Patents

Literature

108results about How to "Guarantee the quality of gluing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

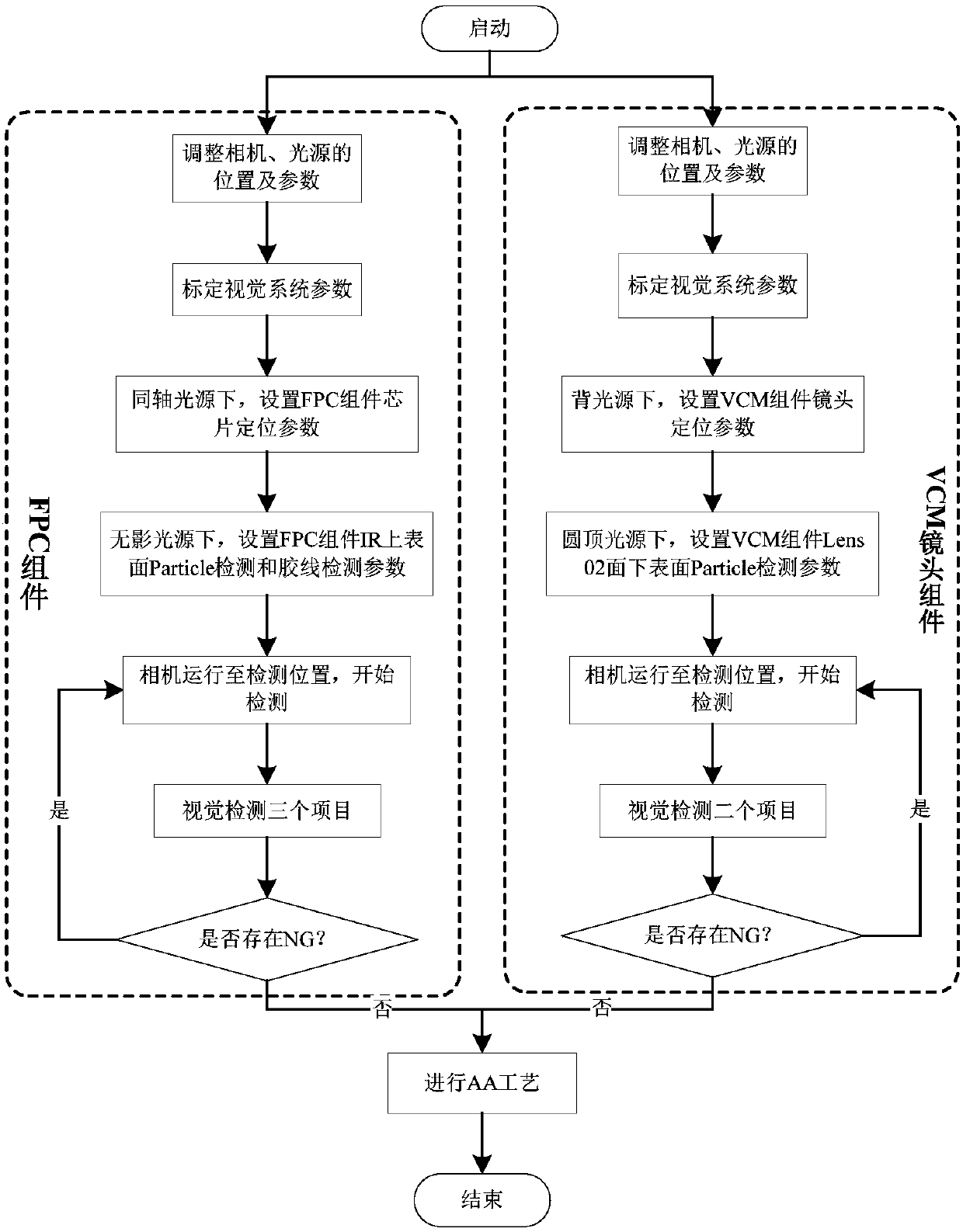

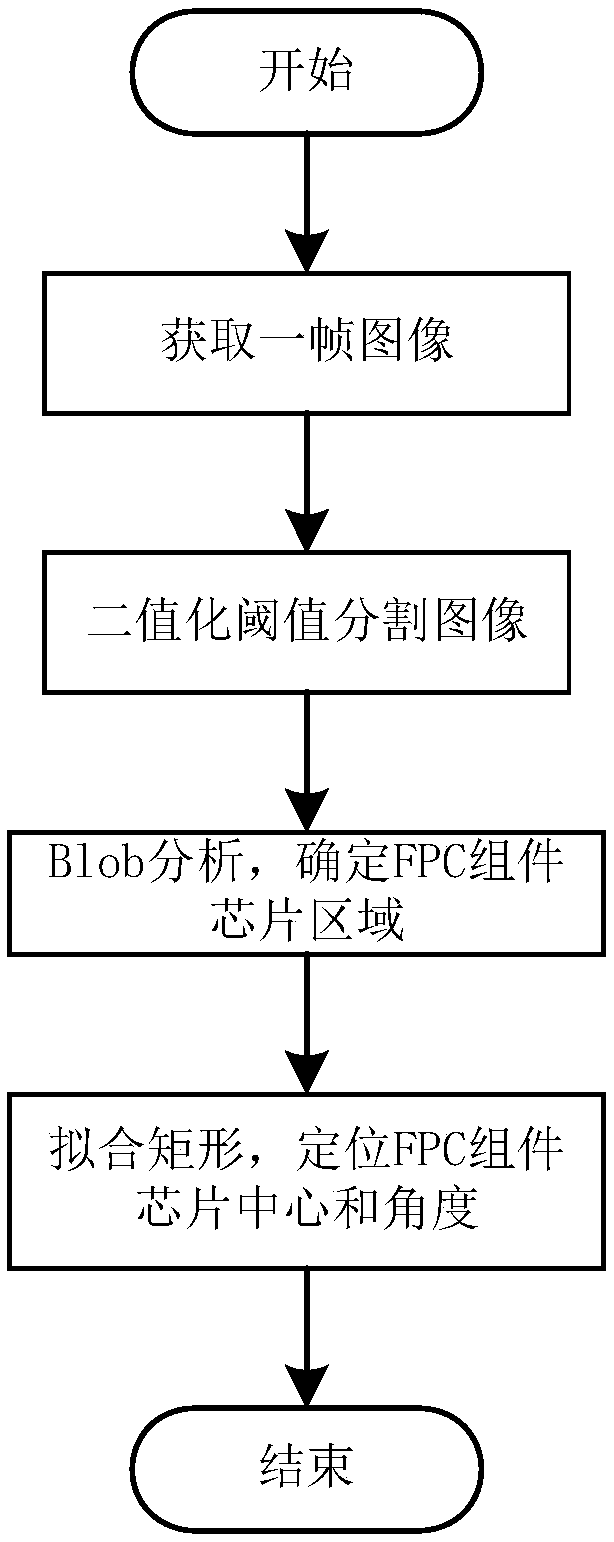

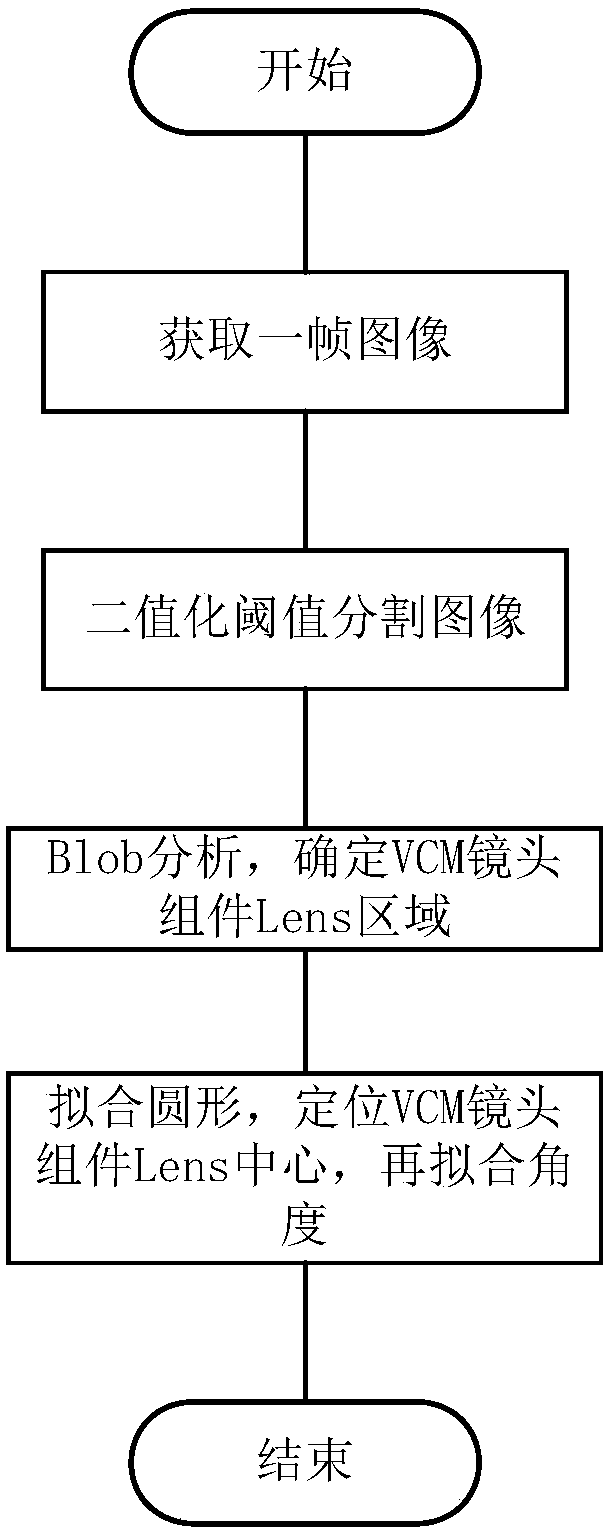

Device detection method

ActiveCN107796825AAccurate locationHelp with assemblyOptically investigating flaws/contaminationIntegrated operationsIrradiation

The invention discloses a device detection method, which comprises the following steps: irradiating the surface of a device for a test by a first light source, taking a photo of the device under the irradiation of the first light source to obtain a first image; according to the first image, positioning the device; irradiating the surface of the device by a second light source, taking a photo of the device under the irradiation of the second light source to obtain a second image; and analyzing the second image to determine whether the device is qualified or not. The provided method can carry out positioned detection and defect detection on a device, the position where the device stays can be accurately positioned, at the same time, the device can be detected to determine whether the deviceis qualified or not, the subsequent operation such as calibration, assembling, and the like, becomes convenient, and the product quality is improved effectively. Moreover, the integrated operation ofpositioning and defect detection is realized, the device does not need to be transmitted between different stations, and the detection efficiency is improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

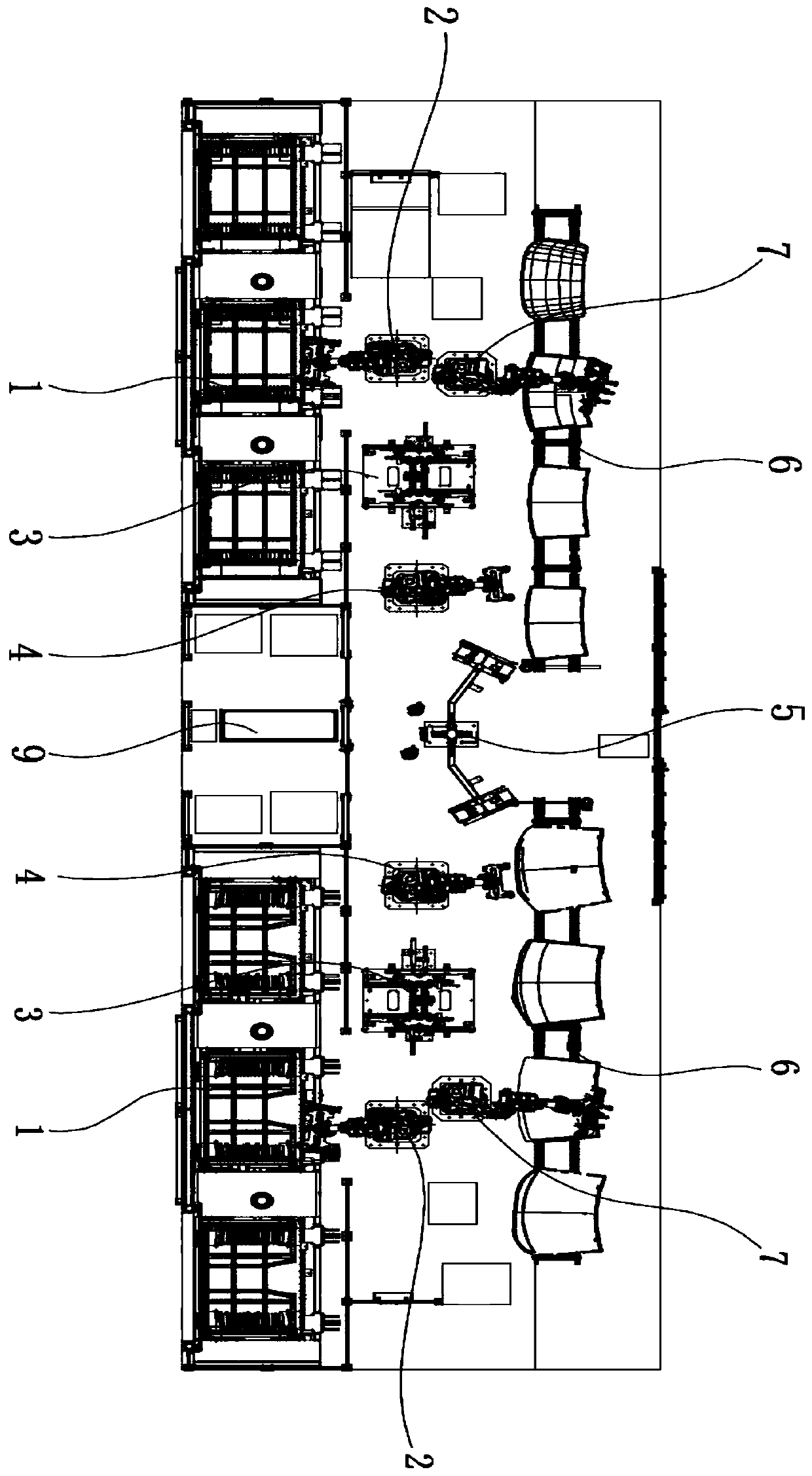

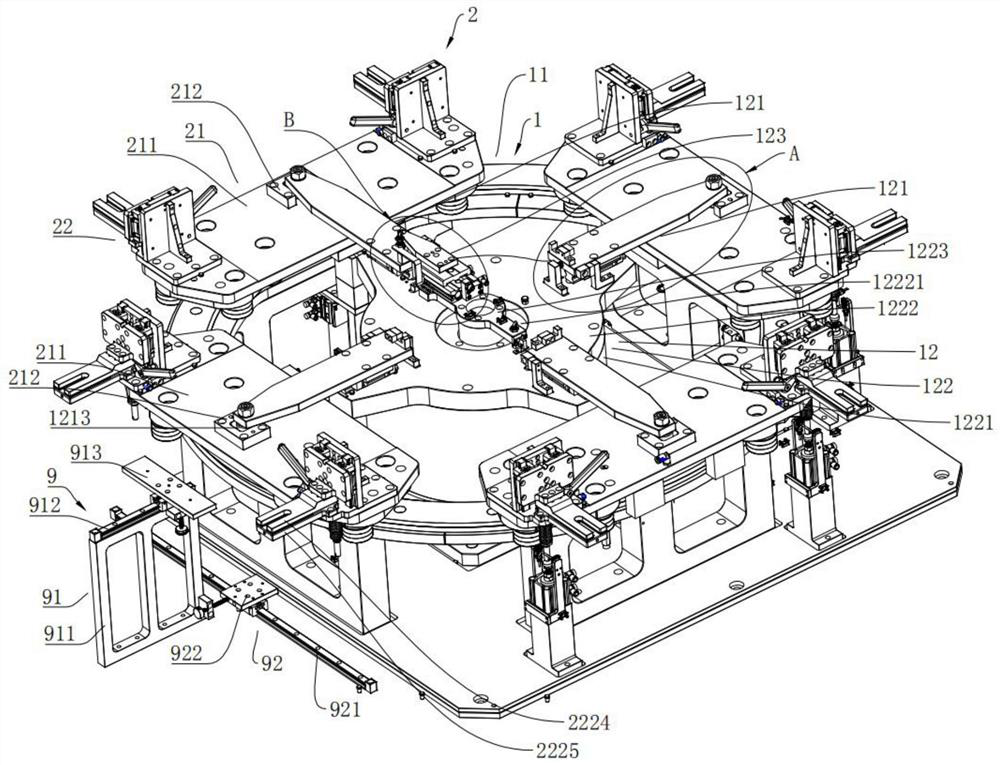

Car windshield glue coating system

ActiveCN109954627AAddressing inhomogeneitySolve efficiency problemsPretreated surfacesCoatingsCoating systemEngineering

The invention provides a car windshield glue coating system. The car windshield glue coating system comprises a pre-coating robot and a pre-coating device; the pre-coating device is used for providinga pre-coating agent during pre-coating, the pre-coating robot is used for grabbing glass at the corresponding position, them moving to the lower part of the pre-coating device and driving the glass to move according to the specified trajectory, and thus the glass is coated with the pre-coating agent. Manual operation is replaced by the pre-coating robot and the pre-coating device, the problems ofuneven coating, low efficiency and health damage caused by manual operation are solved, the car windshield glue coating system further comprises a first feeding device, a feeding robot, a centering device, a second feeding device and a glue coating robot, the manual operation is completely replaced by the robot, workers only need to place material frames onto the first feeding device, the automatic degree is high, and the glue coating quality can be ensured.

