Patents

Literature

41results about How to "Small cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

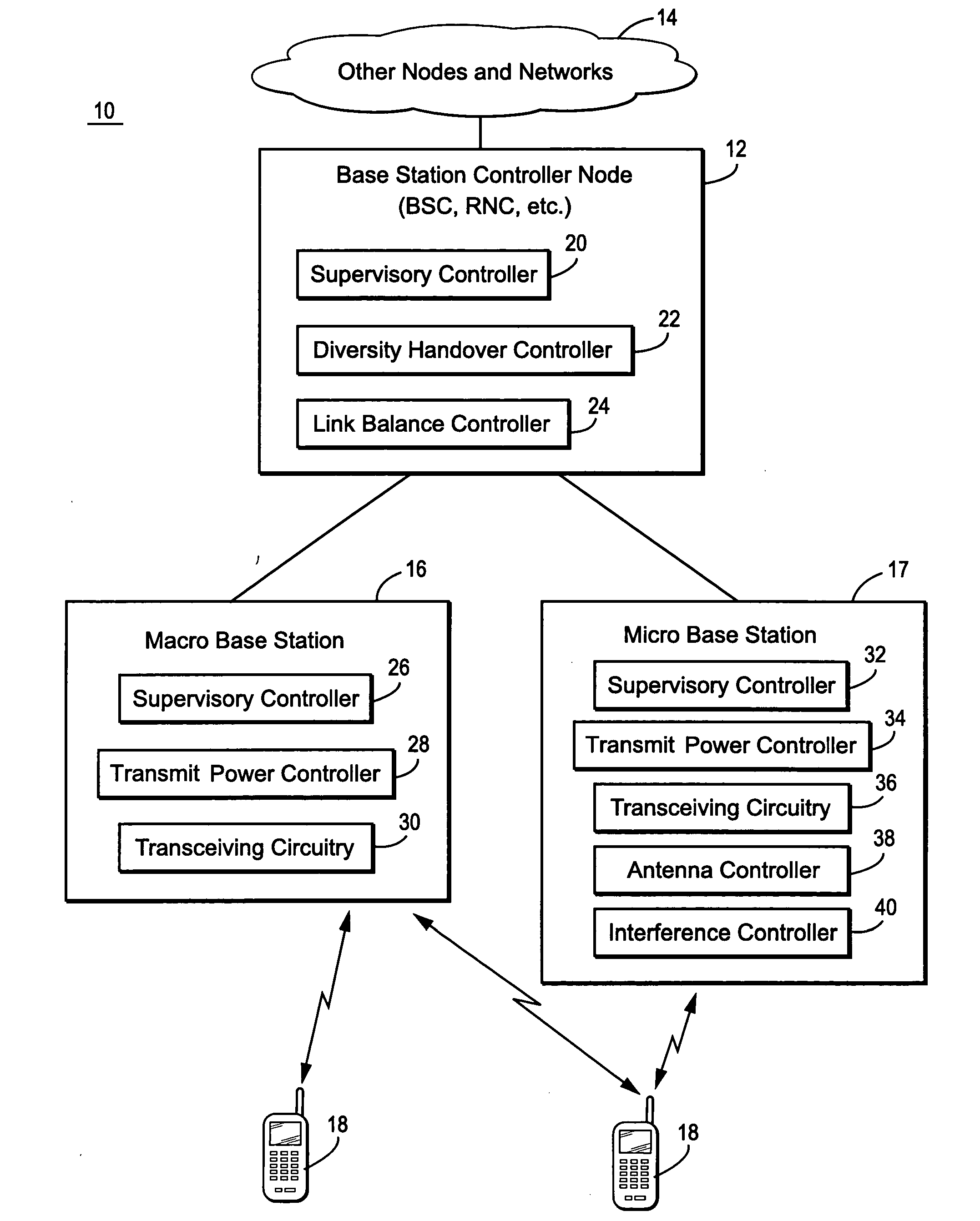

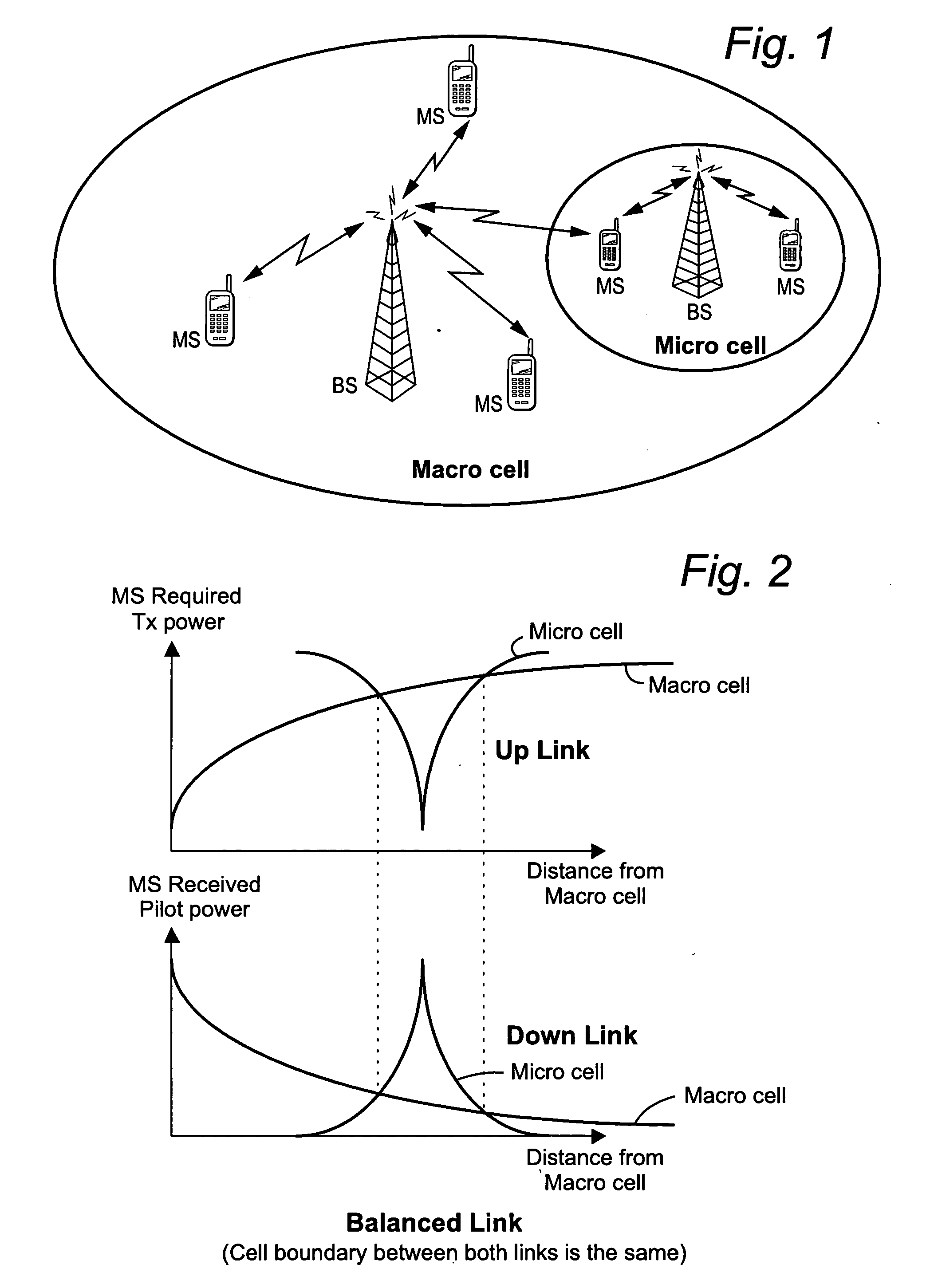

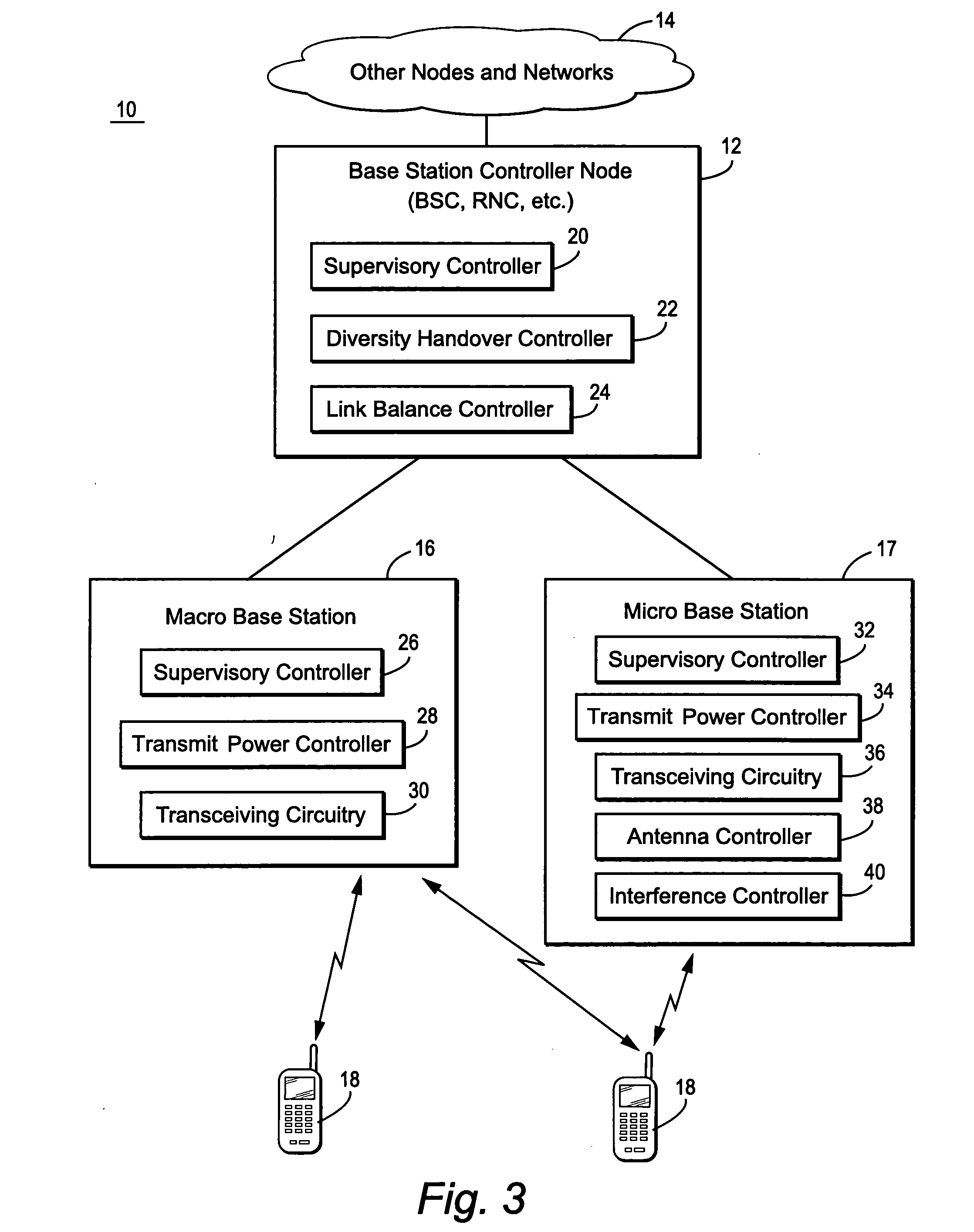

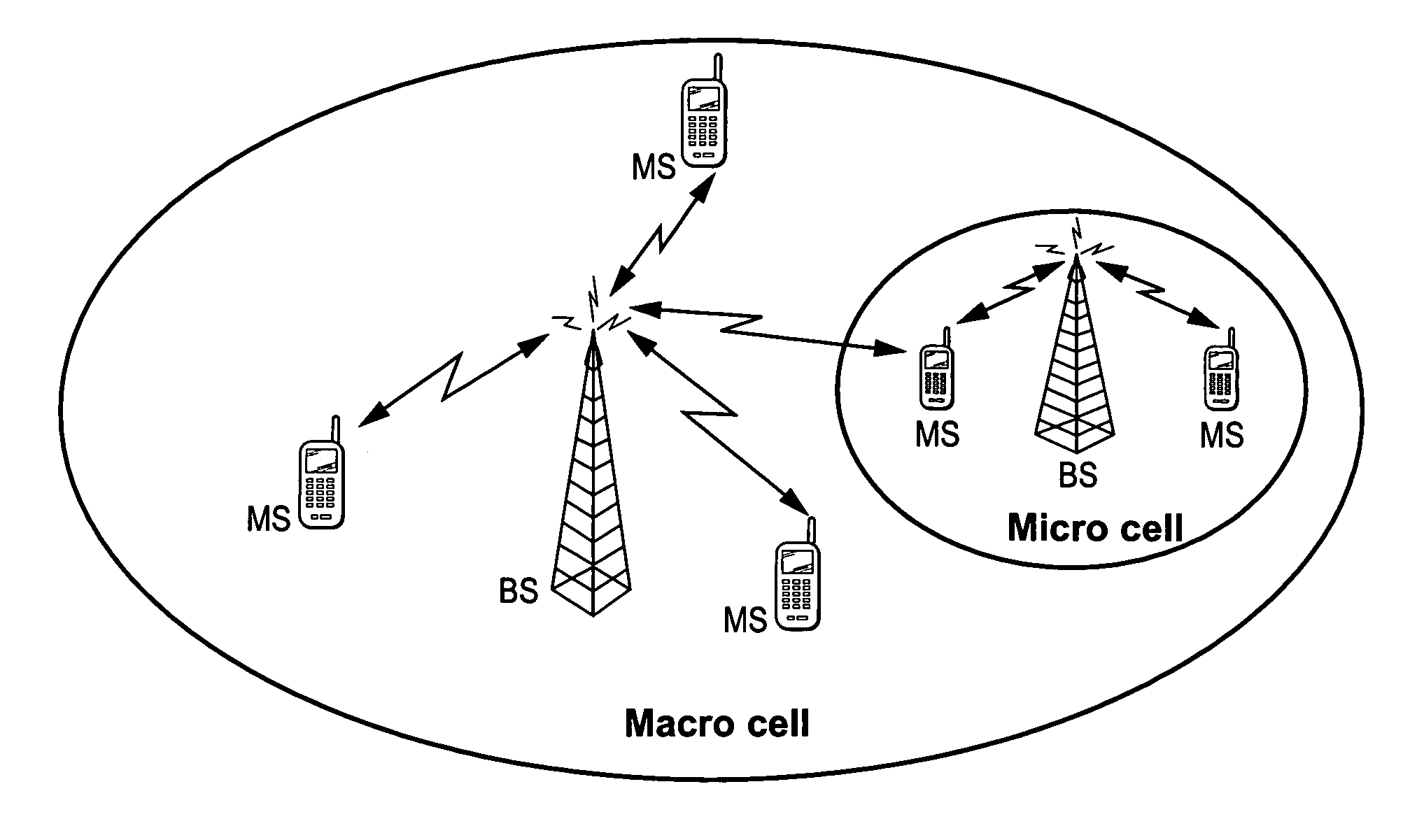

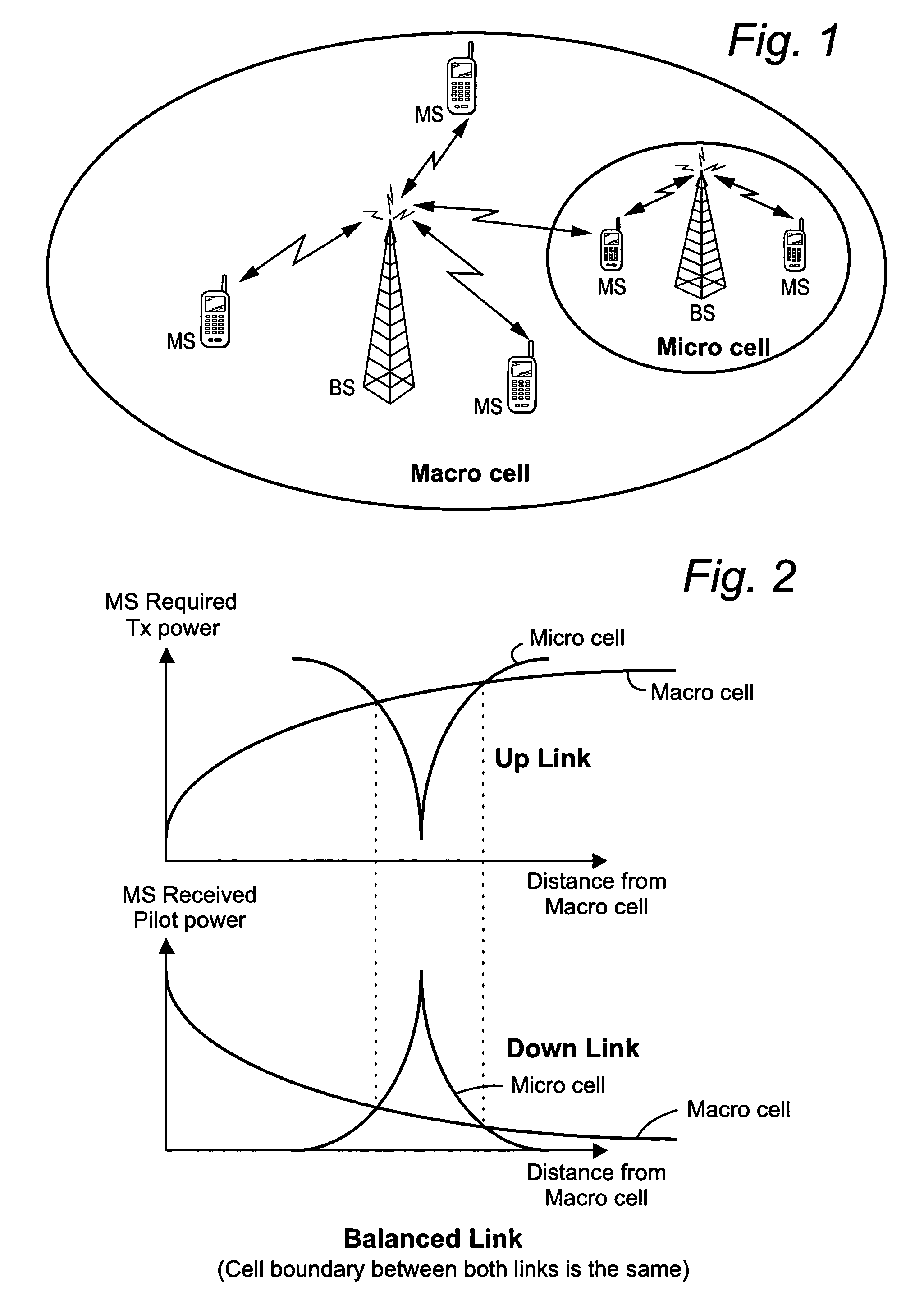

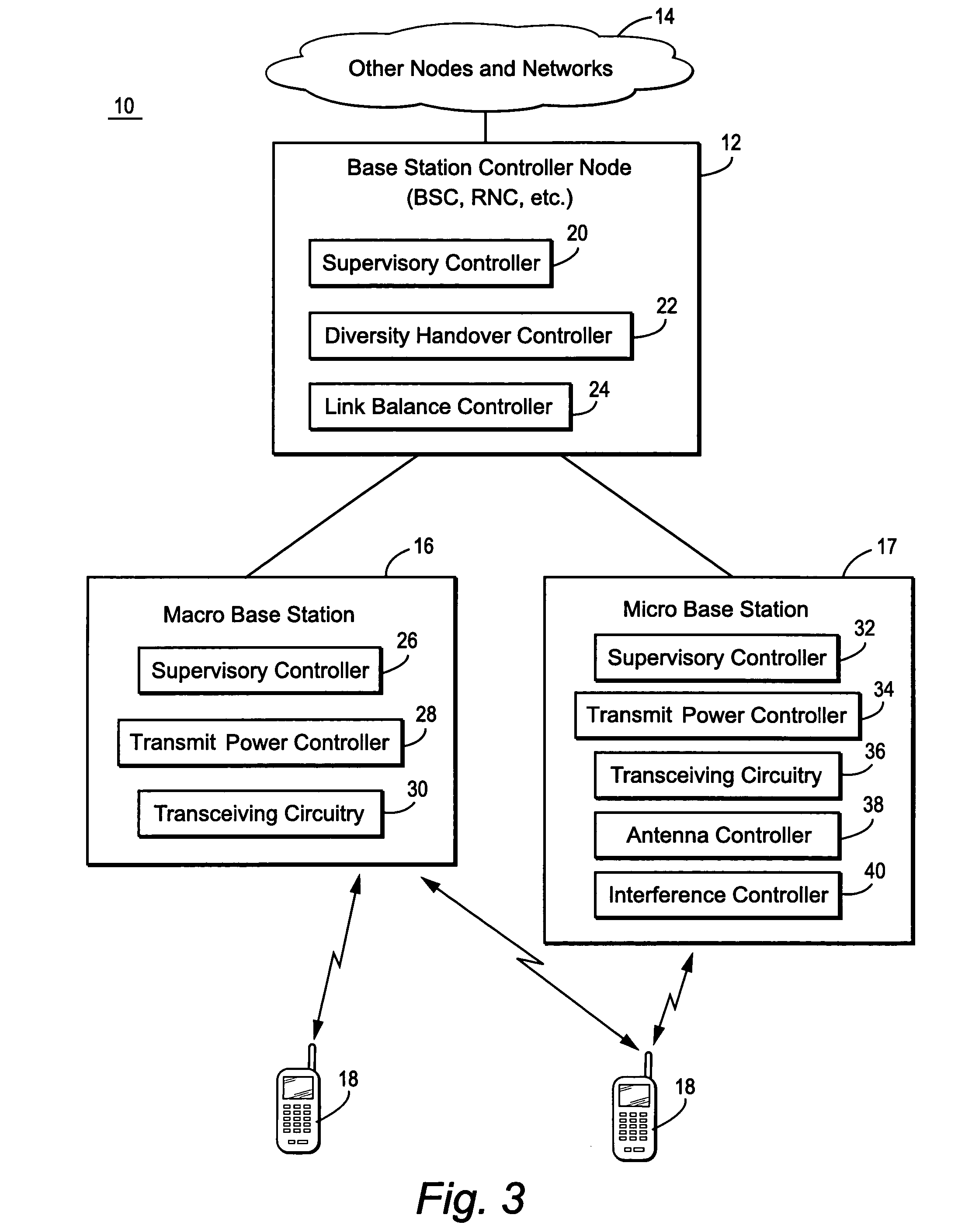

Mobile communications in a hierarchical cell structure

InactiveUS20050130662A1Prevent handoverIncrease speedCode division multiplexRadio/inductive link selection arrangementsRadio networksFrequency band

A hierarchical cell structure (HCS) cellular communications system includes a macro cell encompassing a smaller micro cell that employ the same frequency band. The macro cell includes a macro cell base station, and the micro cell includes a micro cell base station. An uplink communication cell boundary between the macro cell and the micro cell is established, and a downlink communication cell boundary between the macro cell and the micro cell is established. A radio network controller determines whether a condition exists in the HCS system which indicates that the uplink and downlink micro cell boundaries should be unbalanced. If the condition is met or exists, the power and / or antenna beam tilt of a downlink transmission from the micro cell base station is reduced to unbalance the uplink and downlink micro cell boundaries. Alternatively, the radio network controller may employ an offset value to mathematically reduce mobile detected pilot power levels associated with the micro base station.

Owner:TELEFON AB LM ERICSSON (PUBL)

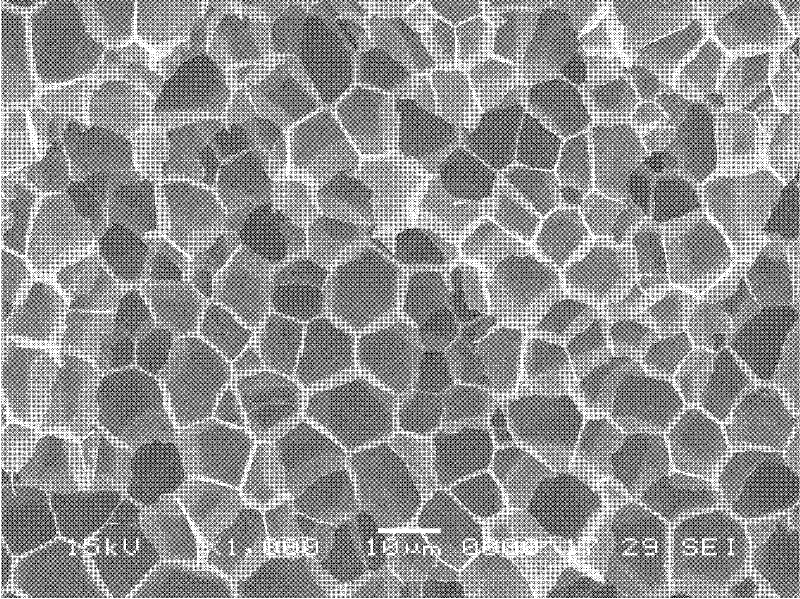

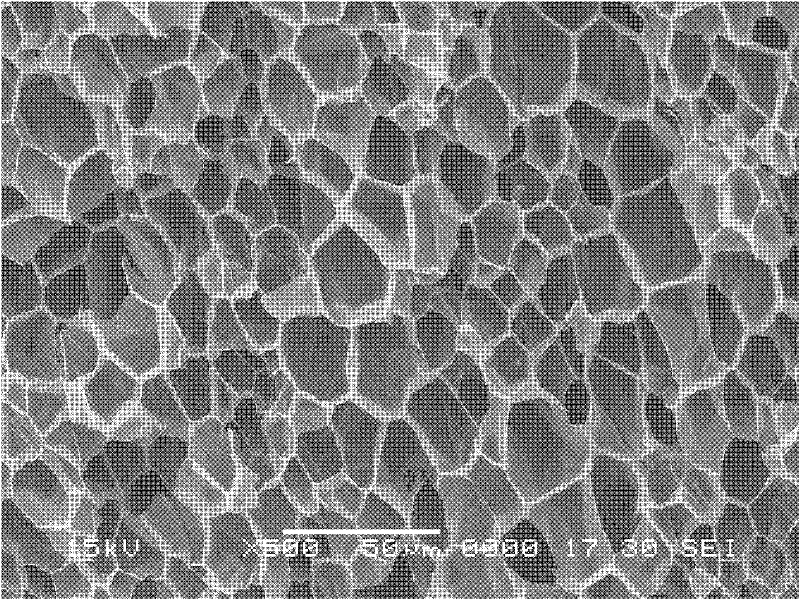

