Patents

Literature

916results about How to "Antiseptic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing preserved kiwi fruit by vacuum freeze drying

InactiveCN102742711AAdjust acidity properlyGood hardening effectConfectionerySweetmeatsLiquid glucoseActinidia

A method for preparing preserved kiwi fruit by vacuum freeze drying. The method comprises steps of: peeling and slicing kiwi fruit, immersing the kiwi fruit in color protecting liquid, and then placing the kiwi fruit in a hardening liquid for hardening; after hardening, conducting an ultrasonic pretreatment in liquid glucose; and then successively carrying out vacuum sugar permeability, prefreezing, vacuum freeze drying, and packing to obtain the preserved kiwi fruit. According to the present invention, glucose lactone is added into a calcium chloride hardening liquid to coagulate protein in the fruit pieces and significantly improve hardening effect. The ultrasonic pretreatment and vacuum sugar permeability avoid a heat treatment process of rapid heating for a long time or short time, so that the kiwi fruit slices are still bright green (quite similar with an original fruit color). Vacuum freeze drying on the kiwi fruit realizes a high nutrient conservation rate.

Owner:NORTHWEST UNIV(CN)

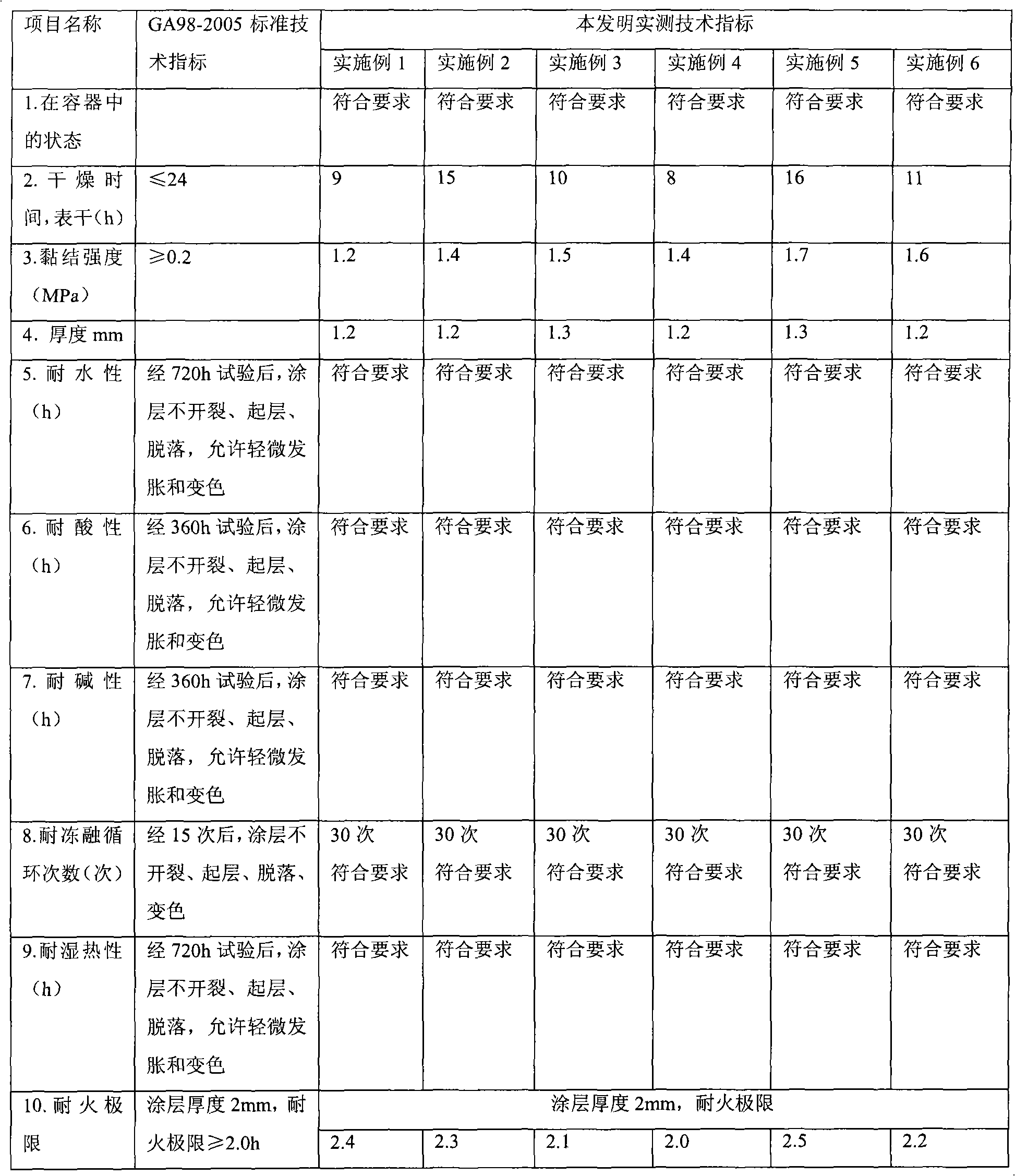

Fire-retardant paint with steel structure

ActiveCN101857756AExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

The invention relates to fire-retardant paint with a steel structure, which is prepared from the following raw materials proportioning by weight: 45 to 60 of composite substrate resin, 6 to 8 of melamine, 6 to 8 of pentaerythritol, 16 to 20 of ammonium polyphosphate, 4 to 10 of expansible graphite, 2 to 5 of nano magnesium hydroxide, 1 to 3 of zinc phosphate, 1 to 3 of zinc borate, 2 to 5 of aluminum hydroxide, 3 to 5 of aluminum polyphosphate, 6 to 9 of titanium dioxide, 0.5 to 0.8 of flatting agent and 15 to 20 of acetone. The paint has excellent capabilities of fire prevention and corrosion prevention.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