Owner:GUANGQI HONDA

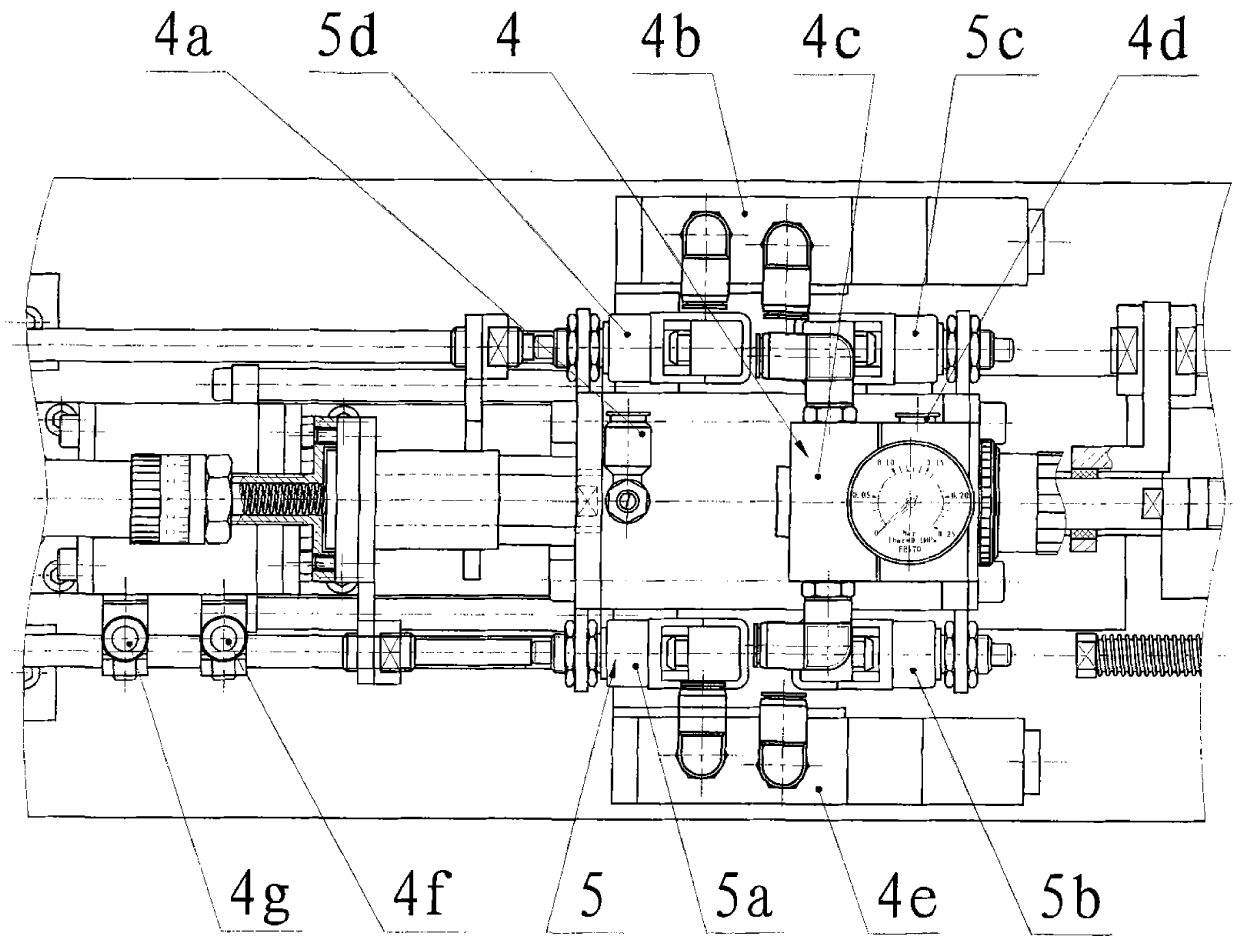

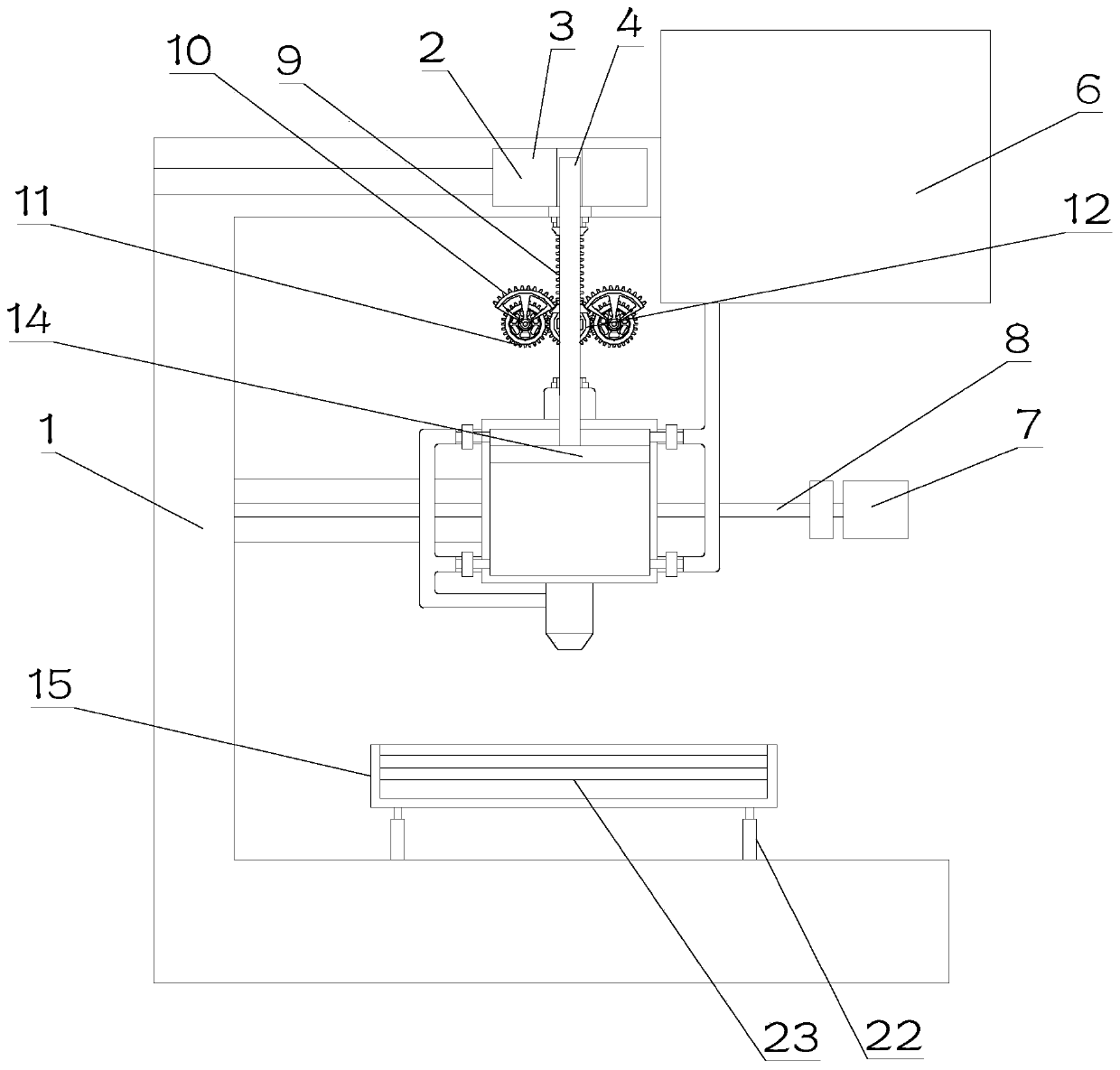

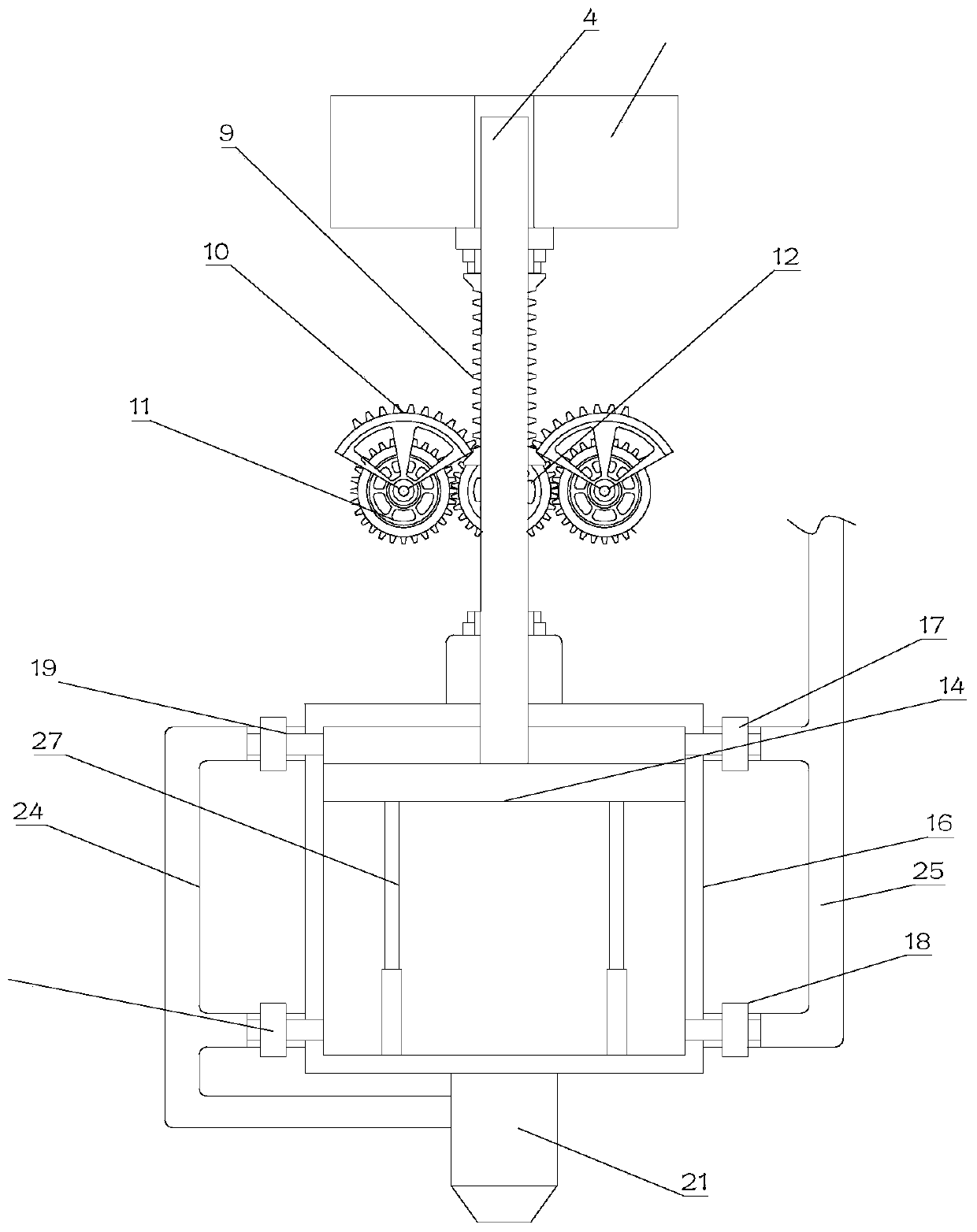

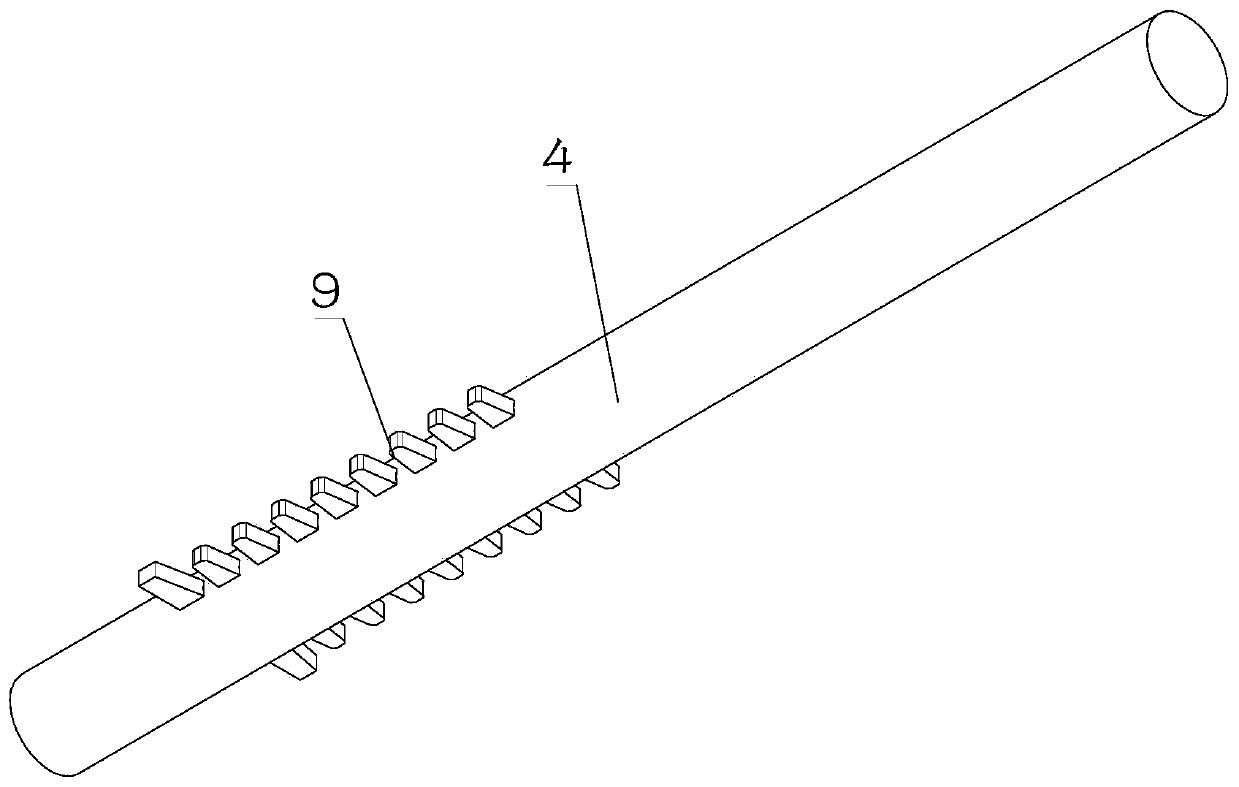

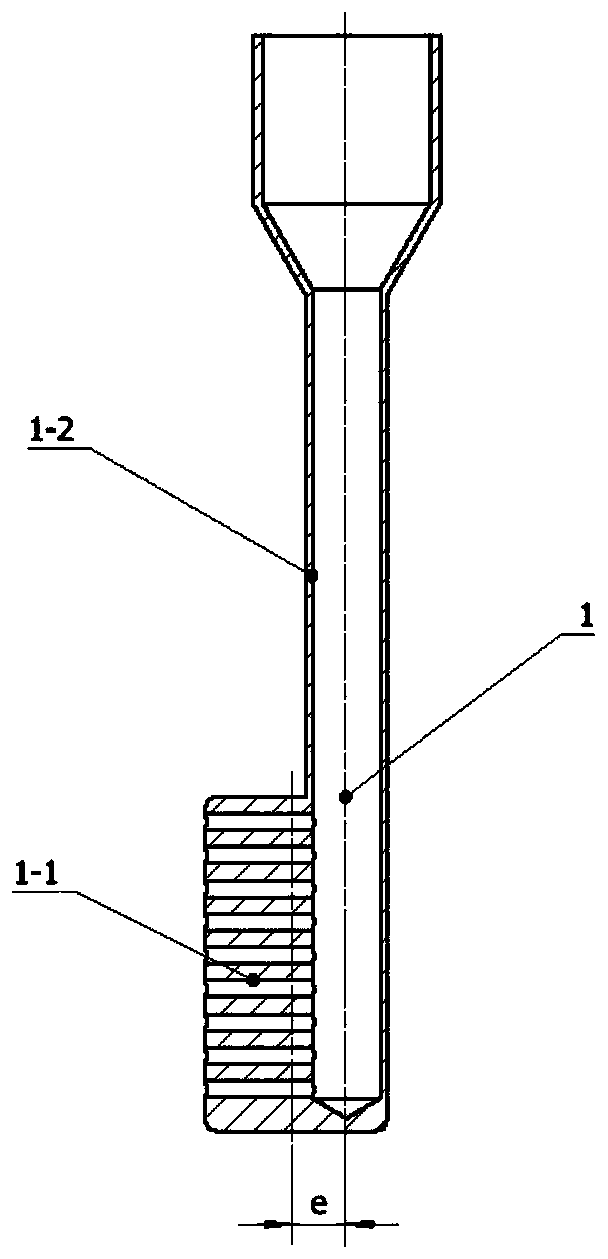

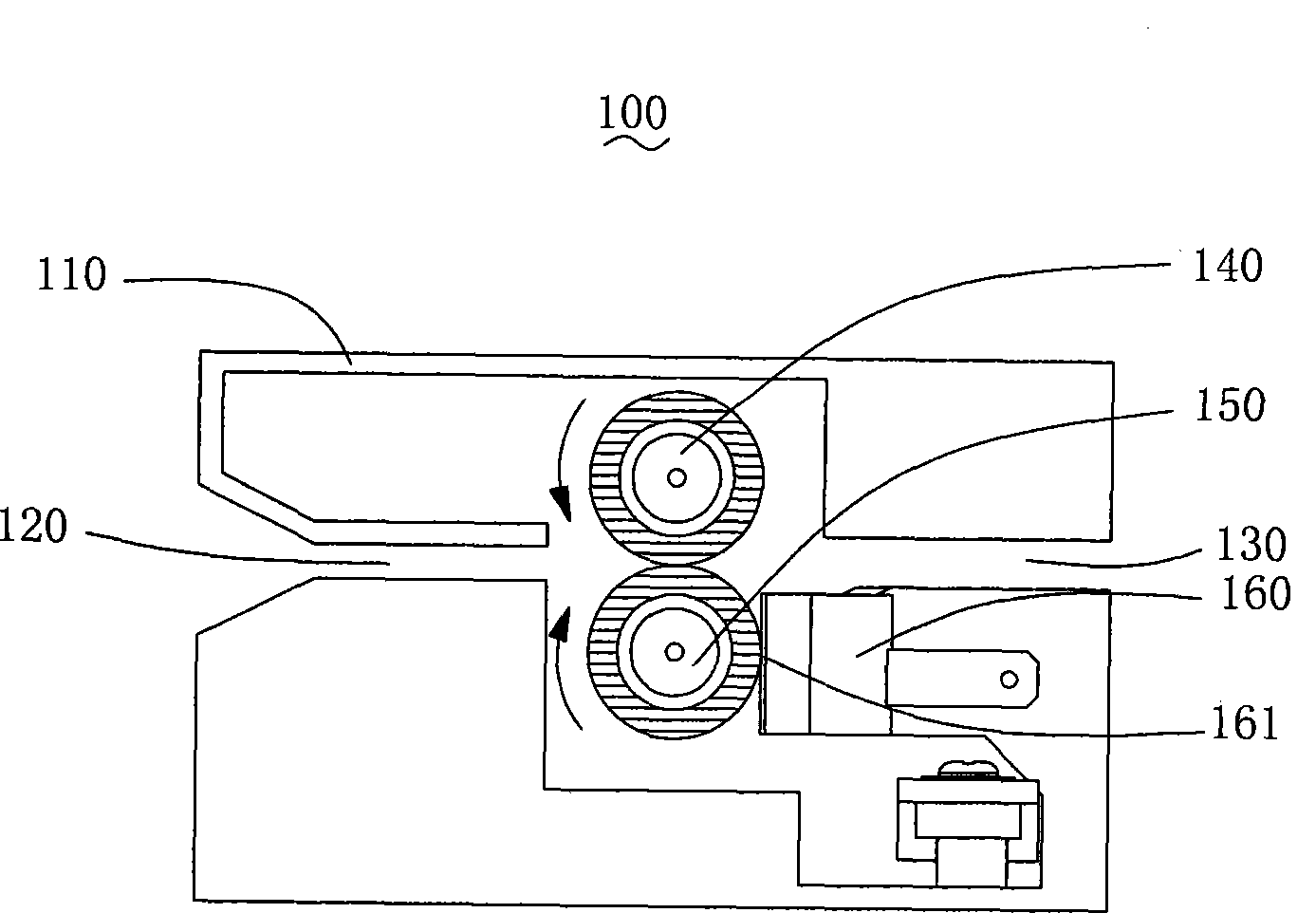

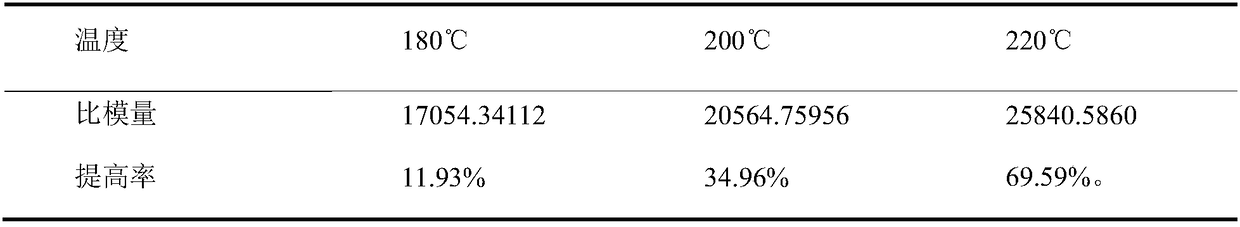

Pre-gluing machine of bolt

ActiveCN101816996AGuaranteed lengthGuaranteed positionLiquid surface applicatorsCoatingsGas cylinderElectric control

The invention discloses a pre-gluing machine of a bolt. The machine is characterized in comprising a gluing head, a gluing opening turning on-off mechanism, a pushing mechanism, an electric control device system, a glue storing cylinder and an adjusting component, wherein the glue storing cylinder is connected with a glue inlet of the gluing head; the gluing head comprises a baffle ring of an opening of a gluing cavity, a gluing cavity sleeve, a gluing cavity sleeve seat, a pushing rod, a gluing cavity, a gluing opening and a glue storing cavity; an annular gluing opening is formed between the baffle ring of the gluing cavity and the gluing cavity sleeve; the pushing mechanism and the gluing opening turning on-off mechanism respectively comprises a gas cylinder; the gluing opening turning on-off mechanism and the pushing mechanism are driven by the gas cylinders to realize the sequential linkage; the pushing rod gradually and axially pushes a bolt of a work piece; glue liquid is peripherally, axially and continuously injected among screw thread teeth of the bolt of the work piece from the gluing opening along the bolt of the work piece; and the adjusting component can adjust the action position of the pushing rod, the turning on-off position of the gluing opening, the opening width of the gluing opening, and the opening pressure of the gluing opening. The pre-gluing machine can peripherally, axially and fast inject the glue into an elastic die cavity, can evenly and exactly glue, guarantees the gluing length and position, and guarantees the quality.

Owner:FAWER AUTOMOTIVE PARTS

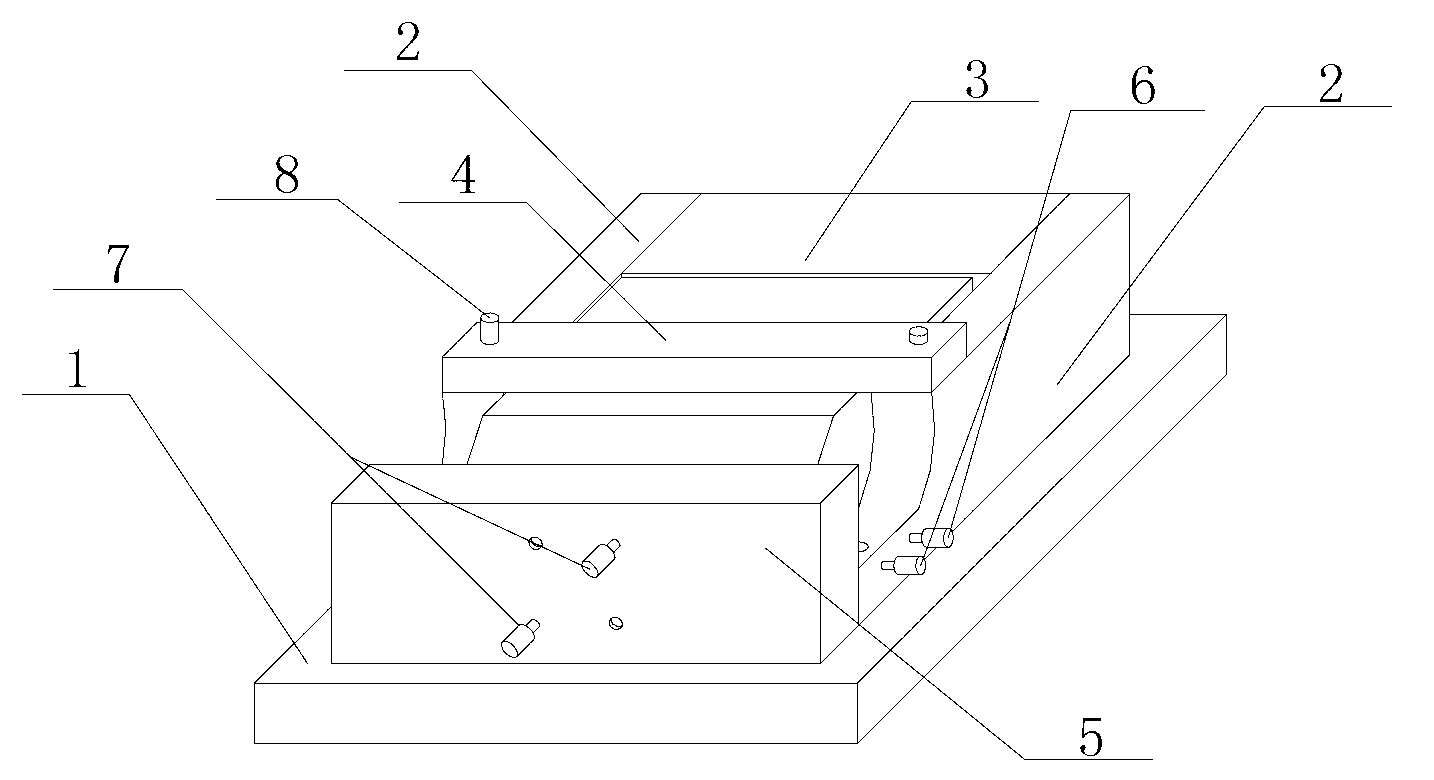

Gluing device for continuous glue feeding of PCB

InactiveCN111085396AEasy to glueGuarantee the quality of gluingLiquid surface applicatorsCoatingsAdhesive gluePiston

The invention discloses a gluing device for continuous glue feeding of a PCB, and relates to the technical field of PCB production. The device comprises a main body frame, a glue outlet mechanism is arranged on the main body frame, a bearing seat is arranged below the glue outlet mechanism, the bottom of the bearing seat is mounted on a lifting cylinder, the lifting cylinder is fixedly mounted onthe main body frame, the glue outlet mechanism comprises a glue box and a supporting block slidably arranged on the main body frame, a piston sliding up and down is arranged in the glue box, and a one-way valve C and a one-way valve A communicating with each other are arranged on the upper portion of the piston. A one-way valve D and a one-way valve B communicating with each other are arranged onthe lower portion of the piston. The output end of the one-way valve C and the output end of the one-way valve D communicate with a first pipeline, the output end of the first pipeline is connected tothe input end of a glue nozzle, and the glue nozzle is fixedly installed at the bottom of the glue box. The input end of the one-way valve A and the input end of the one-way valve B communicate witha second pipeline, and the input end of the second pipeline is externally connected with glue. The gluing device is stable in glue discharge and can achieve continuous glue discharge.

Owner:南京奥亚美电子科技有限公司

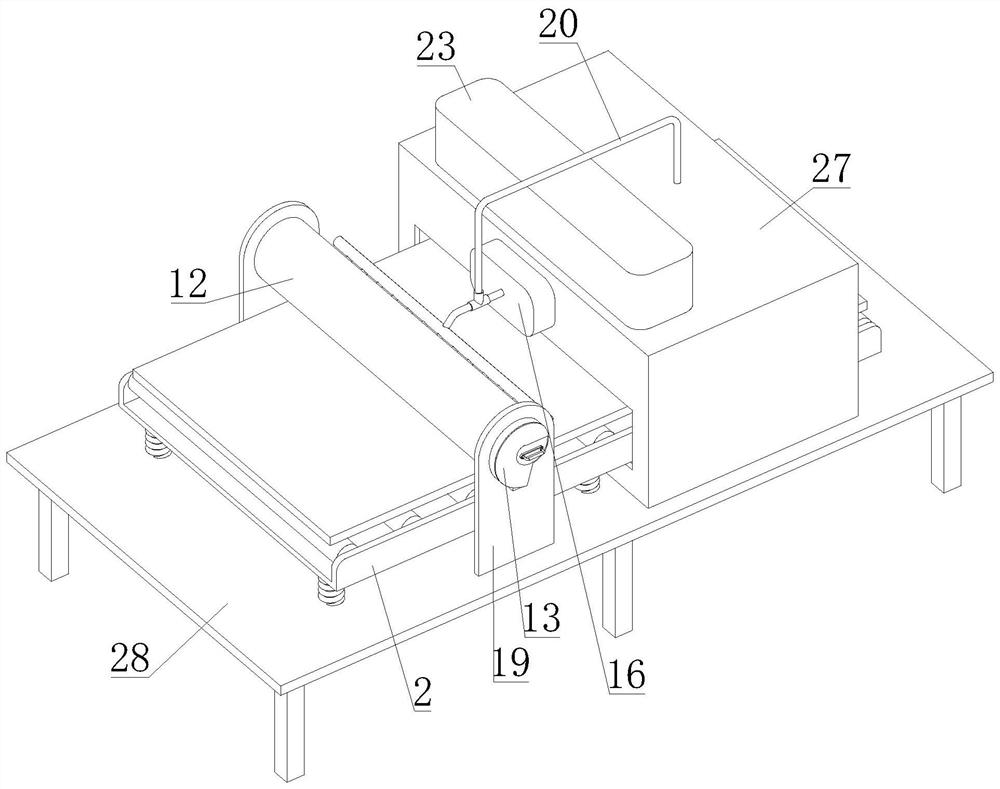

High-speed paper bag bottom gluing device

PendingCN111114010AEasy to fold and shapeSolve efficiency problemsBag making operationsPaper-makingAdhesive glueSpring force

The invention discloses a high-speed paper bag bottom gluing device. The high-speed paper bag bottom gluing device comprises a glue applying shaft, a glue spraying roller arranged on the glue applyingshaft in a sleeving mode and a plurality of glue spraying heads, wherein the glue spraying roller is installed on the glue applying shaft in a sealed mode, so that an annular cavity allowing glue tobe fed from an inlet pipeline is formed between the glue spraying roller and the glue applying shaft, each glue spraying head comprises a valve seat installed on the glue spraying roller, a valve element arranged in the corresponding valve seat, a compressed spring abutting against the bottom of the corresponding valve element and a sealing ring arranged at a glue outlet of the corresponding valveseat, the upper ends of the valve elements can stretch out of the glue outlets formed in the tops of the valve seats and can seal the glue outlets by using the sealing rings under the action of the compressed springs, and the glue spraying heads can enable the valve elements to overcome spring force to enable the glue outlets to discharge the glue in the glue applying process. The high-speed paper bag bottom gluing device has the advantages that high-speed running of more than 500 paper bags per minute can be achieved, the glue is not thrown, the bottoms of the paper bags are stably and automatically coated with the glue, the paper bags can be conveniently folded and formed, so that the gluing quality is guaranteed, continuous automatic production can be achieved, and then the problem ofthe efficiency of a paper bag machine is solved.