Method for preparing polymer microporous foaming material by supercritical mould foaming

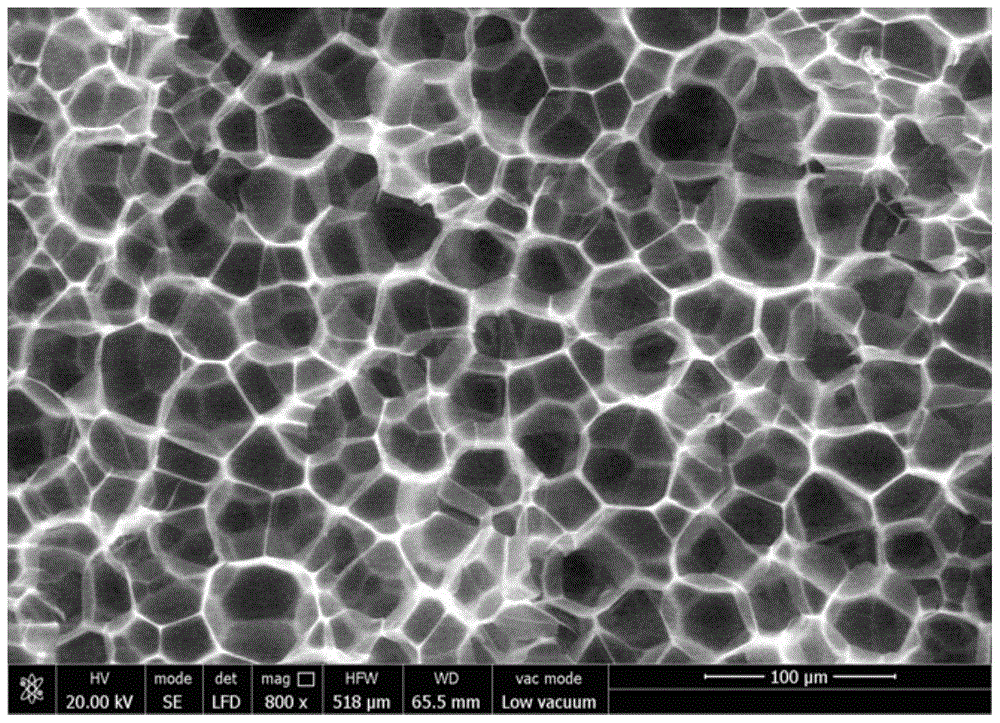

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:常州福源科技新材料有限公司

Mobile communications in a hierarchical cell structure

InactiveUS7142861B2Long talk timeIncrease capacityCode division multiplexRadio/inductive link selection arrangementsRadio networksCommunications system

A hierarchical cell structure (HCS) cellular communications system includes a macro cell encompassing a smaller micro cell that employ the same frequency band. The macro cell includes a macro cell base station, and the micro cell includes a micro cell base station. An uplink communication cell boundary between the macro cell and the micro cell is established, and a downlink communication cell boundary between the macro cell and the micro cell is established. A radio network controller determines whether a condition exists in the HCS system which indicates that the uplink and downlink micro cell boundaries should be unbalanced. If the condition is met or exists, the power and / or antenna beam tilt of a downlink transmission from the micro cell base station is reduced to unbalance the uplink and downlink micro cell boundaries. Alternatively, the radio network controller may employ an offset value to mathematically reduce mobile detected pilot power levels associated with the micro base station.

Owner:TELEFON AB LM ERICSSON (PUBL)

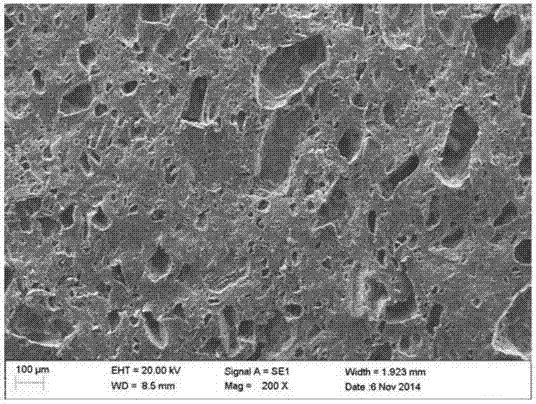

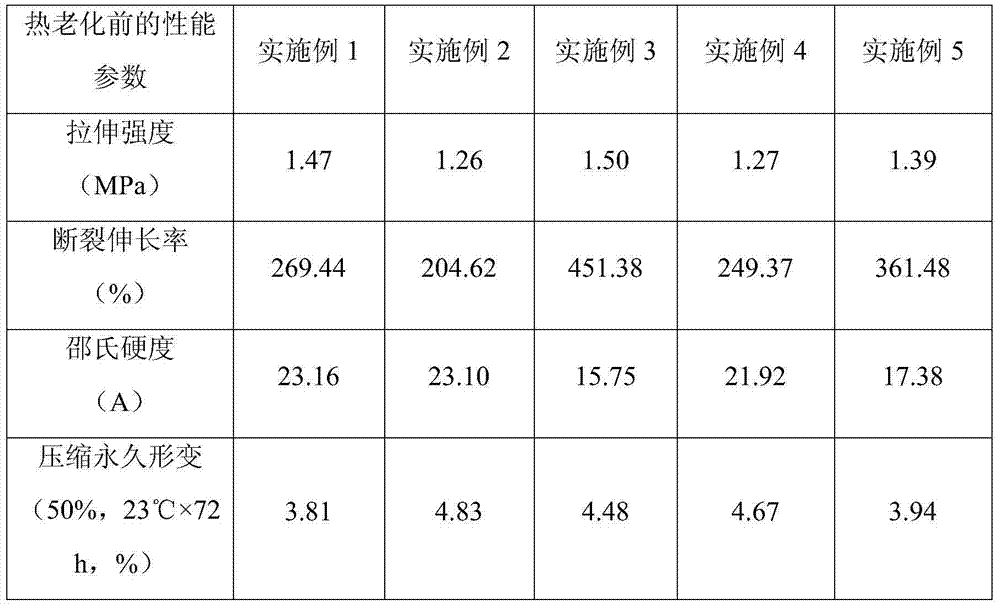

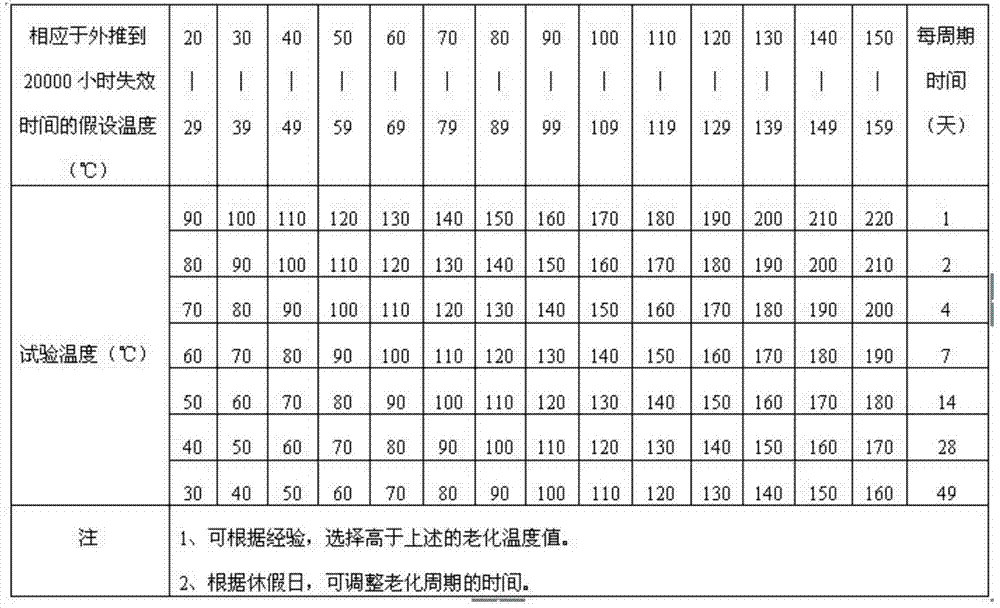

High-temperature-resistant silicone rubber foam material and preparation method thereof