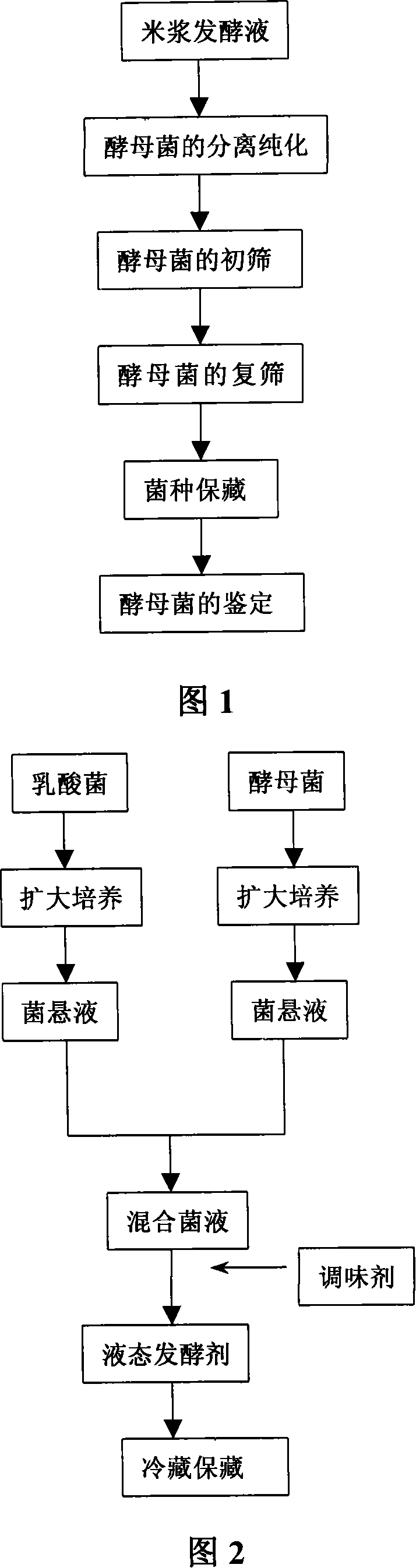

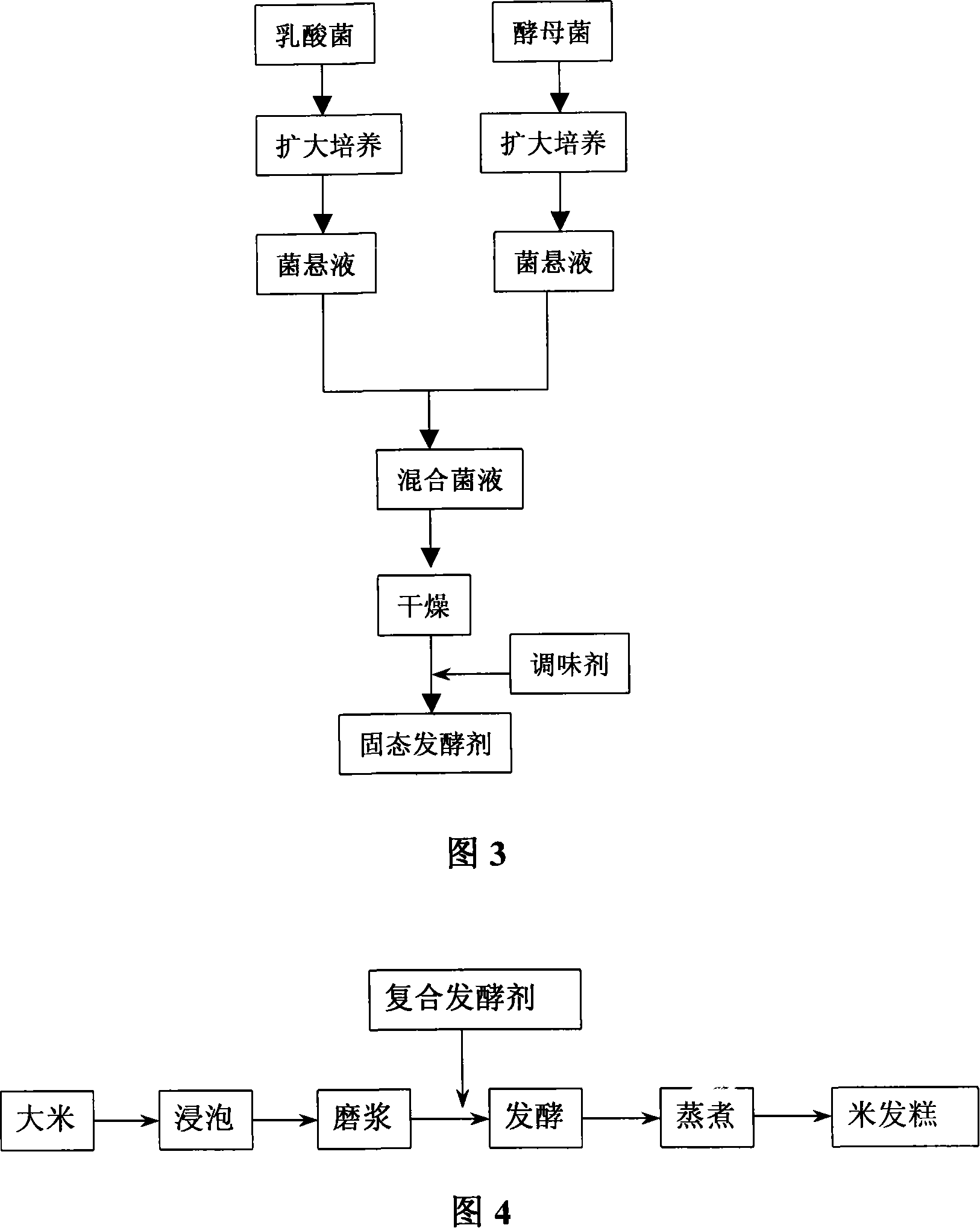

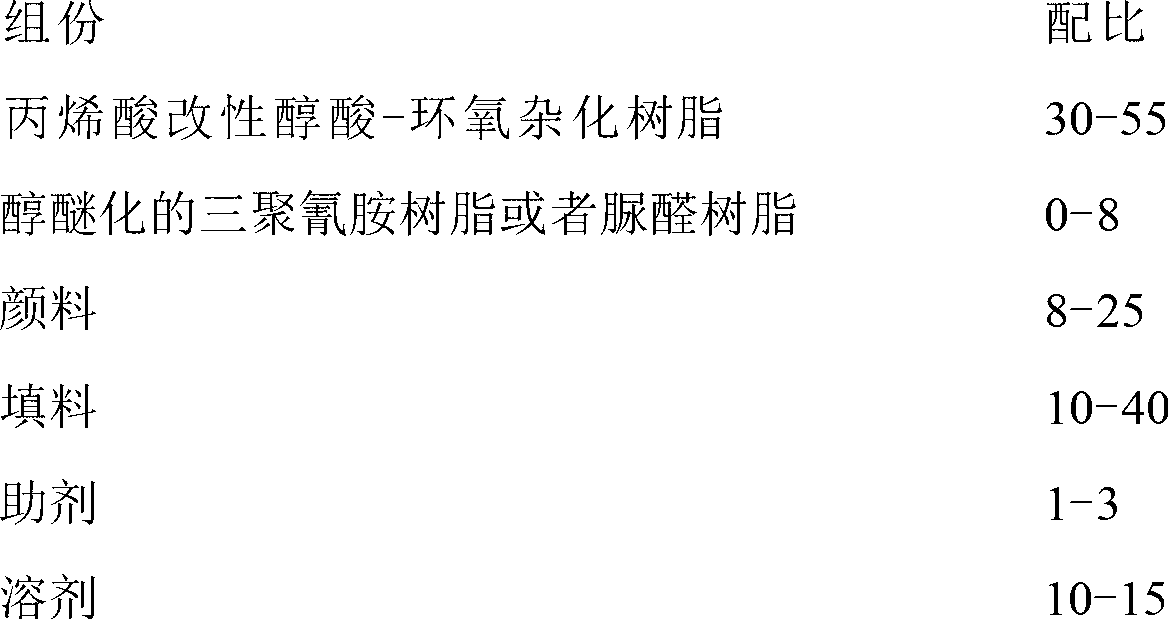

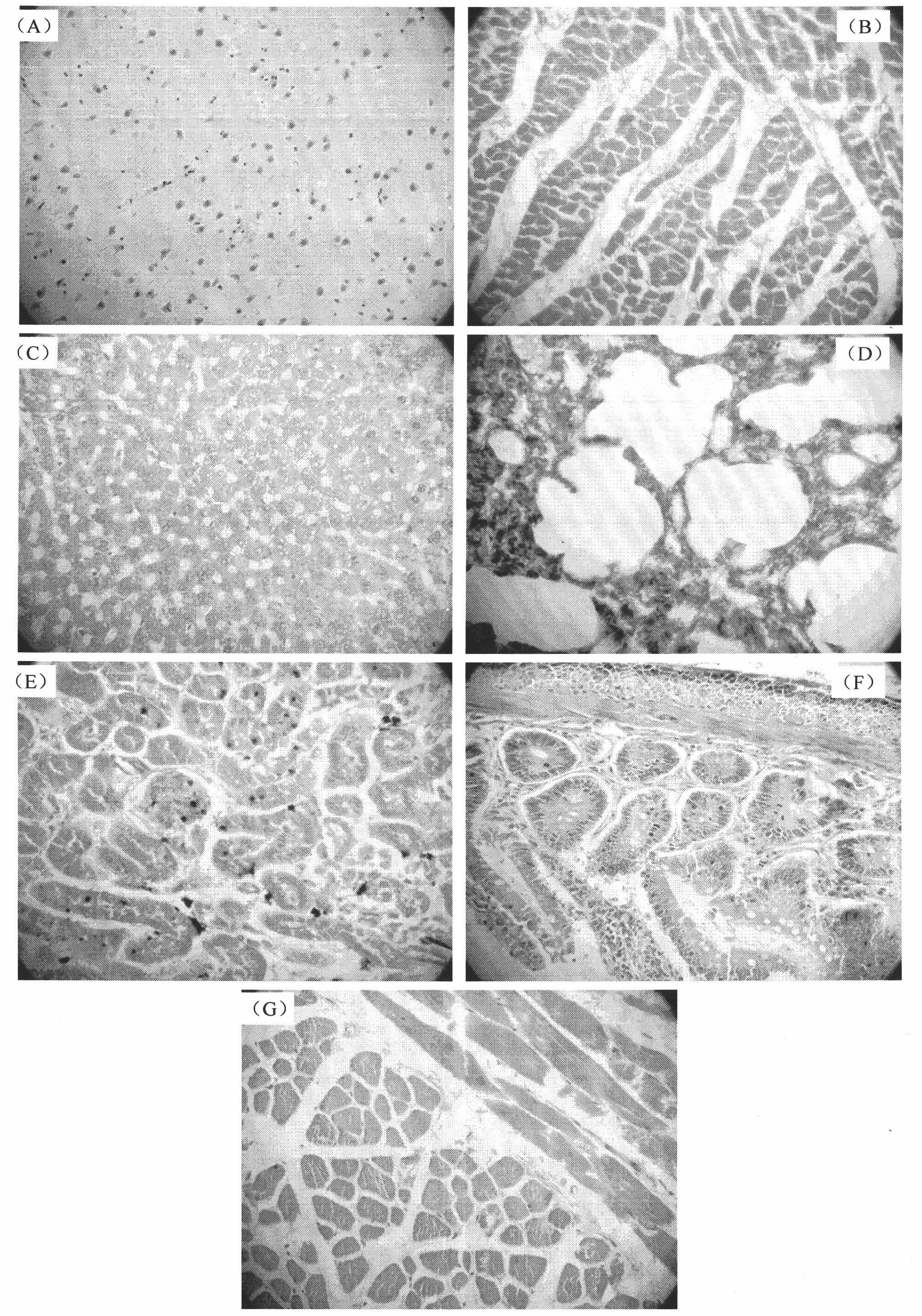

Mycopremna as microorganism leaven, composite leaven containing the mycopremna and application of the same

InactiveCN101173223AShort fermentation timeGood fermentation propertiesFungiMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a strain used as hametz of microorganism, belonging to technical field of processing agricultural microorganism and food, which comprises the strain and the compound hametz ofplant lactocin as well as the application. The invention is characterized in that: the microzyme-Custer bouquet yeast strain can obtain by separating and filtering, which is suitable for fermenting the rice steamed sponge cake; the yeast strain is preserved in Chinese typical culturing and preserving centre and the preserved number is CCTCC NO: M207150. The microorganism compound hametz can be made by the ZSM-001 Custer bouquet yeast strain and AS1.510 plant lactocin (Lactobacillus plantarum), and can be used in rice fermented products, such as rice steamed sponge cakes. The invention has theadvantages of good fermenting performance and easy commercial process, and the products made by the invention have a typical sweet and sour perfume.

Owner:HUAZHONG AGRI UNIV

Wood wax oil for protecting lumber and preparation technique thereof

InactiveCN101407068AStay flexibleKeep greenCoatingsWood impregnation detailsVegetable oilHazardous substance

The invention discloses wood wax oil for protecting wood and a method for preparing the same. The raw materials of the wood wax oil comprise vegetable oil and wax, and the wood wax oil is characterized in that the compositions of the raw materials of the wood wax oil comprise vegetable oil, animal or vegetable wax, ferric oxide and a catalyst. The wood wax oil and the preparing process can protect the wood completely, can keep the elasticity and environmental protection performance of wood, can prevent the wood from cracking effectively and enable the wood to have various comprehensive properties such as drying, as well as corrosion, insects, moisture, mildew, termite, anti-cracking, and fire-retardant resistance, and the like, and meet all requirements of environmental protection, and does not to release any harmful substance during long-term use. The preparing process of the wood wax oil is simple and no organic solvent is needed to be added, thereby avoiding the incorporation of harmful substances.

Owner:张海林

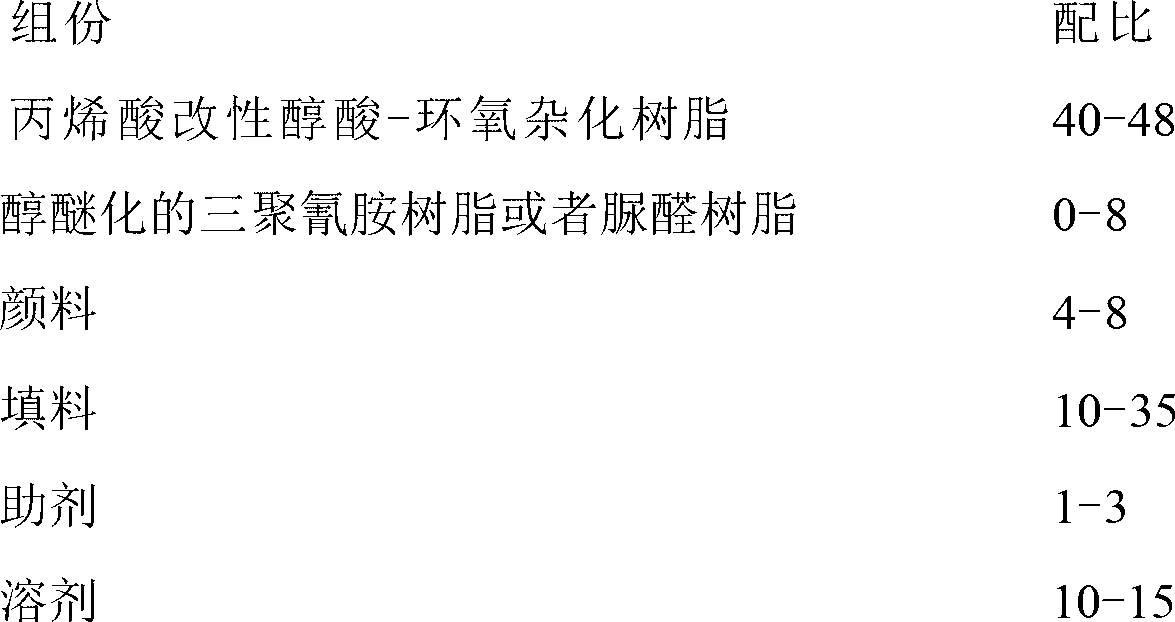

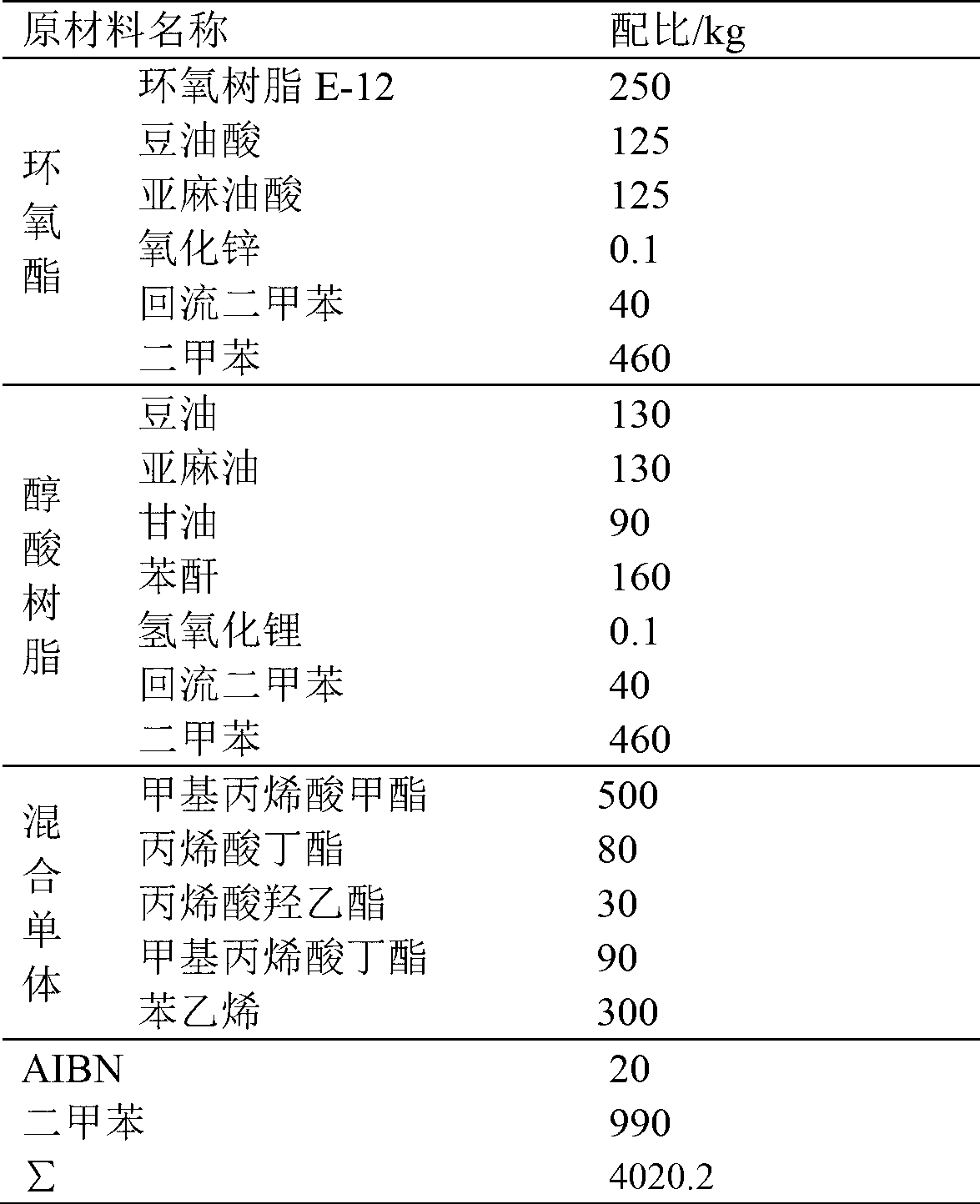

Acrylic-modified alcohol acid-epoxy ester hybrid resin and paint thereof

The invention relates to an acrylic-modified alcohol acid-epoxy ester hybrid resin which is prepared by the following steps: carrying out high-temperature esterification reaction on an epoxy resin and fatty acid under the action of an esterification catalyst to obtain epoxy ester; carrying out alcoholysis on vegetable oil and polyalcohol at high temperature, cooling, and adding polybasic acid for esterification, thereby obtaining an alkyd resin; and adding acrylic monomers into the epoxy ester-alkyd resin mixed solution, and carrying out graft polymerization under the action of an initiator to obtain the hybrid resin. The hybrid resin can be used as a main film forming material to prepare a high-temperature baking varnish together with a crosslinking agent. The high-temperature baking varnish can be used as various curtain-coating mirror back paints, including silver mirror back paints, aluminum mirror back paints, glass paints and the like, can satisfy the technological requirements for application of curtain coating production lines of which the width exceeds 3m, has a stable curtain coating, and can become completely dry after being baked at 150-130 DEG C for 3-5 minutes. The product has the advantages of low-temperature quick drying, high hardness, excellent adhesive force, dampness-heat resistance, chemical resistance, salt-fog resistance and the like.

