High-early-strength mineral additive for concrete

A mineral admixture and concrete technology, applied in the field of building materials, can solve the problems of increased self-drying shrinkage, slow strength development, and prolonged setting time of concrete, and achieves good strength development status, high early activity index, and good strength development status. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

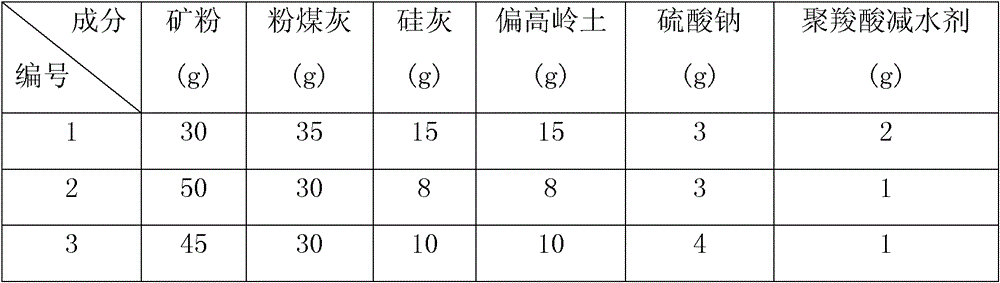

[0025] The raw material ratios of high early strength mineral admixtures for concrete are shown in Table 1.

[0026] Table 1 Proportion of high early strength mineral admixture

[0027]

[0028] Above-mentioned a kind of preparation method for the high early strength mineral admixture of concrete, it comprises the steps:

[0029] 1) Grinding mineral powder and fly ash to control its specific surface area at 550-600kg / m 2 within the scope;

[0030] 2) According to the ratio in Table 1, mix mineral powder, fly ash, silica fume, metakaolin, sodium sulfate and polycarboxylate water reducer to obtain a high early strength mineral admixture for concrete.

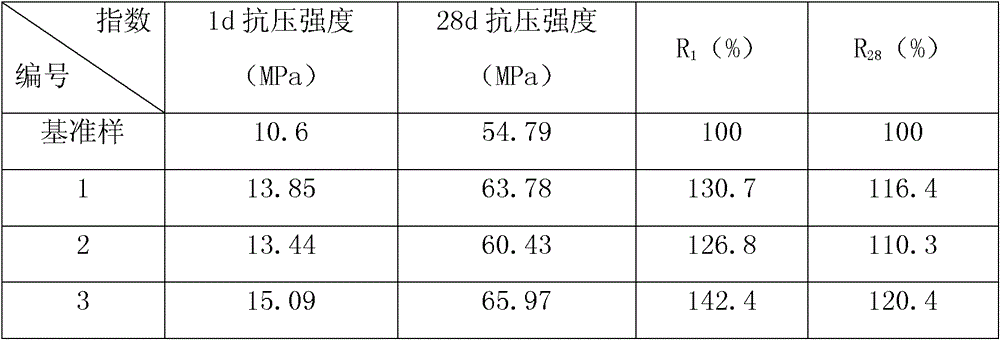

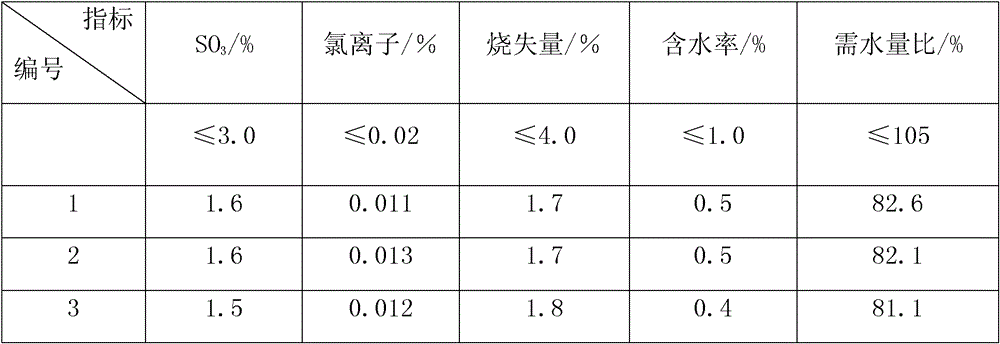

[0031] Performance test method:

[0032] 1. Preparation of benchmark sample: Use 450g of P.O 52.5 cement, 1350g of standard sand, and 225ml of water, according to GB / T2419-2005 (method for fluidity determination of cement mortar), and form a 40×40×160mm mortar specimen, Maintain at a temperature of 20±2°C and a humidity of ...

Embodiment 4

[0051] Take 41g of mineral powder, 35g of fly ash, 5g of silica fume, 15g of metakaolin, 2g of sodium sulfate, and 2g of polycarboxylate superplasticizer, mix them evenly, and replace cement with 10% dosage to prepare concrete.

[0052] The performance test method is the same as in Example 1, and the results are shown in Table 6-8.

Embodiment 5

[0054] Take 38g of mineral powder, 30g of fly ash, 15g of silica fume, 10g of metakaolin, 5g of sodium sulfate, and 2g of polycarboxylate superplasticizer, mix well, and replace cement with 10% dosage to prepare concrete.

[0055] The performance test method is the same as in Example 1, and the results are shown in Table 6-8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com