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Micro-foaming polypropylene composite material and preparation method thereof

The invention discloses a micro-foaming polypropylene composite material and a preparation method thereof. The micro-foaming polypropylene composite material is composed of the following components by weight: 100 parts of polypropylene, 40 to 60 parts of bamboo powder, 10 to 15 parts of foaming agent, 1 to 5 parts of foaming assistant, 1 to 5 parts of antioxygen, 1 to 3 parts of nucleating agent and 5 to 10 parts of compatilizer. The micro-foaming polypropylene composite material is wide in raw material resource, low in cost, simple to operate and wide in application prospect. The micro-foaming polypropylene composite material which has small bubble holes, is even, compact, light in weight, good in impact performance and environment-friendly.

Owner:常熟市威腾进出口有限公司

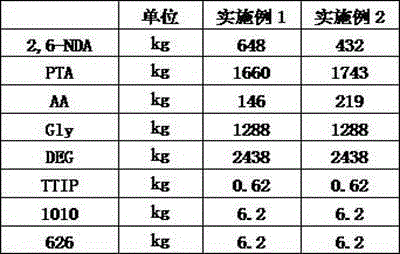

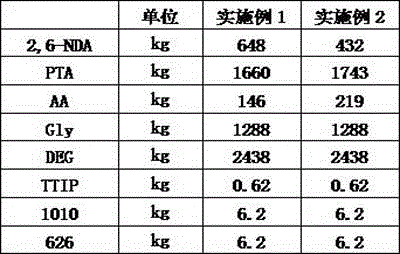

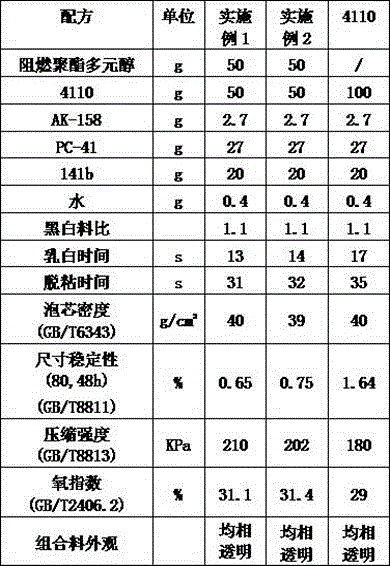

Novel aromatic high-fire-retardant polyester polyol as well as preparation method and application thereof

InactiveCN104448272AImprove flame retardant performanceImprove mechanical propertiesPolyesterPorosity

The invention discloses a novel aromatic high-fire-retardant polyester polyol as well as a preparation method and an application thereof. The novel aromatic high-fire-retardant polyester polyol is applied to a fire-retardant polyurethane material, and is applied to the field of building heat preservation. The novel aromatic high fire-retardant polyester polyol is obtained by esterification reaction of naphthalene-based aromatic dibasic acid, binary acid and small molecular alcohol or acid under the action of a catalyst and an antioxidant; the mass ratio of naphthalene-based aromatic dibasic acid to binary acid to the small molecular alcohol or acid is (0.7-1.5) to (2.8-4.6) to (5.7-8.6); the average functional group degree is 2; the acid value is smaller than 1mgKOH / g; the average hydroxyl value is 400-660mgKOH / g; the average molecular weight is 170-300g / mol; and the viscosity is 2500-4500mPa.s. The polyester polyol disclosed by the invention has high flame retardant property and excellent mechanical property; the polyurethane foam prepared by the method has thermal stability, good activity and good fire-retardant property, and also has good physical properties such as compression strength, closed porosity, abrasive resistance, ageing resistance and heat resistance. The novel aromatic high-fire-retardant polyester polyol is simple in synthesis process, is good in compatibility with other polyesters and polyester polyol; and the rigid polyurethane foam prepared by the novel aromatic high fire-retardant polyester polyol has relatively good heat resistance and fire resistance, and is applied to the field of building heat preservation.

Owner:滕州市科米特新材料有限责任公司

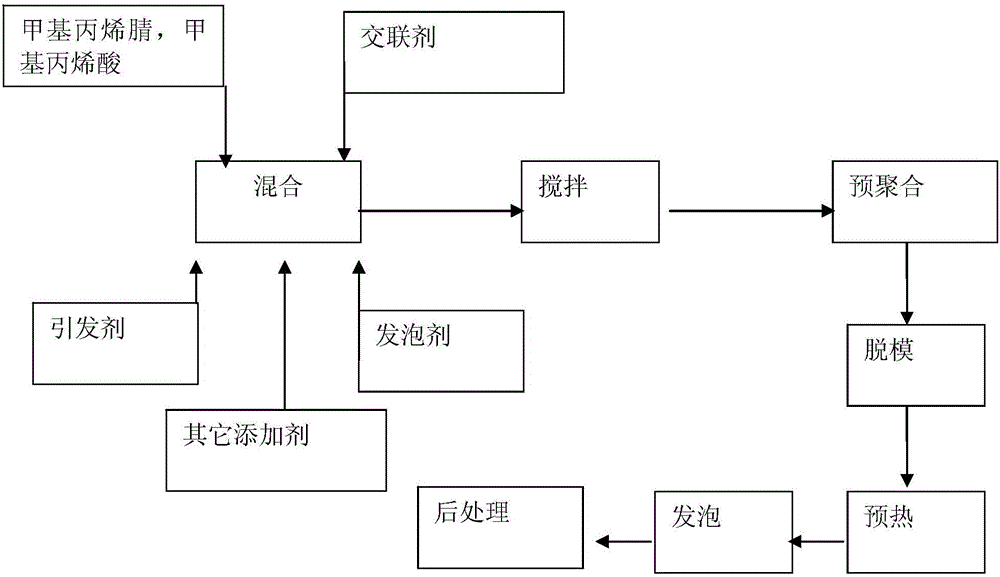

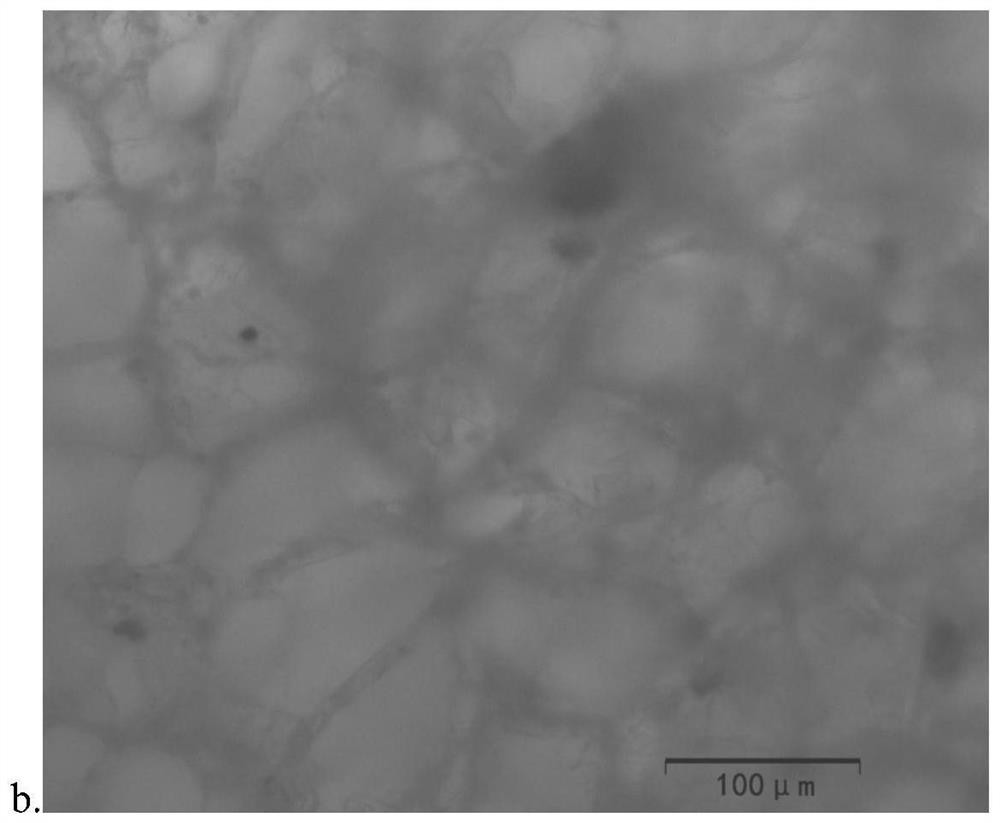

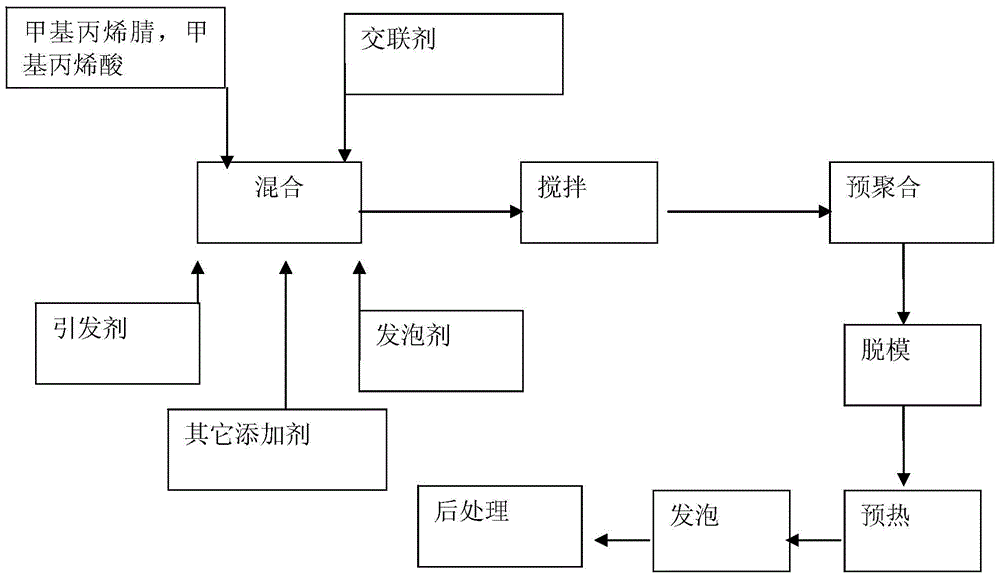

Micropore polymethacrylimide foam with high thermal deformation temperature and preparing method thereof

ActiveCN105037618AImprove heat resistanceHigh heat distortion temperatureCross-linkHeat deflection temperature

The invention relates to micropore polymethacrylimide foam with high thermal deformation temperature. The foam comprises, by mass, 35-60 parts of methacrylic acid (MAA), 65-40 parts of acrylonitrile, 0.10-4.0 parts of initiators, 1.0-20 parts of foaming agents, 1-5 parts of nucleating agents, 0.1-5 parts of cross-linking agents and 5-10 parts of heat-resisting additives; the initiators are azo-bis(4-cyano valeric acid) or mixtures of azo-bis(4-cyano valeric acid) and other azo compounds. The other azo compounds are azodiisobutyronitrile AIBN, azobisisovaleronitrile or azobisisoheptonitrile. According to the micropore polymethacrylimide foam high in thermal deformation temperature, the foam has the small pore diameter phi of 0.1-0.3 mm, thermal resistance is high, the thermal deformation temperature is high and is larger than 200 DEG C, and the mechanical property is excellent.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