Owner:常州市弘可利办公用品有限公司 +1

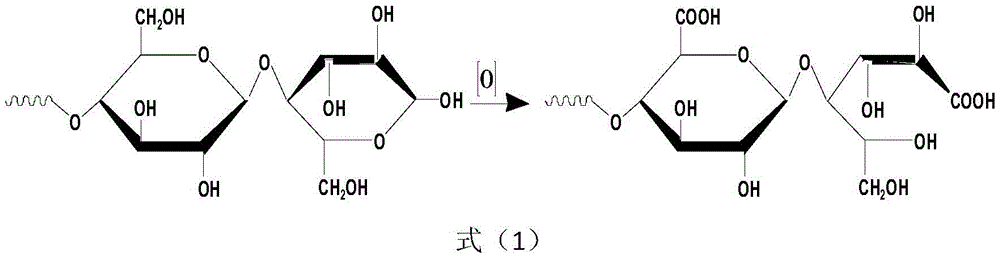

Starch adhesive with nanometer oxidized cellulose size as matrix and preparation method of starch adhesive

ActiveCN105542676AAvoid replacementPrevent drynessNon-macromolecular adhesive additivesStarch derivtive adhesivesPolymer scienceSlurry

The invention discloses a starch adhesive with nanometer oxidized cellulose size as the matrix. The starch adhesive is prepared from, by weight, 100 parts of nanometer oxidized cellulose size with the oxidation rate of 5-30%, 10-40 parts of starch, 2-5 parts of oxidizing agent, 0.1-2 parts of stabilizer, 0.1-2 parts of preservative and 0.1-2 parts of emulsified paraffin. The preparation method includes the steps of preparing nanometer oxidized cellulose size the with oxidation rate of 5-30%, adding starch and 2-5 parts of oxidizing agent to the prepared nanometer oxidized cellulose size in batches, adding stabilizer, preservative and emulsified paraffin after sufficient stirring, and sufficiently stirring the components at a temperature of 50-70 DEG C till all the components are evenly dispersed to obtain the starch adhesive. The starch adhesive is high in bonding strength and high in water resistance. By means of the preparation method, the solvent replacement and drying process is avoided, energy consumption is greatly lowered, and labor intensity is reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

