Patents

Literature

84results about How to "Does not affect bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

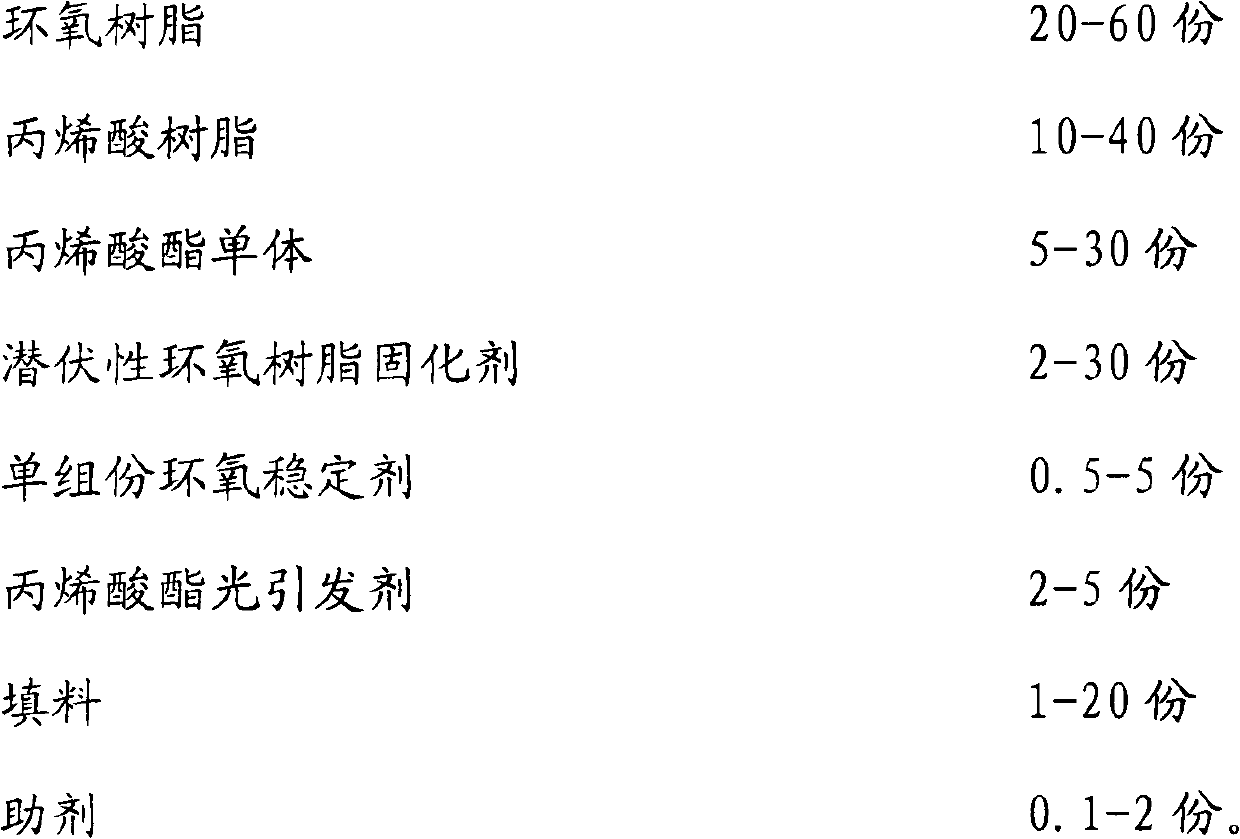

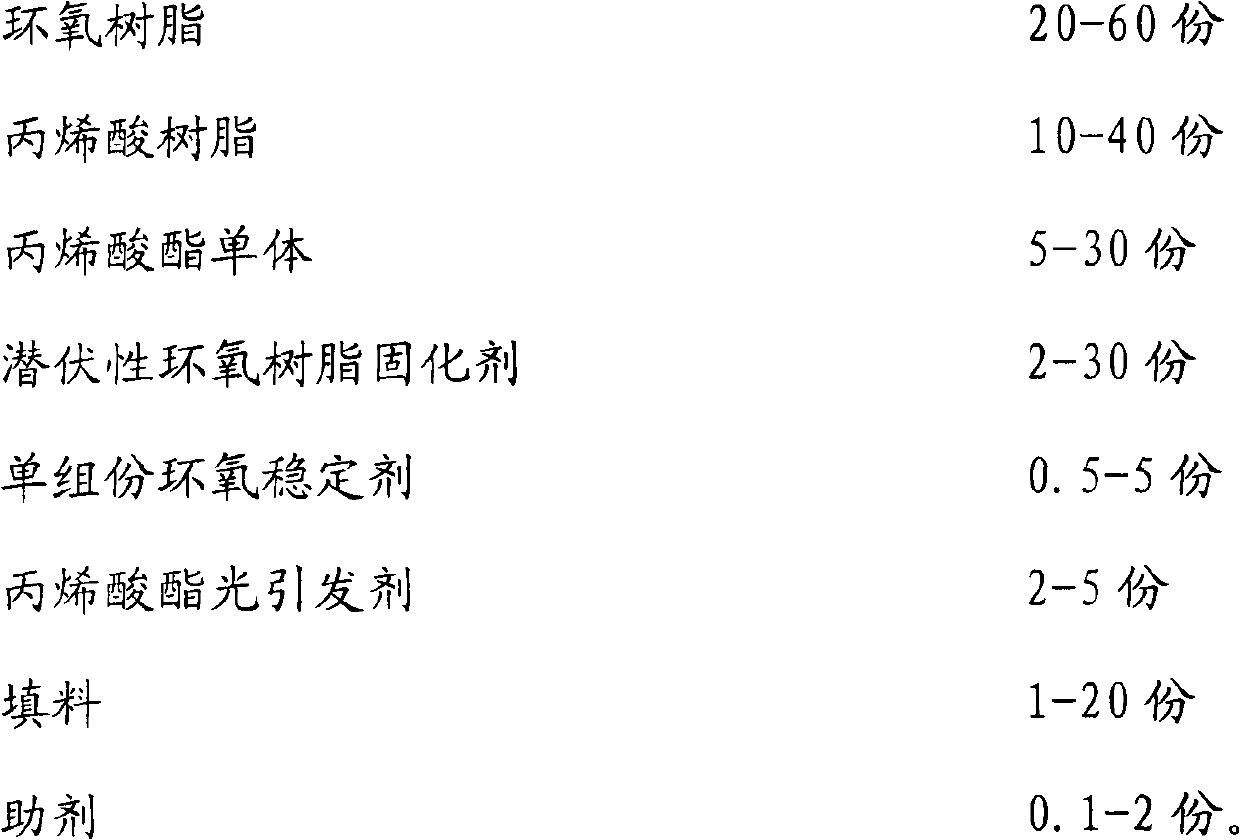

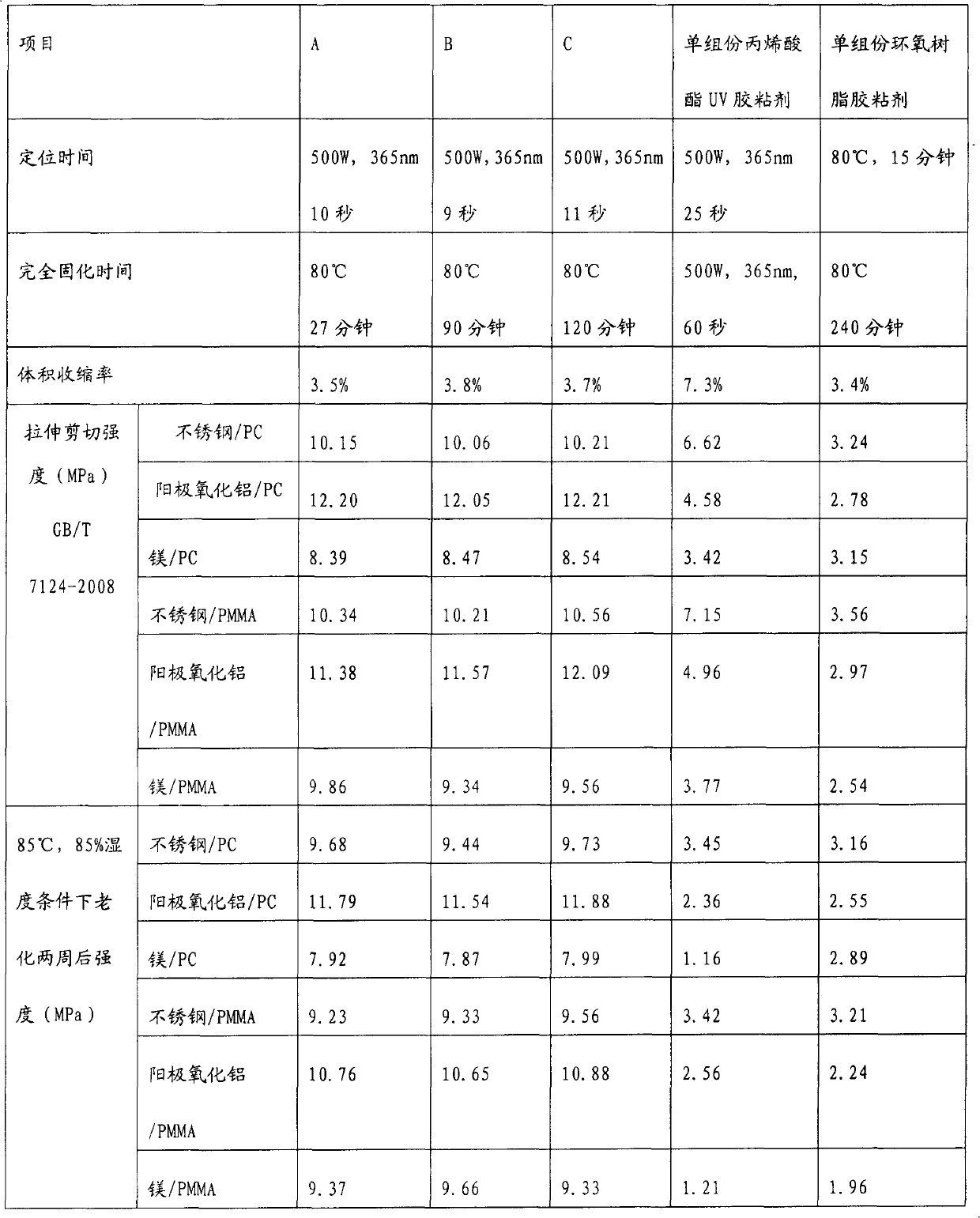

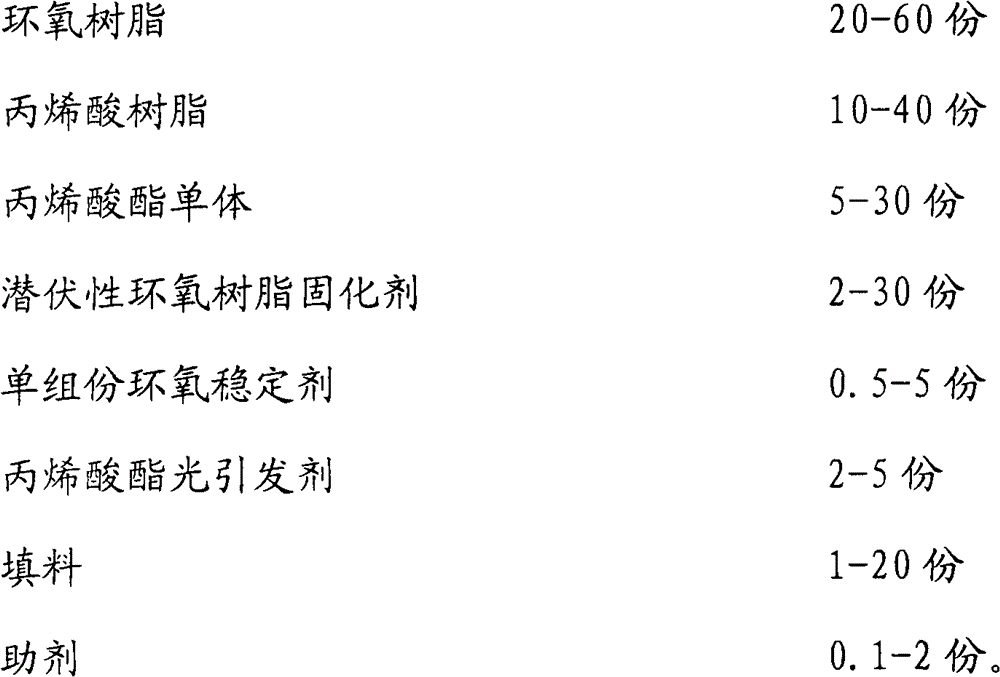

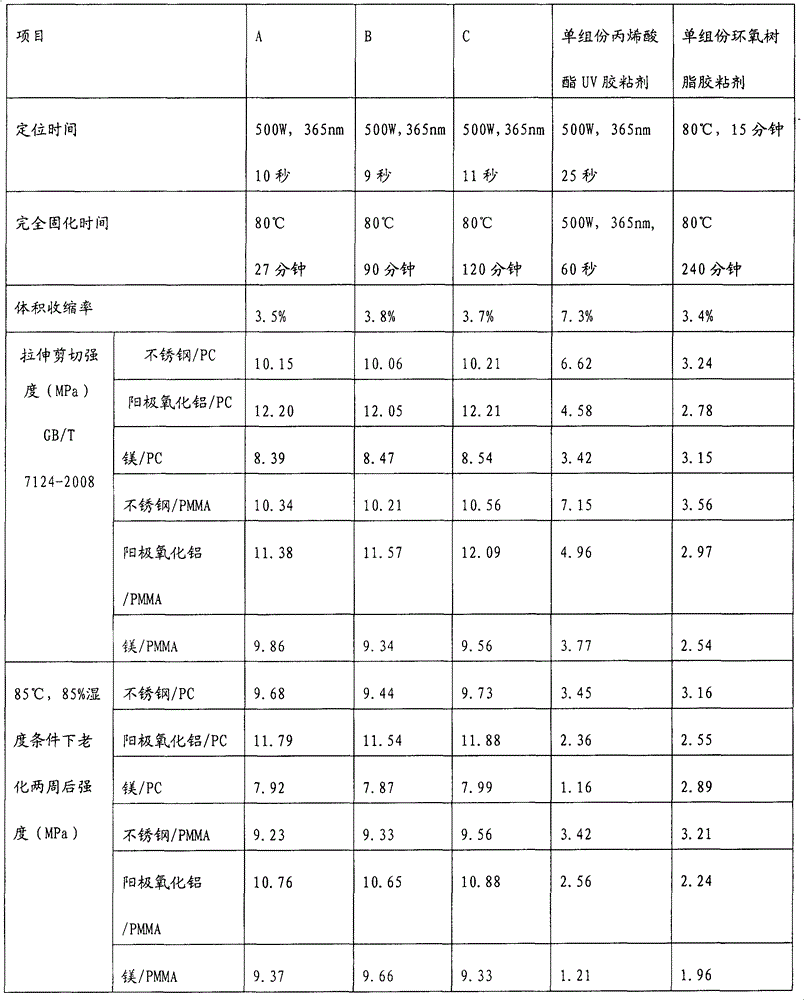

Fast-curing structural adhesive and preparation method thereof

ActiveCN103305132ADoes not affect bond strengthResolution timeOrganic non-macromolecular adhesiveEpoxyAcrylic resin

The invention discloses a fast-curing structural adhesive comprising the following components: 20-60 parts of epoxy resin, 10-40 parts of acrylic resin, 5-30 parts of acrylate monomers, 2-30 parts of a latent epoxy resin curing agent, 0.5-5 parts of an one-component epoxy stabilizer, 2-5 parts of an acrylate photoinitiator, 1-20 parts of fillers, and 0.1-2 parts of an auxiliary agent. The invention further discloses a preparation method of the fast-curing structural adhesive. The fast-curing structural adhesive prepared according to the components and the preparation method effectively solves defects and insufficiencies of long positioning time and fully cured time, and poor resistance to heat aging properties.

Owner:塔威新材料科技(上海)有限公司

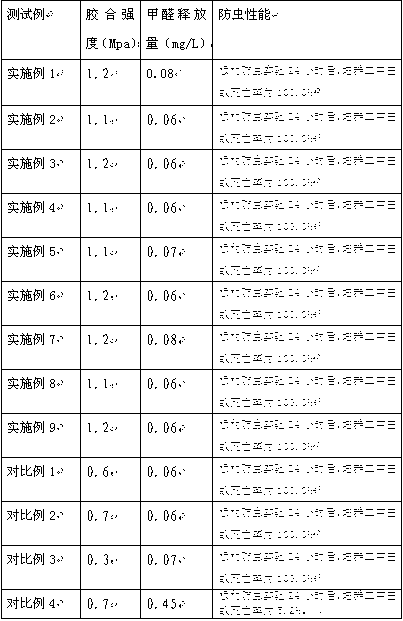

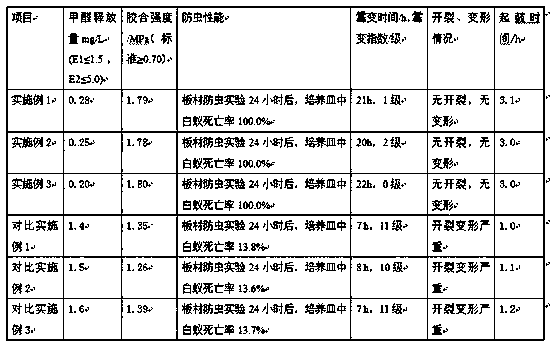

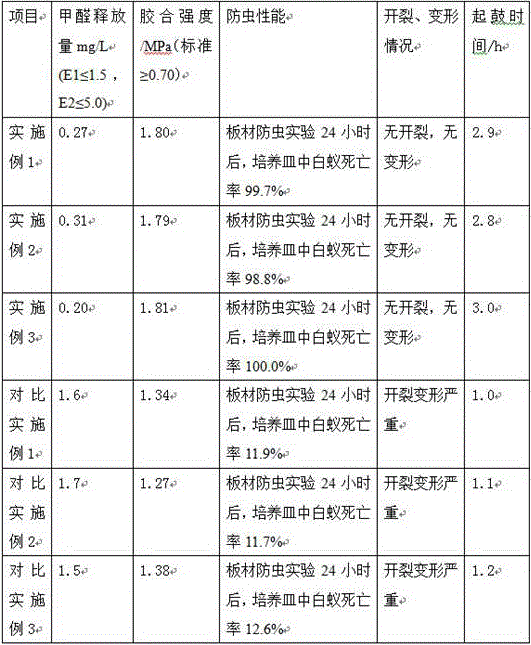

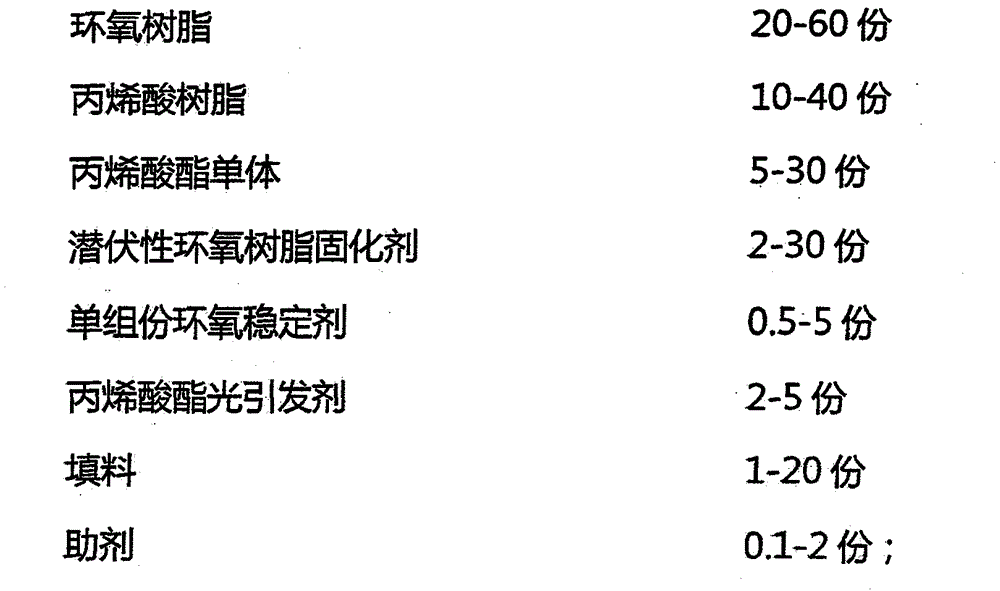

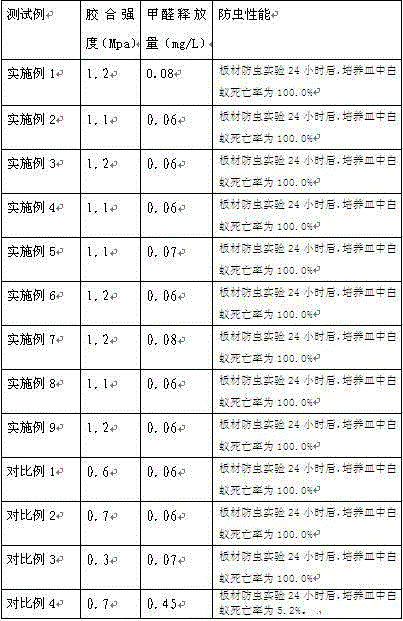

Soybean glue and preparation method thereof

ActiveCN103184032AImprove adhesion strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesResistWater based

The invention relates to an adhesive and the field of preparation of the adhesive, and in particular relates to a soybean glue and a preparation method thereof. The soybean is prepared from the following raw materials in parts by mass: 100 parts of water, 15-400 parts of soybean derivative, 3-8 parts of alkaline, 0.5-3 parts of silicate, 0.2-5 parts of modifying agent, 0.3-2.5 parts of curing agent, 0.1-4 parts of acid, 0.1-20 parts of water-based acrylic resin, 0.1-1.5 parts of insect-resist agent and 1-10 parts of filler. The soybean glue prepared in the invention has high adhesive strength and low formaldehyde emission and further has mould-proof, corrosion-proof, mothproof and waterproof functions.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