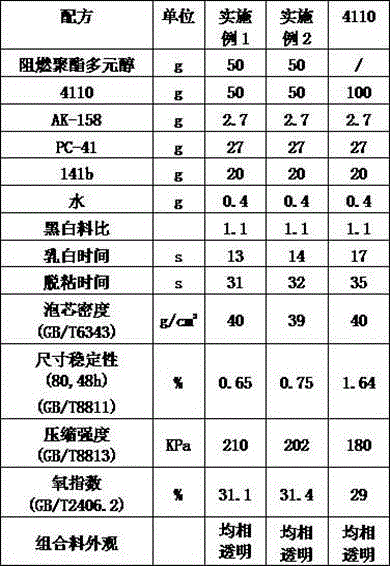

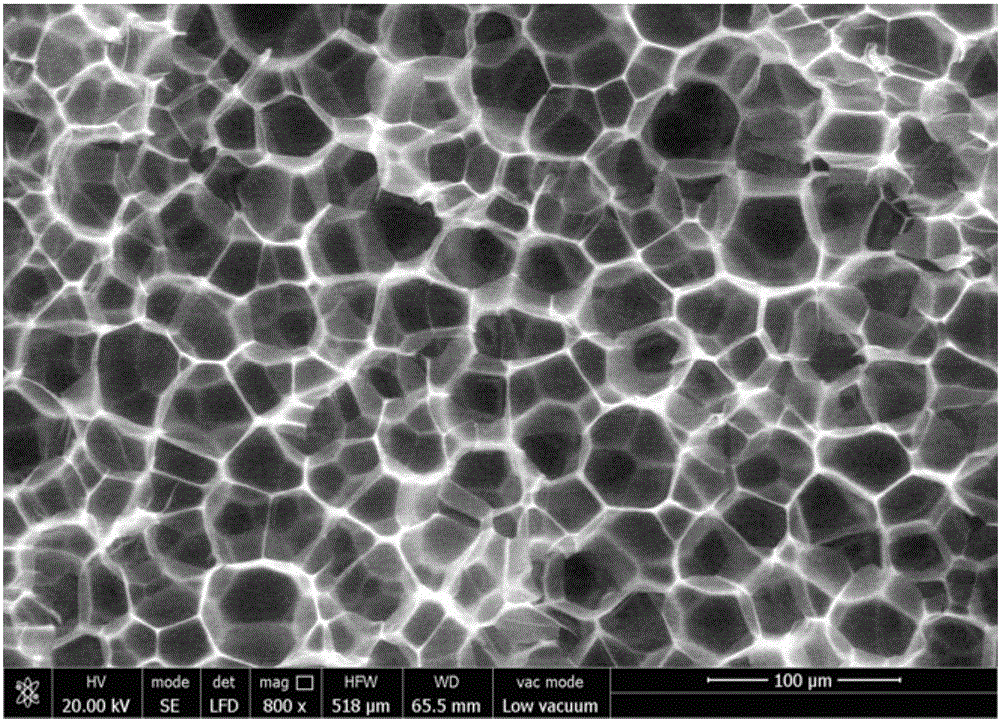

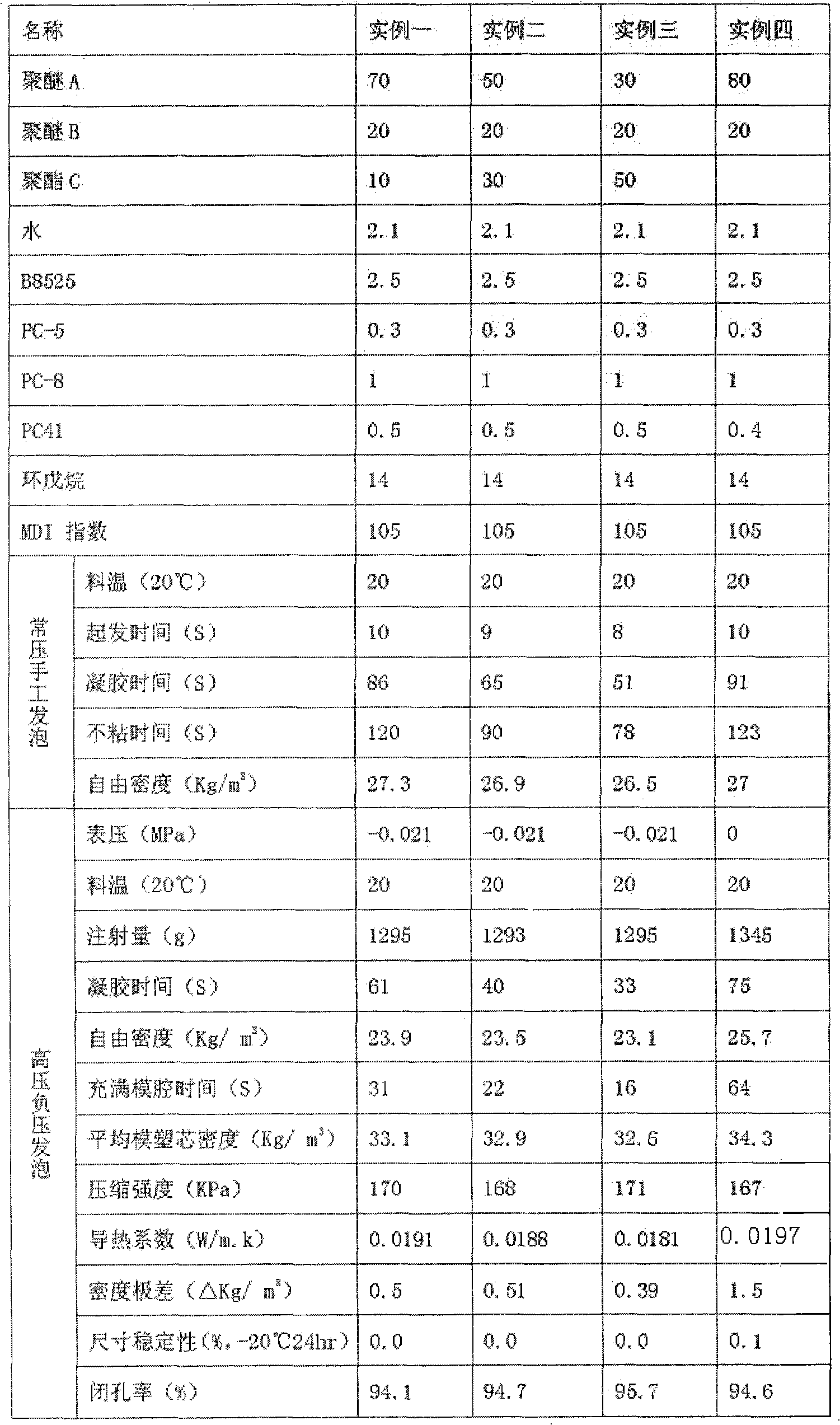

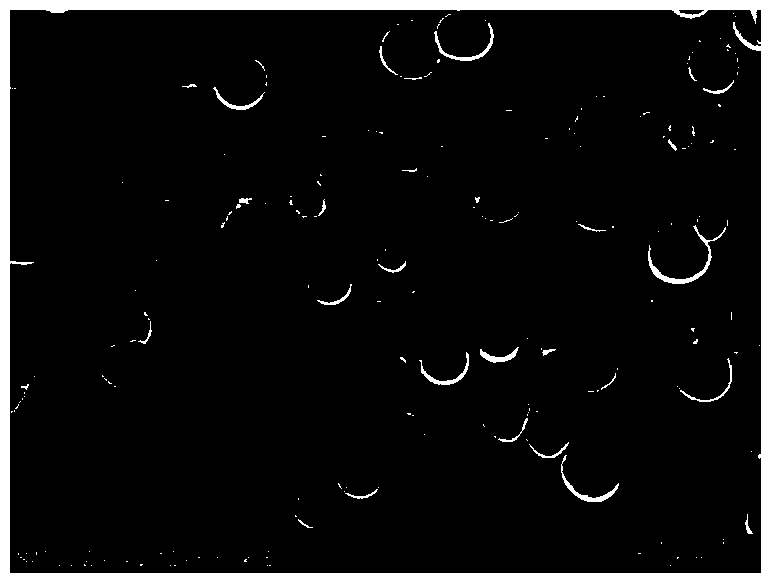

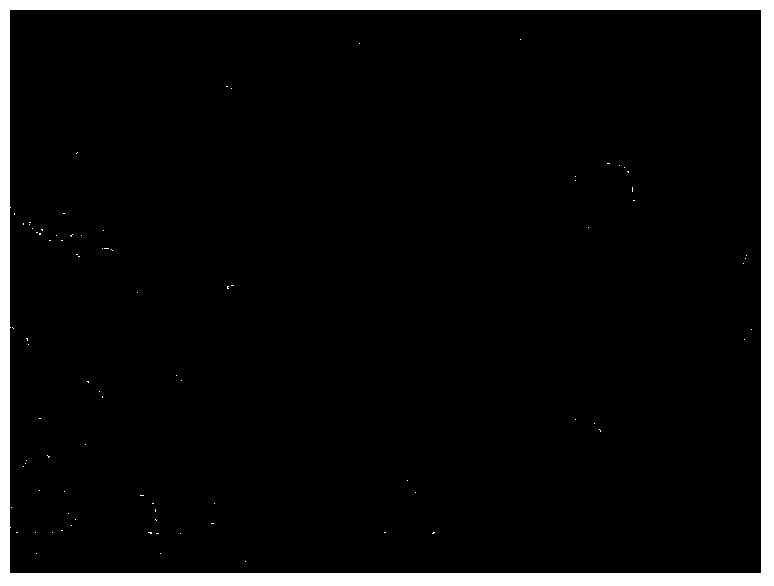

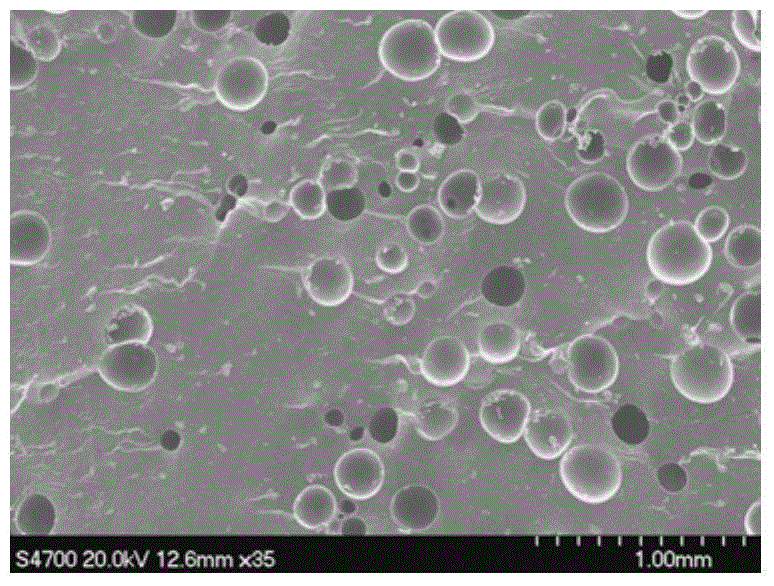

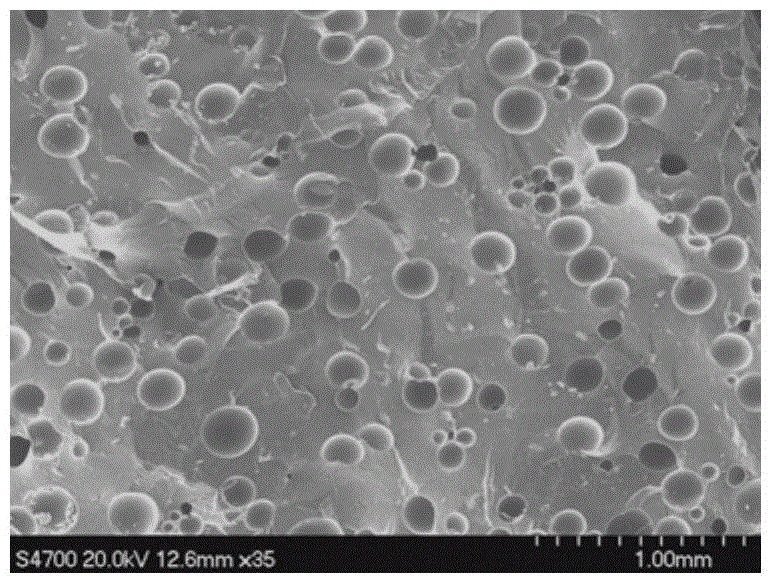

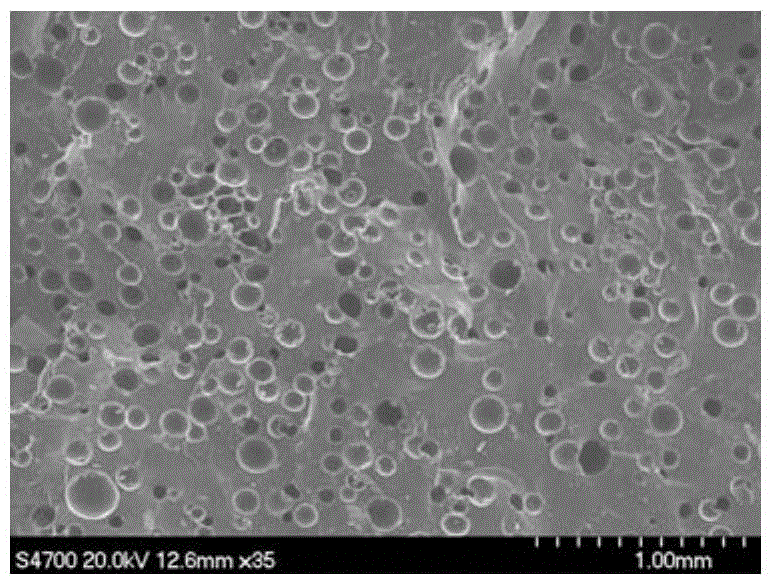

Hard polyurethane molding foam negative pressure foaming raw material formula and hard polyurethane molding foam negative pressure foaming production method

The invention relates to a formula of a hard polyurethane molding foam negative pressure foaming raw material, wherein the raw material is prepared by mixing polyether polyol, a polyester polyol, a foam stabilizer, a catalyst and water, and a weight ratio of the polyether polyol to the polyester polyol to the foam stabilizer to the catalyst to the water is 50-90:10-50:2-3:2-3:1-2.5. The hard polyurethane molding foam negative pressure foaming production method comprises carrying out hard polyurethane foaming under a state with a negative pressure of 0 to -0.025 MPa, wherein polyurethane foaming is performed under the negative pressure state so as to reduce polyurethane raw material requirements. In addition, a high functionality polyester polyol can be adopted as a main polyol to prepare a combination polyether so as to carry out foaming, such that a mold cavity can be filled in a short time, and the prepared foam has characteristics of thin cell, high strength and good size stability.

Owner:绍兴广佳庄鑫建材制造有限公司

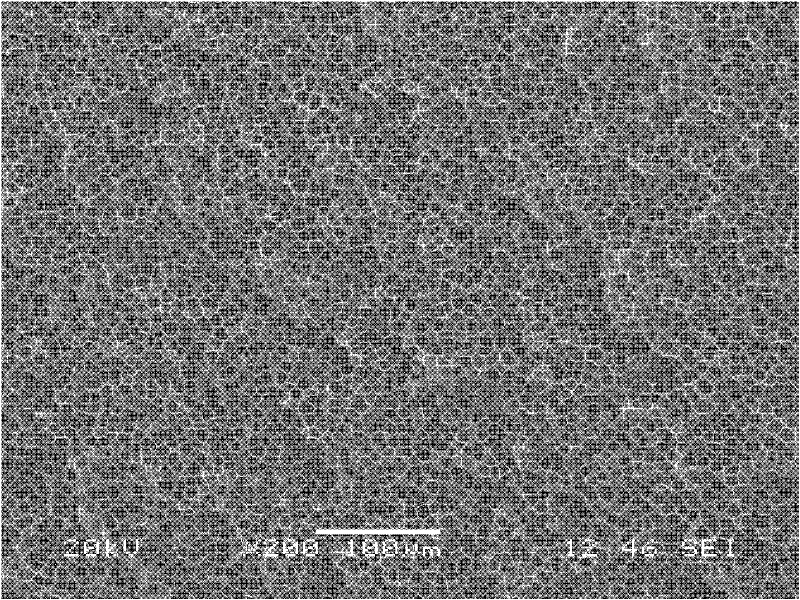

Nano composite foaming agent and preparation method and foamed product thereof

The invention relates to a nano composite foaming agent and a preparation method and a foamed product thereof. The foaming agent is compounded from layered montmorillonite and 4,4-oxo-bis hydrazide, wherein the mass ratio of the 4,4-oxo-bis hydrazide to the montmorillonite is 1:(4-16). The composite foaming agent is obtained by a method of recombining and compounding the layered montmorillonite with the 4,4-oxo-bis hydrazide after stripping in preparation of the foaming agent. The foaming agent has the advantages that an organic foaming agent is embedded between nanoscale montmorillonite layers, so that the foaming agent is refined, the dosage of the foaming agent is effectively controlled, a nucleating point is increased, the foaming efficiency is improved, formed bubbles are even and small in holes, and meanwhile, the property of the obtained foamed product is also improved to a certain extent by adding of an inorganic material.

