Patents

Literature

265 results about "Patch material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

These 15" x 15" blank patch material squares are made from a twill fabric and are perfect for making patches on your embroidery machine. These are basically finished patches without a border. You can cut any size or shape of of this material to make your own custom patches for embroidery machines.

Double membrane tissue patching material and preparation method thereof

The invention discloses a double-layer membranous tissue repair material and a preparation method thereof, wherein, a cell-free membranous biological derivative material is used as a surface layer, and a fibroblast is compounded in the interior of a biological support material to form a substrate, and then the surface layer and the substrate are combined in a chimeric way to form the double-layer membranous tissue repair material; a compact surface layer structure can effectively reduce the loss of water, electrolytes and protein from surface of wound, avoid the invading and the reproduction of bacteria to the impaired surface of wound as well as prevent the infection of the surface of wound, thus being beneficial to epitheliosis and epithelial growth; the substrate can directly repair the surface of wound, promote the ingrowth of cells around the surface of wound and the angiogenesis, induce the differentiation from stem cells to skin cells and quicken wound healing; compared with the existing products, the tissue repair material has the advantages of being capable of promoting the regeneration of skin, improving the elasticity, the flexibility and the mechanical abrasion resistance of skin after the surface of wound is healed, reducing hyperplasia of scar tissues, controlling the contracture, having excellent biocompatibility, increasing the success rate of transplant and improving the quality of healing; the invention has wide material resources and simple production method; the double-layer membranous tissue repair material prepared is applicable to the clinical treatment of skin defect caused by inflammation, ulcer, thermal burns, iatrogenicity and the like.

Owner:SHAANXI RUISHENG BIOTECH

Polyurethane resin composition, preparation method and application thereof

InactiveCN101735595AImprove water resistanceImprove featuresBallastwayTrack maintainencePolyolefinAlcohol

The invention provides a polyurethane resin composition, a preparation method and application thereof. The polyurethane resin composition comprises a component A and a component B, wherein the component A contains polyolein polyatomic alcohol, a plasticizer, an anti-settling agent and other auxiliary agents; the component B is isocyanate or prepolymer of the isocyanate; and the mass ratio of the A to the B is 10:1-1:10. A pouring material containing the resin composition can be used as a patching material for a cement road bed, a boss resin layer and a mortar packing layer of a railway plate-type unballasted track and has the advantages of high water resistance, ageing resistance and low temperature resistance, long service life and capability of being used at a low temperature.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

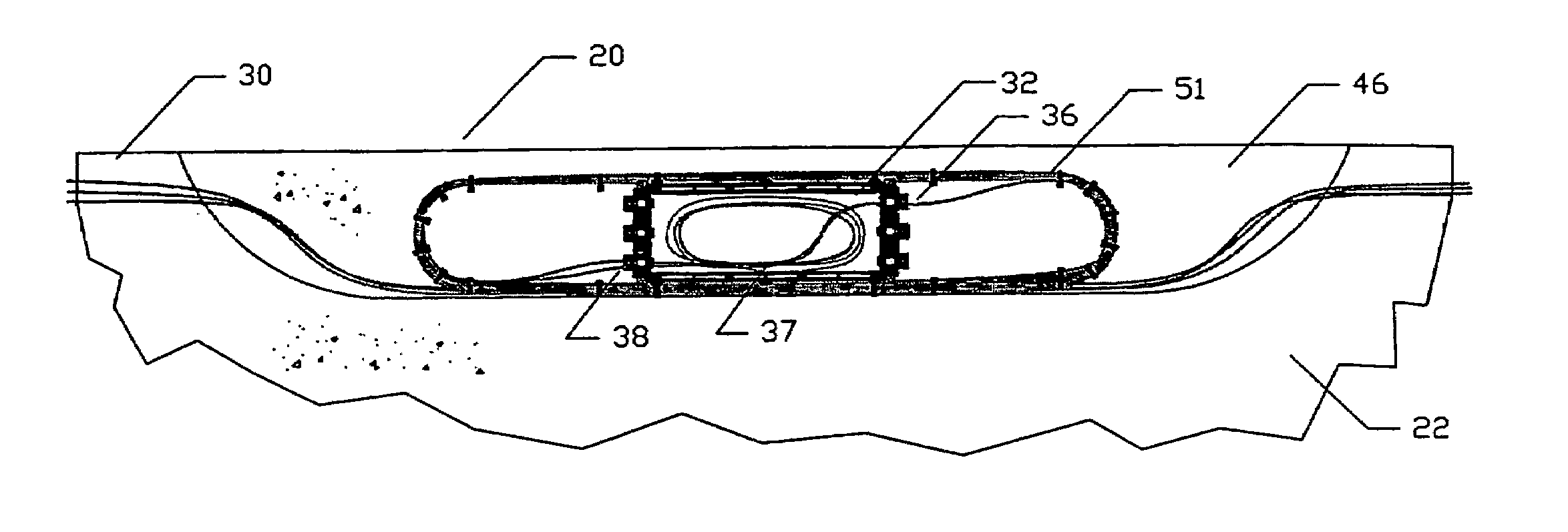

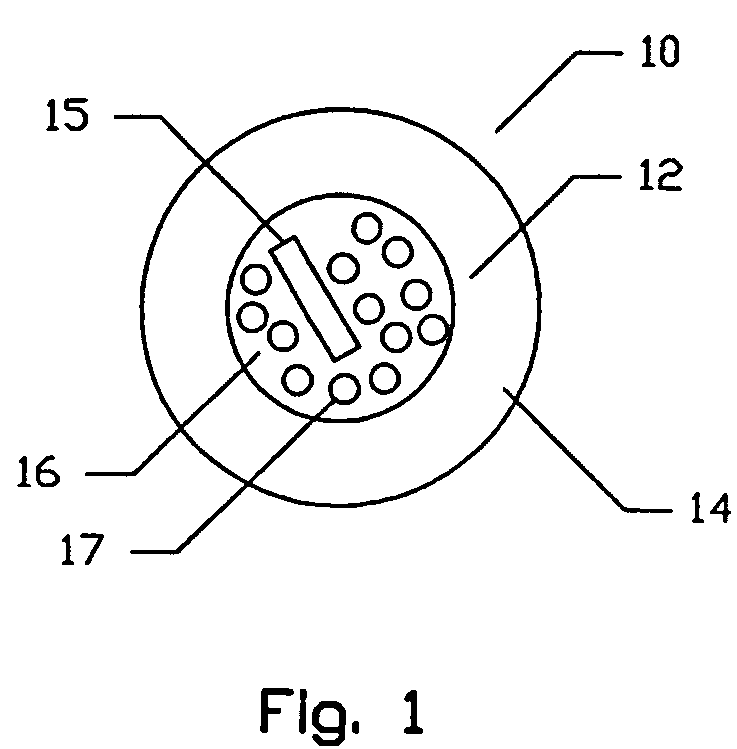

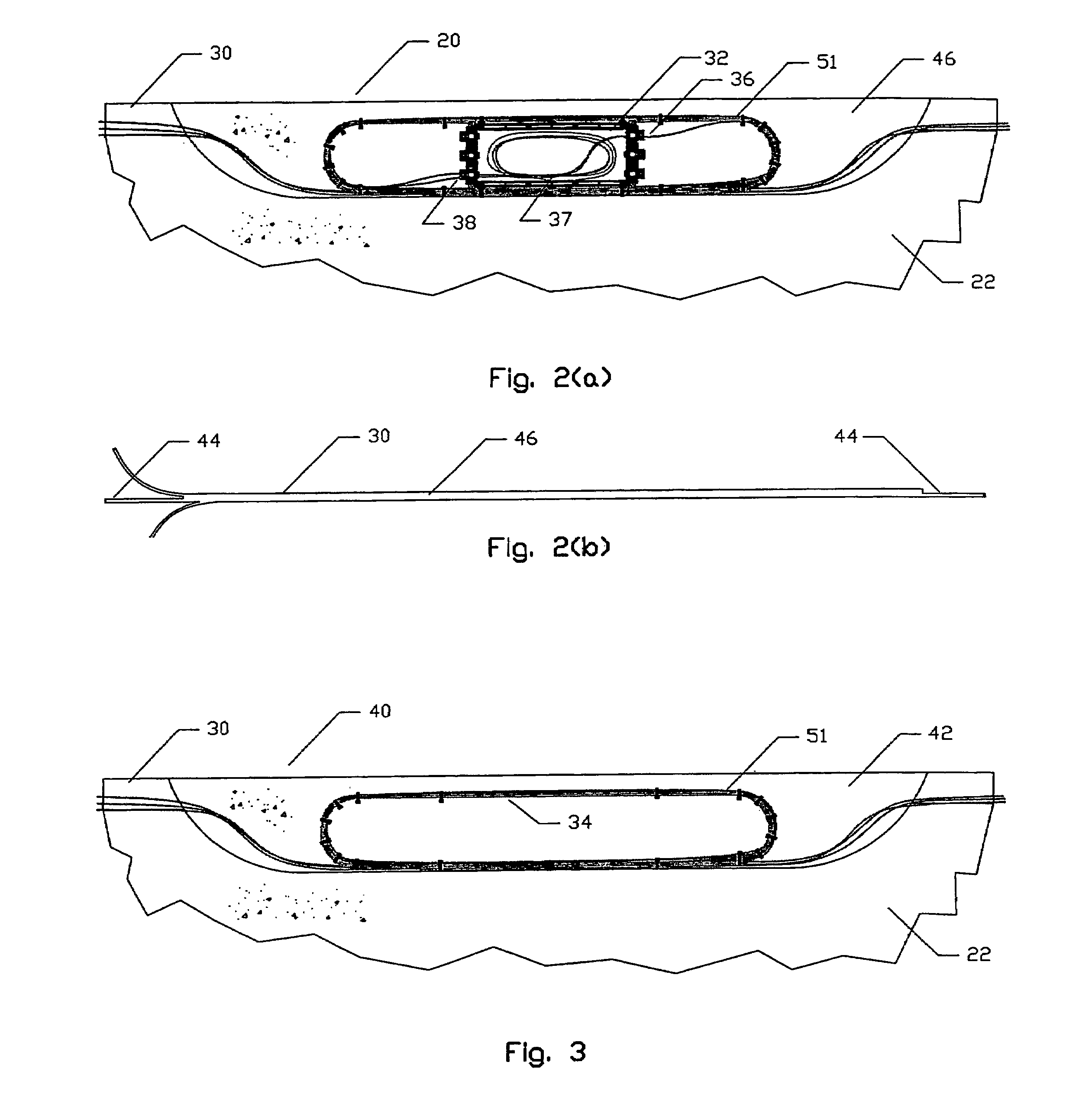

Subsurface fibre optic cable network installation

InactiveUS7050683B2Rigid enoughImprove rigidityCable installations on groundOptical fibre/cable installationFiberRoad surface

A method of installing fibre optic cables consists of cutting a shallow and narrow trench or channel within a road surface or building wall. A narrow fibre optic cable is laid within the channel, and subsequently covered with a patch material. A branching cable network is provided by cutting at periodic and selected locations, a slightly broader and deeper region of the channel, within which cable loops and / or junction boxes are installed. The nodes may consist of branching nodes, or alternatively non-branching nodes containing a cable loop and / or junction box, the installation of which at a location permits a junction node to be formed at a close by location. The invention also consists of a junction box for use with the system.

Owner:TERASPAN NETWORKS

Method for repairing crack and chipping of shunt ring of case

InactiveCN102430889AReduce investmentReduce repair costsElectrode supporting devicesFurnace typesEngineeringGrinding wheel

The invention relates to a method for repairing a crack and a chipping a shunt ring of a case, which comprises the following steps of: (1) trimming and polishing the chipping part of the shunt ring to form a square or oblong notch by using an air drill and a grinding wheel; (2) performing dyeing inspection on the periphery of the polished notch, and determining as qualified if no crack exists; (3) taking a patch material from the corresponding portion of a discarded case by using a linear cutting method, trimming the patch material by using the grinding wheel according to the shape of the notch so that the trimmed patch is matched with the notch; (4) placing the trimmed patch in the notch, supporting the patch with a support frame, firstly performing positioning welding on the patch by using low current argon arc welding, and then performing sectional symmetry welding; (5) performing dyeing inspection on the welding portion, and determining as qualified if no crack or eyehole exists; and (6) eliminating welding stress by ultrasonic waves. The repairing method provided by the invention has the advantages of low equipment investment, low repairing expense and short repairing period.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

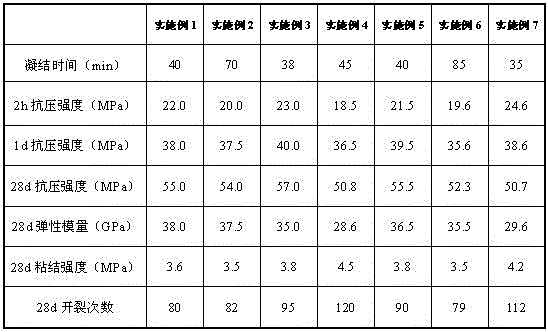

Anti-impact and wear-resistant mortar

The invention discloses an anti-impact and wear-resistant mortar, belonging to the field of a repairing material in water-power engineering. The difficulty that the constructions in the conventional water-power engineering is difficult to repair after being damaged by rushing and abrading with water with sands and stones can be solved. The anti-impact and wear-resistant mortar comprises the following components in parts by weight: 39-48 parts of silicate cement, 45-50 parts of graded hard fine aggregate, 0.05-0.25 parts of water reducing agent, 0.05-0.3 parts of de-foaming agent and 0.05-1.5 parts of nanometer material. The anti-impact and wear-resistant mortar provided by the invention has the advantages of high anti-impact and wear-resistant strength, low elasticity modulus and good anti-crack property, and is a finished product material with a higher application value for repairing through irrigation works.

Owner:POWERCHINA CHENGDU ENG +1

Epoxy resin base fast repairing material and preparation method thereof

InactiveCN101121812ANo toxicityNon-toxic or minimally toxicBuilding repairsPaving detailsEpoxyPolyamide

The invention provides an epoxy resin-based rapid repair material and a preparation method thereof. The epoxy resin-based rapid repair material is made of sand, talcum powder, epoxy resin, polyamide and thinner. The preparation method comprises:) uniformly mixing epoxy resin and diluent, adding polyamide and stirring uniformly to form epoxy slurry; mixing sand and talc powder uniformly; stirring epoxy slurry evenly with the mixture of sand and talc powder; Oxygen resin-based rapid repair materials can achieve moderate cost, early strength (3d can reach 60MPa) but moderate later strength, good bonding, convenient construction, short construction period, and no need to close traffic. It can be used for repairing concrete buildings such as bridges, tunnels, roads and houses.

Owner:SOUTH CHINA UNIV OF TECH

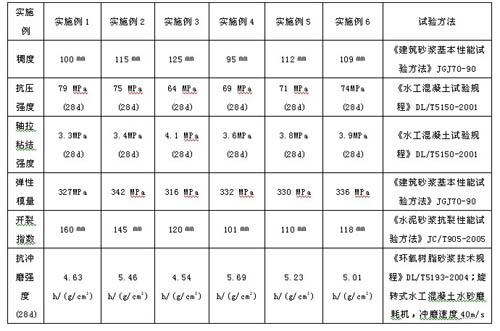

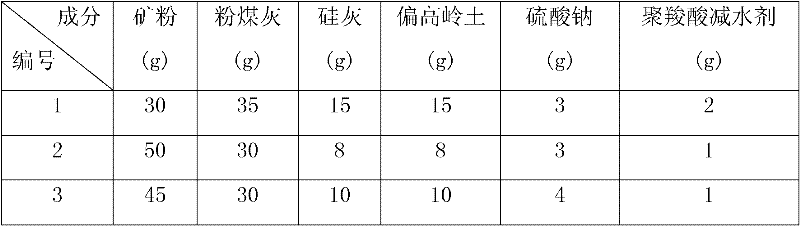

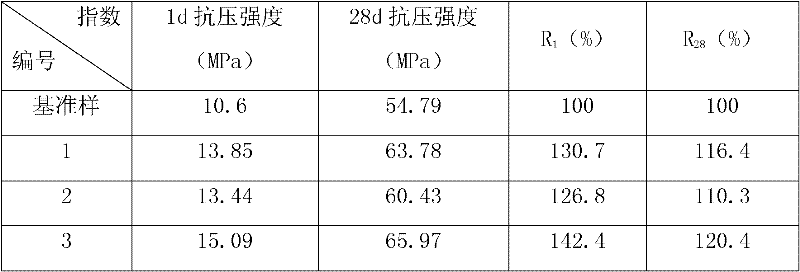

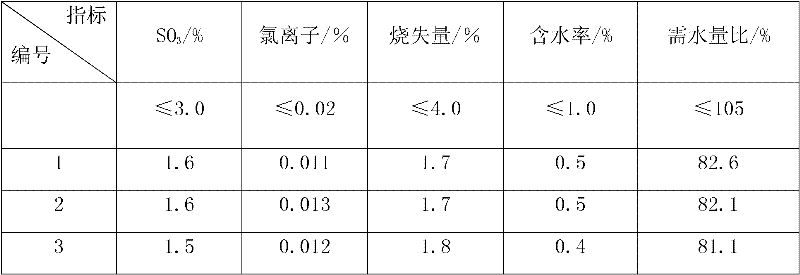

High-early-strength mineral additive for concrete

The invention relates to a high-early-strength mineral additive for concrete, which is characterized in that the high-early-strength mineral additive consists of the following ingredients which are mixed by mass percent: 30-50 percent of mineral powder, 20-35 percent of pulverized coal ash, 5-15 percent of silicon ash, 5-15 percent of metakaolin, 2-5 percent of sodium sulfate and 1-2 percent of polycarboxylate water reducing agent The high-early-strength mineral additive provided by the invention can be used for concrete prefabricated members, grouting materials, patching materials and the like. When 10 percent of high-early-strength mineral additive is added to replace cement to prepare the concrete, the water demand is small, the early activity index is high, the strength development situation is good, and compared with common cement and mineral additives, the dry shrinkage resistance is improved greatly.

