Flame-retardant toughening agent, epoxy curing agent prepared from flame-retardant toughening agent and seam beauty agent epoxy resin composition

An epoxy curing agent and epoxy resin technology, applied in the epoxy resin field, can solve the problems of insufficient toughness and non-flame retardant, and achieve the effect of smooth and continuous glue shovel and improved toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Preparation of flame retardant toughening agent

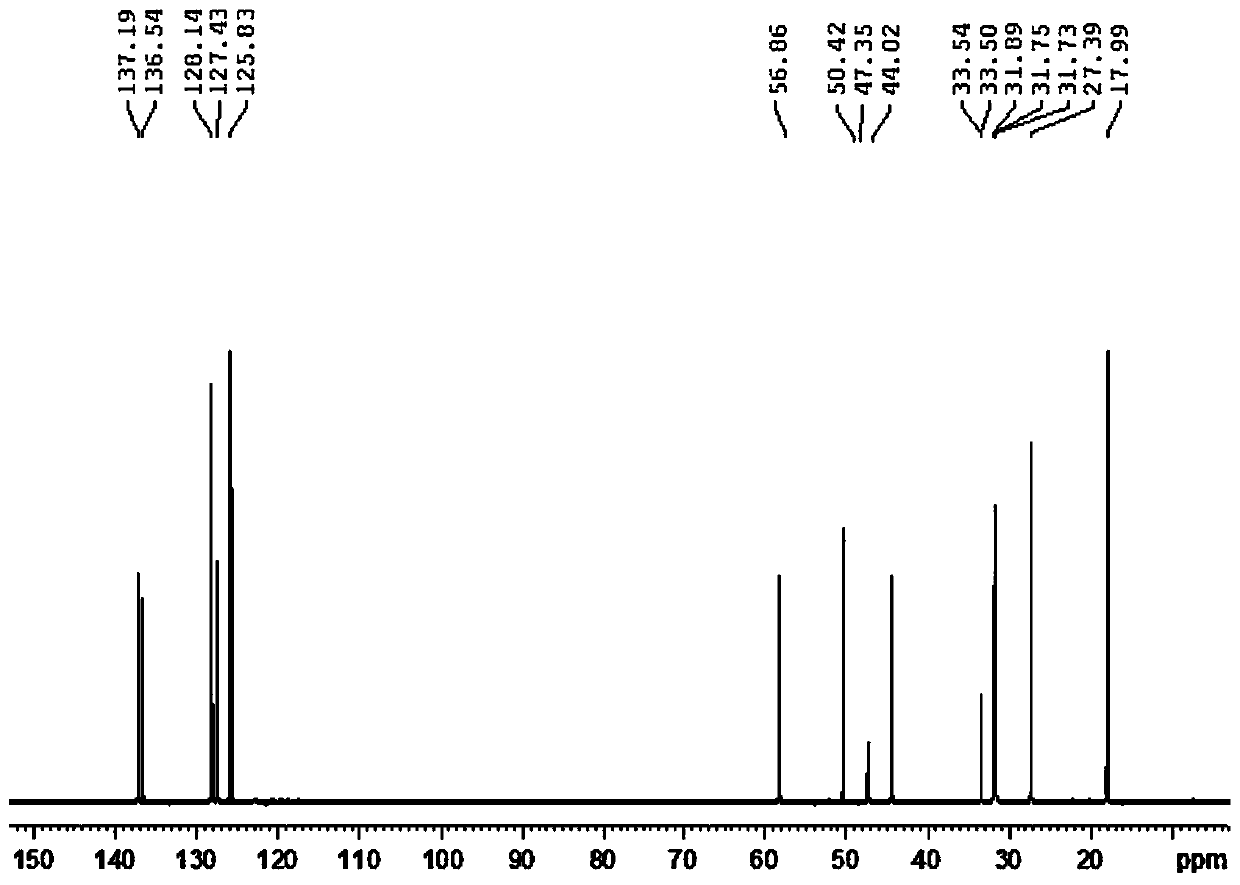

[0070] S1: Under the protection of nitrogen, the reaction pressure is controlled at 1MPa, and 210g H 12 MDA was reacted with 104 g of styrene under reflux of 200 g of ethanol at 100°C for 12 hours, and the ethanol was removed by rotary evaporation to obtain the reaction intermediate M. The characterization results of intermediate M are shown in the appendix figure 1 .