Owner:BEIJING UNIV OF CHEM TECH

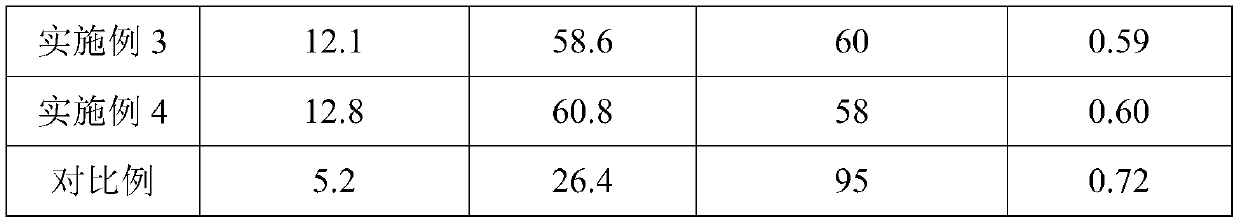

Method for preparing polymer microporous foaming material by supercritical mould foaming

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:SHINCELL NEW MATERIAL CO LTD

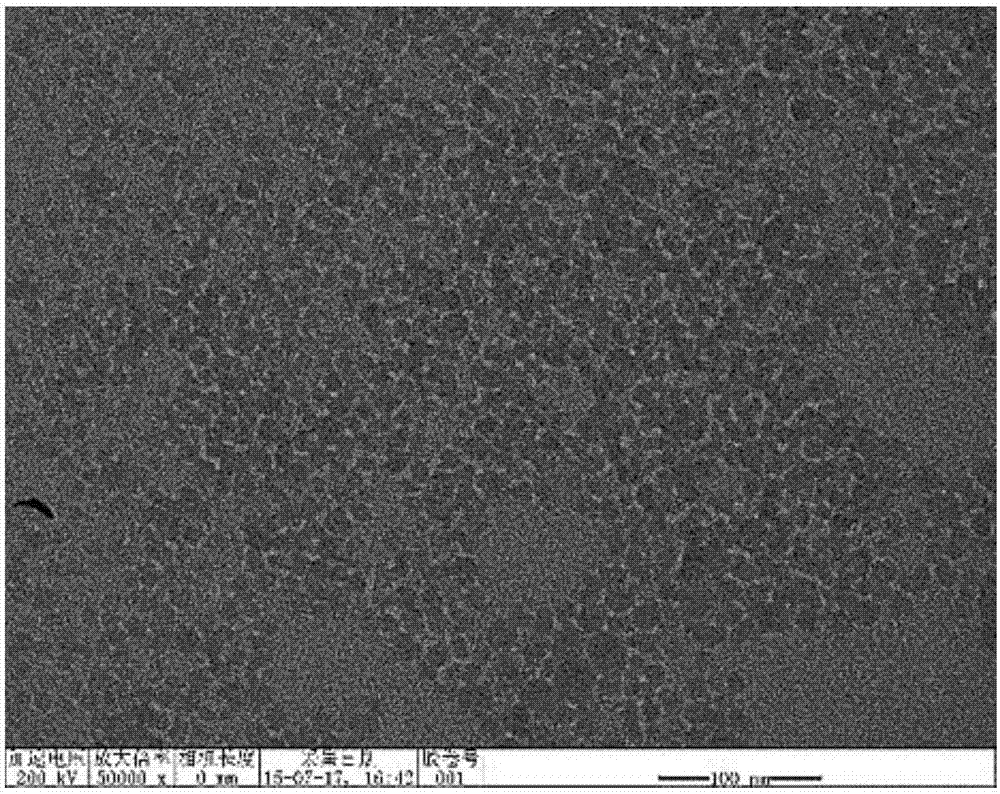

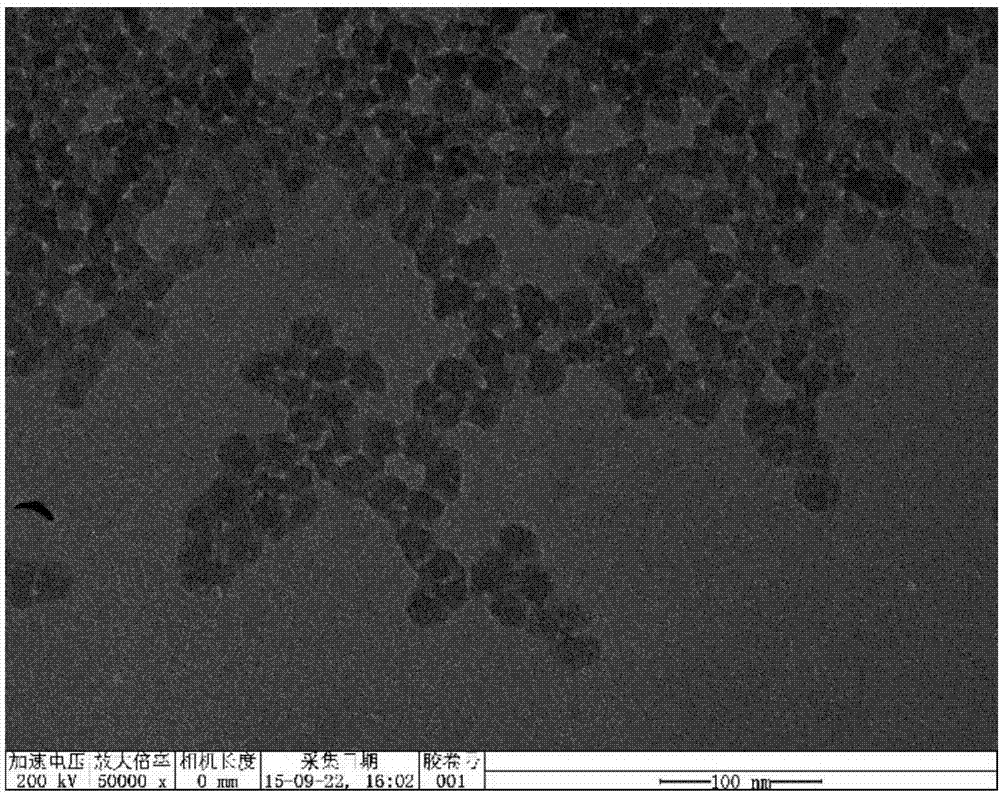

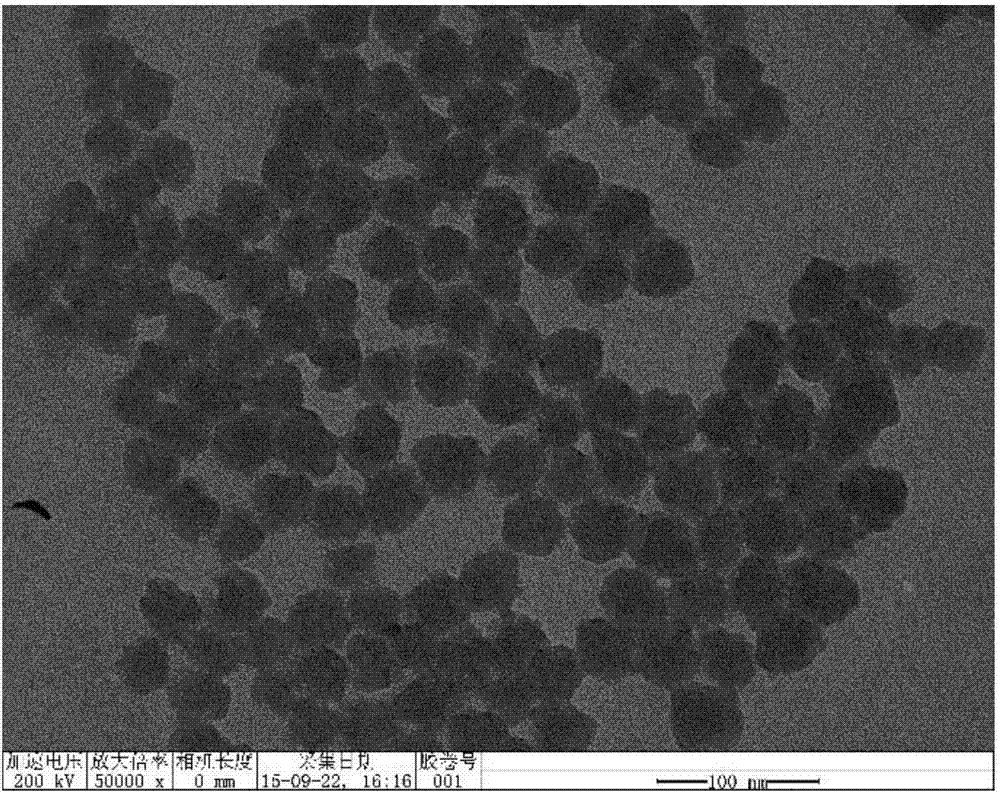

Preparation method of monodispersed mesoporous silica, and nano-composite foaming agent as well as preparation method and application thereof

The invention provides a preparation method of monodispersed mesoporous silica, and a nano-composite foaming agent as well as a preparation method and application thereof. The preparation method of the monodispersed mesoporous silica comprises the steps of preparing silica sol by taking monatomic silicon powder as a silicon source, adjusting the particle sizes of the silica sol by supplementing silica powder and a sodium hydroxide solution, synthesizing the silica sol into urea formaldehyde resin / SiO2 composite microspheres by using a polymerization-induced colloid aggregation method, and calcining to obtain the monodispersed mesoporous silica. The nano-composite foaming agent is prepared by compounding the monodispersed mesoporous silica and azodicarbonamide. The composite foaming agent prepared by the method not only is small in particle size, and is high in loading amount of a chemical foaming agent, thus being used for preparing microcellular foam plastics with better foaming quality and having wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

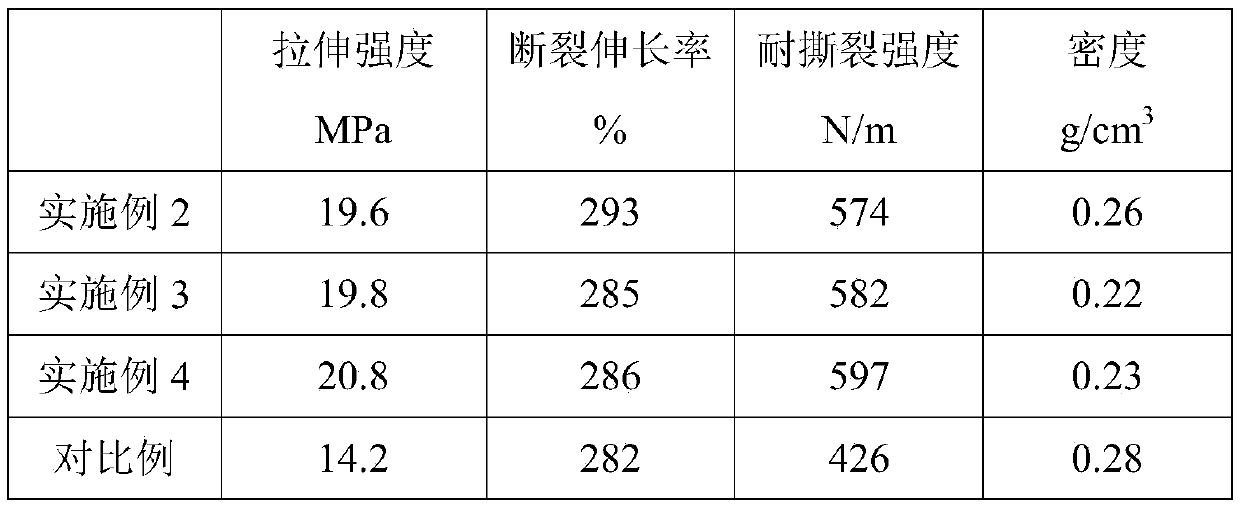

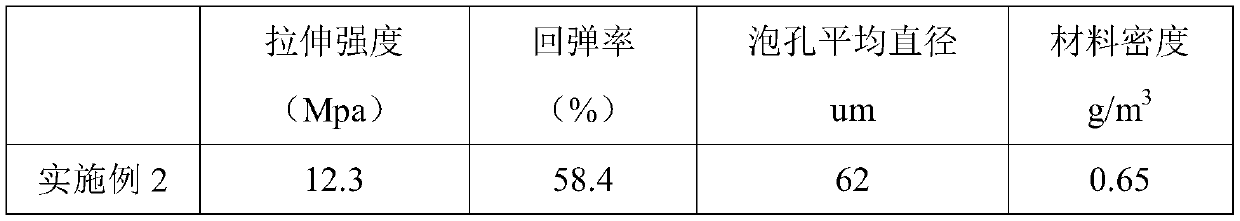

TPU/EVA supercritical foam composite material and preparation method thereof

InactiveCN110724375AGood foaming effectGood foaming efficiencyPolymer scienceThermoplastic polyurethane

The invention discloses a TPU / EVA supercritical foam composite material and a preparation method thereof. The TPU / EVA supercritical foam composite material is prepared from, by weight, 300-360 parts of a thermoplastic polyurethane elastomer, 66-73 parts of an ethylene-vinyl acetate copolymer, 25-33 parts of a maleic anhydride grafting modifier, 9-14 parts of peroxide and 1.2-1.6 parts of a nucleating agent. The TPU / EVA supercritical foam composite material has the advantages of good foaming effect, high foaming efficiency, uniform, small and dense cells, excellent mechanical properties and useproperties such as light weight and high strength, high tensile strength, large elongation at break, good mechanical properties, high tear strength, good tear resistance and low density.

Owner:福建安达福新材料科技有限公司

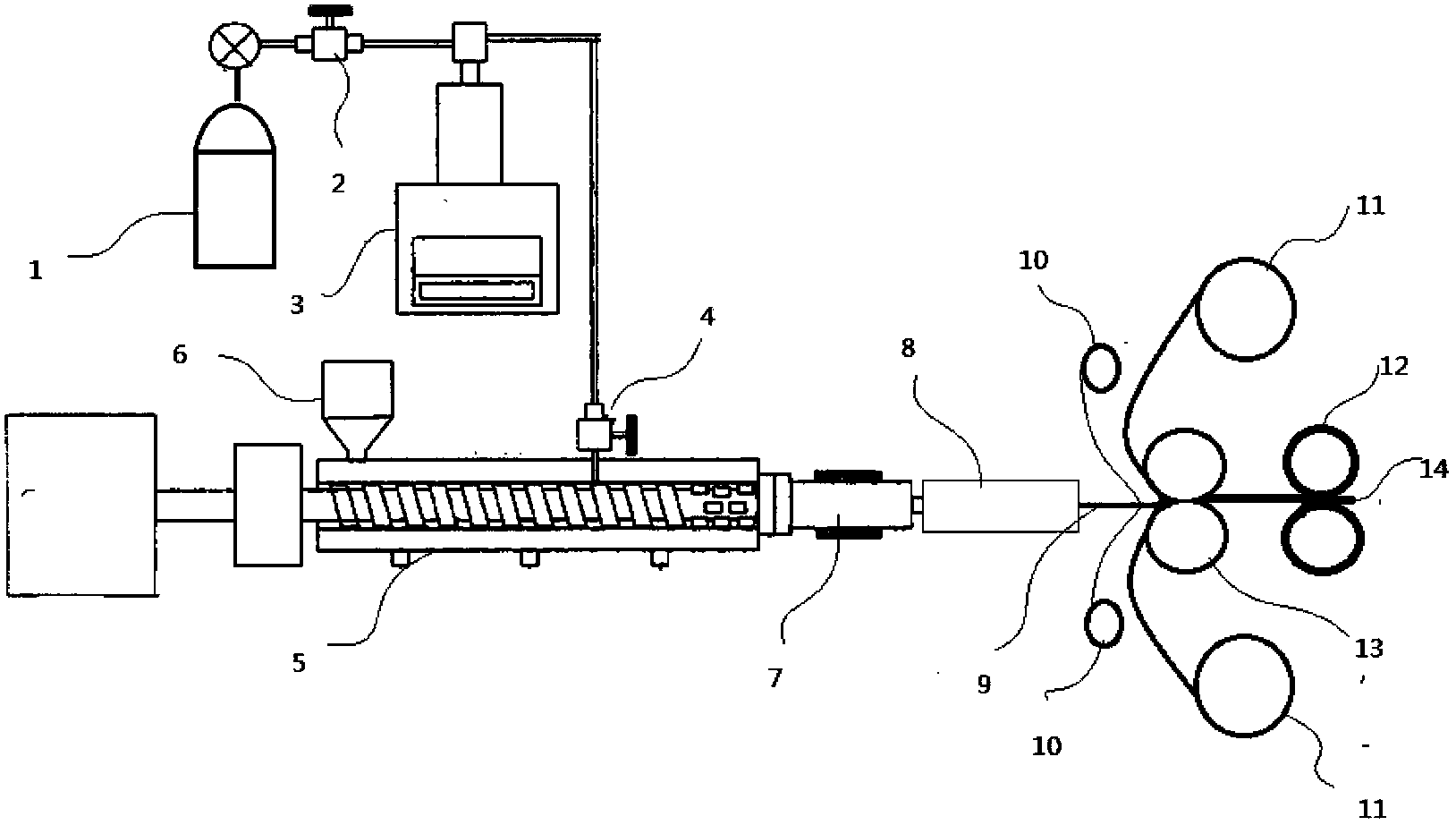

Polypropylene injection molding chemical micro-foamed composite material and preparation method thereof

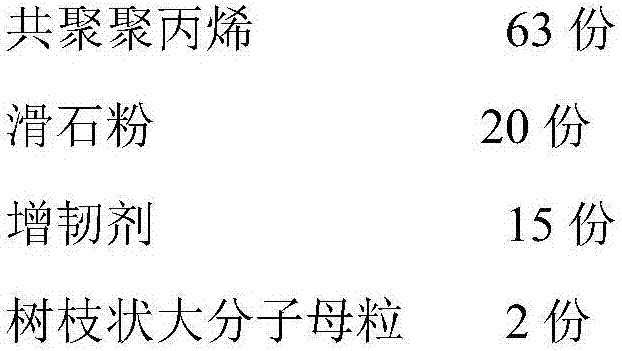

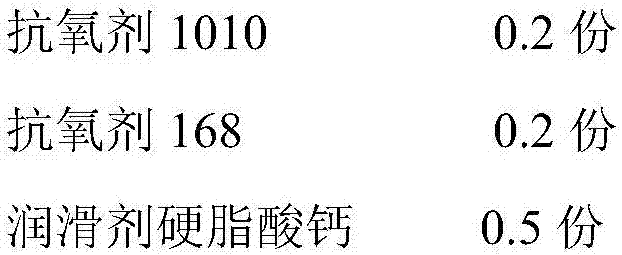

The invention provides a preparation method of a polypropylene injection molding chemical micro-foamed composite material. The polypropylene micro-foamed composite material is prepared by uniformly mixing a polypropylene composite material and a foaming agent and molding an obtained mixture by adopting a secondary mold opening process, wherein the polypropylene composite material is prepared from the following materials in parts by weight: 57 to 63 parts of polypropylene, 0.1 to 25 parts of talcum powder, 0.1 to 20 parts of flexibilizer, 2 to 10 parts of dendritic macromolecule master batch, 0.2 to 0.4 part of antioxidant, 0.5 to 1 part of lubricating agent, and 0 to 3 parts of other additives, wherein the chemical foaming agent is sodium hydrogen carbonate master batch of LDPE carriers. Melt strength of the polypropylene composite system is mutually entangled and regulated with a matrix by virtue of the special dendritic structure of the dendritic macromolecule, after the foaming, a core layer presents in an obvious sandwiched structure, the diameter of a foam hole is 60 micrometers, and the foam holes are uniform and dense; and in addition, the heat insulation, sound insulation and noise reduction can be achieved, a novel solution is provided for developing the light-weight material, and the prepared polypropylene injection molding chemical micro-foamed composite material can be widely applied to products such as automotive interior door panels, instrument panels.