Owner:赖斌

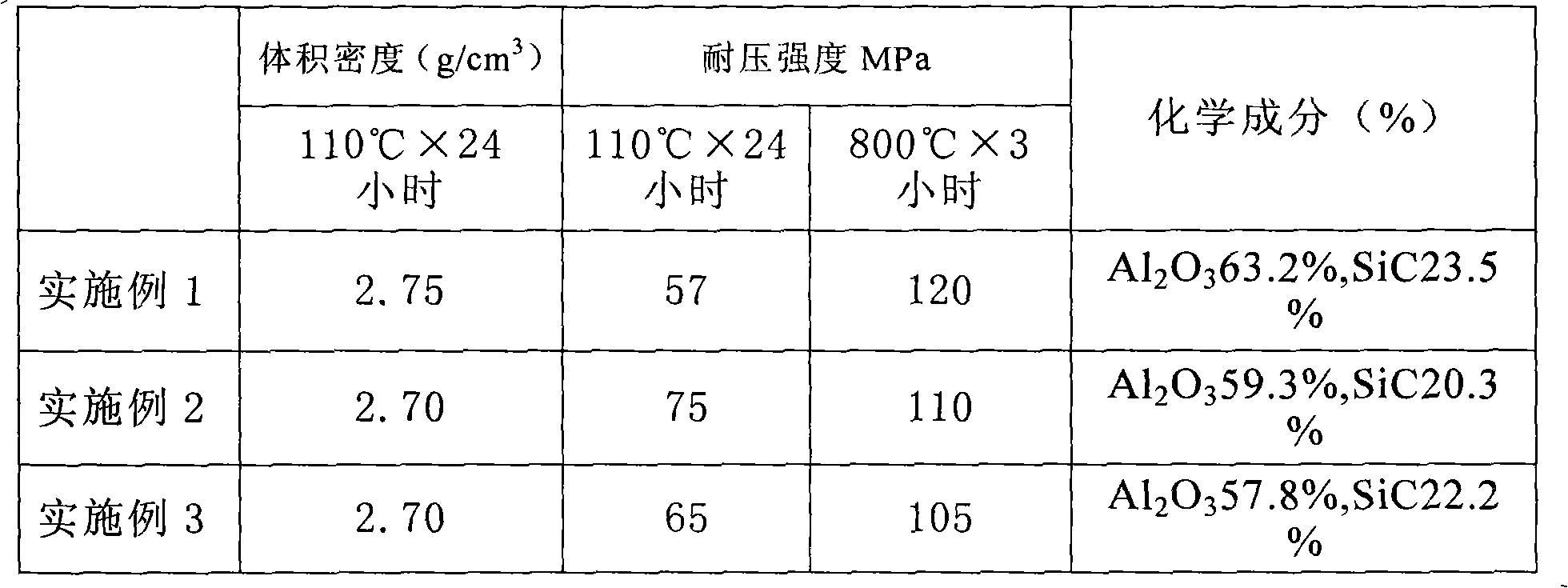

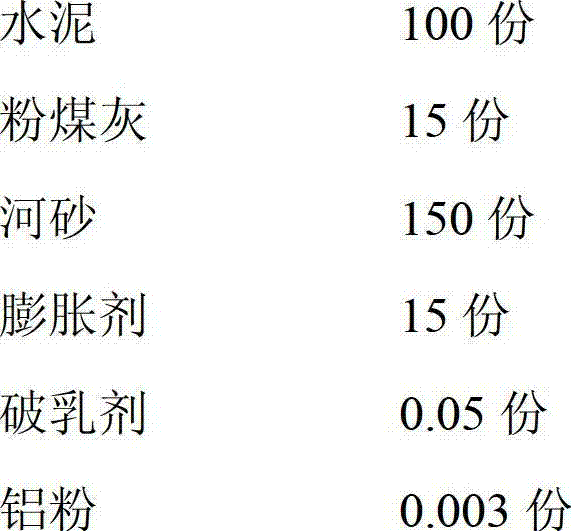

Dry coke quenching furnace circular passage tilt channel regional patching material

InactiveCN101618967AImprove volume stabilityMake up for the defect of medium temperature strength dropAluminateHeat resistance

The invention relates to a dry coke quenching furnace circular passage tilt channel regional patching material, comprising 65wt% of aggregate part and 35wt% of substrate part; the formula is as follows: 5-42 parts of fused brown aluminium oxide, 10-30 parts of mullite, 5-13 parts of silicon carbide, 8-15 parts of active alpha-Al2O3 powder, 3-8 parts of active silicon dioxide micropowder, 5-11 parts of silicon carbide powder, 3-7 parts of silicon carbide ultrafine powder, 3-9 parts of high purity aluminate, 0.2-0.4 part of composite dispersant and 1-3 parts of heat resistance stainless steel fiber. The invention has the advantage that the optimization of grain composition of particles in the aggregate part and the substrate part and the use of the composite dispersant ensure that the self-flow patching material has good flowing property in the simple and fast way and the patching material has good workability.

