High-performance polyurea damping material and preparation method thereof

A damping material and high-performance technology, applied in the field of damping materials, can solve the problems of poor resistance to liquid media, low construction efficiency, thick coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing the above-mentioned high-performance polyurea damping material, comprising the following steps:

[0056] (1) Preparation of component A: Prepare raw materials according to the formula, add polyols and reactive liquid flame retardants into a closed high-speed disperser mixing tank for pre-mixing for 10-15 minutes, control the speed at 200-400r / min, Then put it into the reactor with nitrogen protection, heat to 95-100°C under stirring, dehydrate under vacuum -0.1MPa for 5-6h, release the vacuum, cool down to below 50°C and add polyisocyanate, at 80-85°C React for 3-4 hours. After the reaction is over, measure the -NCO value and discharge the material, filter and pack;

[0057](2) Preparation of component B: Prepare raw materials according to the formula, add steric chain extender, amino-terminated polyether, polyol, dispersant, defoamer, ultrafine powder flame retardant and flake functional filler to the Pre-mix ...

Embodiment 1

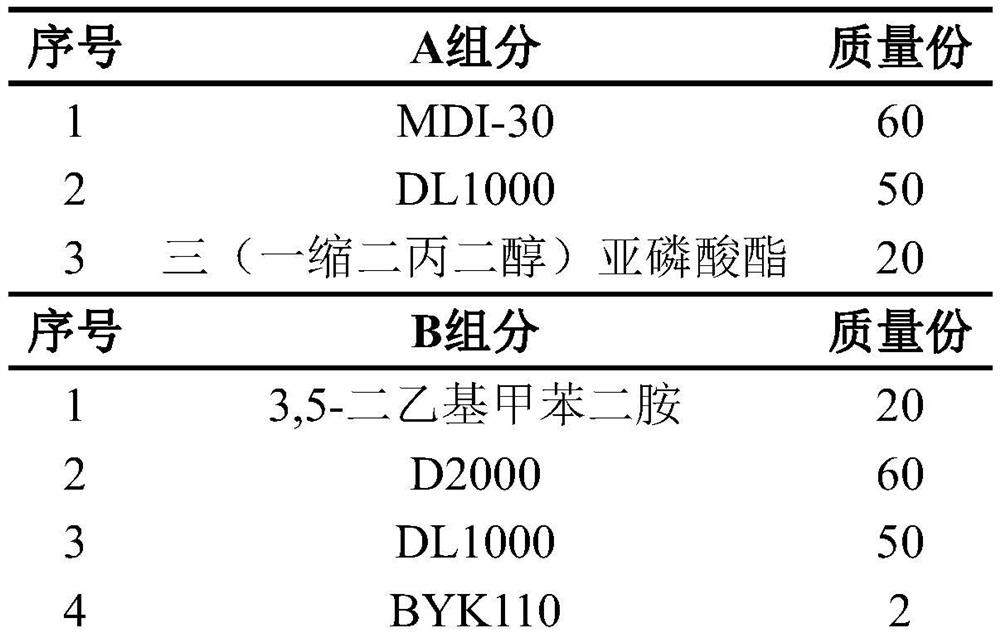

[0060] A kind of high-performance polyurea damping material, its formula composition is as shown in table 1:

[0061] Table 1 Embodiment 1 High-performance polyurea damping material formula composition

[0062]

[0063]

[0064] The preparation method of above-mentioned high-performance polyurea material is:

[0065] (1) Synthesis of component A of terminal isocyanate prepolymer: add 50 parts of DL1000 and 20 parts of tris(dipropylene glycol) phosphite according to the formula amount into a closed high-speed disperser mixing tank for pre-mixing 10- 15min, the rotation speed is controlled at 200-400r / min, and then put into the reaction kettle protected by nitrogen gas, heated to 95℃~100℃ under stirring, dehydrated under vacuum -0.1MPa for 5-6h, release the vacuum, and cool down to 50 Add 60 parts of MDI-30 below ℃, react at 80-85℃ for 3-4h, after the reaction, measure -NCO value reaches 12.5±0.5%, discharge the material, filter and pack;

[0066] (2) Preparation of comp...