Owner:ORINKO NEW MATERIAL CO LTD

High-performance hard PVC foamed plastic and preparation method thereof

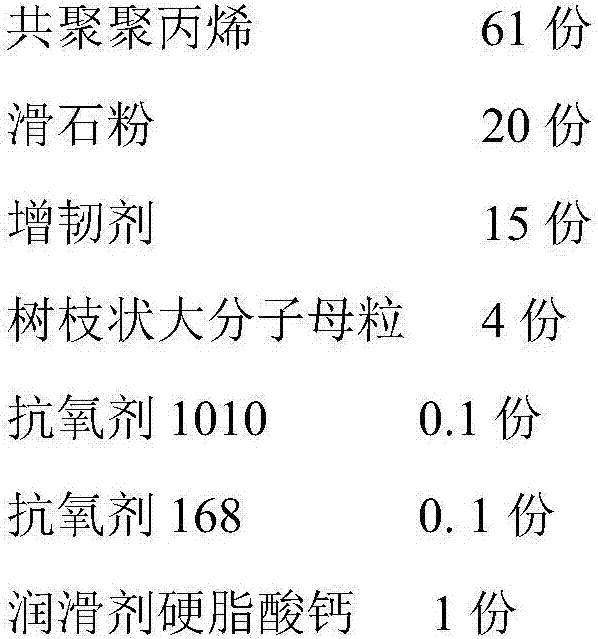

The invention relates to high-performance hard PVC foamed plastic and a preparation method thereof. The high-performance hard PVC foamed plastic is technically characterized by comprising the following components: 100 parts of polrvinyl chloride (PVC), 10 parts of stearate, 23 parts of foaming agent, 5 parts of activated calcium carbonate, and 5-30 parts of PhMI-MMA-AN terpolymer high-molecule heat-resisting modifier. The preparation method of the high-performance hard PVC foamed plastic comprises the following steps: stirring and uniformly mixing after metering PVC, the PhMI-MMA-AN terpolymer high-molecule heat-resisting modifier, the foaming agents and processing agents according to formula, and carrying out compression molding in a two-step method. The high-performance hard PVC foamed plastic is good in processing property, good in heat resistance, high in mechanical property, and low in water absorption rate and oil absorption rate; and the PhMI-MMA-AN terpolymer high-molecule heat-resisting modifiers is excellent in performance, has a single higher glass-transition temperature, and is good in compatibility with PVC. Meanwhile, the synthetic material is a traditional material, and is low in cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

PLA/TPU supercritical foaming composite material and preparation method thereof

The invention discloses a PLA / TPU supercritical foaming composite material and a preparation method thereof. The PLA / TPU supercritical foaming composite material is prepared from the following raw materials in parts by weight: 300 to 370 parts of polylactic acid, 130 to 155 parts of polyether polyurethane, 40 to 48 parts of organic silicon modified polyurethane, 20 to 27 parts of hydroxyl siliconeoil, 14 to 18 parts of maleic anhydride grafted polyethylene, 15 to 25 parts of glass fiber, 7 to 10 parts of a nucleating agent, 6 to 8 parts of a chain extender and 5 to 8 parts of a cross-linkingagent. The PLA / TPU supercritical foaming composite material disclosed by the invention is relatively high in tensile strength and good in mechanical property; the rebound rate is high, and the reboundperformance is excellent; the density is low, the foaming ratio is high, the pore size (diameter) is moderate, pores are uniform, and the foaming effect is good; the composite material has comprehensive mechanical properties such as ultra-light weight and good elasticity; in addition, the composite material is degradable and environment-friendly.

Owner:福建安达福新材料科技有限公司

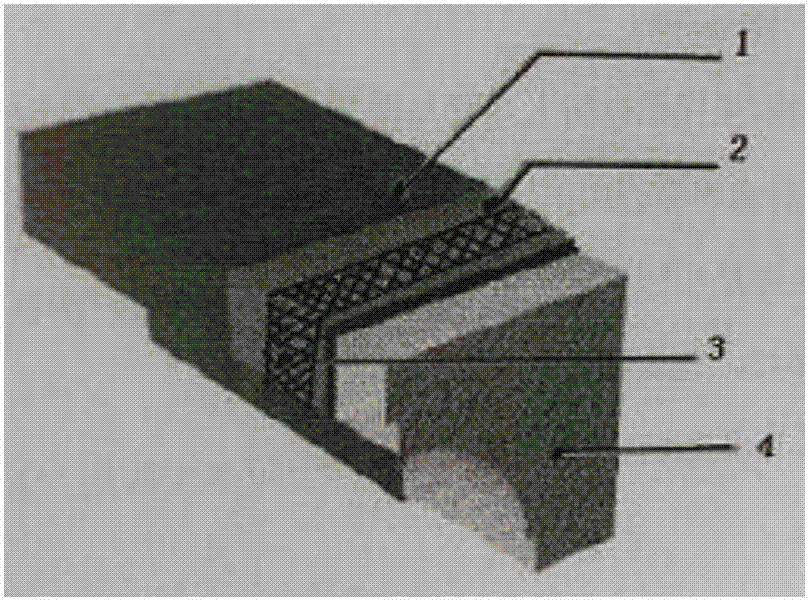

Core layer material of halogen-free flame retardant aluminum-plastic plate and manufacturing method thereof

The invention discloses a core layer material of a halogen-free flame retardant aluminum-plastic plate. The core layer material is characterized by comprising the following components by weight percent: 10-70% of resin, 20-80% of inorganic fire retardant, 0.1-5% of synergistic fire retardant, and 0.05-10% of assistant. The core layer material of the halogen-free flame retardant aluminum-plastic plate has the advantages that supercritical fluid of nitrogen or carbon dioxide is adopted as a foaming agent; the core layer material is friendly to environment, and does not generate any bad effect on the environment; meanwhile, the solubility of supercritical nitrogen or carbon dioxide in melt is better than that of a chemical foaming agent; the supercritical nitrogen or carbon dioxide can be evenly dispersed into the filled melt; evenly dispersed foams can be formed; the size of each foam is smaller than that of abscess of the chemical foaming agent; the condition that the foamed aluminum-plastic plate has better strength and better heat-insulating property is ensured.

Owner:JIANGSU KEYUE NEW MATERIAL CO LTD

Lignin-containing biodegradable polyester compound bead foaming material with high crystallization rate and preparation method thereof

The invention discloses a lignin-containing biodegradable polyester compound bead foaming material with a high crystallization rate and a preparation method thereof, the preparation method comprises the following steps: (1) melting and blending poly (butylene adipate terephthalate), an anhydride compound and a peroxide cross-linking agent to obtain MAH-g-PBAT particles; (2) carrying out blending granulation on the particles, degradable resin, lignin and a chain extender to obtain biodegradable polyester compound beads; and (3) putting the biodegradable polyester composite beads into a high-pressure mold, and carrying out mold pressing foaming by taking foaming gas as a foaming agent, thereby obtaining the biodegradable polyester composite beads. The MAH-g-PBAT and the chain extender can synergistically improve the compatibility of PBAT, PLA and lignin, promote chain branching and chain intertwining, successfully combine two melting points into one melting point, broaden the foaming interval, improve the foaming performance and facilitate steam forming of beads.

Owner:NANJING UNIV OF TECH

Nylon/polyurethane supercritical foamed composite material and preparation method thereof

The invention discloses a nylon / polyurethane supercritical foamed composite material and a preparation method thereof. The nylon / polyurethane supercritical foamed composite material is prepared from the following raw materials in parts by weight: 300-350 parts of polyamide, 60-72 parts of polyurethane, 40-48 parts of a polyamide-polysiloxane segmented copolymer, 6-8 parts of graphene fiber, 5-7 parts of a cross-linking agent and 3-4 parts of a nucleating agent. The nylon / polyurethane supercritical foamed composite material disclosed by the invention is good in foaming effect and high in foaming efficiency; the foam holes are uniform, small and compact; the advantages of high resilience rate, low water absorption rate, good dimensional stability, small irreversible deformation after being pressed, high tensile strength, good mechanical properties, light weight, high strength and the like excellent mechanical properties and use properties are achieved.

Owner:福建安达福新材料科技有限公司

Biodegradable plastic sole material and preparation method thereof

InactiveCN109181086AGood moisture-proof and water-proofImprove toughnessSolesFoaming agentWear resistance

The invention discloses a biodegradable plastic sole material and a preparation method thereof. The biodegradable plastic sole material is prepared from the following raw material components in partsby weight: 80-100 parts of EVA aggregates, 20-30 parts of high-density polyethylene, 25-35 parts of ethylene-acrylate copolymers, 10-30 parts of ethylene-octene copolymers, 30-40 parts of modified poplar powder, 5-8 parts of activator mixture, 2-4 parts of talcum powder, 2-4 parts of foaming agent and 3-5 parts of crosslinking agent. A sole prepared according to a formula has good dampproof and waterproof effects and also has good toughness, wear resistance and slip resistance, and the plastic sole is degradable so that environment pollution can be avoided.

Owner:ANHUI TONGLI NEW MATERIALS

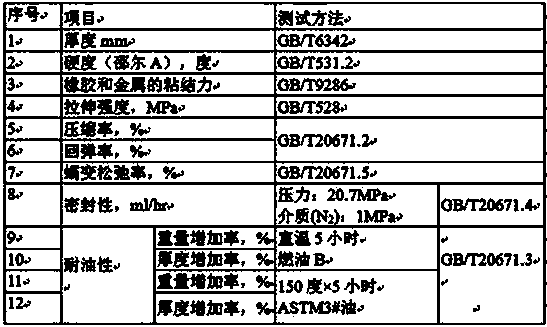

Preparation method of anti-attenuation gasket

ActiveCN109703035AImprove performanceImprove sealingDomestic articlesFlat articlesMaterials preparationUltrasound attenuation

The invention provides a preparation method of an anti-attenuation gasket, belonging to the technical field of sealing material preparation. The preparation method of the anti-attenuation gasket is characterized in that the anti-attenuation gasket comprises a spring steel belt and a foaming rubber layer; the foaming rubber layer is arranged on one side or two sides of the spring steel belt, and the preparation method is characterized by comprising the following steps of: carrying out surface treatment to the spring steel belt; preparing the foaming rubber; carrying out compounding, curing, checking, stamping forming and ribbing treatment on the foaming rubber and the spring steel belt sequentially so as to obtain a finished product. The foaming rubber and the spring steel belt provided bythe invention are tightly bonded, and are not easy to peel off, the product is environment-friendly, nontoxic and odorless, has a large compression amount, good rebound resilience and good flexibility, and a framework adopts the spring steel belt, so that the framework can maintain elasticity for a long time due to a honeycomb structure of the foaming rubber after being stressed, and the moment can be maintained for a long time without attenuation.

Owner:南阳天一密封股份有限公司

Small cell polymethacrylimide foam with high heat distortion temperature and preparation method thereof

The invention relates to micropore polymethacrylimide foam with high thermal deformation temperature. The foam comprises, by mass, 35-60 parts of methacrylic acid (MAA), 65-40 parts of acrylonitrile, 0.10-4.0 parts of initiators, 1.0-20 parts of foaming agents, 1-5 parts of nucleating agents, 0.1-5 parts of cross-linking agents and 5-10 parts of heat-resisting additives; the initiators are azo-bis(4-cyano valeric acid) or mixtures of azo-bis(4-cyano valeric acid) and other azo compounds. The other azo compounds are azodiisobutyronitrile AIBN, azobisisovaleronitrile or azobisisoheptonitrile. According to the micropore polymethacrylimide foam high in thermal deformation temperature, the foam has the small pore diameter phi of 0.1-0.3 mm, thermal resistance is high, the thermal deformation temperature is high and is larger than 200 DEG C, and the mechanical property is excellent.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Special seam splicing adhesive for double-T plate

InactiveCN111793461ALarge specific surface areaLow costNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePropanoic acid

The invention relates to a special seam splicing adhesive for a double-T plate. The special seam splicing adhesive comprises the following components by weight: 150-250 parts of polypropylene oxide glycol, 100-150 parts of MDI, 20-40 parts of propane and butane, 10-20 parts of ethylene glycol dimethyl ether, 70-100 parts of superfine coal powder, 1-2 parts of simethicone, 0.5-1.5 parts of dibutyltin dilaurate, 10-20 parts of polysilsesquioxane, 10-20 parts of hollow glass micro-beads, 1-3 parts of bimorpholine, 0.1-5 parts of a foaming agent and 3 parts of tetra(beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid)pentaerythritol ester. The special seam splicing adhesive disclosed by the invention has the advantage of high strength.

Owner:浙江正立高科建设有限公司

Heat insulation decoration line

InactiveCN107366410ANot subject to temperature changesSmall cellClimate change adaptationHeat proofingToxic materialEngineering

The invention relates to a heat insulation decoration line, which belongs to a novel outer wall decoration line and component, and is suitable to be arranged on an EPS and XPS heat insulation wall body of an outer wall, so that the European, classical and elegant decoration styles can be shown; and the outer wall of a main body building can be enabled not to generate cold and heat bridge effects. For the European styles of a high-rise building, the construction period is long; cracks can occur after a long time; and the durability is poor. Therefore the heat insulation decoration line and component are used; the installation is convenient; economical performance is realized; and the durability is long. The heat insulation decoration line and component are compounded by using demolded B2 grade fireproof graphite polystyrene as a main body, sticking alkaline-resistant fiberglass gridding cloth and adding a special bonding outer protection layer. The heat insulation decoration line and component is not influenced by temperature change, achieves cold-resistant and heat-resistant effects, and cannot be influenced by humid climate and acid rain. The heat insulation decoration line can achieve the fire-proof performance, cannot give out toxic substances and is an environment-friendly high-quality product.