Owner:上豪包装机械(镇江)有限公司

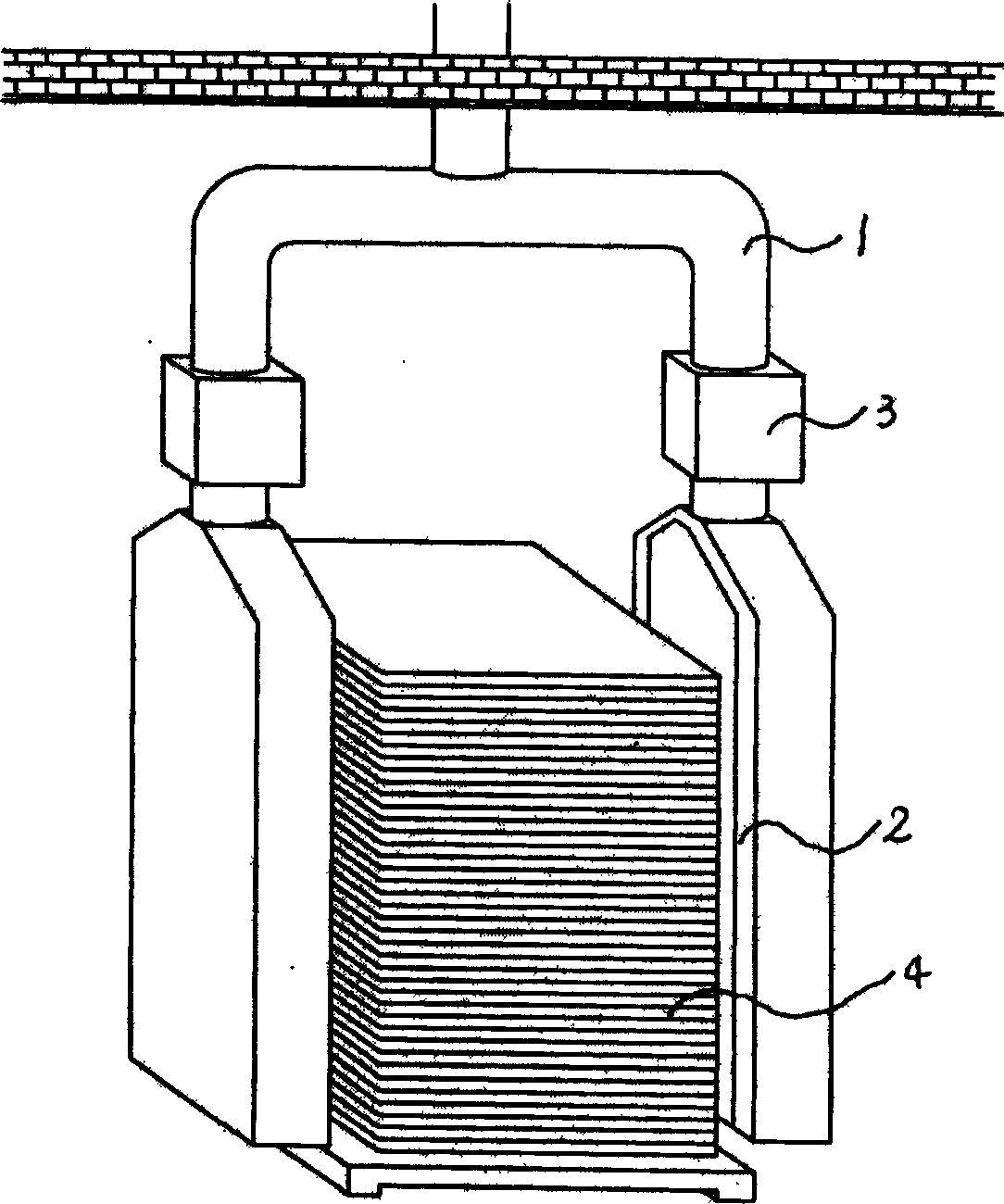

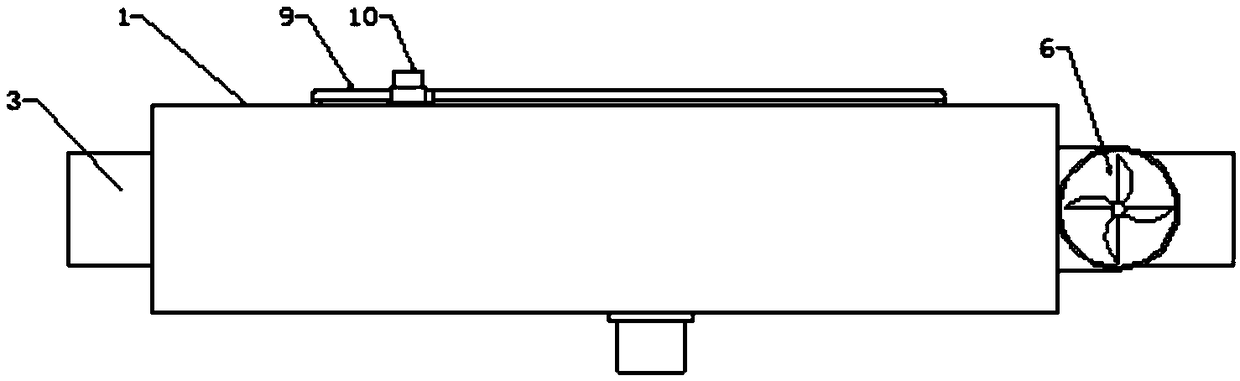

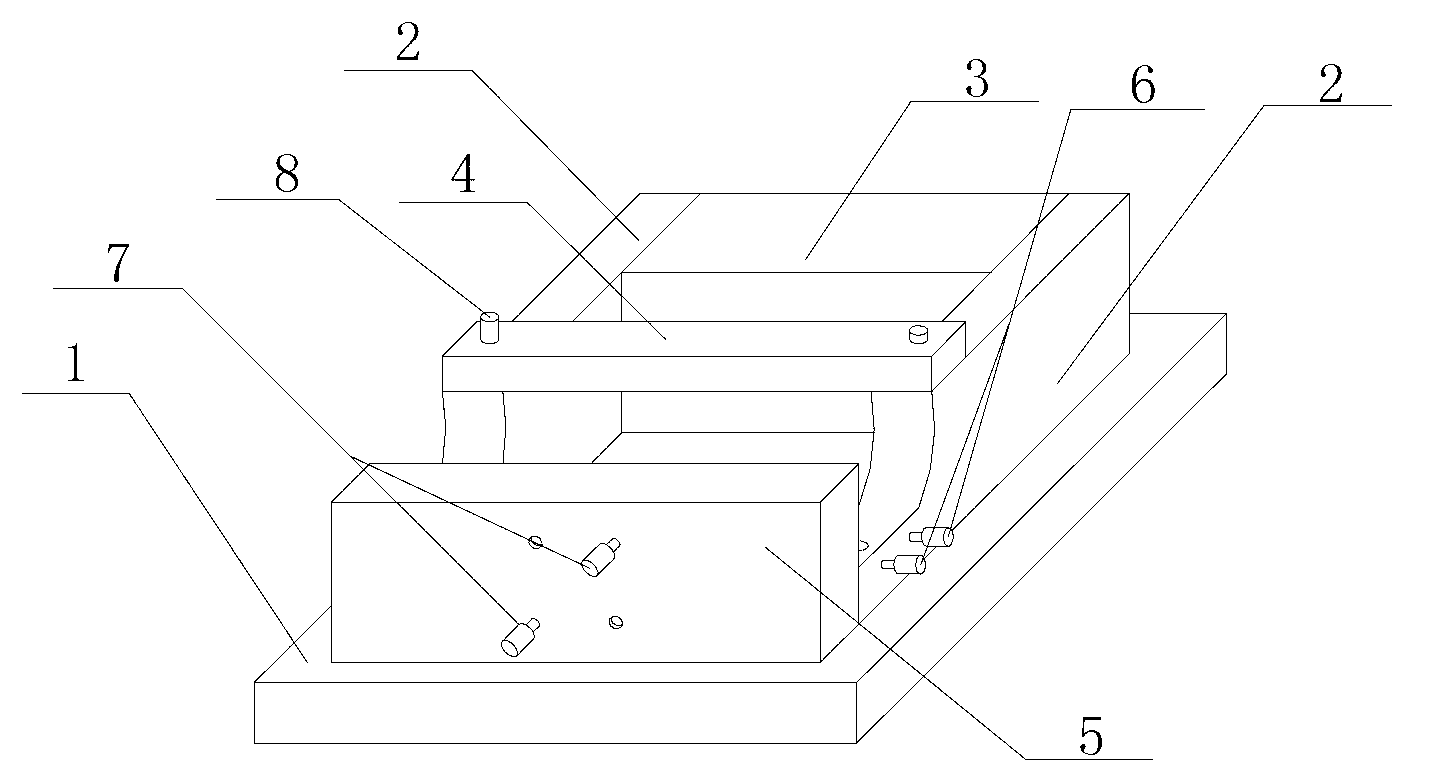

Technique and equipment for lowering formaldehyde in procedure for processing lumber-core board

InactiveCN1796070AReduce the content of free formaldehydeLow free formaldehyde contentCoating impregnationCoatingsMachining processPressure - action

The present invention discloses a formaldehyde-reducing process in the production process of veneered strip-glued board and its equipment. Said equipment mainly includes ventilating ducts and fan, and its formaldehyde-reducing process includes the following steps: spaced stacking the adhesive-coated mechanically-matched or hot-pressed board blanks, making the air inlets of ventilating ducts be positioned at two sides of board blank stack respectively, making the air outlets of ventilating ducts be positioned in the exterior of processing field, under the action of the fan a negative pressure action is formed around the board blank stack, so that the peripheral air of the board blank stack can be led out to the exterior of processing field so as to quickly discharge out free formaldehyde produced in the adhesive-coating process, and effectively prevent the free formaldehyde from being absorbed by board core and finished product board and can reduce formaldehyde content in the product obviously.

Owner:CHANGLIN WOOD IND

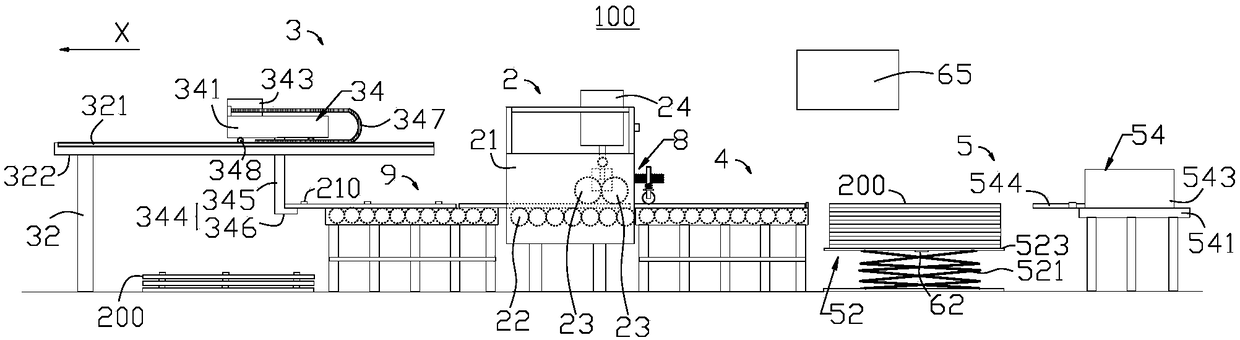

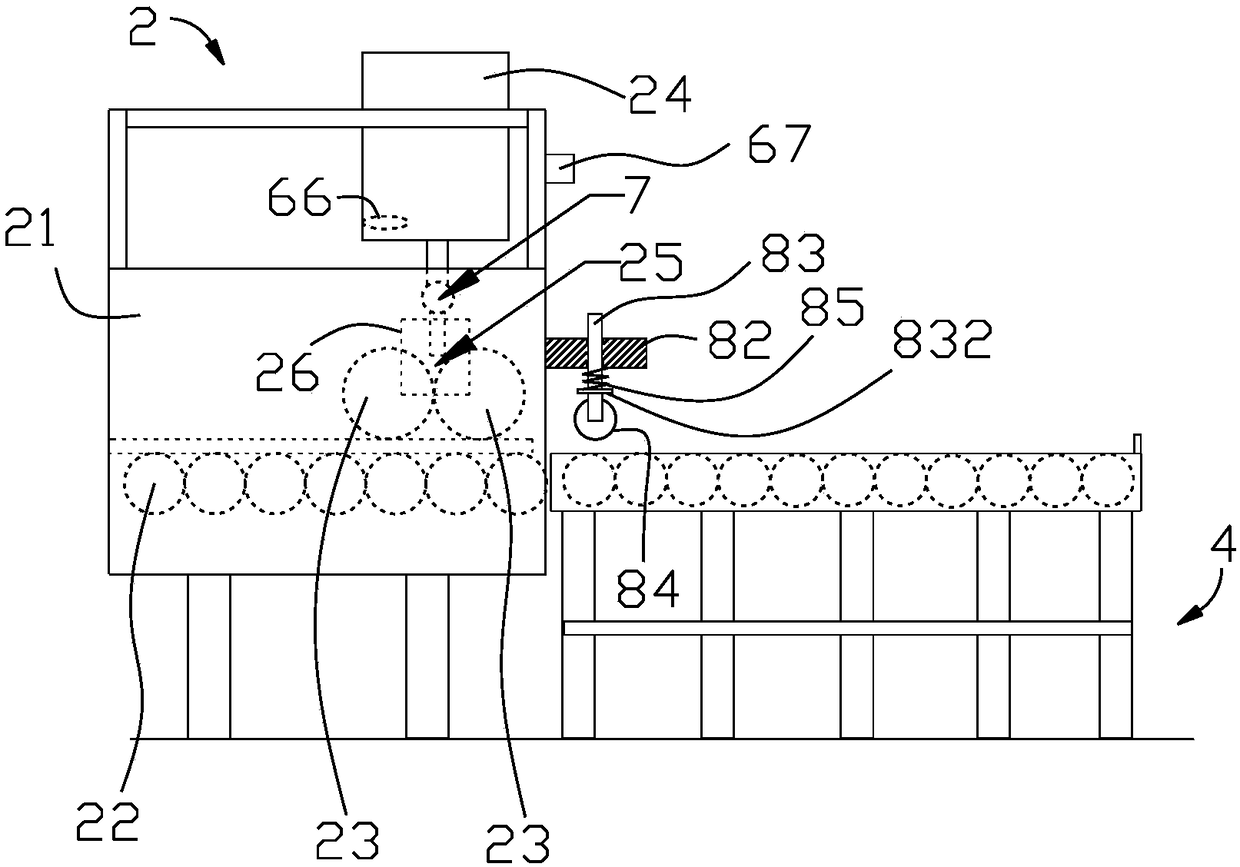

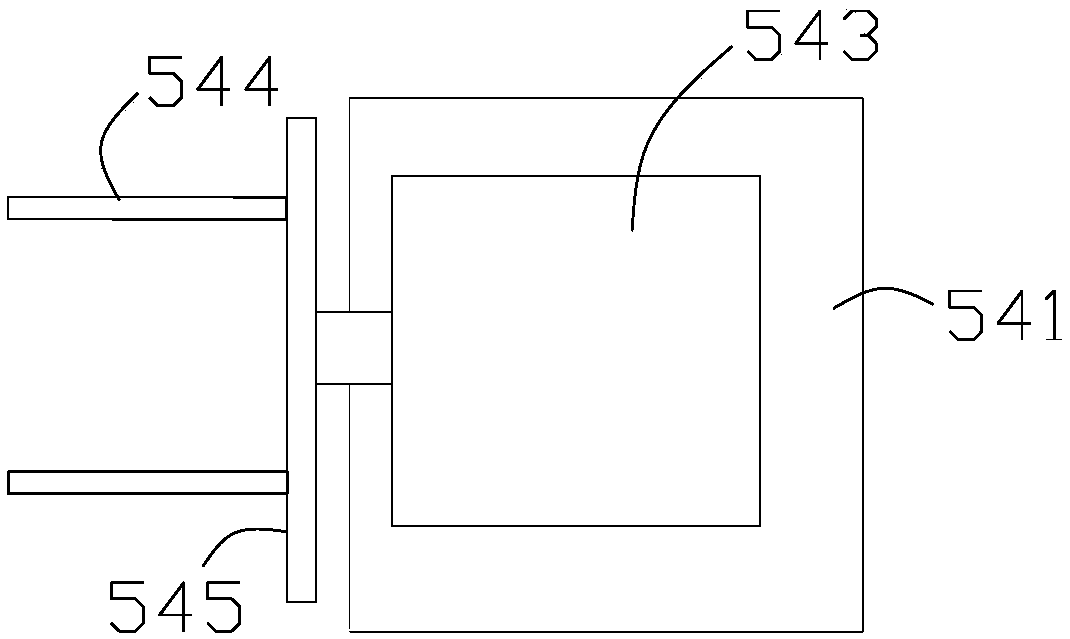

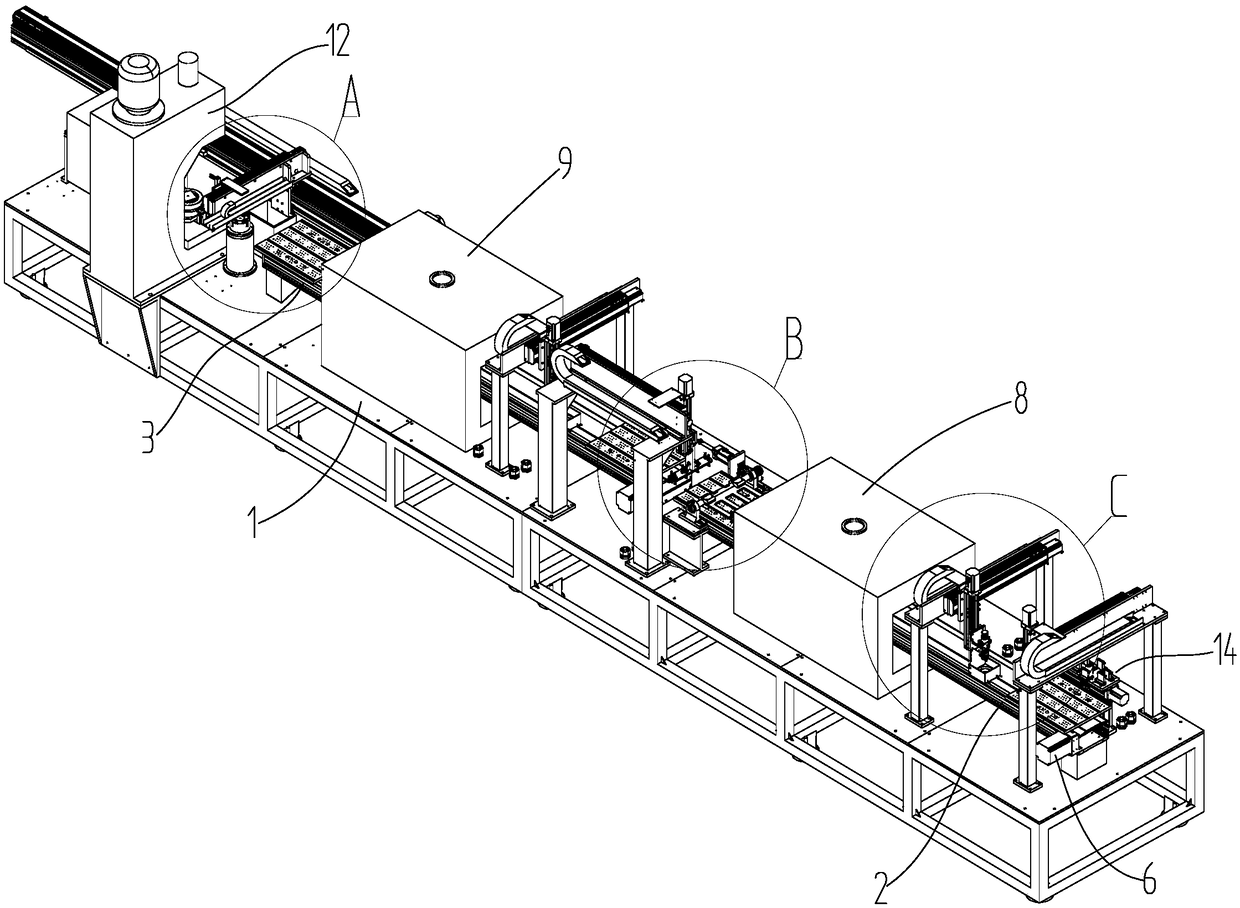

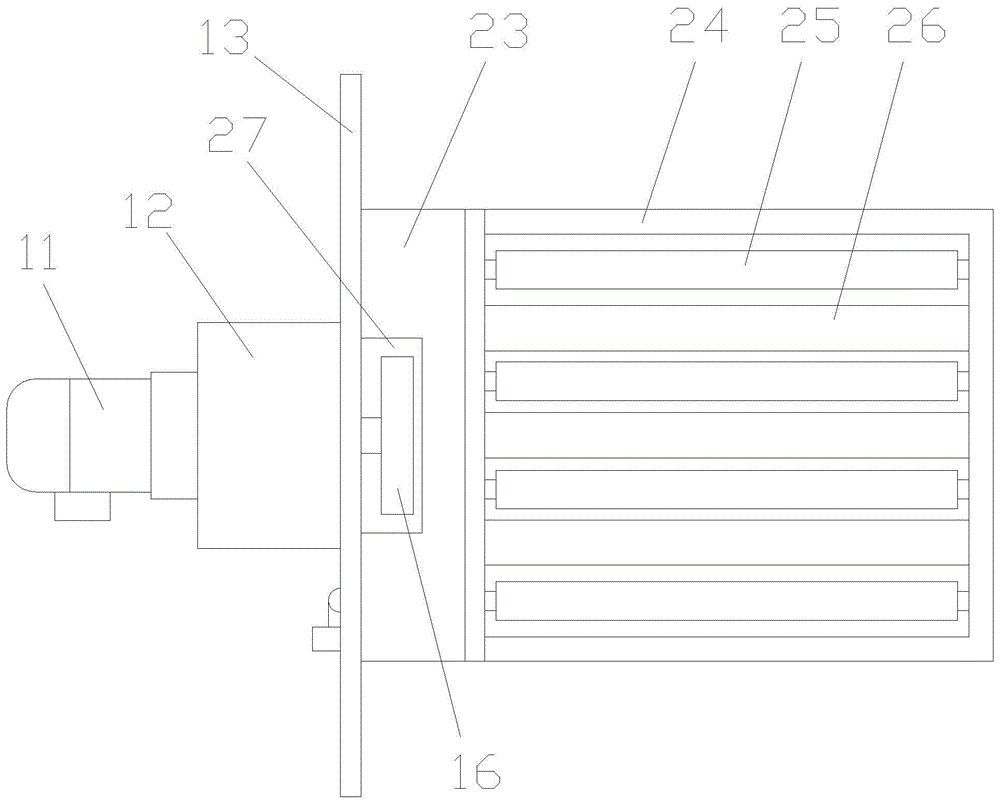

Automatic gluing machine for panels

PendingCN108114852AGuarantee the quality of gluingReduce labor intensityLiquid surface applicatorsCoatingsEngineeringCable carrier

The invention provides an automatic gluing machine for panels. The automatic gluing machine comprises a gluing mechanism and an unloading mechanism, wherein the gluing mechanism comprises a stander, aplurality of conveying rollers, two gluing rollers and a glue bucket, wherein the conveying rollers are rotatably arranged on the stander; the two gluing rollers are rotatably arranged on the stander; the glue bucket is arranged on the stander; the unloading mechanism comprises a mounting rack and an unloading component, a guide rail and a positioning rail are arranged on the mounting rack; the unloading component comprises a base, a walking driving component, a support frame and a dragging chain, the base is arranged on the guide rail in a sliding manner, the walking driving component is connected with the base so as to drive the base to move along the guide rail, the support frame is fixedly connected with the base, can support one sides of panels and can move the direction, far from the gluing mechanism, of the base so as to drive the glued panels to be stacked to an appointed position; and one end of the dragging chain is fixed on the positioning rail, and the other end of the dragging chain is fixedly connected with the base. According to the automatic gluing machine, the glued panels can be automatically stacked to the appointed position, so that the production efficiency isimproved.