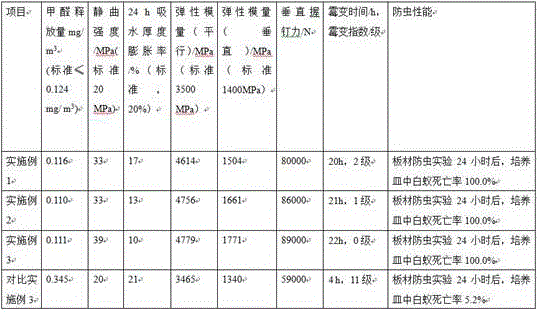

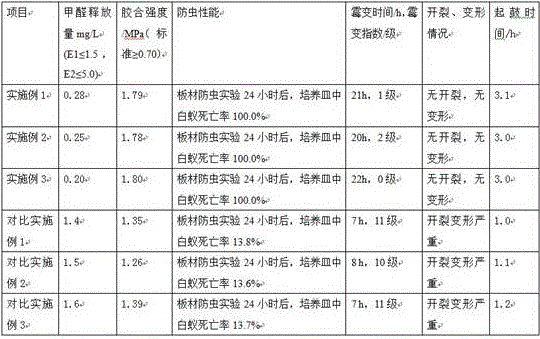

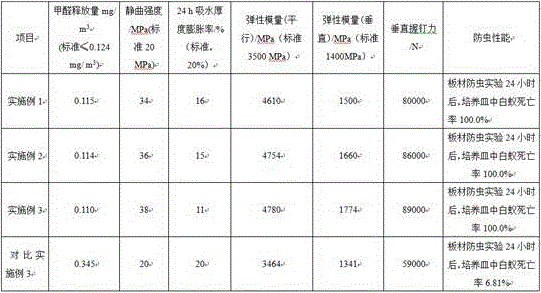

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

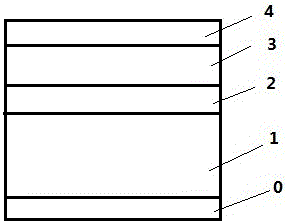

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

Photocatalystc composite floor board and production process of photocatalystc composite floor board

InactiveCN104989066ADoes not affect bond strengthAffect bond strengthLaminationLamination apparatusWood shavingsSurface layer

The invention relates to a photocatalystc composite floor board, and belongs to the field of a functional environment-friendly healthy floorboard. The formaldehyde emission content of the composite floorboard is less than 0.3mg / L; the antibacterial rate is higher than or equal to 90 percent; the surface wear-resistant coefficient is less than or equal to 0.08g / 100r; a substrate layer is an oriented shaving board layer; the oriented shaving board layer comprises an upper surface layer and a lower surface layer which are formed by glue mixing wood shavings in longitudinal arrangement according to the fiber direction and a core layer shaving layer formed by glue mixing wood shavings in transverse arrangement according to the fiber direction; and a decoration layer, a wear-resistant primer layer and a photocatalystc antibacterial paint decoration layer are sequentially arranged on the substrate layer. A production process of the photocatalystc composite floor board comprises the steps of shaving board layer sorting, glue preparation, glue distribution and assembling for the first time, cold pressing for the first time, core trimming, glue distribution and assembling for the second time, cold pressing for the second time, hot pressing for the first time, fixed-thickness sanding, edge cutting, puttying, polishing, sorting, reconditioning, glue distribution and veneering, cold pressing for the third time, hot pressing for the second time, multi-blade sawing, sanding, double-end milling, priming, finish paint preparing and finish paint painting. The composite floorboard has the advantages of good antibacterial function, high strength, good wear-resistant performance and comfortable foot feeling.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

