Patents

Literature

149results about How to "Aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Borosiloxane and preparation method thereof

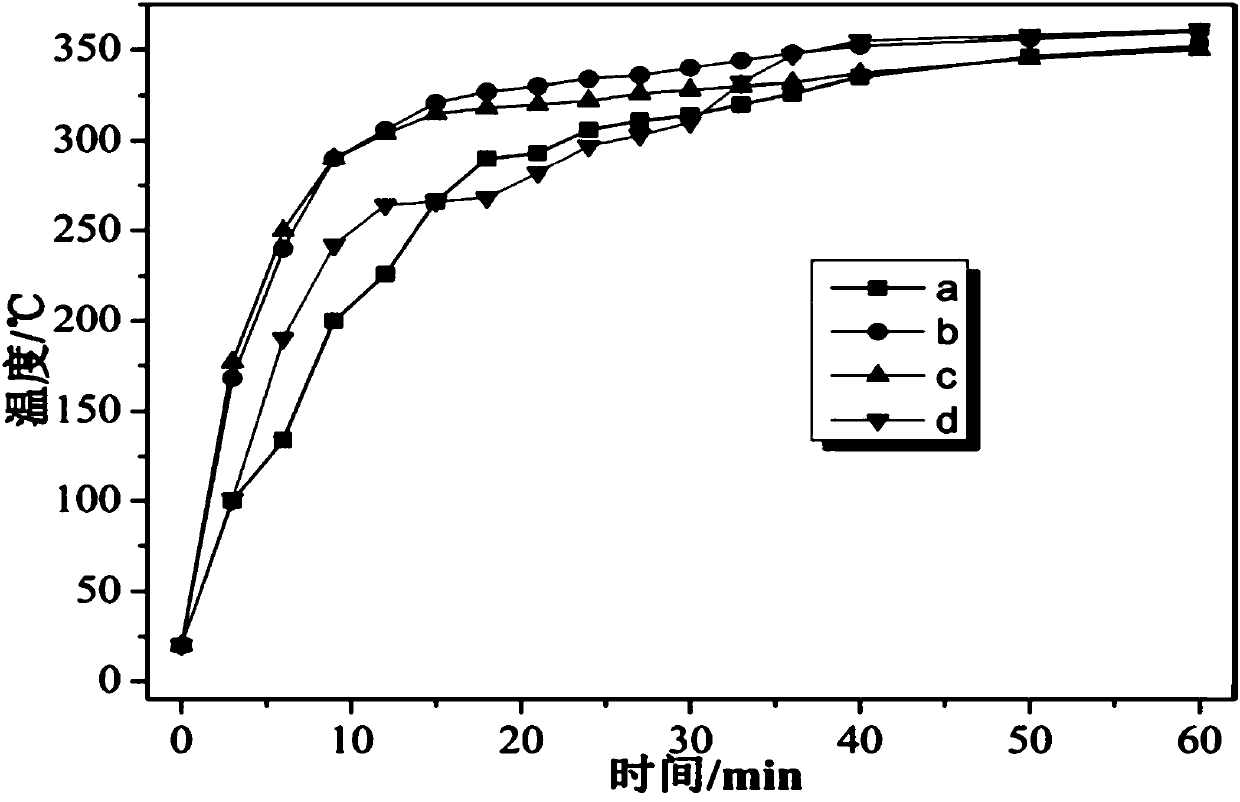

The invention relates to borosiloxane and a preparation method thereof. According to the method, a hydrolysis solvent and a boron compound are mixed proportionally and added to a reactor, the temperature keeps from 10 DEG C to 35 DEG C, and a mixed monomer is slowly dropwise added under the stirring condition for a hydrolysis reaction; the dropwise-adding time is controlled in 3-6 hours, the reactor is slowly heated to the temperature ranging from 55 DEG C to 65 DEG C after the dropwise-adding is finished, a stirring reaction is performed for 1 hour, and still standing is performed; acid water on the lower layer is separated and neutralized to be neutral, a saturated NaCl solution is used for washing, and an oil phase material is obtained; reduced pressure distillation is performed to remove the solvent, a catalyst I is added, the mixture is heated to 110-130 DEG C, and the rearrangement reaction is performed for 3-5 hours; the mixture is heated to 150-160 DEG C, the splitting cyclization reaction is performed for 2-5 hours, the reaction is finished, the mixture is cooled, and a polyborosiloxane prepolymer is obtained; an end-capping reagent and a catalyst II are added to a system and heated to 110-130 DEG C, and react for 2-4 hours; and pressure is reduced to remove a low-boiling-point substance, and a polyborosiloxane resin is obtained. The borosiloxane and the preparation method have the advantages of good temperature resistance, ageing resistance, impact resistance, toughness and low-temperature flexibility, high adhesion and the like.

Owner:上海爱世博有机硅材料有限公司

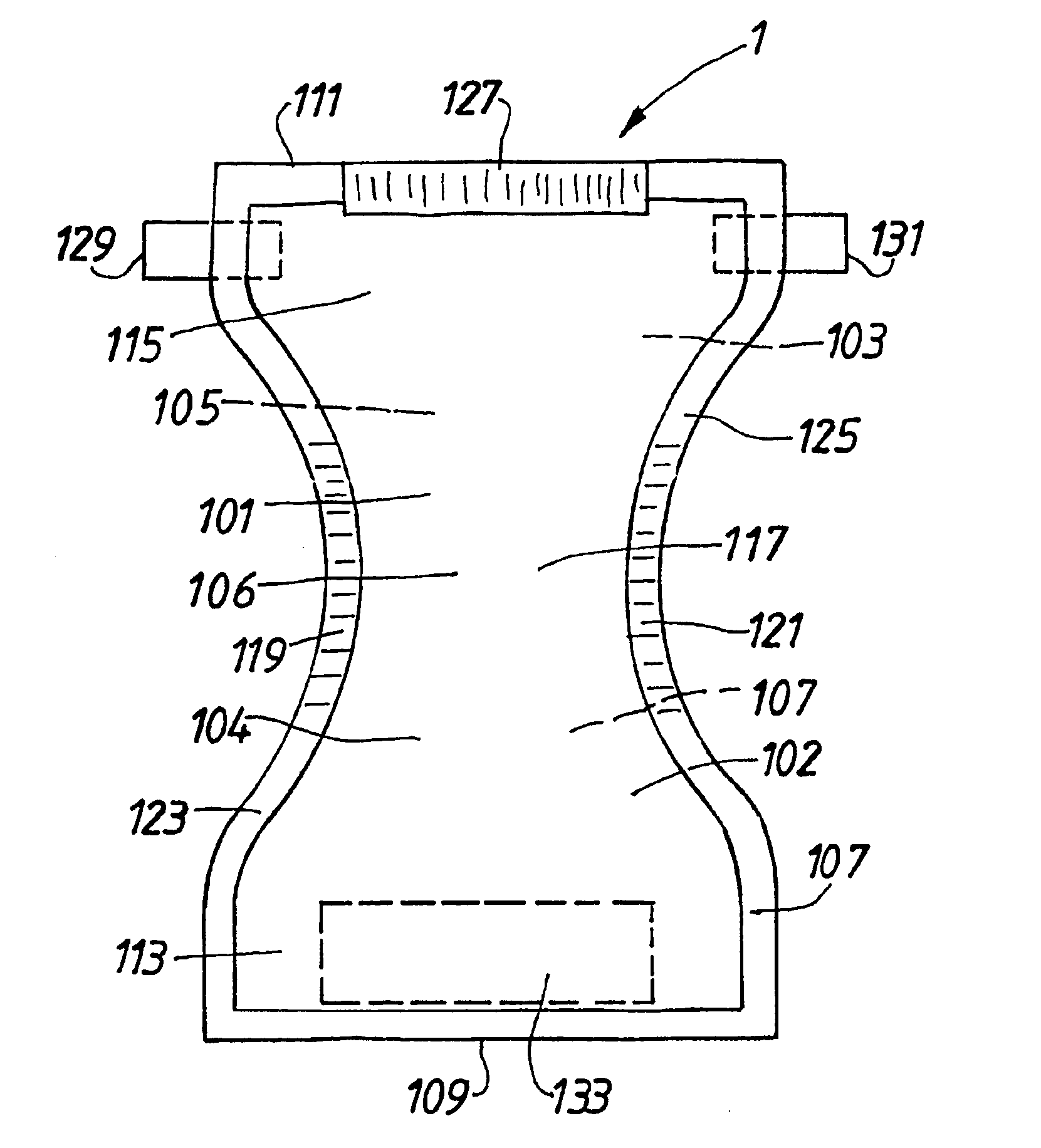

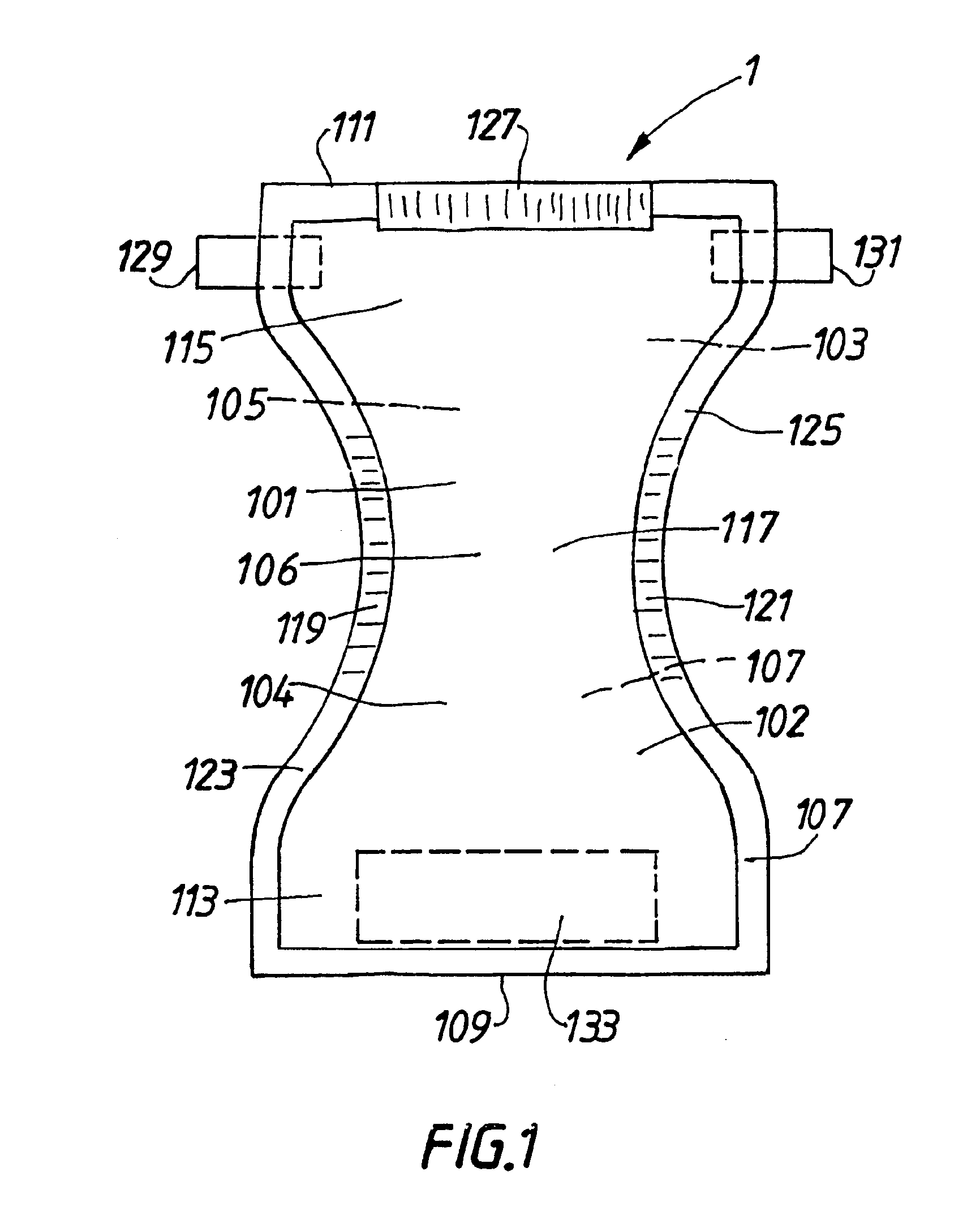

Fibrous structure and absorbent article including such a fibrous structure

InactiveUS6878857B1Well definedAging resistanceUltrasonic/sonic fibre treatmentBaby linensWettingEngineering

A fibrous structure is described for use in hygienic articles such as diapers, sanitary napkins, incontinence guards, wipes and the like, having one or more polar, silicon containing compounds bound to at least one portion of the surface of the fibrous structure by interaction between the surface and the silicon containing compounds. The fibrous structure exhibits a predetermined degree of hydrophilicity and adhesion properties which are substantially unaffected by wetting of the fibrous structure. Absorbent, hygienic and textile articles comprising such a fibrous structure are also described.