Owner:BEIJING RUIPU TONGCHUANG TECH DEV

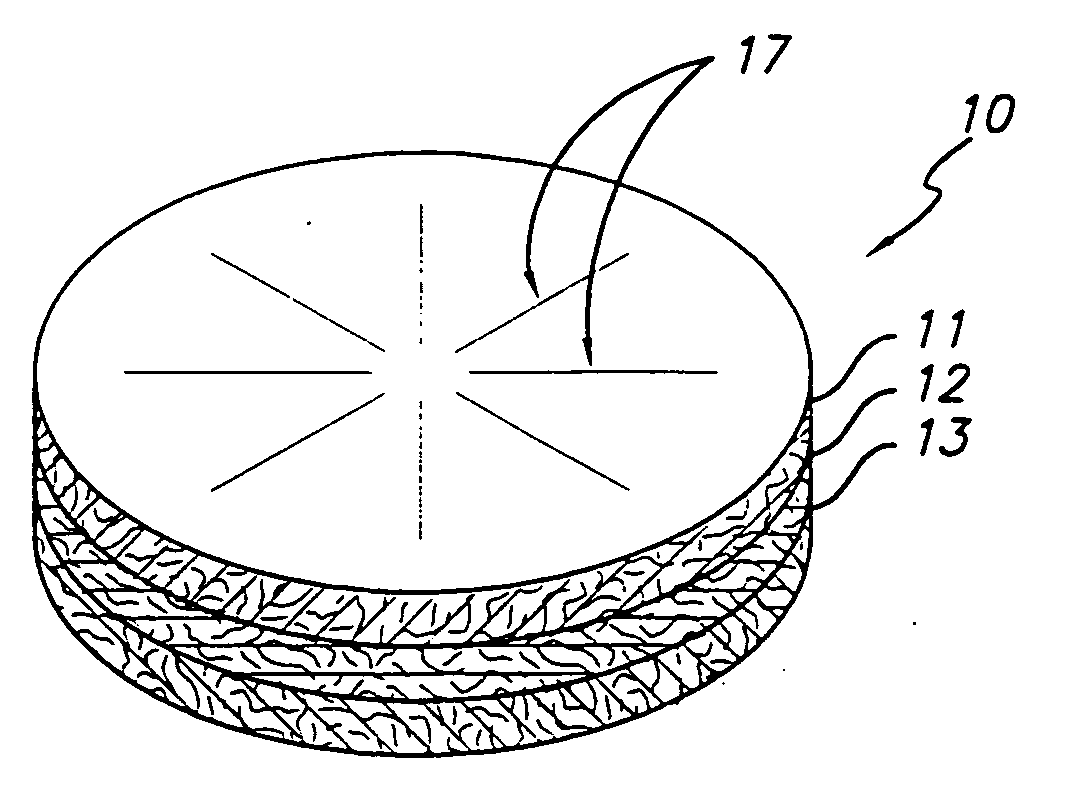

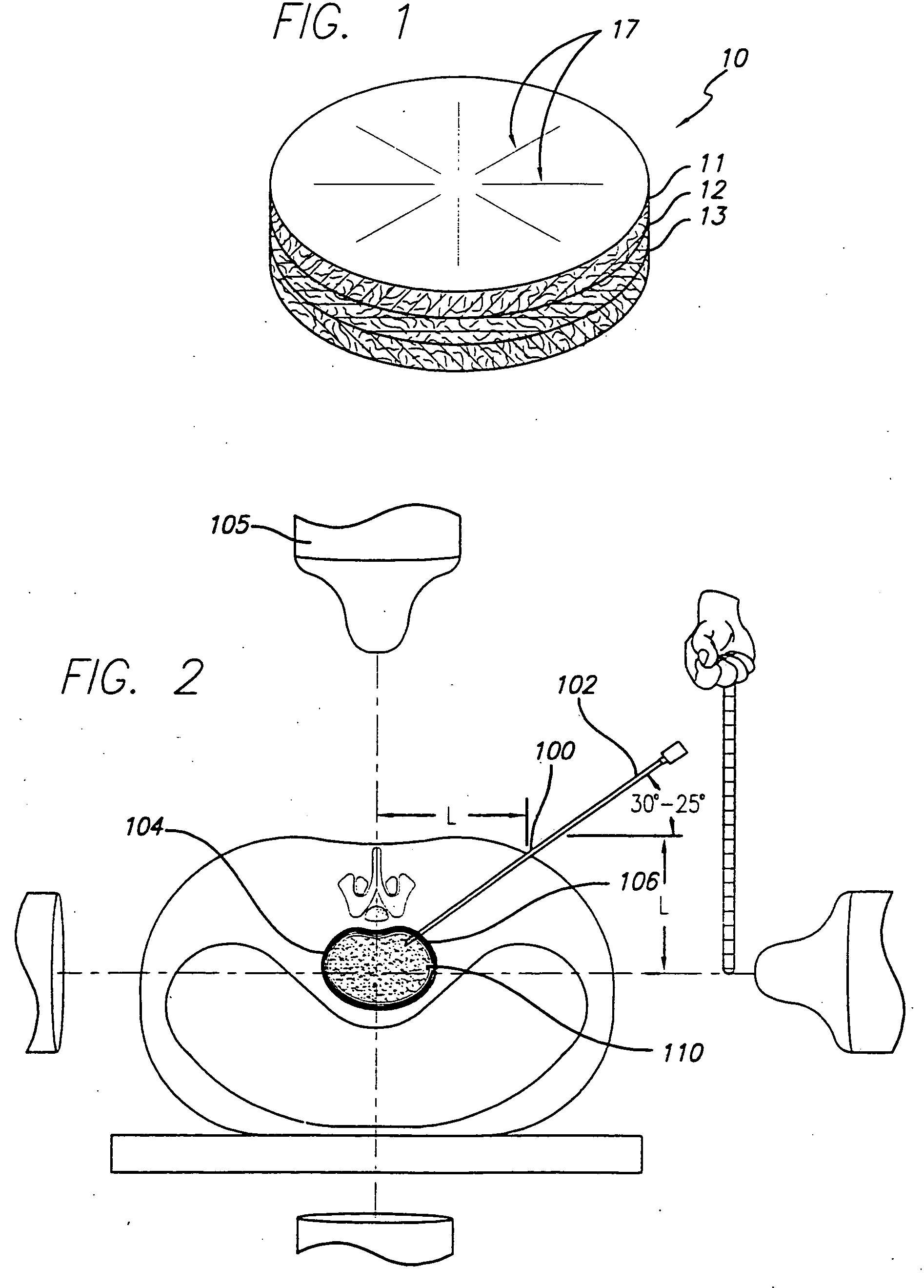

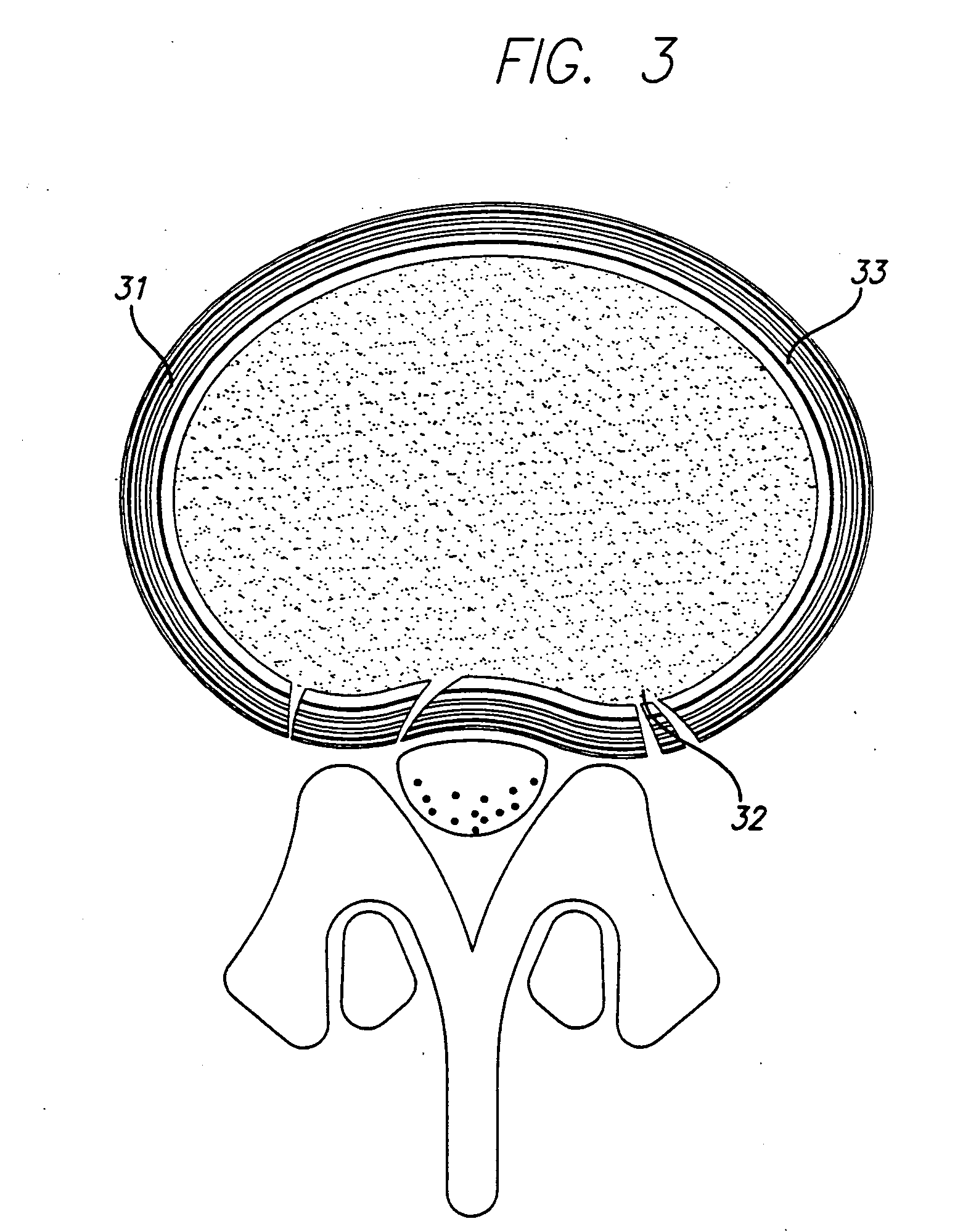

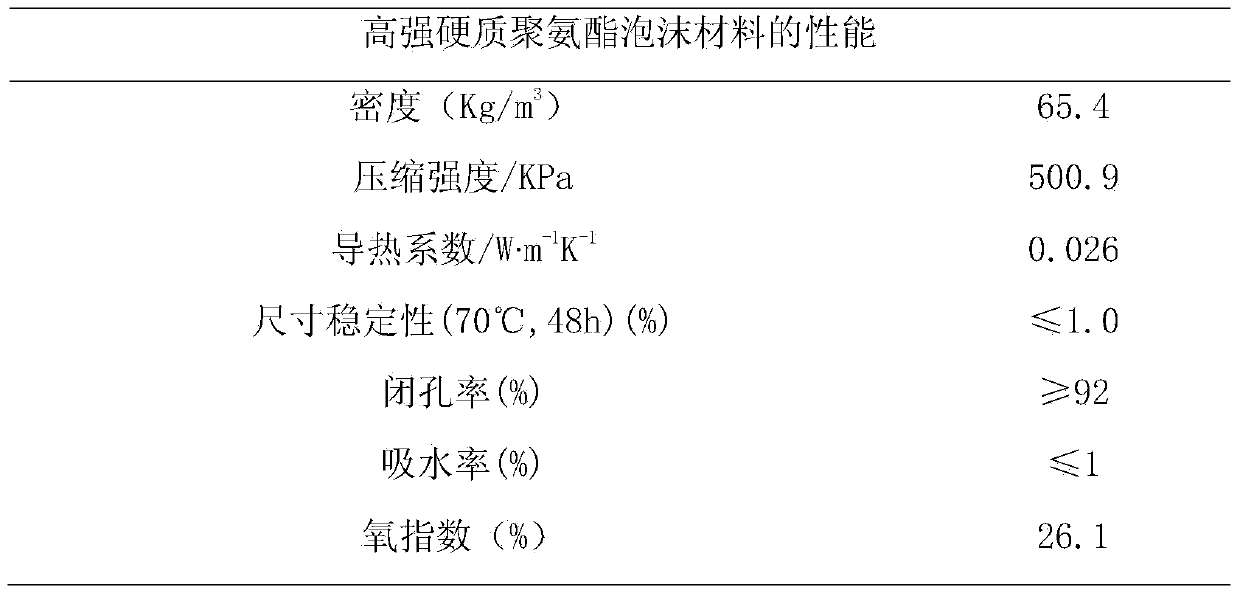

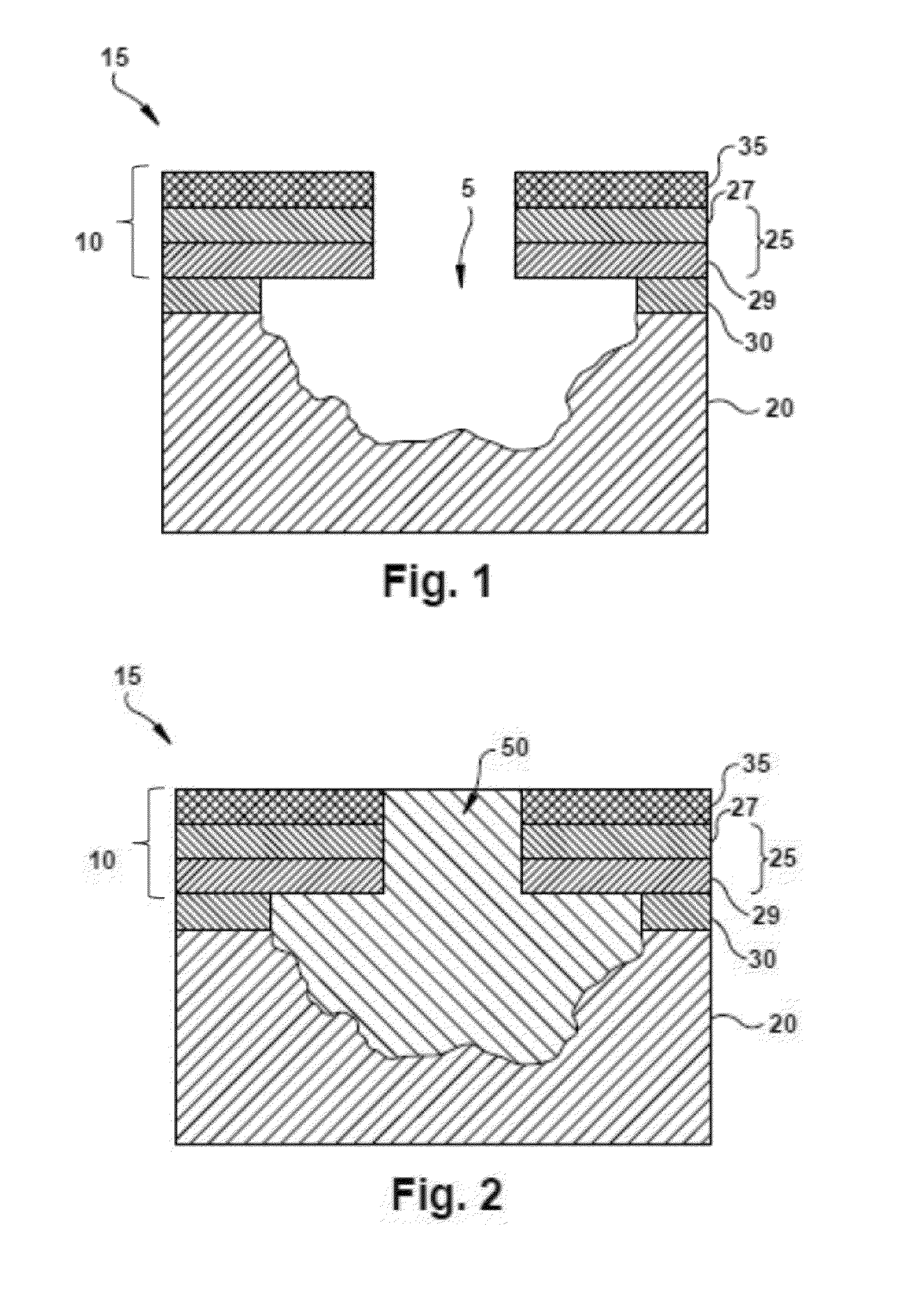

Patch material for intervertebral disc annulus defect repair

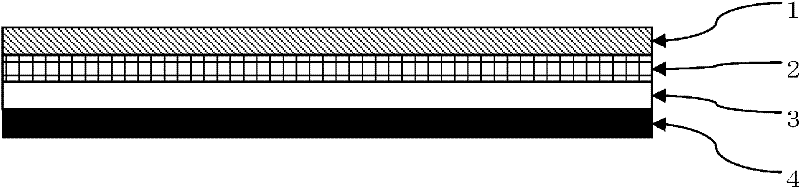

A patch for repairing defects in a intervertebral disc annulus, including a substantially thin layer of animal collagen arranged in a substantially circular shape, a fabric layer disposed beneath the layer of animal collagen and coupled to the layer of animal collagen by biological glue, a barrier layer of liquid resistant material disposed beneath the fabric layer, and coupled to the fabric layer by an adhesive, a plurality of flexible fibers disposed on a top surface of the patch and oriented in a radial direction and at least one suture disposed through the patch, the suture acting as a handle.

Owner:TSOU PAUL M

Novel patching material

The invention relates to a novel patching material which comprises the following components in percentage by mass: 70-75% of ash, 20-22% of polymer emulsion and 5-8% of fiber, wherein the ash comprises quick-hardening sulphoaluminate cement, a water reducing agent, an expanding agent and a setting accelerator. The patching material prepared according to the proportion can be used for quick patching of concrete bridges, dams, roads and buildings, and has the advantages of close bonding with concrete, high strength, endurable water resistance and corrosion resistance. When in use, the patching material of the invention does not need to level the construction base level or make a protective layer, thereby saving time and labor and being a nontoxic no-pollution environment-friendly patching material.

Owner:TONGJI UNIV

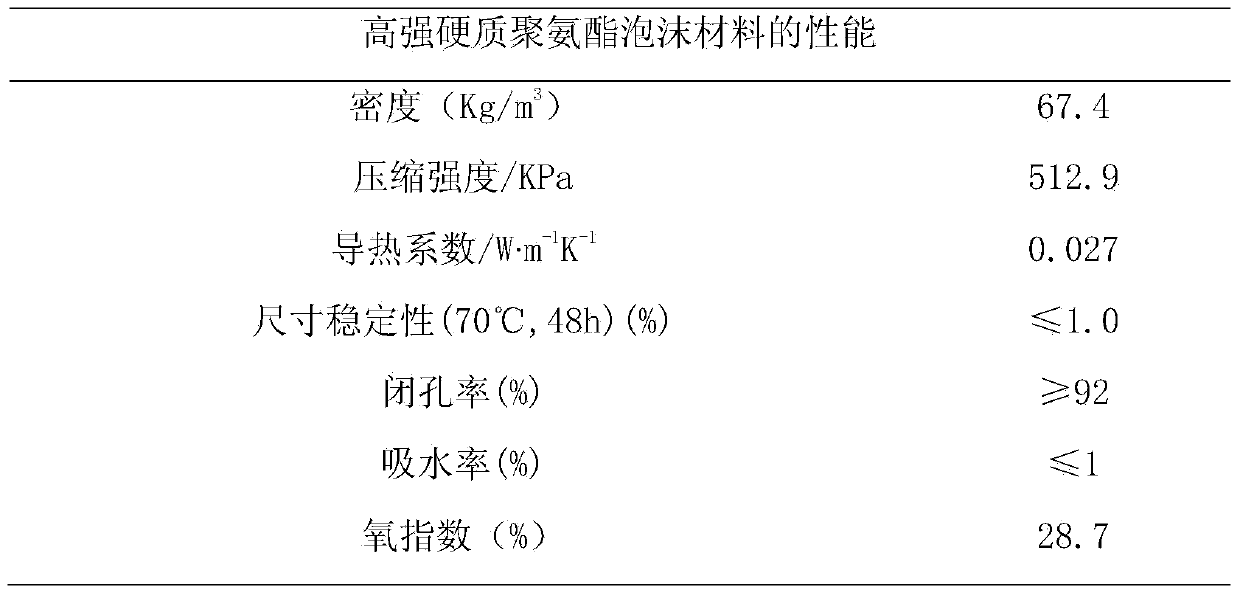

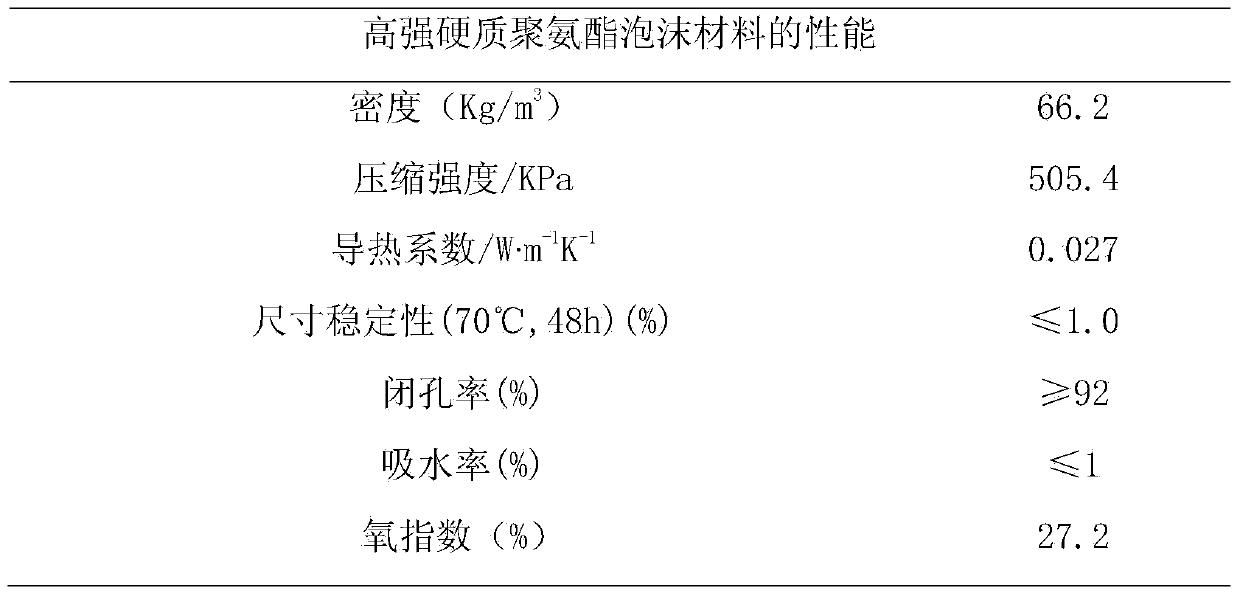

Rigid polyurethane casting material

The invention relates to a rigid polyurethane casting material and a preparation method thereof. The rigid polyurethane casting material is prepared from a component A and a component B, wherein the component A is polymethylene polyphenyl polyisocyanic acid ester of which NCO accounts for 30.5-32.5% in percentage by mass, the functionality degree of the component A is within 2.5-3.0, and the use amount of the component A is 100 parts by weight; the component B comprises the following components: 30-80 parts of polyester polyol, 10-30 parts of polyether polyol, 20-50 parts of flame-retardant polyhydric alcohol, 4-5 parts of foam stabilizer, 0.5-2 parts of catalyst, 8-30 parts of foaming agent, 2-8 parts of chain extender, 1-4 parts of cross-linking agent and 10-30 parts of flame retardant. The rigid polyurethane casting material provided by the invention has the characteristics of light weight, high specific strength, good sound insulation property, rich foam pore in a sealed manner, low heat conduction coefficient, good corrosion resistance, good shake resistance, good size stability and the like, is applicable to various crack filling materials, repairing materials, building wall body heat-preservation materials, sound insulation materials and the like, and is good in flame retardance.

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH

Flame-proof mending material for foundry ladle and manufacturing method thereof

The invention relates to a fire proof patching material used for foundry ladle and a preparation method thereof, the fire proof patching material is a combination, and the contained components and weight percentage occupied in the combination contain: 55 to 90 percent of patching material basal body, 1 to 35 percent of carborundum, 3 to 15 percent of monox micro powder or / and alumina micro powder, 0.5 to 15 percent of calcium aluminate cement, 0.01 to 3 percent of trimeric sodium phosphate or sodium hexametahposphate and 0.001 to 2 percent of sodium cellulose or sodium alginate; the patching material basal body is the combination of one or several corundum, bauxite and flint clay. The preparation method has the following steps: first uniformly mixing the patching material basal body, then adding other components to be uniformly mixed, and finishing goods. The fire proof patching material contains the carborundum, the carborundum has the characteristic of anti-corrosion to low-melting-point materials of fluorite, lime, soda, and the like, makes anti-corrosion performance of the patching material be enhanced, makes the patching material be not easy to be peeled off, and makes the life of the foundry ladle be enhanced. The preparation method of the fire proof patching material is simple and has low cost.

Owner:武钢集团有限公司

Rapid repair material based on building broken stones and preparation method thereof

The invention relates to building stone repairing. A rapid repair material based on building broken stones comprises a gelation mixture which quickly solidifies with water, wherein the gelation mixture comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. A preparation method of the materials comprises the following steps of: 1, preparing the magnesium phosphate cement; 2, mixing the magnesium phosphate cement, the sand and the silica sol so as to form the gelation mixture which comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. The gelation mixture can be quickly solidified with the water to repair the stones. In addition, the gelation mixture is gelatineous before being solidified and facilitates construction; after the solidification, the small solidification shrinkage rate and a durable effect are obtained; and the repair material has high hardness and good water resistance after the solidification.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

Composite combining silica thermal repairing material and preparation method thereof

The invention discloses a composite bonded silicious hot repair material, which belongs to the technical field of refractory materials. The repair material comprises the following compositions in percentage by weight: 45 to 55 percent of silicious clinker aggregate, 8 to 12 percent of silicious clinker powder, 20 to 30 percent of natural silica powder, 8 to 12 percent of complex binder, 3 to 5 percent of plasticizer, and 1 to 1.5 percent of dispersant. The silicious clinker aggregate and the silicious clinker powder are waste main crown silica bricks (SiO2 is more than or equal to 95 percent) and fused quartz tubes or fused quartz wedges (SiO2 is more than or equal to 98 percent), SiO2 is more than or equal to 96 percent in natural silica, the complex binder is formed by compounding an SiO2 ceramic bond and a phosphorous acid (phosphate) chemical bond, the plasticizer is white clay or bentonite, and the dispersant is silica fume. The repair material is processed according to the particle size. The invention can satisfy various conditions proposed by hot repair of a kiln to the repair material, can also realize the aims of saving energy sources and increasing the service life of the kiln, and can also be used for filling or building positions which are not suitable for silica brick masonry during the cold repair at the same time.

