Environment-friendly stabilizer for CA mortar and preparation method thereof

An environmentally friendly, stabilizer technology, applied in the field of road materials, can solve the problems affecting the strength and other properties of CA mortar layers, poor compatibility, poor stability, etc., to improve anti-shrinkage performance, maintain compactness, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

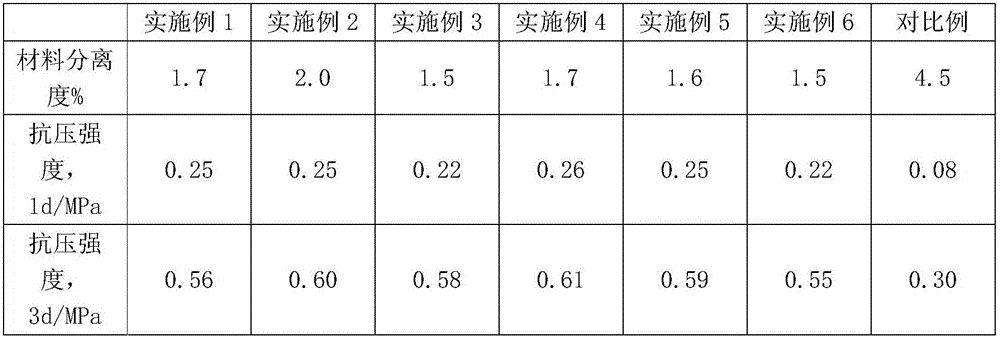

Examples

Embodiment 1

[0041] A stabilizer for environment-friendly CA mortar, in parts by weight, comprises the following components:

[0042] 3 parts of water-soluble polymer monomer,

[0043] 20 parts of polymer latex,

[0044] 2 parts cationic emulsifier,

[0045] 0.8 part of cellulose ether,

[0046] 1 part metakaolin,

[0047] 1 part dextrin,

[0048] 0.5 part of dispersant,

[0049] 50 parts of deionized water.

[0050] Its preparation method comprises the following steps:

[0051] (1) Mix the water-soluble polymer monomer, polymer latex, cationic emulsifier and deionized water into a high-speed mixer, and stir for 1 hour at 5000 rpm to obtain a mixed emulsion;

[0052] (2) Add cellulose ether, metakaolin, dextrin and dispersant to the mixed emulsion obtained in step (1), mix and stir evenly, and ultrasonicate for 2 hours at a power of 500W to obtain a stabilizer for environment-friendly CA mortar.

Embodiment 2

[0054] A stabilizer for environment-friendly CA mortar, in parts by weight, comprises the following components:

[0055] 5 parts of water-soluble polymer monomer,

[0056] 50 parts of polymer latex,

[0057] 4 parts cationic emulsifier,

[0058] 1.2 parts of cellulose ether,

[0059] Metakaolin 1.5 parts,

[0060] 2 parts of dextrin,

[0061] 0.8 part of dispersant,

[0062] 60 parts of deionized water.

[0063] Its preparation method comprises the following steps:

[0064] (1) Mix the water-soluble polymer monomer, polymer latex, cationic emulsifier and deionized water into a high-speed mixer, and stir for 2 hours at 8000 rpm to obtain a mixed emulsion;

[0065] (2) Add cellulose ether, metakaolin, dextrin and dispersant to the mixed emulsion obtained in step (1), mix and stir evenly, and ultrasonicate for 5 hours at a power of 1000W to obtain an environment-friendly stabilizer for CA mortar.

Embodiment 3

[0067] A stabilizer for environment-friendly CA mortar, in parts by weight, comprises the following components:

[0068] 3.5 parts of water-soluble polymer monomers,

[0069] 30 parts of polymer latex,

[0070] 3 parts cationic emulsifier,

[0071] 1 part cellulose ether,

[0072] Metakaolin 1.2 parts,

[0073] 1 part dextrin,

[0074] 0.65 parts of dispersant,

[0075] 50 parts of deionized water.

[0076] Its preparation method comprises the following steps:

[0077] (1) Mix the water-soluble polymer monomer, polymer latex, cationic emulsifier and deionized water into a high-speed mixer, and stir for 1.2 hours at 6000 rpm to obtain a mixed emulsion;

[0078] (2) Add cellulose ether, metakaolin, dextrin and dispersant to the mixed emulsion obtained in step (1), mix and stir evenly, and ultrasonicate for 3 hours at a power of 600W to obtain a stabilizer for environment-friendly CA mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com