Owner:RES CORP TECH INC +1

Dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy anticorrosive coating and preparation method thereof

InactiveCN101798484ASolve pollutionNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCross-link

The invention discloses a dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy anticorrosive coating and a preparation method thereof. Compositions of the coating mainly comprise dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy emulsion, anticorrosive pigment and filler, pigment dispersing agent, a film forming aid, a water-based additive, a cross-linking curing agent and deionized water, wherein the dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy emulsion is prepared by the following steps: prepolymerizing a polyurethane hydrophilic branch; preparing a dendritic polyurethane intermediate product by adopting hyperbranched synthesis technology; inoculating organic-inorganic hybrid into a nano material by adopting a in-situ polymerization; and simultaneously grafting epoxy resin with hydroxyl; and the prepared emulsion is compounded with the anticorrosive pigment and filler and the like to prepare the anticorrosive coating. The anticorrosive coating radically solves the VOC pollution problem of solvent-type anticorrosive coating, and simultaneously solves a series of problems such as poor roughness, weatherability, ageing resistance, alkali resistance and solvent resistance of the conventional water-borne anticorrosive coating.

Owner:SICHUAN UNIV +1

Asphalt waterproof paint for building and preparation method thereof

InactiveCN101921545AUnique performanceImprove performanceUnspecified rubber coatingsBituminous coatingsChemical industryBituminous waterproofing

The invention relates to an asphalt waterproof paint for a building and a preparation method thereof, belonging to the technical field of chemical industry. The asphalt waterproof paint for a building comprises the following raw materials according to parts by weight: 20-25 parts of plasticizer, 6-8 parts of modifier, 25-30 parts of asphalt, 20-30 parts of filler, 4-6 parts of tackifier, 0.2-0.3 parts of crosslink coupling agent, and 0.3-0.5 parts of dispersing agent. The invention has the advantages of reasonable compound design, good intensity, safety, environmental protection and stable product quality, and is capable of adapting the climatic conditions at high and low temperatures.

Owner:嘉兴市博豪家纺有限公司

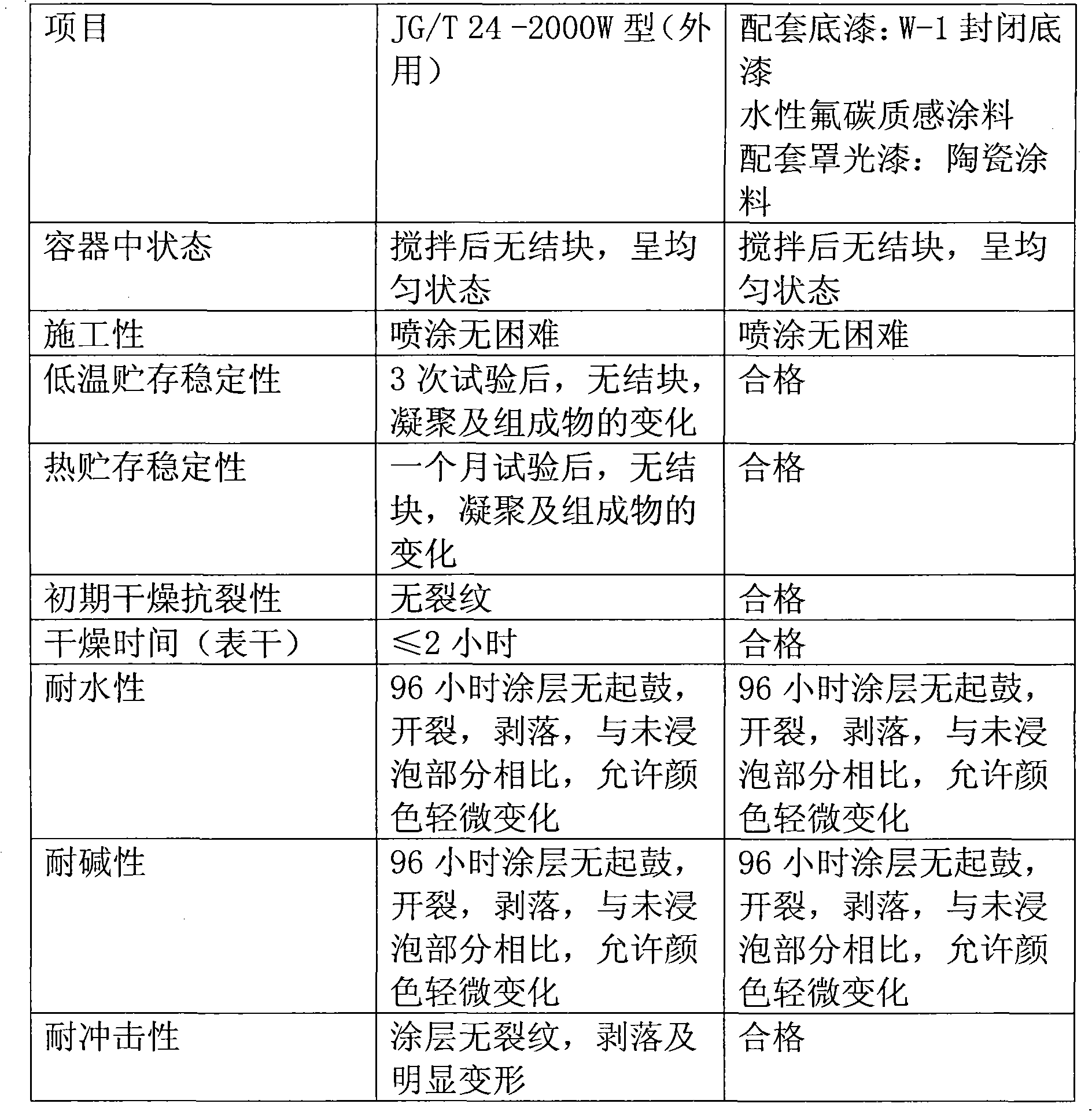

Waterborne fluorocarbon texture coating and preparation method and application thereof

InactiveCN101851450AImprove water resistancePollution resistantBuilding constructionsCoatingsLow speedWeather resistance

The invention discloses a waterborne fluorocarbon texture coating and a preparation method and application thereof. The coating comprises the following components in part by weight: 141 to 180 parts of fluorocarbon emulsion, 5 to 12 parts of film-forming aid, 5 to 6 parts of cosolvent, 80 to 100 parts of water, 1 to 2 parts of antifoaming agent, 3 to 6 parts of disinfectant, 1 to 3 parts of mildew preventive, 2 to 3 parts of pH regulator, 5 to 10 parts of thickening agent, 600 to 1,000 parts of color sand, and 0 to 89 parts of sheet. The preparation method comprises the following steps of: under the stirring at a high speed, adding the film-forming aid, the cosolvent, the antifoaming agent, the disinfectant, and the mildew preventive in turn, stirring at the high speed and reducing the stirring speed; adding the fluorocarbon emulsion, regulating the pH value, and regulating the viscosity by using the thickening agent to obtain pulp; stirring the pulp at a low speed, adding the color sand and sheet, and mixing to obtain the waterborne fluorocarbon texture coating. The waterborne fluorocarbon texture coating applied to a coated outer wall surface has good protection functions of water resistance, weather resistance, smudge resistance, and the like, and makes the wall surface have elegant, harmonious and serious aesthetic feeling.

Owner:SHANGHAI HENGFENG FLUOROCARBON MATERIAL

High-temperature-resistant environment-friendly composite pigment and production method thereof

InactiveCN104861742AImprove light fastness and weather resistanceBright colorPigment physical treatmentPigment treatment with non-polymer organic compoundsWeather resistanceNickel oxides

The invention relates to the technical field of chemical pigment fabrication and discloses a high-temperature-resistant environment-friendly composite pigment and a production method thereof. Inorganic titanium yellow pigment carriers are enveloped with organic yellow pigments to form the composite pigment. The preparation method comprises processing titanium dioxide and nickel oxide into mixed-phase inorganic titanium yellow pigment carriers to be mixed with organic yellow pigments with negative charges, and performing enveloping treatment through positive and negative charge particle attraction action to achieve composition of organic and inorganic pigments. By nanometer fine processing, surface charges are increased, the envelop is dense, the structure force is large, the composition process is environmentally friendly, the composite pigment is non-toxic, the composite titanium yellow carriers can protect the sensitive organic pigments from ultraviolet attack like ultraviolet absorbers, and accordingly, the weather resistance and the light resistance of the pigment are improved greatly, and the pigment has the advantages of being environmentally friendly, weather resistant, light resistant, heat resistant, anti-ageing, bright in organic pigment color and high in tinting strength.

Owner:HUNAN JUFA TECH

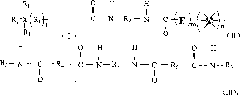

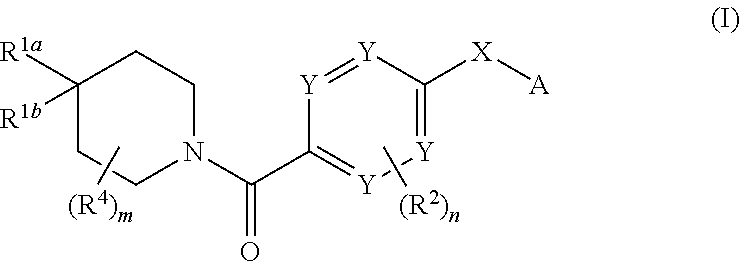

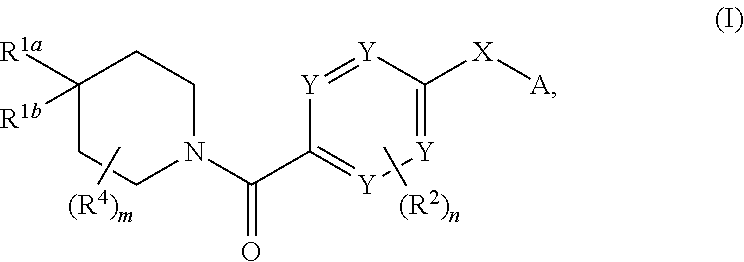

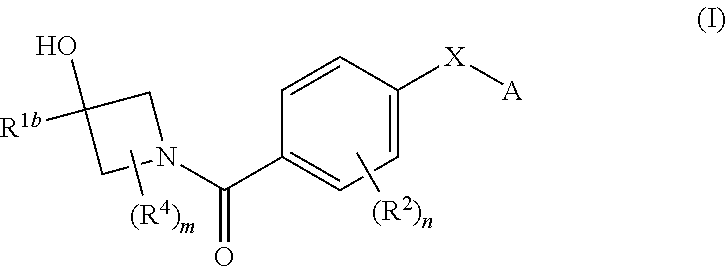

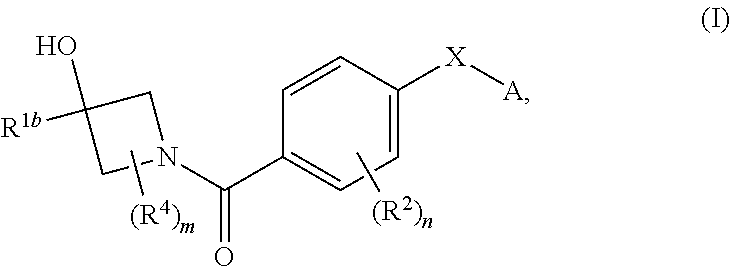

Therapeutic compounds and compositions

ActiveUS9108921B2Extended service lifeHigh affinityOrganic active ingredientsGroup 5/15 element organic compoundsDiseaseKinase

Compounds of general formula I:and compositions comprising compounds of general formula I that modulate pyruvate kinase are described herein. Also described herein are methods of using the compounds that modulate pyruvate kinase in the treatment of diseases.

Owner:AGIOS PHARM INC

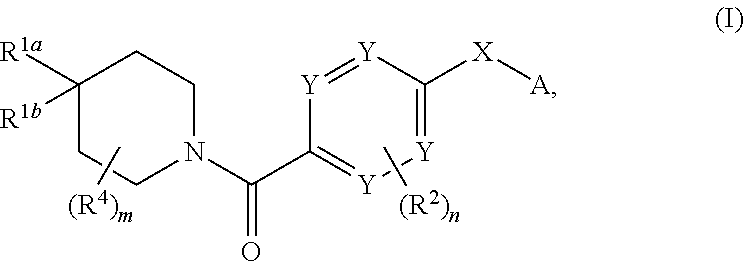

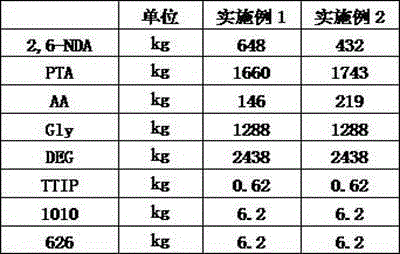

Novel aromatic high-fire-retardant polyester polyol as well as preparation method and application thereof

InactiveCN104448272AImprove flame retardant performanceImprove mechanical propertiesPolyesterPorosity

The invention discloses a novel aromatic high-fire-retardant polyester polyol as well as a preparation method and an application thereof. The novel aromatic high-fire-retardant polyester polyol is applied to a fire-retardant polyurethane material, and is applied to the field of building heat preservation. The novel aromatic high fire-retardant polyester polyol is obtained by esterification reaction of naphthalene-based aromatic dibasic acid, binary acid and small molecular alcohol or acid under the action of a catalyst and an antioxidant; the mass ratio of naphthalene-based aromatic dibasic acid to binary acid to the small molecular alcohol or acid is (0.7-1.5) to (2.8-4.6) to (5.7-8.6); the average functional group degree is 2; the acid value is smaller than 1mgKOH / g; the average hydroxyl value is 400-660mgKOH / g; the average molecular weight is 170-300g / mol; and the viscosity is 2500-4500mPa.s. The polyester polyol disclosed by the invention has high flame retardant property and excellent mechanical property; the polyurethane foam prepared by the method has thermal stability, good activity and good fire-retardant property, and also has good physical properties such as compression strength, closed porosity, abrasive resistance, ageing resistance and heat resistance. The novel aromatic high-fire-retardant polyester polyol is simple in synthesis process, is good in compatibility with other polyesters and polyester polyol; and the rigid polyurethane foam prepared by the novel aromatic high fire-retardant polyester polyol has relatively good heat resistance and fire resistance, and is applied to the field of building heat preservation.