Owner:山西高科耐火材料股份有限公司

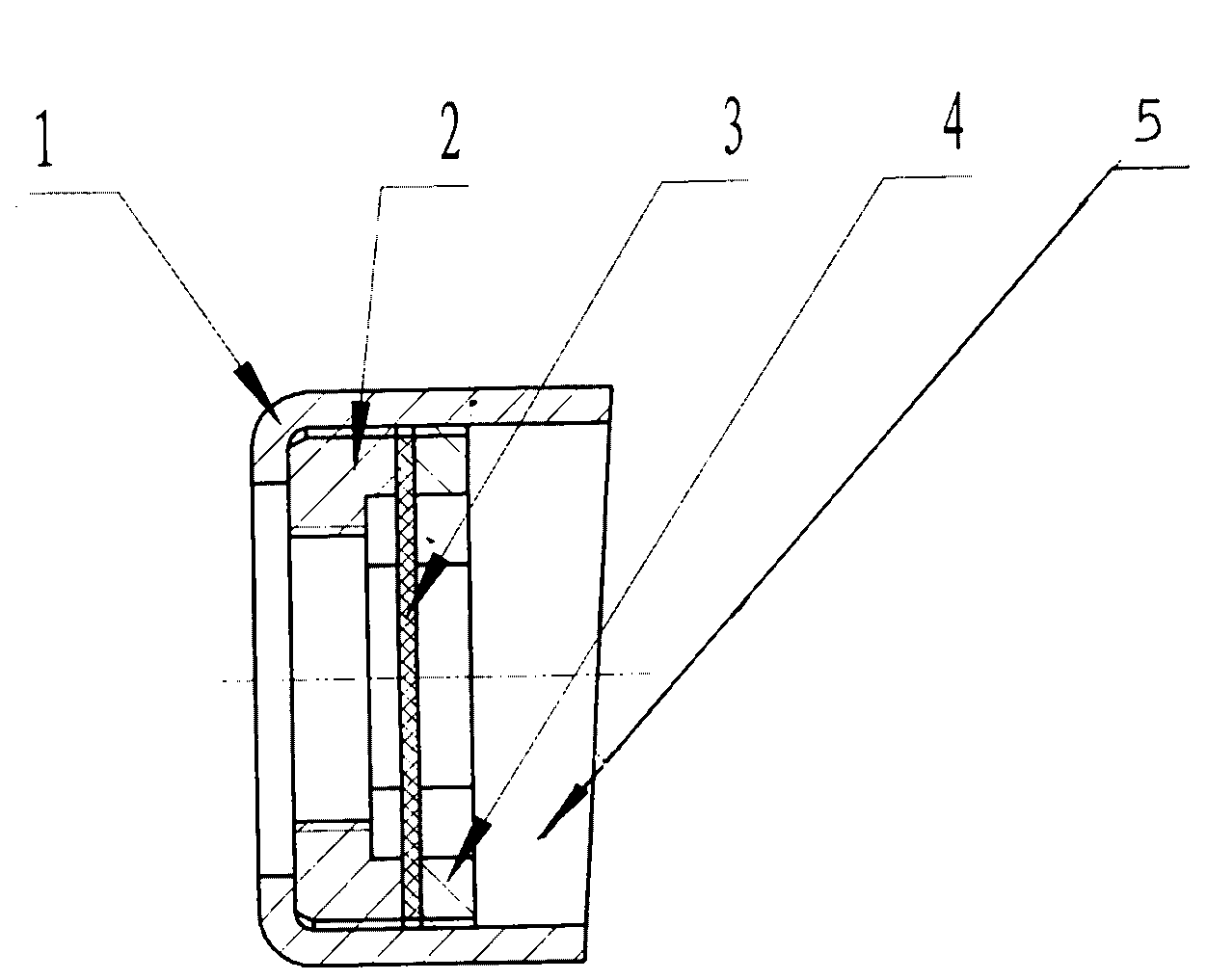

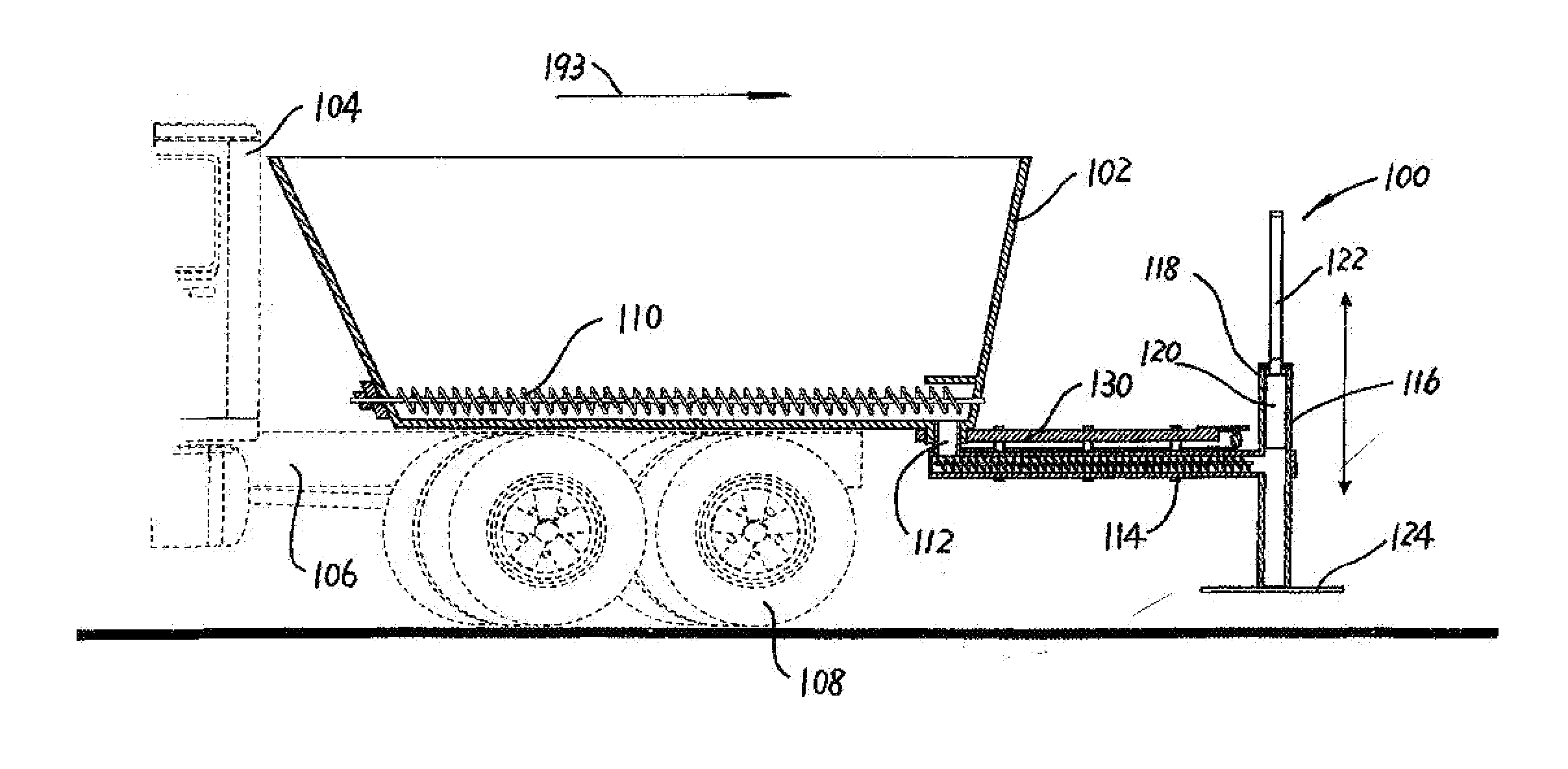

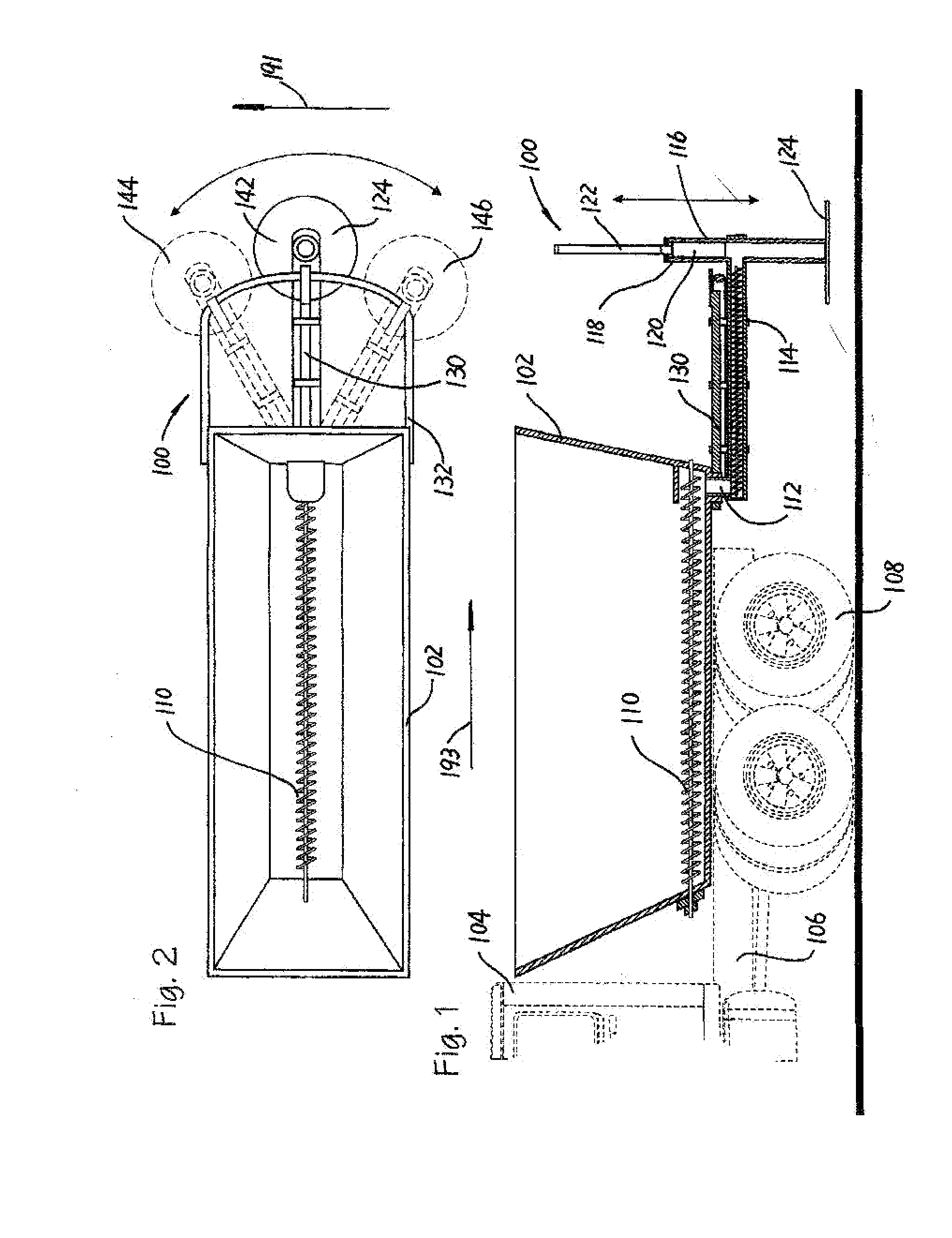

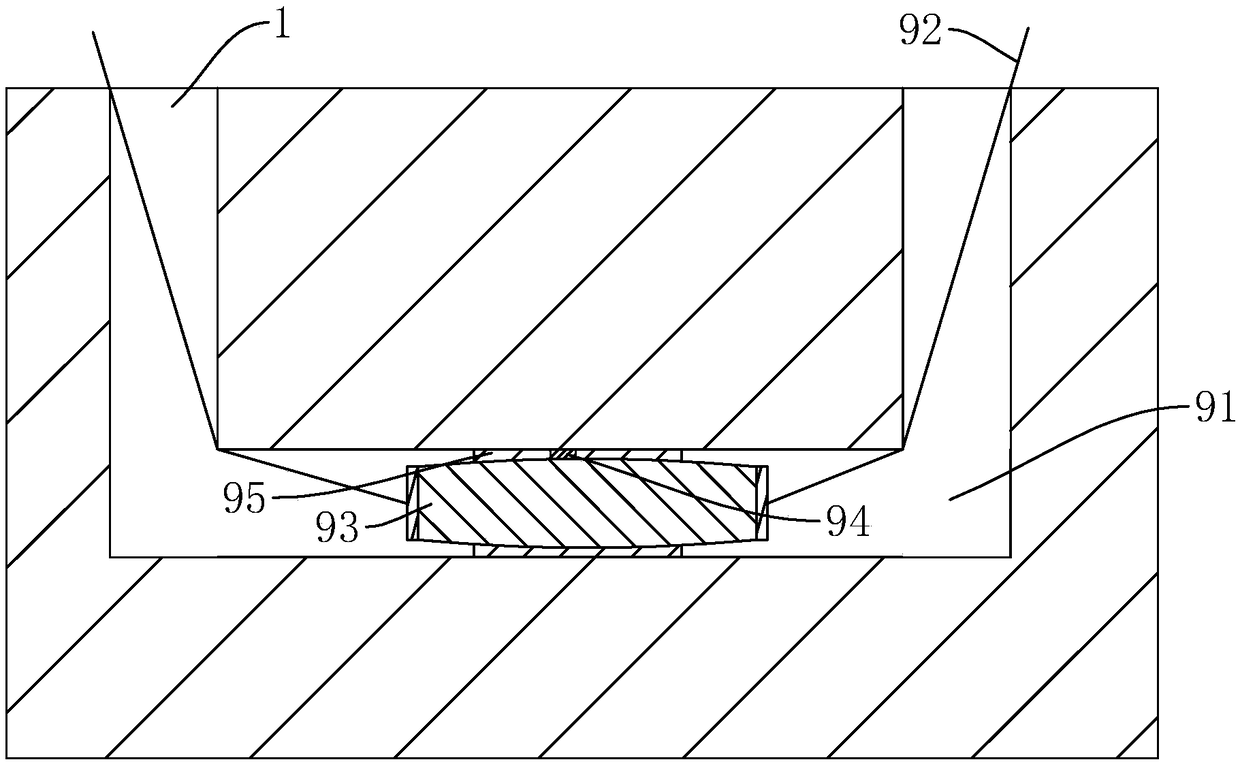

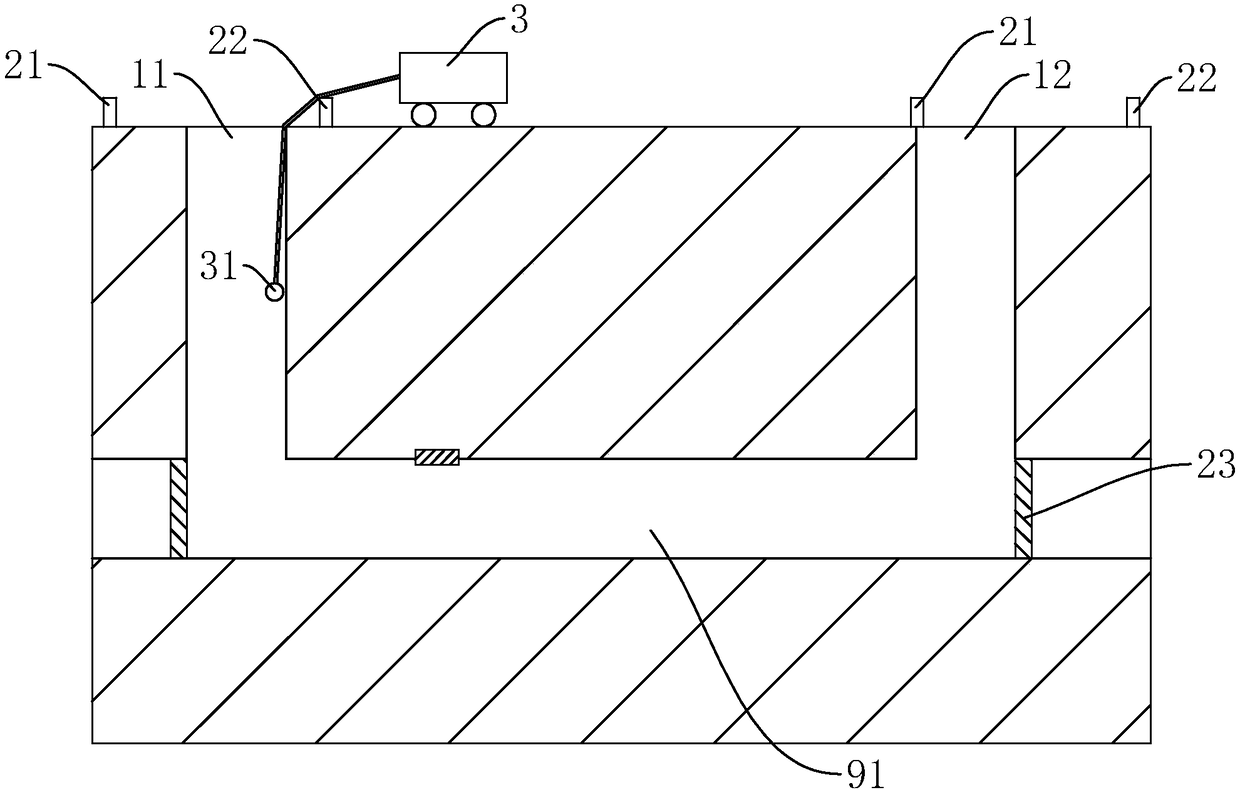

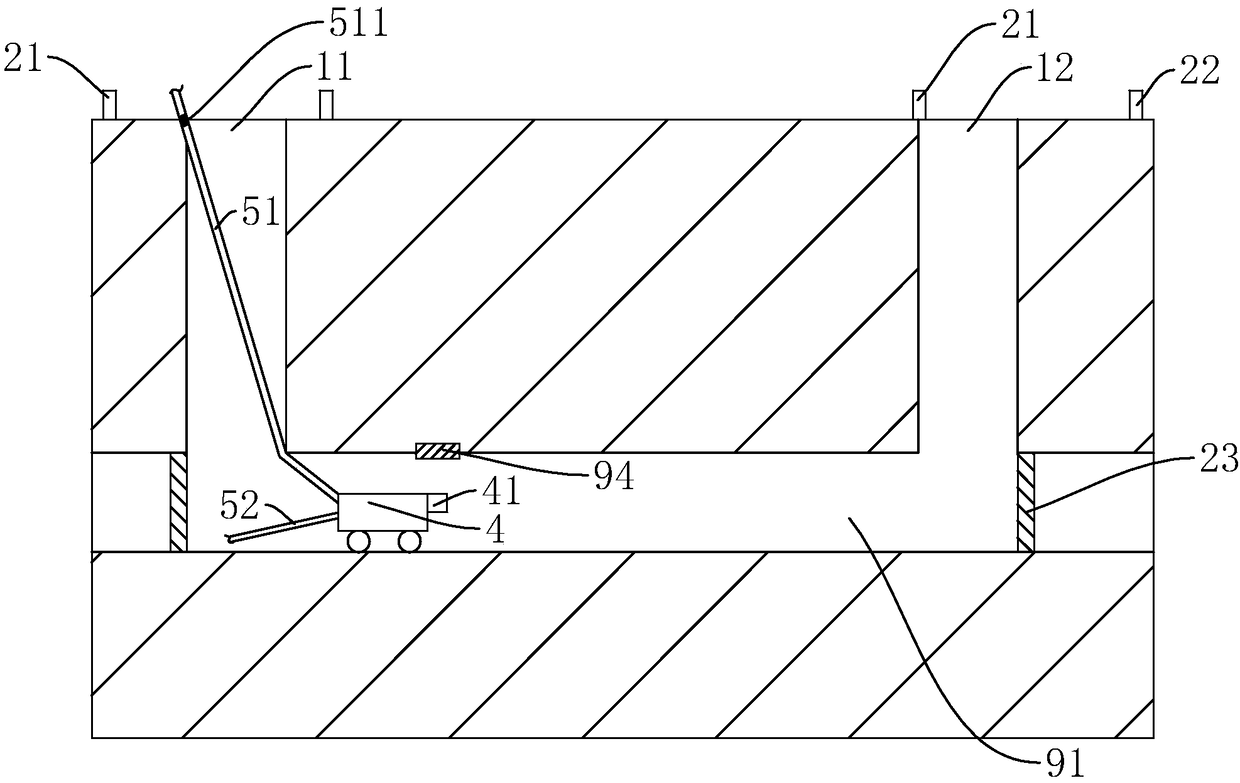

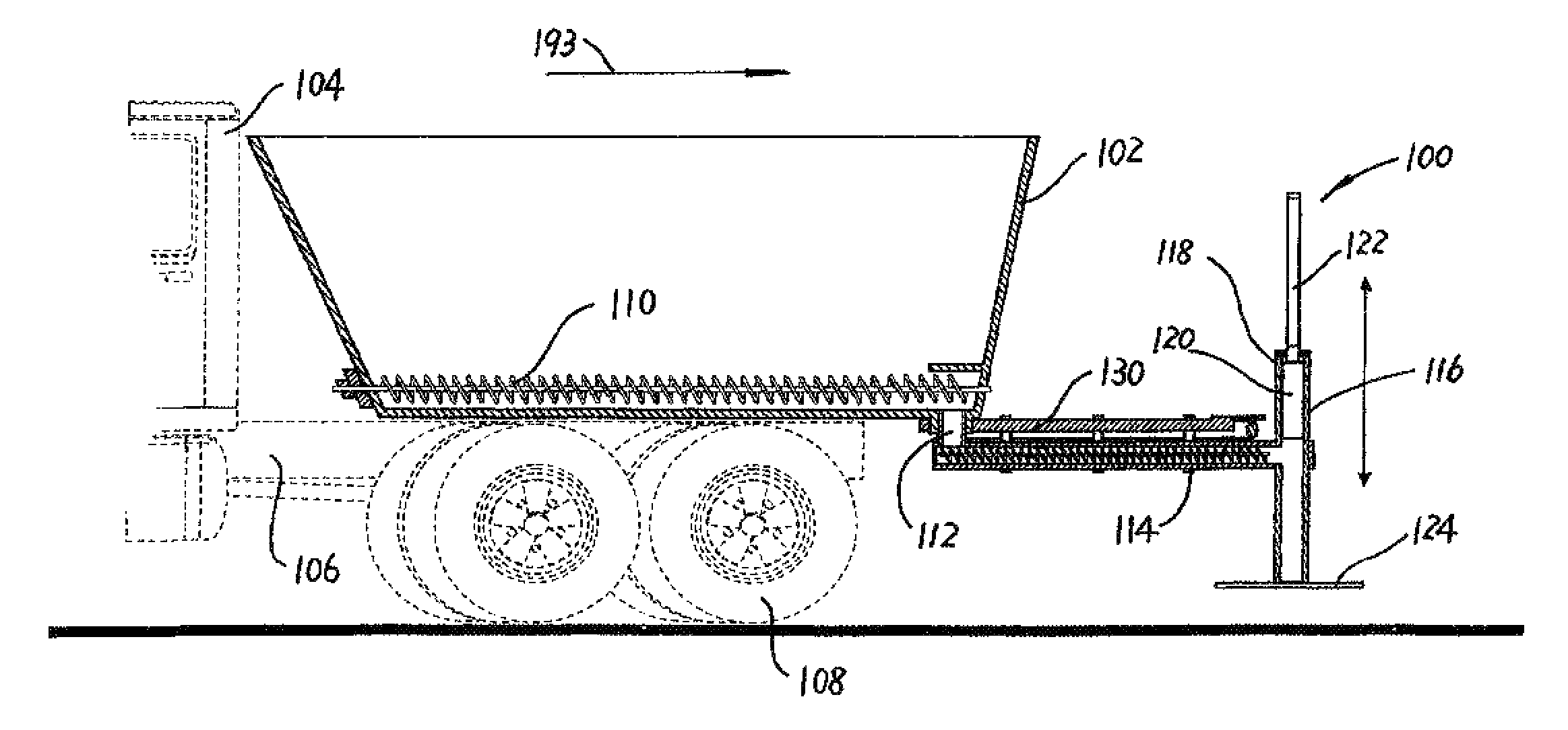

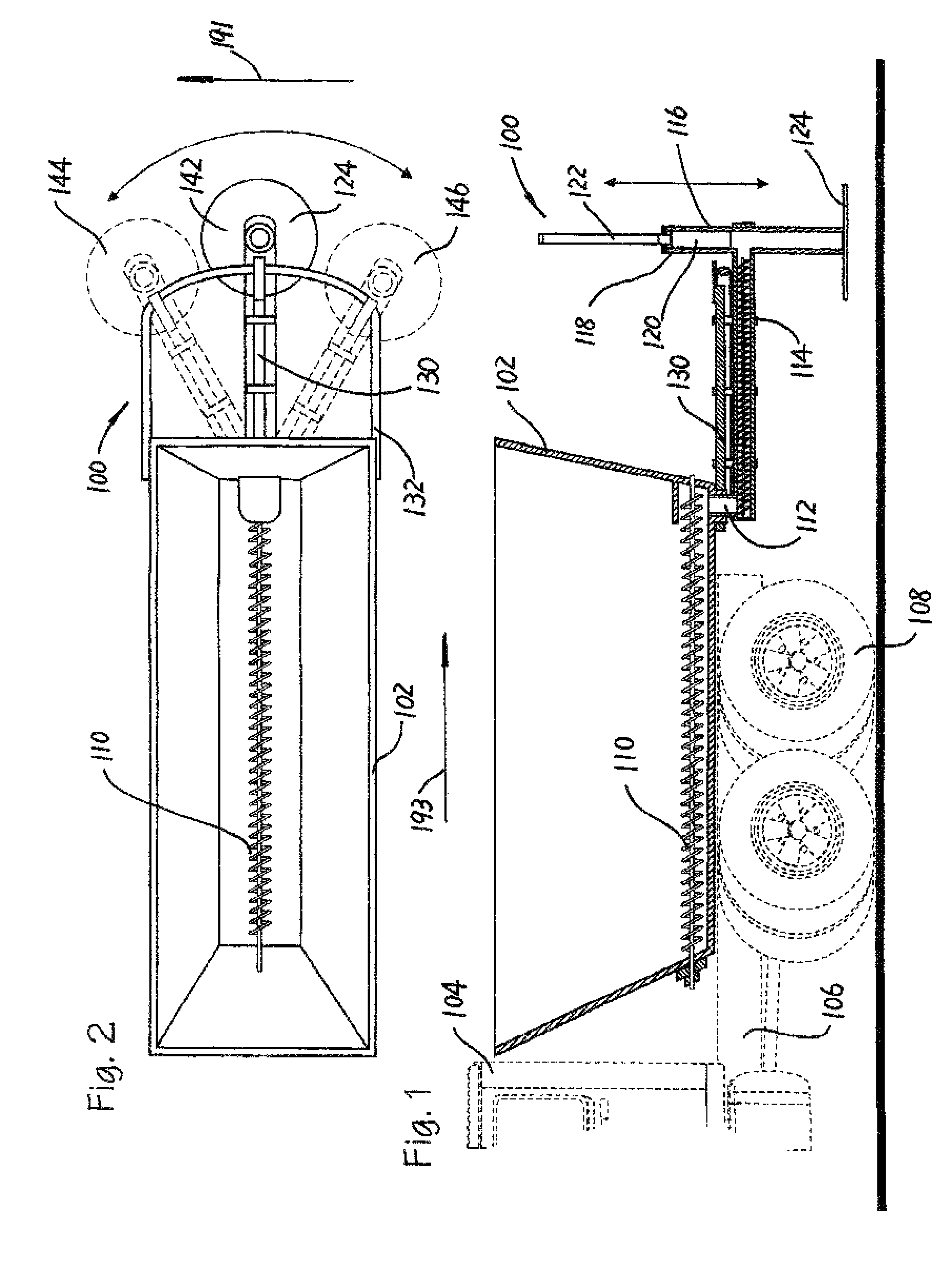

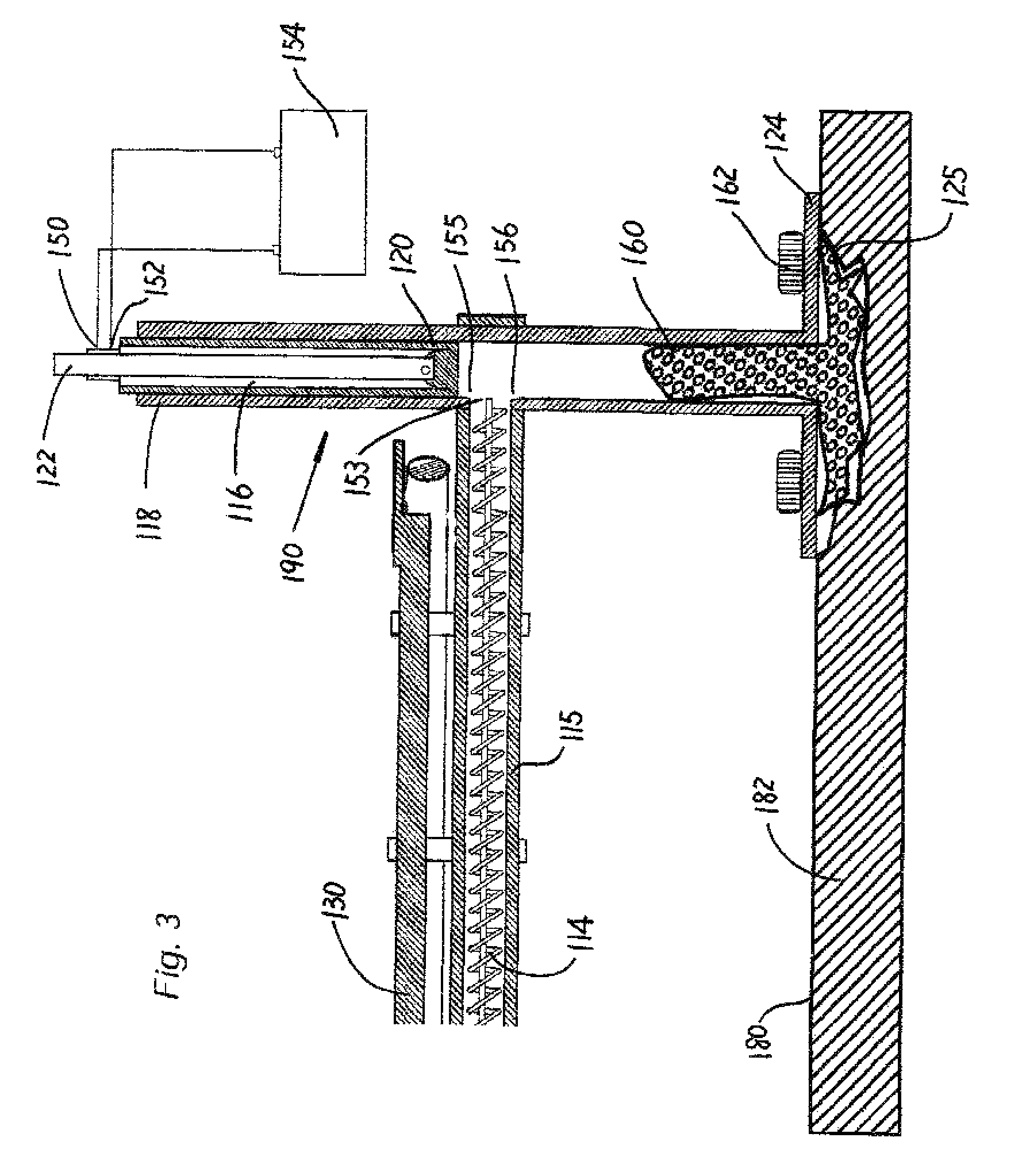

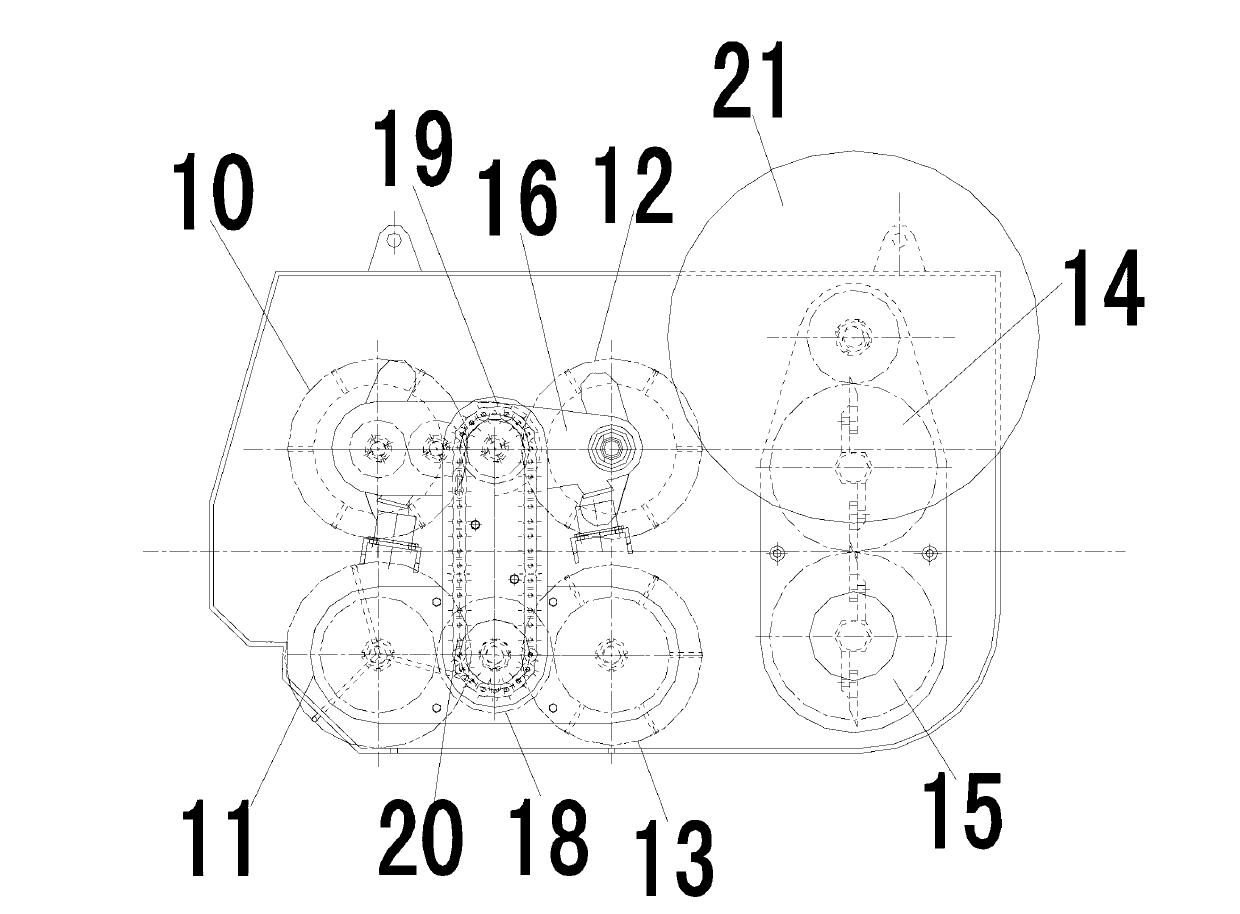

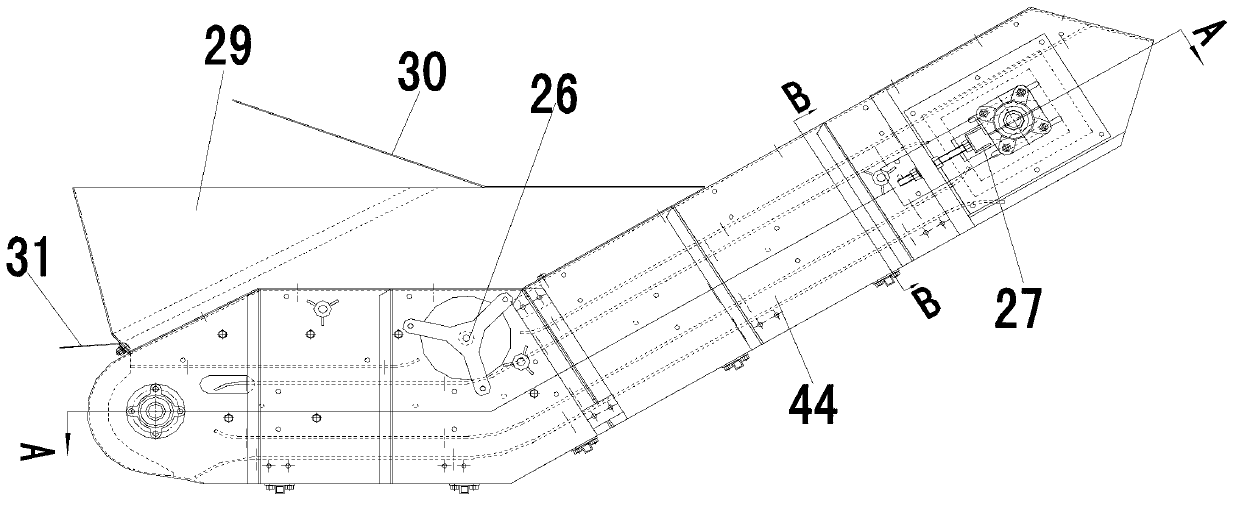

Pothole patching machine

A pothole patching machine includes a container for storage of patch material, and a auger screw conveyor for conveying the patch material from the container to a ram. The ram is adapted to forcibly urge the patch material into a pothole. The ram is moveable between a retracted position and an extended position which completes one fill stroke. The ram also includes a foot plate dimensioned for positioning over the pothole and sensors for sensing when the pothole has been filled.

Owner:RYAN KEITH A

Concrete repairing material and preparation method thereof

The invention provides a concrete repairing material and a preparation method thereof. The concrete repairing material is prepared from the following components in parts by weight: 10-30 parts of waterborne epoxy resin, 5-15 parts of waterborne epoxy firming agent, 1-4 parts of coupler, 25-55 parts of quartz sand, 10-25 parts of cement and 8-15 parts of water which are totally 100 parts by weight. The material provided by the invention has the action of repairing, reinforcing, protecting, and the like as well as long maneuverability time, is suitable for repairing a wet substrate, rapidly develops the strength after solidification, has high bonding strength with original cement and is particularly suitable for repairing reinforced concrete poles in service.