Owner:柳城县迪森人造板有限公司

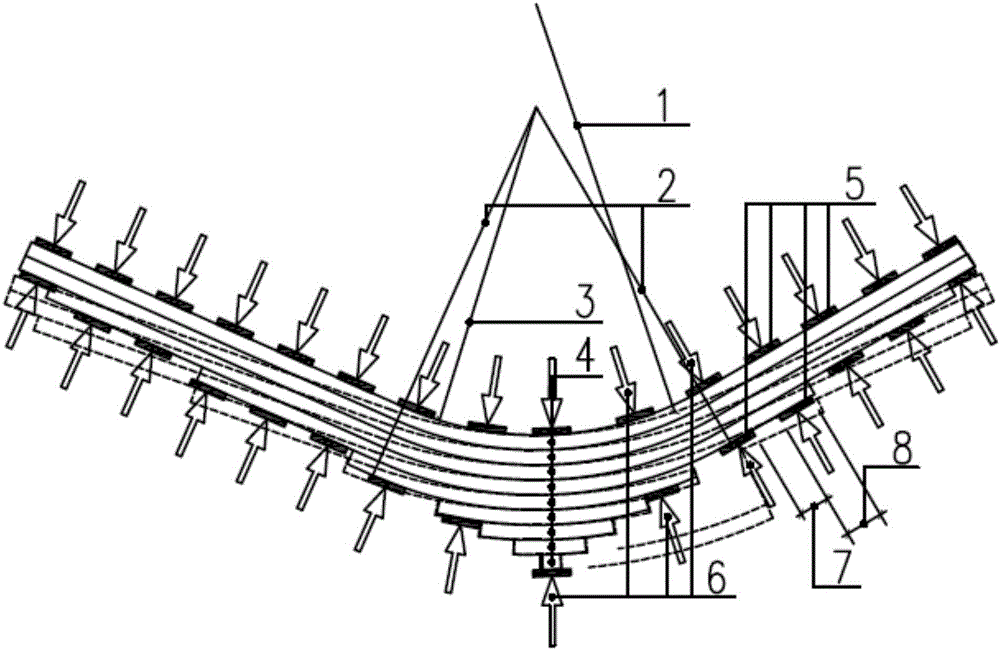

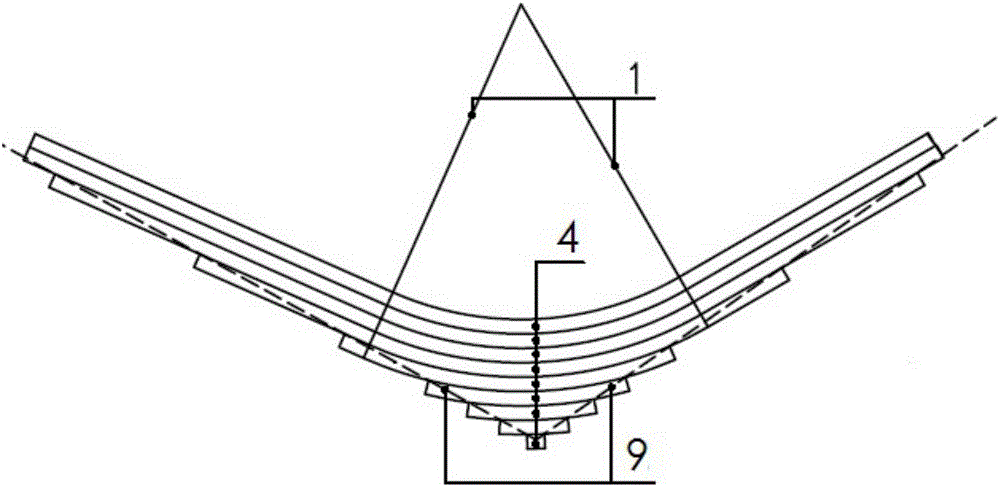

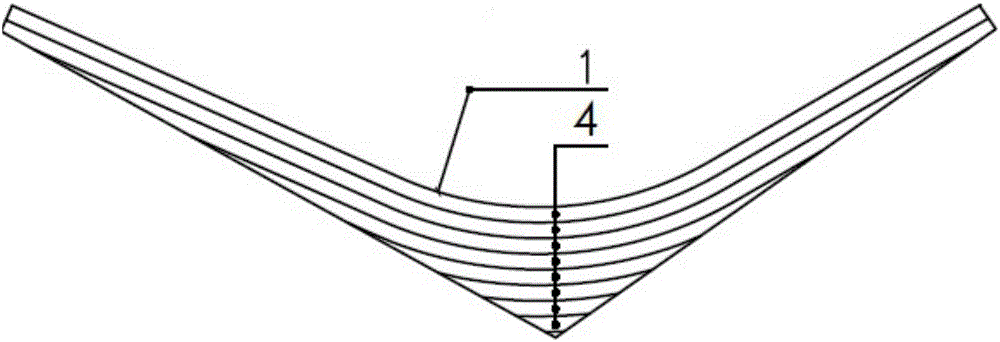

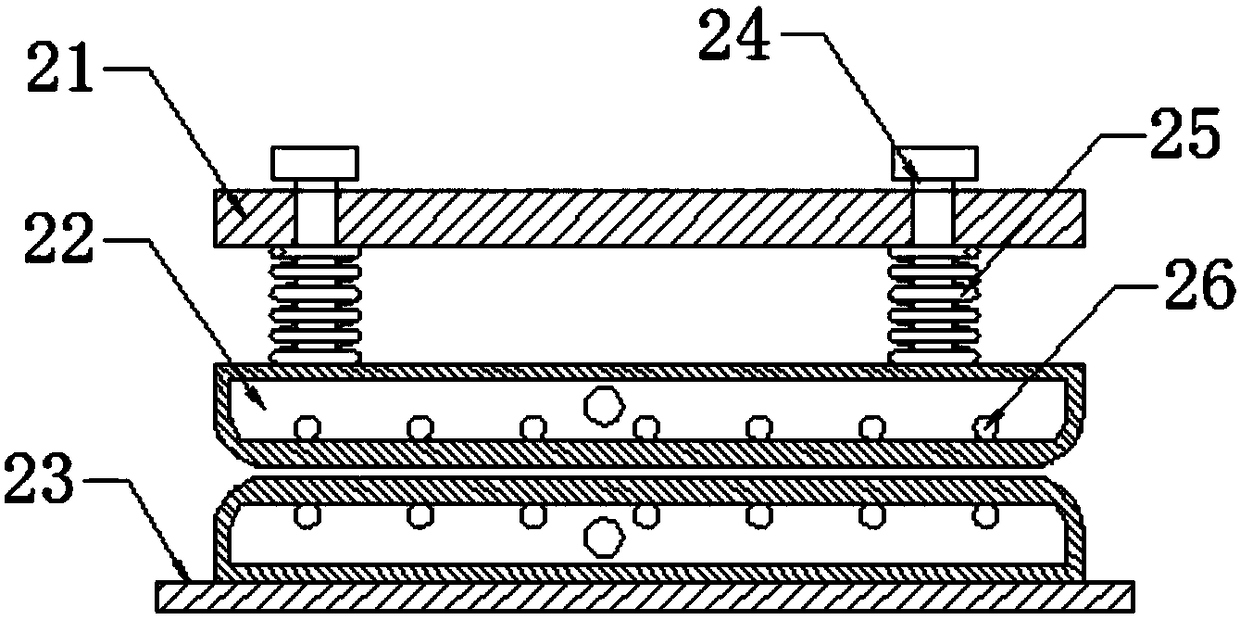

Overbending correcting forming method for variable-section arc glue laminated wood member

ActiveCN106182223AGuaranteed shapeQuality assuranceOther plywood/veneer working apparatusLaminationMachiningSizing

The invention discloses an overbending correcting forming method for a variable-section arc glue laminated wood member and belongs to the field of preparing of glue laminated wood. The method includes the steps including five processes of wood laminate length fixing, adhesive coating, wood laminate profiling modeling, pressurizing sizing and member deep machining; the preparing curvature radius of the variable-section arc glue laminated wood member is determined and the appearance of the variable-section arc glue laminated wood member is ensured according to the number of wood laminates and the design curvature radius of the variable-section arc glue laminated wood member; and the gluing quality of the glue laminated wood member is ensured by setting the minimum pressurizing distance of a distribution type pressing machine. According to the method, the problem that the preparing curvature radius of the variable-section arc glue laminated wood member and the minimum pressurizing distance during multi-point pressurizing are determined only through experience is solved according to the number of the wood laminates and the design curvature radius of the glue laminated wood member and by setting the minimum pressurizing distance of the distribution type pressing machine, the phenomenon that shape rebounding caused after gluing pressure forming of the variable-section arc glue laminated wood member cannot be predicted traditionally is avoided, and the gluing quality of the variable-section glue laminated wood is ensured.