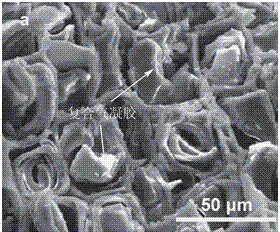

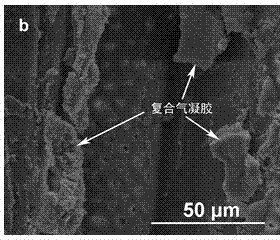

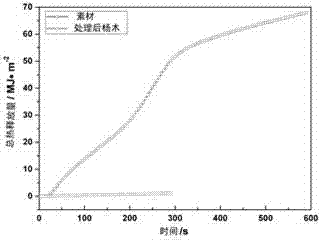

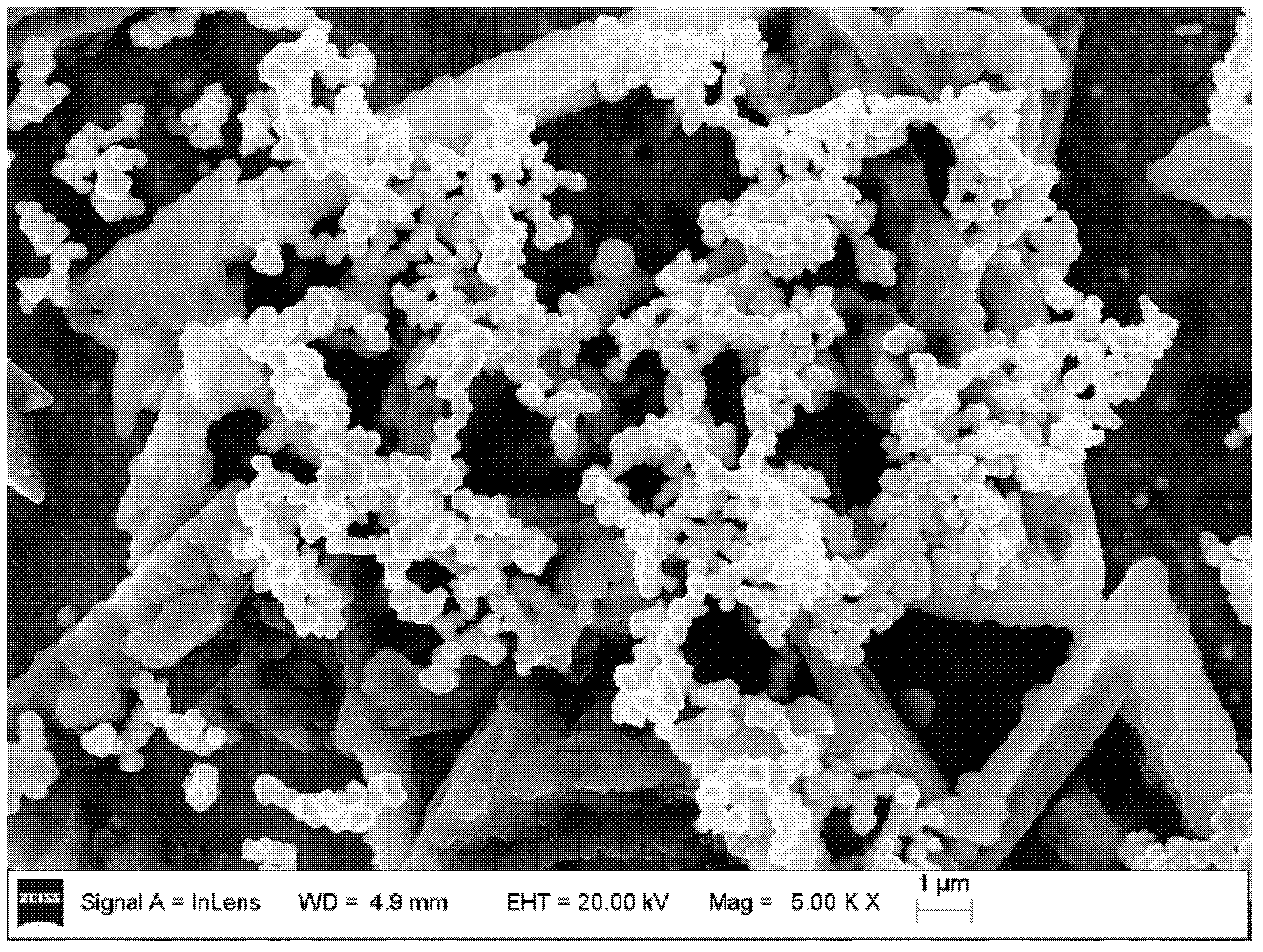

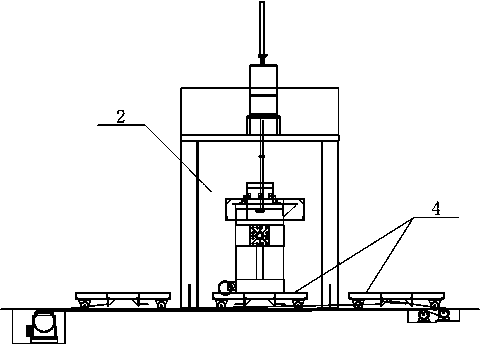

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

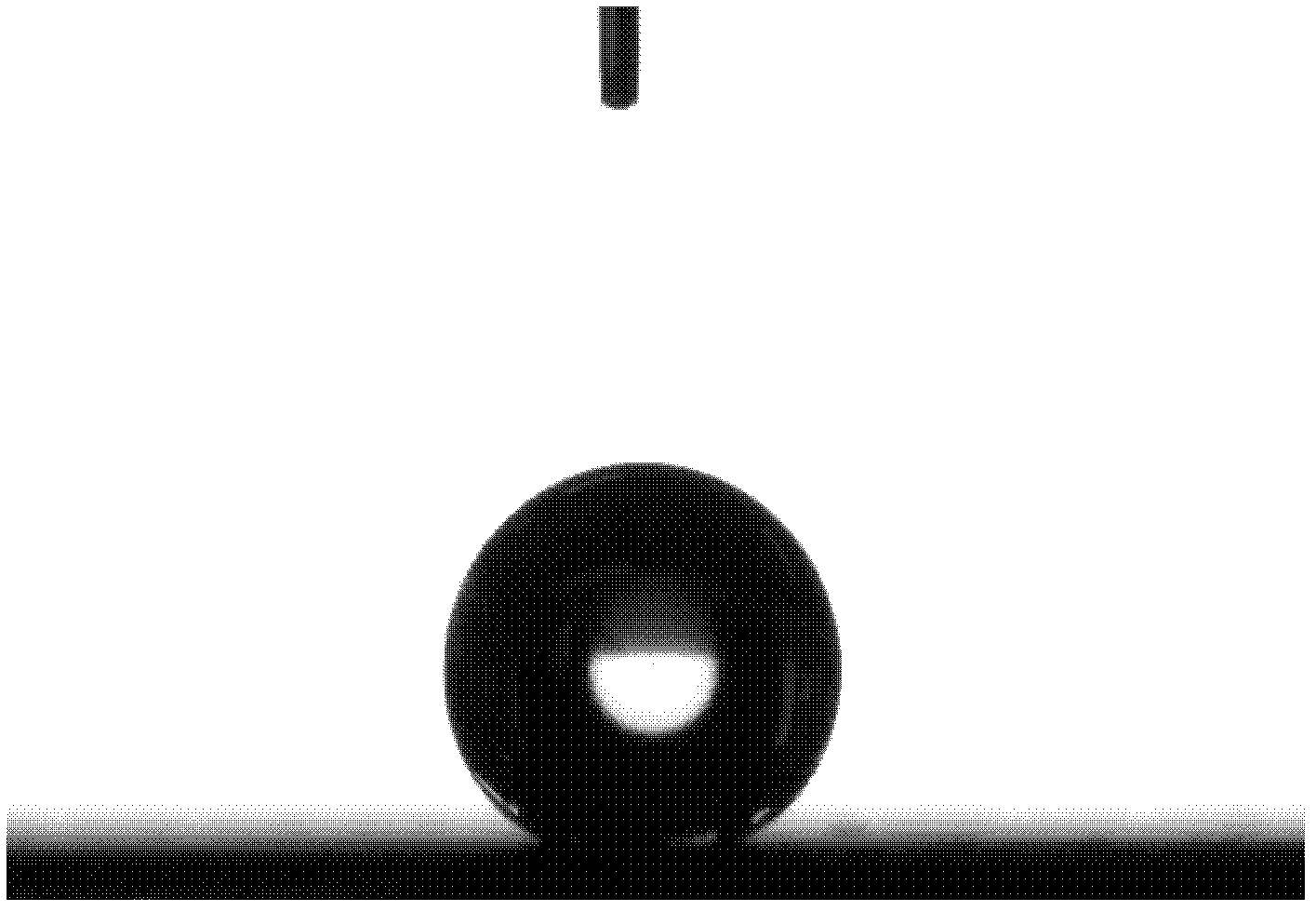

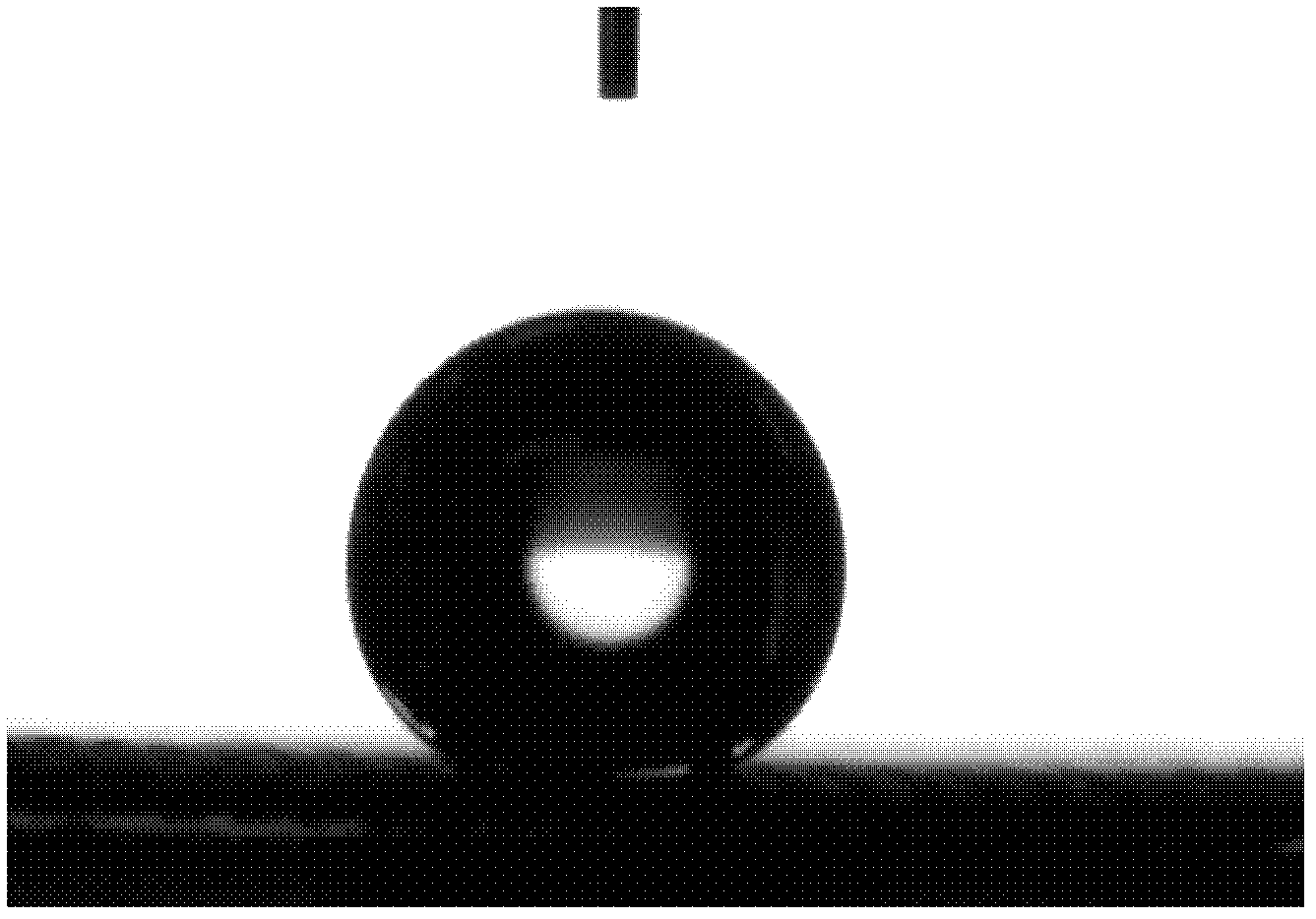

Drag reduction superhydrophobic coating and preparation method thereof

InactiveCN102492942AImprove hydrophobicityAntisepticVacuum evaporation coatingSputtering coatingReduction rateStrong acids

A drag reduction superhydrophobic coating and a preparation method thereof belong to the technical field of functional nanometer material application. A base of the drag reduction superhydrophobic coating adopts electroless metal deposition technique, a precious metal micro-nanometer binary grading composite structure is constructed on the base and decorated by a low surface energy material, a water static contact angle of the coating is larger than 150 degrees, and a rolling angle is smaller than 5 degrees. The drag reduction superhydrophobic coating is used for a model with motive power by itself, running speed of the model is obviously increased, and drag reduction rate is as high as 20%. The drag reduction superhydrophobic coating has good corrosivity resistance and can resist corrosion of strong acid and strong base solutions. The drag reduction superhydrophobic coating has repairability, and the preparation method can enable hydrophobicity of damaged areas to be rapidly recovered in a short period. The preparation method of the drag reduction superhydrophobic coating is simple, short in preparation period, and high in drag reduction rate.

Owner:BEIJING UNIV OF CHEM TECH

Absorbable iron-based alloy implantable medical device

ActiveCN106806938AReduce design sizeShort period of complete absorptionSurgeryPharmaceutical delivery mechanismZinc compoundsWater soluble

The invention relates to an absorbable iron-based alloy implantable medical device, which comprises an iron-based alloy matrix and a degradable polymer arranged on the surface of the iron-based alloy matrix, as well as a zinc-containing protecting body arranged on the surface of the iron-based alloy matrix. The zinc-containing protecting body is selected from a zinc compound, or a mixture of at least one of phosphate radical compound, a degradable binder and a water-soluble binder, and the zinc compound. The weight percentage of the zinc compound in the mixture is more than or equal to 20% and less than or equal to 100%. The zinc-containing protecting body can slow down the corrosion of the iron-based alloy matrix during the implanting early stage of the device, the no corrosion of the iron-based alloy matrix during the implanting early stage can be basically realized, and the clinically mechanical performance requirement of the device during implanting early stage can be met.

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

Soybean glue and preparation method thereof

ActiveCN103184032AImprove adhesion strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesResistWater based

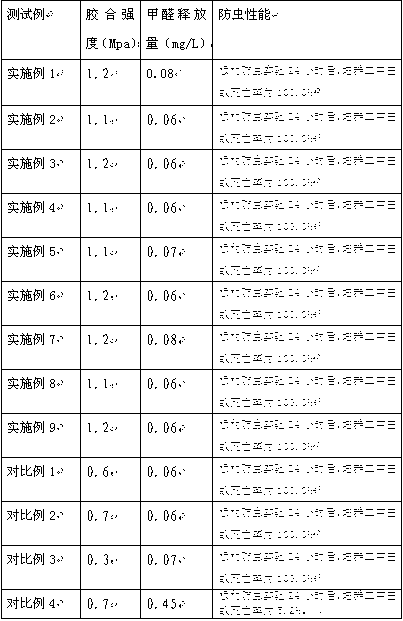

The invention relates to an adhesive and the field of preparation of the adhesive, and in particular relates to a soybean glue and a preparation method thereof. The soybean is prepared from the following raw materials in parts by mass: 100 parts of water, 15-400 parts of soybean derivative, 3-8 parts of alkaline, 0.5-3 parts of silicate, 0.2-5 parts of modifying agent, 0.3-2.5 parts of curing agent, 0.1-4 parts of acid, 0.1-20 parts of water-based acrylic resin, 0.1-1.5 parts of insect-resist agent and 1-10 parts of filler. The soybean glue prepared in the invention has high adhesive strength and low formaldehyde emission and further has mould-proof, corrosion-proof, mothproof and waterproof functions.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

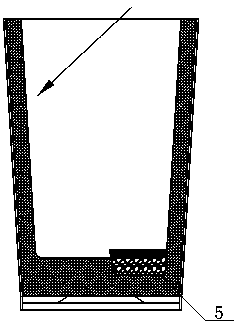

Bamboo waterproof antiseptic coloring plate and preparation method thereof

The invention discloses a bamboo waterproof antiseptic coloring plate and a preparation method thereof. The preparation method of the bamboo waterproof antiseptic coloring plate comprises the steps of cutting off bamboo materials, slicing, coarsely planing, drying, vacuum high-temperature high-pressure antiseptic coloring carbonization treatment, secondary drying, precision planing, sorting, gluing and thermal pressing, polishing and planing on four sides. The bamboo material is processed in the vacuum high-temperature high-pressure antiseptic coloring carbonization manner, the process is novel, the manipulability is strong, the produced bamboo board has a waterproof function, an antiseptic function and rich colors and can be used as an outdoor building material and indoor decoration material, and the application range is wide.

Owner:福建省祥福工艺有限公司

Superstrong water absorber and its preparation method and selenium-enriched plant antidraught agent using same as raw material

InactiveCN1869084ASimple production processLow costBiocideSelf-acting watering devicesOxygenNitrogen gas

An ultra-strong water absorbent for agricultural purpose is prepared from bentone, acrylamide, acrylic acid and urea through radiated copolymerization. A Se-enriched drought resisting agent for plants is prepared from said ultra-strong water absorbent, Se, plant growth regulator, oxygen releasing agent, antibacterial antiseptic, cold resisting agent, penetrant, trace elements and additive.

Owner:王树禹

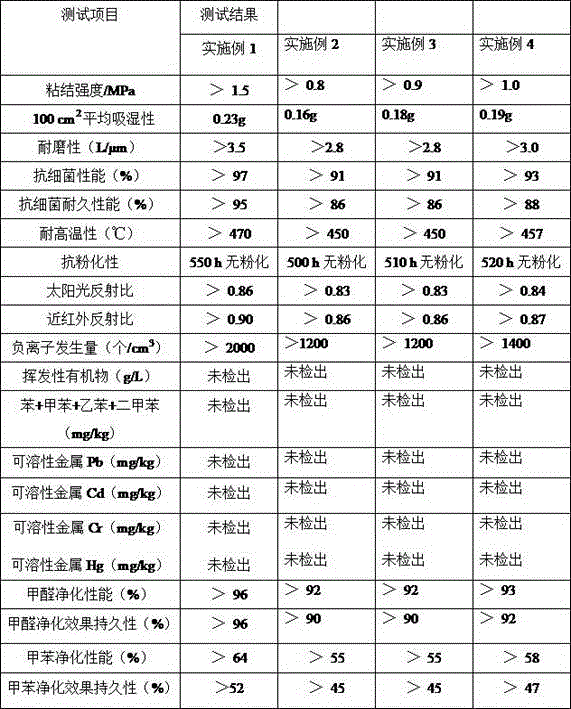

Multifunctional inorganic interior wall coating and preparation method thereof

ActiveCN106752157AIncreased versatilityNo smellFireproof paintsAntifouling/underwater paintsSodium BentoniteOxygen ions

The invention relates to a multifunctional inorganic interior wall coating and a preparation method thereof. The coating comprises the following components in percentage by weight: 5-15 percent of potassium silicate, 2-5 percent of lithium silicate, 5-20 percent of silica sol, 5-15 percent of diatomite, 5-10 percent of shell powder, 5-15 percent of photosensitive auxiliary-supported tourmaline, 5-15 percent of radiation-resistant-bactericidal auxiliary-supported bentonite, 1-10 percent of nano SiO2 dispersing liquid, 2-8 percent of calcined kaolin, 3-12 percent of anatase titanium dioxide, 2-8 percent of alumina powder and 10-25 percent of water; the total percentage by weight of all the components is 100 percent. The preparation method provided by the invention is simple; the obtained interior wall coating has the advantages of being non-toxic, odorless, green and environment-friendly, radiation-resistant, bactericidal and bacteriostatic, capable of eliminating formaldehyde and other organic pollutants, self-clean, capable of purifying air, releasing negative oxygen ions and regulating the humidity, fire-proof and flame-retardant, high temperature-resistant, water-resistant, scrubbing-resistant, aging-resistant, powdering-resistant and corrosion-resistant, thereby having wide market prospect.