Owner:TIANJIN QICAI TECH DEV

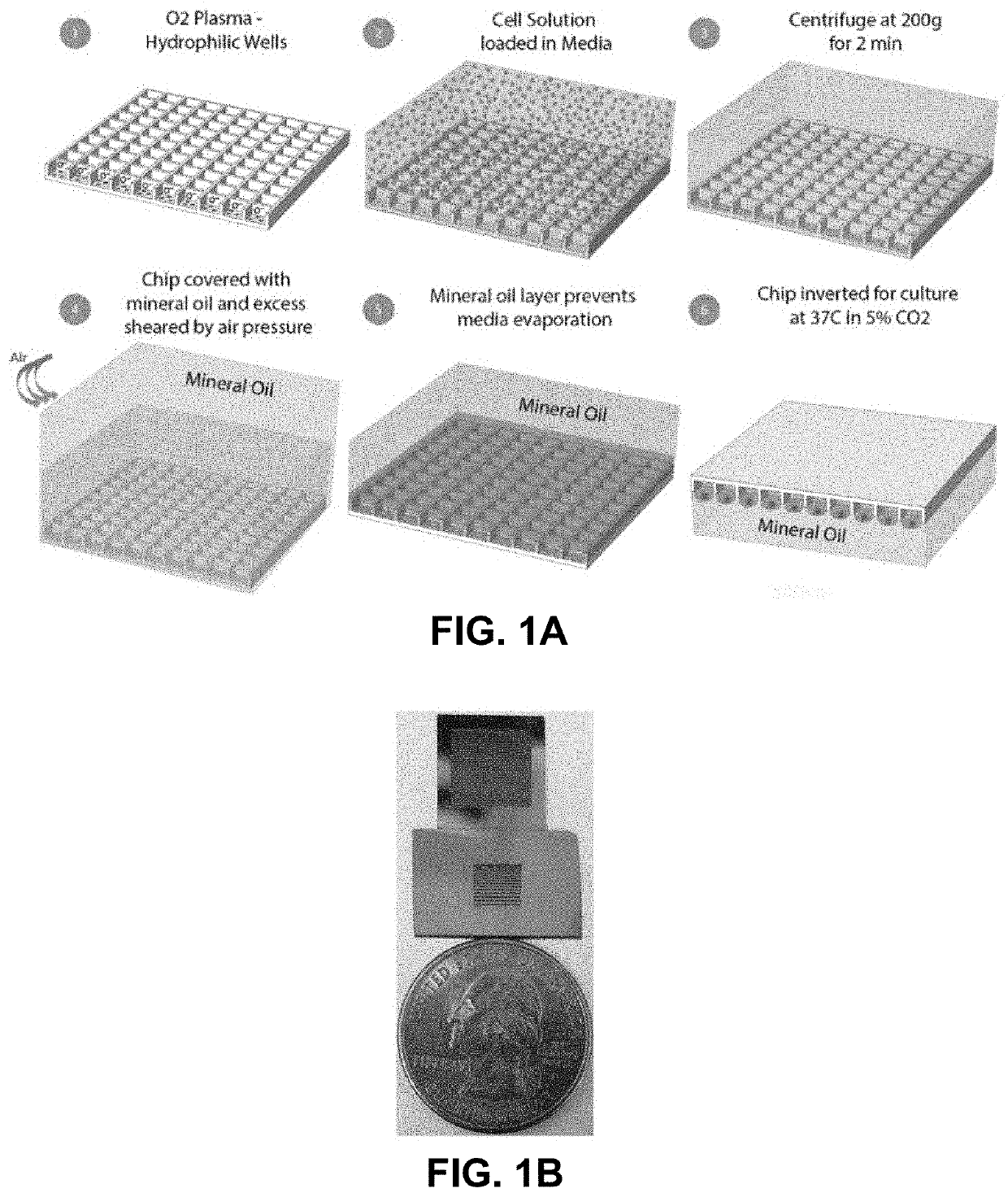

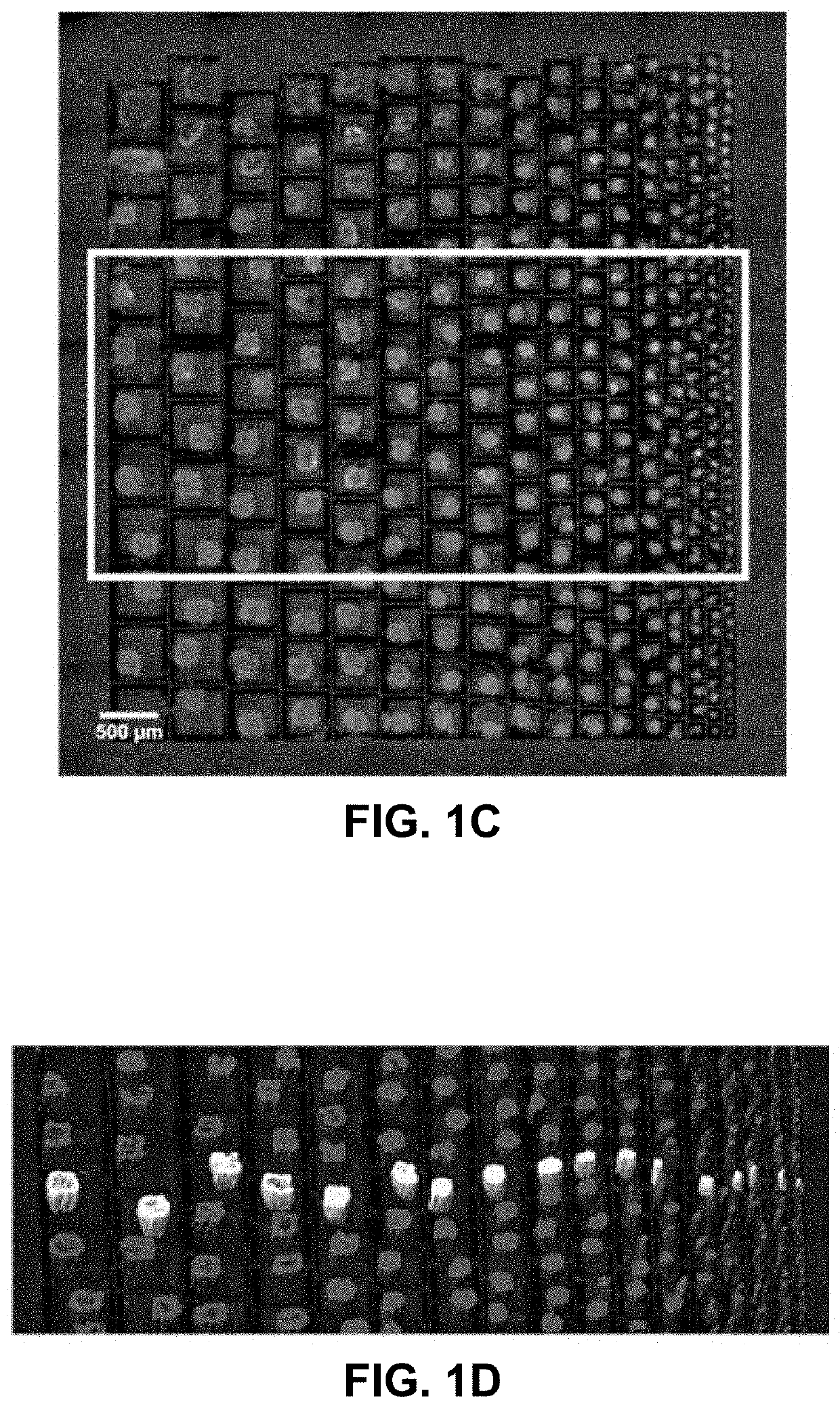

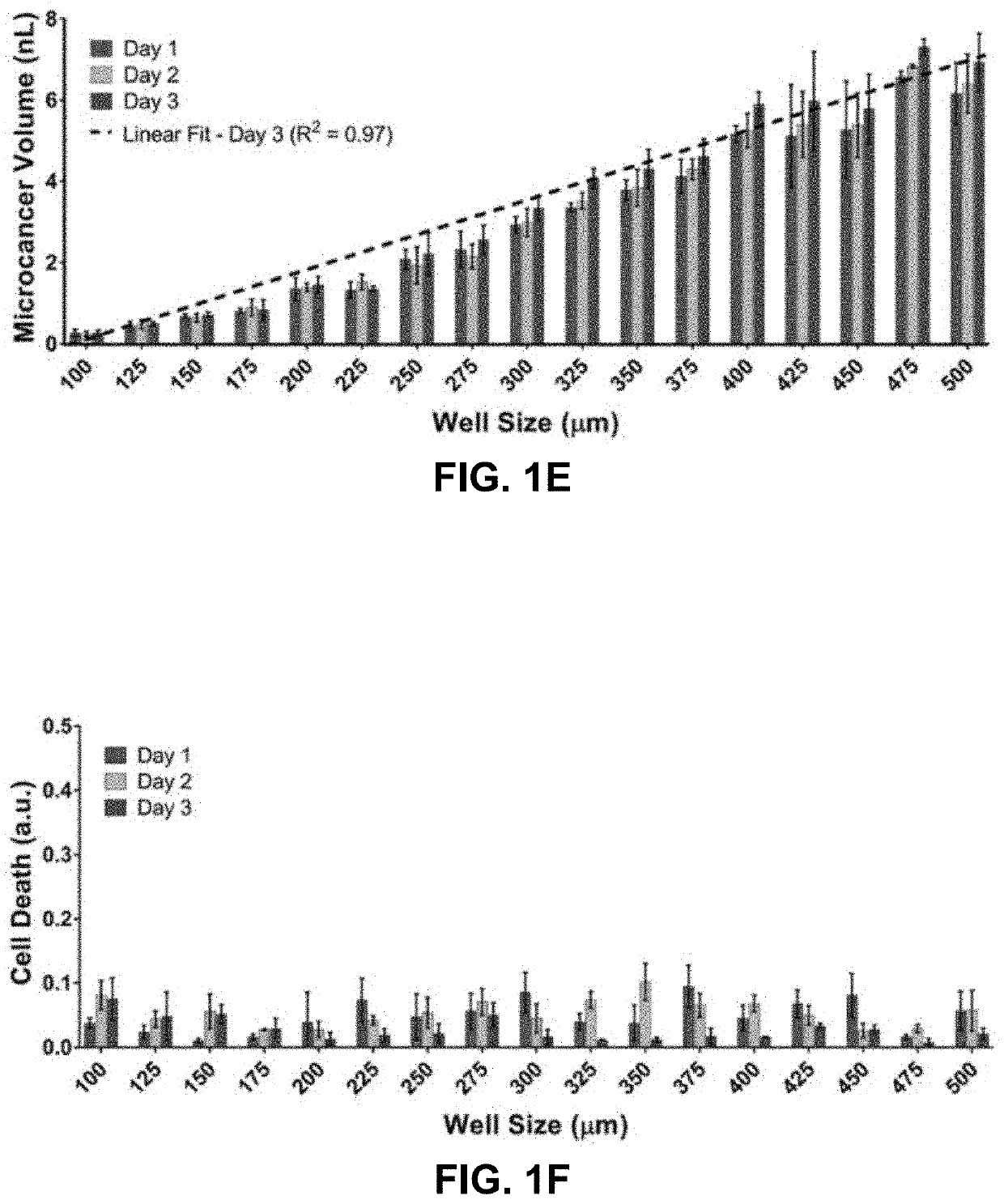

Microchip high density hanging drop three-dimension culture platform

PendingUS20210339244A1High tensionHigh viscosityBurettes/pipettesTissue/virus culture apparatusHigh densityBiomedical engineering

Provided are methods and related devices for preparing a cell and tissue culture, including a hanging drop culture. Microwells are specially loaded with cell mixtures using a removable reservoir and forcing cells into the underlying microwells. The removable reservoir is removed and the cells partitioned into the individual microwells and covered by an immiscible layer of fluid. The microwells and immiscible layer is inverted and the cells in the microwells cultured. The microwells may have shape-controlling elements to control the three-dimensional shape of the culture.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

