Rigid polyurethane casting material

A technology of rigid polyurethane and pouring materials, which is applied in the field of building materials, can solve the problems of affecting the closed cell rate and density of materials, the inability to promote large-scale use, and poor adaptability to wet environments, etc., and achieve good dimensional stability, light weight, and sound insulation sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

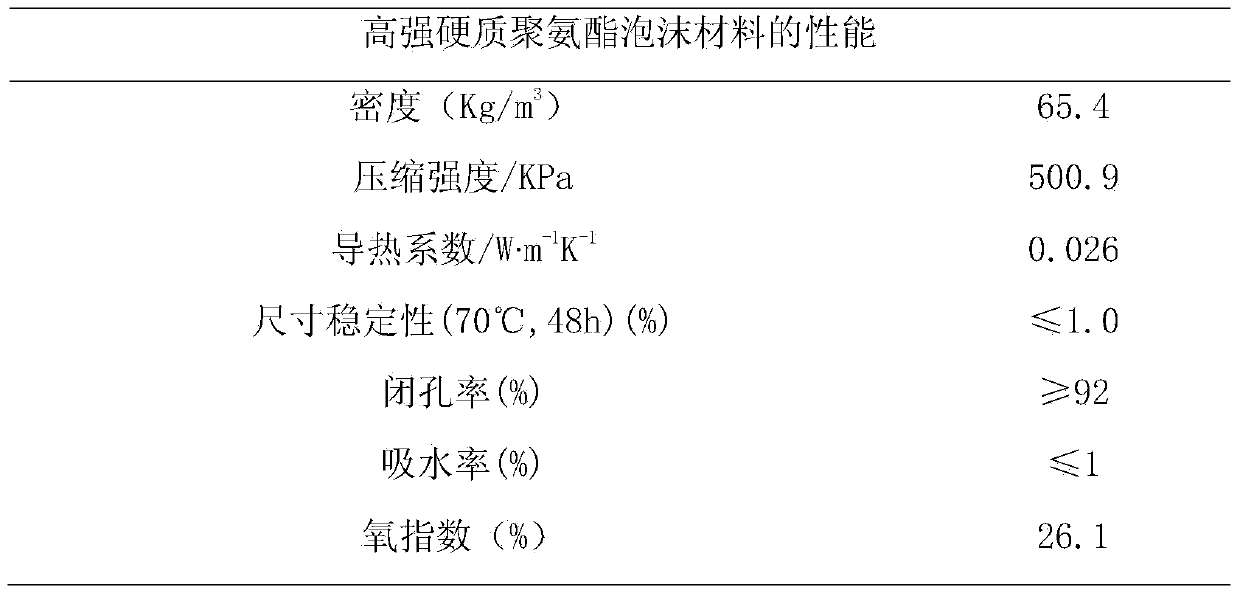

Embodiment 1

[0027] Component A: Accurately weigh 100 parts of polyphenyl polymethylene polyisocyanate PAPI, brand Wannate PM-200, mass fraction of NCO is 30.2-32.0%, viscosity (25°C) is 150-250mPa·s average functionality It is 2.7 (Yantai Wanhua Polyurethane Co., Ltd.).

[0028]Preparation of component B: at a temperature of 25°C, accurately weigh 4.0 parts of foam stabilizer AK-8872, 0.2 parts of triethylenediamine, 0.3 parts of dimethylcyclohexylamine, 0.6 parts of Polycat SA- 1. Add 20.0 parts of HFC-245fa, 6.0 parts of propylene glycol, 3.0 parts of glycerin, 10.0 parts of TCEP and 13.0 parts of DMMP, and accurately weigh 60 parts of polyether polyol U-8345 and 15 parts of polyester polyol Alcohol PS-4027 and 25 parts of flame-retardant polyol Friol-7190 were stirred by a stirrer for 300s at a speed of 120r / min. Among them, polyether polyol U-8345 has a hydroxyl value of 450mgKOH / g and a viscosity (25°C) of 8000mPa s (Shanghai Younot Industrial Co., Ltd.); polyester polyol PS-4027 ha...