Owner:滕州市科米特新材料有限责任公司

High-functionality polyester polyol and preparation method thereof

The invention relates to high-functionality polyester polyol and a preparation method thereof. The polyol is prepared from 400-450 parts of PTA oxidation residue, 180-210 parts of glycerol, 80-140 parts of diglycol, 20-30 parts of pentaerythritol, 50-90 parts of oleic acid and 1-2 parts of catalyst. The preparation method comprises the following steps of: extracting various raw materials according to the proportion, sending the raw materials into a reaction kettle, heating, stirring and introducing nitrogen gas; evaporating all water of the raw materials in the kettle; cooling after evaporating all water, and stopping the introduction of nitrogen gas; heating and vacuumizing the kettle to form high temperature and high vacuum; polymerizing all raw materials at high temperature and in high vacuum, and greatly increasing the molecular weight of polyester; and discharging to obtain the finished product after various indexes of the molecular weight of polyester are measured to reach specified values. The high-functionality polyester polyol has the advantages of high wear resistance, strength, stability, heat resistance, aging resistance and the like.

Owner:CHANGZHOU KANGHONG DECORATION MATERIAL

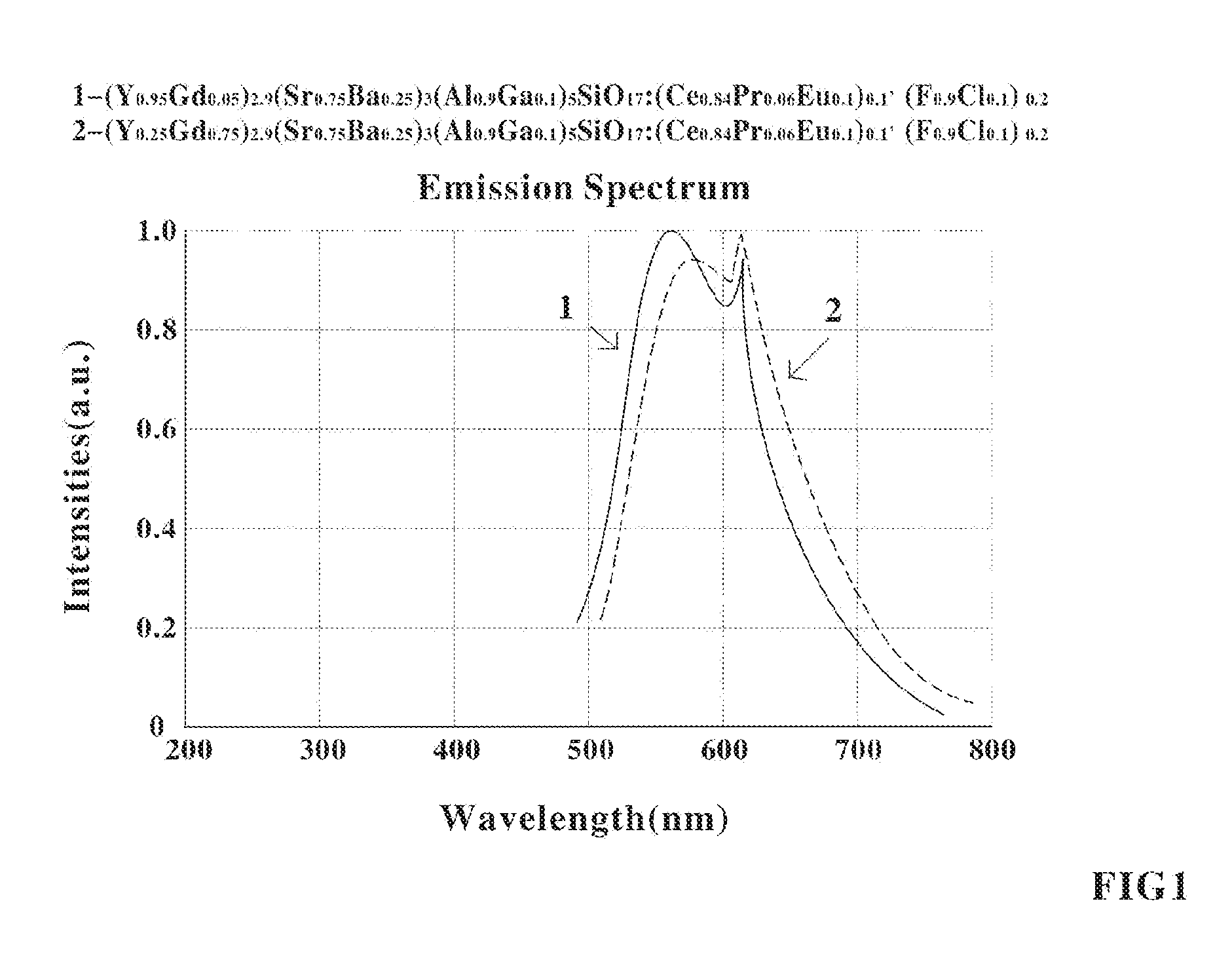

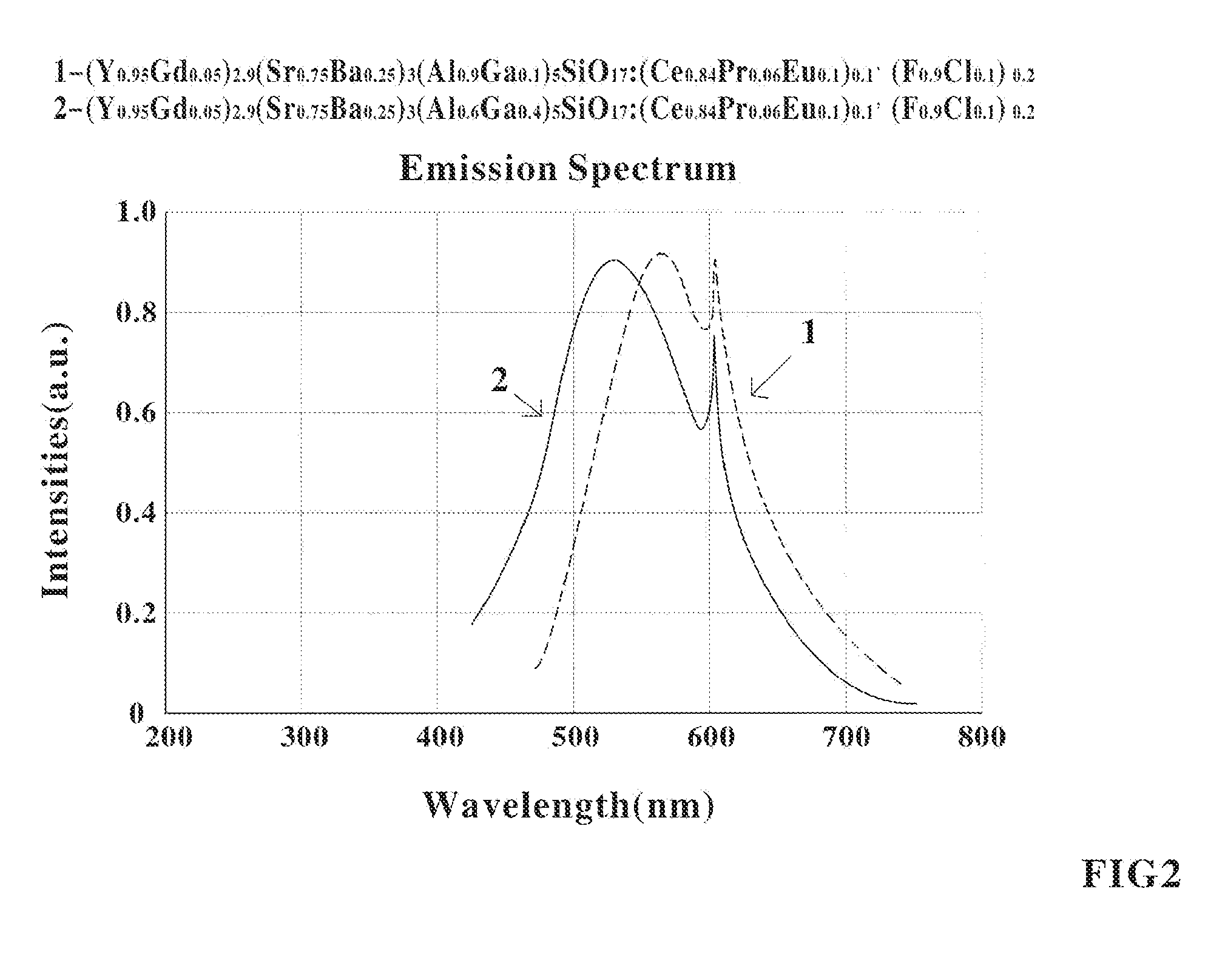

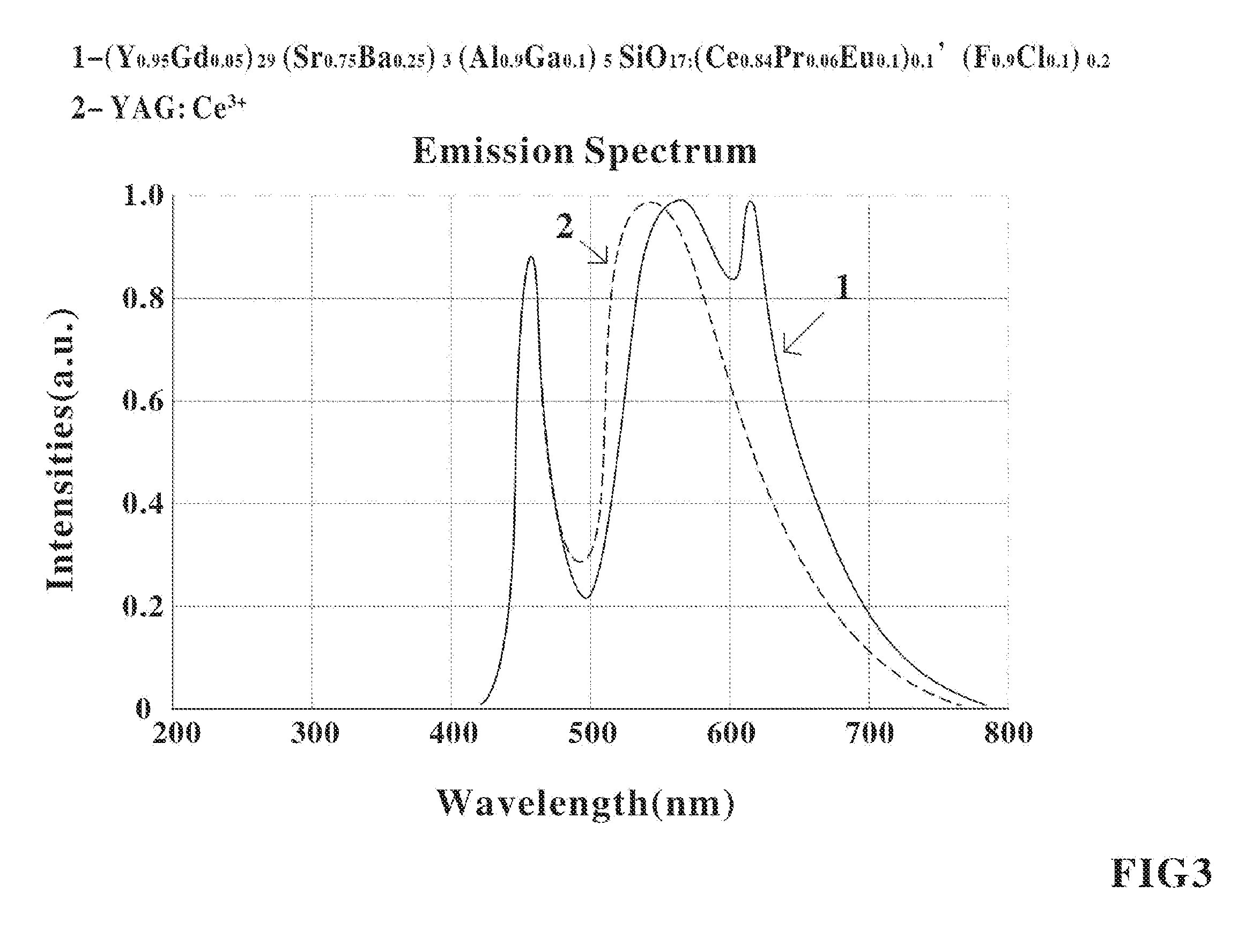

One silicon-aluminate light-conversion fluorescence material co-activated with halogen for white-light LED

InactiveUS20110155972A1Increase light intensityLow costGas discharge lamp usageLuminescent compositionsAluminateOxalate

One silicon-aluminate light conversion fluorescence material co-activated with halogen for white-light LED, which features a general formula as R(3-a)M3N5CO17:Rea,Xb, where R is one or more selected from the oxide or hydroxide or oxalate or carbonate of La, Y, Lu, Gd, Tb, Nd, Ho elements, M is one or more selected from the carbonate, hydroxide, fluoride and or / chloride of Ca, Mg, Ba, Sr, Zn elements, C is the oxide of Si, Ge, N is one or more selected from the oxide or hydroxide or oxalate or carbonate or fluoride of B, Al, Ga and In elements, Re is the activator which is one or more selected from the oxide, hydroxide, oxalate or carbonate of Ce, Dy, Pr, Eu, Tm, Er, Sm, Yb, Sc, X is co-activator which is one or more selected from AlF3, CaF2, MgF2, BaF2, SrF2 and ZnCl2, as well as 0.001≦a≦0.5, 0.01≦b≦1.