Owner:NANJING UNIV OF TECH

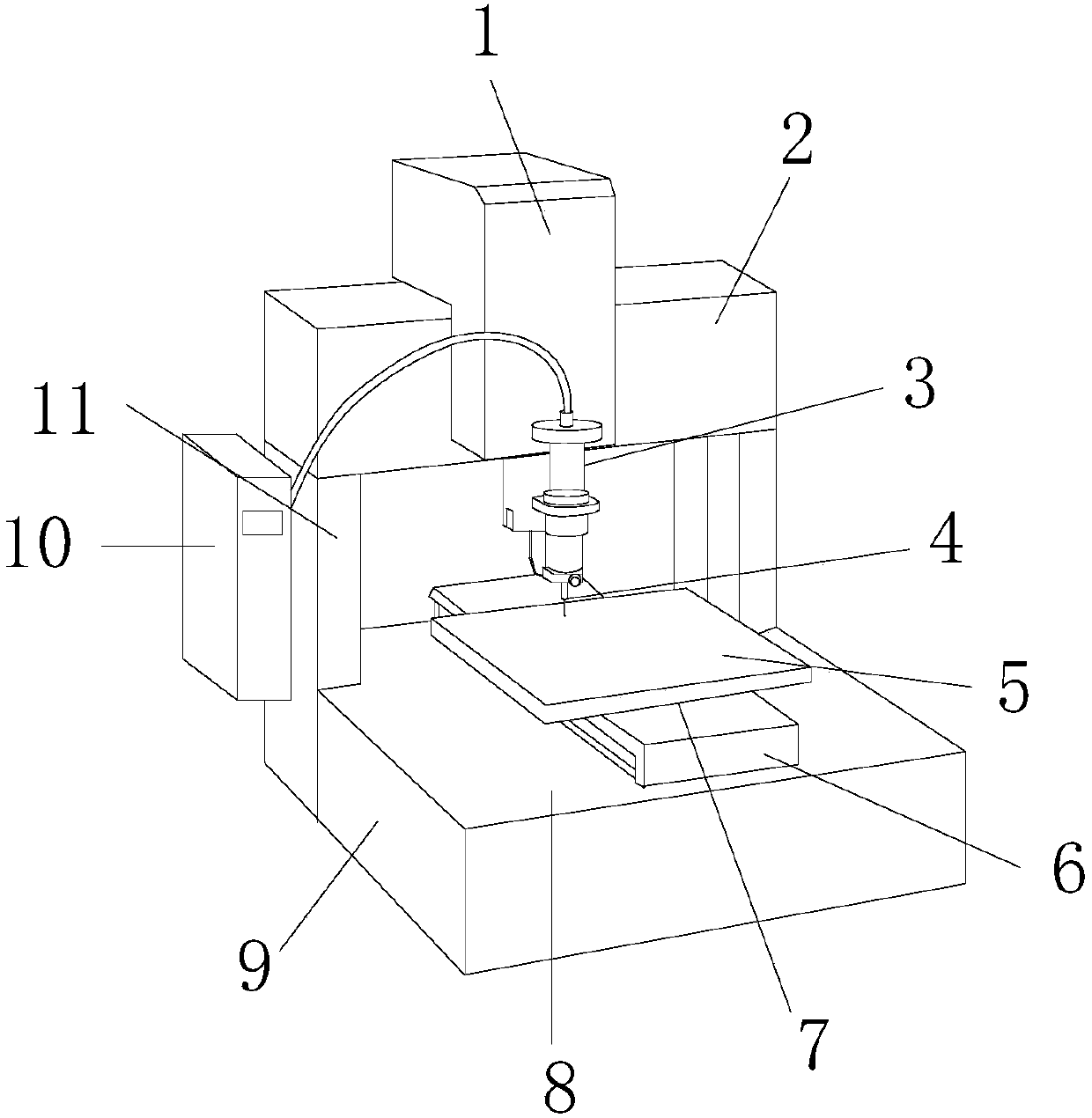

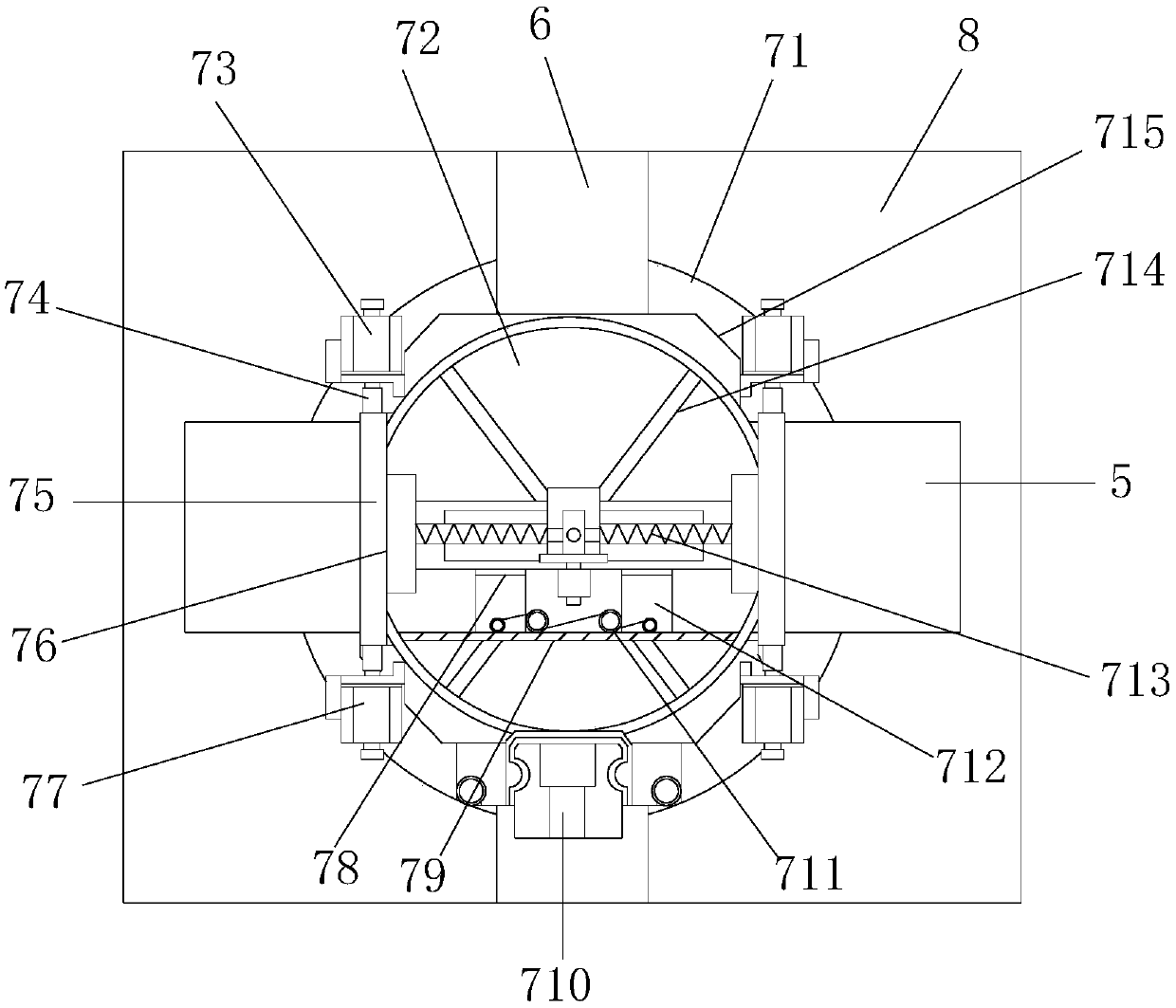

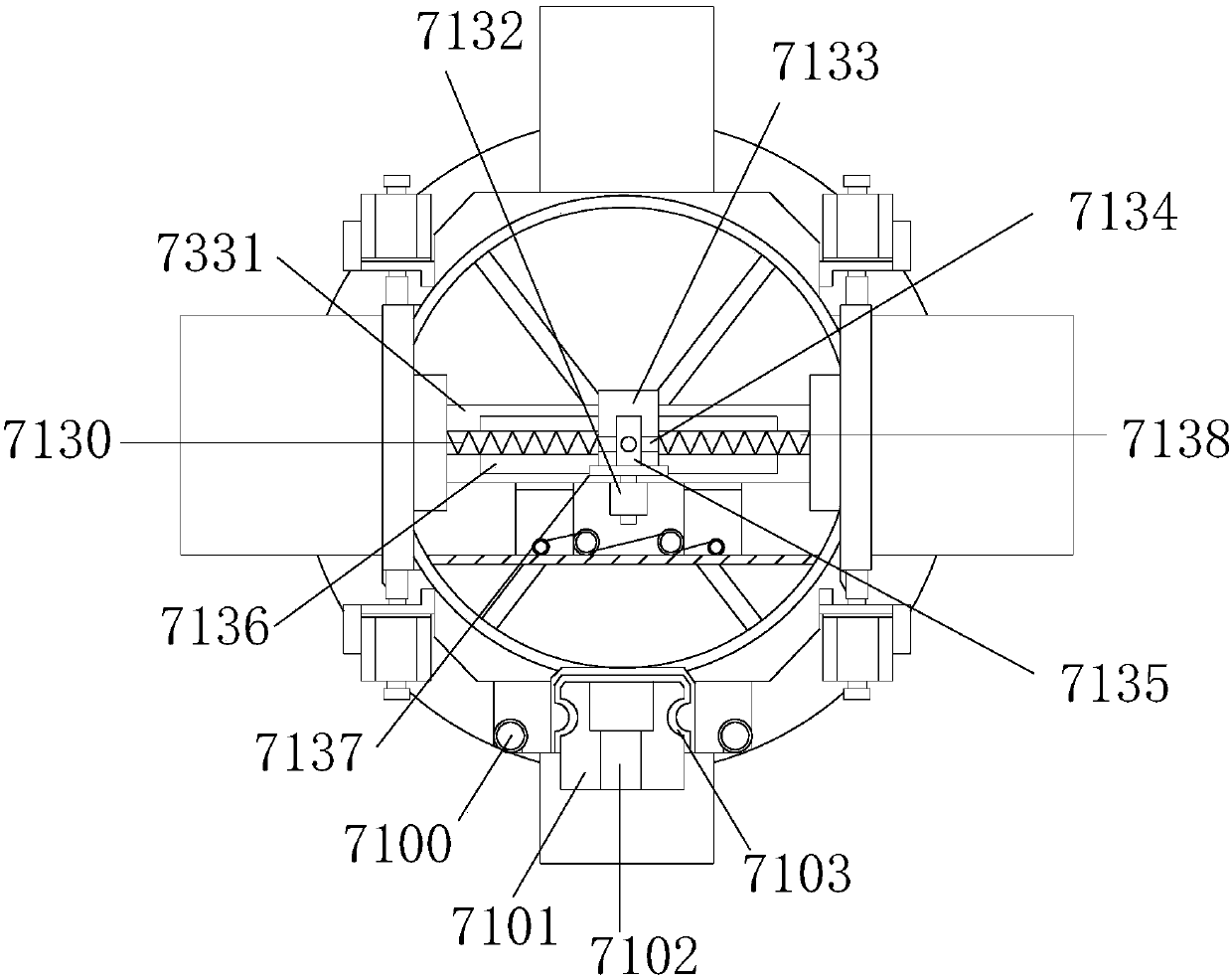

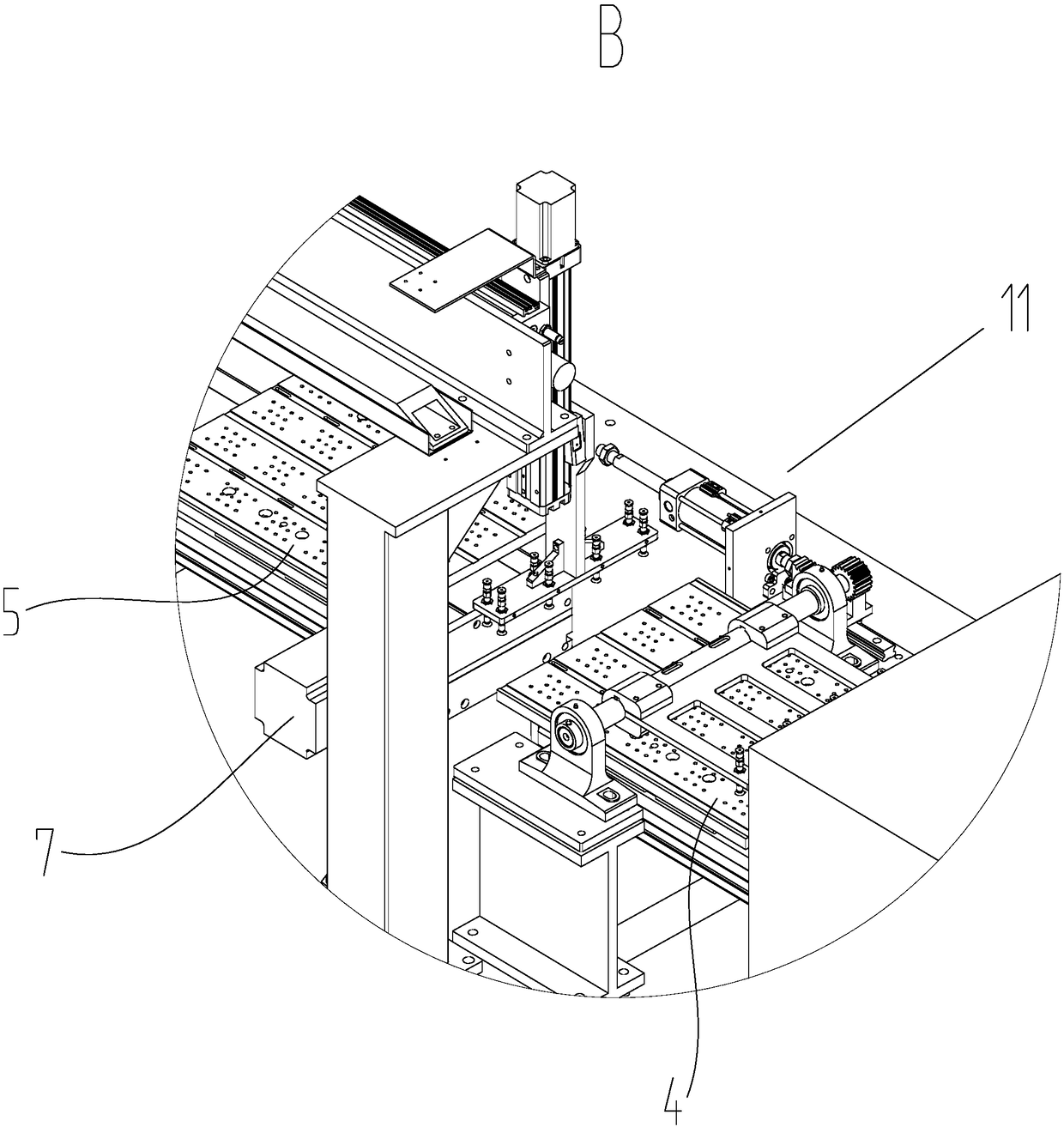

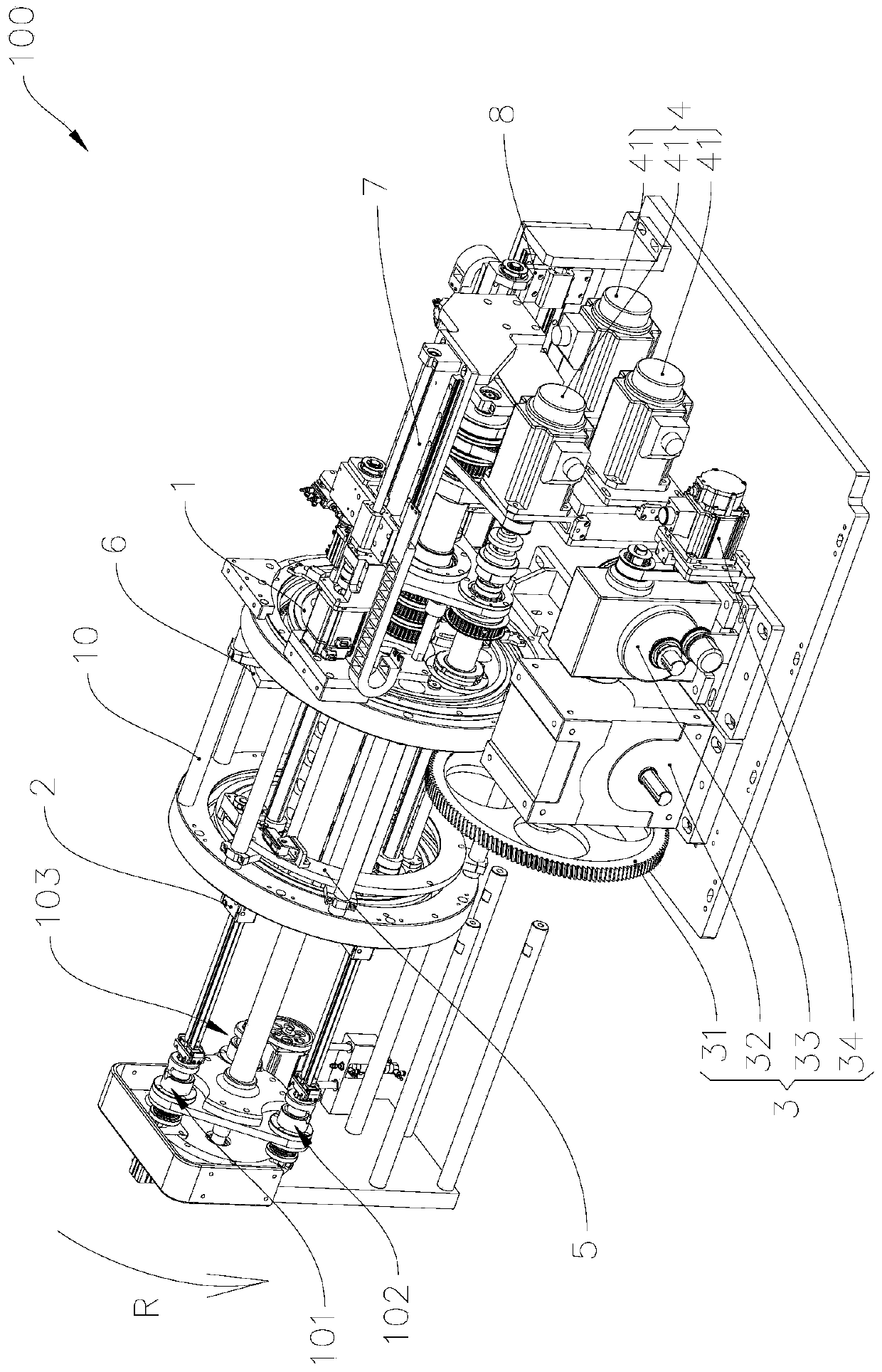

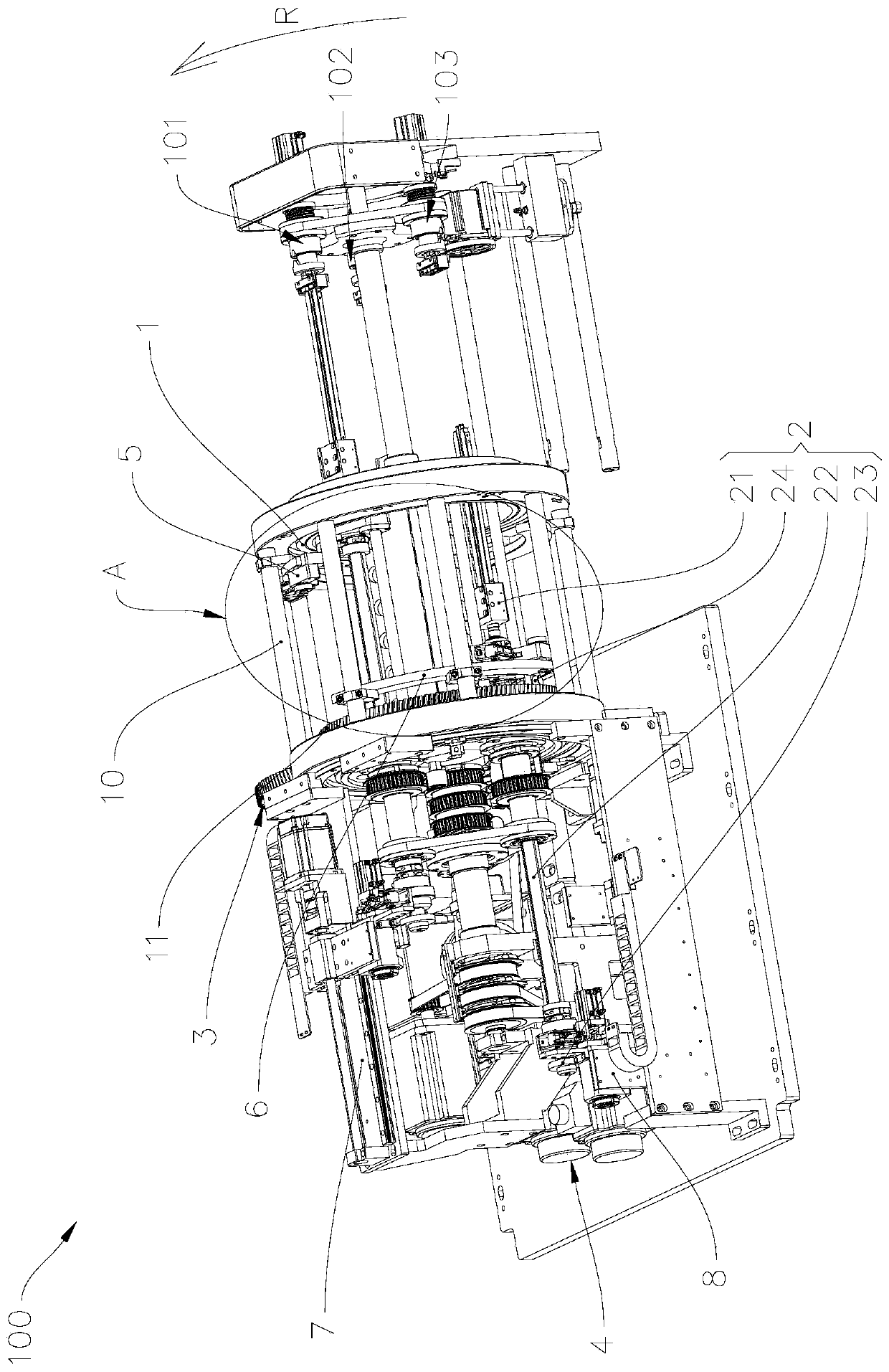

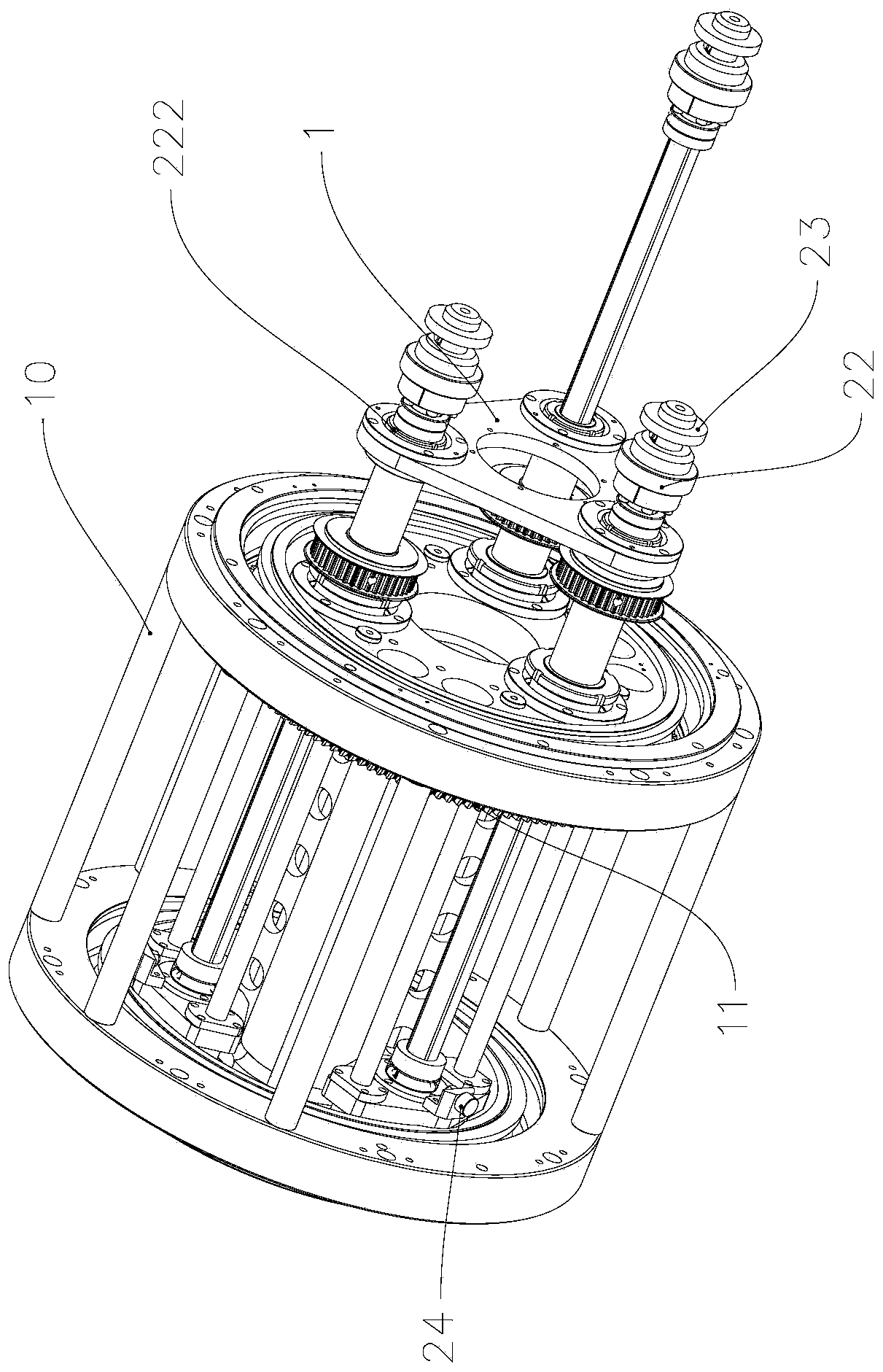

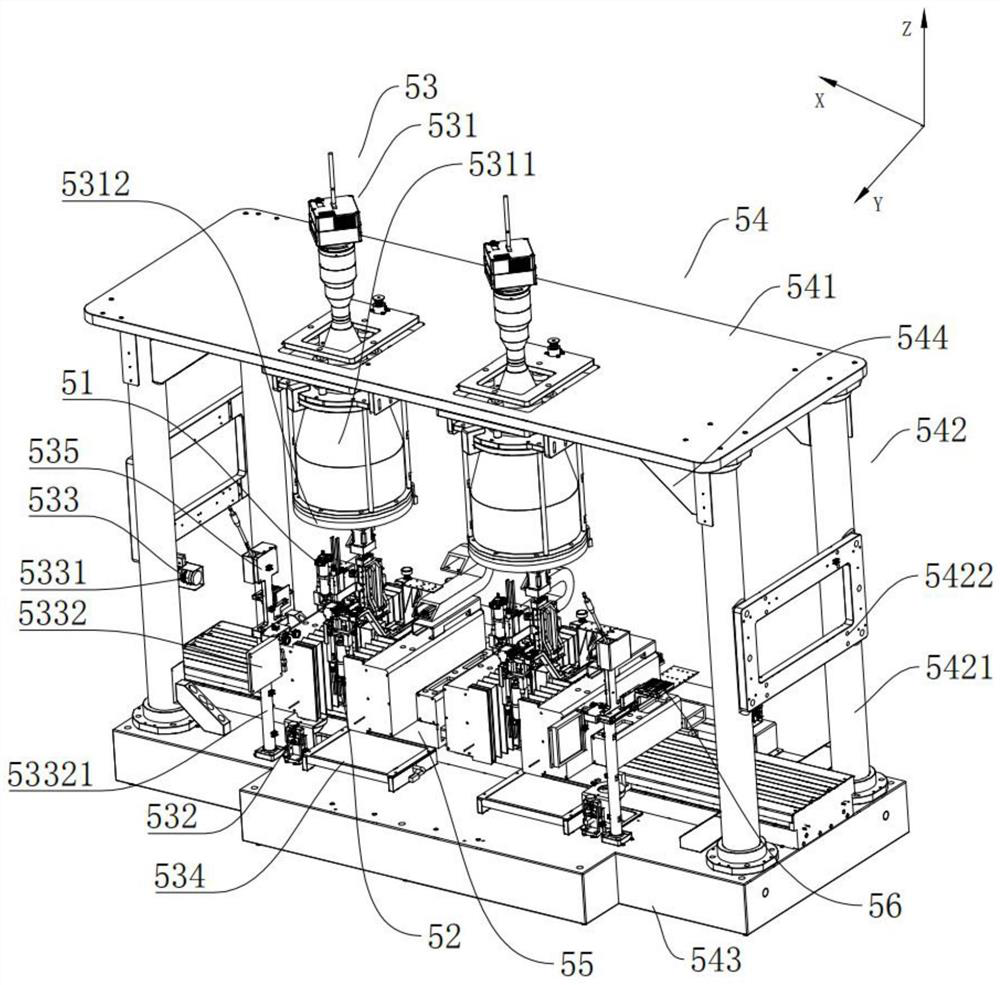

Automatic gluing machine used for automobile luggage rack

InactiveCN107774516APositioning balancePrecise positioningLiquid surface applicatorsCoatingsCircular discElectric machinery

The invention discloses an automatic gluing machine used for an automobile luggage rack. The structure of the automatic gluing machine comprises a gluing stroke moving shaft, a sliding rail rest, a glue storage bottle, a gluing valve head, a workpiece fixing rack, a bottom slide rail, a multi-station rotary positioning mechanism, a working table, a fixed base, a gluing controller and a rack, wherein the fixed base is of a square structure, the top end of the fixed base and the working table are of an integrated structure, and the left and right ends of the rear end of the working table are fixedly connected with and vertical to the rack. According to the invention, a driving motor is used for driving a rotating disk to rotate and driving a workpiece on the workpiece fixing rack to rotate to generate gluing tracks in multiple directions, so as to enlarge the gluing scope, and thus realizing uniform gluing of the product; and under the actions of an offset rod and a magnetic block, the workpiece can be located in a center position more easily and be positioned precisely, and deviation and displacement can be reduced; and an elastic plate can reduce vibration when the workpiece is machined, so as to increase gluing stability, increase the working efficiency and improve the product machining quality.