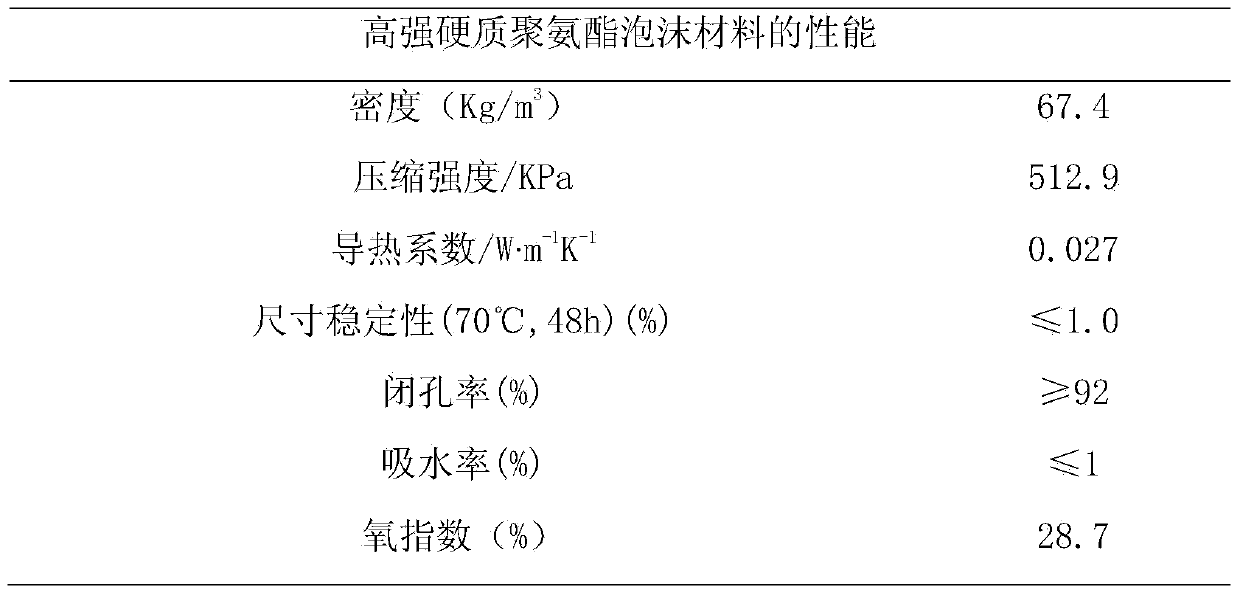

Embodiment 2

[0034] Component A: Accurately weigh 100 parts of polyphenyl polymethylene polyisocyanate PAPI, brand Wannate PM-200, mass fraction of NCO is 30.2-32.0%, viscosity (25°C) is 150-250mPa·s, average functional The degree is 2.7 (Yantai Wanhua Polyurethane Co., Ltd.).

[0035] Preparation of component B: at a temperature of 25°C, accurately weigh 4.0 parts of foam stabilizer AK-8872, 0.2 parts of triethylenediamine, 0.3 parts of dimethylcyclohexylamine, 1.0 parts of Polycat SA- 1. Add 20.0 parts of HFC-245fa, 6.0 parts of propylene glycol, 4.0 parts of glycerin, 15.0 parts of TCEP and 20.0 parts of DMMP, and accurately weigh 40 parts of polyether polyol U-8345 and 15 parts of polyester polyol Alcohol PS-4027 and 45 parts of flame-retardant polyol Friol-7190 were stirred by a stirrer for 300s at a speed of 120r / min. Among them, polyether polyol U-8345 has a hydroxyl value of 450mgKOH / g and a viscosity (25°C) of 8000mPa s (Shanghai Younot Industrial Co., Ltd.); polyester polyol PS-...

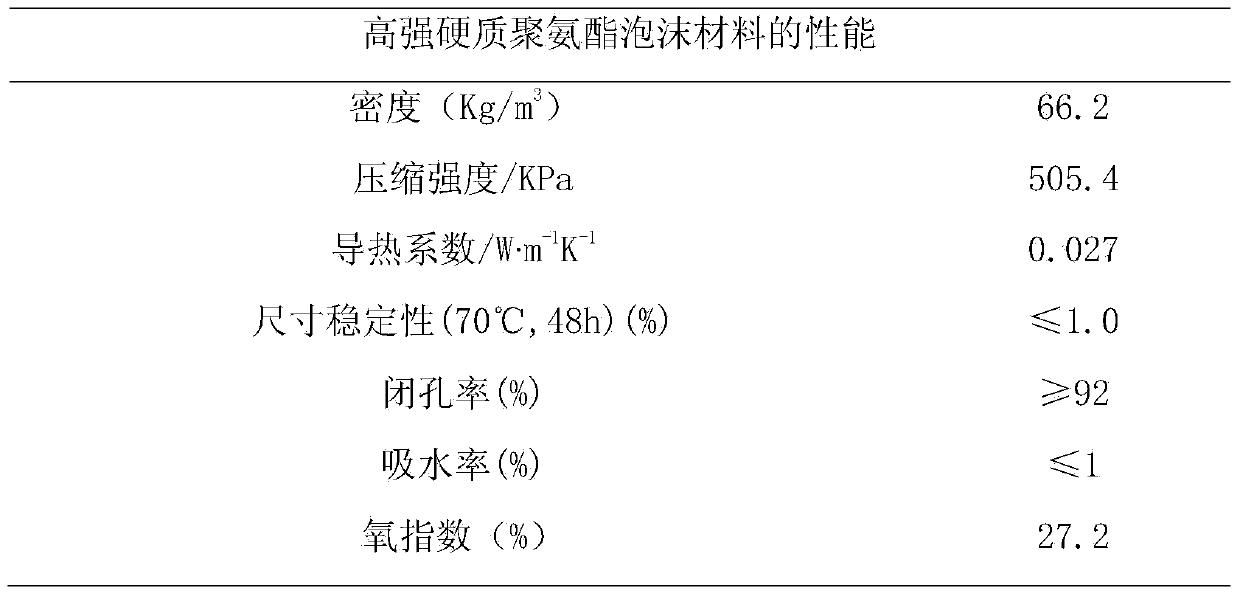

Embodiment 3

[0041] Component A: Accurately weigh 100 parts of polyphenyl polymethylene polyisocyanate PAPI, brand Wannate PM-200, mass fraction of NCO is 30.2-32.0%, viscosity (25°C) is 150-250mPa·s, average functional The degree is 2.7 (Yantai Wanhua Polyurethane Co., Ltd.).

[0042] Component B includes 30-80 parts of polyester polyol, 10-30 parts of polyether polyol, 20-50 parts of flame-retardant polyol, 4-5 parts of foam stabilizer, 0.5-2 parts of catalyst, 8-2 parts of foaming agent 30 parts, chain extender 2-8 parts, cross-linking agent 1-4 parts and flame retardant 10-30 parts.

[0043] Preparation of component B: at a temperature of 25°C, accurately weigh 5.0 parts of foam stabilizer AK-8872, 0.1 parts of triethylenediamine, 0.1 parts of dimethylcyclohexylamine, 0.5 parts of Polycat SA- 1. Add 10.0 parts of HFC-245fa, 3.0 parts of propylene glycol, 2.0 parts of glycerin, 10.0 parts of TCPP and 2.0 parts of TDCPP, and accurately weigh 50 parts of polyether polyol SC-4110 and 24 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com