Owner:JIANGSU ELECTRIC POWER RES INST

Strength controllable coal ash-based polymer concrete and preparation method thereof

The invention provides a strength controllable coal ash-based polymer concrete. The polymer concrete comprises a mixed solid phase and a mixed liquid phase, wherein the weight ratio of the mixed solid phase and the mixed liquid phase is 11:1, the mixed solid phase comprises the following components in parts by weight: 45-55 parts of coarse aggregate gravel, 13-33 parts of fine aggregate natural sand, 19-27 parts of coal ash, 0-8 parts of silica fume, and 0.05-0.12 part of sodium tripolyphosphate, and the mixed liquid phase comprises the following components in parts by weight: 67-75 parts of liquid sodium silicate for industrial use, and 25-33 parts of 10-18mol / L of sodium hydroxide solution. A preparation method for the coal ash-based polymer concrete is simple, has no toxicity and no contamination, and has low cost, and the raw material spreads all over the world and is expected to be used in fields such as corrosion resistant concrete construction, utilization of industrial wastes, rapid patching materials, high-strength high performance materials and the like. Furthermore, according to the coal ash-based polymer concrete, large amount of industrial waste coal ash can be efficiently used, so that the coal ash-based polymer concrete has great significance to conservation of energy and resources and environment protection. The invention also provides the preparation method of the coal ash-based polymer concrete.