Owner:HONG TAI TRADE

Self-cleaning decontamination-type interior wall latex paint as well as preparation method and coating method thereof

InactiveCN102391749AAging resistanceImprove pollutionLiquid surface applicatorsAntifouling/underwater paintsPolymer scienceEmulsion

The invention discloses a self-cleaning decontamination-type interior wall latex paint as well as a preparation method and a coating method thereof. The self-cleaning decontamination-type interior wall latex paint comprises the following compositions of pure water, thickening agent, multifunctional accessory ingredient, antifoaming agent, wet dispersing agent, antiseptic bactericide, pigment filler, nanometer decontamination factor, modified crylic acid emulsion, film forming accessory ingredient, cosolvent and flatting agent. The self-cleaning decontamination-type interior wall latex paint has the advantages of excellent washability, excellent contamination-resistant self-cleaning property, excellent decontamination property, excellent repairable property and soft surface texture.

Owner:NIPPON PAINT YASHILI

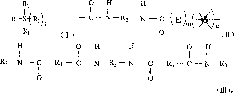

Therapeutic compounds and compositions and their use as PKM2 modulators

InactiveUS9458132B2Extended service lifeHigh affinityOrganic chemistryAntineoplastic agentsPyruvate kinaseStereochemistry

Compositions comprising compounds of general formula (I) that modulate pyruvate kinase are described herein. Also described herein are methods of using the compounds that modulate pyruvate kinase in the treatment of diseases.

Owner:AGIOS PHARM INC

Mold pressing production process for SMC (sheet molding compound) insulators

The invention discloses a mold pressing production process for SMC (sheet molding compound) insulator, and relates to a production process for insulators. The process includes using different matrix resin, packing and auxiliaries; manufacturing an SMC sheet with high insulating performance and flame retardant property by processes of mixing, paste scraping and doffing, impregnating and thickening; and then carrying out mold pressing and solidifying for the SMC sheet and an insulator core to obtain an SMC insulator product. The insulators produced by the method have the advantages of high product strength, good electric insulating performance, convenience in construction, excellent flame retardant property and ageing resistance and low cost.

Owner:SHANDONG JINGUANG COMPOSITE MATERIALS

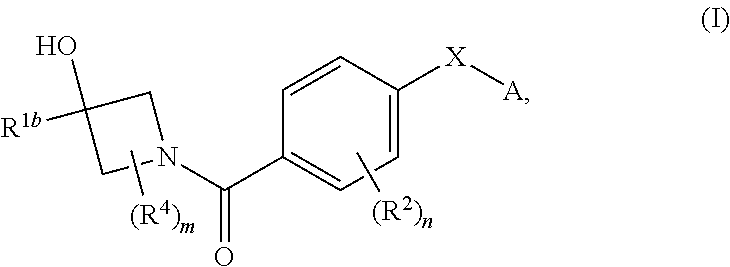

Special rubber powder for non-cured rubber asphalt waterproof coating and preparation method thereof

The invention discloses special rubber powder for a non-cured rubber asphalt waterproof coating and a preparation method thereof. The special rubber powder is prepared from, by weight parts, 50-65% of tire rubber powder, 20-40% of butyl rubber powder, 0.1-1.5% of activator, 0.1-1.0% of viscosity reducer and 5-15% of separant. The preparation method comprises the following steps: 1) stirring the tire rubber powder and the butyl rubber powder; 2) heating the activator and spraying the activator to the rubber powder obtained in the step 1), and then performing stirring and pre-activation; 3) mixing the pre-activated rough rubber powder obtained in the step 2) with the viscosity reducer and the separant, forming fine rubber powder through grinding, sieving the fine rubber powder, and performing packaging to obtain the finished product. Through the compounding of the waste tire rubber powder and the butyl rubber powder, the performance can meet the creep property, cohesiveness, self-healing property and ageing resistance requirements of the non-cured rubber asphalt waterproof coating. The added amount of plasticizer and polymerization modifiers is reduced effectively, and the cost can be reduced by over 10%.

Owner:GUANGXI YUANJING RUBBER TECH

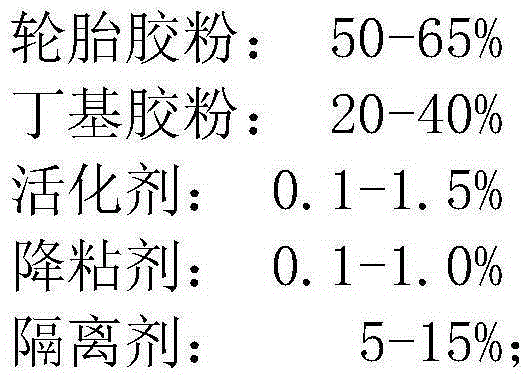

Epoxy acrylic cathode electrophoretic coating resin emulsion and preparation method thereof

ActiveCN109294314AGood storage stabilityAnti-corrosionAnti-corrosive paintsPaints for electrolytic applicationsEpoxyOrganic acid

The invention relates to the technical field of electrophoretic coating, and particularly relates to epoxy acrylic cathode electrophoretic coating resin emulsion and a preparation method thereof. Thepreparation method mainly comprises the following steps: firstly, synthesizing acrylic resin containing a reactive functional group; then, performing chain extension on epoxy resin until the epoxide equivalent is 400-900 with chain extender, and sequentially reacting the epoxy group in the chain-extended epoxy resin sequentially with organic secondary amine and the acrylic resin containing a reactive functional group to prepare epoxy acrylic resin; and mixing the epoxy acrylic resin with full-closed polyisocyanate, neutralizing the mixture with organic acid, and dispersing the mixture with deionized water to prepare the epoxy acrylic cathode electrophoretic coating resin emulsion. The resin emulsion is stable, has low solvent content and can be used as a film forming component of cathode electrophoretic coating; and the film has corrosion resistance, aging resistance and decorating performance, functions of priming coat and finishing coat can achieved by once electrophoretic coating, the coating process can be simplified, and the coating cost can be reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +3

