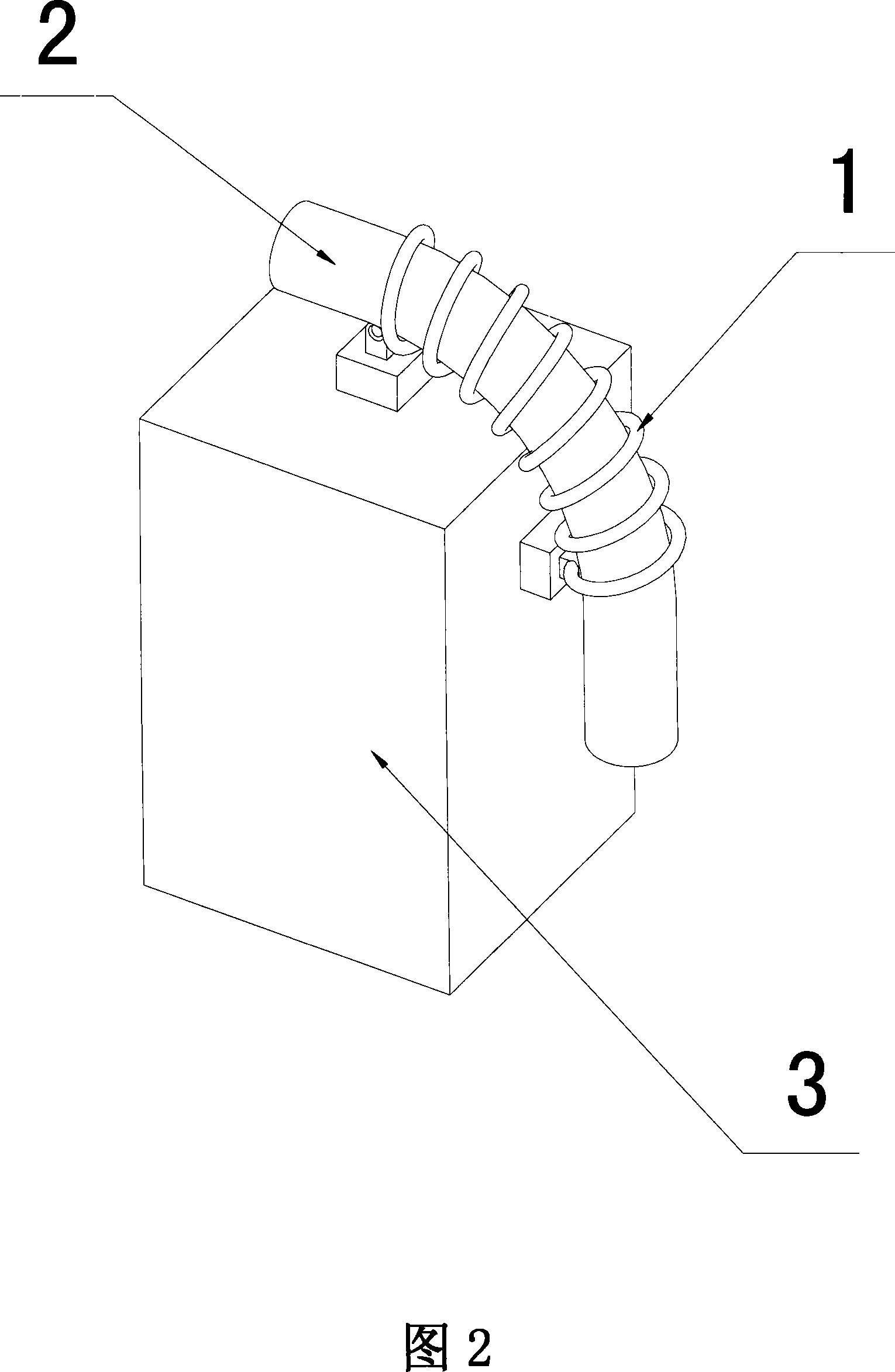

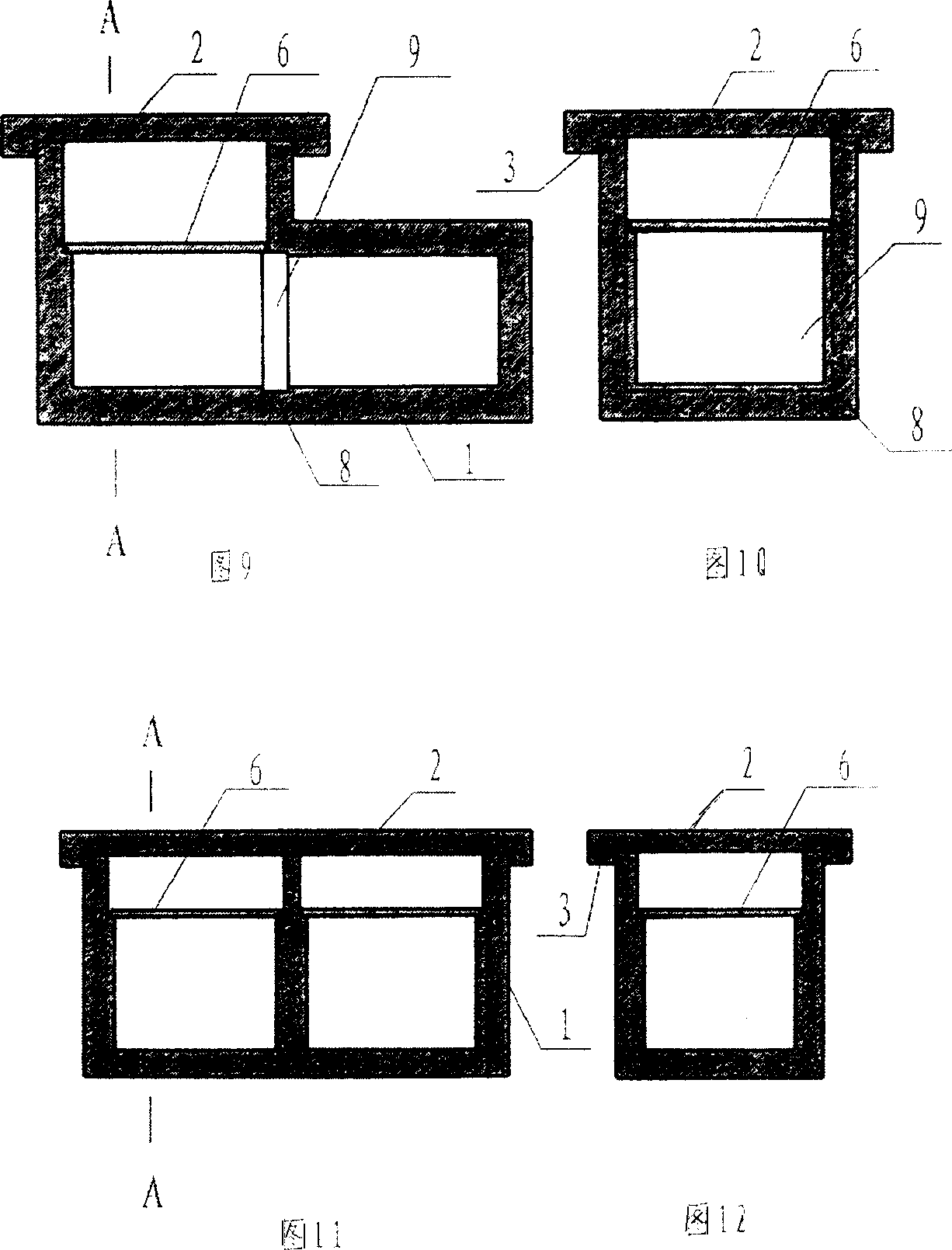

Pipe shrinking prevention device of refrigerating device soft pipeline

InactiveCN101158433AGuaranteed unobstructedImprove anti-shrinkage performancePipe elementsEngineeringRefrigeration