Owner:WENZHOU UNIVERSITY

Road surface repairng material and its making method and use

InactiveCN1514063AReduce violenceImprove surface affinityRoads maintainenceEpoxy resin adhesivesRoad surfaceWear resistance

Owner:熊瑛

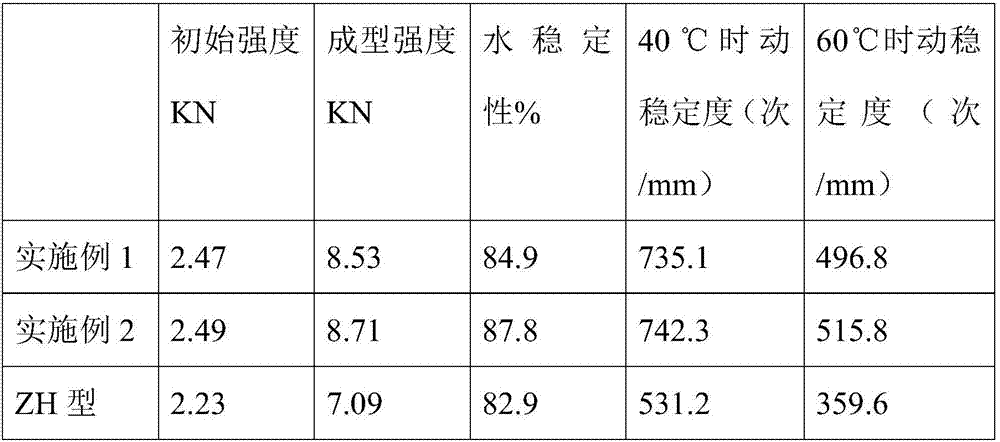

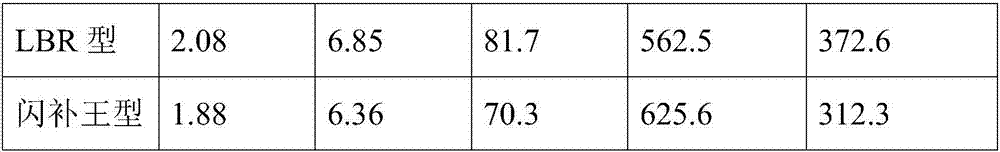

Cold patch asphalt mixture and preparation method thereof

The invention discloses a cold patch asphalt mixture and a preparation method thereof. The preparation method comprises the following steps: heating and dewatering petroleum asphalt, then adding a diluent, a tackifier and an anti-stripping agent in sequence according to weight parts, uniformly mixing, and then adding waterborne epoxy emulsion and a waterborne epoxy curing agent, and uniformly mixing, thus obtaining cold patch asphalt liquid; uniformly mixing the cold patch asphalt liquid with an aggregate at 60 to 70 DEG C, thus obtaining a mixture A; and finally, adding mineral powder into the mixture A, uniformly stirring, thus obtaining the cold patch asphalt mixture which is used for repairing recesses in a pavement. By the adding of epoxy components, curing reaction of the epoxy components increases the strength increase speed of the mixture; and particularly, by the use of initial strength formation, after the cold patch asphalt mixture is paved, the load bearing capacity is relatively high, and the traffic can be quickly opened. The water stability and the high temperature stability of the cold patch asphalt mixture are improved to a certain extent; by high pavement performance, the service life of a novel cold patch material can be prolonged; and therefore, the pavement repair quality is improved, and occurrence of secondary damage to the pavement is reduced.

Owner:CHANGAN UNIV

Positioning method of underground pipe non-excavation repair defect points

The invention discloses a positioning method of underground pipe non-excavation repair defect points, and solves the problem of a difficulty how to determine defect points of underground pipes alwaysin the repair process caused by people incapable of entering the pipes to examine the defect points. The positioning method comprises the following steps: a dredging car is cleaned; a connecting ropeis arranged on a remote control car provided with a camera, and the defect points in the pipes are searched through the camera; a first positioning mark is arranged in the position, positioned in an opening of a drainage well, of the connecting rope; a positioning rope is bound on a pipe repair airbag, and is provided with a second positioning mark corresponding to the first positioning mark; thesurface of the pipe repair airbag is coated with a repair material; after the second positioning mark is positioned in the opening of the drainage well, the pipe repair airbag is used for repair; andmultiple defect points can be once determined, and can be gradually repaired, so that the time and the times of the remote control car searching the defect points are saved, the working efficiency isimproved, and the repair flow is simplified.

Owner:浙江景迈环境科技有限公司

Pothole patching machine

A pothole patching machine includes a container for storage of patch material, and a auger screw conveyor for conveying the patch material from the container to a ram. The ram is adapted to forcibly urge the patch material into a pothole. The ram is moveable between a retracted position and an extended position which completes one fill stroke. The ram also includes a foot plate dimensioned for positioning over the pothole and sensors for sensing when the pothole has been filled.

Owner:RYAN KEITH A

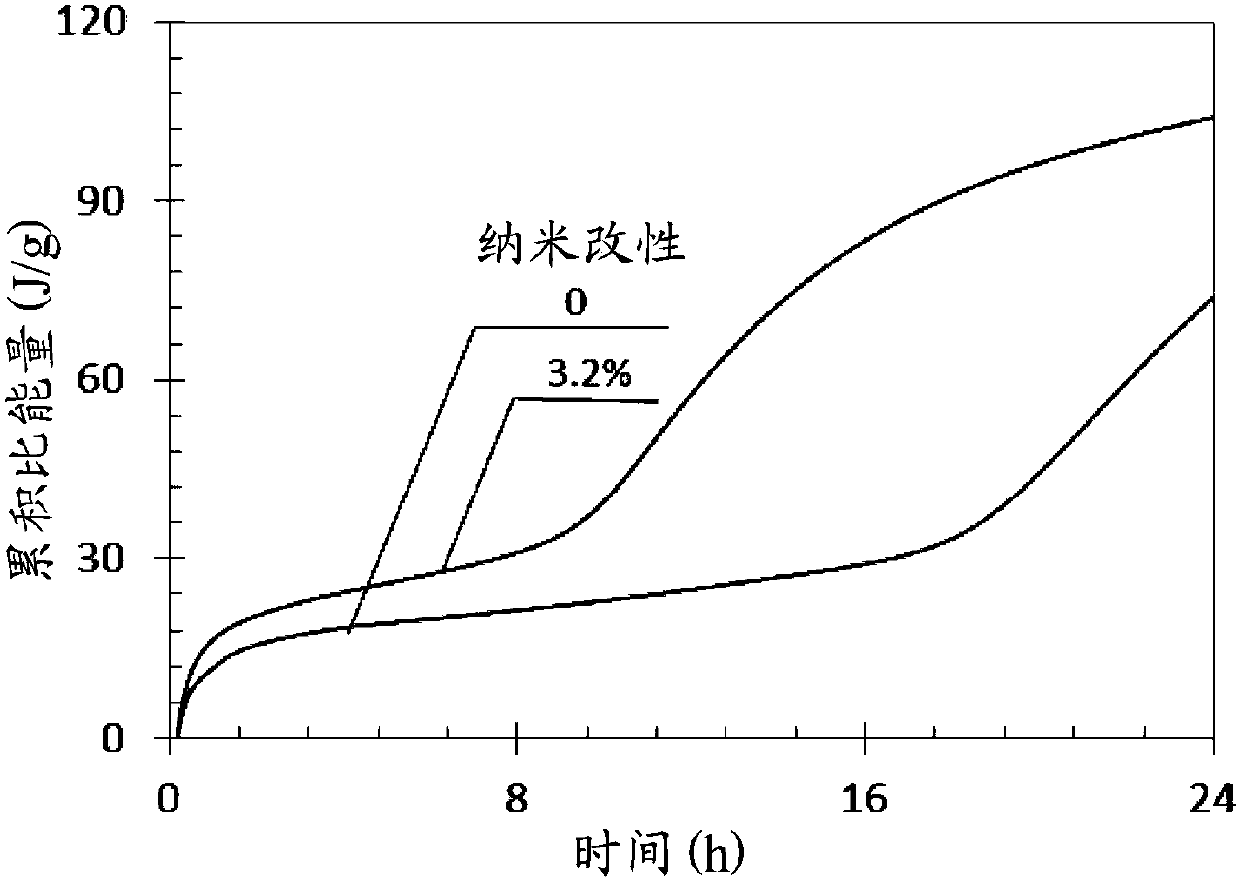

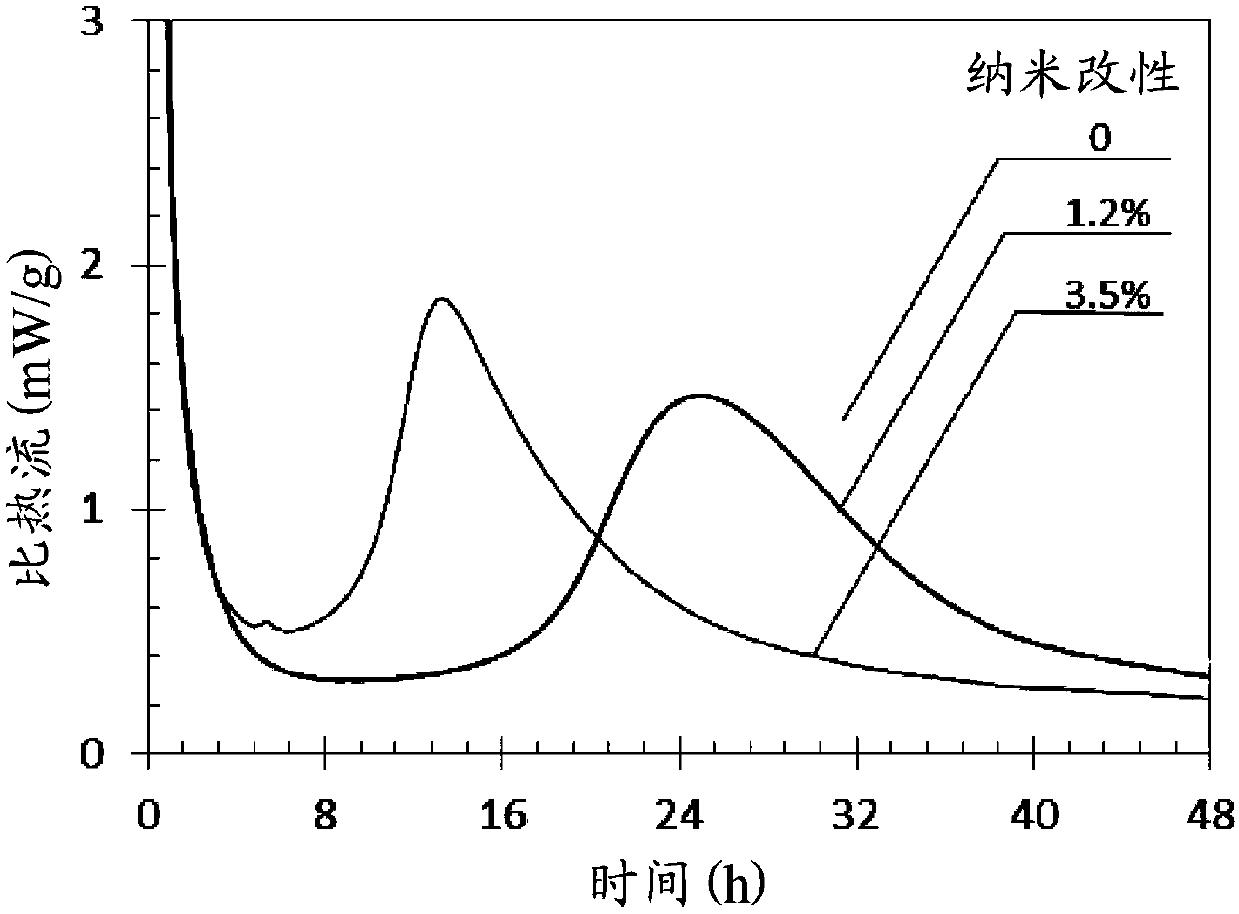

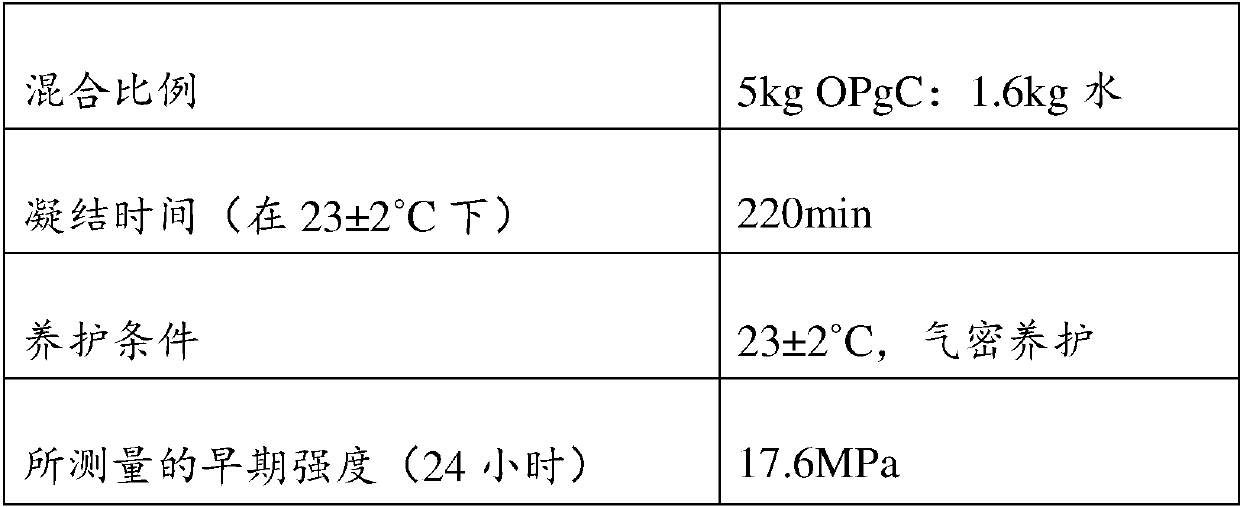

Nano-modified alkali-activated cementitious materials for rapid repair

A nano-modified dry-mixed alkali-activated cementitious, or one-part geopolymer cement (OPgC), material with high early strength is provided for rapid repair of cement-based infrastructure components.The OPgC may include an aluminosilicate rich material, an alkali material and a nano-modifier, and optionally include other functional admixtures and fibers. The OPgC can be freshly mixed with waterto obtain a repairing material. The OPgC may mix with water and fine or coarse aggregate to form mortar or concrete. The OPgC can be an alternative binding matrix for the development of an environmentally friendly and cost effective rapid repair material and can replace conventional adhesive matrix (including Portland cement, organic adhesives, etc.).

