A profiling and gluing device for automobile windshield glass

A technology for automobile windshields and gluing devices, which is applied to the device and coating of the surface coating liquid, which can solve the problems of unsmooth gluing, high investment cost, and limited progress, and achieves simple structure, easy operation, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

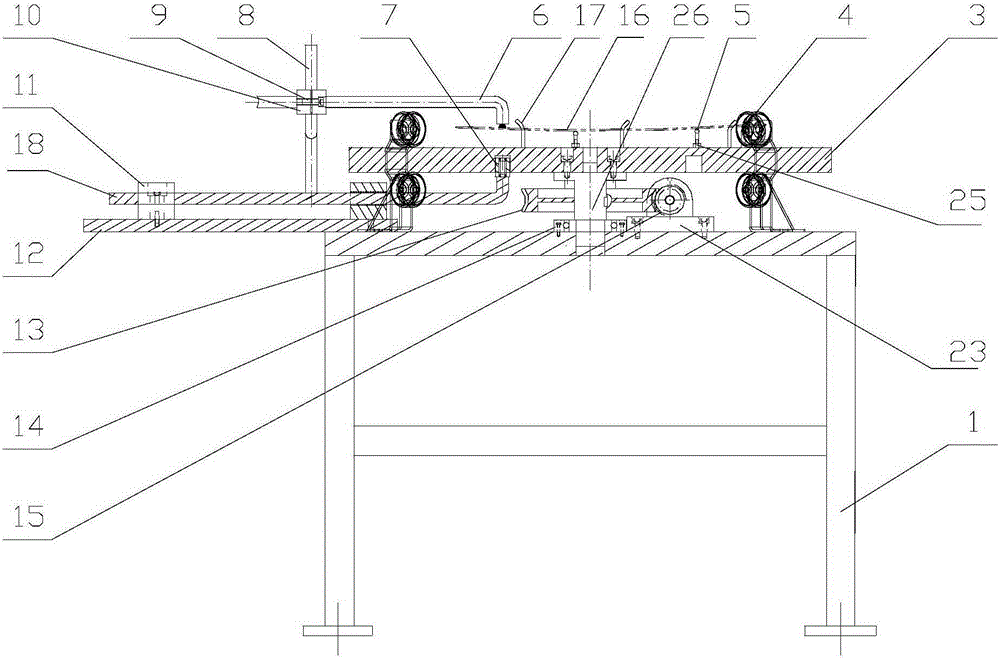

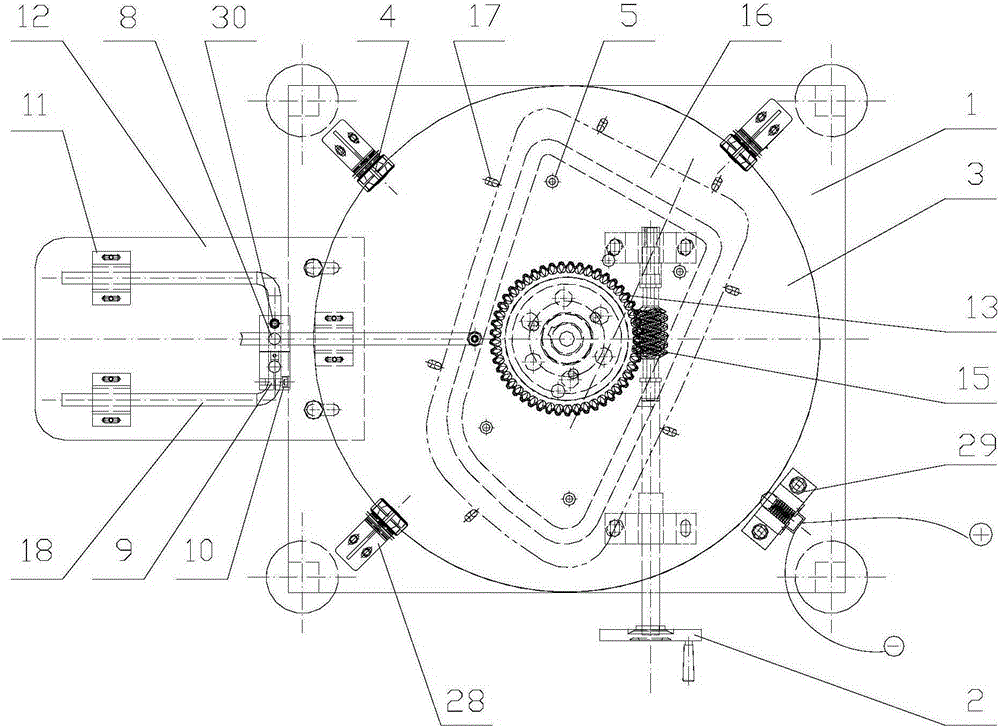

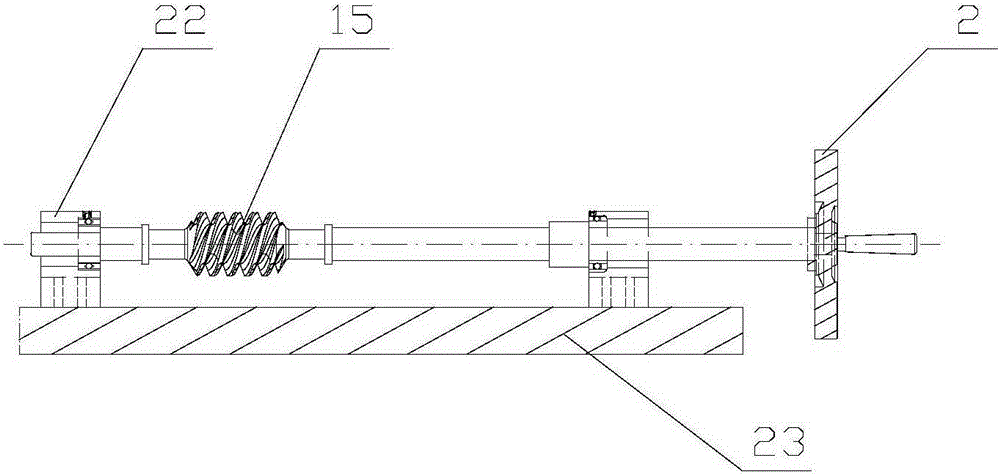

[0028] see figure 1 , figure 2 ,See image 3 , Figure 4 and Figure 5 , the workbench 1 is a square platform designed according to ergonomics, and the turntable 3 is installed on the workbench 1 by using the rotating shaft 26 and the rolling bearing 14 to rotate. A windshield supporting device is provided on the upper surface, and a profiling groove 24 which is exactly the same as the profile of the windshield adhesive and is on the same vertical center line is provided at the lower part of the turntable 3, and a guide work is installed on the workbench 1. Table 12, one end of slide bar 18 adopts slide bar seat 11 to be slidably installed on the guiding workbench 12, and slide bar 18 uses light-weight material with smooth surface, and slide bar seat 11 uses ball slide seat so that reduce frictional force, and slide bar 18 The other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com