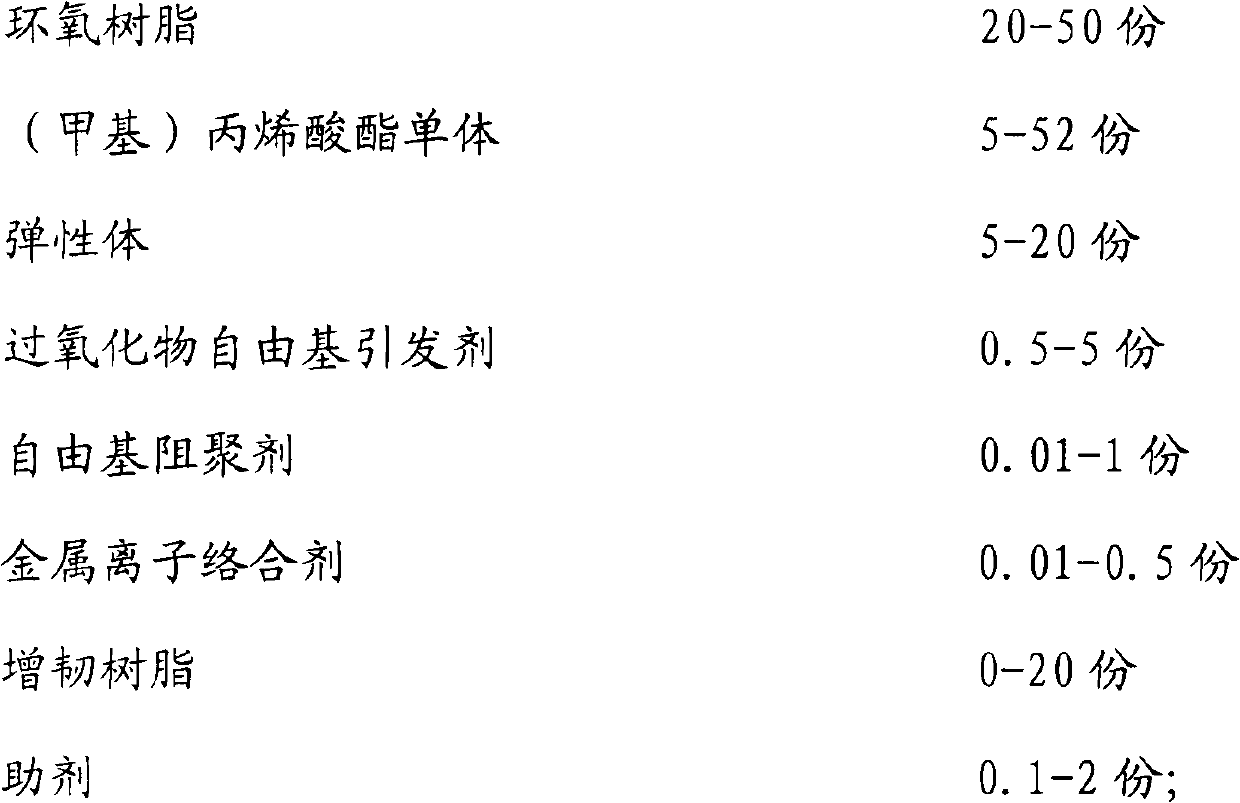

Adhesive having rapid fixing structure, and preparation method thereof

ActiveCN103305130ADoes not affect bond strengthResolution timeOrganic non-macromolecular adhesivePolyether adhesivesMethacrylateElastomer

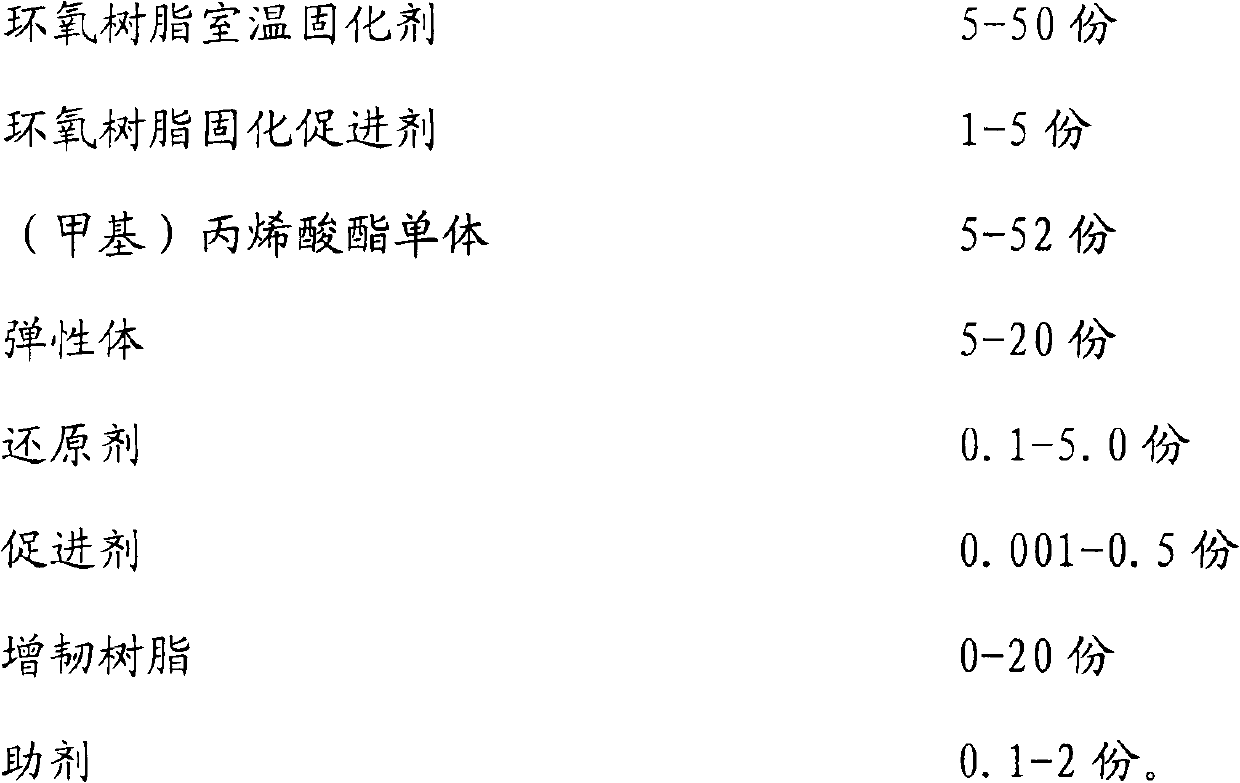

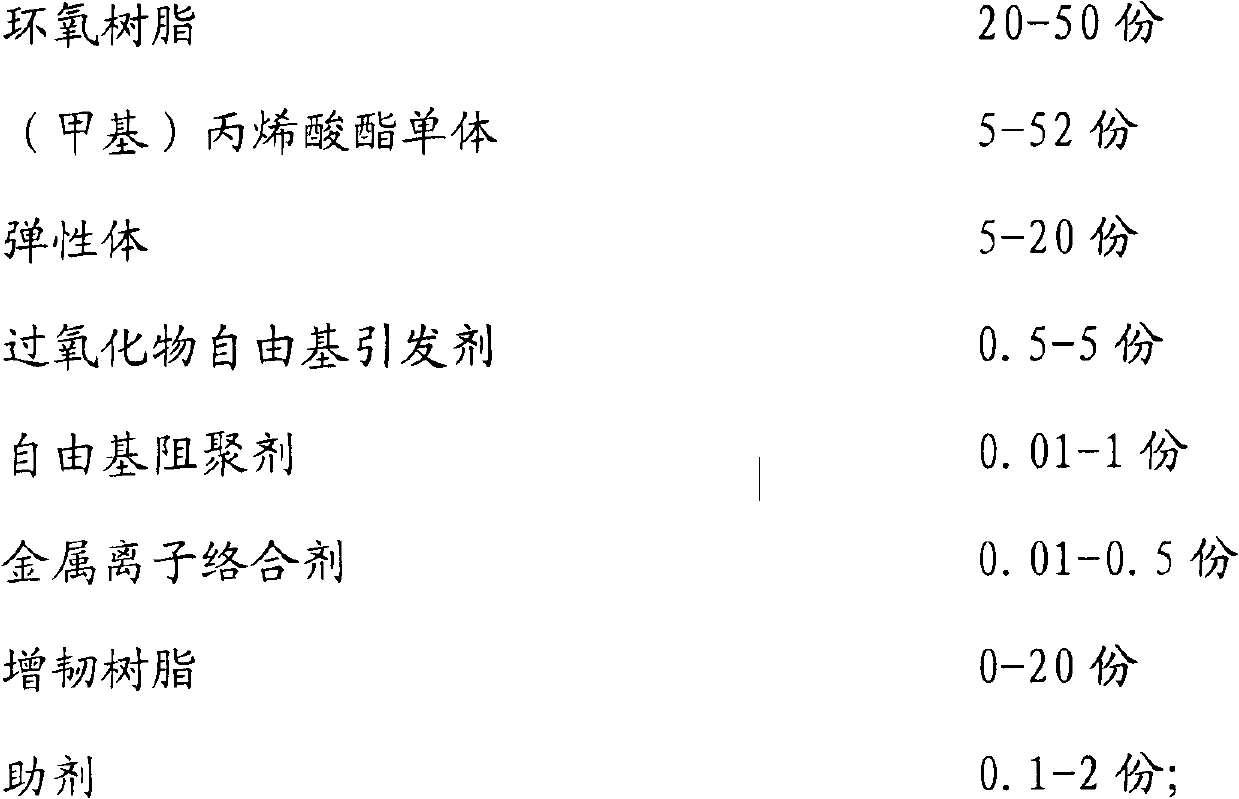

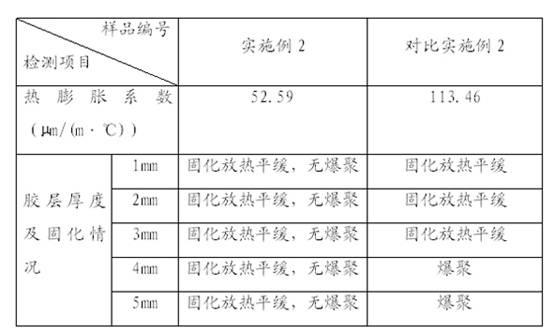

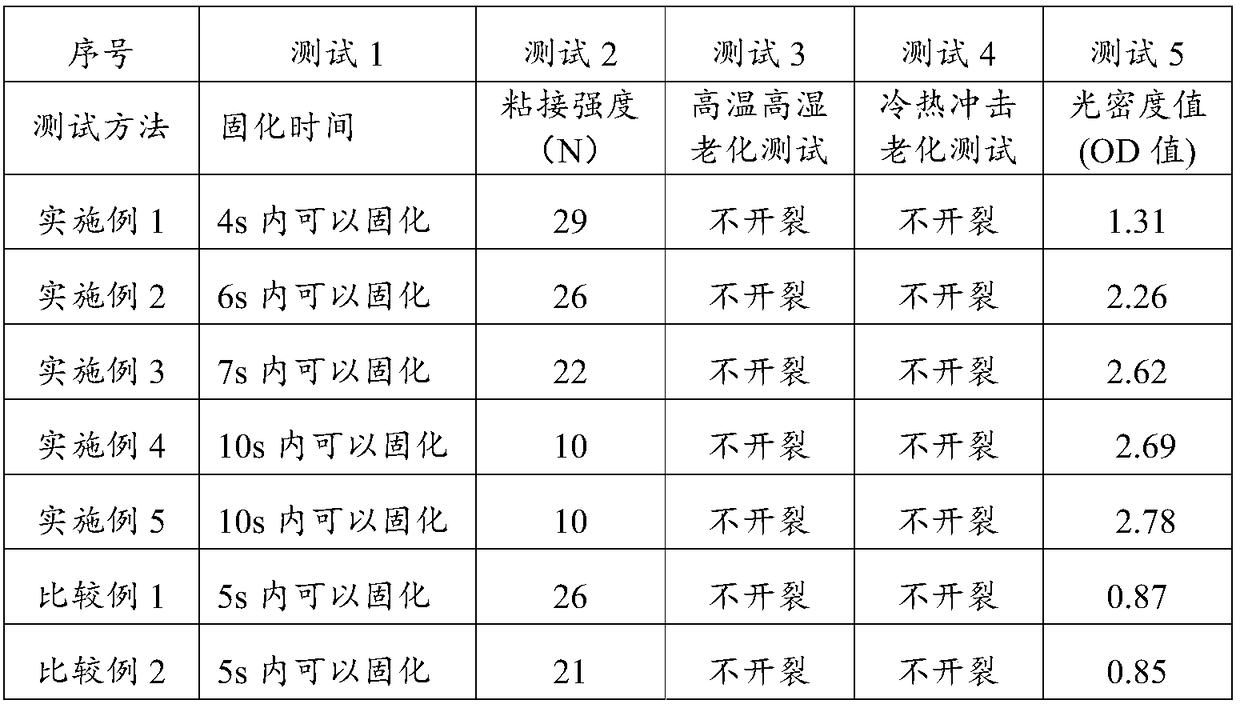

The invention discloses an adhesive having a rapid fixing structure. The adhesive comprises a component A and a component B, the component A comprises 20-50 parts of an epoxy resin, 5-52 parts of a (methyl) acrylate monomer, 5-20 parts of an elastomer, 0.5-5 parts of a peroxide radical initiator, 0.01-1 part of a free radical polymerization inhibitor, 0.01-0.5 parts of a metal ion complexing agent, and 0.1-2 parts of an assistant, and the component B comprises 5-50 parts of an epoxy resin room-temperature curing agent , 1-5 parts of an epoxy resin curing promoter, 5-52 parts of the (methyl) acrylate monomer, 5-20 parts of the elastomer, 0.1-5.0 parts of a reducing agent, 0.001-0.5 parts of a promoter, and 0.1-2 parts of the assistant. The adhesive having a rapid fixing structure prepared by using the above components and the preparation method effectively solves the disadvantages of long fixing time, long complete curing time, bad damp-heat aging resistance and the like of the prior art.