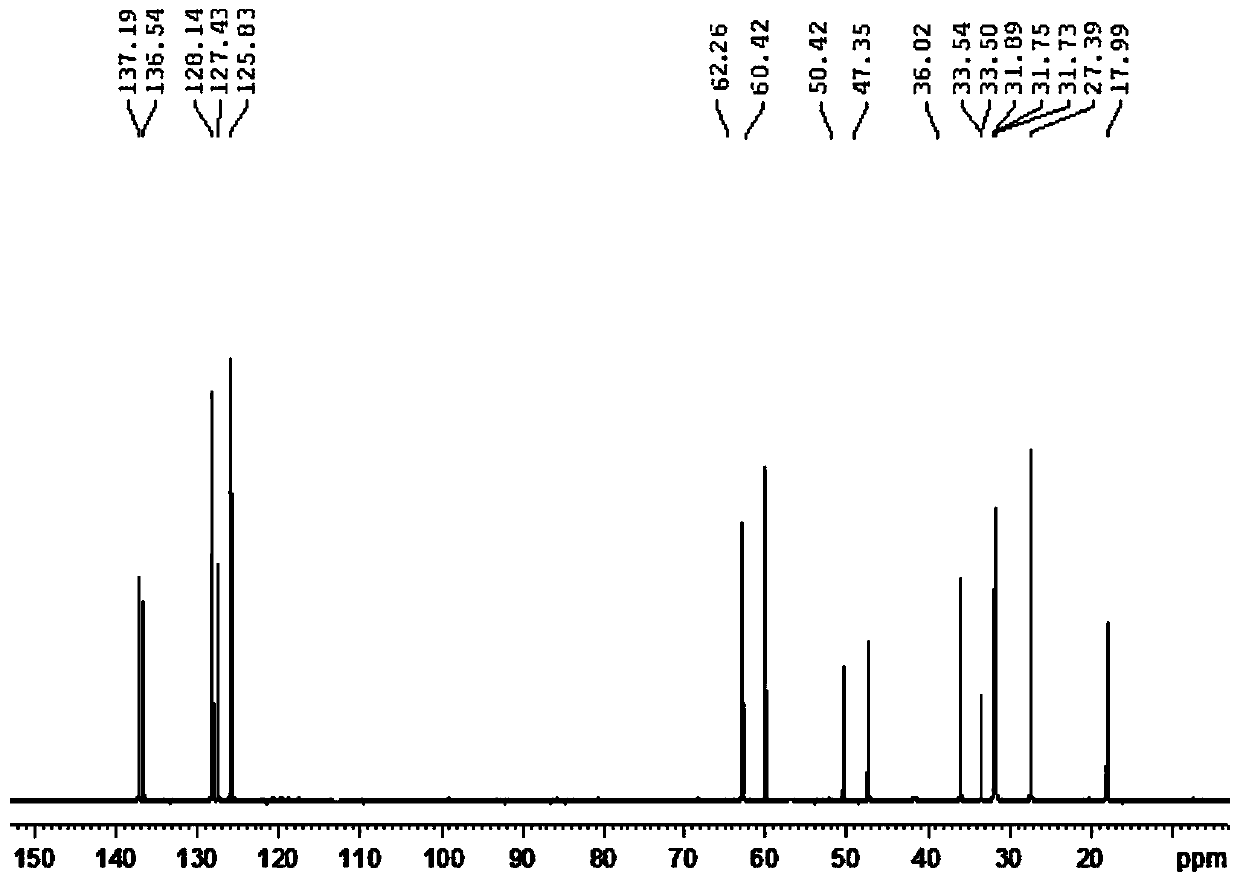

[0071] S2: Under the protection of nitrogen, 314g of intermediate M and 178g of diethyl allyl phosphate were catalyzed by 1.2g of phosphoric acid in 400g of ethanol, and reacted at 100°C for 12h, and the ethanol was removed by rotary evaporation to obtain the target toughening agent. The characterization results of the target product toughener are shown in the attached figure 2 .

[0072] (2) Preparation of epoxy curing agent

[0073] Will 8100 polyetheramine 10g, H 12 MDA 20g, benzyl alcohol 25g, E51 epoxy resin 15g, stir at 300rpm for 20min...

Embodiment 2

[0079] (1) Preparation of flame retardant toughening agent

[0080] S1: Under the protection of nitrogen, the reaction pressure is controlled at 1MPa, and 210g H 12 MDA and 109g styrene were reacted in 300g ethanol at 80°C for 8h, and the ethanol was removed by rotary evaporation to obtain the reaction intermediate M.

[0081] S2: Under the protection of nitrogen, 300g of intermediate M and 187g of allyl diethyl phosphate were catalyzed by 1.2g of phosphoric acid in 300g of ethanol, and reacted at 80°C for 8h, and the ethanol was removed by rotary evaporation to obtain the target toughening agent.

[0082] (2) Preparation of epoxy curing agent

[0083] Will 8100 polyetheramine 15g, H 12 15g of MDA, 25g of benzyl alcohol, 15g of E51 epoxy resin, stirred at 300rpm for 20min and mixed evenly, kept at 80°C for 2h, cooled to room temperature, added 10g of toughening agent, 20g of dodecylphenol, stirred at 300rpm for 20min and mixed to obtain epoxy Hardener.

[0084] (3) Prepa...

Embodiment 3

[0089] (1) Preparation of flame retardant toughening agent

[0090] S1: Under the protection of nitrogen, the reaction pressure is controlled at 1MPa, and 210g H 12 MDA and 109g styrene were reacted in 300g ethanol at 120°C for 10h, and the ethanol was removed by rotary evaporation to obtain the reaction intermediate M.

[0091] S2: Under the protection of nitrogen, 300g of intermediate M and 180g of allyl diethyl phosphate were catalyzed by 1.2g of phosphoric acid in 300g of ethanol, and reacted at 120°C for 8h, and the ethanol was removed by rotary evaporation to obtain the target toughening agent.

[0092] (2) Preparation of epoxy curing agent

[0093] Will 8100 polyetheramine 15g, H 12 MDA 10g, benzyl alcohol 30g, E51 epoxy resin 10g, stir at 300rpm for 20min to mix evenly, keep warm at 80°C for 2h, add 15g of toughening agent after cooling to room temperature, 20g of nonylphenol, stir at 300rpm for 20min and mix to obtain epoxy curing agent .

[0094] (3) Preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com