Owner:UNIV OF JINAN

Aqueous polyaniline anti-corrosive paint and preparation method thereof

ActiveCN102702920AGood anti-corrosion effectGood water resistanceAnti-corrosive paintsEpoxy resin coatingsSolventIon

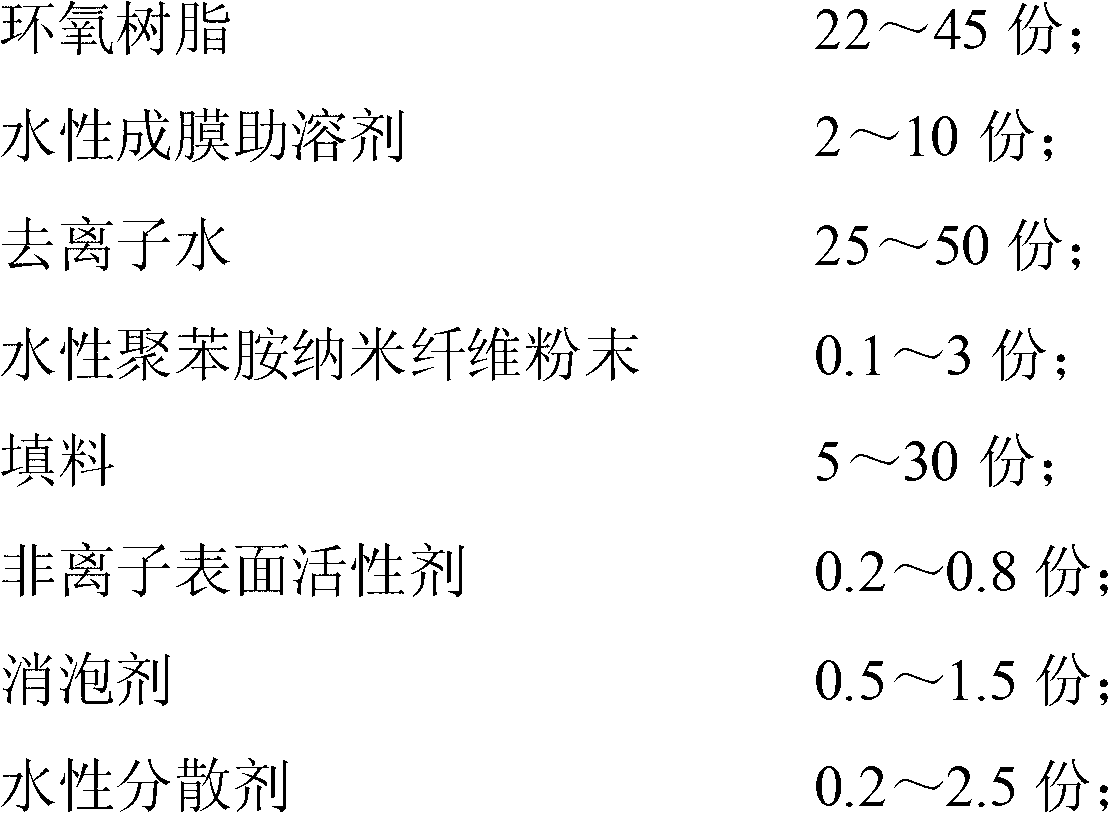

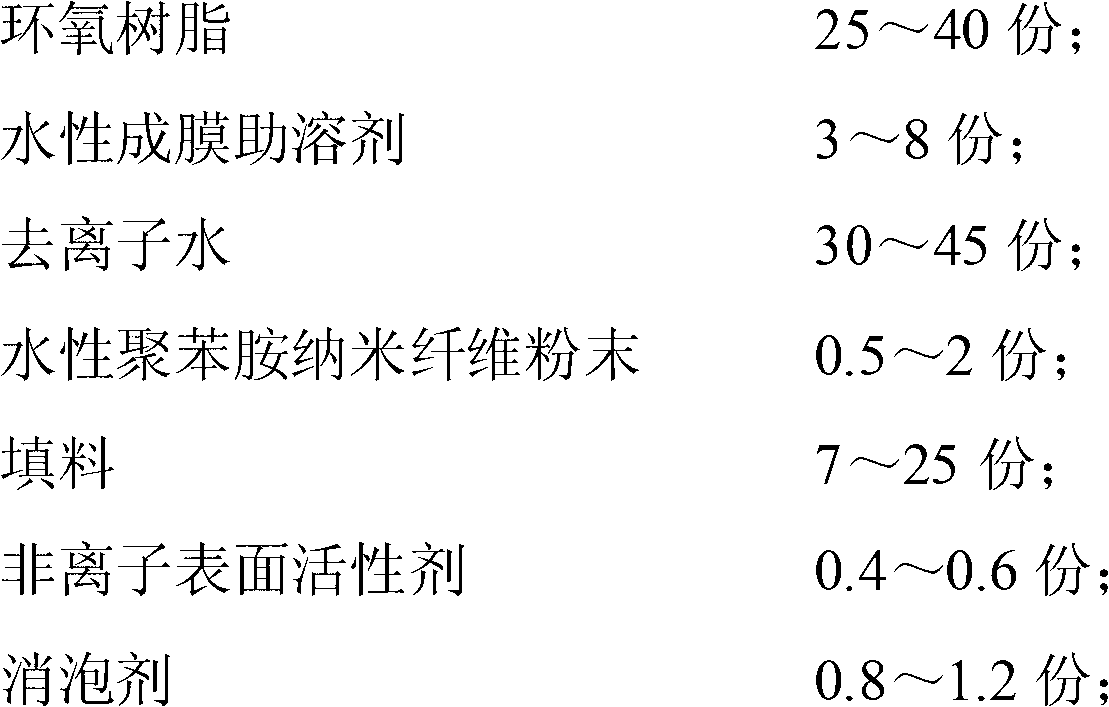

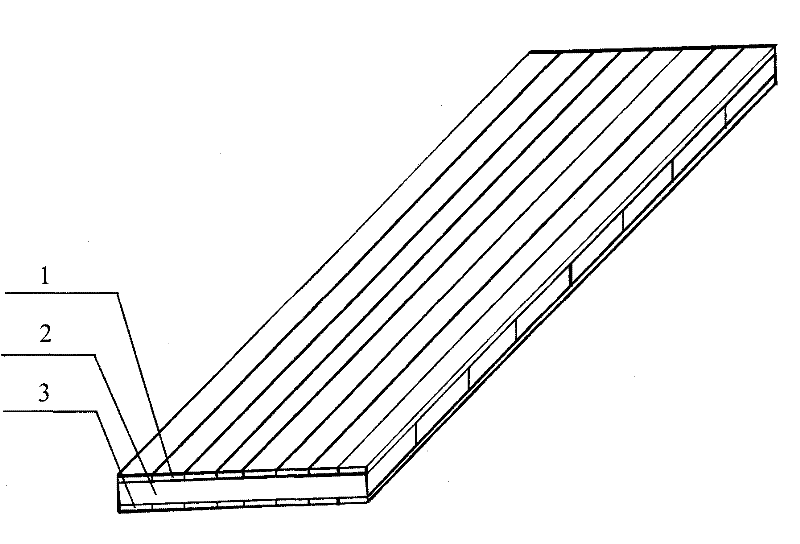

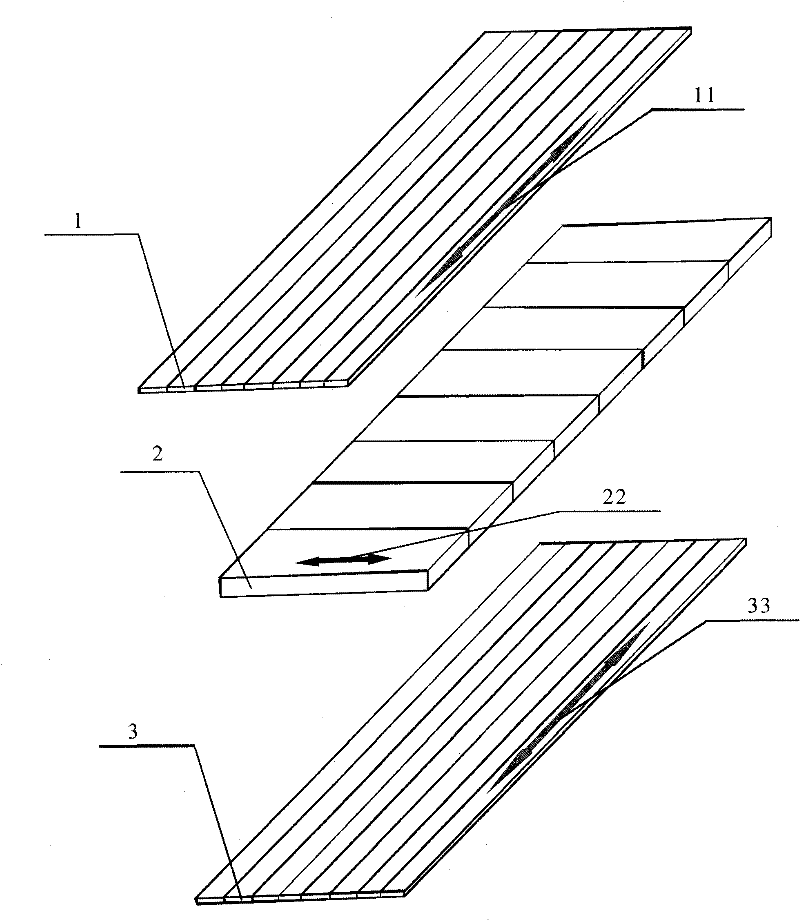

The invention provides an aqueous polyaniline anti-corrosive paint and a preparation method thereof, belongs to the technical field of paint, and is used for solving the problem that the traditional polyaniline anti-corrosive paint causes pollution to the environment and harms the human body. The paint comprises a component A and a component B, wherein the component A comprises 22-45 parts by weight of epoxy resin, 2-10 parts by weight of aqueous film-forming cosolvent, 25-50 parts by weight of deionized water, 0.1-3 parts by weight of aqueous polyaniline nano fiber powder, 5-30 parts by weight of filler, 0.2-0.8 part by weight of non-ionic surfactant, 0.5-1.5 parts by weight of defoaming agent, 0.2-2.5 parts by weight of aqueous dispersant; and the component B comprises 35-65 parts by weight of aqueous curing agent, 28-62 parts by weight of deionized water and 0.2-5 parts by weight of leveling agent. The aqueous polyaniline anti-corrosive paint is a green and environment-friendly type anti-corrosive paint and has an excellent anti-corrosive property.

Owner:HUNAN BENAN YADA NEW MATERIALS

Glass fiber reinforcement cement board and production method thereof

InactiveCN101386509AGuaranteed StrengthGuaranteed lifeSolid waste managementCeramicwareExpanded clay aggregateCement board

The invention relates to a building material and a method for preparing the same, in particular to a glass fiber reinforced cement board and a method for preparing the same. The glass fiber reinforced cement board comprises the following components in weight portion: 100 portions of Portland cement, 13.6 to 15 portions of high alumina cement, 3.1 to 3.4 portions of fly ash, 5.7 to 6.3 percent of plaster stone powder, 120 to 132 portions of ceramsite, 6.5 to 7.1 percent of foaming agent, 74.5 to 81.3 percent of dispersing agent, 53 to 58.7 portions of pure water and 3.6 to 4 portions of plastic-coated glass fiber grid cloth. The preparation method sequentially comprises the following steps: mixing weighed-up solid materials, adding weighed-up liquid materials in the previous step, cavity forming, roll extruding, vibration, cutting and curing. The invention has the advantages that: the glass fiber reinforced cement board has advantages of light volume weight, high strength, low dry shrinkage wet swelling coefficient, no after expansion and shrinkage, corrosion resistance, sound insulation, heat insulation, fire resistance and non-combustion; the preparation method has the characteristics of scientific and reasonable method, continuous production, high efficiency and low cost, flat board surface, convenient in-site mounting and the like; the glass fiber reinforced cement board is good in water resistance, and particularly applied to the finishing of internal and external walls and ceilings of various buildings in wet environments; moreover, the glass fiber reinforced cement board and a method for preparing the same have the advantages of ensuring the strength and service life of cement due to the adoption of the plastic-coated anti-alkali glass fiber grid cloth, along with reasonable blending ratio and reduced alkalinity.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

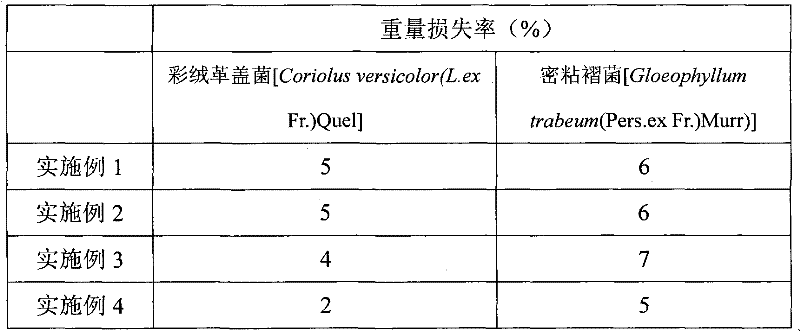

Bamboo-wood composite board and preparation method thereof

InactiveCN101745947AFully absorbedReach the designed drug loadingWood veneer joiningThermal compressionHigh surface

