Water-resistant fatigue-resistant subgrade grouting material, and preparation method and applications thereof

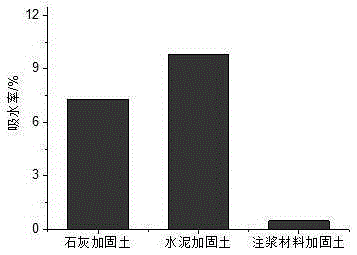

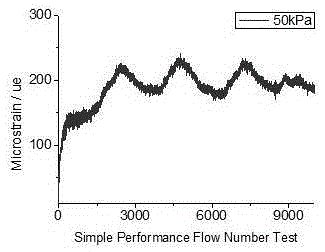

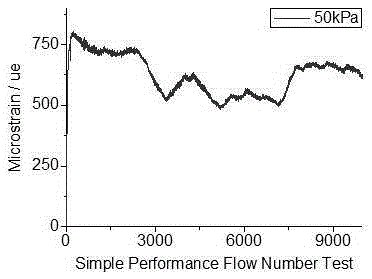

A grouting material and water-resistant technology, applied in roads, roads, infrastructure engineering, etc., can solve problems such as low early strength, subgrade disease, subgrade subsidence, etc., achieve high unconfined compressive strength, and increase fatigue resistance. , the effect of promoting the hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 A water-resistant and fatigue-resistant roadbed grouting material, the grouting material is mixed with the following weight percentages (g) of raw material components at a water-binder ratio of 0.28: 90% cementitious material, 0.44 alkali-activated component %, water-resistant latex 9%, water reducing component 0.5%, stable component 0.02%, retarding component 0.04%.

[0038] The preparation method of the water-resistant and fatigue-resistant roadbed grouting material includes the following steps:

[0039] ⑴Weigh the gelling material, alkali-stimulating component, water-resistant latex, water reducing component, stabilizing component and retarding component according to the ratio;

[0040] ⑵ Determine the amount of water according to the water-to-glue ratio;

[0041] (3) Add the alkali excitation component to the water and stir until it is completely dissolved to obtain the alkali excitation component solution;

[0042] ⑷ After mixing the gelling material, water-resis...

Embodiment 2

[0044] Example 2 A water-resistant and fatigue-resistant roadbed grouting material, the grouting material is mixed with the following weight percentage (g) of raw material components at a water-binder ratio of 0.28: 93% of the cementing material, 0.24 of the alkali stimulating component %, water-resistant latex 6.2%, water-reducing component 0.5%, stable component 0.02%, retarding component 0.04%.

[0045] The preparation method of the water-resistant and fatigue-resistant roadbed grouting material is the same as Example 1 .

[0046] The application of the water-resistant and fatigue-resistant subgrade grouting material refers to: injecting the water-resistant and fatigue-resistant subgrade grouting material in a slurry manner at 10% of the weight of the soil in the subgrade or base soil to be reinforced.

Embodiment 3

[0047] Example 3 A water-resistant and fatigue-resistant roadbed grouting material. The grouting material is made up of the following weight percentages (g) of raw material components mixed with a water-binder ratio of 0.28: 95% cementitious material, 0.13 alkali stimulating component %, water resistant latex 4.3%, water reducing component 0.5%, stable component 0.02%, retarding component 0.05%.

[0048] The preparation method of the water-resistant and fatigue-resistant roadbed grouting material is the same as Example 1 .

[0049] The application of the water-resistant and fatigue-resistant roadbed grouting material refers to: injecting the water-resistant and fatigue-resistant roadbed grouting material in a grout method according to 9% of the soil weight in the roadbed or base soil to be reinforced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com