Owner:塔威新材料科技(上海)有限公司

High-temperature resistant single-component epoxy structure glue, preparation method and using method thereof

InactiveCN101928539AImprove thermal conductivityGentle exothermic reactionNon-macromolecular adhesive additivesEpoxynovolac adhesivesInternal stressSingle component

The invention relates to a high-temperature resistant single-component epoxy structure glue, a preparation method and a using method thereof. The epoxy structure glue is prepared by raw materials based on parts by weight: 100 parts of epoxy resin, 10-25 parts of toughening agent, 20-40 parts of filler, 1-5 parts of coupling agent, 5-10 parts of curing agent and 3-8 parts of thixotropic agent. The high-temperature resistant single-component epoxy structure glue has certain properties in the aspects of metal and nonmetal, thus not only having the adhesive bonding function, but also being used for filling gaps; and due to the low coefficient of thermal expansion, the cured product can be used for a long time at higher temperature and does not crack by internal stress.

Owner:YANTAI DARBOND TECH

UV (ultraviolet)-curable adhesive composition and application thereof

ActiveCN108219736ASolve problems that cannot be curedDoes not affect bond strengthPolyureas/polyurethane adhesivesOligomerLiquid-crystal display

The invention relates to UV (ultraviolet)-curable adhesive composition and an application thereof. The UV-curable adhesive composition is prepared from the following components in parts by weight: 50-60 parts of a polyurethane acrylate oligomer, 30-40 parts of an acrylate monomer, 3-5 parts of a photoinitiator and 1-5 parts of discoloration powder, wherein the discoloration powder is blackened after being irradiated by UV light and is irreversibly discolored. The UV-curable adhesive composition can be used in assembly of LCD (liquid crystal display) and OLED (organic light emitting diode) display products.

Owner:上海昀通电子科技有限公司

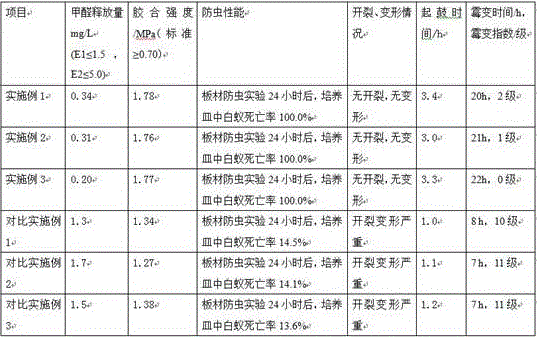

Method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin

ActiveCN106182218AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantAdditive ingredient

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

Method for producing antiseptic oriented strand board through full-eucalyptus leftover materials

InactiveCN106239689AWhite colorGood film formingWood veneer joiningDomestic articlesDusting powdersOptoelectronics

The invention provides a method for producing an antiseptic oriented strand board through full-eucalyptus leftover materials. The method comprises the procedures of material preparing, drying, peel and impurity removing, sorting and storing, surface layer and core layer gluing, classified paving, preheating press forming, sanding facing and the like. A surface layer is coated with an isocyanate wood dust powder composite adhesive, a core layer is coated with an antiseptic composite urea-formaldehyde resin adhesive, and core layer wood shavings are of three-layer structures including a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer. The core layer middle layer is longitudinally laid, and the core layer upper surface layer, the core layer lower surface layer and the surface layer are transversely laid. According to the oriented strand board prepared through the method, the static bending intensity in the parallel direction ranges from 34 MPa to 38 MPa, and the parallel elasticity modulus ranges from 4,610 MPa to 4,780 MPa; and the vertical elasticity modulus ranges from 1,500 MPa to 1,774 MPa, the water absorption thickness swelling rate in 24 h ranges from 11% to 16%, and the vertical nail holding force reaches up to 89,000 N. Meanwhile, through adding of an antiseptic agent, the problem that panels are prone to suffering from corrosion of wood-destroying fungi, moulds and white ants is thoroughly solved, and the service life of the panels is prolonged.

Owner:广西横县新威林板业有限公司

Method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin

ActiveCN106335120AReduce formaldehyde contentGood gluing propertiesOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerSurface layer

A method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin comprises steps as follows: rotary cutting of a board to form pieces; single plate drying; adhesive coating; three times of cold pressing; leaving to stand for reconditioning; three times of hot pressing; heat dissipation for reconditioning; fixed-thickness sanding of plate blanks; adhesive coating of base material surface layers; reconditioning and grooving; paint coating, drying and setting. The key of the production method is that melamine modified urea-formaldehyde resin is used as a main adhesive material; oxidized starch is added as a viscous compound; polyvinyl alcohol is added as a toughening agent; hydrogenated rosin is added as an anti-oxidant; polyisocyanate is added as a curing agent; isobutyltriethoxysilane is added as a bridging agent; phenolated lignin is added as a formaldehyde catching agent; an anti-insect and anti-mildew agent is added; anti-insect and anti-mildew composite urea-formaldehyde resin is prepared; and the parquet prepared from anti-insect and anti-mildew composite urea-formaldehyde resin has the advantages of being low in formaldehyde residual amount and good in anti-insect and anti-mildew effect, has the relatively high inhibition effect on breeding of Aspergillus, Trichoderma and Penicillium and has the instant killing force and the long-acting preventive effect on board powder-pest beetles.

Owner:广西横县正林木业有限公司

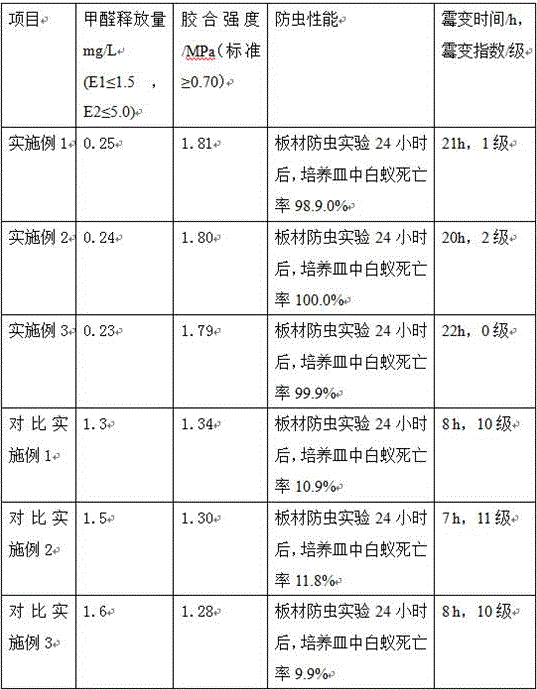

Method for producing particle board through anti-insect and anti-mold composite urea formaldehyde resin

ActiveCN106363760AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantPolyvinyl alcohol

The invention discloses a method for producing a particle board through anti-insect and anti-mold composite urea formaldehyde resin. The method comprises the procedures like material preparation, drying, veneer removing and grit removing, mixing glue, and hot press molding. The key of the production method is that melamine modified urea formaldehyde resin is adopted as a main material of an adhesive; oxidized starch is added as a viscous complexing agent; polyvinyl alcohol is adopted as a flexibilizer; hydrogenated rosin is adopted as an antioxidant; polyisocyanate is adopted as a curing agent; and triethoxyisobutylsilane is adopted as a bridging agent. According to the method, the anti-insect and anti-mold composite urea formaldehyde resin is prepared through adopting phenolated lignin as a formaldehyde capture agent and adding an anti-insect and anti-mold agent, and the particle board produced through the anti-insect and anti-mold composite urea formaldehyde resin has the advantages that the residual amount of formaldehyde is low and the anti-insect and anti-mold effect is good, has a quite high inhibiting effect on breeding of aspergillus, trichoderma and penicillia, and has instantaneous killing force and a long-term prevention effect on board powder-post beetles.

Owner:广西横县新威林板业有限公司

Watersoluble neoprene adhesive agent and preparation thereof

InactiveCN101343515AReduce emulsification processReduce the amount addedChloroprene adhesivesAlcoholAdhesive

The invention relates to an aqueous neoprene adhesive agent and the preparation method, which belongs to the fields of the elastic bonding adhesive with porous material and the preparation. According to the mass ratio, the aqueous neoprene adhesive agent comprises 100 mass parts of high crystalline aqueous neoprene latex, 10 mass parts to 35 mass parts of polyacrylate, 0.2 mass part to 2 mass parts of aromatic poly alcohol and ether aqueous dispersion, 0.001 to 0.01 mass part of penetrating agent, and 0.001 to 0.01 mass part of defoaming agent. The invention provides the aqueous neoprene adhesive agent without the pollutant of triphen and the like which is urgently need on the market. The aqueous neoprene adhesive agent has the advantages that the viscosity is moderate, the operating time is long, the adhesive agent can be suitable for the flow line production, spraying and brushing, different construction conditions and operating requirements can be satisfied, and the application scope is wide.

Owner:任占国

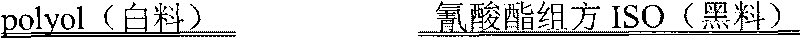

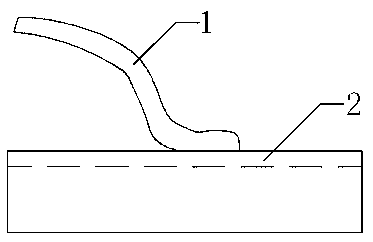

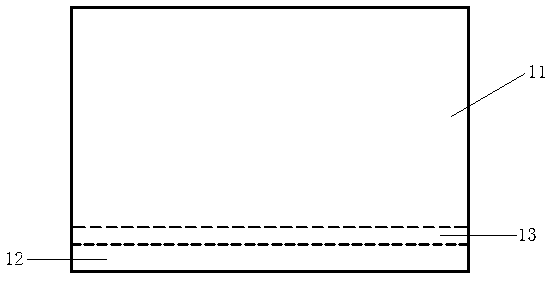

Polyurethane two-component foaming adhesive used for adhering internal wall and external wall and method for producing same

InactiveCN101735762APaste time controllableHigh strengthPolyureas/polyurethane adhesivesAdhesiveCement board

The invention relates to polyurethane two-component foaming adhesive used for the building to adhere boards, metal, glass, marble, polystyrene boards, extruded boards (XPS), polyurethane boards, cement boards and other materials. The polyurethane two-component foaming adhesive has controllable adhering time, high strength and strong adhesive power, can resist heat, coldness and hydrolysis, does not need the fastener and can be directly adhered to the old wall to save the labor hour and the cost. The polyurethane two-component foaming adhesive is formed by mixing white adhesive A and fulvous adhesive B which have wide mass ratio range, and if being formed by 100 portions of adhesive A and 50-110 portions of adhesive B, the polyurethane two-component foaming adhesive can be still adhesive, can not be affected in the adhesive strength and can be operated between 3 DEG C below zero and 5 DEG C below zero. The adhesive A and the adhesive B can be proportioned accurately and can be adhesive after being stirred evenly. The polyurethane two-component foaming adhesive can be slightly foamed if the wall is slightly uneven so as to fill in the gap between the wall and the board and prevent the rainwater entering the gap to generate the isolating layer. The polyurethane two-component foaming adhesive can achieve better effect of insulating heat.