The invention relates to an anti-corrosion bamboo-wood composite board and a preparation method thereof. The preparation method of the anti-corrosion bamboo-wood composite board comprises the following steps: firstly preparing anti-corrosion bamboo strips and heat-treated wood; next, respectively assembling and compressing the anti-corrosion bamboo strips and the heat-treated wood into anti-corrosion bamboo wood and a heat-treated sheet material; and then carrying out assembling and hot compression on the anti-corrosion bamboo wood and the heat-treated sheet material to obtain the anti-corrosion bamboo-wood composite board. The bamboo-wood composite board prepared by the method of the invention has excellent corrosion resistance which reaches the corrosion resisting level specified in national standard GB / T13942.1-1992 Method for Laboratory Test of Natural Decay Resistance of Woods, and also has very high surface abrasion resistance and high mechanical strength which reach the national standards in GB / T 18103-2000 national composite floor.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

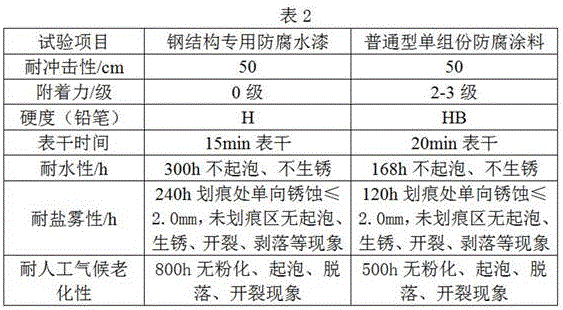

Special anticorrosion water paint for steel structure and preparation method thereof

ActiveCN106221458AReduce air permeabilityImprove anti-corrosion performanceAnti-corrosive paintsEpoxyOrganic solvent

The invention relates to the technical field of paint compositions, particularly relates to the technical field of waterborne antirust paint, and particularly discloses special anticorrosion water paint for a steel structure. The special anticorrosion water paint comprises a base material, an assistant and a pigment filler, wherein the base material is prepared by blending 30-40% of a waterborne epoxy modified acrylic emulsion and 10-15% of a waterborne one-component self-crosslinking fluorinated siloxane-acrylate emulsion in percentage by weight; the assistant comprises a neutralizer, deionized water, a wetting dispersant, a defoaming agent, a coalescing agent, an antiflash rusting agent, a thickener and an anti-settling agent. The invention further discloses a preparation method of the anticorrosion water paint, and the anticorrosion water paint is prepared by adding and blending the components step by step. The anticorrosion water paint does not use an organic solvent, does not contain toxic heavy metals, is non-toxic, has no pungent odor, is harmless to a human body, does not pollute the environment, and is also excellent in anticorrosive property, water fastness and water tolerance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Method for preparing portable fresh-keeping sweet wine

The invention relates to a method for preparing portable fresh-keeping sweet wine, which is characterized by comprising the following steps: 1, preparing fumet sweet wine; 2, preparing a massive solid matter of the sweet wine; 3, preparing a seasoning bag; and 4, packaging a finished product. The sweet wine prepared by the method is portable and convenient; and the fresh-keeping period can reach 12 months.

Owner:湖南长乐情食品科技股份有限公司

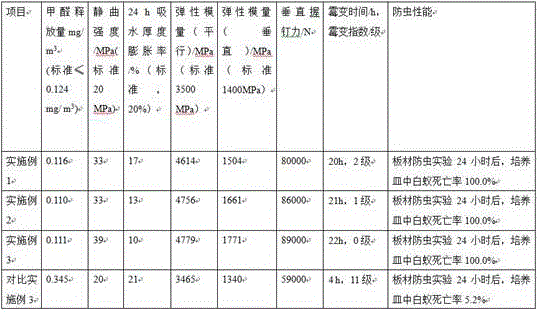

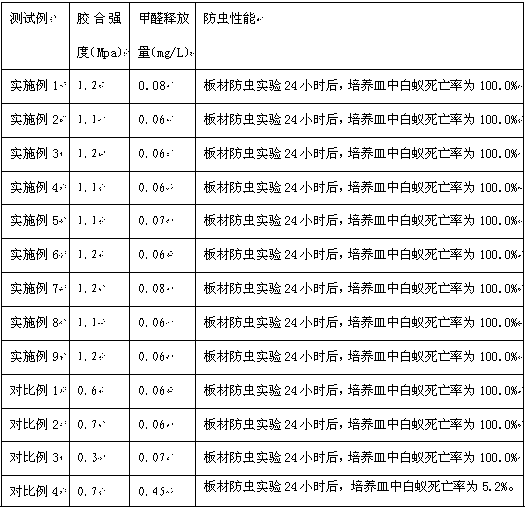

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

Plant and animal-derived green environment-friendly pesticide and preparation method thereof

The invention relates to the technical field of pesticides and discloses a plant and animal-derived green environment-friendly pesticide and a preparation method thereof. The green environment-friendly pesticide is composed of wild plants, edible crops and animal bile, wherein the wild plants comprise Datura stramonium, castor seed and herba hydrocotylis wilfordi, the edible crops comprise king capsicum, garlic, Sichuan pepper and berberine, and the animal bile is fish bile, chicken bile or pig bile. The preparation method comprises the following steps: washing, crushing and squeezing the wild plants, carrying out chemical examination and extraction of alkaloid and screening out moisture impurities; washing and juicing or soaking the edible crops; washing an animal gallbladder and broking the animal gallbladder to obtain bile; and carrying out mixing and uniform stirring to obtain the pesticide. The pesticide prepared in the invention has bactericidal and anti-decay effects and the advantages of reasonable preparation, a cheap price, convenience in usage, capacity of being both sprayed and poured, no residual poison, no pollution, greenness and environment-friendliness and is applicable to poisoning of a variety of insects on a variety of plants like wheat, corn, cotton, fruit trees, vegetable, fruit and flowers and trees.

Owner:LUOYANG CLOUDS NET TECH

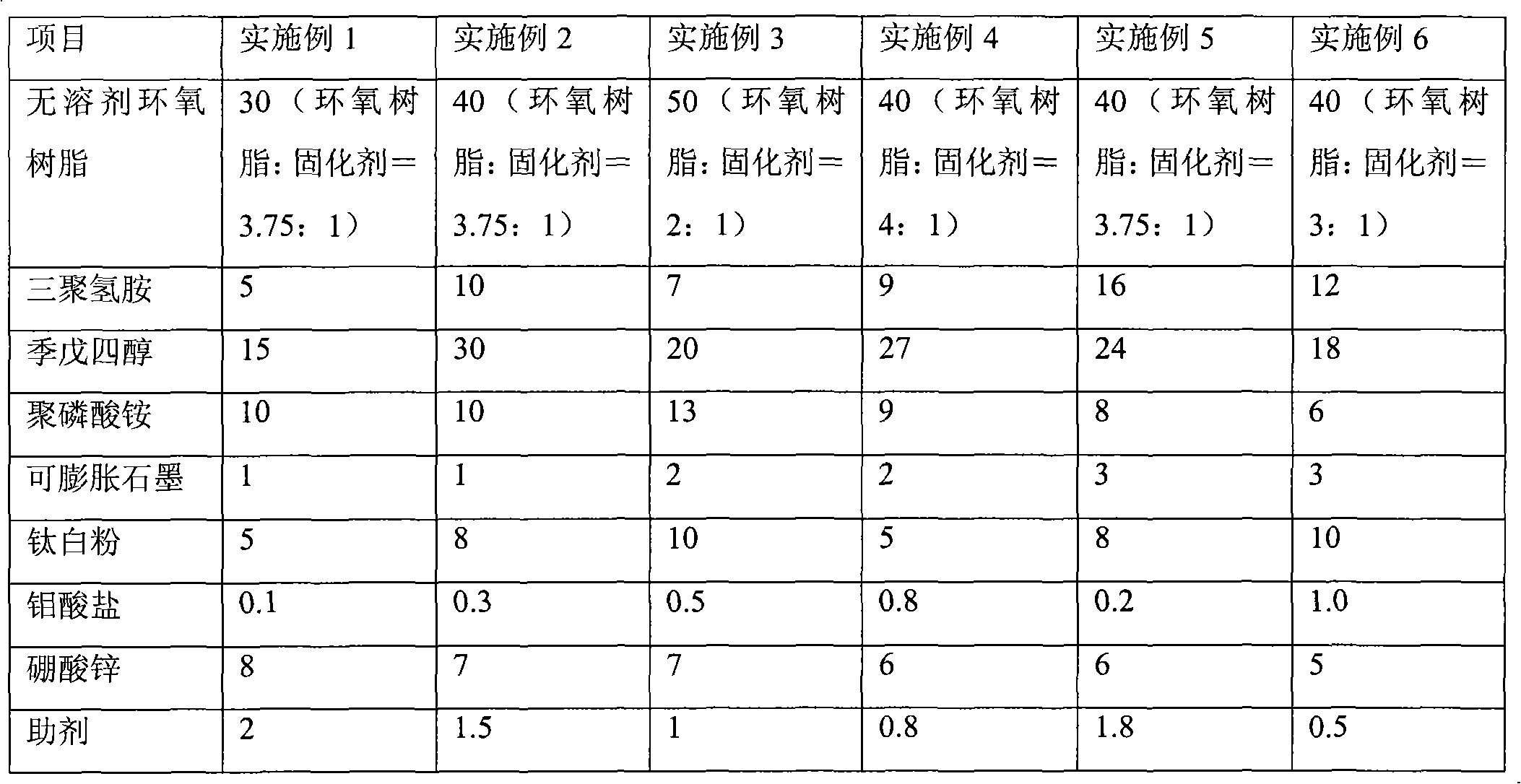

Solvent-free epoxy resin fire-resistant coating for ultrathin steel structure

InactiveCN102061119AEnvironmentally friendlyHigh bonding strengthFireproof paintsAnti-corrosive paintsEpoxySolvent free

The invention provides a solvent-free epoxy resin fire-resistant coating for an ultrathin steel structure, which comprises the following components in part by mass: 30 to 50 parts of solvent-free epoxy resin, 30 to 50 parts of inflame retarding system, 5 to 10 parts of titanium white, 5 to 8 parts of zinc borate, 1 to 3 parts of expanded graphite, 0.1 to 1 part of smoke inhibitor and 0.5 to 2.0 parts of various aids, wherein the inflame retarding system is a complex system of melamine, pentaerythritol and ammonium polyphosphate in a ratio of 1:3:2 or 1:3:1 or 2:3:1. The solvent-free epoxy resin fire-resistant coating has the advantages that: (1) the coating technology of solvent-free epoxy resin terrace is applied to the fire-resistant coating for the ultrathin steel structure, so that the fire-resistant coating for the ultrathin steel structure has the advantage of epoxy coatings and properties of fire prevention; (2) the fire-resistant coating for the ultrathin steel structure has the characteristic of environmental protection; (3) the coatings have high matching performance and can be better compatible with epoxy zinc-rich anticorrosion primers; and (4) the fire-resistant coating has high bonding strength which is more than or equal to 1.5 MPa, and has the characteristics of water prevention, corrosion prevention, high surface decoration and the like.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Environment modifier for disinfection with dry powder

InactiveCN101703072AInhibition of reproductionEliminate odorBiocideDigestive systemDiarrheaDisinfectant

The invention relates to an environment modifier for disinfection with dry powder. The modifier is prepared from adsorbent, disinfectant and environment modifier and has multifunctional dry powder formula for disinfecting the piggery, removing peculiar smell in the piggery, preventing neonate pigs from infecting diseases, reducing the humidity in the piggery, drying the neonate pigs rapidly so as to eat colostrums quickly to obtain immunity, preventing endometritis of sow, treating wound, preventing piglet from fighting as a result of ablactation and reducing the diarrhea. The environment modifier for disinfection with dry powder is simple to use, has high efficiency and little use amount, is environment-friendly, has no residual toxicity, remarkably improves the weight and the survival rate of piglet, greatly reduces the working capacity and labour cost and provides guarantee for environment disinfection and epidemic prevention.

