Novel aromatic high-fire-retardant polyester polyol as well as preparation method and application thereof

A technology of polyester polyol and aromatic dibasic acid, which is applied in the field of new aromatic high flame-retardant polyester polyol and its preparation, can solve the problem of inability to meet the requirements of high flame-retardant performance and physical and mechanical processing performance of building insulation materials. Reduction, migration of flame retardant performance and other problems, to achieve the effect of superior flame retardant performance, good activity and flame retardancy, high flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation method of the present invention mainly comprises the following steps:

[0027] The first step: synthesis of hydroxyl-terminated polyester under the condition of excess alcohol. Add monomer raw materials, catalysts, antioxidants, etc. into the reactor, gradually raise the temperature to 220-240°C, and react for 8-10 hours. In the early stage of the reaction, it is carried out under normal pressure and under the protection of nitrogen. When it reaches the set acid value, hydroxyl value and viscosity range, under reduced pressure, 190-230 ° C, react for 1.5-2 hours, and the reaction can be carried out when the required index is reached. complete. ,

[0028] A novel highly flame-retardant aromatic polyester polyol of the present invention is obtained by esterification of naphthalene-containing aromatic dibasic acids, dibasic acids and small molecule alcohols or acids under the action of catalysts and antioxidants. The average functional group degree is 2, the...

Embodiment 1

[0041] The preparation of polyester polyol: take by weighing 2,6-naphthalene dicarboxylic acid, terephthalic acid, adipic acid, glycerol, diethylene glycol and catalyst tetraisopropyl titanate according to the proportioning ratio of embodiment 1 in the table , Antioxidants 1010 and 626 were added to the reaction kettle, and nitrogen was introduced for protection, then the temperature was raised, stirred, and gradually raised to 150°C, and after 2 hours of normal pressure reaction, the temperature was programmed to rise to 190°C, and water distillation began When it reaches 240°C, keep it warm for 5 hours. When the water output reaches 80% of the water output, stop feeding nitrogen, cool down to 180°C, start vacuuming in sections, and gradually increase the vacuum degree until the pressure reaches 0.01MPa. Heating while evacuating to raise the temperature to 230° C., and reacting under the above conditions for 1.5 to 2 hours. After testing, the acid value of the product was red...

Embodiment 2

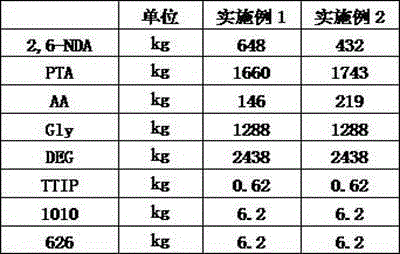

[0044] Proportion of New Aromatic High Flame Retardant Polyester Polyol

[0045]

[0046] 2,6-NDA is 2,6-naphthalene dicarboxylic acid,

[0047] PTA is terephthalic acid,

[0048] AA is adipic acid,

[0049] Gly is glycerol,

[0050] DEG is diethylene glycol,

[0051] TTIP is tetraisopropyl titanate.

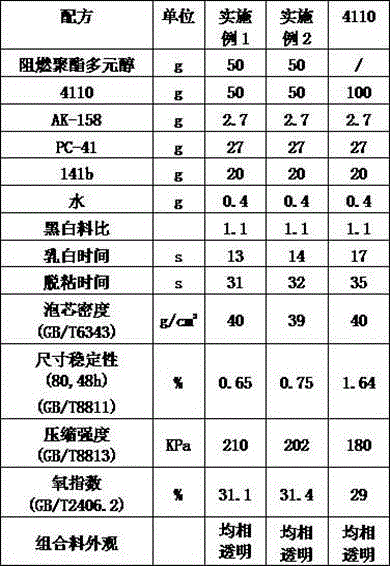

[0052] The new aromatic highly flame-retardant polyester polyol prepared in Embodiment 1 and Embodiment 2 of the present invention is compounded with the commonly used polyether polyol 4110 as the base polyol, and the polyether (white material) is configured and combined according to the formula in Table 1, and then mixed with Multi-subunit polyphenyl polyisocyanate PM-200 (black material) was mixed with high-speed stirring for foaming experiments; and the flame retardancy and mechanical properties of the prepared polyurethane rigid foam were tested; and the commonly used polyester polyol 4110 was used as a comparison.

[0053]

[0054] The results of comparative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com