PLA/TPU supercritical foaming composite material and preparation method thereof

A composite material and supercritical technology, which is applied in the field of foam materials, can solve the problems of low tensile strength of polylactic acid foam materials, poor elasticity of polylactic acid foam materials, poor heat resistance and use performance, etc., so as to improve the processing flow. Good performance, foaming effect, good effect for processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A PLA / TPU supercritical foaming composite material is made of raw materials comprising the following parts by weight:

[0060] 300-370 parts of polylactic acid,

[0061] 130-155 parts of polyether polyurethane,

[0062] Silicone modified polyurethane 40~48 parts,

[0063] 20-27 parts of hydroxyl silicone oil,

[0064] 14-18 parts of maleic anhydride grafted polyethylene,

[0065] 15-25 parts of glass fiber,

[0066] 7-10 parts of nucleating agent,

[0067] 6-8 parts of chain extender,

[0068] 5-8 parts of cross-linking agent.

[0069] In this embodiment, the PLA / TPU supercritical foam composite material is preferably, but not limited to, made of raw materials including the following parts by weight:

[0070] 335 parts of polylactic acid,

[0071] 143 parts of polyether polyurethane,

[0072] Silicone modified polyurethane 44 parts,

[0073] Hydroxy silicone oil 23.5 parts,

[0074] Maleic anhydride grafted polyethylene 16 parts,

[0075] 20 parts of glass f...

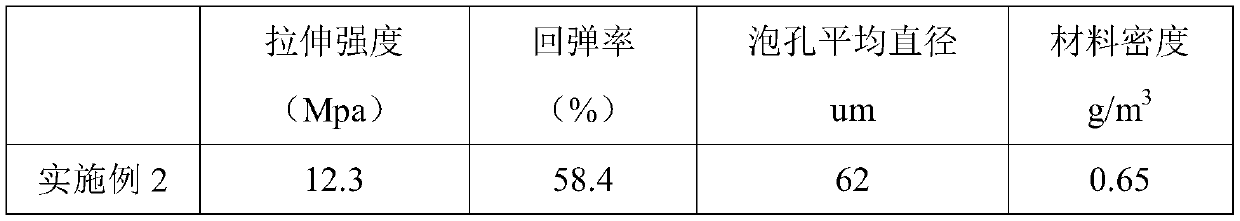

Embodiment 2

[0092] A PLA / TPU supercritical foaming composite material is made of raw materials comprising the following parts by weight:

[0093] 300 parts of polylactic acid,

[0094] 130 parts of polyether polyurethane,

[0095] Silicone modified polyurethane 40 parts,

[0096] Hydroxy silicone oil 20 parts,

[0097] 14 parts of maleic anhydride grafted polyethylene,

[0098] 15 parts of glass fiber,

[0099] 7 parts of nucleating agent,

[0100] 6 parts of chain extender,

[0101] 5 parts of crosslinking agent.

[0102] In this embodiment, the nucleating agent is a mixture of nucleating agent TMC-328 and zinc acrylate.

[0103] In this embodiment, the mass ratio of the nucleating agent TMC-328 and zinc acrylate in the mixture of the nucleating agent TMC-328 and zinc acrylate is 1:0.35.

[0104] In this embodiment, the chain extender is a mixture of the polyurethane chain extender MCDEA and 4-hydroxyethyloxyethyl-1-hydroxyethylphenylene diether.

[0105] In this embodiment, the...

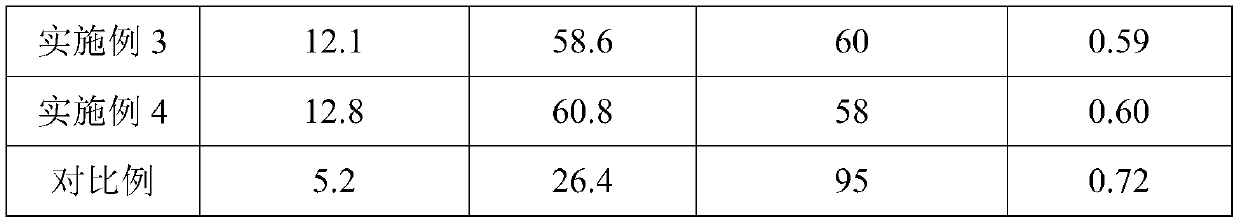

Embodiment 3

[0115] A PLA / TPU supercritical foaming composite material is made of raw materials comprising the following parts by weight:

[0116] 370 parts of polylactic acid,

[0117] 155 parts of polyether polyurethane,

[0118] Silicone modified polyurethane 48 parts,

[0119] Hydroxy silicone oil 27 parts,

[0120] 18 parts of maleic anhydride grafted polyethylene,

[0121] 25 parts of glass fiber,

[0122] 10 parts of nucleating agent,

[0123] 8 parts of chain extender,

[0124] 8 parts of crosslinking agent.

[0125] In this embodiment, the nucleating agent is a mixture of nucleating agent TMC-328 and zinc acrylate.

[0126] In this embodiment, the mass ratio of the nucleating agent TMC-328 and zinc acrylate in the mixture of the nucleating agent TMC-328 and zinc acrylate is 1:0.42.

[0127] In this embodiment, the chain extender is a mixture of the polyurethane chain extender MCDEA and 4-hydroxyethyloxyethyl-1-hydroxyethylphenylene diether.

[0128] In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com