Owner:张同兵

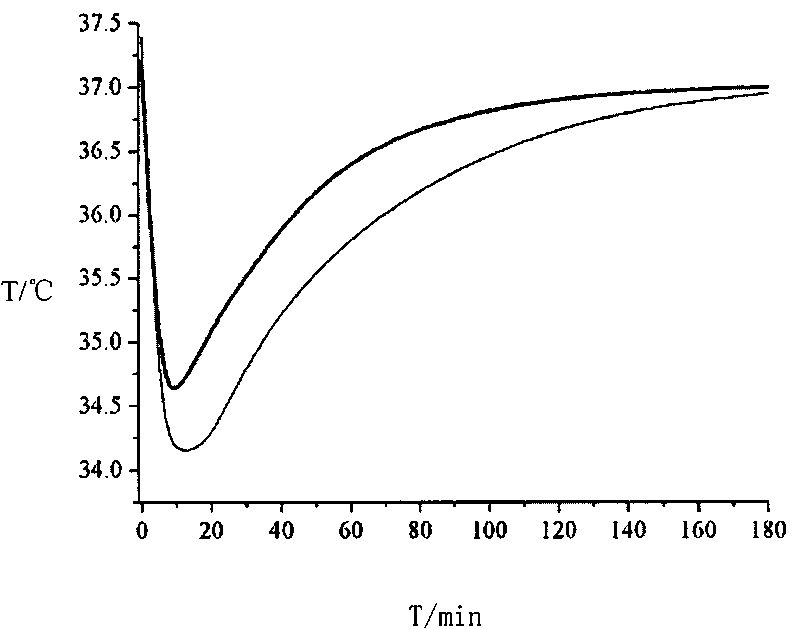

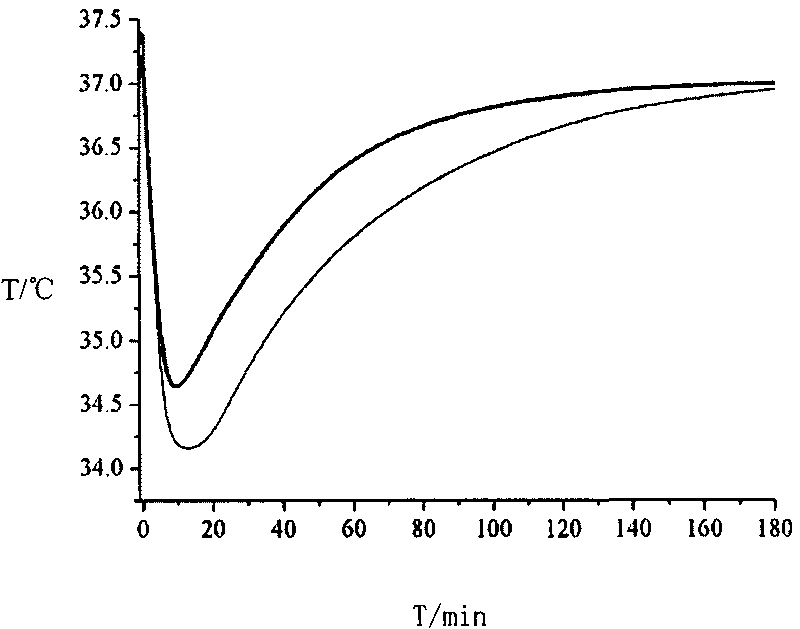

Aquatic product low temperature speed freezing liquid with antioxidation and color-protecting function

The invention relates to an aquatic product low temperature speed freezing liquid with antioxidation and color-protecting functions. The freezing liquid comprises the following substances by weight percent: 5%-8% of sodium chloride, 1%-5% of sorbitol, 0.05%-0.1% of sodium D-isoascorbate, 22%-40% of ethanol and the balance water and the speed freezing liquid can be kept in liquid state at -20 DEG Cto -50 DEG C. when the low temperature speed freezing liquid of the invention is used to perform aquatic product low temperature speed freezing, the cells of the frozen aquatic product can be kept perfectly, the shape can be kept in the original state and the state can be maintained in the refrigeration process of the frige so that the aquatic product can keep the original characteristics of color, flavor, texture and nutrition after unfreezing.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

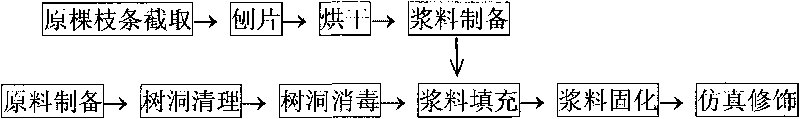

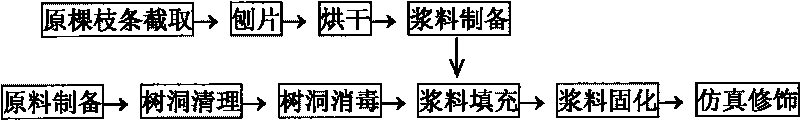

Method for mending primary tree hole

InactiveCN101731105AImprove reinforcement effectResilientHorticulture methodsPlant protectionWood shavingsFiber

The invention relates to a method for mending a primary tree hole, which comprises the following steps: preparing raw materials; cleaning up the tree hole; sterilizing the tree hole; preparing a sizing agent: mixing and stirring dried wood flour, fiber or fine wood shavings with an inorganic adhesive in a mass ratio of 1-2:1 to prepare the sizing agent; filling the sizing agent: after an inner wall of the tree hole is dried until the water ratio is smaller than 14 percent, pouring the sizing agent into the tree hole, and sealing and fixing outside the hole opening until the sizing agent is filled in the gap in the hole to ensure that the sizing agent is filled and adhered to an inner side of the tree hole; curing the sizing agent; and performing simulation modification. Therefore, the sizing agent filled in the tree hole has natural characteristic index which is more approximate to the tree per se, and has toughness, corrosion resistance and fire resistance and enhances the effect of strengthening the tree. In addition, the technology is simple and the repair quality is reliable.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Photocatalystc composite floor board and production process of photocatalystc composite floor board

InactiveCN104989066ADoes not affect bond strengthAffect bond strengthLaminationLamination apparatusWood shavingsSurface layer

The invention relates to a photocatalystc composite floor board, and belongs to the field of a functional environment-friendly healthy floorboard. The formaldehyde emission content of the composite floorboard is less than 0.3mg / L; the antibacterial rate is higher than or equal to 90 percent; the surface wear-resistant coefficient is less than or equal to 0.08g / 100r; a substrate layer is an oriented shaving board layer; the oriented shaving board layer comprises an upper surface layer and a lower surface layer which are formed by glue mixing wood shavings in longitudinal arrangement according to the fiber direction and a core layer shaving layer formed by glue mixing wood shavings in transverse arrangement according to the fiber direction; and a decoration layer, a wear-resistant primer layer and a photocatalystc antibacterial paint decoration layer are sequentially arranged on the substrate layer. A production process of the photocatalystc composite floor board comprises the steps of shaving board layer sorting, glue preparation, glue distribution and assembling for the first time, cold pressing for the first time, core trimming, glue distribution and assembling for the second time, cold pressing for the second time, hot pressing for the first time, fixed-thickness sanding, edge cutting, puttying, polishing, sorting, reconditioning, glue distribution and veneering, cold pressing for the third time, hot pressing for the second time, multi-blade sawing, sanding, double-end milling, priming, finish paint preparing and finish paint painting. The composite floorboard has the advantages of good antibacterial function, high strength, good wear-resistant performance and comfortable foot feeling.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

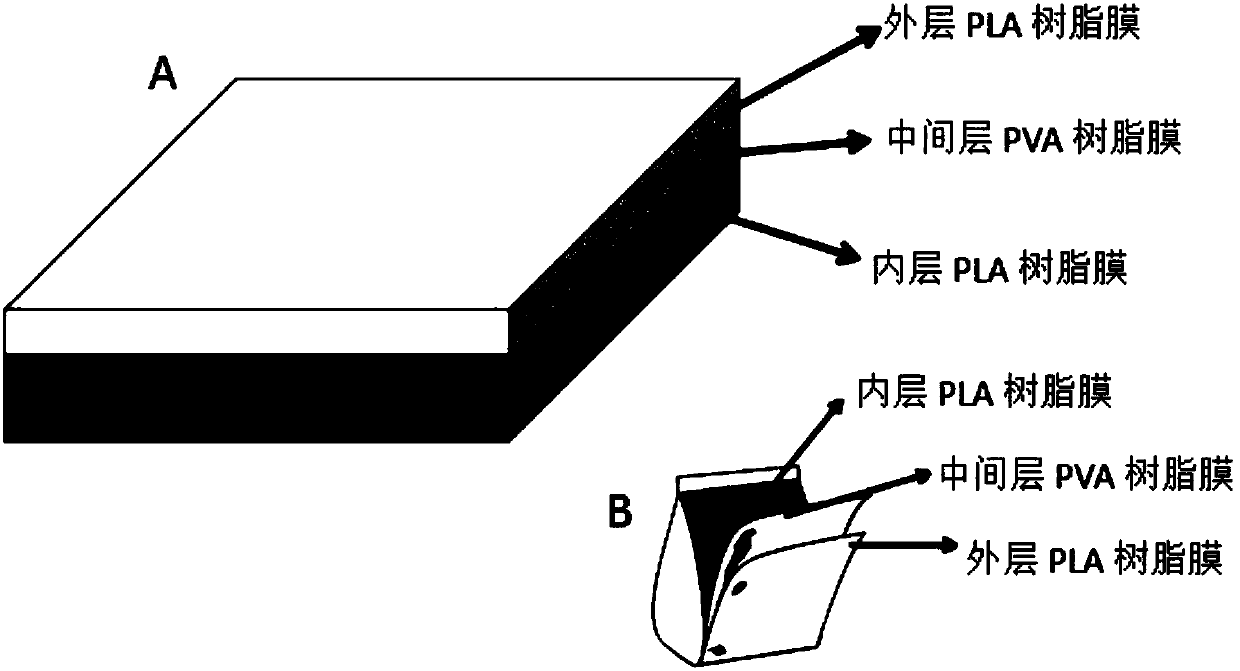

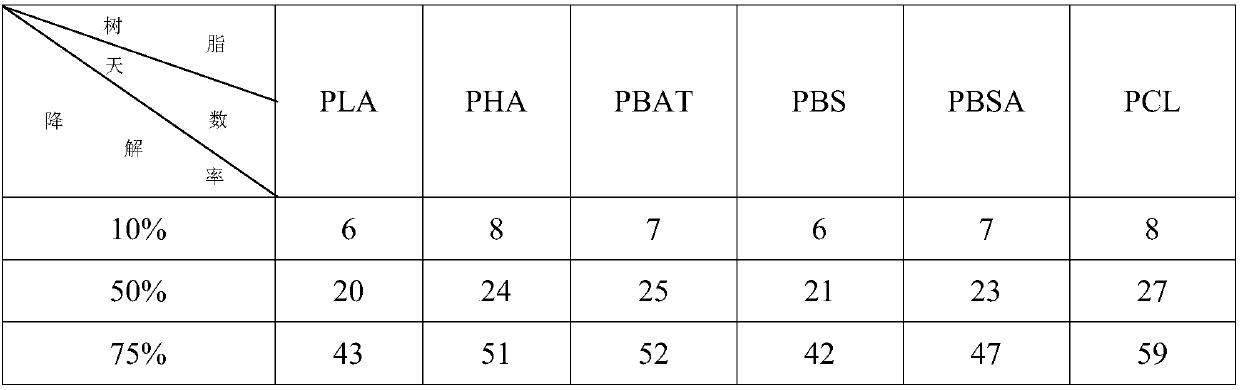

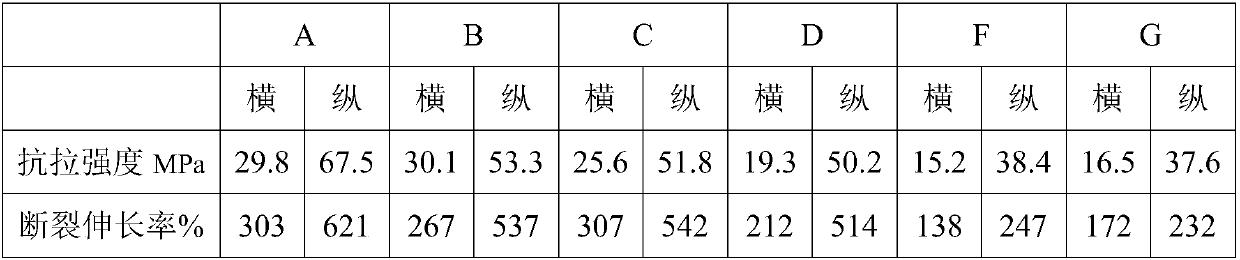

Degradable high barrier active preservative film and preparation method thereof

InactiveCN107627706ARemain biodegradableOvercome the disadvantage of moisture permeabilityFlexible coversWrappersPlastic packagingMoisture barrier

Belonging to the plastic packaging field, the invention in particular relates to a degradable high barrier active preservative film and a preparation method thereof. The degradable high barrier activepreservative film consists of an inner layer PLA resin film, a middle layer PVA resin film and an outer layer PLA resin film from the inside out in order, the inner layer PLA resin film, the middle layer PVA resin film and the outer layer PLA resin film all include a matrix and an assistant, and the inner layer PLA resin film also includes a bacteriostatic active ingredient. The degradable high barrier active preservative film provided by the invention has excellent moisture barrier properties, gas barrier properties, bacteria resistance, oil resistance and degradability, can effectively prevent moisture or oil loss, oxidation, corruption or degradation of food and fresh and raw food, extend the shelf life, and improve the quality guarantee effect.