Owner:金陈敏

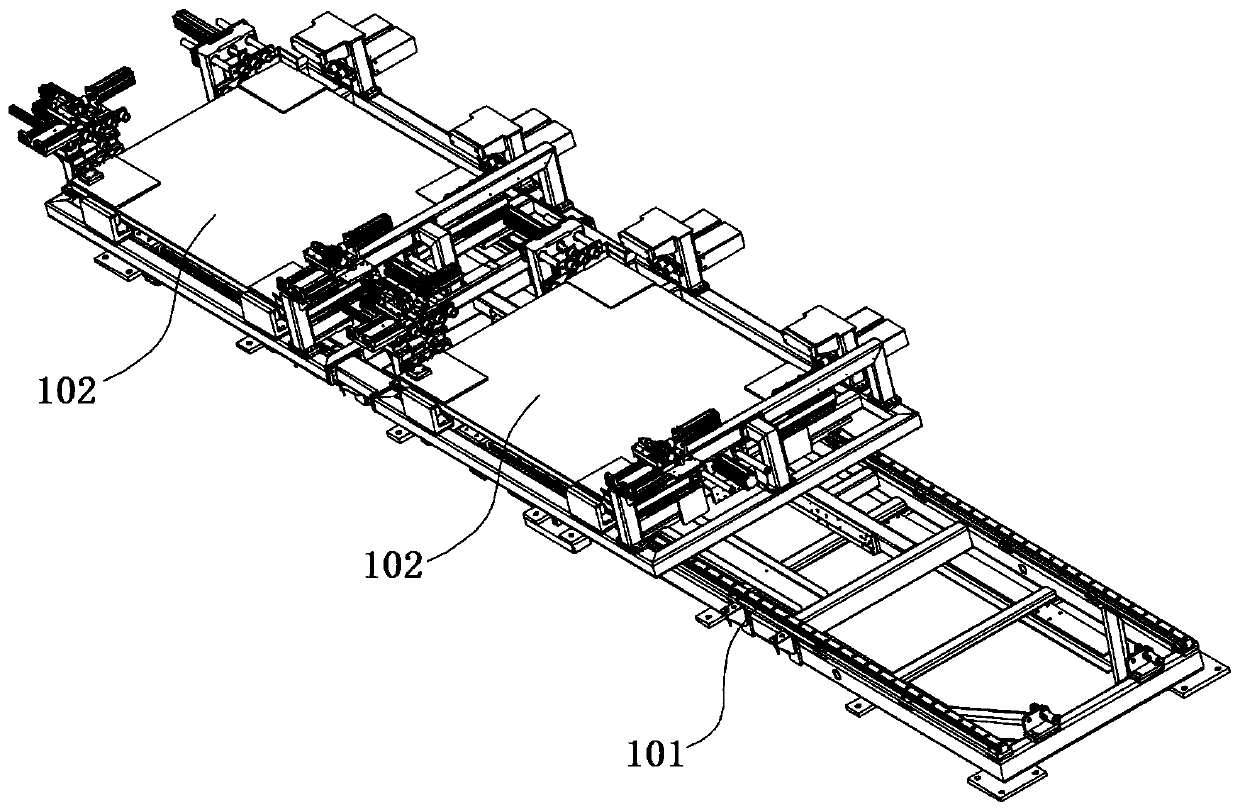

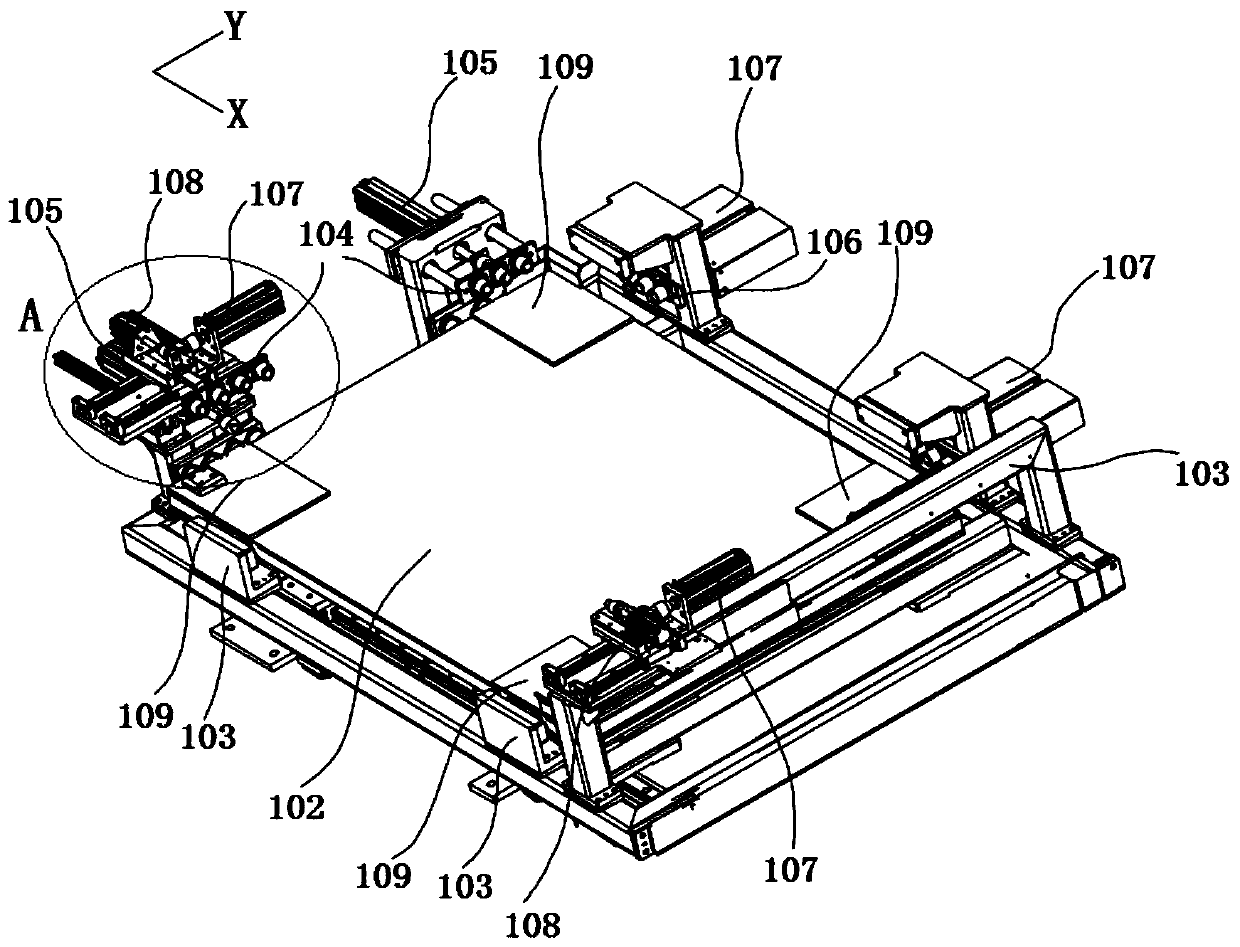

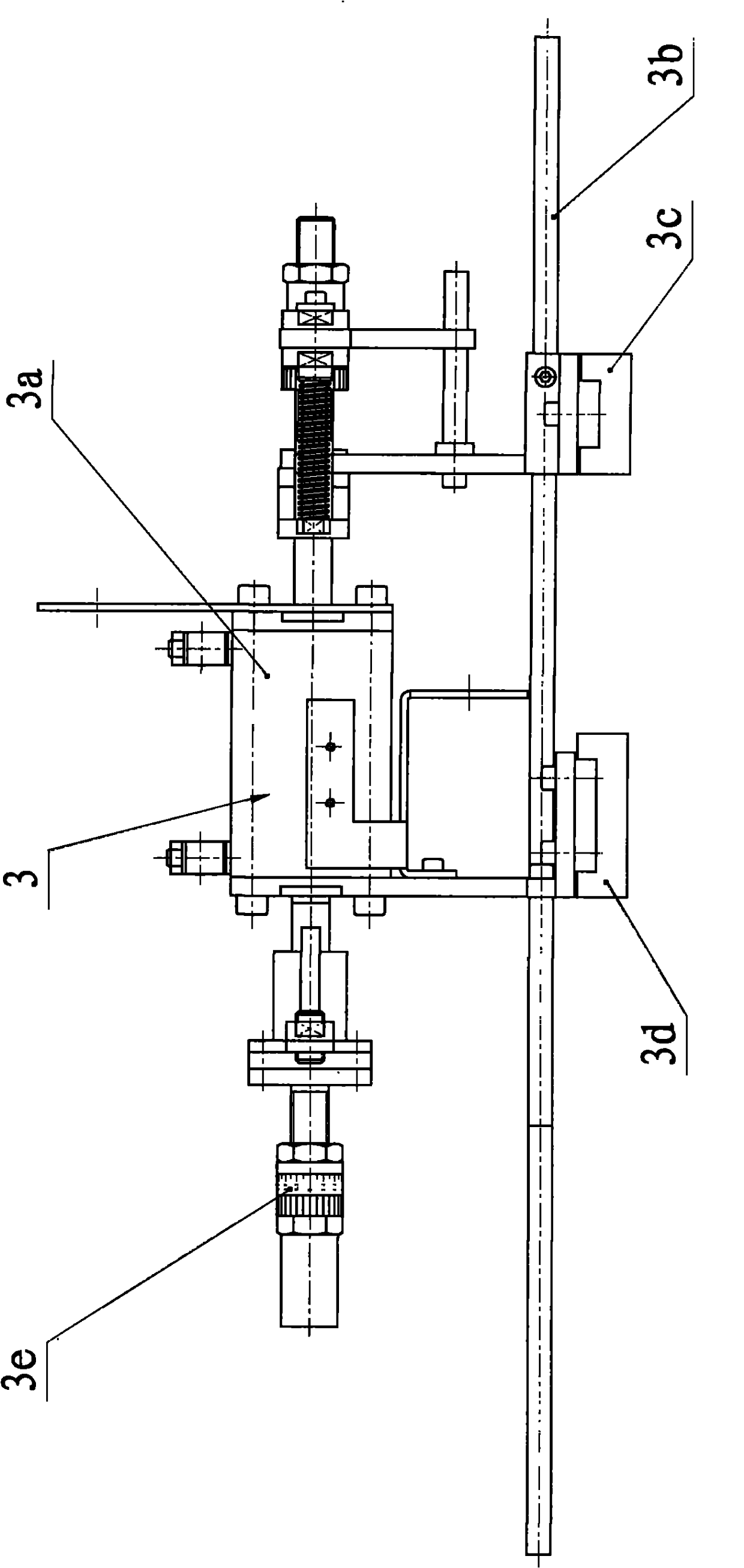

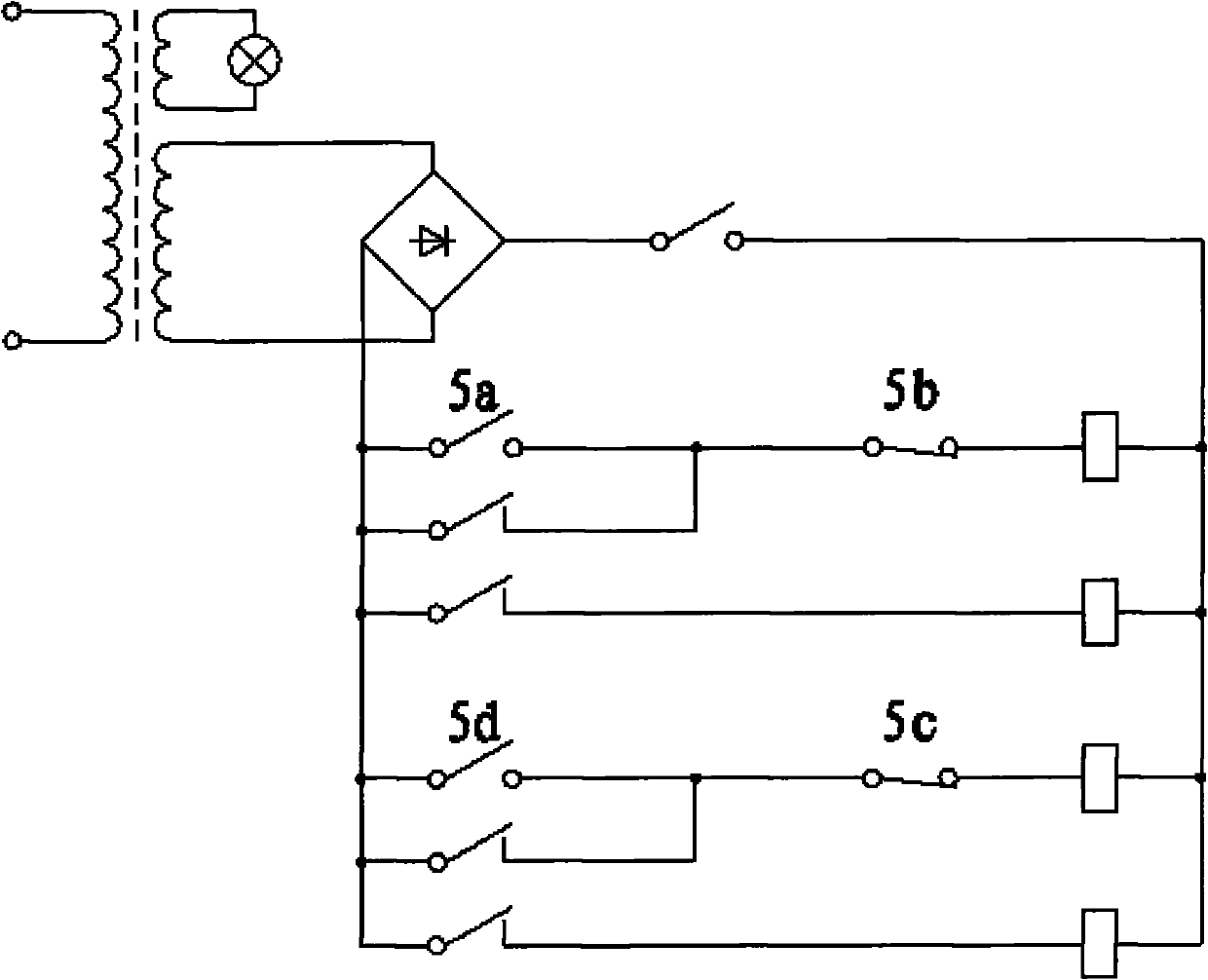

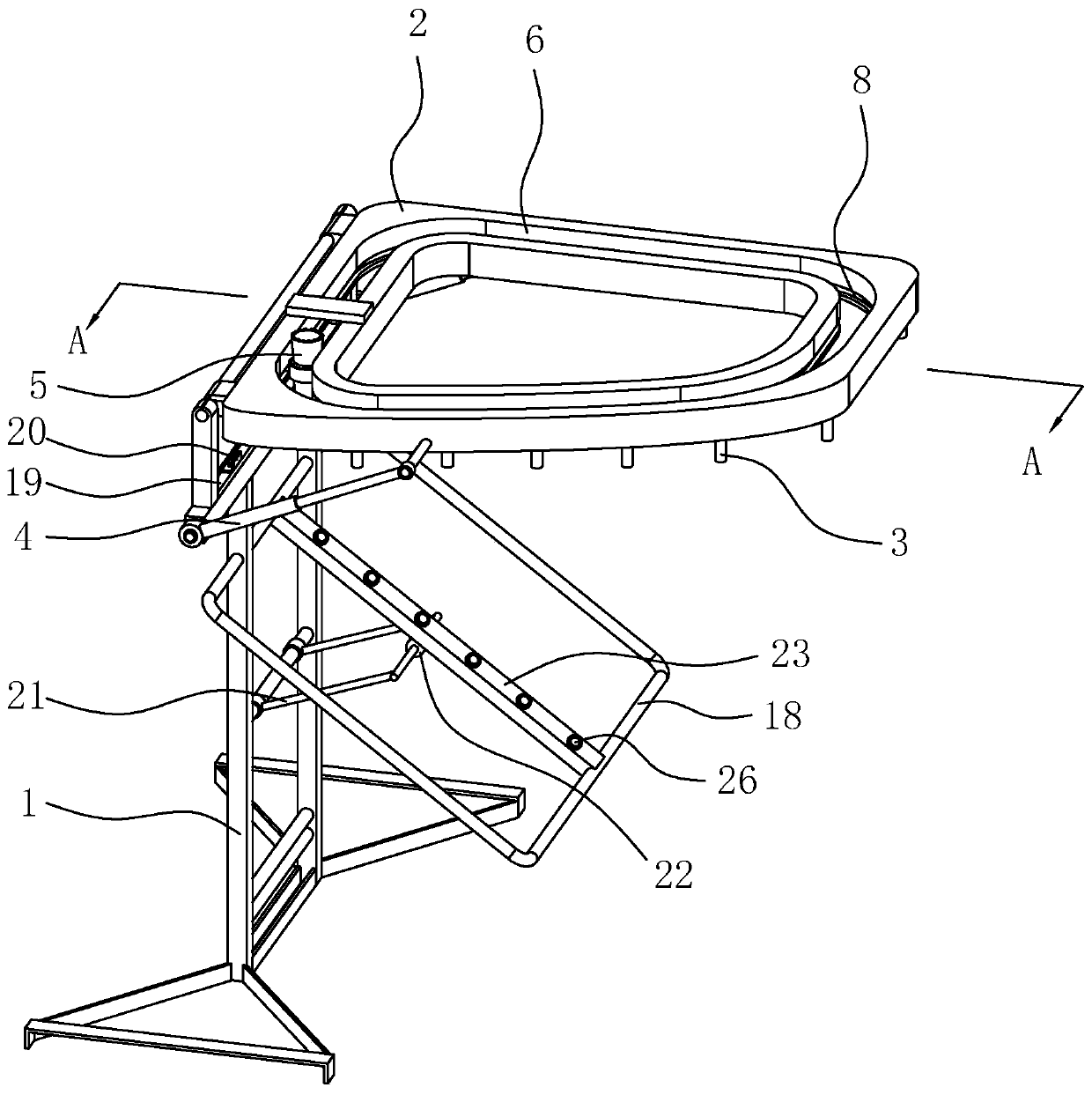

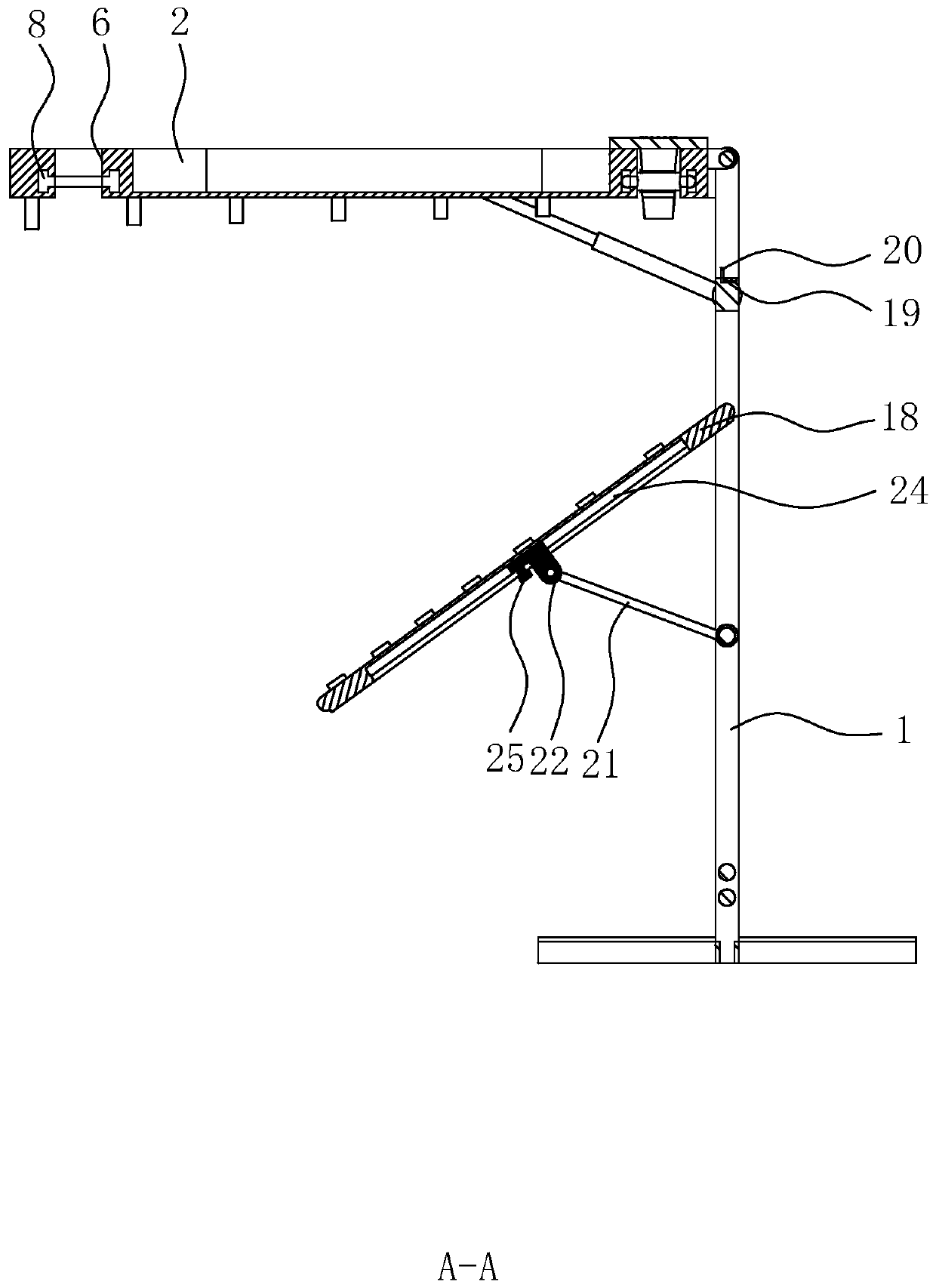

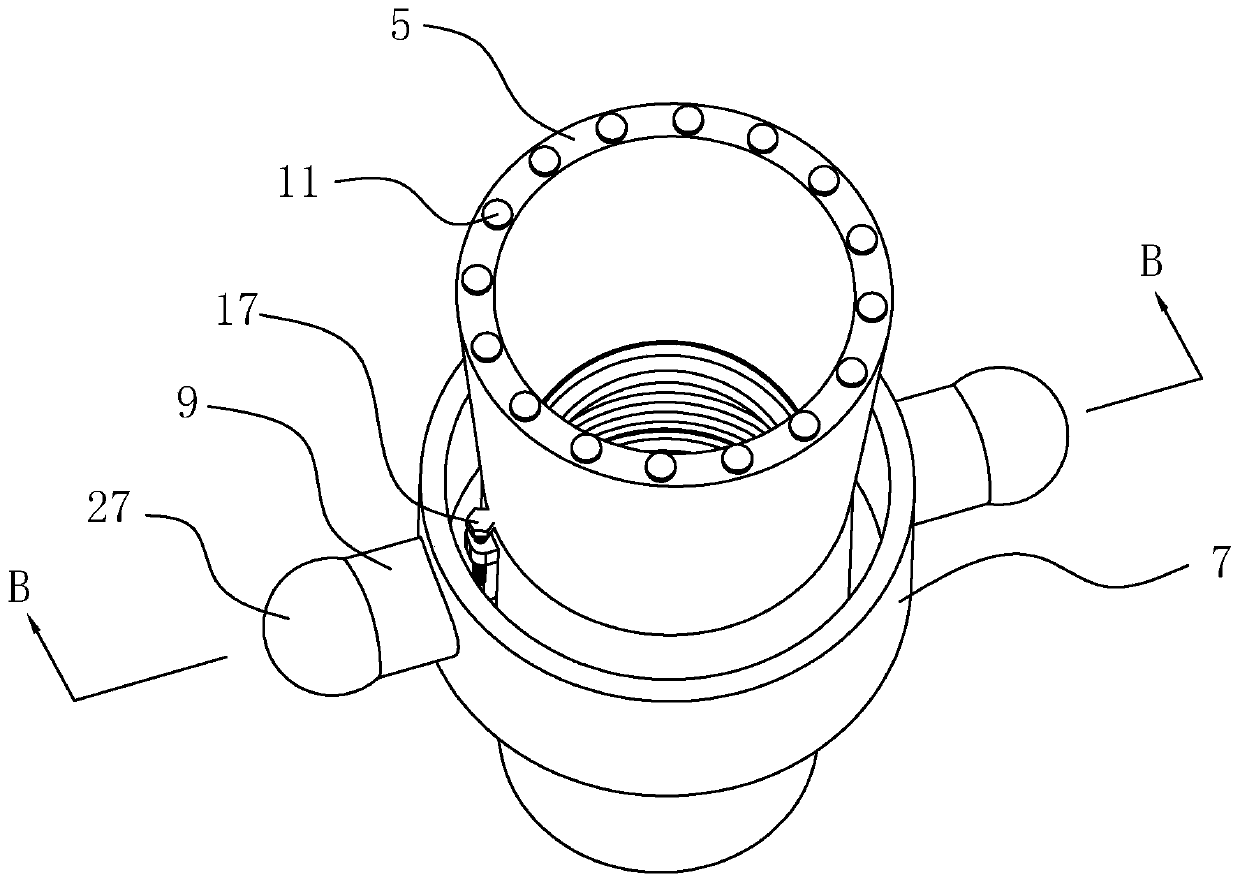

Automobile door glue coating frame

ActiveCN110605214AImprove gluing efficiencyImprove accuracyLiquid surface applicatorsCoatingsGas springEngineering

The invention discloses an automobile door glue coating frame, and relates to the technical field of automobile part machining auxiliary equipment. The automobile door glue coating frame comprises a frame body. A positioning device used for positioning an automobile door is arranged on the frame body. A rail frame is arranged at the upper end of the frame body in a turnover manner, wherein the contour of the rail frame is matched with the three-dimensional track of an automobile door gluing part. Multiple pressing columns corresponding to automobile door concave positions are fixedly connectedto the lower end of the rail frame. Gas springs are arranged between the frame body and the rail frame. A positioning barrel for a glue outlet pipe of a glue gun to penetrate through is arranged on the rail frame along the contour of the rail frame in a slippage manner. A prompting device used for prompting the contact state of the glue outlet pipe of the glue gun and an automobile door is arranged on the positioning barrel. The glue outlet pipe of the glue gun penetrates into the positioning barrel and conducts glue coating on parts, to be subjected to glue coating, of the automobile door when sliding along the contour of the rail frame, and the glue coating efficiency and accuracy can be effectively improved.

Owner:湖北澳美斯汽车零部件有限公司

Rope winding gluing device for net rope processing

InactiveCN110791987AImprove drying efficiencyImprove gluing effectPretreated surfacesRope making machinesAir pumpAdhesive glue

The invention discloses a rope winding gluing device for net rope processing. The rope winding gluing device comprises a box, the left sides of the inner walls of two sides of the box are connected with two feed rollers through bearings, two first limit rollers are arranged at the bottoms of the inner walls of the two sides of the box, two second limit rollers are arranged at the tops of the innerwalls of the two sides of the box, four mounting plates are arranged at the tops of the inner walls of the two sides of the box, two adjacent mounting plates are positioned on two sides of the secondlimit rollers, and uniformly distributed heating resistance wires are arranged on the outer wall of one side of each mounting plate. When the rope winding gluing device is used, net ropes are limitedby the first limit rollers and the second limit rollers, immersed into glue, dried in the air after leaving the glue, immersed into the glue again and finally dried in the air and discharged, the netropes are heated and dried by the heating resistance wires while the net ropes are dried in the air, an air pump blows air into the mounting plates, airflow is sprayed from a first air outlet, the drying efficiency of the net ropes is accelerated, impregnation can be implemented twice, and gluing effects are improved.

Owner:天门市锦鳞绳网有限公司

Environmentally-friendly filler of adhesive for sheet and application method of filler

InactiveCN110373130ALow costHigh bonding strengthNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesCelluloseClay minerals

The invention discloses an environmentally-friendly filler of an adhesive for a sheet. The filler is prepared by uniformly mixing the following raw materials, in percentages by weight: 26%-44% of claymineral powder, 42%-56% of an inorganic filler, 7%-24% of an organic filler, and 1%-5% of a thickening modifier, wherein the clay mineral powder is one or more selected from the group consisting of sepiolite, montmorillonite, attapulgite and kaolinite; the inorganic filler is one or more selected from the group consisting of calcite powder, talcum powder and quartz powder; the organic filler is one or more selected from the group consisting of puffed corn flour, flour, starch and wood flour; and the thickening modifier is one or more selected from the group consisting of cellulose, polyvinylalcohol, polyacrylamide, sodium polyacrylate, sodium silicate and vegetable gum. The invention also provides an application method of the filler. According to the environmentally-friendly filler of the adhesive for the sheet provided by the invention, the finally prepared adhesive has obviously-improved water resistance and bonding strength, and an inhibitory effect on formaldehyde release.

Owner:湘潭海泡石科技有限公司

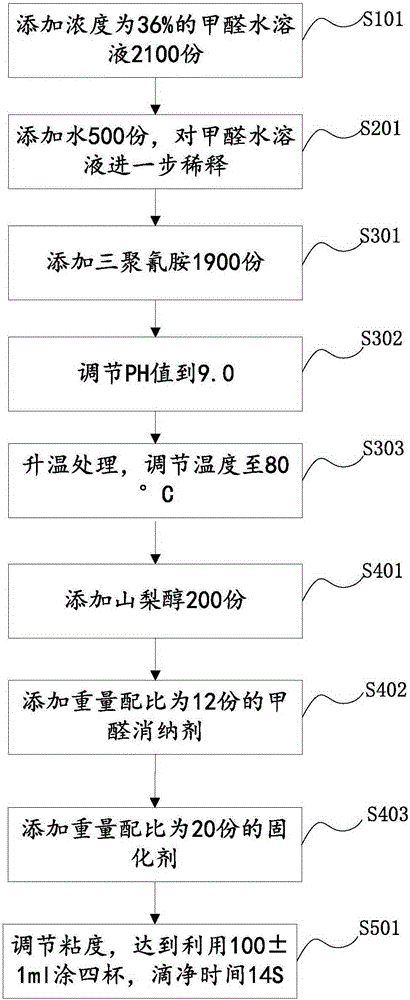

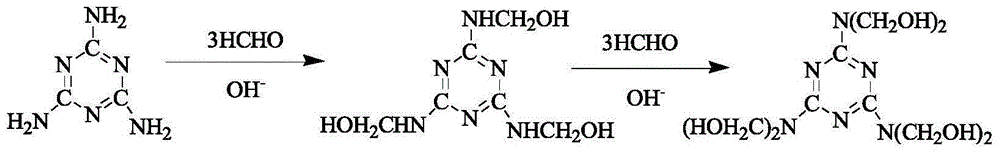

Low-formaldehyde triamine adhesive and method for preparing same

ActiveCN105199064AGuaranteed waterproof and moisture-proof performanceGuarantee the quality of gluingNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveMelamine

The invention provides low-formaldehyde triamine adhesive and a method for preparing the same. The low-formaldehyde triamine adhesive comprises, by weight, 2100 parts of formaldehyde aqueous solution with the concentration of 36%, 1900 parts of melamine, 500 parts of water, 200 parts of sorbitol, 12 parts of formaldehyde absorptive agents and 8 parts of triethanolamine. The low-formaldehyde triamine adhesive and the method have the advantage that problems of excessively high content of formaldehyde in triamine adhesive in the prior art and high manufacturing cost can be solved by the aid of the low-formaldehyde triamine adhesive and the method.