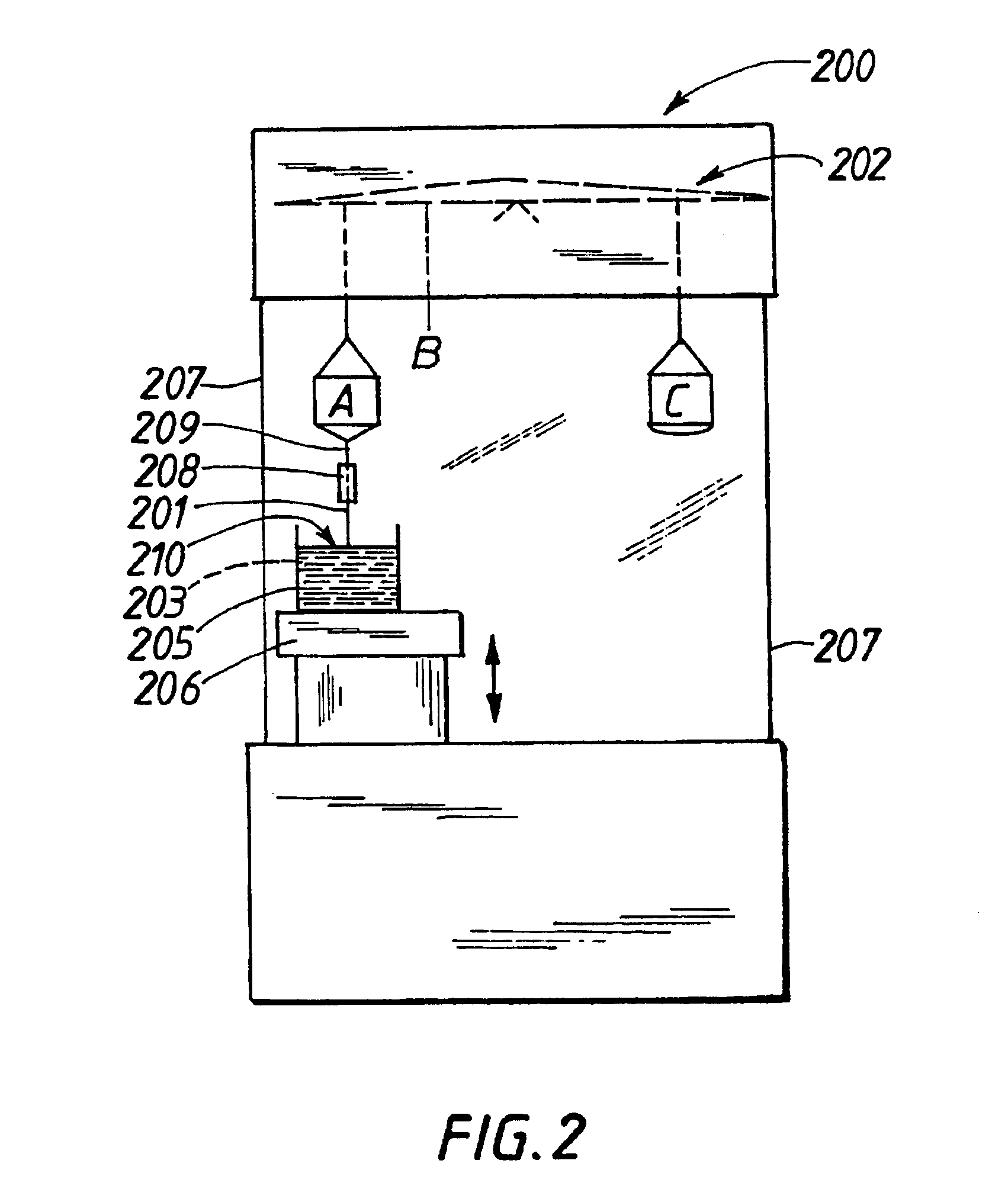

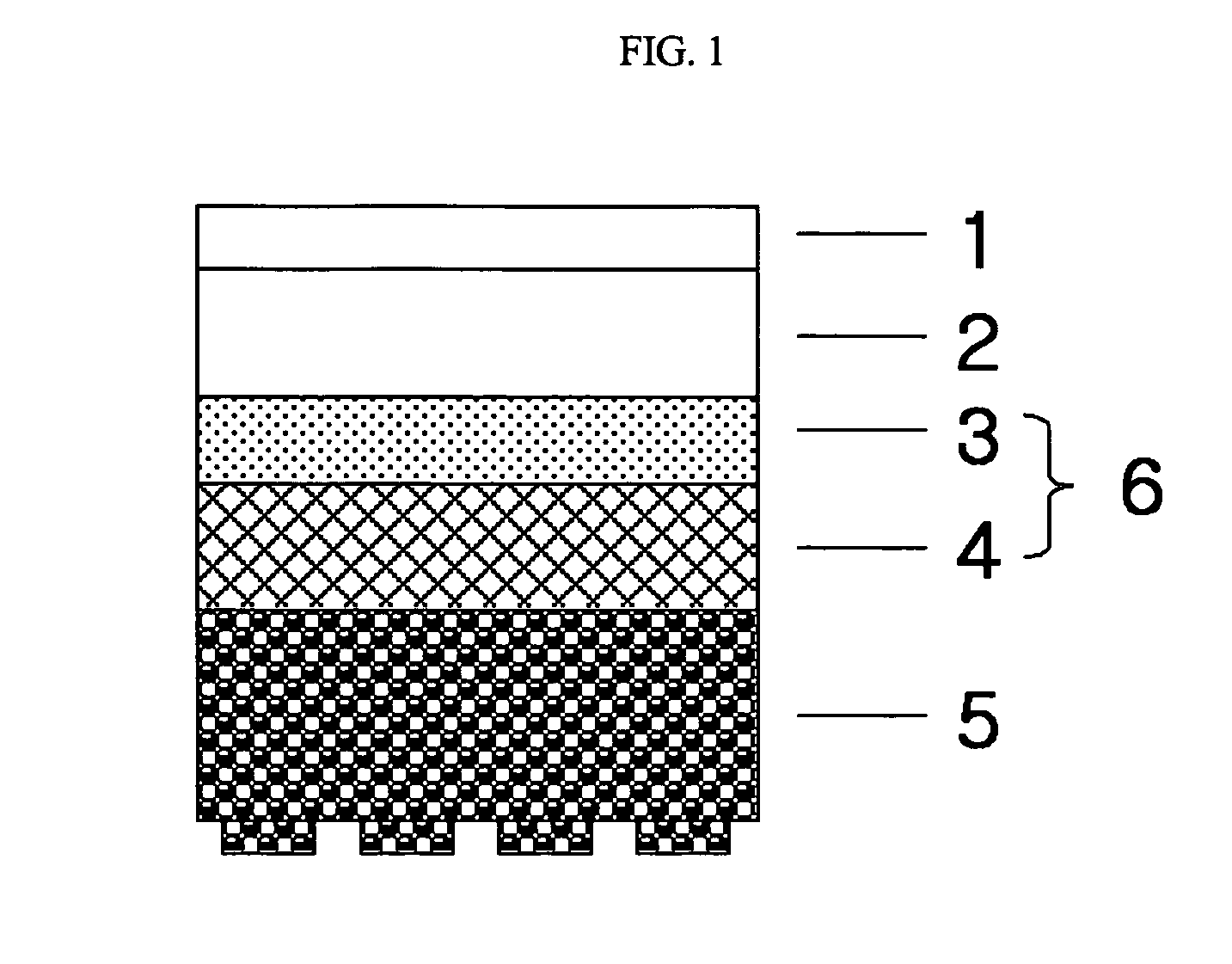

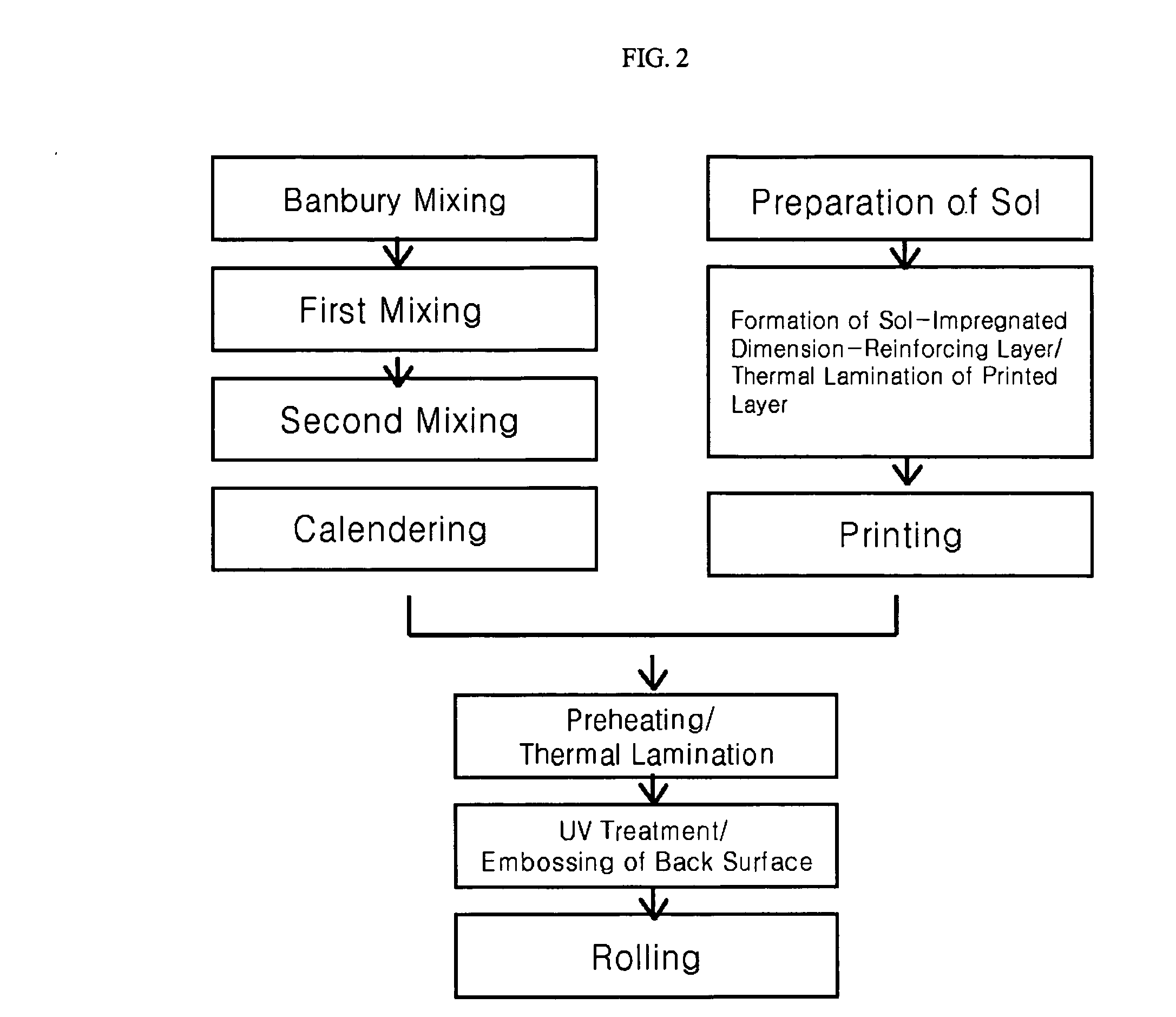

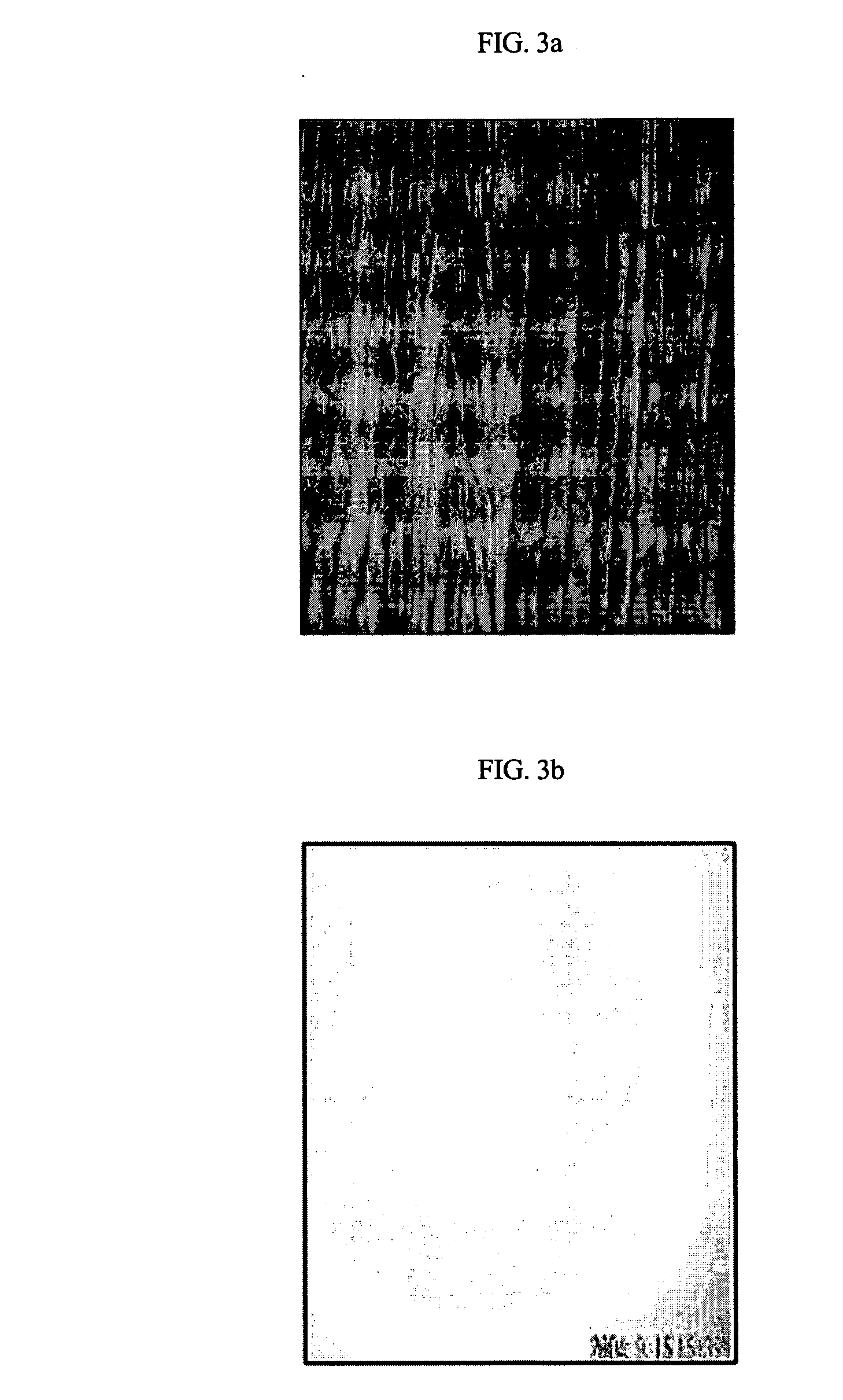

Non-PVC flooring made of thermo plastic elastomer and method for producing the same

InactiveUS20060105189A1Aging resistanceResistance to heat discolorationLamination ancillary operationsSynthetic resin layered productsElastomerPerturbateurs endocriniens

Disclosed herein is a method for producing a transparent or opaque flooring sheet or a flooring using a styrene-butadiene copolymer resin (as a thermoplastic elastomer) by calendering. The flooring causes no problems associated with environmental hormones, and generates no halogen gases or endocrine disruptors, such as dioxin, during incineration. Further, the flooring can be regenerated and reused at any time, and exhibits superior stability upon installation and mounting and excellent elastic restoration after application of stress due to inherent flexibility of rubber.

Owner:LG CHEM LTD

Water-tolerant and ageing-resistant waterborne polyurethane coating

InactiveCN104610872ACompatibleGood compatibilityPolyurea/polyurethane coatingsEpoxyGlass microsphere

The invention discloses a water-tolerant and ageing-resistant waterborne polyurethane coating which comprises the following components in parts by weight: 60-85 parts of waterborne fluorinated polyurethane-acrylate, 3-10 parts of epoxy resin, 2-10 parts of hydroxyl-terminated polybutadiene liquid rubber, 5-12 parts of nano calcium carbonate, 3-12 parts of hollow glass microspheres, 3-10 parts of nano titanium dioxide, 2-3 parts of butyl glycol ether, 1-3 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), 20-45 parts of deionized water, 2-3.5 parts of a curing agent, 2-4.5 parts of a coupling agent, and 1-3.5 parts of an additive. The water-tolerant and ageing-resistant waterborne polyurethane coating disclosed by the invention is good in water tolerance and ageing resistance, short in curing time, and excellent in mechanical properties.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Inorganic external wall coating

InactiveCN102863828ANo pollution to the environmentWater resistantAlkali metal silicate coatingsSodium silicateCalcium carbonate

The invention discloses inorganic external wall coating. The inorganic out-wall coating comprises, by weight, 80-100 parts of potash water glass, 40-60 parts of talcum powder, 20-30 parts of kaolin, 10-20 parts of light calcium carbonate, 1-3 parts of sodium hexametaphosphate, 2-5 parts of sodium silicate, 1-3 parts of hydroxyethyl cellulose, 2-5 parts of sodium alkyl sulfate, 2-5 parts of bentonite, and 80-120 parts of water. Compared with the prior art, the inorganic external wall coating has the advantages of water, acid and alkali resistance, high-temperature resistance, ageing resistance, high surface rigidity, low film forming temperature, high suitability for external walls of buildings, and non-toxic, odourlessness and no pollution to the environment by taking water as dispersion medium.