Owner:SHANGHAI OCEAN UNIV

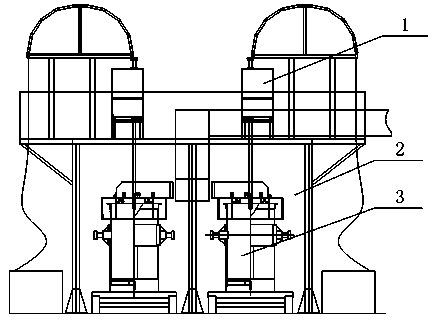

Method for preparing centrifugal nodular cast iron pipe

ActiveCN104480382AImprove appearance qualityRefining material organizationLiquid surface applicatorsCoatingsIRON PREPARATIONSCast iron pipe

The invention discloses a method for preparing a centrifugal nodular cast iron pipe. The method discloses the preparation process of the centrifugal nodular cast iron pipe of high quality, the preparation process comprises a series of operation processes of molten iron preparation, nodulizing of molten iron, centrifugal casting, annealing treatment, pipe body shaping and coating protection and the like. The method is suitable for preparation of cast iron pipes of the specification of DN 80-1000 mm, the application range is wide, and the preparation process is simple. The cast iron pipe prepared through the method has the characteristics of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with existing steel pipes and gray iron pipes, the cast iron pipe prepared through the method has better decay resistance and tensile property.

Owner:SICHUAN CHUANJIAN PIPES

Diluent for blood cell analyzer

InactiveCN101975850AAntisepticPrevent solidificationPreparing sample for investigationBiological testingDimethylol ureaSodium azide

The invention provides a diluent for a blood cell analyzer. The diluent consists of edentate, sodium sulfate, sodium chloride, dimethylol urea, biological buffer, a betain type nonionic surfactant, sodium azide and water. The diluent solves the problems that the osmotic pressure of a bottom layer is higher than that of an upper layer and the solution is not uniform or stable when the diluent for the blood cell analyzer stands for a long time.

Owner:南京卡博生物科技有限公司

Thin blockboard and manufacturing method thereof

ActiveCN103213178AEasy to useImprove adhesion strengthProtein adhesivesLaminationSolid woodOptoelectronics

The invention relates to the field of thin blockboard manufacturing, in particular to a thin blockboard and a manufacturing method of the thin blockboard. The thin blockboard comprises a China fir core board layer in the middle, poplar single board layers which are respectively spliced on the upper surface of the China fir core board layer and the lower surface of the China fir core board layer, and Okoume single board layers which are respectively spliced on the outer surfaces of the poplar single board layers. Adjacent board layers are spliced according to the perpendicular direction of wood texture, and modified soya bean glue is adopted to splice adjacent board layers. The solid thin blockboard has high splicing strength and is low in formaldehyde release amount, and at the same time, has the advantages of being mould-proof, corrosion-proof, insect-proof and water-proof.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Low-toxicity, environment-friendly short-term remains preservative and usage thereof

ActiveCN102461496AReasonable formulaAppropriate proportionDead animal preservationChemistryOrganic acid

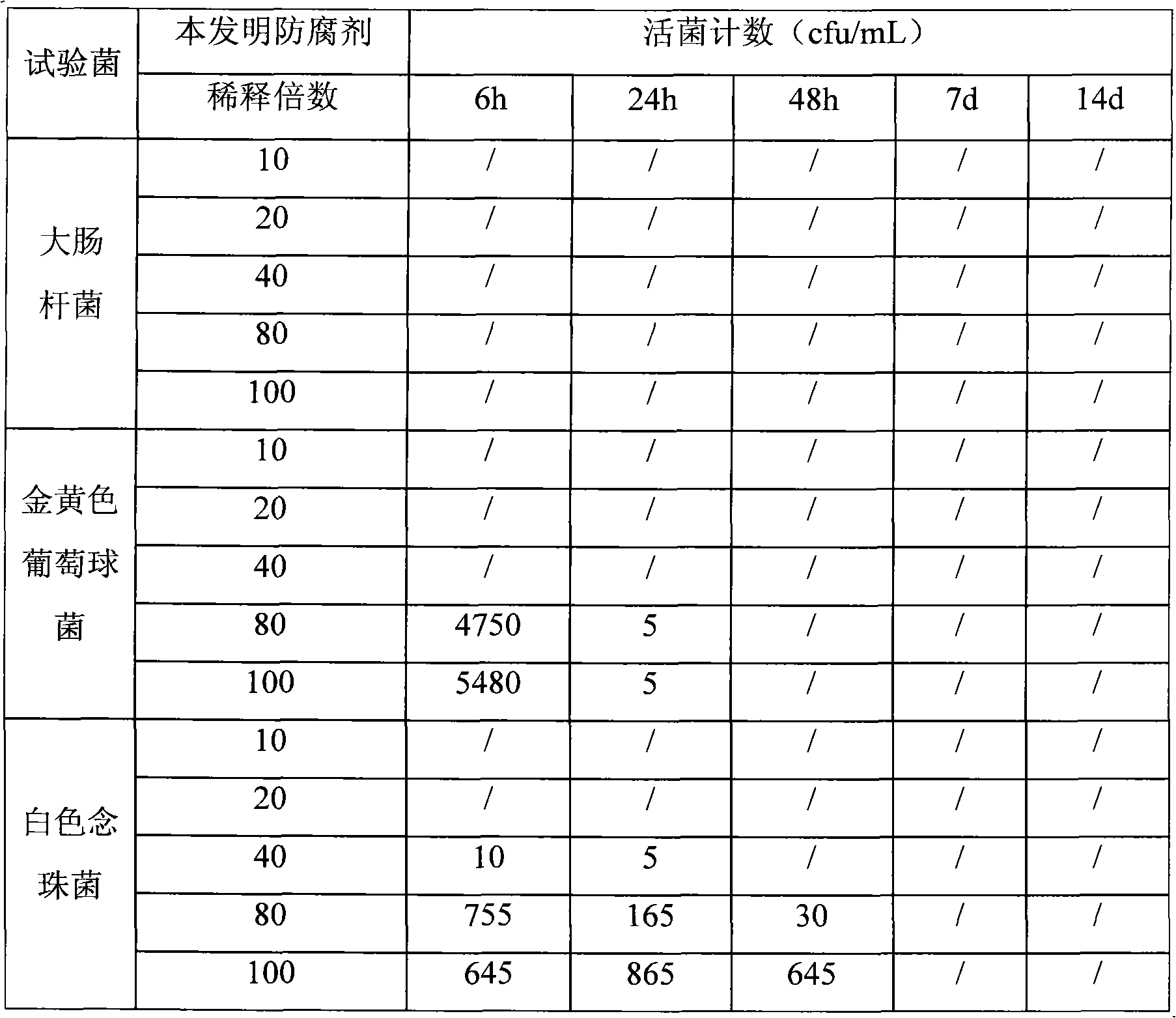

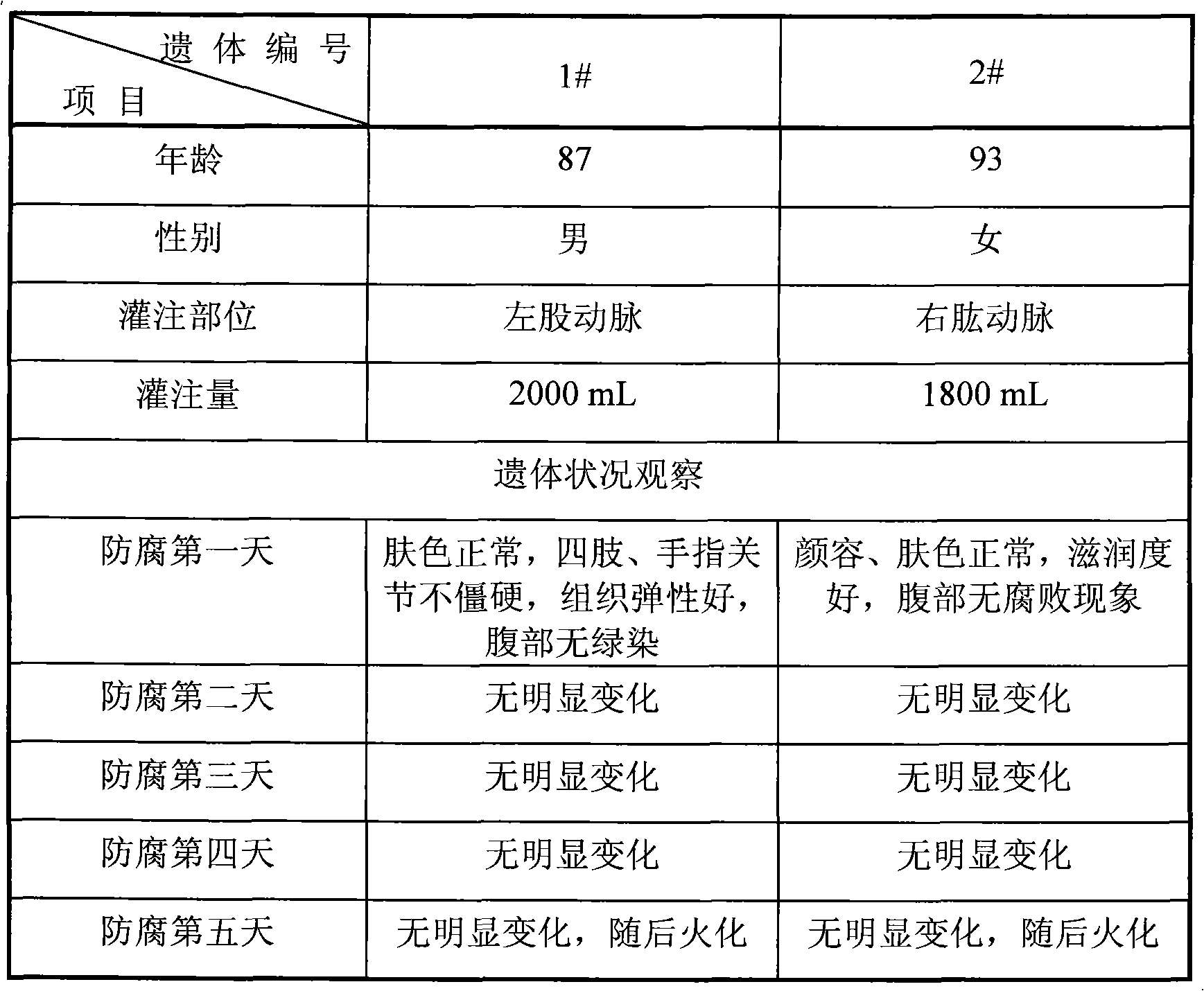

The invention relates to a low-toxicity, environment-friendly short-term remains preservative based on alcohols and usage thereof. The remains preservative mainly comprises 60 to 75 percent of ethanol, 5 to 20 percent of propylene glycol, 3 to 15 percent of organic acid, 0 to 0.3 percent of essence and 10 to 40 percent of distilled water according to volumetric proportion as well as 0.2 to 10 percent of nipagin ester, 0.3 to 3 percent of thymol, 0.5 to 3 percent of mannitol (or sorbierite) and 0.05 to 0.5 percent of low-toxicity metal salt according to weight ratio. The invention can adopt the immersion method or the infusion method to preserve and fix remains (tissues), and the preservative can be infused via the aorta (arch) and injected via the thoracic cavity and the abdominal cavity, and has the fast and effective effects of disinfection, embalmment and preservation. The preservative is highly antibacterial, can effectively prevent bacteria from corroding the remains and the autolysis of the tissues, can be used as histocyte fixative, and is applicable to short-term remains embalmment or specimen preservation in domestic and foreign funeral homes and medical academies.

Owner:民政部一零一研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com