Solvent-free epoxy resin fire-resistant coating for ultrathin steel structure

A technology of epoxy resin and fire retardant coating, applied in epoxy resin coating, fire retardant coating, anti-corrosion coating and other directions, to achieve the effect of strong surface decoration, good matching and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

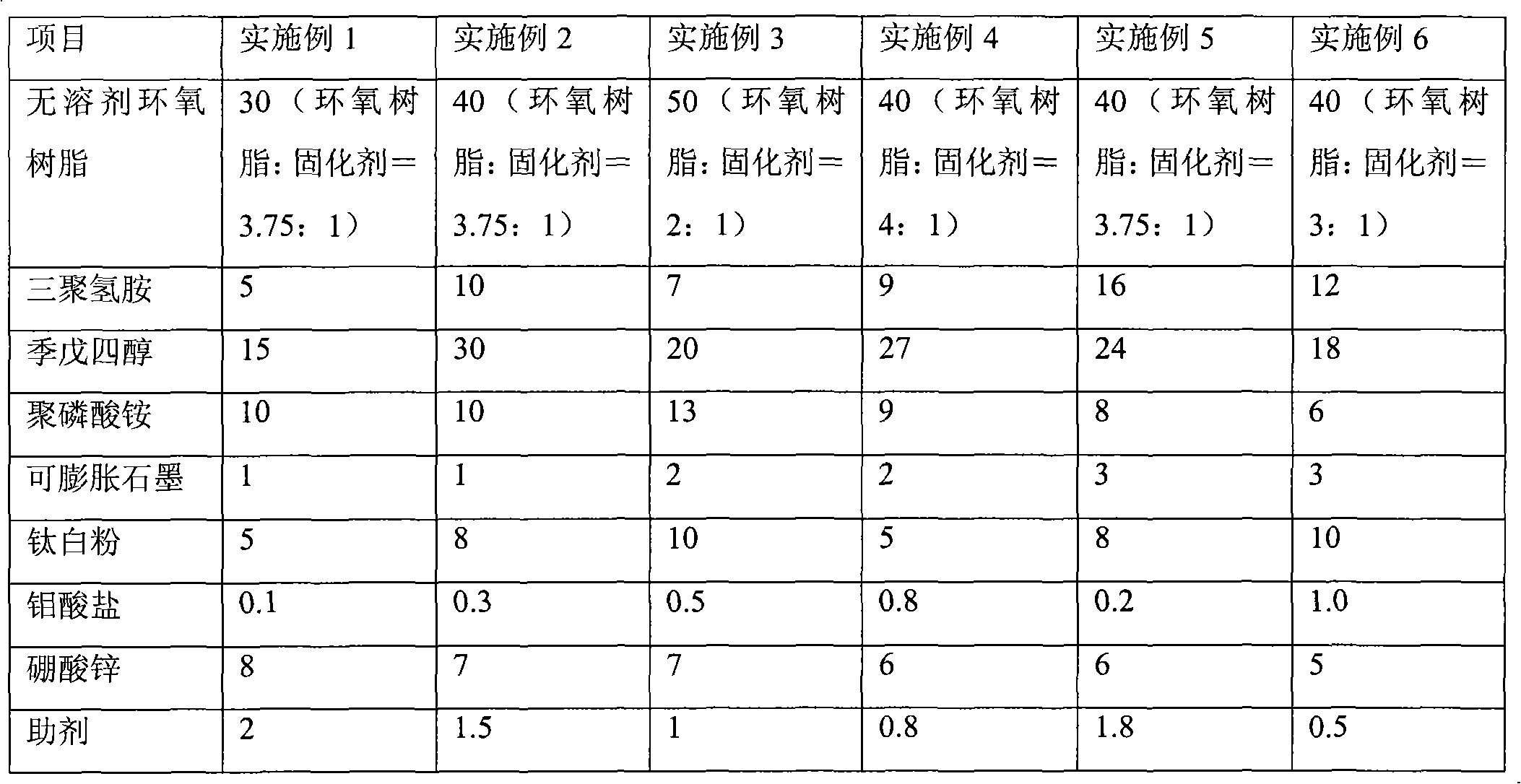

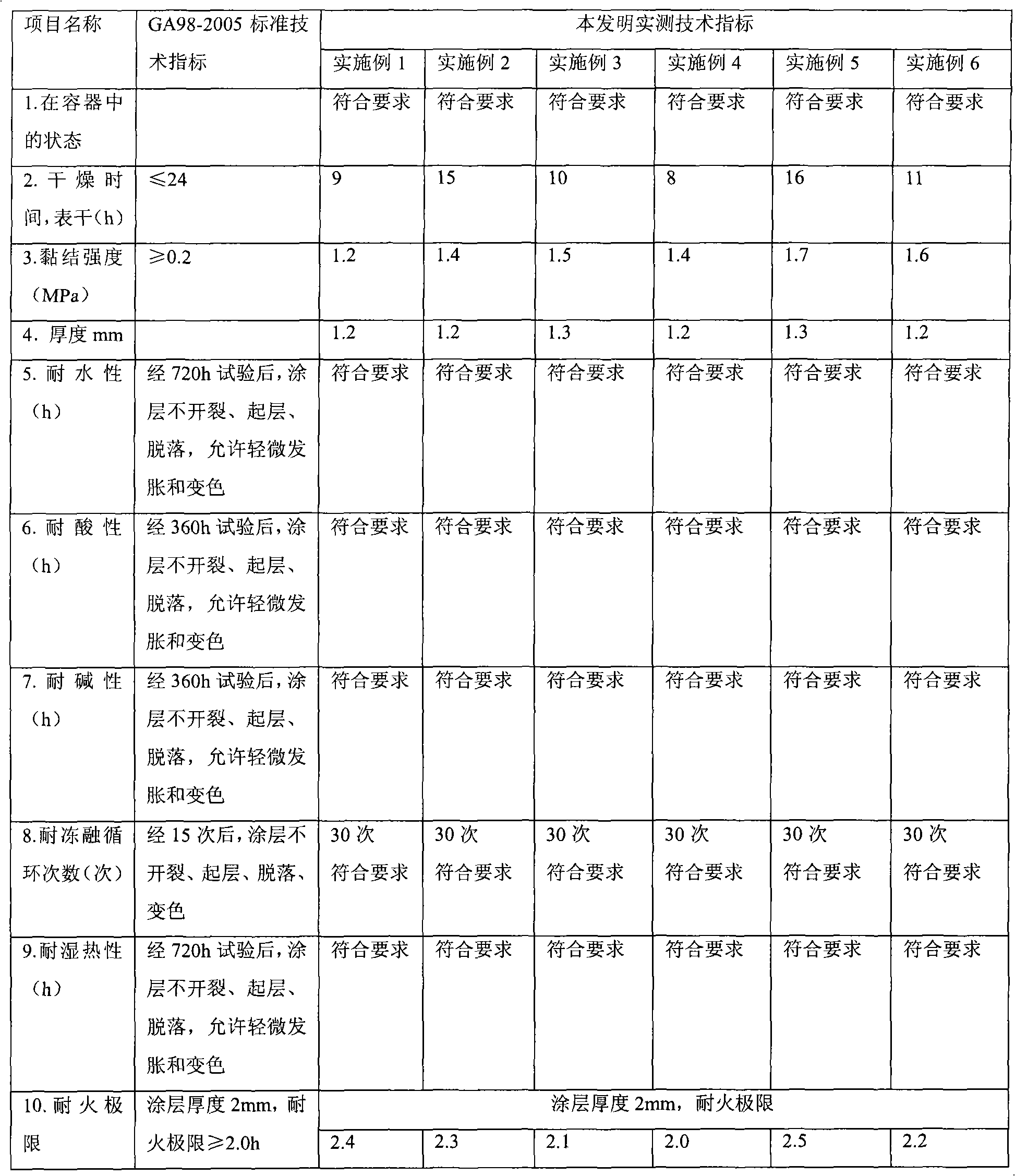

[0020] The present invention will be further described below in conjunction with specific examples, and the following examples are only used to illustrate the present invention rather than limit the present invention. Table 1 is an embodiment.

[0021] Table 1

[0022]

[0023] The manufacture method of above-mentioned each embodiment is identical, and its method is as follows:

[0024] 1. First, according to the dosage in Table 1, add expandable graphite, titanium dioxide, molybdate, zinc borate, etc. to component A of epoxy resin, disperse in a high-speed disperser for 10 minutes, transfer to a sand mill, and grind Until the coating fineness is 50u~80u, a part of the sample of solvent-free epoxy resin is made.

[0025] 2. Add melamine, pentaerythritol, and ammonium polyphosphate flame retardant to curing agent B component, disperse in a high-speed disperser for 10 minutes, transfer to a sand mill, grind until the coating fineness is 50u~80u, and make a non-toxic Anothe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com