The present invention discloses a deflated-pipe preventing device used for a soft pipeline of a refrigeration equipment, comprises a spring and the soft pipeline connected with associated functional elements of the refrigeration equipment, and is characterized in that the spring is sleeved and arranged on the soft pipeline. The present invention makes use of the principle of absorption and sustained release of deformed potential energy of the spring, guarantees the assisted extension of the spring under the condition that the soft pipeline is bended caused by force, thus leading no deformation caused by the collapse of the pipe, improving the performance of the collapse resistance of the refrigeration equipment soft pipeline, guaranteeing the smoothness of the fluid inside the refrigeration circulating system, and having strong practicability. Compared with a bend preventing device inserted into the soft pipeline, the present invention does not reduce the overall utilization rate of the soft pipeline by the reduction of the inner diameter of the soft pipeline, has more convenience and easy operation, and saves the materials and the production cost of the soft pipe.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

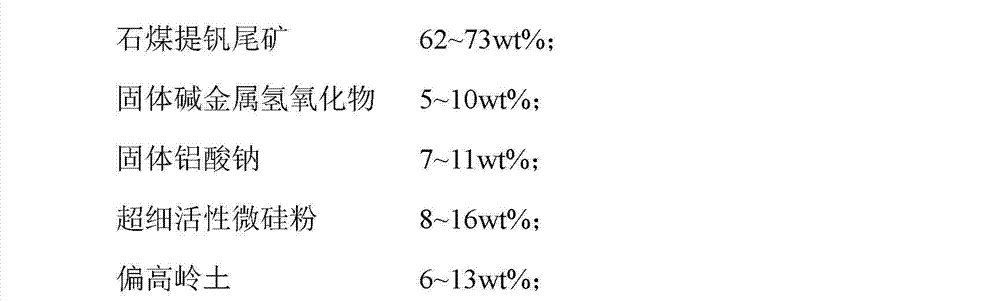

Geopolymer-like cement and preparation method thereof

ActiveCN102180606BSolve stacking problemsBroaden sources of raw materialsSolid waste managementCement productionEtchingSodium aluminate

The invention relates to geopolymer-like cement and a preparation method thereof. The geopolymer-like cement is prepared from the following components by weight percent: 62-73wt% of stone coal vanadium tailings, 5-10wt% of solid alkali metal hydroxide, 7-11wt% of solid sodium aluminate, 8-16wt% of superfine activated microsilica and 6-13wt% of metakaolin. The preparation method comprises the following steps: adding the solid alkali metal hydroxide in the stone coal vanadium tailings, stirring, performing dry ball milling and calcining; adding the solid sodium aluminate, the superfine activated microsilica and the metakaolin in the calcined mixture, stirring, and performing dry ball milling, so as to prepare the finished geopolymer-like cement; and when in use, adding water in the finishedcement, stirring and simultaneously grouting so that hardened slurry is formed at room temperature. According to the invention, the operation is simple, the cost is low, and the chemical corrosion degree on containers and human bodies is low; the hardened slurry of the prepared geopolymer-like cement has the advantages of high compression strength and folding strength, strong resistance to sulfate etching, water etching and alkali-aggregate reaction and good air shrinkage.

Owner:WUHAN UNIV OF TECH

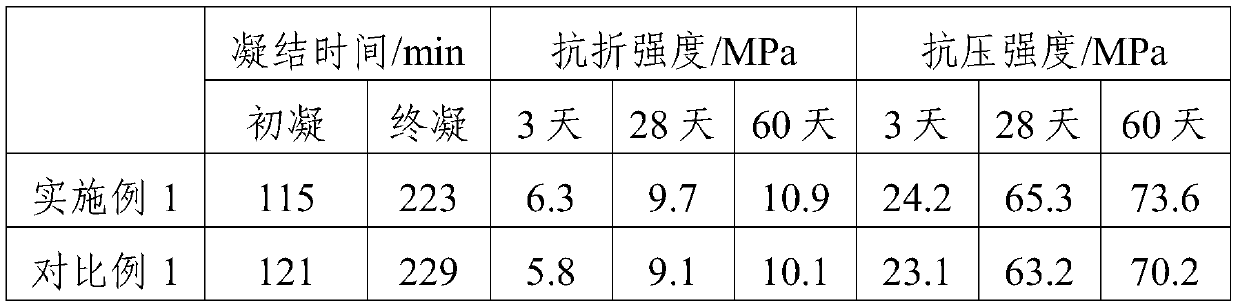

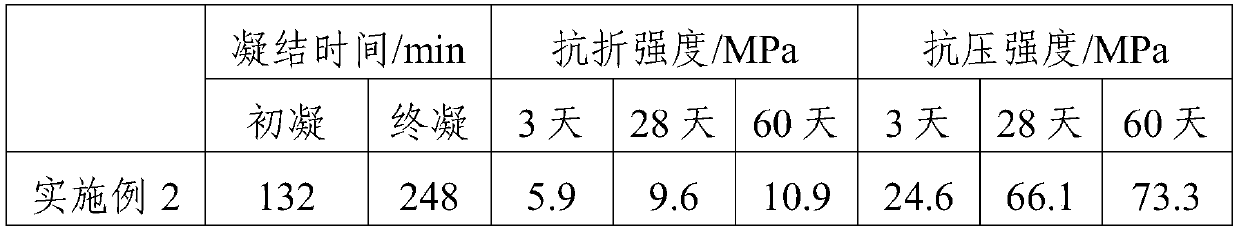

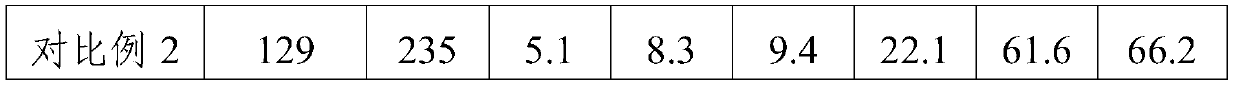

A kind of sulfur-fixed ash-fly ash composite environment-friendly hollow-out grouting material and its preparation method and application

ActiveCN110482995BAdjustable and controllable intensityMaintain volume expansionBridge erection/assemblyBridge strengtheningSlagEnvironmental engineering

The invention provides a sulfur fixation ash-fly ash compounded environment-friendly void grouting material as well as a preparation method and application thereof. The void grouting material is prepared from sulfur fixation ash, fly ash, a curing agent, an early strength agent, a water reducing agent, a defoaming agent, an expanding agent and water. In terms of performance, the strength of the grouting material can be adjusted and controlled by adjusting the proportion of the sulfur fixation ash, the fly ash and the curing agent in the formula; through the contents of the auxiliary agent andthe curing agent, the characteristics of high early strength and short curing time can be realized. Meanwhile, industrial solid wastes such as the sulfur fixation ash and the fly ash are adopted, so that the development requirement of China on environmental protection is met. Compared with a common cement-based grouting material on the market at present, the grouting material disclosed by the invention has the advantages of no air shrinkage phenomenon after being cured, capacity of keeping volume micro-expansion and excellent air shrinkage resistance. The cost of the disclosed grouting material is less than 180 yuan / m<3>, the cost performance is greatly improved, and the disclosed grouting material has great economic and social benefits.