Owner:山东东宇鸿翔装饰材料有限公司

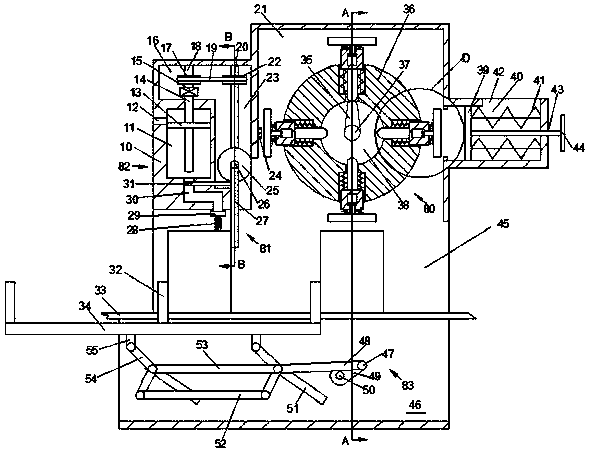

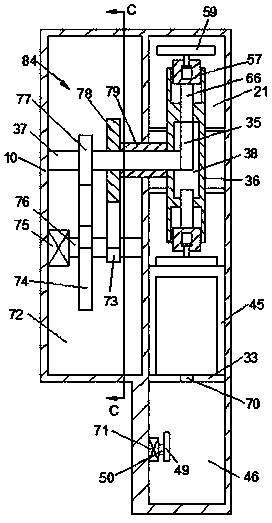

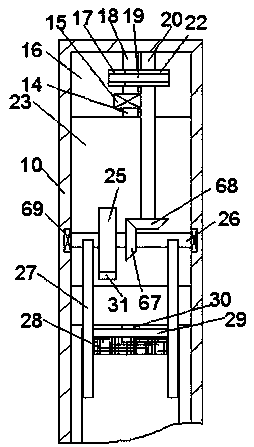

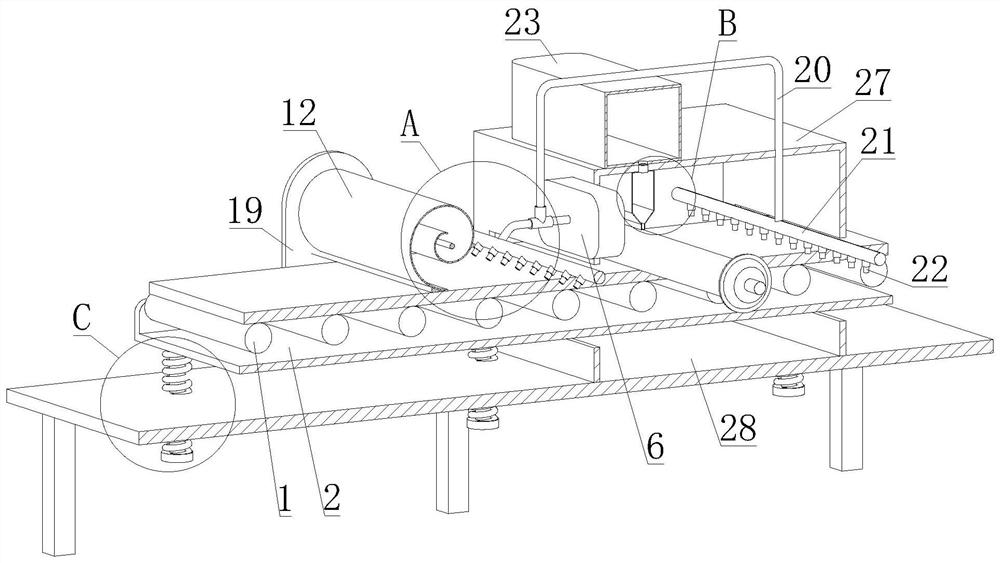

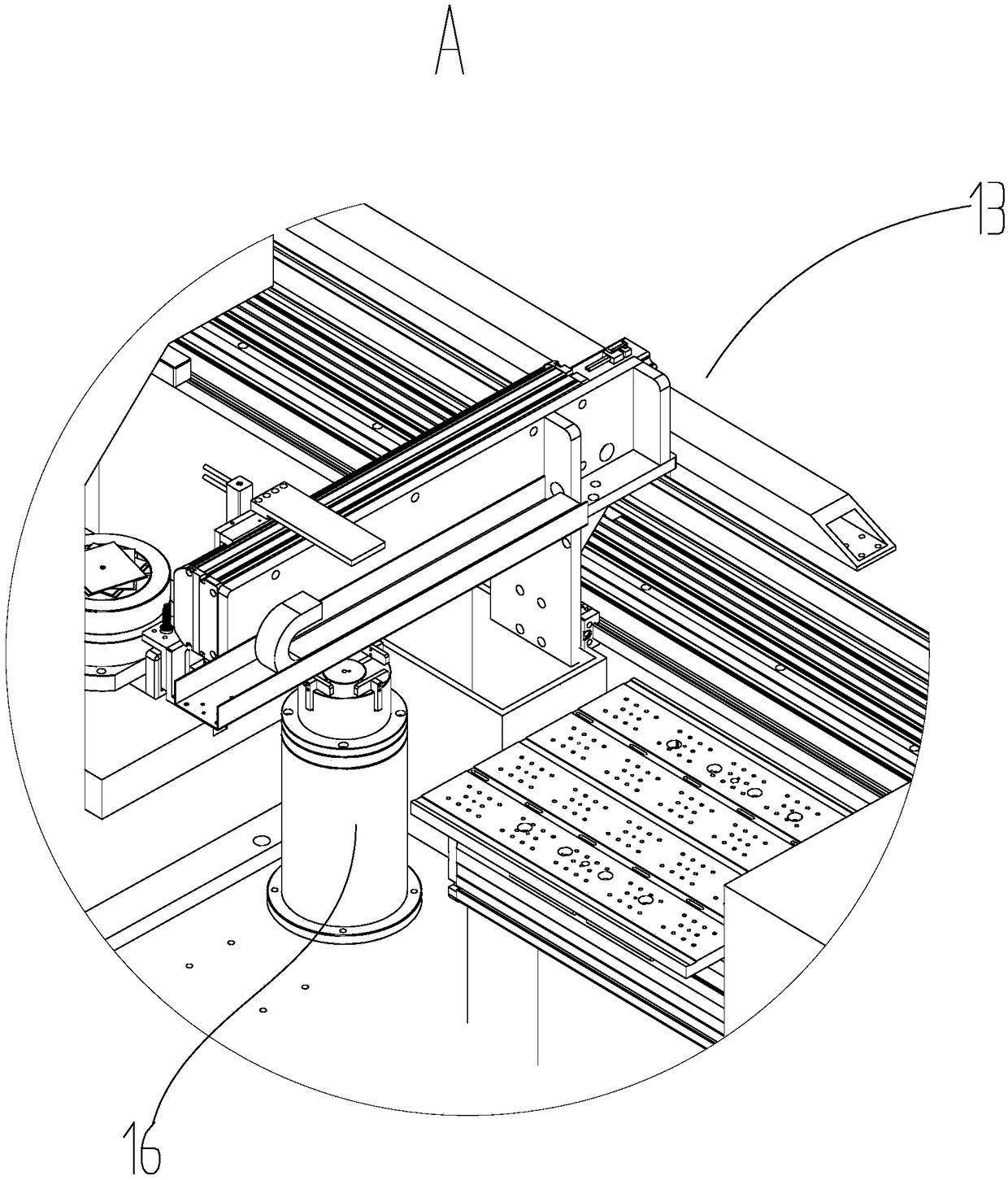

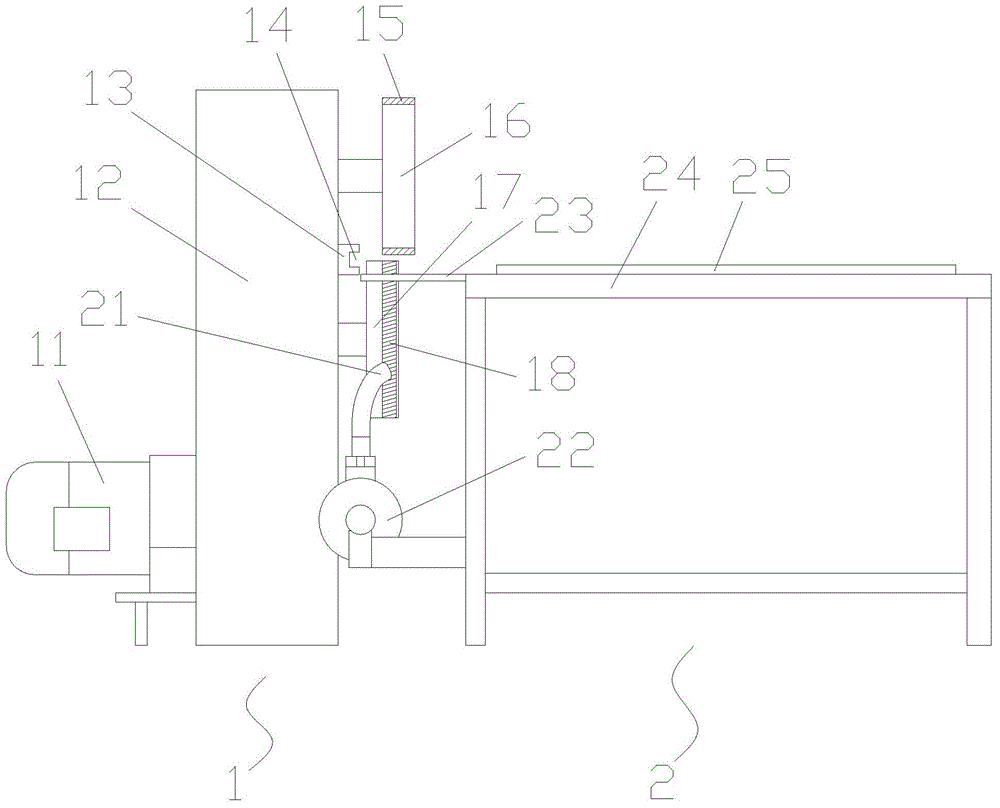

Device capable of conducting automatic feeding, glue coating and labeling on relay

ActiveCN110949814AGuarantee the quality of gluingSimple and efficient operationLabelling machinesAdhesive glueEngineering

The invention discloses a device capable of conducting automatic feeding, glue coating and labeling on a relay. The device comprises a main machine body. A first transmission cavity is formed in the main machine body. A label cavity communicating with the first transmission cavity is formed in the right side of the first transmission cavity. A labelling device used for taking out a label in the label cavity and pasting the label on the relay is arranged in the first transmission cavity. A workpiece cavity communicating with the first transmission cavity is formed in the lower side of the firsttransmission cavity. The left side and the right side of the workpiece cavity communicate with the outer portion of the main machine body. A glue coating device conducting glue coating on the labeledface of the relay is arranged in the workpiece cavity. A glue cavity is formed in the left side of the first transmission cavity. The device is easy and convenient to operate and low in manufacturingcost, automatic feeding, glue coating and labeling can be conducted on the relay, automatic label taking can also be achieved, pressure can also be exerted on glue in the glue cavity during glue coating, and the glue coating quality is ensured.

Owner:浙江金果知识产权有限公司

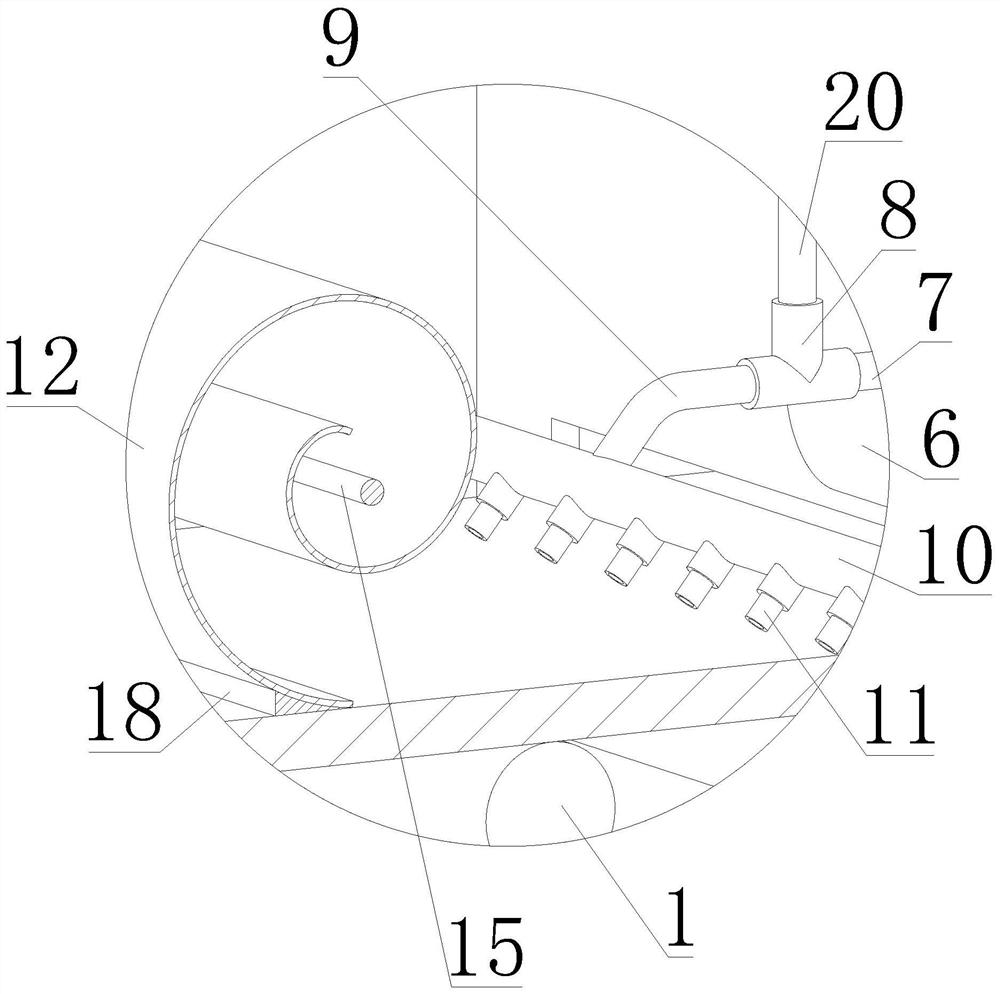

Gluing device for wood-plastic floor production

InactiveCN112718375APrevent adhesionGuarantee the quality of gluingPretreated surfacesDirt cleaningDust controlStructural engineering

The invention discloses a gluing device for wood-plastic floor production. The gluing device comprises a fan, an air outlet pipe, a three-way pipe, a first air conveying pipe, a first exhaust pipe, a first nozzle, an air guide piece, a support, a second air conveying pipe, a second exhaust pipe, a second nozzle, a glue storage box, a connecting pipe, a glue discharging barrel, a gluing roller, a mounting cover and a machining table. A conveying mechanism used for conveying floors is arranged on the machining table. The air guide piece is of a spiral plate-shaped structure, the two longitudinal ends of the air guide piece are connected with side plates, and an air inlet channel and a dust accumulation cavity which communicate with each other are formed between the air guide piece and the side plates. The output end of the fan communicates with the air outlet pipe, the three-way pipe is provided with an air inlet end and two air outlet ends, the air inlet end communicates with the air outlet pipe, the two air outlet ends communicate with the first air conveying pipe and the second air conveying pipe correspondingly, the end, away from the three-way pipe, of the first air conveying pipe communicates with the first exhaust pipe, and the first nozzle communicates with the first exhaust pipe. According to the gluing device, dust removal treatment can be conducted on a floor before gluing, drying treatment can be conducted after gluing, and the gluing quality is guaranteed.

Owner:杭州易薪科技创新有限公司

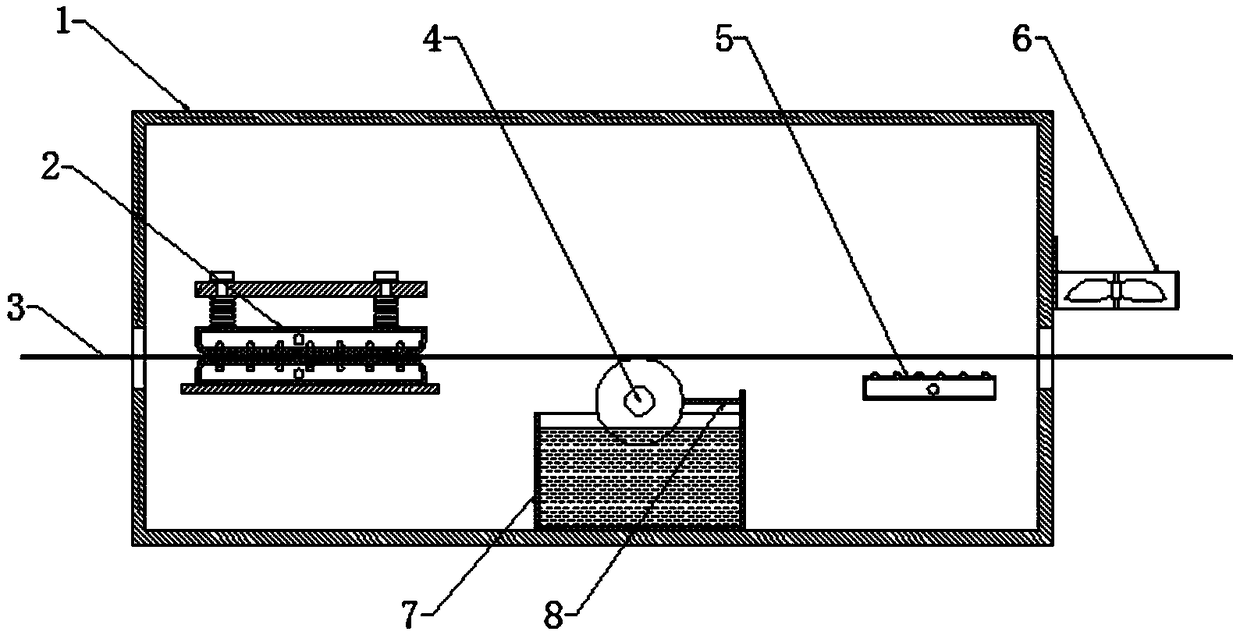

Gluing device for performing processing production on carpets

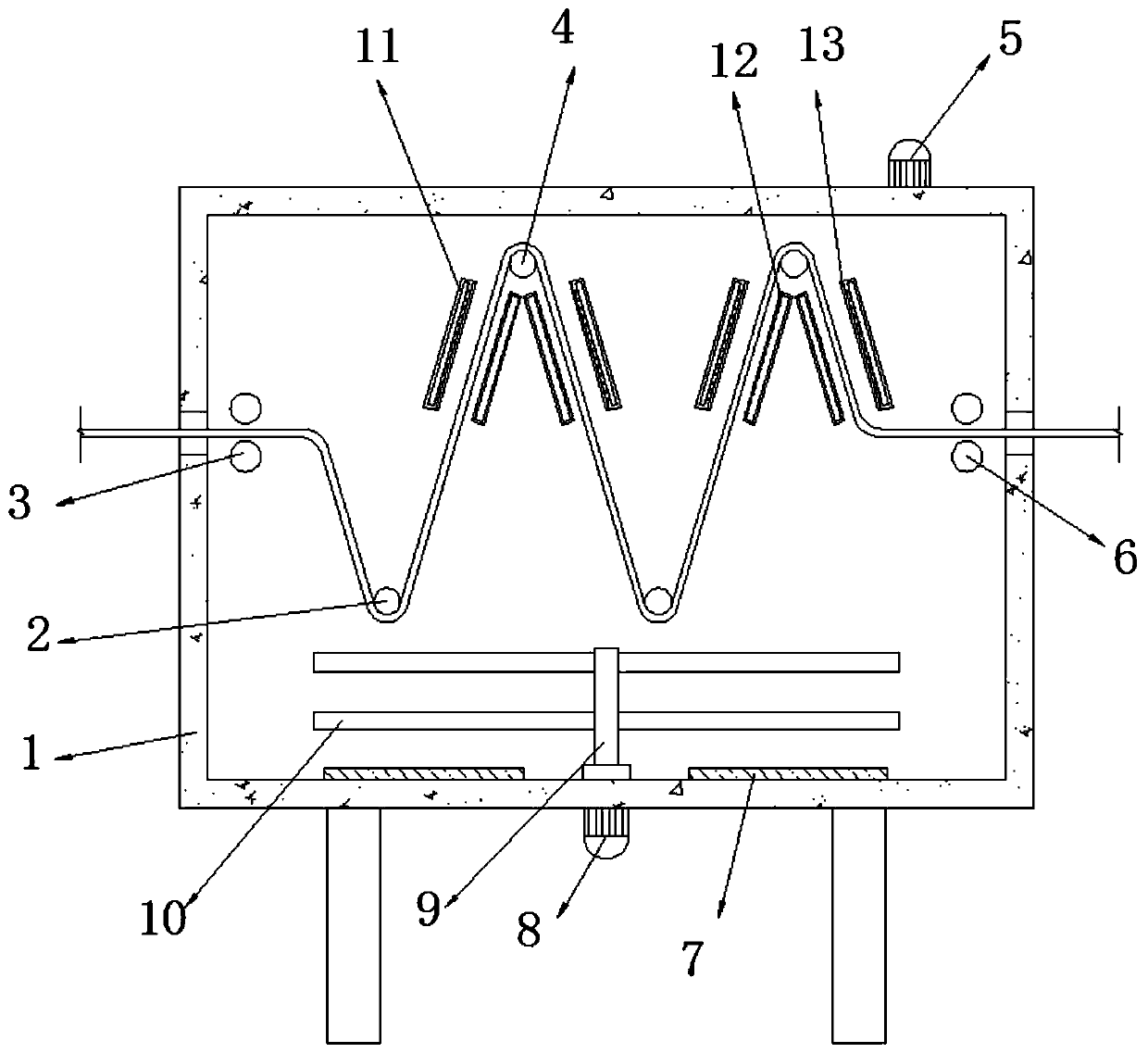

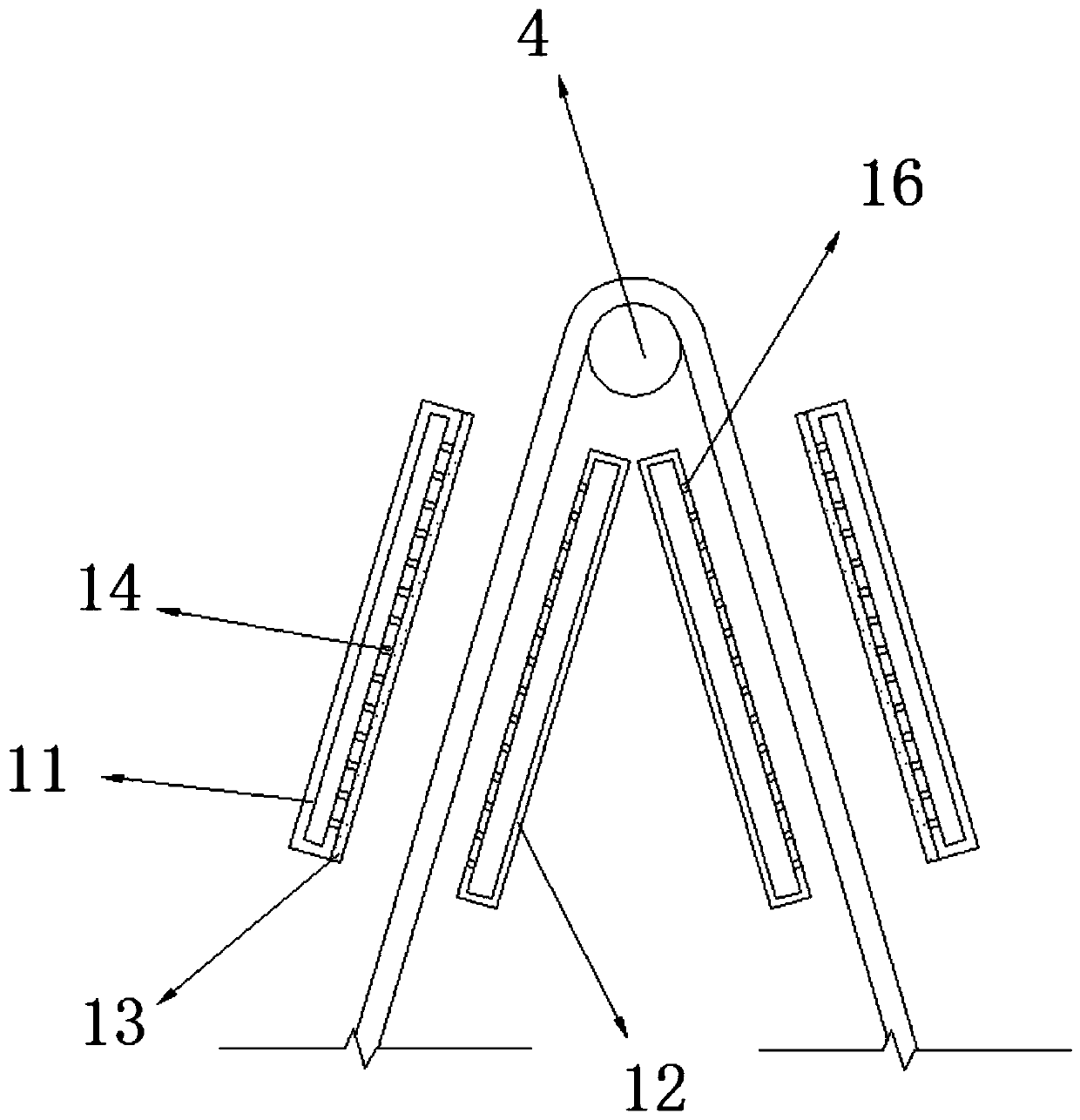

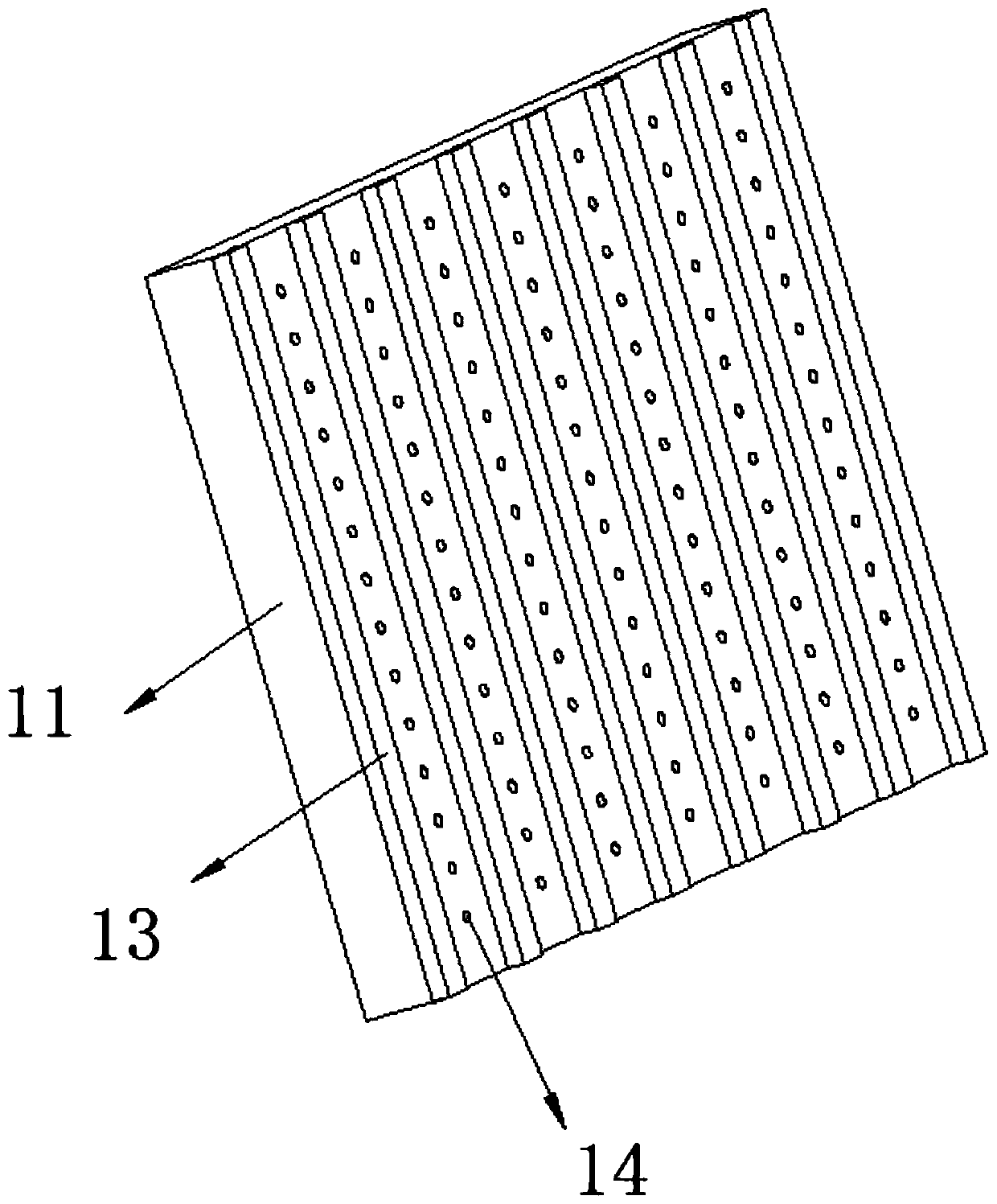

PendingCN108787314AGuaranteed smoothGuarantee the quality of gluingPretreated surfacesCoatingsPulp and paper industryProduction quality

The invention discloses a gluing device for performing processing production on carpets. The gluing device comprises a box body, a flattening device, a carpet grey fabric, and a gluing roller, whereinthe carpet grey fabric transversely passes through the inner side of the box body; the flattening device is arranged at the left end, positioned on the inner side of the box body, of the carpet greyfabric; the gluing roller is arranged at the lower end of the middle part of the carpet grey fabric; a glue pool is arranged under the gluing roller; and the gluing roller is arranged on the upper port part of the glue pool. According to the gluing device disclosed by the invention, the carpet grey fabric is flattened by using the arranged flattening device before gluing, so that flatness of the gluing surface of a carpet is ensured, uniform gluing is realized, and the gluing equality is ensured; electric heating tubes are arranged on the inner sides of an upper flattening block and a lower flattening block; the carpet grey fabric is pre-heated before being glued while the carpet grey fabric is flattened by using the flattening blocks at the same time, so that the gluing effect of the carpet is ensured, and the production quality of the carpet is improved.