Owner:苏州燕泥地热地板科技有限公司

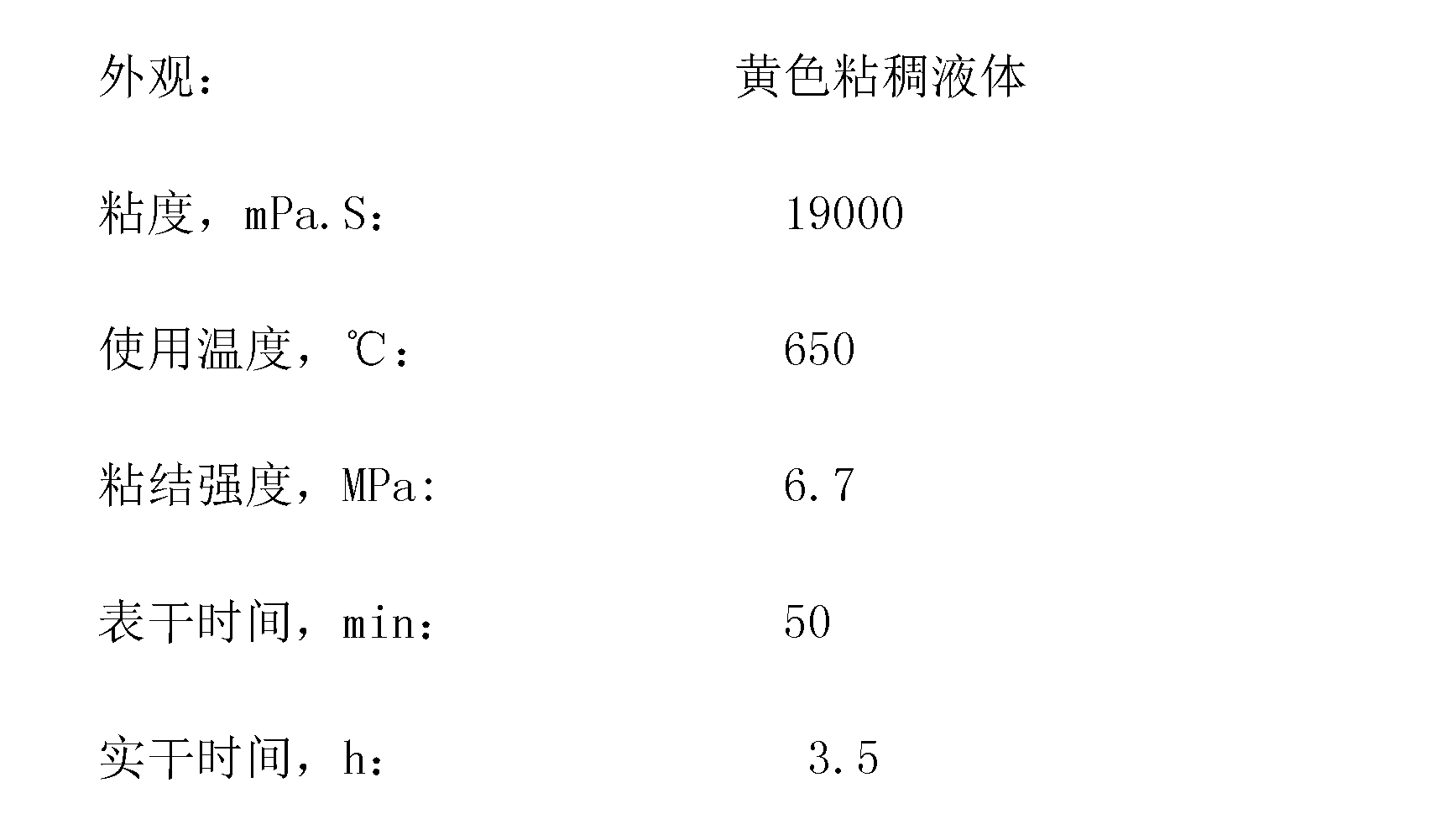

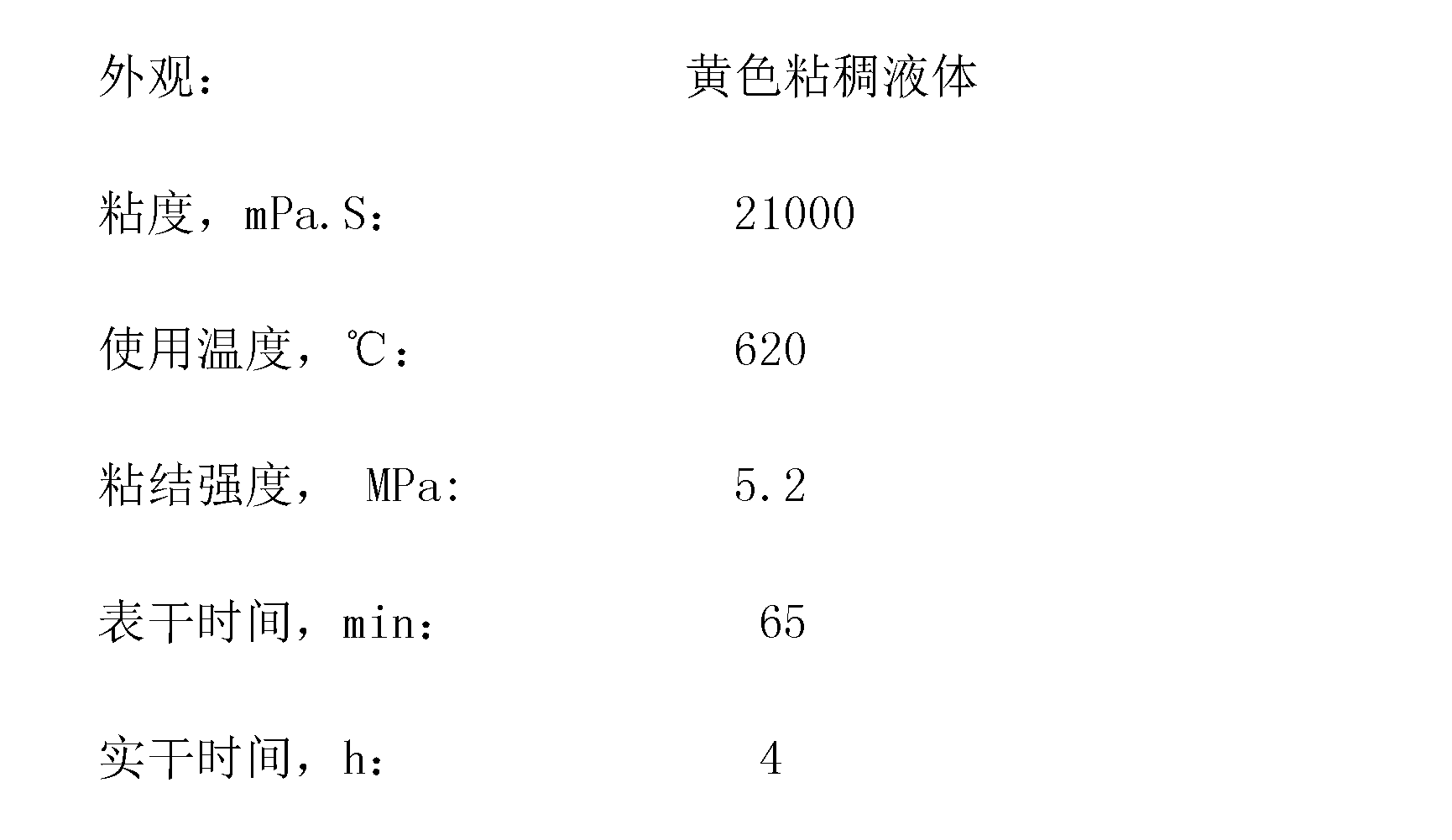

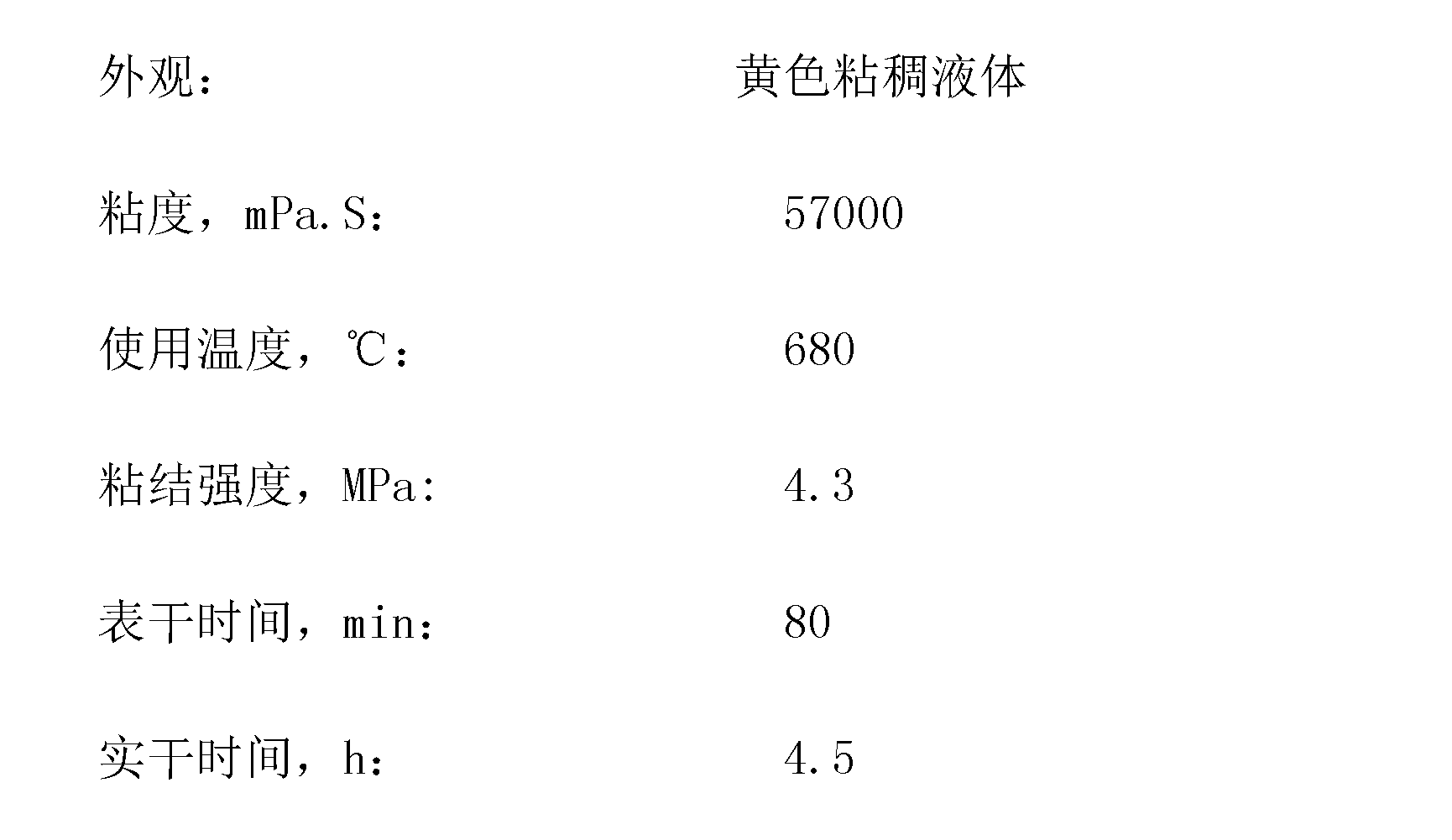

Cohesive glue for flexible decorative tile and manufacturing method thereof

ActiveCN101701138AHigh initial bond strengthLight weightEster polymer adhesivesHydrocarbon polymer adhesivesAntioxidantUltraviolet

The invention relates to cohesive glue for a flexible decorative tile and a manufacturing method thereof; the cohesive glue is composed of the following raw materials by weight proportion: 0.3-1.5 percent of water-retaining agents, 28-48 percent of water, 0.3-2 percent of thickeners, 48-68 percent of polymer latex, 0-0.35 percent of ultra-violet absorber, 0-0.42 percent of antioxidant, and 0.7-4.2 percent of film-forming additives; the manufacturing method is that: 1-3 percent of the water-retaining agents, 93-97 percent of water and 1-4 percent of the thickeners are mixed to prepare water-holding thickening liquid for spare, and then 94-98 percent of the polymer latex, 0-0.5 percent of the ultra-violet absorber, 0-0.6 percent of the antioxidant and 1-6 percent of the film-forming additives are mixed to prepare polymer film-formation weather-proofing modified liquid for spare, and 30-50 percent of the water-holding thickening liquid and the polymer film-formation weather-proofing modified liquid are formulated to prepare the cohesive glue for the flexible decorative tile. The cohesive glue has the advantages of no taste, no toxicity, high first sticking intensity, low volume weight and rapid construction speed.

Owner:烟台同化防水保温工程有限公司

Semi-aromatic copolyamide and process for preparing same

InactiveUS20110195215A1Improve propertiesImprove mechanical propertiesNon-fibrous pulp additionLayered productsPolymer sciencePolyamide

The invention relates to a copolyamide comprising at least two units corresponding to the following general formula:A / 10,Tin which:A is chosen from a unit obtained from an amino acid, a unit obtained from a lactam and a unit corresponding to the formula (Ca diamine).(Cb (cyclo)aliphatic diacid), with a representing the number of carbon atoms of the diamine and b representing the number of carbon atoms of the diacid, a and b each being between 4 and 36;10,T denotes a unit obtained from the polycondensation of 1,10-decanediamine and terephthalic acid,characterized in that it has a polydispersity index, denoted by Ip, of less than or equal to 3.5, measured by gel permeation chromatography.The invention also relates to the process for preparing said copolyamide, a composition comprising this polyamide and also the use of this polyamide and of such a composition.