Owner:SHANDONG UNIV

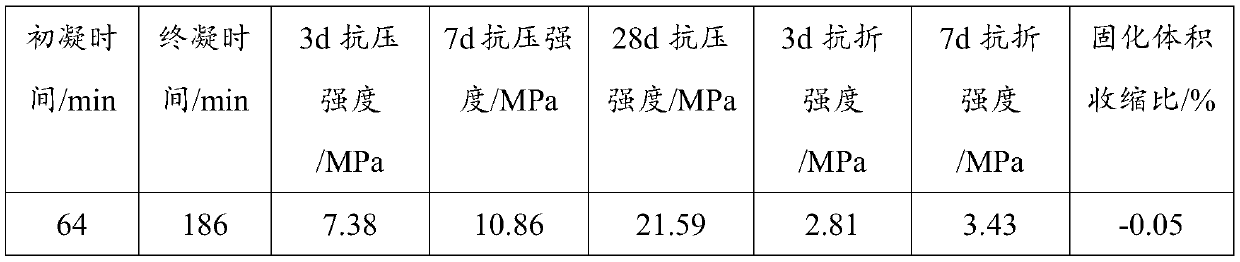

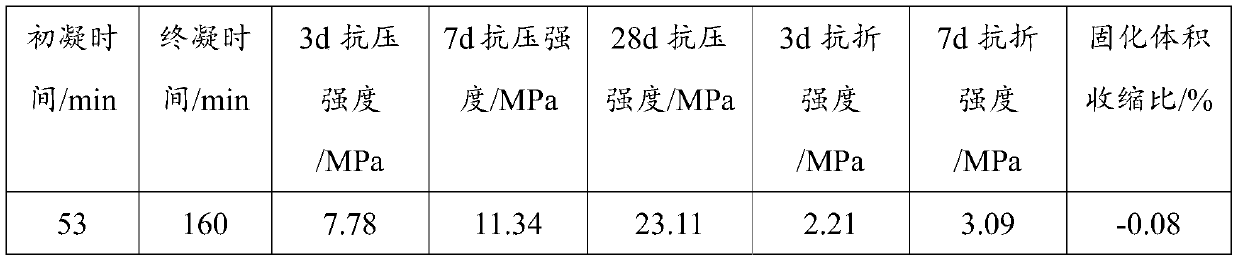

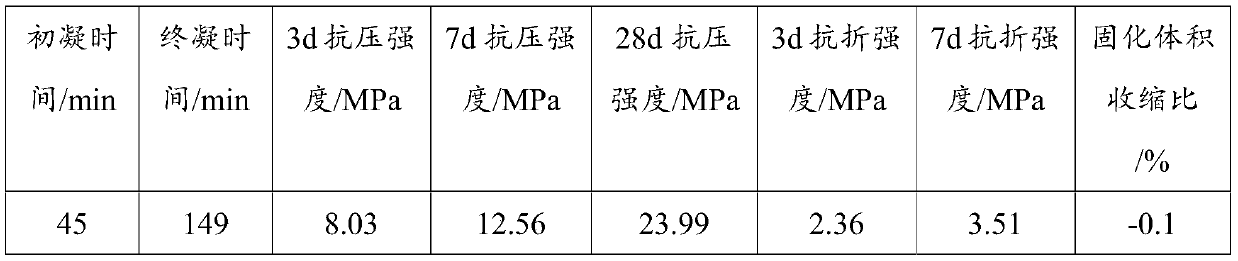

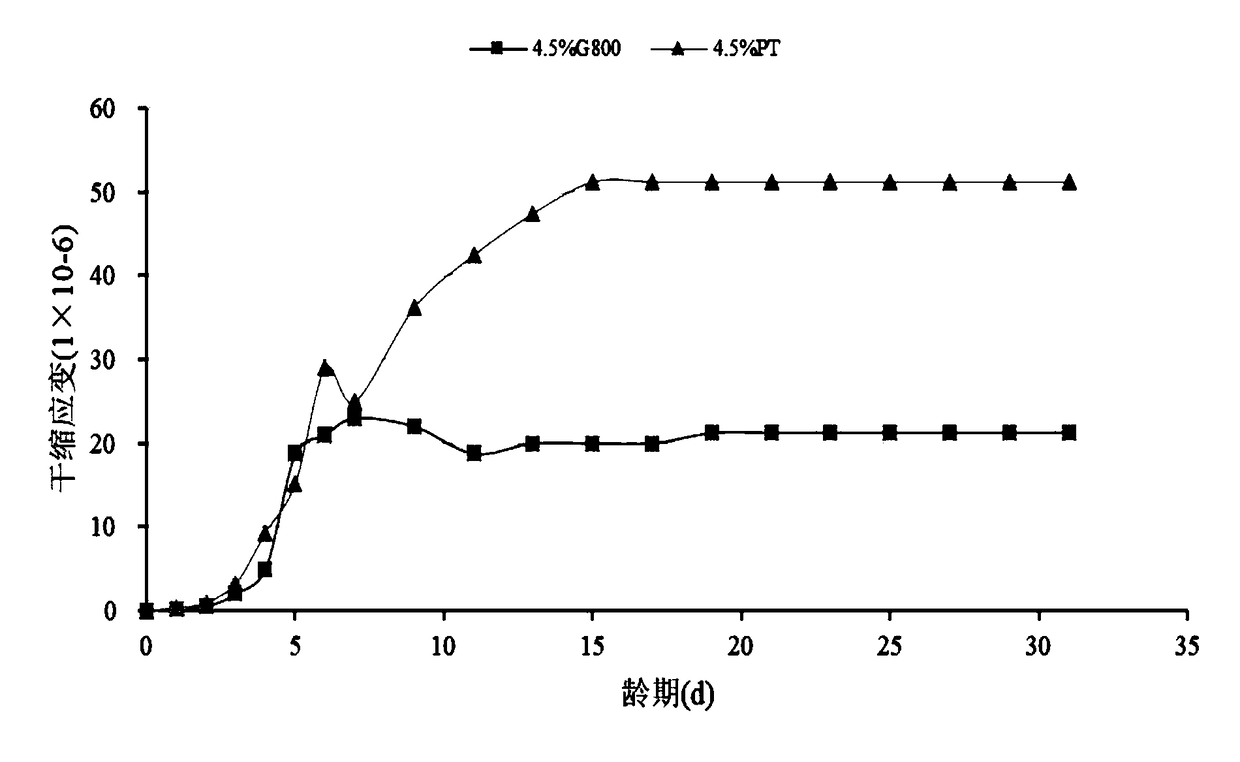

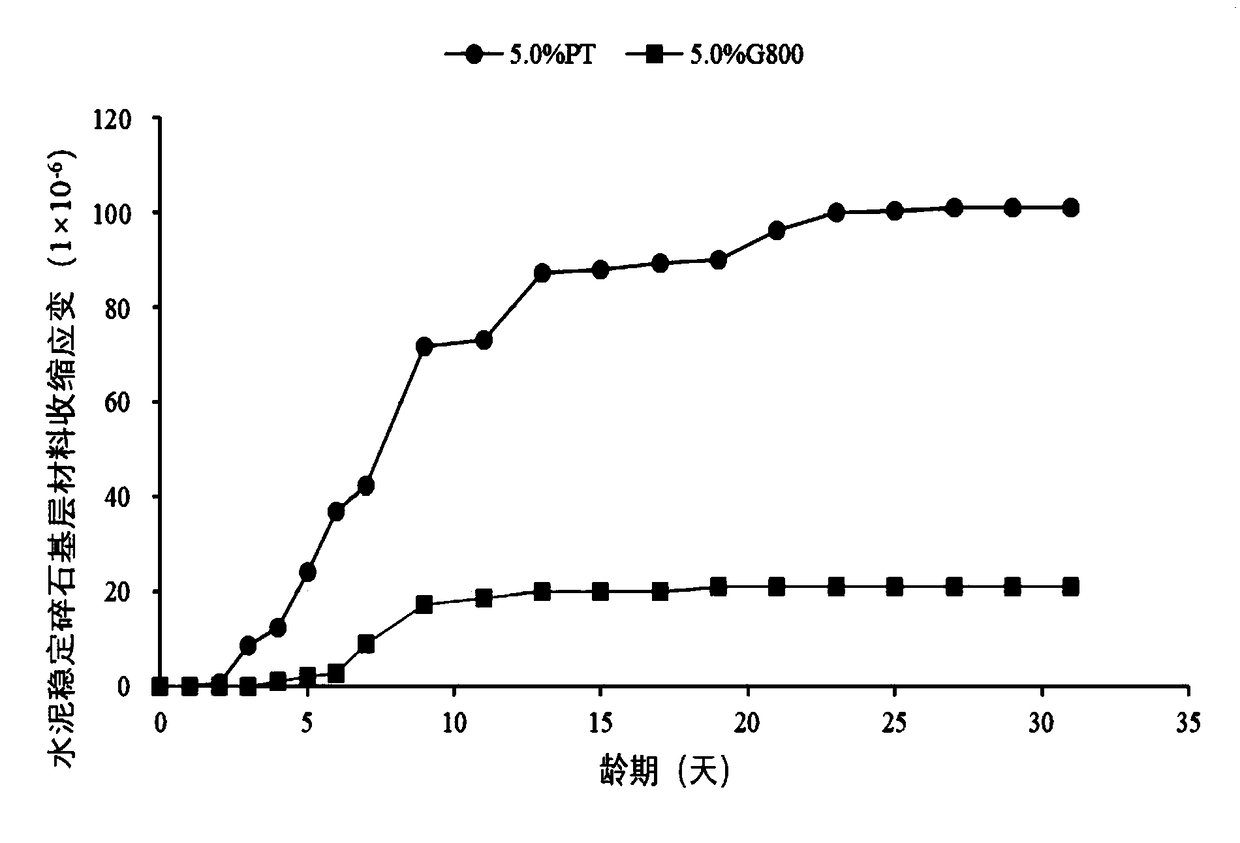

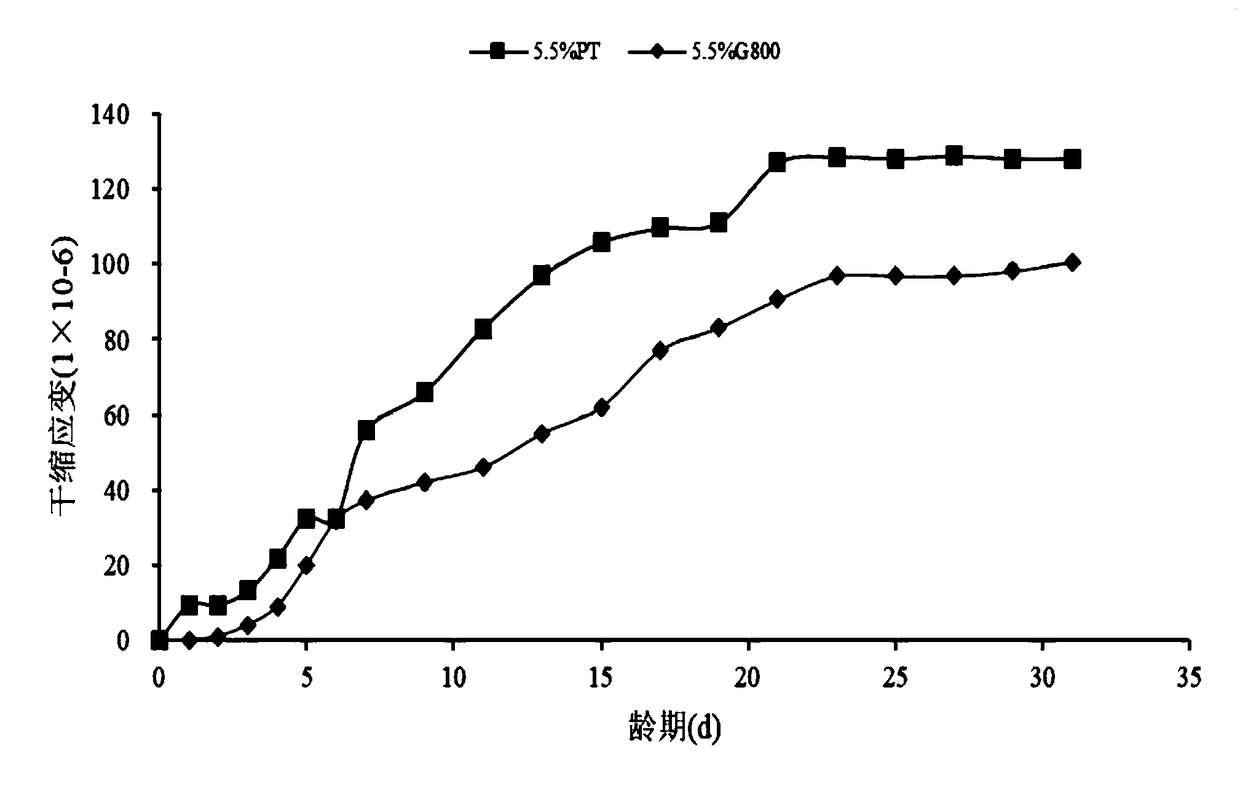

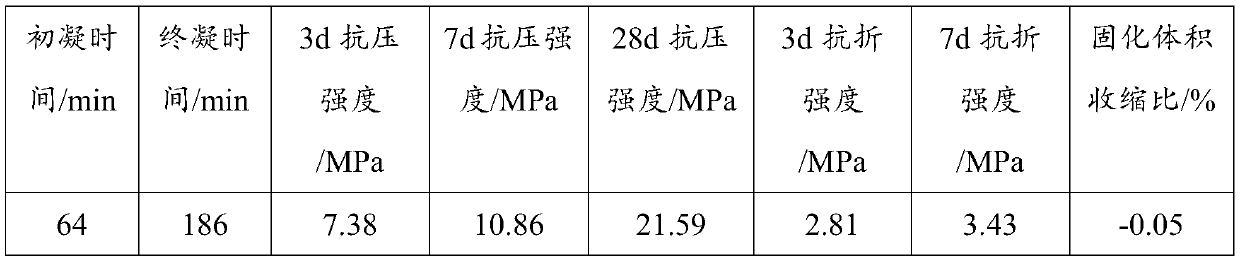

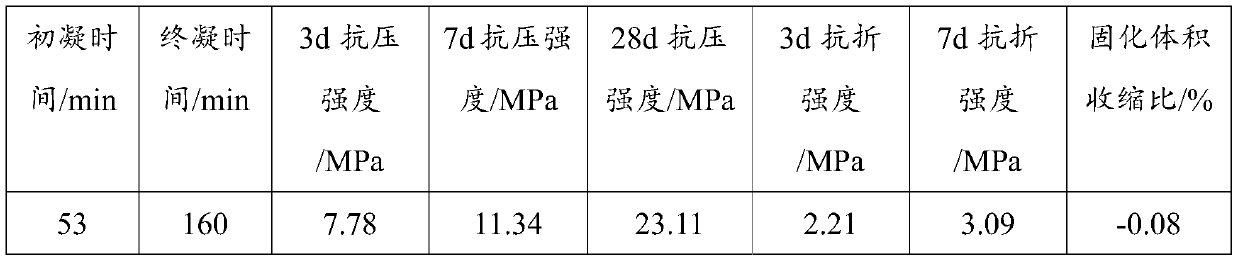

Method for improving dry shrinkage resistance of cement stabilized macadam base material

The invention discloses a method for improving the dry shrinkage resistance of a cement stabilized macadam base material. The method includes the following steps: according to JTG D50-2006 'Specifications for Design of Highway Asphalt Pavement' and JTG E42-2005 'Test Methods of Aggregate for Highway Engineering', designing a cement stabilized macadam base material mixing proportion according to gradation of various grades of aggregates; then according to JTG E51-2009 'Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering', carrying out compaction test, and determining the optimal water content of the cement stabilized macadam base material at specific cement dosage; and blending magnetized water with the optimal water content, macadam and cement to obtain thecement stabilized macadam base material. The magnetized water is prepared according to the following way: using three GMX800 magnetizers, according to the water flow direction indicated by the magnetizers, successively placing on the outer wall of a rubber pipe with the pipe diameter of 20 mm, making the intervals between the magnetizers be 25 mm, and controlling ordinary water to pass through themagnetizers with the flow rate of 225 mL / s, to obtain the magnetized water.

Owner:WUHAN UNIV OF TECH

Sulfur fixation ash-fly ash compounded environment-friendly void grouting material as well as preparation method and application thereof

ActiveCN110482995AExcellent anti-shrinkage abilityLow priceBridge erection/assemblyBridge strengtheningDefoaming AgentsFirming agent