Owner:辽宁鼎力科技有限责任公司

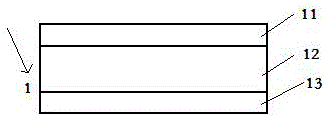

Manufacturing method of high-power field-effect transistor aluminum-gold bonding transition sheet

InactiveCN103295918AReduce adverse effectsDoes not affect bond strengthSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactLead bonding

A manufacturing method of a high-power field-effect transistor aluminum-gold bonding transition sheet includes steps of (1) selecting and cleaning an aluminum sheet; (2) plating gold on one side of the aluminum sheet; (3) alloying and reinforcing ohmic contact between the gold layer and aluminum; (4) cutting to obtain transition sheet materials different in specification as required. When the aluminum-gold bonding transition sheet is used for high-purity aluminum wire bonding, a gold titanium alloy surface (4) of the aluminum-gold bonding transition sheet is welded on a gold plated layer (2) of a gold-plated mandrel through a welding flux (3); high-purity aluminum wires (1) are welded on an aluminum surface (11) of the aluminum-gold bonding transition sheet. The manufactured aluminum-gold bonding transition sheet is used for high-purity aluminum wire bonding and can eliminate adverse affection caused by intermetallic and Kendal effect generated by the aluminum-gold bonding and has no affection on bonding strength and on resistance of wires. Besides, the aluminum-gold bonding transition sheet is applicable to wire bonding of high-power field-effect transistors.

Owner:JIANGXI LIANCHUANG SPECIAL MICROELECTRONICS

Photocatalyst flame-retardant antibacterial floor and production process thereof

InactiveCN105298077ADoes not affect bond strengthAffect bond strengthWood working apparatusFlooring insulationsSurface layerWear resistant

The invention relates to a photocatalyst flame-retardant antibacterial floor and belongs to the field of functional environment-friendly health floors. The floor has a formaldehyde release limit less than 0.3 mg / L, an antibacterial rate not less than 90%, and surface wear resistance not less than 0.08 g / 100r. A base layer is a flame-retardant directional chipboard layer, comprising upper and lower surface layers of glue-mixed shavings, a core shaving layer, a first flame-retardant layer and a second flame-retardant layer; a decorative layer, a wear-resistant undercoat layer and a photocatalyst antibacterial oil facing layer are disposed in order above the base layer; a balance layer is disposed below the base layer. A production process of the floor comprises chipboard layer regulating; glue mixing; first gluing and assembly; first cold pressing; core dressing; second gluing and assembly; second cold pressing; first hot pressing; fixed thickness sanding; edging; puttying; polishing; sorting; curing; gluing and facing; third cold pressing; second hot pressing; multi-piece sawing; sanding; double end milling; undercoating; top coat blending; top-coating. The composite floor has high antibacterial performance, high strength, good wear resistance and good foot comfort.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

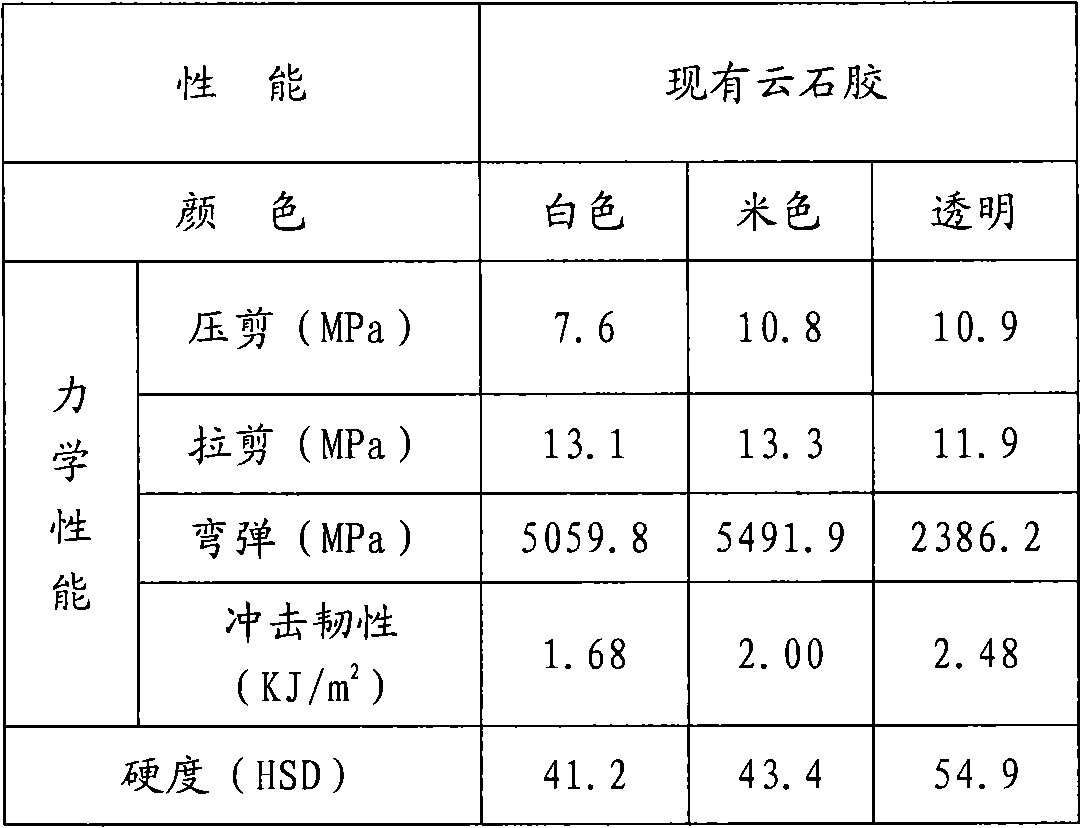

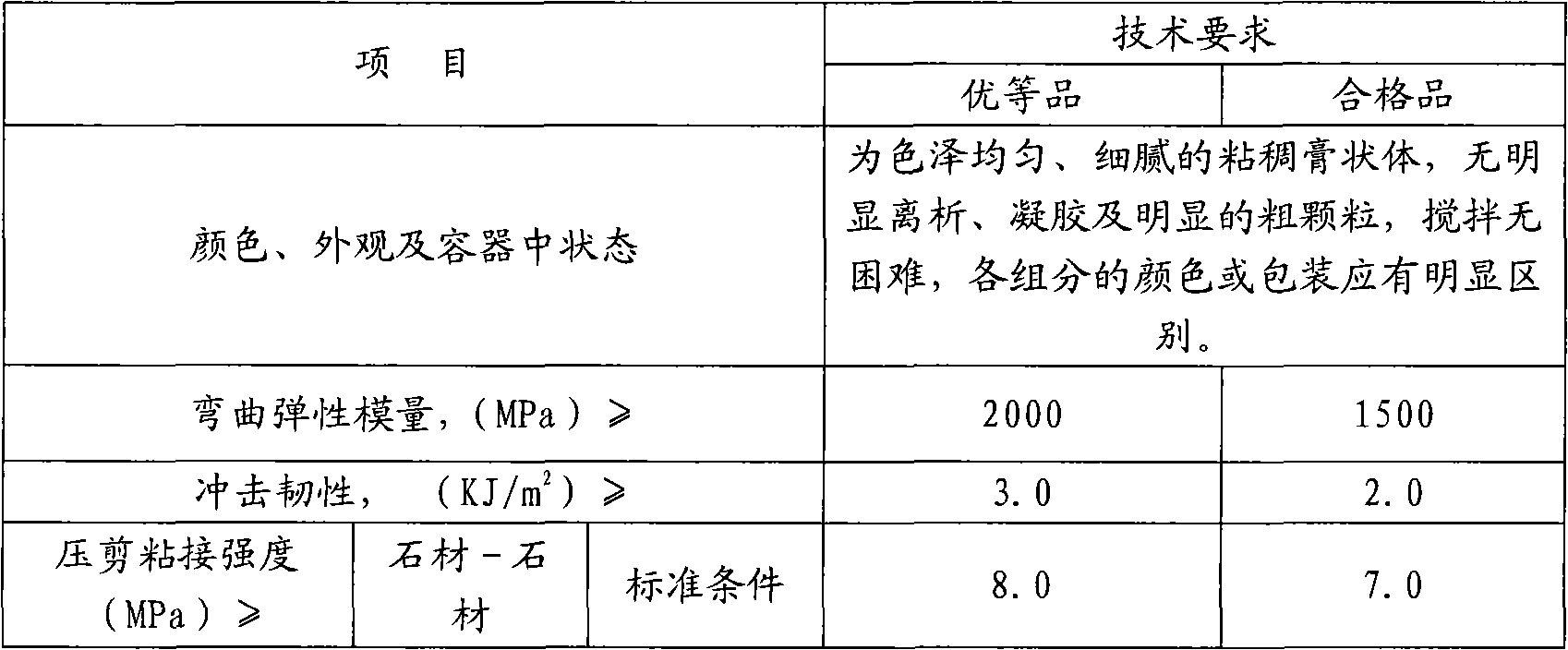

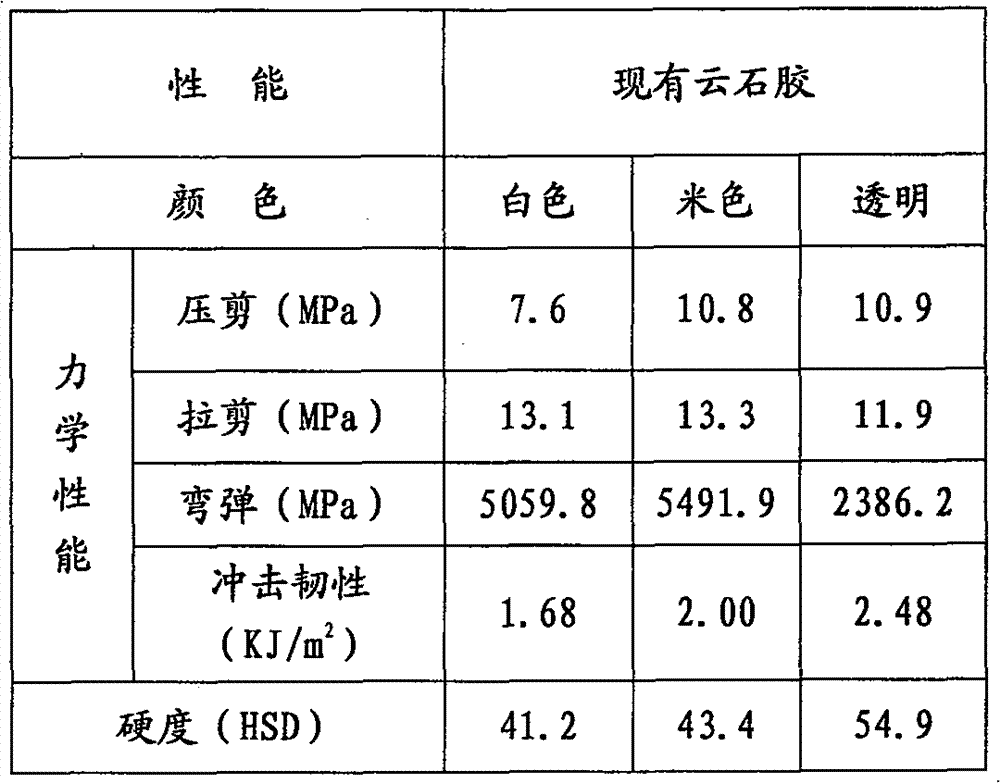

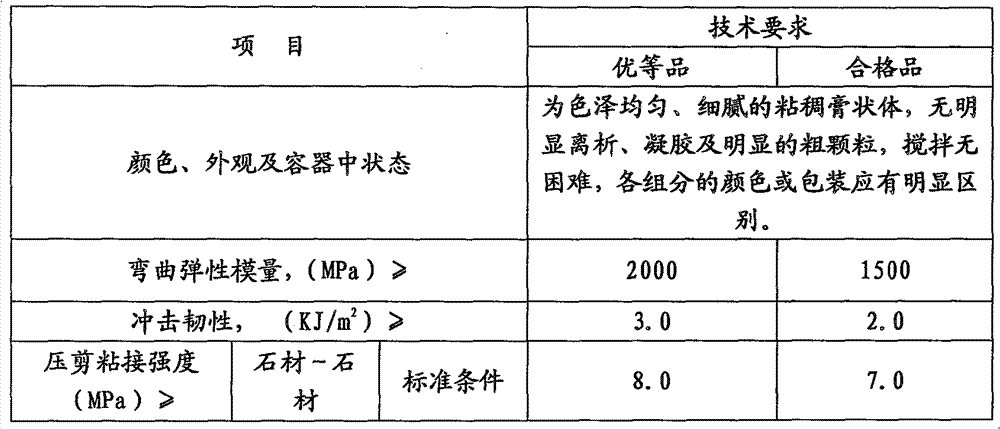

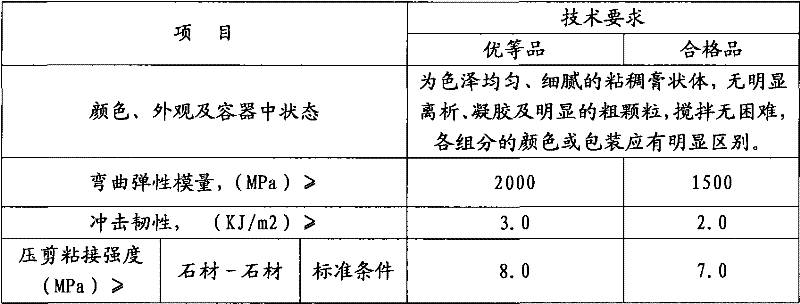

Jointing glue for stone

ActiveCN101851482ASolve the pointing problemHigh hardnessBuilding repairsAdhesivesSilicon dioxideUnsaturated polyester

The invention provides jointing glue for stone, which at least comprises the following components in parts by weight: 100 parts of an air-dried unsaturated polyester resin, 1-5 parts of hydrogenated castor oil, 0-60 parts of micron-sized silica and 1-15 parts of an antishrinking agent. The jointing glue overcomes the defects of taking the existing common marble glue as the jointing glue such as poor air-drying properties, poor antishrinking capability, poor permeability and the like. The jointing glue for stone has the advantages of good permeability, no tackiness after curing, strong antishrinking capability, glue brightness after polishing and the like. The jointing glue enriches varieties of the marble glue and solves the problem of jointing difficulty among the stone.