Owner:NANO & ADVANCED MATERIALS INST

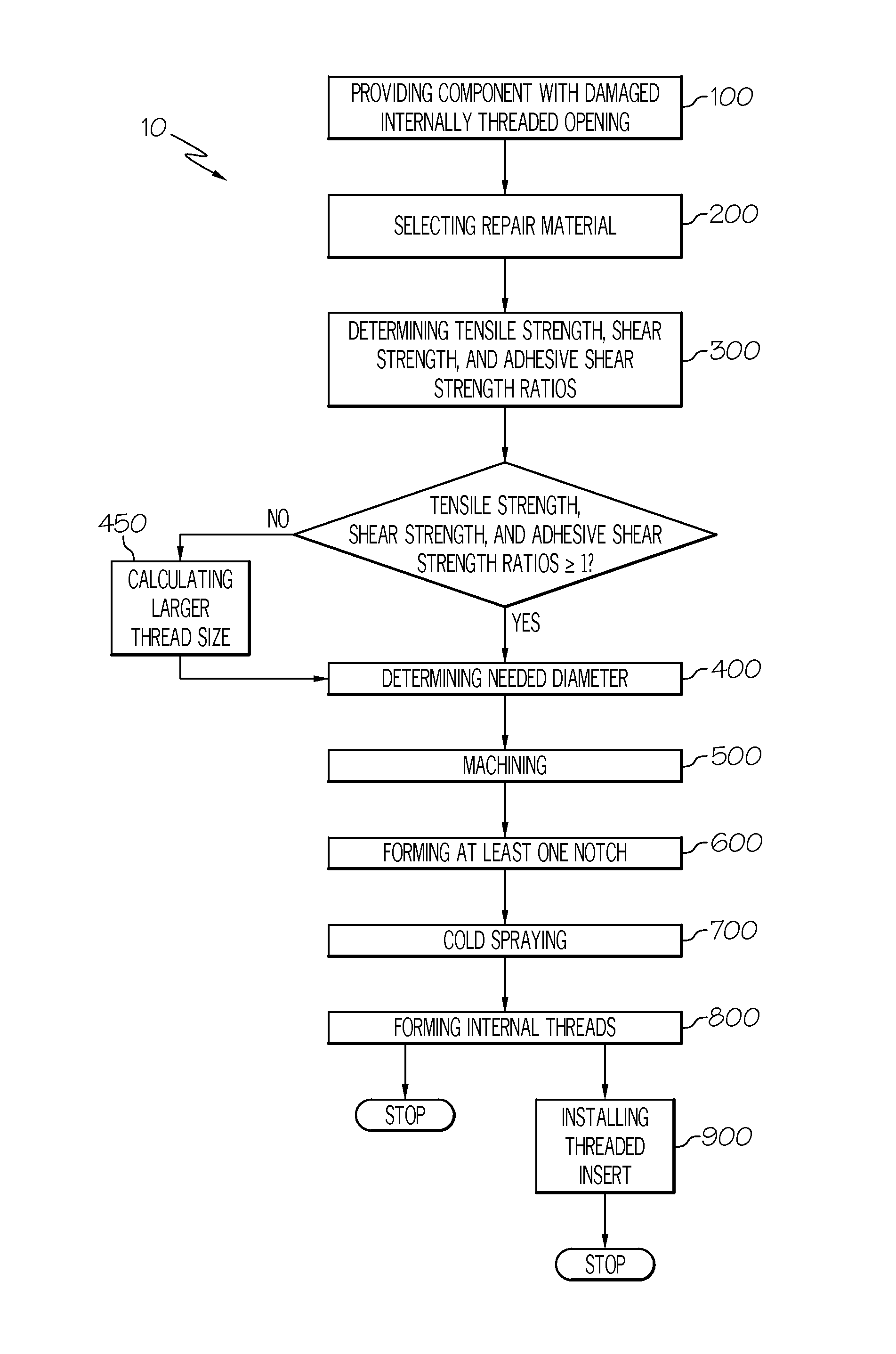

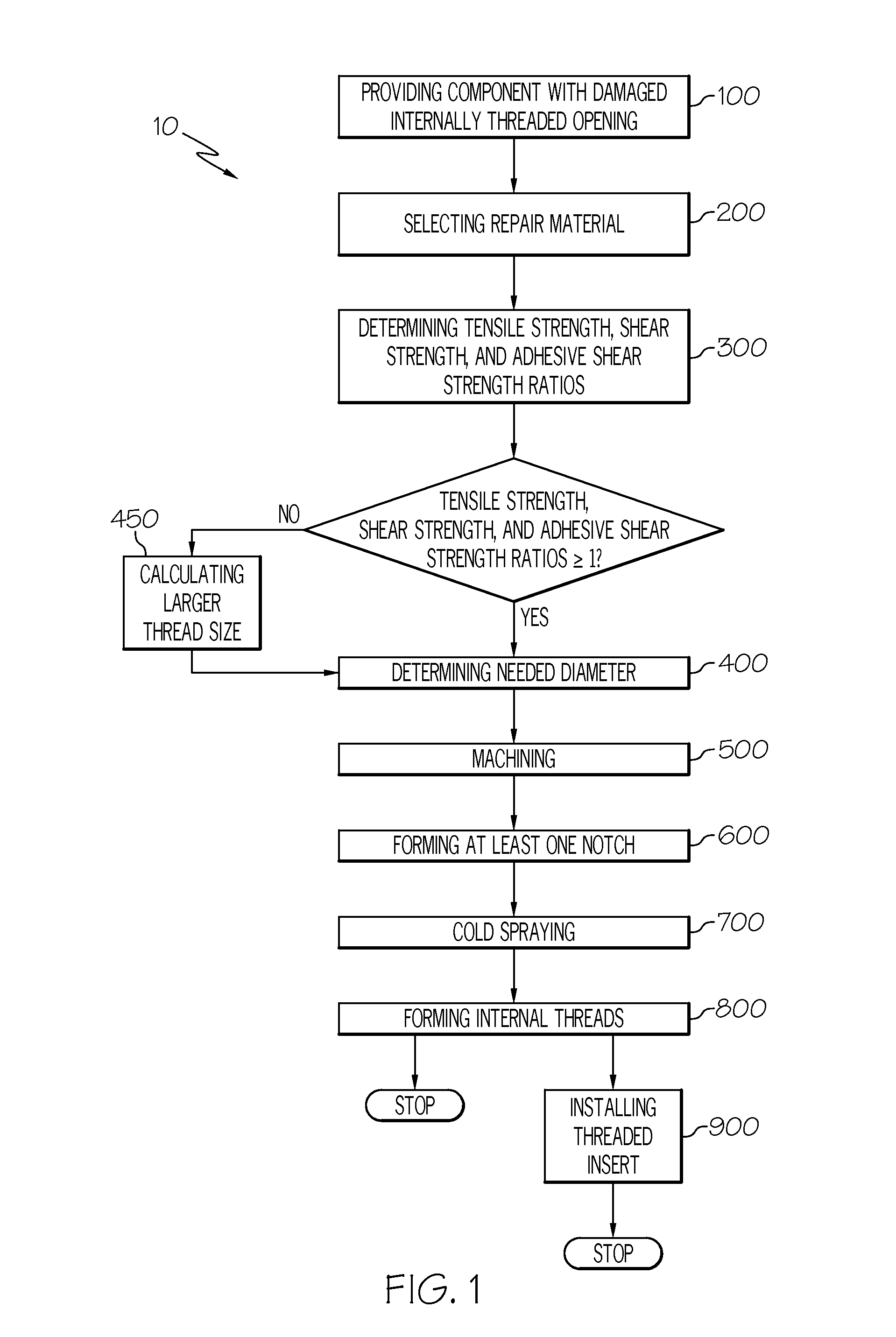

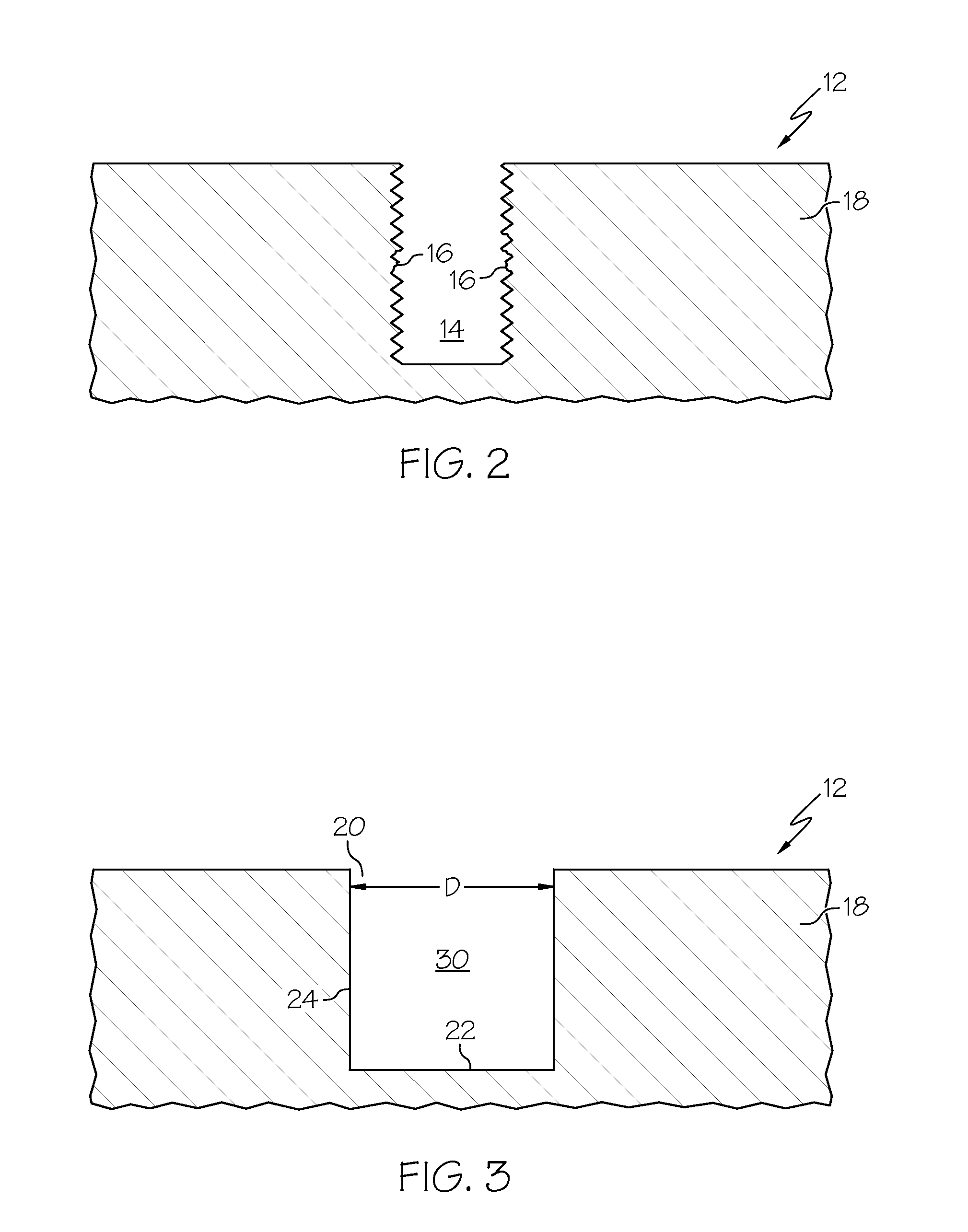

Methods for structural repair of components having damaged internally threaded openings and components repaired using such methods

Methods are provided for structurally repairing a component having a damaged internally threaded opening. The damaged internally threaded opening is machined to a predetermined diameter, thereby forming a machined opening. At least one notch is formed in the machined opening, thereby forming a notched opening. A selected amount of repair material is cold sprayed into the notched opening, including into the at least one notch. A plurality of internal threads is formed from the repair material to form a repaired internally threaded opening in the component. The repaired components are also provided.

Owner:HONEYWELL INT INC

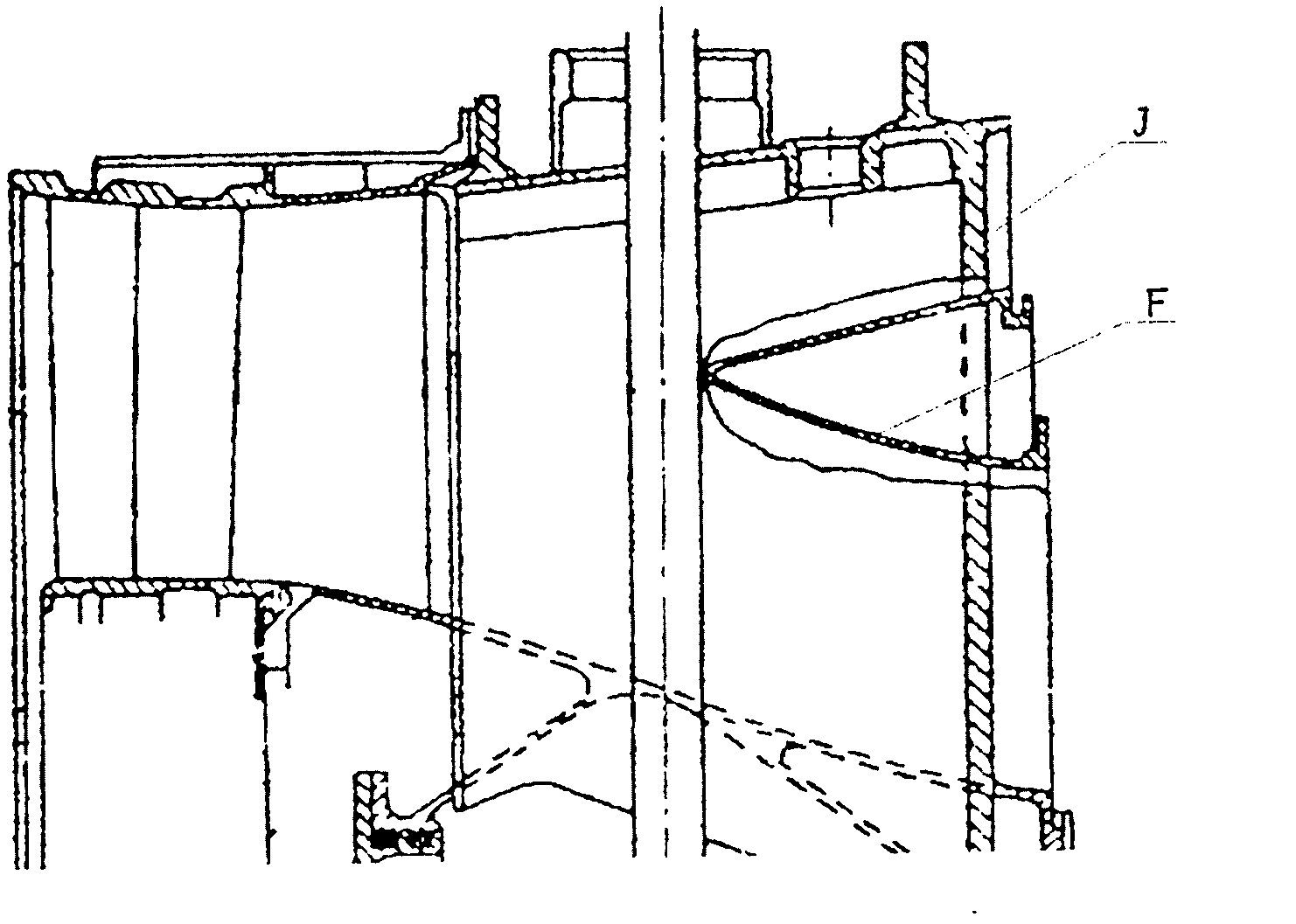

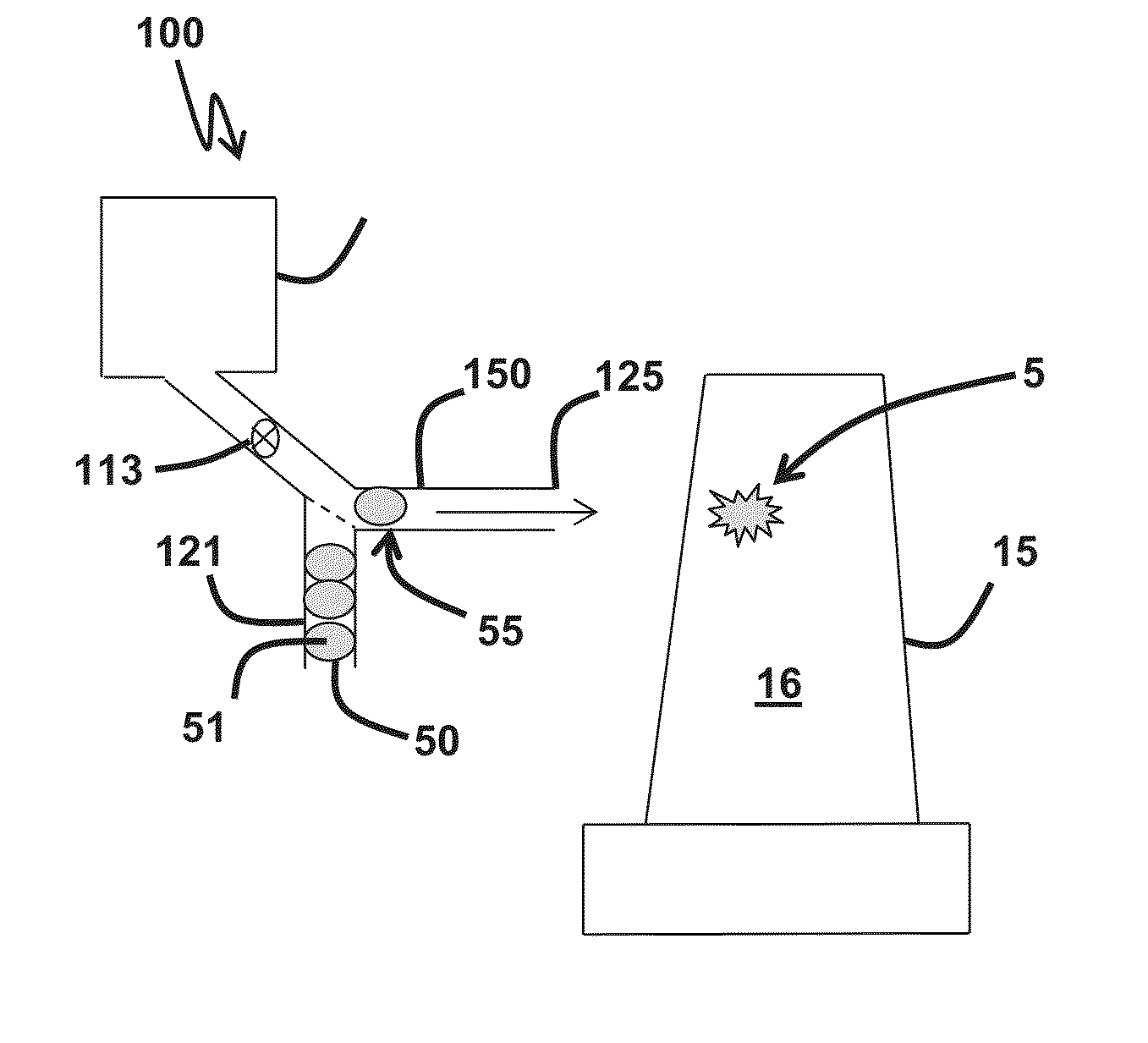

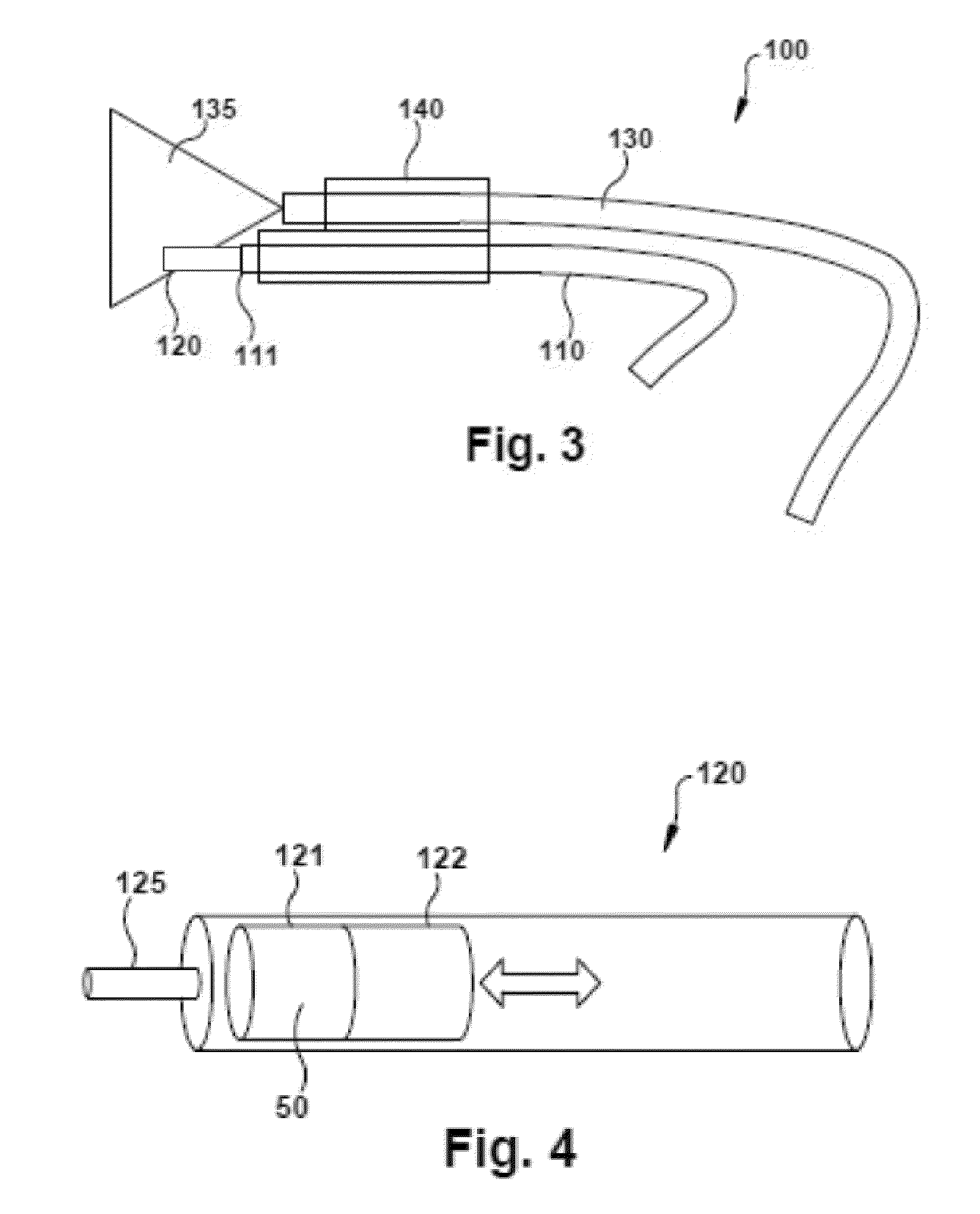

Turbine component patch delivery system

A turbine component patch delivery system can include a support arm and a deposition tool supported by the support arm. The deposition tool can include a reservoir configured to house a turbine component patch material and a dispenser configured to dispense the turbine component patch material from the reservoir onto a surface of a turbine component.