The invention provides a sulfur fixation ash-fly ash compounded environment-friendly void grouting material as well as a preparation method and application thereof. The void grouting material is prepared from sulfur fixation ash, fly ash, a curing agent, an early strength agent, a water reducing agent, a defoaming agent, an expanding agent and water. In terms of performance, the strength of the grouting material can be adjusted and controlled by adjusting the proportion of the sulfur fixation ash, the fly ash and the curing agent in the formula; through the contents of the auxiliary agent andthe curing agent, the characteristics of high early strength and short curing time can be realized. Meanwhile, industrial solid wastes such as the sulfur fixation ash and the fly ash are adopted, so that the development requirement of China on environmental protection is met. Compared with a common cement-based grouting material on the market at present, the grouting material disclosed by the invention has the advantages of no air shrinkage phenomenon after being cured, capacity of keeping volume micro-expansion and excellent air shrinkage resistance. The cost of the disclosed grouting material is less than 180 yuan / m<3>, the cost performance is greatly improved, and the disclosed grouting material has great economic and social benefits.

Owner:SHANDONG UNIV

Cement stabilized macadam base and construction method thereof

InactiveCN111792893AHigh tensile strengthSlow down the rate of crackingRoads maintainenceFiberPolyvinyl alcohol

The invention discloses a cement stabilized macadam base and a construction method thereof, and belongs to the technical field of highway pavement pavements. The cement stabilized macadam base comprises aggregate, cement, water, a polymer mixture, magnetized polyvinyl alcohol fibers and serpentine asbestos powder; and the base is prepared by mixing and constructing the following components, by mass, 