Owner:江苏大力士云石护理材料有限公司

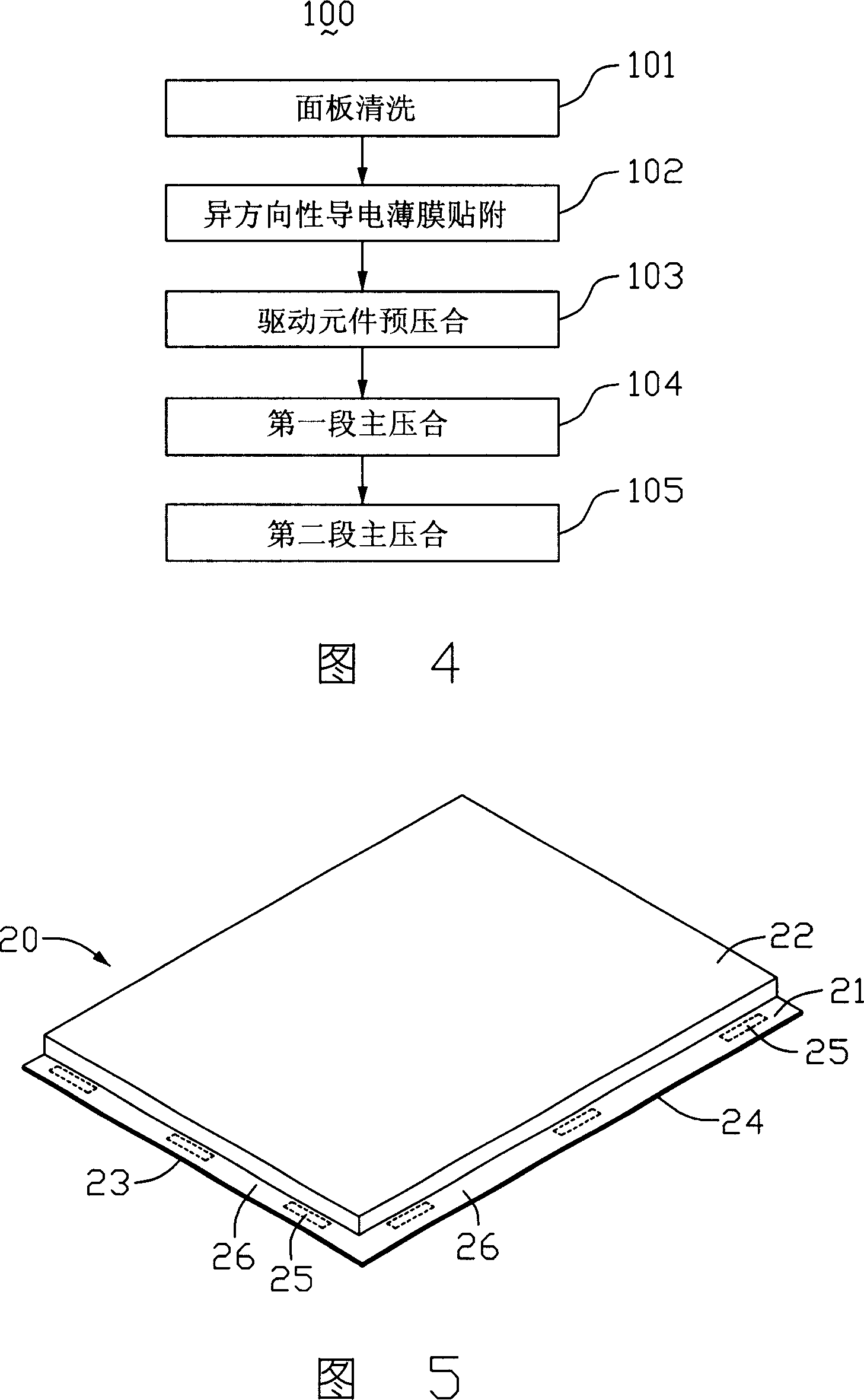

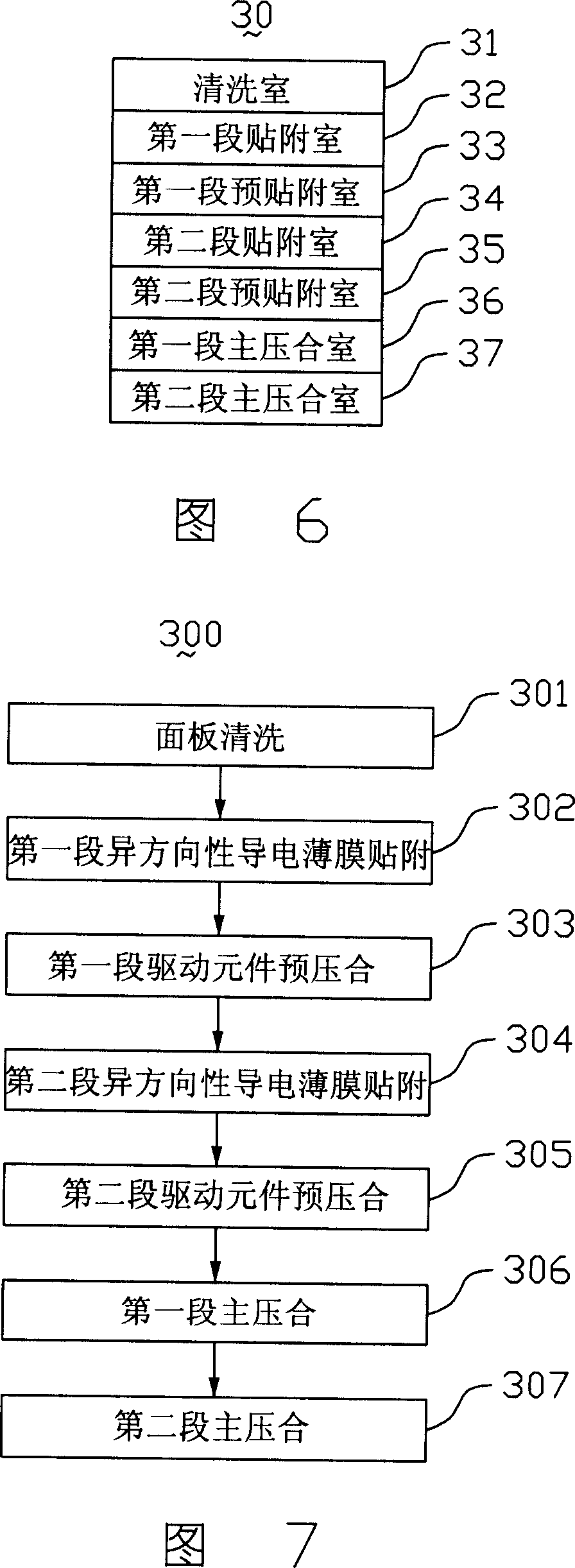

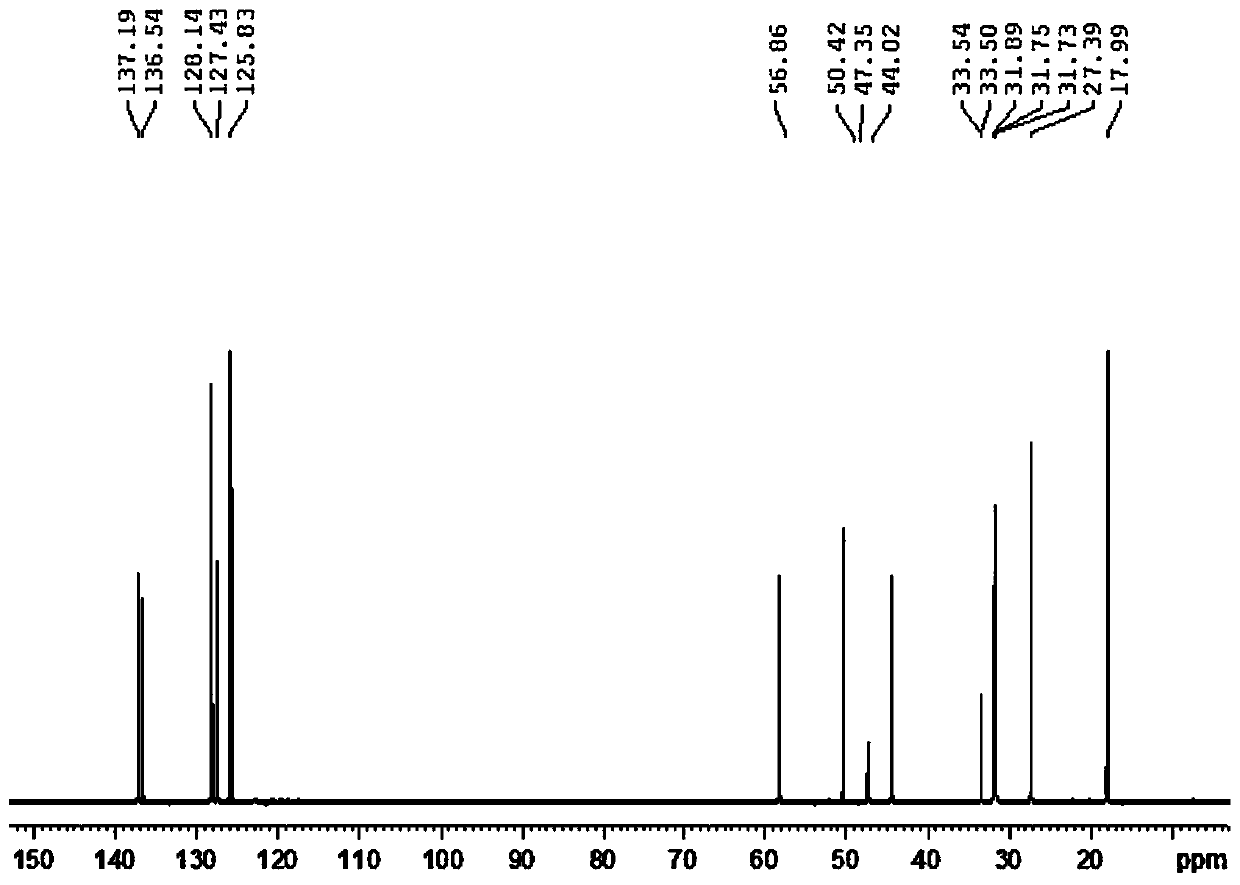

Method and apparatus for adhering driving component

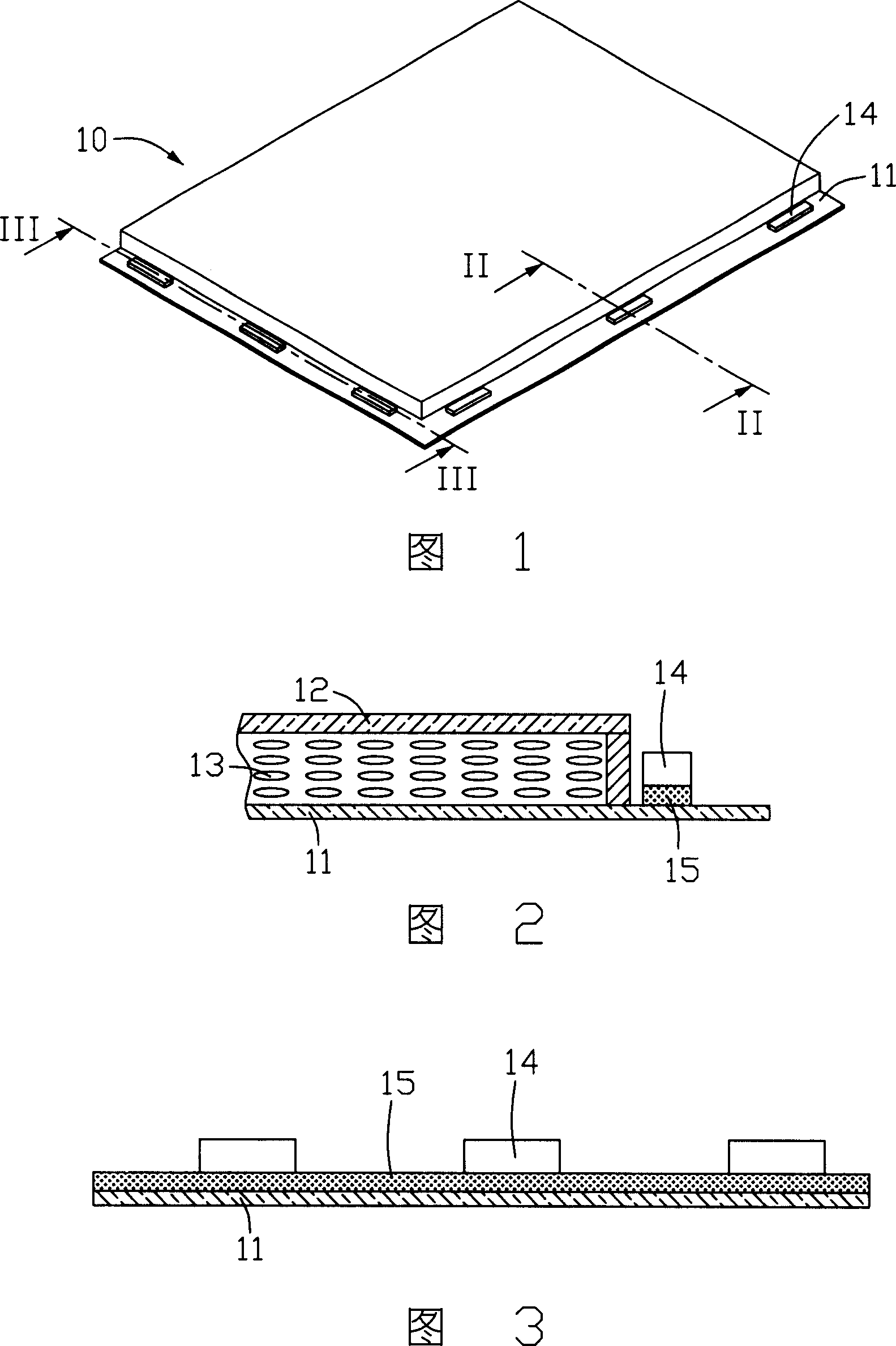

ActiveCN1982996AReduce usageDoes not affect bond strengthStatic indicating devicesNon-linear opticsLiquid-crystal displayDriven element

A method for sticking the driving elements includes providing liquid crystal display face plate with base plate having two ends both being set with sticking region (SR) including connection region, cleaning said SR, sticking heteroscedasticity conduction film at the first end SR and the second end SR of said base plate separately, setting a driving element at the first end connection region and the second end connection region separately then pre-pressing these driving elements, carrying out master pressing on said driving elements at two said ends for making them be connected with said base plate.

Owner:INNOCOM TECH SHENZHEN +1

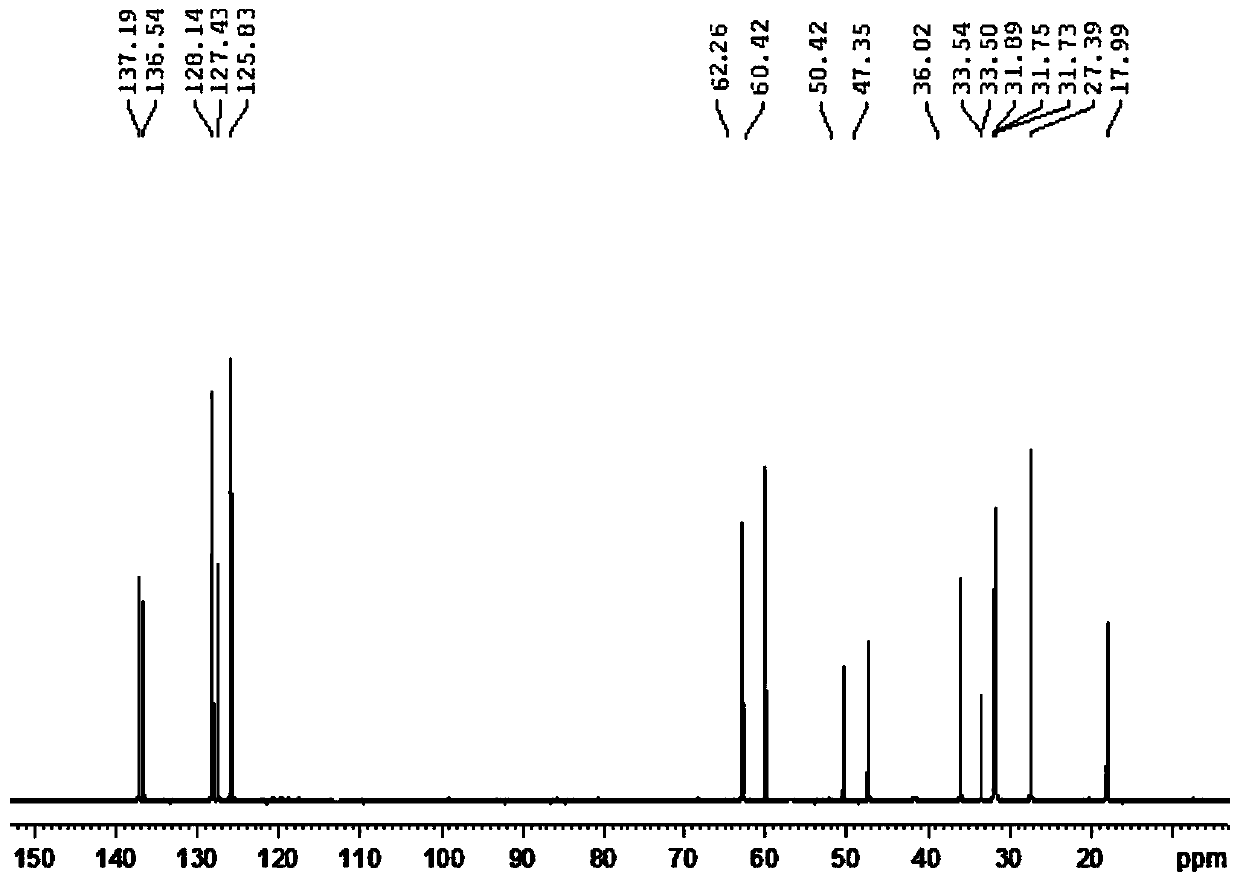

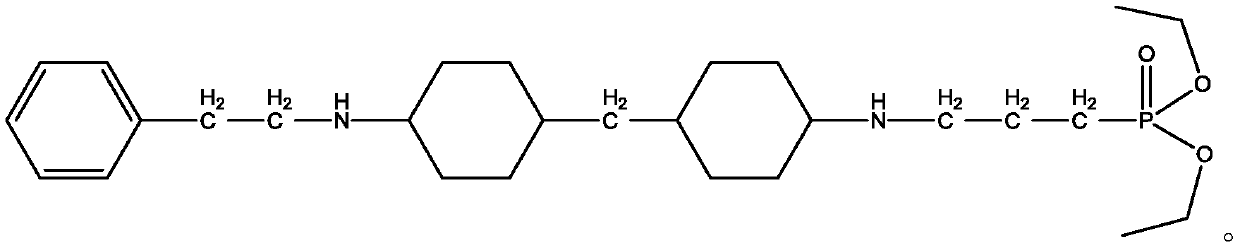

Flame-retardant toughening agent, epoxy curing agent prepared from flame-retardant toughening agent and seam beauty agent epoxy resin composition

The invention provides a flame-retardant toughening agent used for a seam beauty agent, a preparation method of the toughening agent, an epoxy curing agent containing the toughening agent and an epoxyresin composition. The curing agent can meet the requirements of rapid curing and rapid cleaning of the seam beauty agent at room temperature; the introduced special toughening agent can meet the requirement for toughness without glue breakage in the cleaning process of the seam beauty agent and the requirement for flame retardancy; and the epoxy composition using the special toughening agent issuitable for requirements of a seam beauty agent in the field of building decoration.

Owner:WANHUA CHEM GRP CO LTD +1

Special colored stone material caulking sealant

ActiveCN101805581AImprove aging resistanceSolve the pointing problemBuilding repairsMacromolecular adhesive additivesFilling materialsSealant

The invention relates to special colored stone material caulking sealant, which at least comprises 100 weight parts of air-dried unsaturated polyester resin, 1 to 5 weight parts of hydrogenated castor oil, 10 to 250 weight parts of filling materials and 1 to 15 parts of antishrinking agents. The invention overcomes the defects of poor air-dried performance, low antishrinking capability, poor permeability and the like when the existing ordinary marble glue is used as the caulking sealant. The stone material caulking sealant of the invention has the advantages of good permeability, hand inadhesion after being cured, strong antishrinking capability, sealant brightness after grinding and the like. The invention enriches the variety of the marble glue, and solves the caulking problem between stone materials.

Owner:江苏大力士云石护理材料有限公司

Stone material caulking sealant