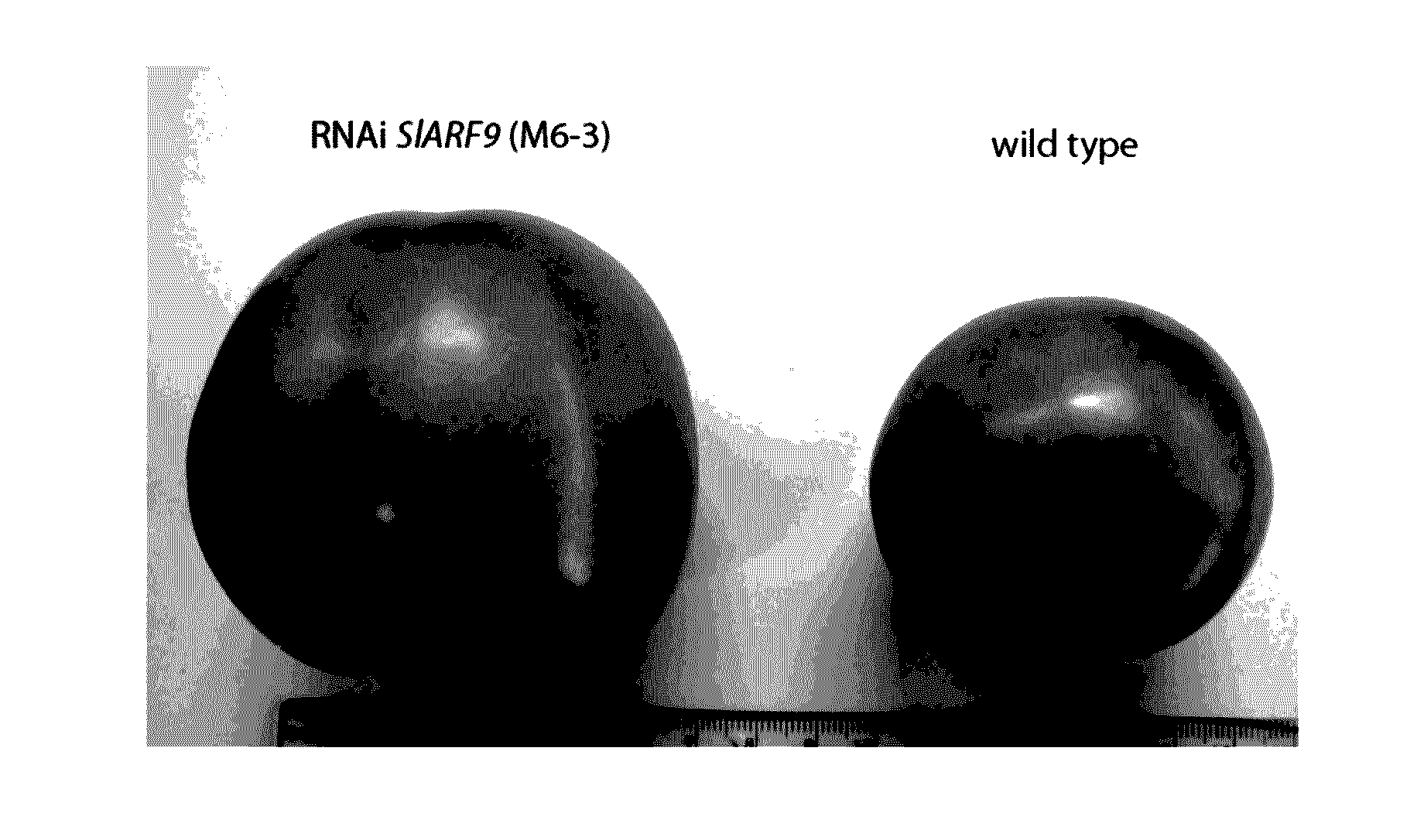

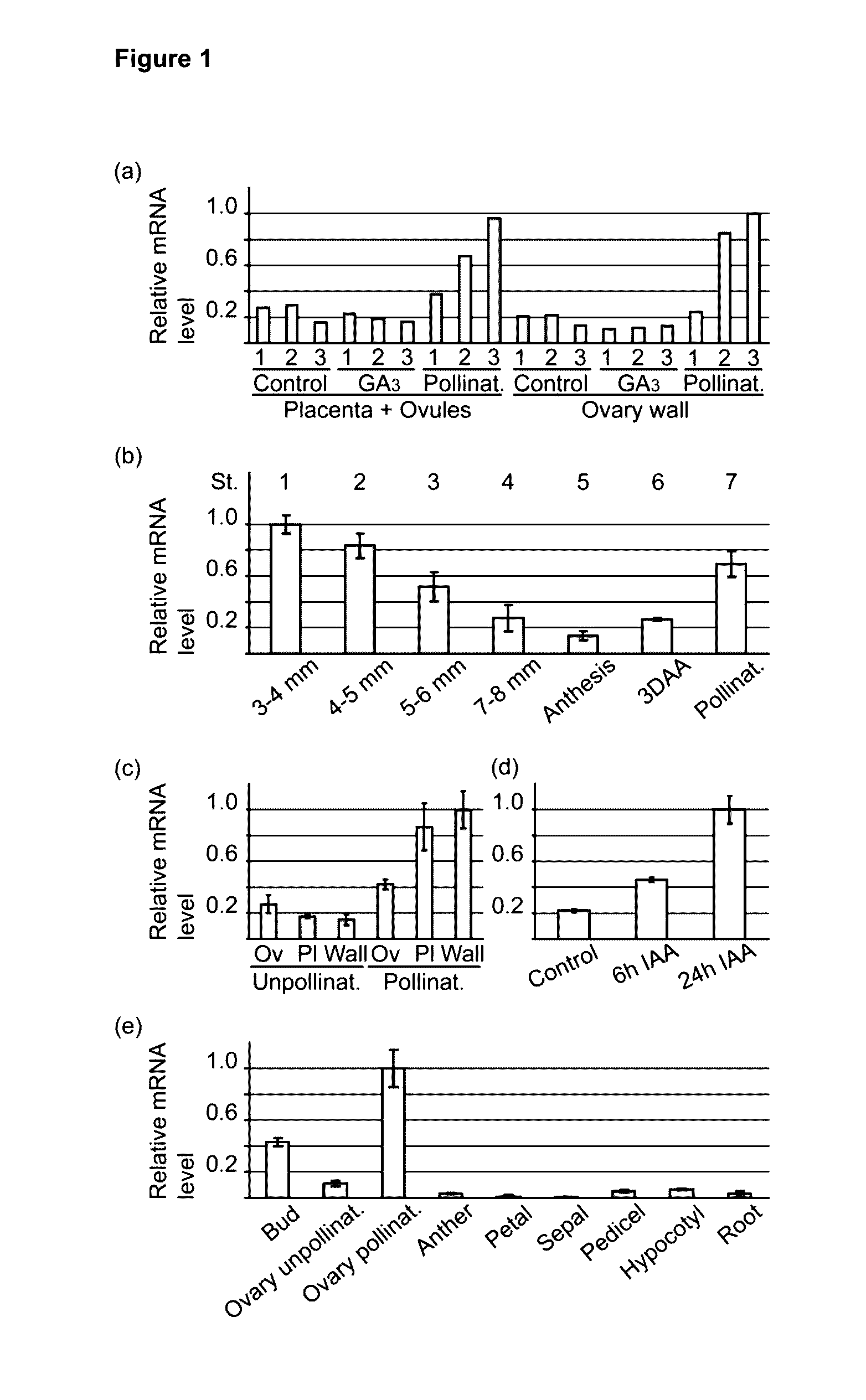

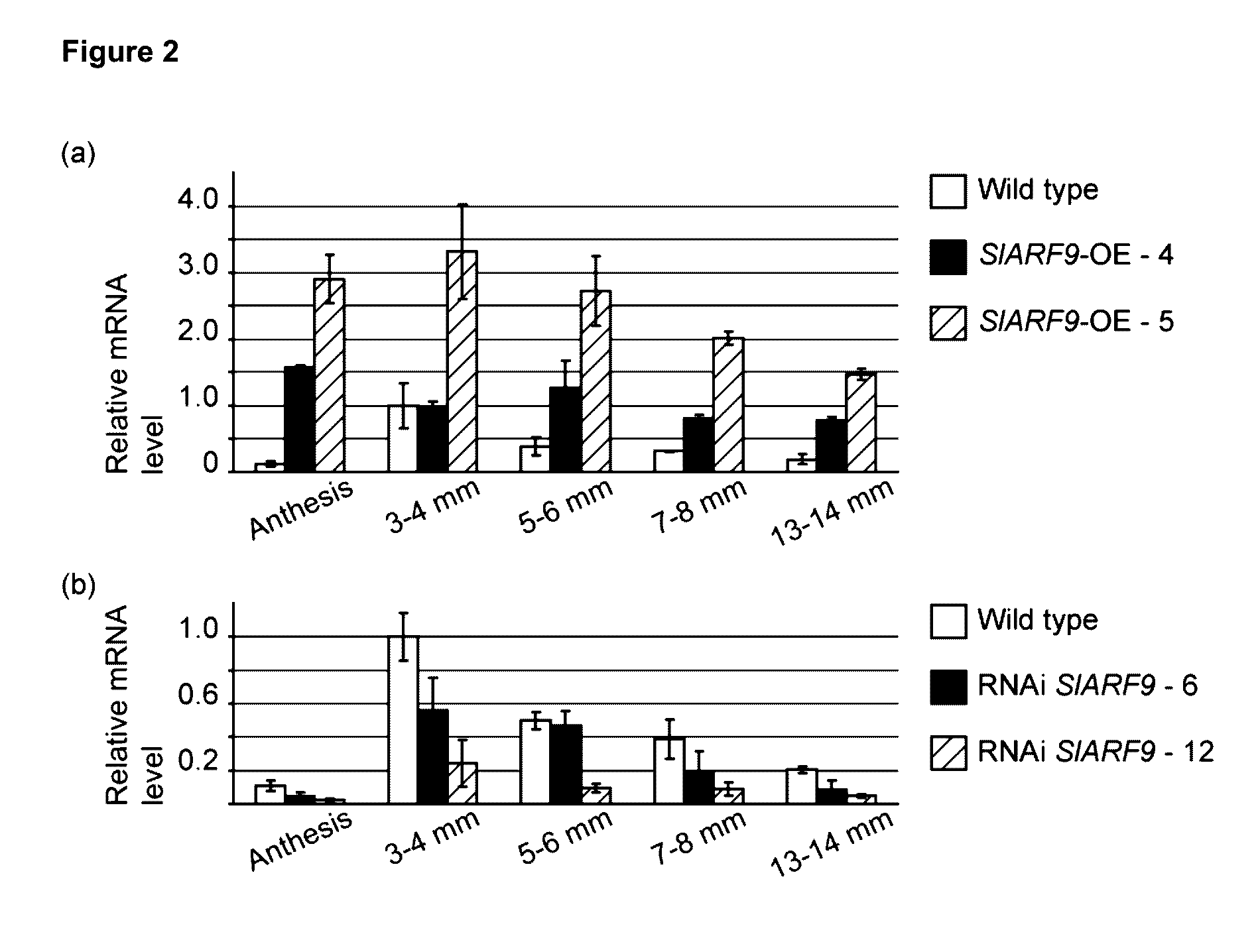

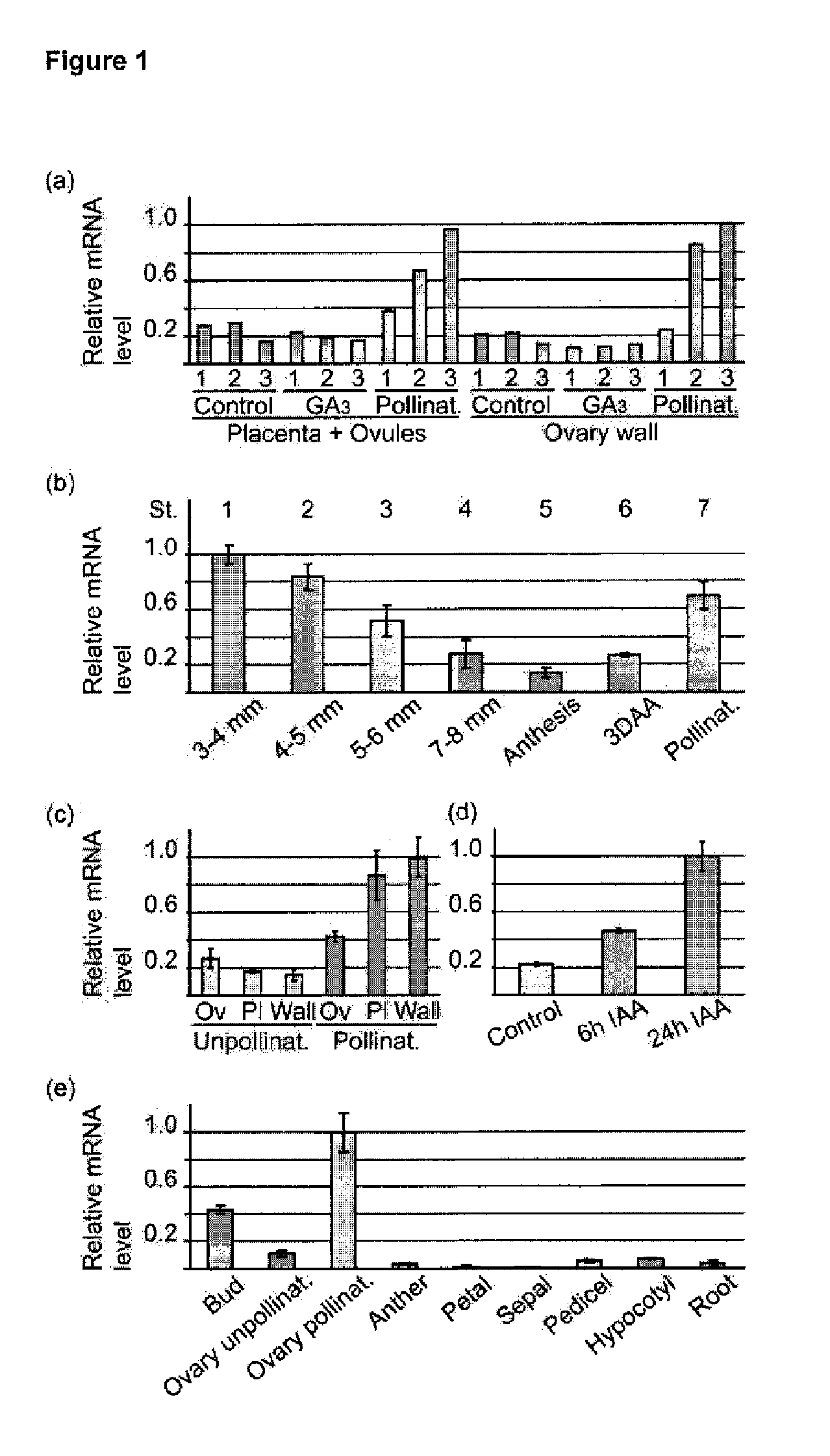

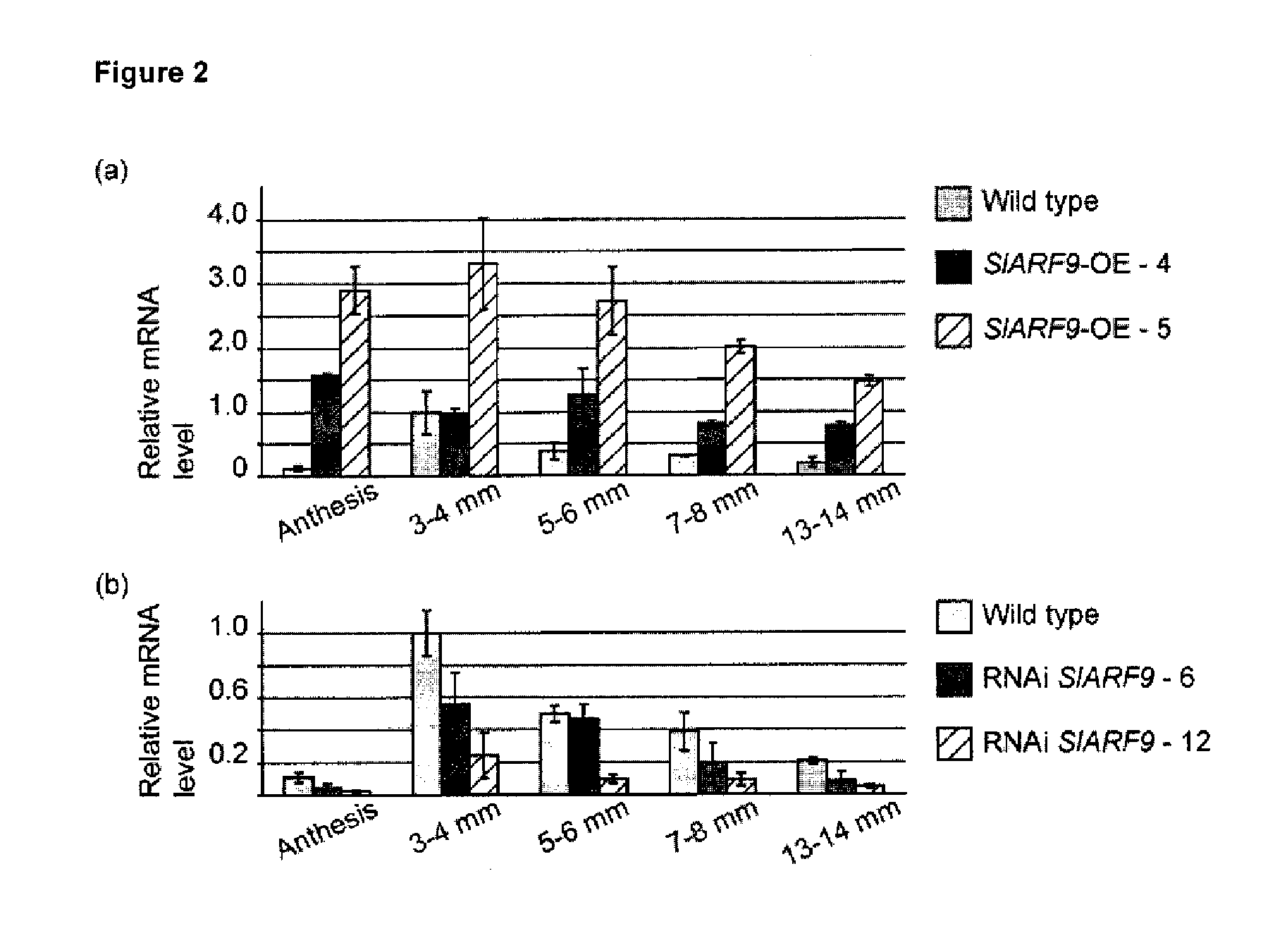

Plants with increased fruit size

InactiveUS20160333368A1Increase cell divisionMany componentClimate change adaptationPlant peptidesAuxin response factorNucleic acid sequencing

The present invention relates to the field of transgenic and non-transgenic plants with novel phenotypes. Provided are Solanum lycopersicum Auxin Response Factor 9 (SlARF9) proteins and nucleic acid sequences encoding these, which are useful in conferring novel phenotypes to plants, especially increased fruit size.

Owner:NUNHEMS BV

A kind of aromatic highly flame-retardant polyester polyol and its preparation method and application

InactiveCN104448272BImprove flame retardant performanceImprove mechanical propertiesPorosityPolyester

Owner:滕州市科米特新材料有限责任公司

Nanocomposite foaming agent and its preparation method and foamed product

The invention relates to a nano composite foaming agent and a preparation method and a foamed product thereof. The foaming agent is compounded from layered montmorillonite and 4,4-oxo-bis hydrazide, wherein the mass ratio of the 4,4-oxo-bis hydrazide to the montmorillonite is 1:(4-16). The composite foaming agent is obtained by a method of recombining and compounding the layered montmorillonite with the 4,4-oxo-bis hydrazide after stripping in preparation of the foaming agent. The foaming agent has the advantages that an organic foaming agent is embedded between nanoscale montmorillonite layers, so that the foaming agent is refined, the dosage of the foaming agent is effectively controlled, a nucleating point is increased, the foaming efficiency is improved, formed bubbles are even and small in holes, and meanwhile, the property of the obtained foamed product is also improved to a certain extent by adding of an inorganic material.

Owner:BEIJING UNIV OF CHEM TECH

Waterproof abutted seam filling agent for ALC

The invention relates to a waterproof abutted seam filling agent for ALC, wherein the waterproof abutted seam filling agent comprises the following components in parts by weight: 150-250 parts of polypropylene oxide glycol, 100-150 parts of MDI, 20-40 parts of propane and butane, 10-20 parts of ethylene glycol dimethyl ether, 70-100 parts of superfine pulverized coal, 1-2 parts of dimethyl silicone oil, 0.5-1.5 parts of dibutyltin dilaurate, 10-20 parts of polysilsesquioxane, 10-20 parts of hollow glass micro-beads, 1-3 parts of bimorpholine and 0.1-5 part of foaming agent. The waterproof abutted seam filling agent has the advantage of high strength.

Owner:浙江正立高科建设有限公司

Plants with Increased Fruit Size

InactiveUS20130145499A1Increase cell divisionMany componentClimate change adaptationOther foreign material introduction processesAuxin response factorNucleic acid sequencing

The present invention relates to the field of transgenic and non-transgenic plants with novel phenotypes. Provided are Solanum lycopersicum Auxin Response Factor 9 (SlARF9) proteins and nucleic acid sequences encoding these, which are useful in conferring novel phenotypes to plants, especially increased fruit size.

Owner:NUNHEMS BV

Airgel composite material and preparation method thereof

The invention provides a preparation method of an aerogel composite, comprising the steps of mixing melamine and a formaldehyde to obtain a melamine prepolymer; mixing the melamine prepolymer with a hardening agent, a foaming agent and deionized water to obtain a foam liquid; foaming the foam liquid to obtain foam; solidifying and annealing the foam to obtain melamine foam; thermally compressing the prepared melamine foam; combining the thermally compressed melamine foam with an aerogel to obtain the aerogel composite. The invention also provides the aerogel composite prepared via the preparation method. The small particle size characteristic of the aerogel and the porosity characteristic of the melamine are complemented; heat conduction ecoefficiency can be significantly improved, and thefragility defect of the aerogel can be overcome.

Owner:HAIER SMART HOME CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com