4.5% of the cement, 4.5% of the water, 0.3-0.97% of the polymer mixture, 0.6-3% of the magnetized polyvinyl alcohol fibers, 1.5% of the serpentine asbestos powder, and the balance of the aggregate.In the present invention, through mutual cooperation of the designed polymer mixture, the magnetized polyvinyl alcohol fibers, the aggregate and the serpentine asbestos powder, the water resistance is improved, the tensile strength of the cement stabilized macadam base can be effectively enhanced, the influence of temperature, humidity and the reaction effect exerted by a running vehicle due to the friction effect on the base can be weakened to a certain extent, cracking is avoided, the drawing effect of external force can be continuously resisted after cracking within a certain extent range,and the cracking speed of the base is effectively reduced.

Owner:浙江省衢州市交通建设集团有限公司

High-performance cement with high-content yellow phosphorus slag and production process of high-performance cement

The invention provides high-performance cement with high-content yellow phosphorus slag and a production process of the high-performance cement, and relates to the technical field of cement, the high-performance cement is prepared from the following raw materials in parts by weight: 100 parts of Portland cement clinker, 5-15 parts of gypsum, 60-110 parts of yellow phosphorus slag powder, 10-35 parts of nickel slag powder, 10-18 parts of zeolite powder, 6-11 parts of rectorite powder, 2-6 parts of hydrotalcite powder, 0.3-1.2 parts of cane sugar and 0.6-1.3 parts of alkali metal hydroxide. According to the invention, the stacking problem of the yellow phosphorus slag and the nickel slag is further solved, the additional value of the waste slag is improved, and the prepared cement product ishigh in strength and good in construction performance by matching with the zeolite powder, rectorite powder, hydrotalcite powder, sucrose, alkali metal hydroxide and the like.