ActiveCN101805581BSolve the pointing problemImprove permeabilityBuilding repairsMacromolecular adhesive additivesFilling materialsSealant

The invention relates to special colored stone material caulking sealant, which at least comprises 100 weight parts of air-dried unsaturated polyester resin, 1 to 5 weight parts of hydrogenated castor oil, 10 to 250 weight parts of filling materials and 1 to 15 parts of antishrinking agents. The invention overcomes the defects of poor air-dried performance, low antishrinking capability, poor permeability and the like when the existing ordinary marble glue is used as the caulking sealant. The stone material caulking sealant of the invention has the advantages of good permeability, hand inadhesion after being cured, strong antishrinking capability, sealant brightness after grinding and the like. The invention enriches the variety of the marble glue, and solves the caulking problem between stone materials.

Owner:江苏大力士云石护理材料有限公司

Method for producing whole eucalyptus plywood by using compound urea-formaldehyde resin against insects and mildew

ActiveCN106182218BReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesPolyvinyl alcoholAntioxidant

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

Middle-high density plywood with added bamboo charcoal and method for adding bamboo charcoal thereof

ActiveCN103481349APlay weak conductivityHas weak conductivityWood working apparatusFlat articlesCycloneHigh density

The invention provides middle-high density plywood with added bamboo charcoal and a method for adding the bamboo charcoal thereof, and belongs to the technical field of density plywood and the method of adding the bamboo charcoal thereof. According to the middle-high density plywood with added the bamboo charcoal, the dosage of bamboo charcoal powder is one tenth to one thousandth of the weight of the density plywood. A hole is formed in a pipeline wall carrying out secondary air supply by large cyclone, the outlet of a spiral conveyer is communicated with the hole in the pipeline wall carrying out the secondary air supply by the large cyclone, the inlet of the spiral conveyer is communicated with a stock bin of the bamboo charcoal powder, the bamboo charcoal powder and wood fibers are sent to a spreading machine through the secondary air supply and are evenly paved on a preforming press, and then hot press molding is carried out. The surface of the middle-high density plywood presents tiny black dots after the bamboo charcoal is added, and physical experiments carried out on the middle-high density plywood shows the facts that the combination intensity of the inner portion of the density plywood is not influenced, the surficial combination intensity of the density plywood is not influenced either, and the veneer attaching of any material on the density plywood added with the bamboo charcoal is not influenced. The middle-high density plywood with added bamboo charcoal and the method for adding the bamboo charcoal thereof meet the technical standard of domestic middle-high density fiberboards.