Embodiment 2

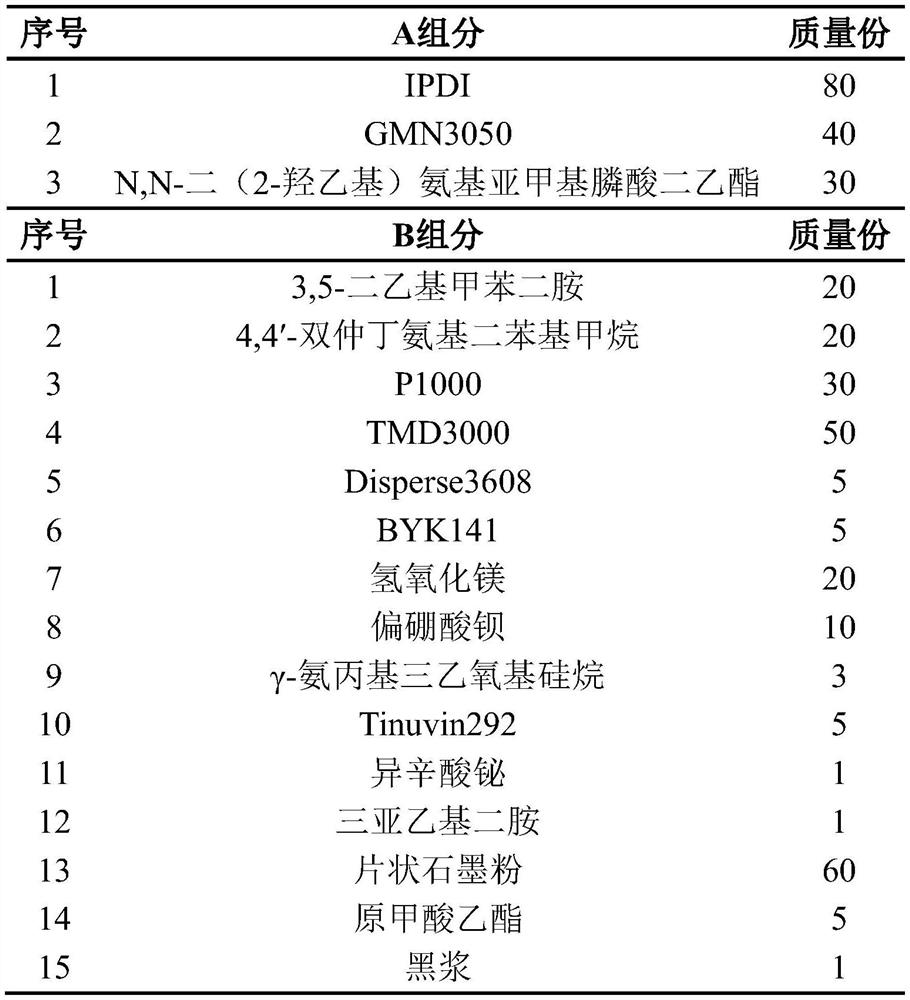

[0069] A kind of high-performance polyurea damping material, its formula composition is as shown in table 2:

[0070] Table 2 Example 2 High-performance polyurea damping material formula composition

[0071]

[0072] The preparation method of above-mentioned high-performance polyurea material is:

[0073] (1) Synthesis of component A of terminal isocyanate prepolymer: add 40 parts of GMN3050 and 30 parts of N,N-bis(2-hydroxyethyl)aminomethylene phosphonic acid diethyl ester according to the formula amount into the closed Premix in the stirring tank of the high-speed disperser for 10-15min, the speed is controlled at 200-400r / min, and then put into the reaction kettle protected by nitrogen, heated to 95°C~100°C under stirring, under vacuum -0.1MPa Dehydration for 5-6 hours, release the vacuum, lower the temperature to below 50°C, add 80 parts of IPDI, react at 80-85°C for 3-4 hours, after the reaction, measure the -NCO value to 15.8±0.5%, discharge the material, filter and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com