Owner:安徽信典网络科技有限公司

Method for preparing geopolymers by taking stone coal vanadium extraction tailings as main raw materials

ActiveCN103482890BFavorable strength developmentHigh compressive strengthCement productionSlagMetakaolin

Owner:WUHAN UNIV OF TECH

Modified planted forest timber and preparation method thereof

ActiveCN101745951BGood dimensional stabilityIncreased anti-swelling ratePressure impregnationWood dampingBulk resistanceHigh dimensional

The invention discloses impregnation reinforcement-thermal treatment modifying technology for planted forest timber. The technology comprises the following steps in order: 1) impregnating the timber by adopting impregnation liquid which uses modified urea resin as a main agent of the impregnation liquid; and 2) thermally treating the impregnated timber in vacuum. The timber prepared by the methodhas high dimensional stability and high strength; the bulking resistance and the corrosion resistance of the timber are improved; the added value of the thermally-treated timber is improved; and the application range of the thermally-treated timber is expanded.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

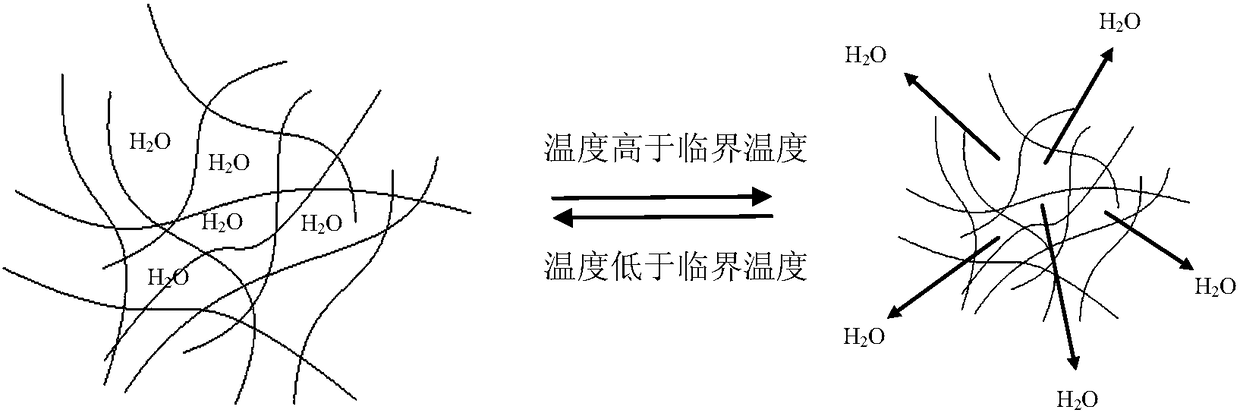

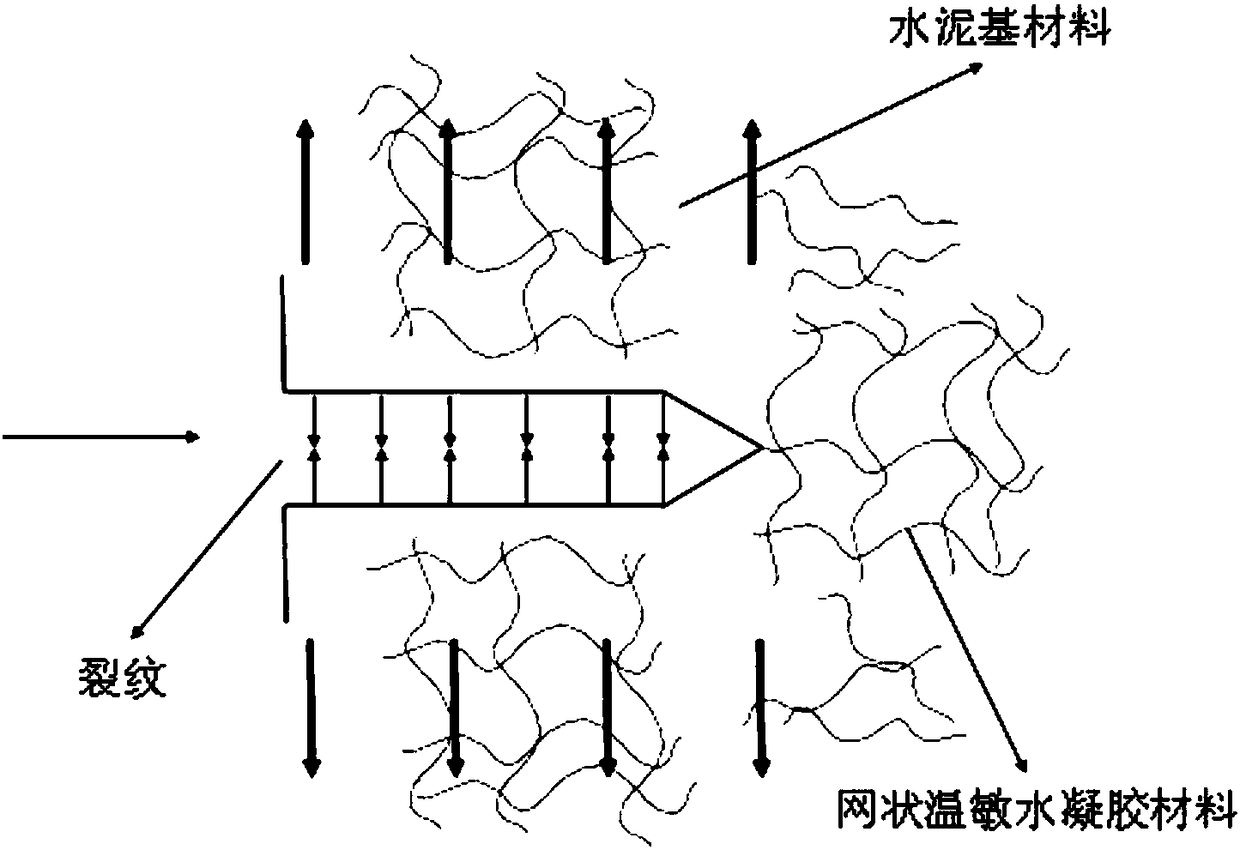

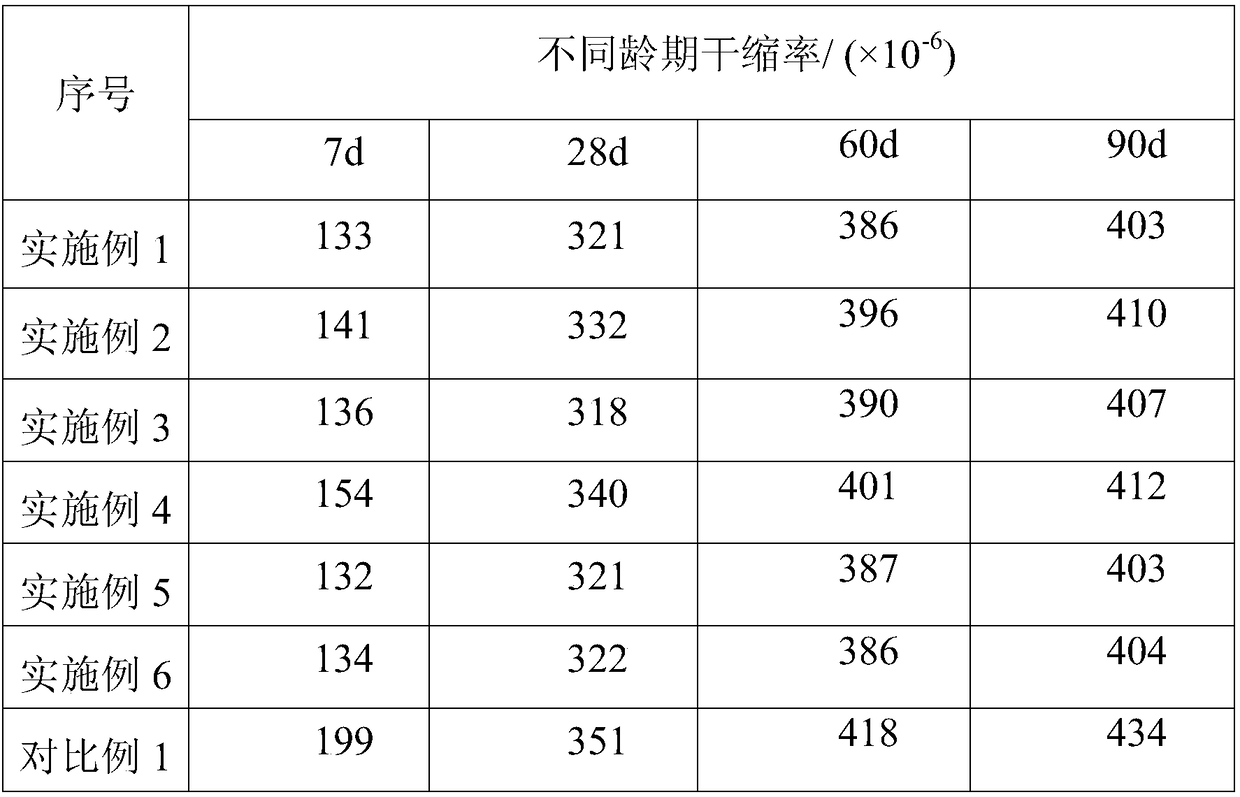

Application of temperature-sensitive hydrogel in improving concrete shrinkage and cracking resistance

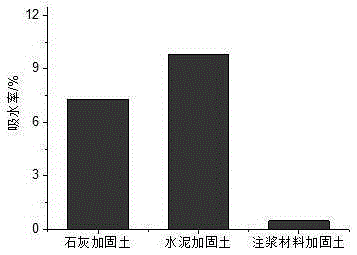

InactiveCN106278030BLow shrinkageImprove anti-shrinkage performanceShrinkage crackingAbsorption rate

The invention provides application of temperature-sensitive hydrogel in improvement of the anti-dry-shrinkage cracking property of concrete. The concrete is prepared from the temperature-sensitive hydrogel, cement, aggregates and water. A preparation method of the concrete comprises the steps that firstly, the temperature-sensitive hydrogel is prepared; secondly, the aggregates and the water are blended to be uniform; lastly, the temperature-sensitive