Owner:辽宁蓝亿实业有限公司

Jointing glue for stone

ActiveCN101851482BSolve the pointing problemHigh hardnessBuilding repairsAdhesivesSilicon dioxideUnsaturated polyester

Owner:江苏大力士云石护理材料有限公司

Method for preparing environment-friendly waterproof fiberboard based on microcapsule

InactiveCN104499378AReduced release rateExtended use timeFibreboardWater-repelling agents additionFiberAdhesive

The invention relates to a method for preparing an environment-friendly waterproof fiberboard based on a microcapsule. The method comprises the following steps: taking paraffin as a core material and gelatin as a wall material, preparing a microcapsule waterproof agent by adopting a single coacervation method and taking the microcapsule waterproof agent as a filler to prepare the waterproof fiberboard. According to the method for preparing the environment-friendly waterproof fiberboard based on the microcapsule, not only is the contact of the paraffin and other waterproof agents with fibers or adhesives isolated so as to achieve the effect that the bonding strength is not influenced as much as possible, but also the release rate of the waterproof agent can be retarded, so that the service life of the waterproof fiberboard with a waterproof effect is prolonged.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for producing total-eucalyptus plywood by adopting anticorrosive composite urea resin

ActiveCN106313201AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesAntioxidantAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting anticorrosive composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, hydrogenated rosin is taken as an antioxidant, polyisocyanate is taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a preservative is also added to prepare the anticorrosive composite urea resin. The total-eucalyptus plywood produced by adopting the anticorrosive composite urea resin has the advantages of low formaldehyde residual volume and good corrosion resistance, is relatively good in resistance to wood-destroying fungi, mould and white ants, and is prolonged in service life.

Owner:广西横县正林木业有限公司

Fast-curing structural adhesive and preparation method thereof

ActiveCN103305132BDoes not affect bond strengthOrganic non-macromolecular adhesiveEpoxyAcrylic resin

The invention discloses a fast-curing structural adhesive comprising the following components: 20-60 parts of epoxy resin, 10-40 parts of acrylic resin, 5-30 parts of acrylate monomers, 2-30 parts of a latent epoxy resin curing agent, 0.5-5 parts of an one-component epoxy stabilizer, 2-5 parts of an acrylate photoinitiator, 1-20 parts of fillers, and 0.1-2 parts of an auxiliary agent. The invention further discloses a preparation method of the fast-curing structural adhesive. The fast-curing structural adhesive prepared according to the components and the preparation method effectively solves defects and insufficiencies of long positioning time and fully cured time, and poor resistance to heat aging properties.

Owner:塔威新材料科技(上海)有限公司

A kind of soybean gum and its manufacturing method

ActiveCN103184032BImprove adhesion strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesWater basedResist

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

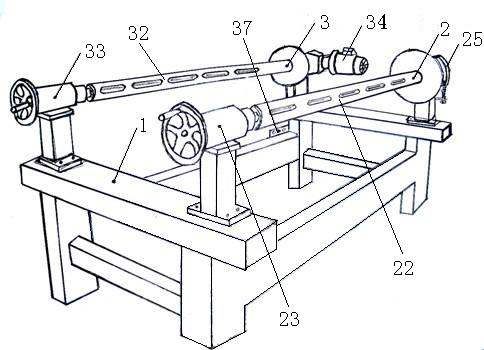

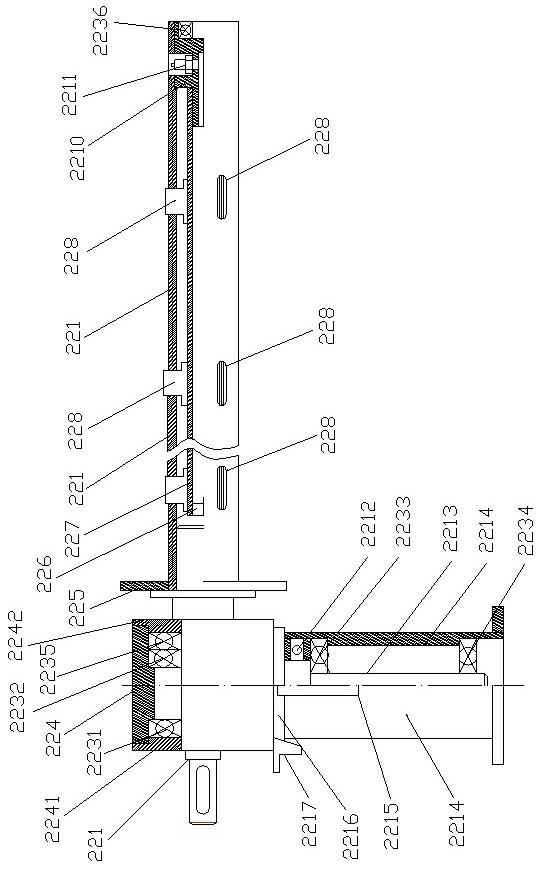

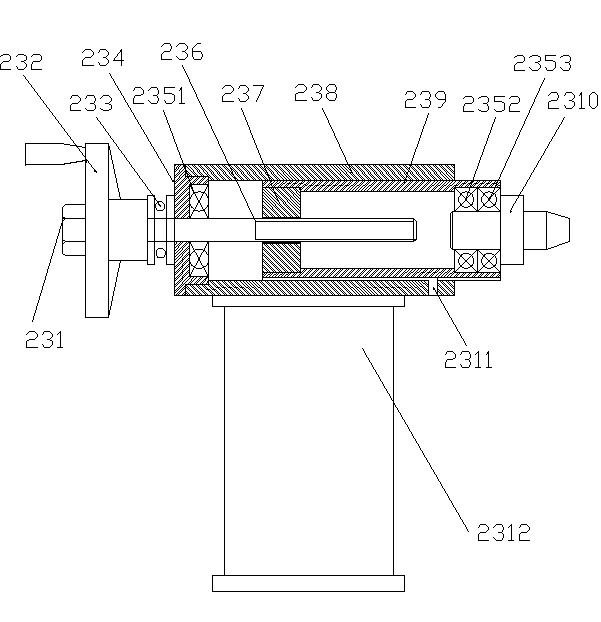

Biaxial turnover cloth inspecting machine and cloth inspecting method for glass fiber felt cloth

ActiveCN102330323ASimple structureReasonable designInspecting textilesTextile testingTextileMechanical engineering

The invention relates to a biaxial turnover cloth inspecting machine and a cloth inspecting method for glass fiber felt cloth. At present, special equipment for glass fiber bonded chopped strand mat cloth inspecting turnover is not available. The cloth inspecting machine provided by the invention comprises a pay-off shaft assembly and a take-up shaft assembly and is characterized in that the pay-off shaft assembly comprises a pay-off rotating shaft device, a pay-off top shaft seat device and a tension regulating device, and the pay-off rotating shaft device comprises a pay-off rotating shaft; the tension regulating device is arranged on a pay-off rotating shaft body seat and connected with one end of the pay-off rotating shaft, and the pay-off top shaft seat device is detachably connected with the other end of the pay-off rotating shaft; the take-up shaft assembly comprises a take-up rotating shaft device, and a take-up top shaft seat device is detachably connected with the other end of a take-up rotating shaft; and the take-up rotating shaft is parallel to the pay-off rotating shaft. The cloth inspecting method sequentially comprises the cloth loading process, the cloth inspecting process and the cloth unloading process. The cloth inspecting machine is reasonable in structural design and can be used for inspecting glass fiber felt cloth and performing turnover treatment on a felt coil of a glass fiber chopped strand mat, wherein black matters are attached to the appearance of the glass fiber chopped strand mat.

Owner:JUSHI GRP CO

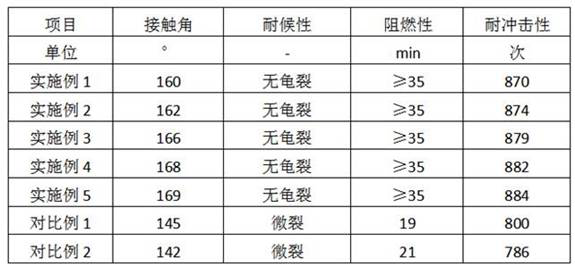

Weather-proof, moisture-proof and fireproof multifunctional mat and preparation method thereof

PendingCN114801402ASimple processEasy to operateLaminationLamination apparatusPolymer scienceGlycidyl methacrylate

The invention discloses a weather-proof, moisture-proof and fireproof multifunctional mat and a preparation method thereof. The weather-proof, moisture-proof and fireproof multifunctional mat comprises a mat body, a first functional layer arranged on the upper surface of the mat body, a second functional layer arranged on the lower surface of the mat body and an anti-skid elastic layer arranged on the lower surface of the second functional layer. The first functional layer and the second functional layer are mutually independently prepared from the following components in parts by weight: 60-80 parts of methyl vinyl silafluorene / N-vinyl carbazole / acrylonitrile / glycidyl methacrylate copolymer, 3-5 parts of 2, 2-bis (3-amino-4-hydroxyphenyl) hexafluoropropane, 10-20 parts of epoxidized natural rubber, 10-20 parts of 2, 2-bis (3-amino-4-hydroxyphenyl) hexafluoropropane, 10-20 parts of 2, 2-bis (3-amino-4-hydroxyphenyl)-1, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate, 10-20 parts of 2, 2, 4-trimethyl-1, 3- The adhesive comprises the following components in parts by weight: 3-5 parts of 2, 4-diamino-6-phenyl-1, 3, 5-triazine, 8-15 parts of filler, 1-3 parts of a dispersing agent, 1-2 parts of a defoaming agent and 20-30 parts of a solvent. The weather-proof, moisture-proof and fireproof multifunctional mat is good in performance stability, sufficient in weather-proof, moisture-proof and fireproof performance and long in service life.

Owner:NINGBO ORIENT SEATS IND

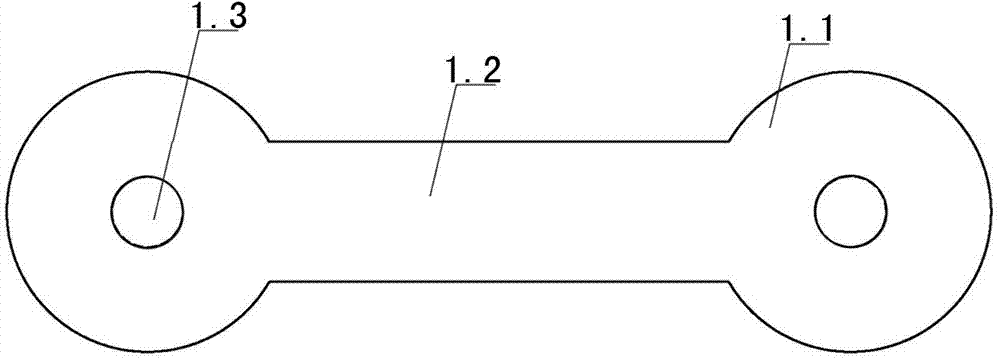

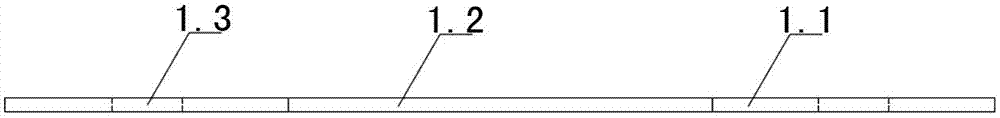

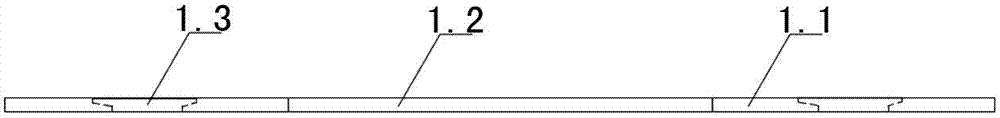

Glass fiber net reinforcement part, exterior wall heat-preservation anti-cracking structure and construction method thereof

ActiveCN104499651AOvercome strengthOvercoming easy crackingHeat proofingBuilding reinforcementsGlass fiberSurface layer

The invention relates to a glass fiber net reinforcement part, an exterior wall heat-preservation anti-cracking structure and a construction method of the exterior wall heat-preservation anti-cracking structure. The glass fiber net reinforcement part is of an integral sheet structure formed by two fixing sheets with the same shape and a connecting bridge connected between the two fixing sheets, and a threaded hole penetrating through a screw is formed at the center position of the fixing sheet. In addition, the glass fiber net reinforcement part is designed to be used for reinforcing the connecting strength of an anti-cracking mortar layer and a heat preservation layer, the glass fiber net reinforcement part has a simple structure, has low cost, can be constructed conveniently, and has a good fixing effect, can compensate the strength loss when the binding power between the anti-cracking mortar layer and the heat preservation layer is low, and can ensure the bonding quality and the construction reliability of the follow-up surface layer, the construction operation is simple, the construction difficulty is not increased, the original construction quality and the construction efficiency are not influenced, the using amount of the anti-cracking mortar can be used to a certain extent, the cost is reduced and the glass fiber net reinforcement part can be widely applied to exterior wall construction.

Owner:BUCG THE EIGHTH CONSTR DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com