Owner:ARKEMA FRANCE SA

Novel inorganic intumescent steel structure fireproof coating and preparation method thereof

ActiveCN109651856AMatching scienceSimple preparation processFireproof paintsAlkali metal silicate coatingsAluminium hydroxideUltimate tensile strength

The invention discloses a novel inorganic intumescent steel structure fireproof coating and a preparation method thereof, and belongs to the field of fireproof coatings, and the novel inorganic intumescent steel structure fireproof coating is characterized in that the fireproof coating mainly comprises the following raw materials in parts by dry weight: 5 to 6 parts of solid sodium silicate, 25 to44 parts of liquid sodium silicate, 20-40 parts of aluminum hydroxide, 3-10 parts of low-melting-point glass powder, 5-20 parts of magnesium oxide, 0-10 parts of redispersible latex powder, 0.1-5 parts of a waterproof agent, 0.1-1 part of a defoaming agent and 0-20 parts of water. Compared with the prior art, the method has the advantages of high expansion layer strength, small smoke amount, good film forming and fireproof performance, low cost, simple preparation process, convenient operation and the like.

Owner:SHIHEZI UNIVERSITY

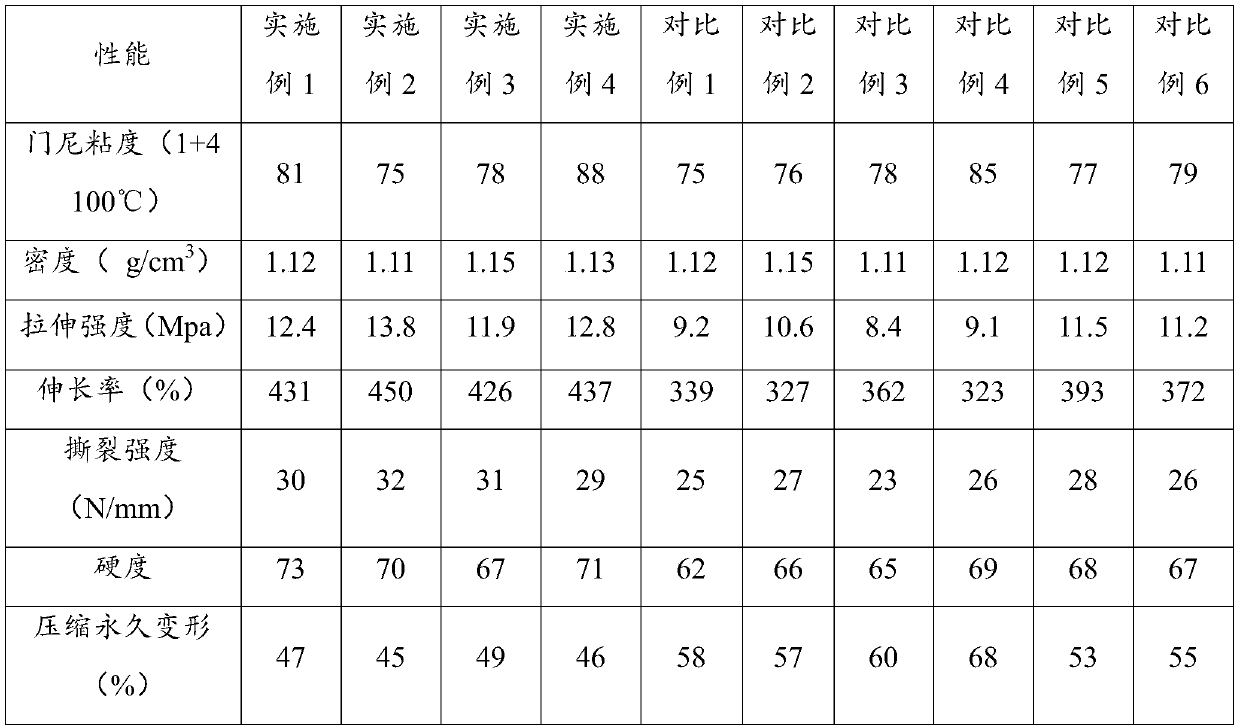

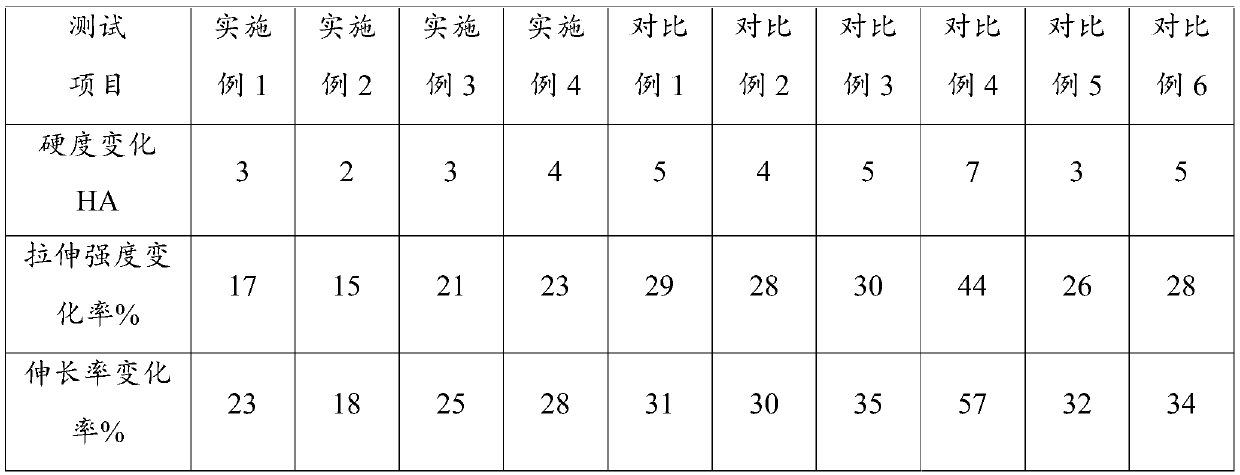

Blend rubber of silicone rubber and ethylene propylene diene monomer, and preparation method thereof

The invention belongs to the field of organic silicon materials, and particularly relates to blended rubber of silicone rubber and ethylene propylene diene monomer, and a preparation method thereof. The blend rubber of the silicone rubber and the ethylene propylene diene monomer is prepared from the following raw materials: raw methyl vinyl silicone rubber, raw ethylene propylene diene monomer, fumed silica, hydroxyl silicone oil, hexamethyl disilazane, dimethyldimethoxysilane, a silane coupling agent, methyl-terminated hydrogen-containing silicone oil, distilled water, zinc oxide, cerium oxide, calcium stearate, an accelerator, dicumyl peroxide, sulfur and auxiliary cross-linking agent. The silicone rubber and the ethylene propylene diene monomer in the blend rubber are good in compatibility, and the blend rubber has good mechanical properties and certain aging resistance.

Owner:SHANDONG UNIV +1

Macromolecule far-infrared electric heating cloth and heating system utilizing same

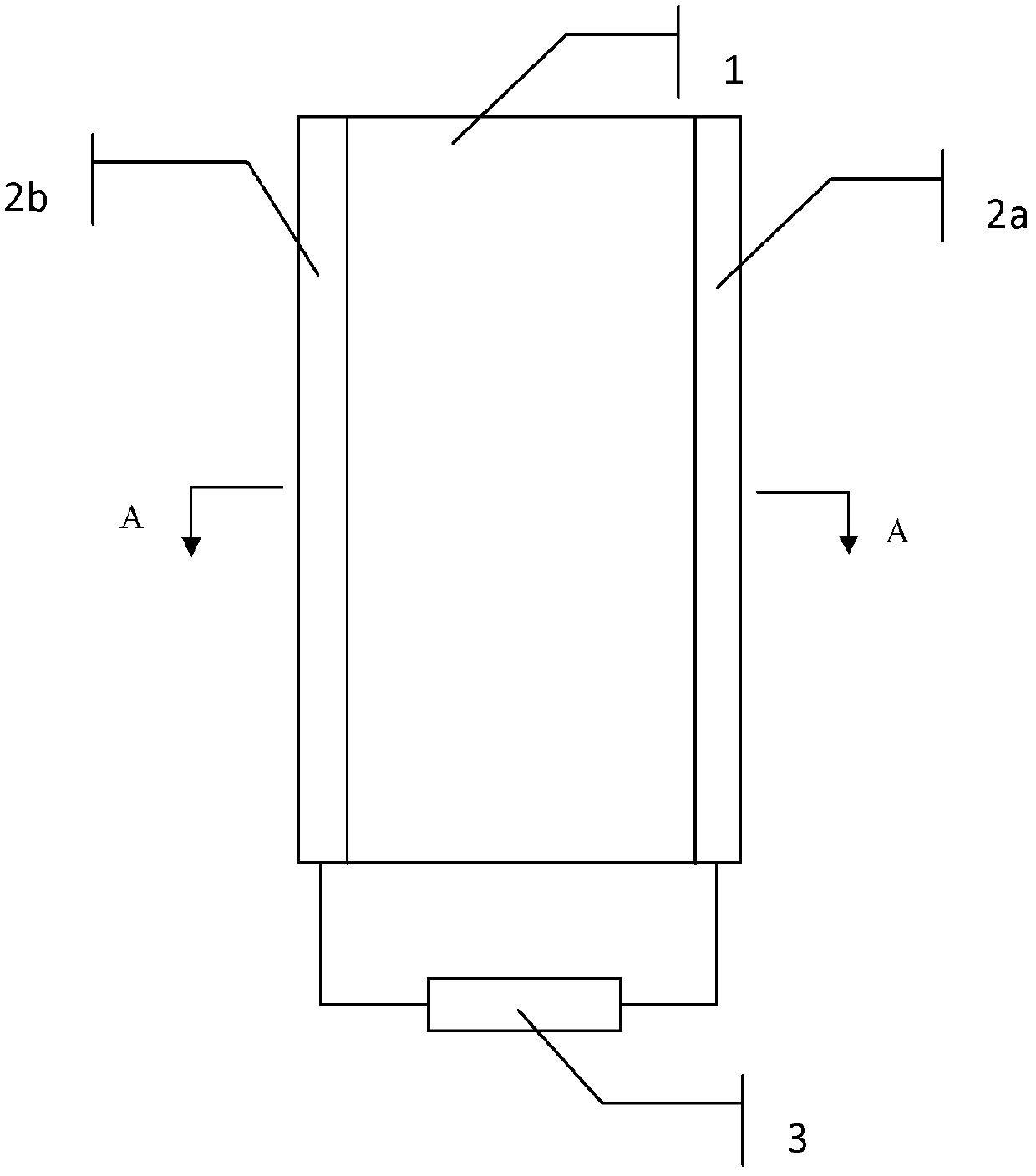

InactiveCN102612179AHigh specific capacityReduce volumeHeating element materialsVegetal fibresCopper foilHeating system

The invention relates to a heating system integrating far-infrared heating and ohmic resistance heating and further relates to an electric heating system. The electric heating system comprises electric heating cloth, two copper foils and a battery pack, wherein the two copper foils are adhered at two ends of the electric heating cloth, the battery pack is connected with the copper foils, two electrodes of the battery pack are connected with the two copper foils respectively, and the battery pack consists of a lithium ion battery with a temperature control switch. The macromolecule electric heating cloth has healthcare function and heating and warming functions and is fast in heating, uniform in heat radiation, high in electric heating transfer rate, resistant to heat, corrosion and ageing and the like.

Owner:中科天达(天津)新能源科技有限公司

Environmentally-friendly tile binder, and preparation method and use method thereof

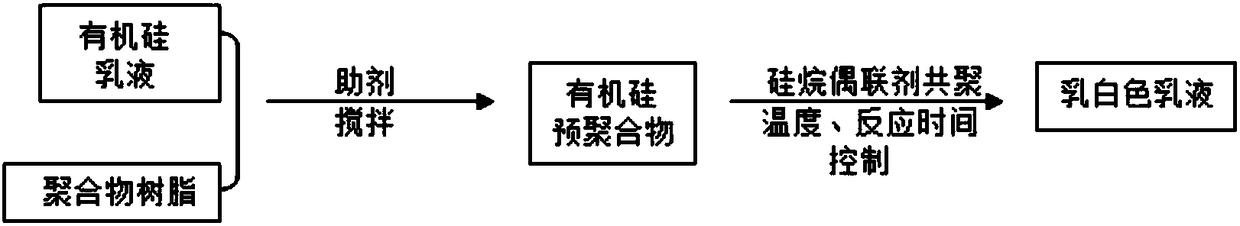

ActiveCN108264872AGood weather resistanceImprove water resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesBridge engineeringWeather resistance

The invention discloses an environmentally-friendly tile binder, and a preparation method and a use method thereof. The environmentally-friendly tile binder comprises, by weight, 70-85% of an organosilicone emulsion, 10-30% of polymer resin, 1.5-3.5% of a silane coupling agent, 0.1-0.3% of a mildew inhibitor, 0.2% of a wetting agent, 0.5-1.5% of an antifreeze agent and 0.1-0.3% of a defoaming agent. The tile binder has the advantages of excellent adhesion, high mechanical stability, good water and weather resistance, low VOC and no environmental pollution problem, is an environmentally-friendly binder, and can be used in large buildings, railway engineering, road and bridge engineering and pipeline engineering.