hydrogel and the water are added, the materials are blended to be uniform, and then the concrete can be prepared. The adopted homemade temperature-sensitive hydrogel is lightly-crosslinked macromolecules which can be polymerized to form a film after releasing water, no hole can be reserved in the cement concrete, and other properties of the cement concrete are not affected while the anti-cracking property of the concrete is improved. The initial volume water content of the concrete is increased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the water storage capacity of the concrete is enhanced by mixing the temperature-sensitive hydrogel; the water absorption rate of the concrete is decreased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the connectivity of capillary pores in the concrete is reduced by mixing the temperature-sensitive hydrogel.

Owner:CHANGAN UNIV

Fiber reinforced artificial stone tomb box and its manufacturing method

InactiveCN100334315CWide variety of sourcesImpact resistantUrnsCeramic shaping apparatusSuperplasticizerSlurry

This invention relates to a fiber reinforced artificial stone tomb box and making method, which contains fiber reinforced artificial stone made box unit with cavity and box cover with lower convex edge engaged with upper edge of box unit. The method contains mixing and agitating raw material into slurry, laying fiber net fabric in mold, putting slurry in mold, by molding, maintenance, stripping, repairing, finishing, spraying surface treating liquid to get products, raw material ratio is 30-60 part of cement, 40-65 part of fine aggregate, 1-4 part fiber filament, 1-8 part of anti-cracking permeability-reducing admixture, 0.2-1 part of superplasticizer, 1-5 part of silicate intensifier, 0-4 part of surface treating liquid, 0-0.5 part antifoaming agent and 0-0.5 part of paint. Said invention has advantages of fine anti-impact ability and impermeability, high strength, fine outline and low cost.