Owner:GENERAL ELECTRIC CO

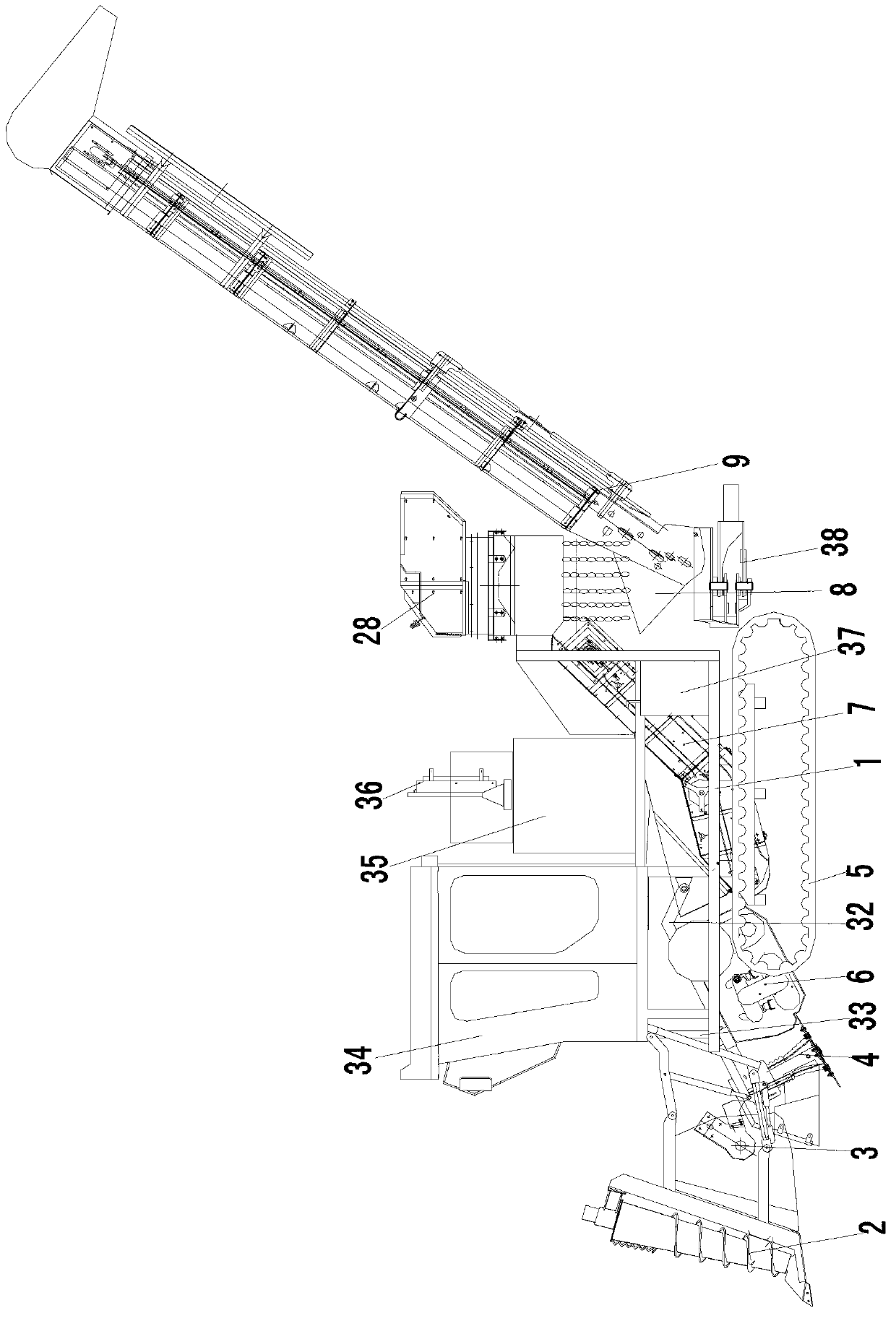

Sugarcane combine-harvester with novel conveying manner

ActiveCN103098615AReduce conveyor path lengthReduce path lengthHarvestersPatch materialCombine harvester

The invention discloses a sugarcane combine-harvester with a novel conveying manner. The sugarcane combine-harvester comprises a machine frame. A spiral branching device, a push-down roller and a cutting table are sequentially arranged at the front end of the machine frame. A walking device is disposed under the machine frame. A level-one roller conveyance and cut-in-section device is mounted at the back of the cutting table. A level-two screen type conveying chain lifting and conveying device is disposed at the back of the level-one roller conveyance and cut-in-section device. A hopper is arranged under the output end of the level-two screen type conveying chain lifting and conveying device. The hopper is connected with a conveying arm. According to the sugarcane combine-harvester with the novel conveying manner, the length of a conveying path on which a whole piece of sugarcane is conveyed in the harvester is reduced, and the problems of blocking in conveying, poor quality, low efficiency and the like caused by the fact that the sugarcane conveying path in the prior art is too long, sugarcane goes out of the path, and sugarcane stems are damaged or broken are resolved. The sugarcane combine-harvester has the advantages of being simple in structure, strong in patch material handling capacity, high in mechanical operation efficiency, good in harvest quality and the like.

Owner:SOUTH CHINA AGRI UNIV

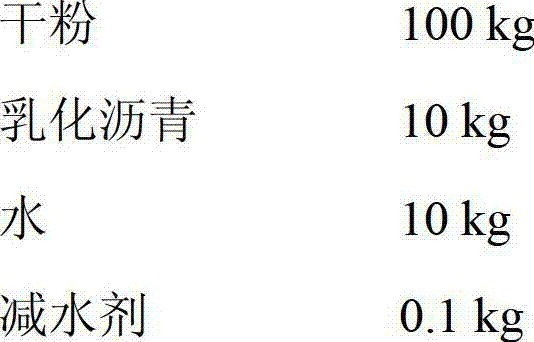

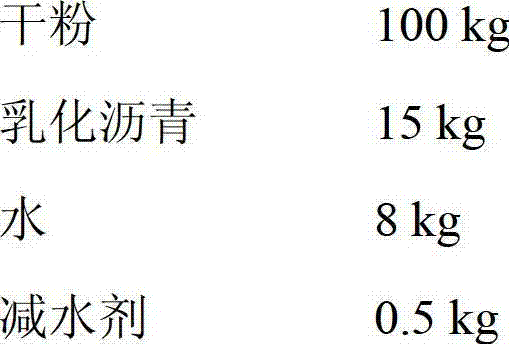

Repair material for bituminous pavement pot holes and method for preparing same

The invention discloses a repair material for bituminous pavement pot holes and a method for preparing the same, wherein the material is prepared by mixing and stirring the following raw materials according to parts by weight: 100 parts of dry powder, 10-20 parts of emulsified asphalt, 5-10 parts of water and 0.1-0.5 part of water reducer. The method for preparing the material comprises the steps of putting the dry powder, the water reducer and water in a stirring machine and stirring at a speed of 200 r / min for 60 s at first, and then adding the emulsified asphalt thereto and stirring at the speed of 200 r / min for 30 s, and finally, stirring at a speed of 400 r / min for 180 s, thereby obtaining the repair material for the bituminous pavement pot holes. The repair material for bituminous pavement pot holes provided by the invention is convenient for storage and does not need to be heated in use, and further is capable of quickly repairing the damaged bituminous pavement pot holes at different temperatures and under the wet conditions; as a result, the repair material can be selected for repairing when the traffic flow is small, so that the normal traffic capacity of the road cannot be affected.

Owner:CHANGAN UNIV

Quick repairing polymer cement base material and its preparing method

The present invention is one polymer and cement-base quick repairing material for water engineering and building engineering. The material consists of portland cement, high-alumina cement, re-dispersed latex powder, high efficiency water reducing adhesive, sodium carbonate and other material in certain proportion. The material has high adhering strength and wide construction adaptability, and is suitable for construction in damp base especially.

Owner:TONGJI UNIV

Bridge expansion joint fast reparation material

The invention relates to a bridge expansion joint fast reparation material which is composed of a component A and a component B. The component A is composed of, by weight, 25-30 parts of fast-hardening sulphoaluminate cement, 5-10 parts of ordinary Portland cement, 1-3 parts of anhydrite, 1-3 parts of silica fume, 55-65 parts of quartz sand, 0.5-1 part of a water reducing agent, 0.5-1 part of boric acid, and 1-3 parts of fiber. The component B is composed of, by weight, 35-45 parts of carboxylic butadiene-styrene latex, 0.5-1 part of lithium salt, 0.5-1 part of a lithium salt defoaming agent, and 55-65 parts of water. The material has the characteristics of high early strength, stably increasing late strength, low elastic modulus, high bonding strength, cracking resistance, and the like. In practical construction, the material is simple to use.

Owner:甘肃省交通规划勘察设计院股份有限公司

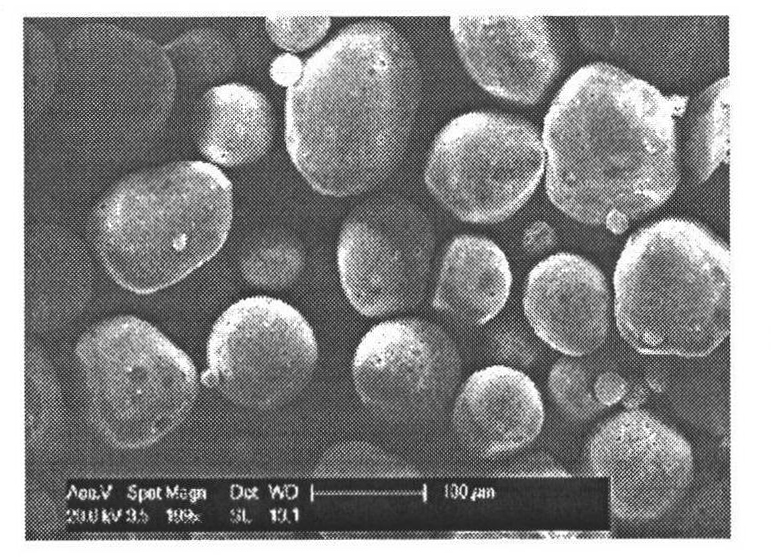

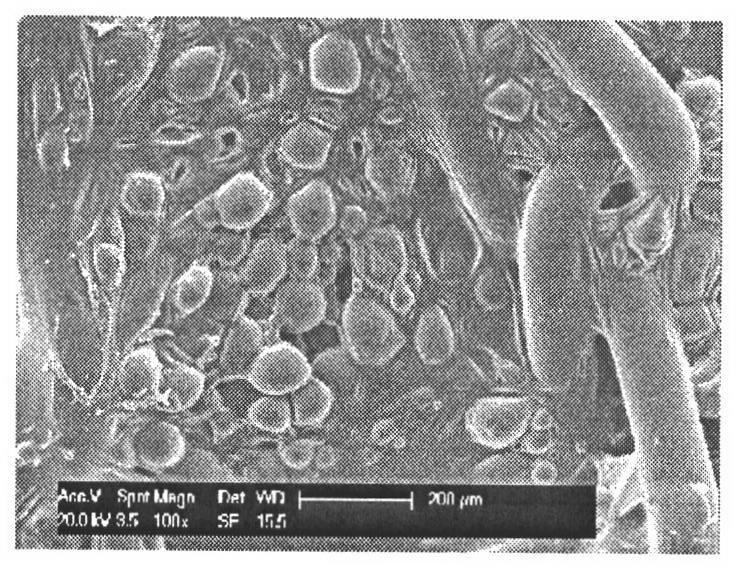

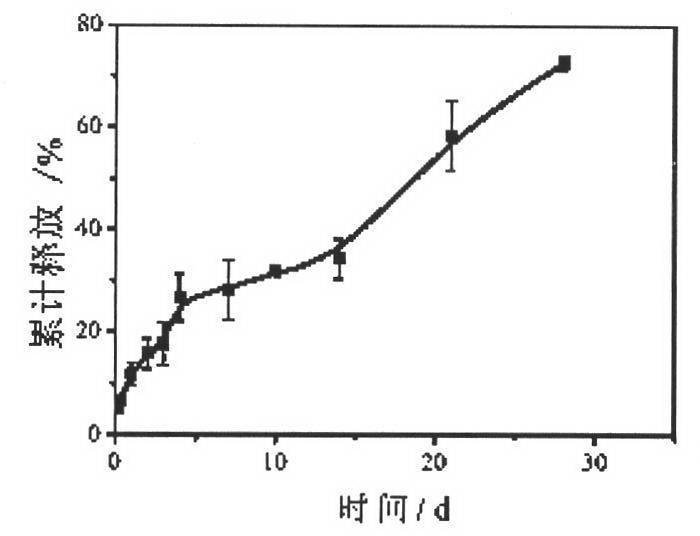

Hernia patch solid-supported with antibiotic and preparation method

InactiveCN102205151AGood biocompatibilityNon-immunogenicAntibacterial agentsPowder deliveryHerniaMicrosphere

The invention relates to a hernia patch solid-supported with antibiotics and a preparation method. The antibiotic hernia patch solid-supported with drug-loaded microspheres comprises drug-loaded microspheres, a patch, and a supporting agent. The sandwich-type antibiotic hernia patch comprises a patch layer, a drug layer, and a film layer. The antibiotic hernia patch solid-supported with drug-loaded microspheres is prepared by solid-supporting the drug-loaded microspheres onto the surface of the patch material by the supporting agent. The drug-loaded microspheres are loaded with water-soluble drugs by a solvent evaporation method. The sandwich-type antibiotic hernia patch is prepared by sandwiching the drug layer between the patch layer and the film layer through a layer-by-layer superposition principle. The antibiotic hernia patch of the invention has a simple and practical preparation method, is suitable for different clinical medication requirements, has obvious slow release performance, has significant antibiotic effect in rats, solves the problem of acute and delayed infection after herniorrhaphy, has good market prospects, and is worthy of popularization and utilization.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

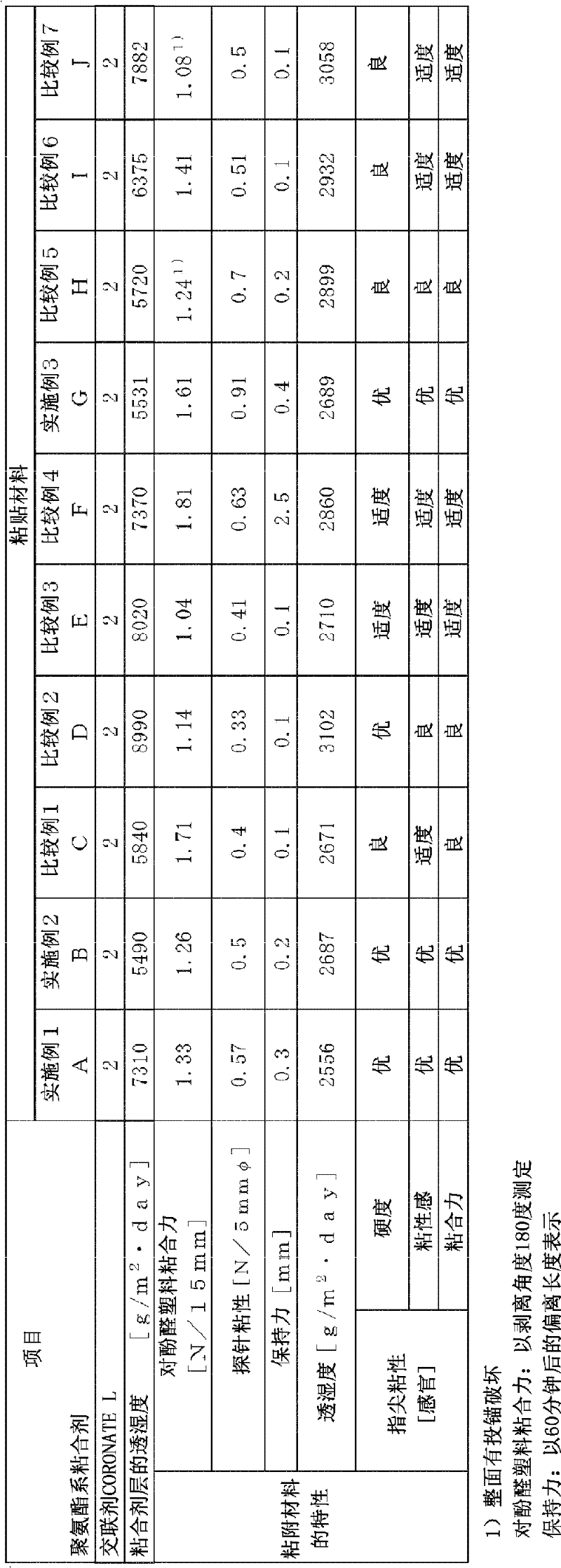

Patch material

InactiveCN102448449AExcellent Adhesive PropertiesGood moisture permeabilityCosmetic preparationsToilet preparationsPolyurethane adhesiveEthylene oxide

It is an objective to provide a patch material having both excellent adhesive property and moisture permeability. The present invention is related to a patch material which comprises a backing material having a water-vapor permeability of 3,000 g / m 2 day or more and an adhesive layer having a water-vapor permeability of 5,000 g / m 2 day or more, wherein the adhesive layer comprises a polyurethane adhesive obtained by reacting (1) an active hydrogen compound having a number-average molecular weight of 5,000 or more and an average number of functional groups of 2 or more, and having a polyoxyalkylene structure, (2) an active hydrogen compound having a number-average molecular weight of 1,500-5,000 and an average number of functional groups of 1, and having polyoxyalkylene structure, and (3) an organic polyisocyanate, wherein an average number of functional groups of all active hydrogen compounds used for obtaining the adhesive is 2-2.6, and the content of ethylene oxide units of all active hydrogen compounds in the adhesive is 3-8% by weight.

Owner:INOAC TECHN CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com