Owner:佛山市洵腾科技有限公司

Environment-friendly waterproof sealing material

PendingCN113549410AWaterproofWith sound insulationNon-macromolecular adhesive additivesMacromolecular adhesive additivesStearic acidRaw material

The invention provides an environment-friendly waterproof sealing material, and belongs to the technical field of materials. The environment-friendly waterproof sealing material is prepared from the following raw materials in percentage: 20 to 30 percent of ethylene butyl rubber, 20 to 30 percent of macromolecular polyisobutene, 20 to 30 percent of nano calcium carbonate, 1 to 2 percent of paraffin oil, 0.5 to 1 percent of stearic acid, 0.5 to 1 percent of carbon black, 0.5 to 1 percent of titanium dioxide, 0.5 to 1 percent of white carbon black and 0.5 to 1 percent of toner. The environment-friendly waterproof sealing material disclosed by the invention has the effects of waterproofness, sound insulation, shock absorption, air permeability and long anti-aging time, and also has relatively high followability; the environment-friendly waterproof sealing material does not contain any harmful component to human bodies and is highly environment-friendly; the environment-friendly waterproof sealing material can be suitable for any material surface and does not corrode any material; and the environment-friendly waterproof sealing material can be compounded with any material.

Owner:黄冈聚奥铭新材料有限公司

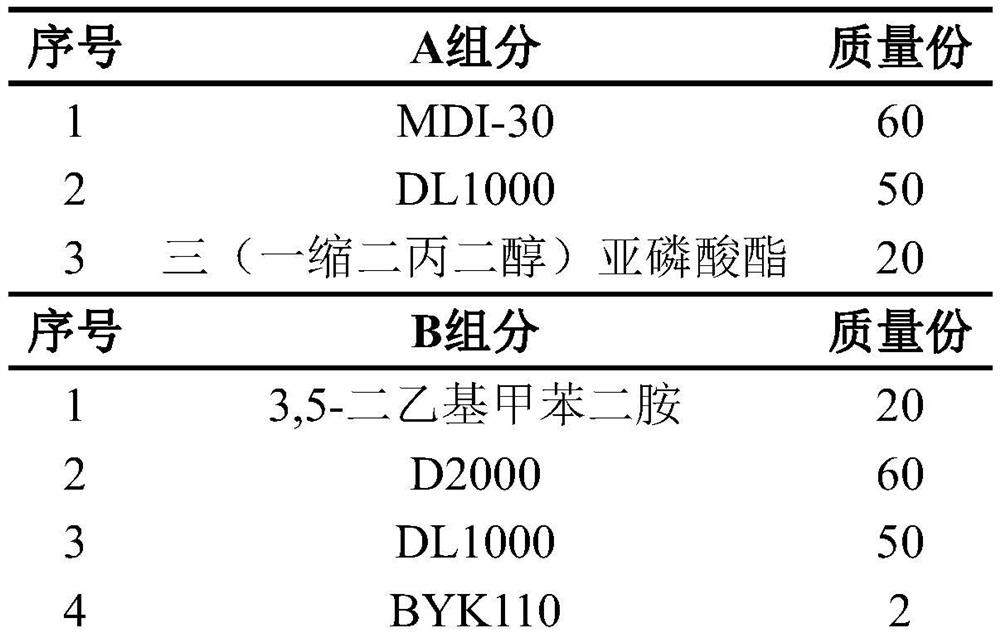

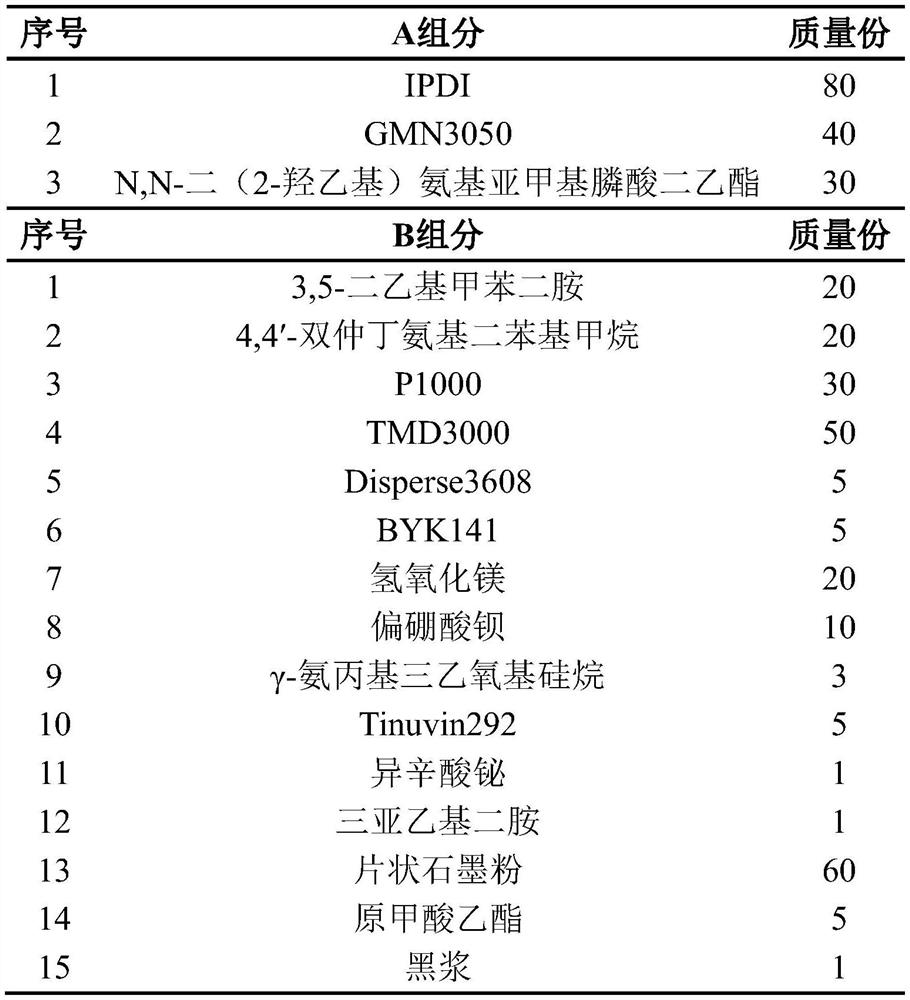

High-performance polyurea damping material and preparation method thereof

InactiveCN112375475AHigh solid contentImprove construction efficiencyFireproof paintsAntifouling/underwater paintsPolymer sciencePtru catalyst

The invention provides a high-performance polyurea damping material, and belongs to the technical field of damping materials. The material is composed of a component A and a component B. The componentA is an isocyanate-terminated prepolymer, and is formed by reacting polyisocyanate, polyol and a reactive liquid flame retardant, and the -NCO content of the component A is 12-16%; the component B isformed by mixing a steric hindrance chain extender, amine-terminated polyether, polyhydric alcohol, a dispersing agent, a defoaming agent, an ultrafine powder flame retardant, a coupling agent, a weather-proof additive, a catalyst, a flaky functional filler, a water removal agent and color paste; and the isocyanate index alpha value of the component A and the component B is 0.9-1.1. The inventionfurther provides a preparation method of the high-performance polyurea damping material. The high-performance polyurea damping material provided by the invention has very excellent mechanical properties and very good damping performance, also has relatively good flame retardance, water resistance, liquid medium resistance, corrosion resistance, mold resistance and aging resistance, and is easy toconstruct, safe, environment-friendly and wide in application range.

Owner:QINGDAO AIR NEW MATERIALS

Semi-aromatic copolyamide and process for preparing same

InactiveUS20170073470A1Improve mechanical propertiesReduce usagePolyamide coatingsThin material handlingPolymer sciencePolyamide

The invention relates to a copolyamide comprising at least two units corresponding to the following general formula:A / 10,Tin which:A is chosen from a unit obtained from an amino acid, a unit obtained from a lactam and a unit corresponding to the formula (Ca diamine).(Cb (cyclo)aliphatic diacid), with a representing the number of carbon atoms of the diamine and b representing the number of carbon atoms of the diacid, a and b each being between 4 and 36;10,T denotes a unit obtained from the polycondensation of 1,10-decanediamine and terephthalic acid,characterized in that it has a polydispersity index, denoted by Ip, of less than or equal to 3.5, measured by gel permeation chromatography.The invention also relates to the process for preparing said copolyamide, a composition comprising this polyamide and also the use of this polyamide and of such a composition.

Owner:ARKEMA FRANCE SA

Phosphate/polyurethane modified waterborne alkyd anticorrosive coating

ActiveCN108276864AAffect water resistanceAffect transparencyAnti-corrosive paintsVegetable oilPhosphate

The invention relates to a phosphate / polyurethane modified waterborne alkyd anticorrosive coating. The coating is composed of phosphate / polyurethane modified waterborne alkyd resin, a cosolvent, a filler, an antirust pigment, an auxiliary agent and deionized water, wherein the phosphate / polyurethane modified waterborne alkyd resin is prepared by performing a reaction on vegetable oil fatty acid, isophthalic acid, an organic acid anhydride, a diol, a branched-chain polyol, dimethylolpropionic acid, alkyl acrylate phosphate, polyisocyanate and a neutralizer. The phosphate / polyurethane modified waterborne alkyd anticorrosive coating provided by the invention has a phosphate group and a metal substrate, forms a compact phosphating film, thereby improving water resistance and rust resistance ofa coating film; and the coating is combined with the characteristics of polyurethane chemical resistance, aging resistance, flexibility and wear resistance, and the prepared phosphate / polyurethane modified waterborne alkyd anticorrosive coating has excellent adhesion, water resistance, flash rust resistance, chemical resistance, aging resistance, corrosion resistance and salt spray resistance.

Owner:ZHUHAI JELEE CHEM ENTERPRISE CO LTD

Rubber hose

The invention discloses a rubber hose. The hose comprises raw materials and additives. Raw materials comprise chlorinated polyethylene, natural rubber and regenerated rubber. Additives comprise a filling agent, a reinforcing agent, a sun-screening agent, a plasticizing agent and an accessory agent, wherein the filling agent is calcium carbonate, the reinforcing agent is carbon black, the sun-screening agent is paraffin, and the plasticizing agent is phosphoric acid fat alcohol ester, adipate or epoxidized soybean oil. The hose has the advantages that the chlorinated polyethylene, the natural rubber and the regenerated rubber are used, the hose is cold resistant and age resistant, the cold resistance of the hose is increased if the natural rubber amount is increased, and the hose is high in tension intensity and free from cracks.

Owner:NANTONG HUANGHAI MOTOR

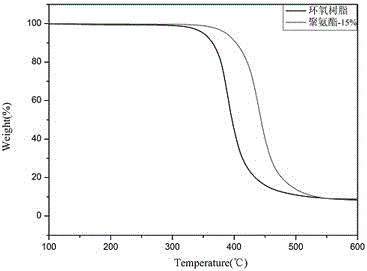

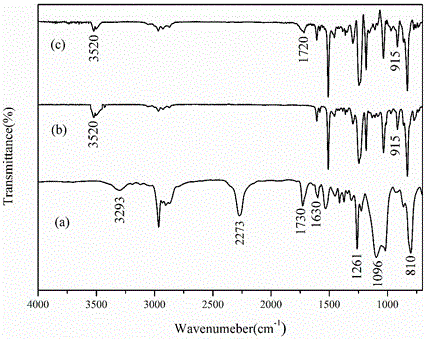

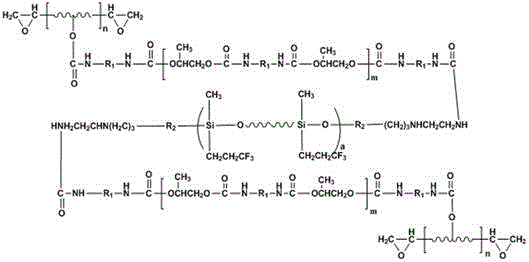

Fluorine and silicon-containing polyurethane prepolymer-modified epoxy resin and preparation method thereof

The invention discloses a fluorine and silicon-containing polyurethane prepolymer-modified epoxy resin and a preparation method thereof. The preparation method comprises the following steps: firstly synthesizing an amino fluorosilicone oil-modified polyurethane prepolymer; and modifying the epoxy resin by using the polyurethane prepolymer. The epoxy resin has relatively good tensile strength and also has good heat stability, and the toughness is greatly improved. The invention provides the preparation method of the fluorine and silicon-containing polyurethane prepolymer-modified epoxy resin. By adopting a simple solution reaction, the preparation process is simple and the method is easy to popularize and apply.

Owner:SUZHOU DEJIE MEMBRANE MATERIAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com