Owner:张正锋

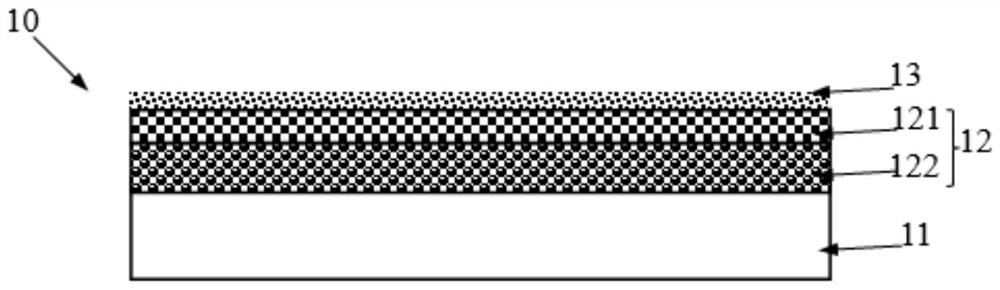

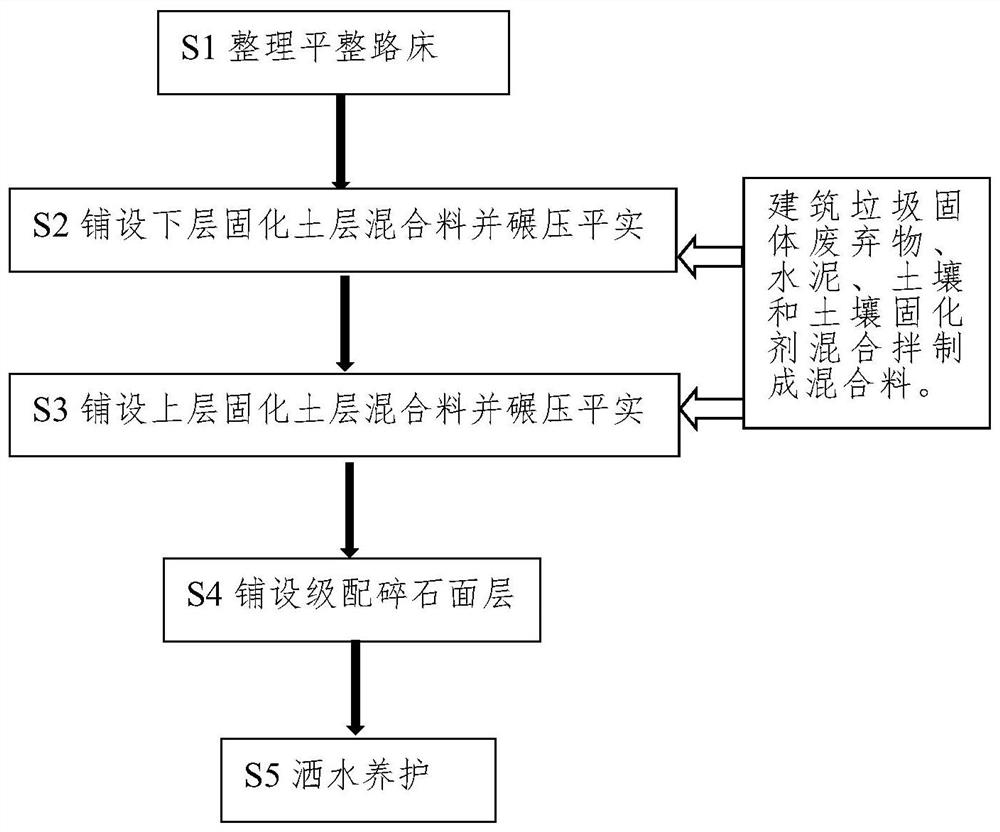

A temporary road pavement structure and road construction method

The invention discloses a temporary road pavement structure which comprises a roadbed, a base layer and a surface layer from bottom to top in sequence, wherein the base layer is a cured soil layer with cement and a soil curing agent; the surface layer is a macadam floor consisting of graded broken stone. By virtue of properties of the soil curing agent, the soil curing agent is mixed with mixing materials, through a series of physical and chemical reactions, the compactness of a soil body is increased, the soil body is a dense stable soil layer, and thus the bearing capability of the roadbed can be greatly improved. The soil curing agent is wide in adaptability, is capable of effectively curing soil, mud, various solid building wastes and the like, and is applicable to large-scale recycledand reused building wastes. The cured soil layer made of the soil curing agent is used as the road base layer, so that compared with a conventional temporary road, the temperature road made with theroad base layer is high in strength and good in water stability and dry shrinkage resistance, the amounts of conventional road construction materials such as lime, cement, coal ash and macadam can bereduced, and the road construction cost can be effectively reduced.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

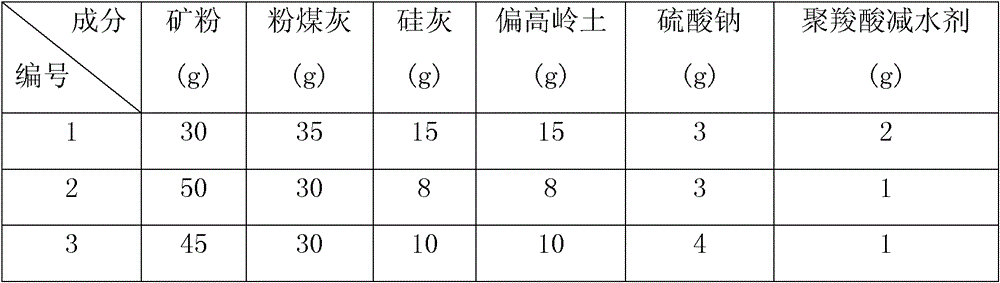

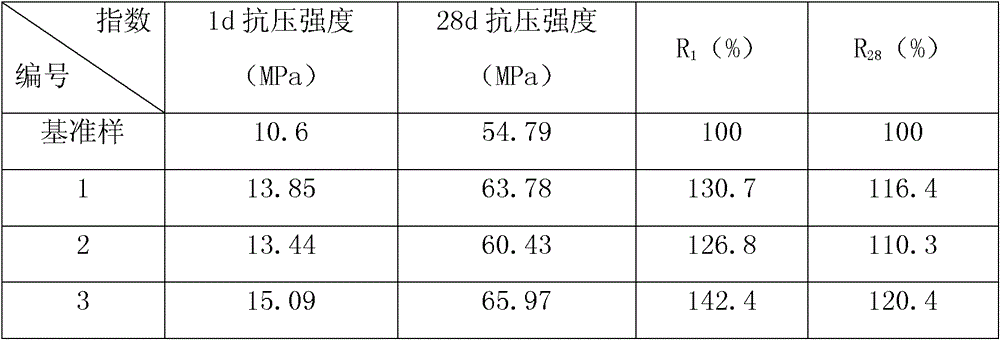

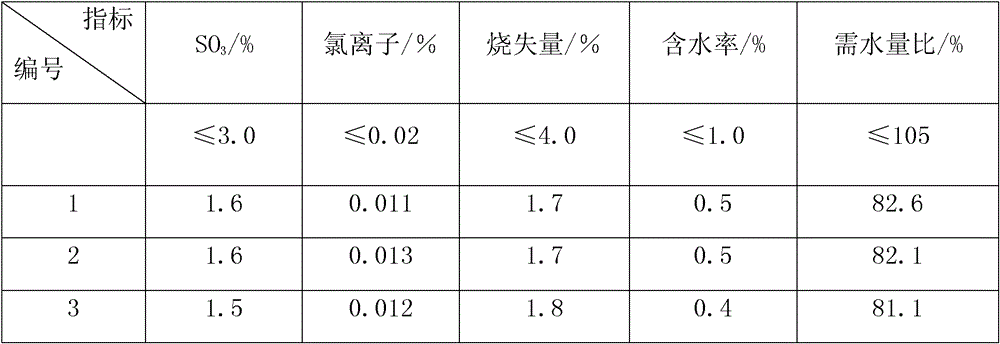

High-early-strength mineral additive for concrete

The invention relates to a high-early-strength mineral additive for concrete, which is characterized in that the high-early-strength mineral additive consists of the following ingredients which are mixed by mass percent: 30-50 percent of mineral powder, 20-35 percent of pulverized coal ash, 5-15 percent of silicon ash, 5-15 percent of metakaolin, 2-5 percent of sodium sulfate and 1-2 percent of polycarboxylate water reducing agent The high-early-strength mineral additive provided by the invention can be used for concrete prefabricated members, grouting materials, patching materials and the like. When 10 percent of high-early-strength mineral additive is added to replace cement to prepare the concrete, the water demand is small, the early activity index is high, the strength development situation is good, and compared with common cement and mineral additives, the dry shrinkage resistance is improved greatly.

Owner:赖斌

A fast-hardening and early-strength composite repair mortar

The invention belongs to the technical field of building materials, and proposes a fast-hardening and early-strength composite repair mortar, which is composed of the following components in weight percent: 5% to 10% of water, 20% to 30% of cement, and 1% to 5% of silica fume. %, fly ash 1% to 5%, quartz sand 50% to 70%, composite early strength agent 0.4% to 0.5%, water reducing agent 0.06% to 0.1%, rubber powder 1% to 5%, mixed fiber 0.06% ~0.8%, the composite early strength agent is composed of A component and B component, the A component is nano-calcium carbonate whiskers, and the B component is a mixture of triisopropanolamine and aluminum sulfate, so The quartz sand is composed of coarse sand, medium sand and fine sand, and the hybrid fiber is composed of basalt fiber and polypropylene fiber. The invention solves the problems in the prior art that the strength of the repair mortar shrinks back, the dry shrinkage rate is large, and the bonding strength is low.

Owner:长春昌驰新材料科技有限公司

Red mud curing agent for paving road and preparation method of red mud curing agent

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com