Owner:ZHEJIANG MEINUO CARPET MFG CO LTD

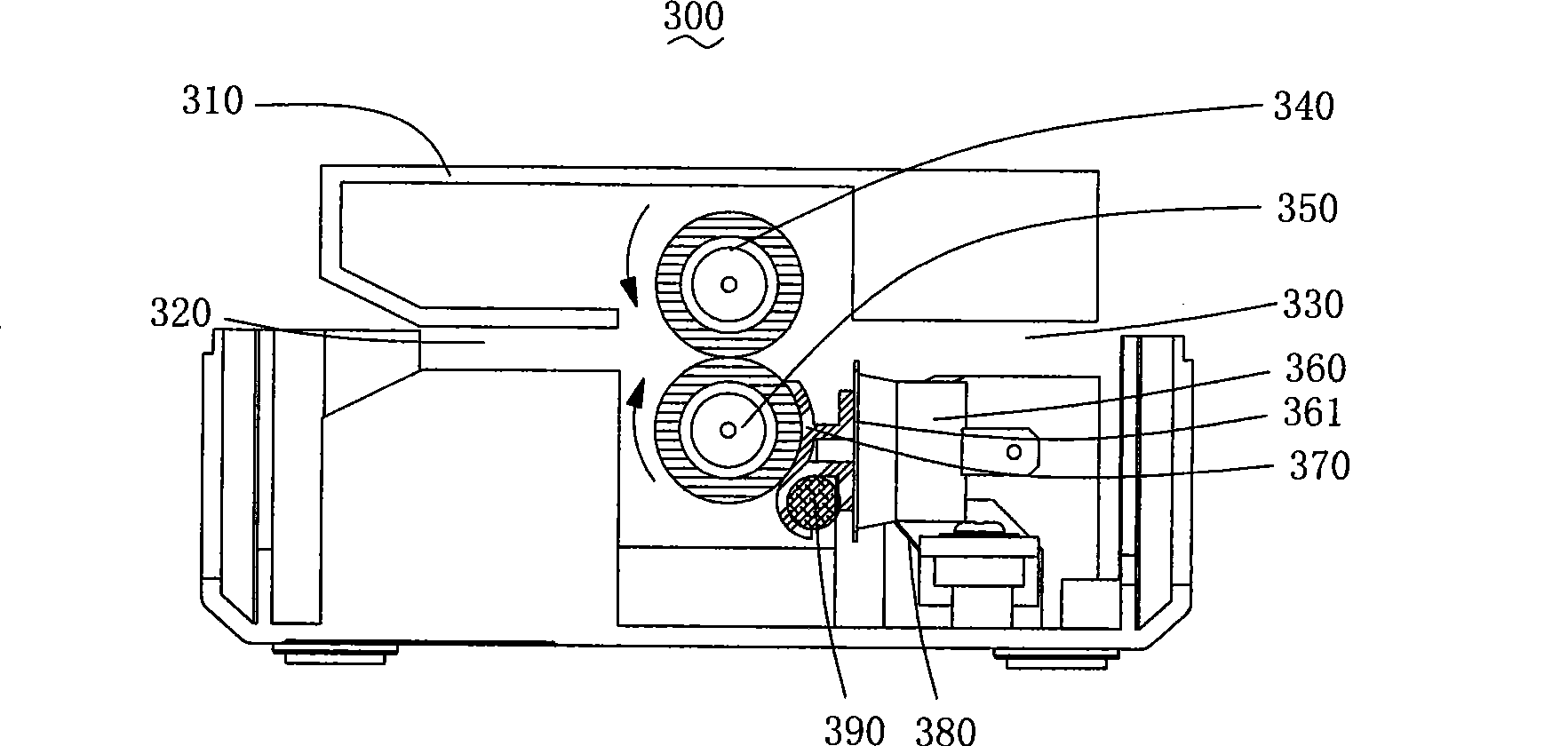

Laminator

ActiveCN109194048AEasy to operateImprove lamination efficiencyManufacturing stator/rotor bodiesArchitectural engineeringEngineering

The invention discloses a laminator laminator including a base, and a first conveyor rack disposed on the base, The base is provided with a second conveying frame mounted on the right end of the firstconveying frame, the first conveying frame and the second conveying frame are slidably connected with a first placing plate and a second placing plate, the left end of the first conveying frame is provided with a first motor, and the left end of the second conveying frame is provided with a second motor. A first drying box is erected on the base on the first conveyor frame, and a second drying box is erected on the second conveyor frame. The left side of the first drying oven and the second drying oven is provided with a silicon steel sheet gluing device on the base; a silicon steel sheet turnover device is mounted on the base at the right end of the first conveying frame. A prepressing device and a silicon steel sheet clamping device are installed on the right end of the second conveyingframe on the base; the laminator is not only easy to operate, but also can greatly improve the laminating efficiency, reduce the manpower input, and ensure the quality of coating and laminating silicon steel sheet.

Owner:宁波傲天阔自动化设备有限公司

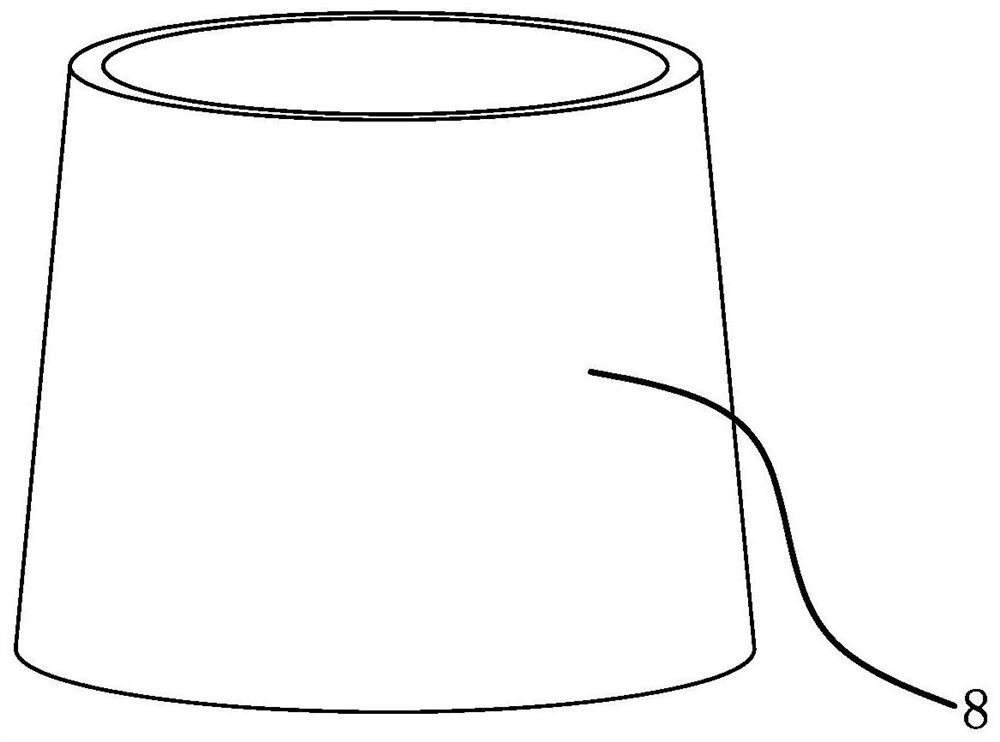

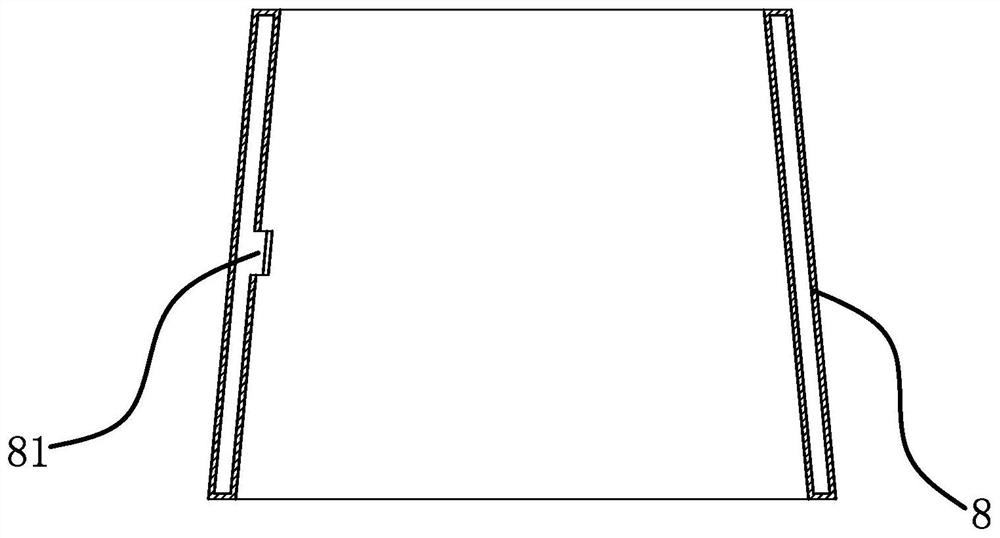

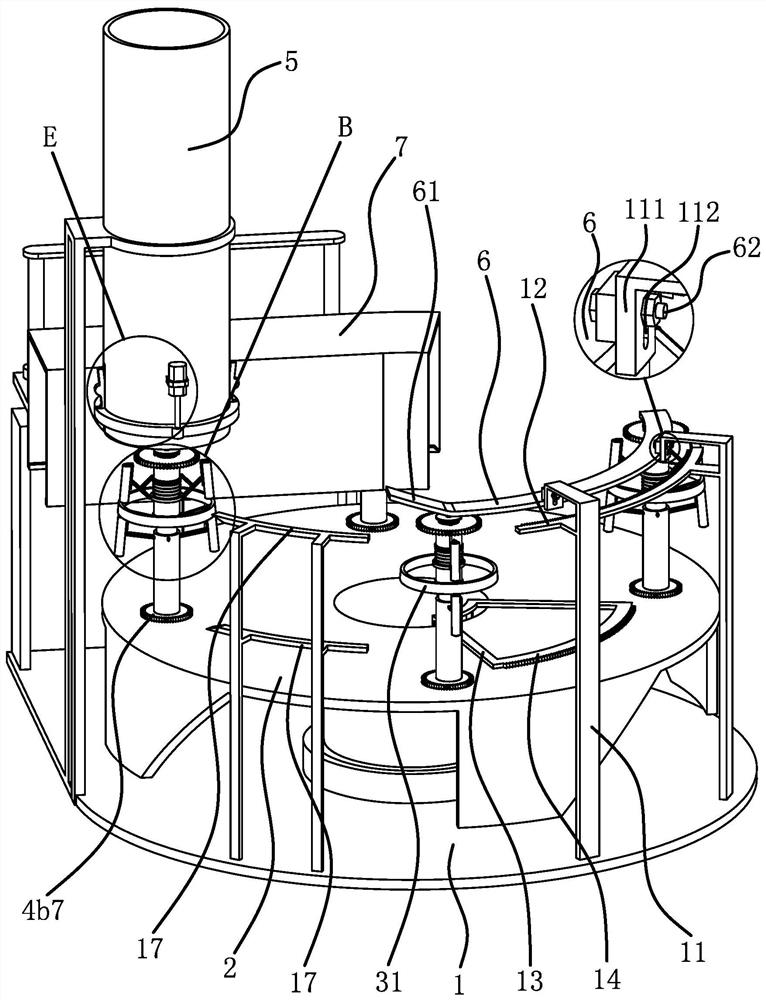

Lampshade gluing device of solar isolation column

ActiveCN111804502APrevent circumferential rotationAvoid problemsLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a lampshade gluing device of a solar isolation column, which belongs to the technical field of energy-saving and environmental protection equipment. The invention solves the problem of poor gluing quality of the lampshade of the solar isolation column in the prior art. The lampshade gluing device of the solar isolation column includes a bottom plate and a frame body; a turntable is connected to the bottom plate; a number of glue distributing tubes are fixed on the turntable; an upper rotating sleeve and a lower rotating sleeve are rotatablely arranged on the glue distributing tubes; a lower gluing roller is connected to the lower rotating sleeve; the upper rotating sleeve is connected with an upper gluing roller through a swing rod; a pressing part is arranged on theframe body; a glue supply structure is also arranged in the glue distributing tube; and the frame body is provided with a transmission part which can drive the upper rotating sleeve and the lower rotating sleeve to rotate in reverse synchronously when the upper gluing roller abuts against the inner peripheral wall of the lampshade. The lampshade gluing device of the solar isolation column can improve the gluing efficiency and improve the gluing quality.

Owner:瞿少卯

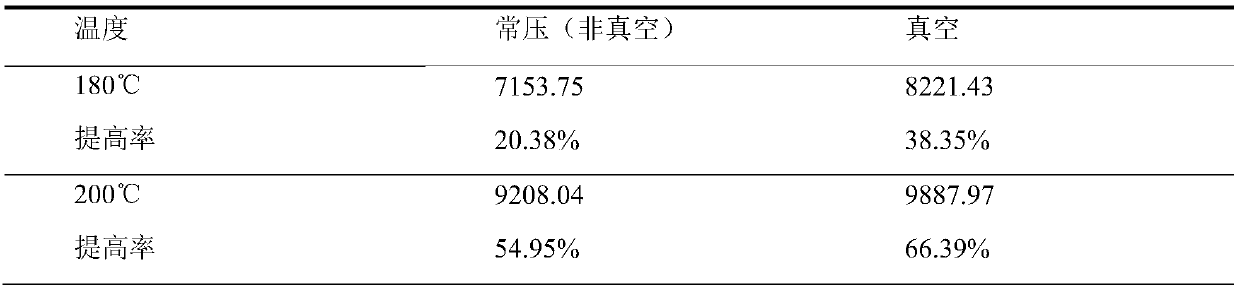

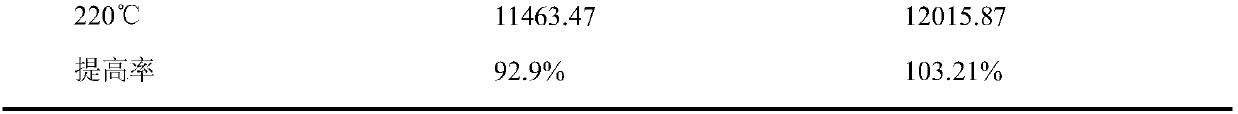

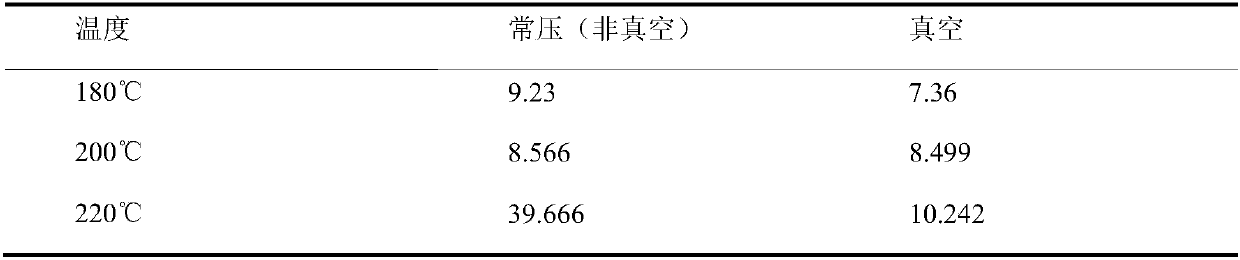

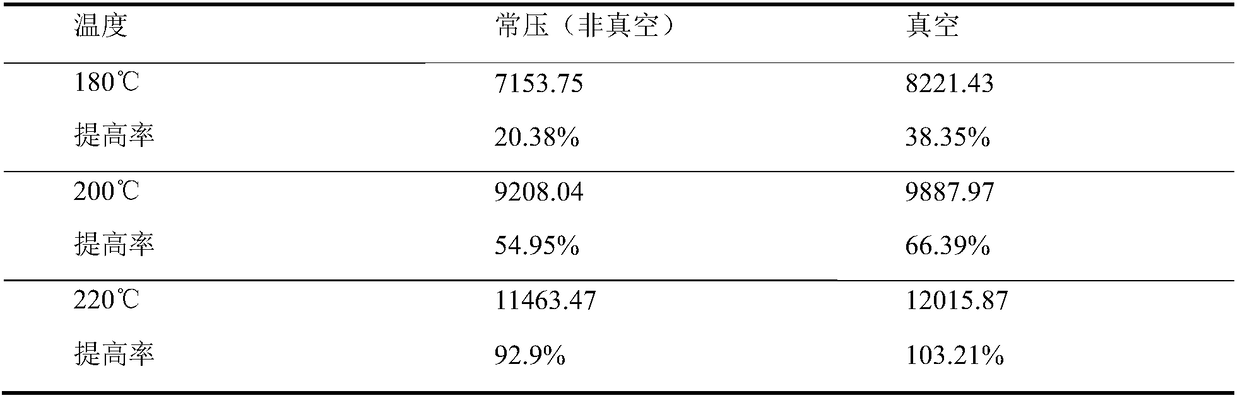

Method for compressing and compacting wood materials in vacuum

ActiveCN109591122ASolve easy discolorationFix stability issuesWood veneer joiningColor changesUltimate tensile strength

The invention discloses a method for compressing and compacting wood materials in vacuum, and belongs to the field of wood material production and preparation. According to the method, the wood materials undergo hot-pressing setting treatment under the vacuum condition, the treated wood materials are large in specific modulus, so that the technical problems that in the case of an existing wood material compression and compaction technology, the hot-pressing setting time is long, the manufacturing efficiency is low, the color change and the size are not stable are solved, the compression and compaction manufacturing of the wood materials is performed under the vacuum condition, so that the gluing strength of the wood gluing materials is also improved.

Owner:NANJING FORESTRY UNIV

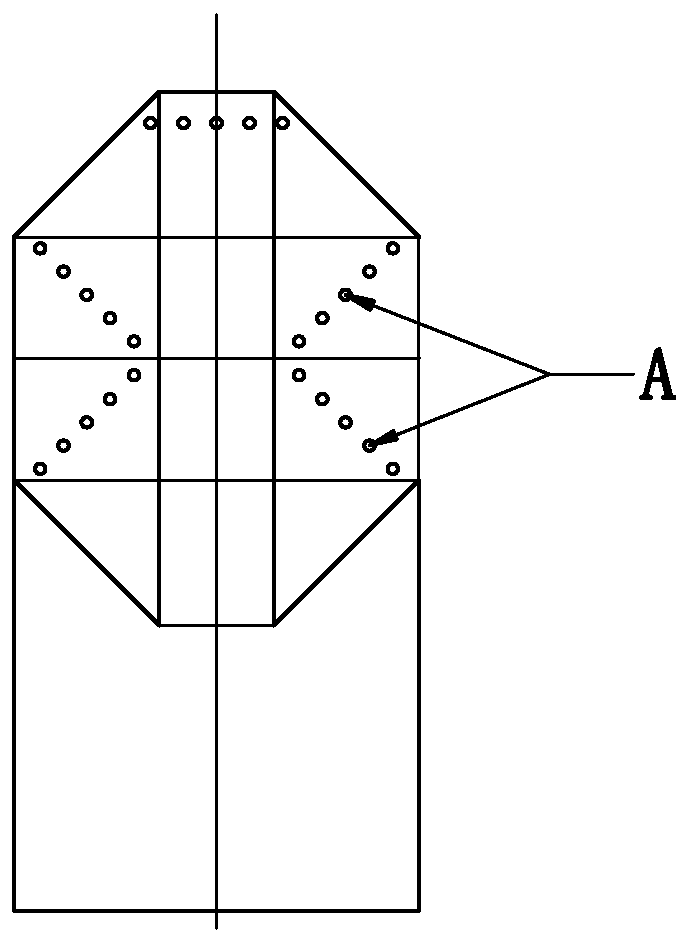

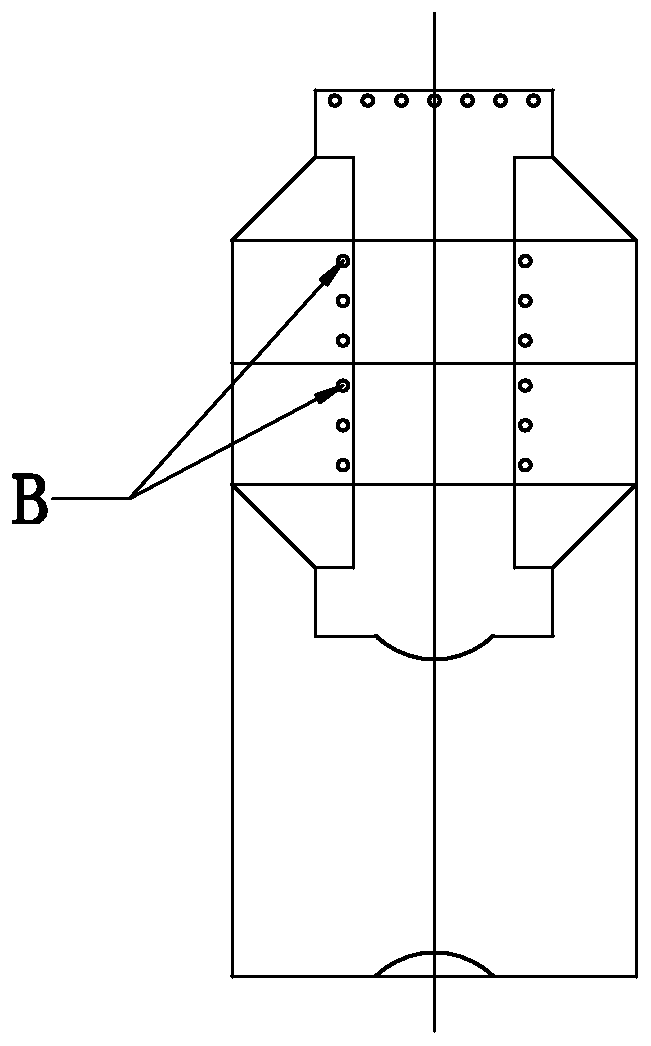

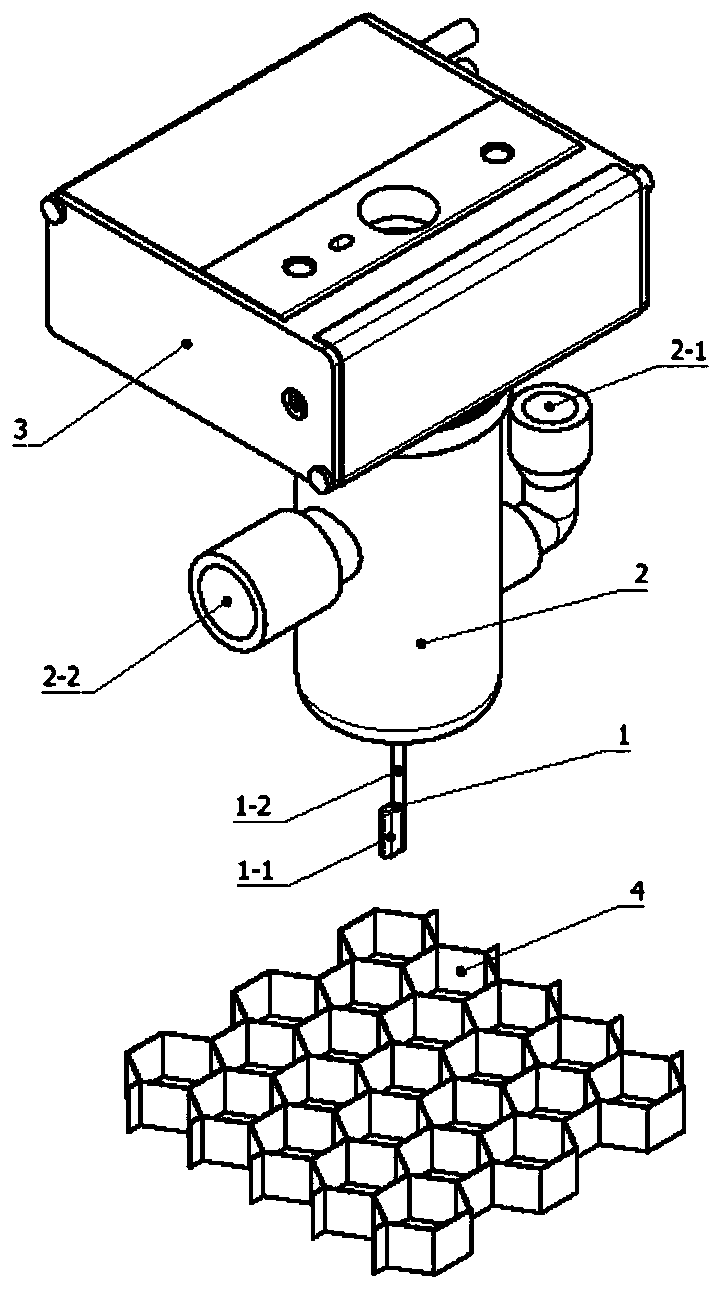

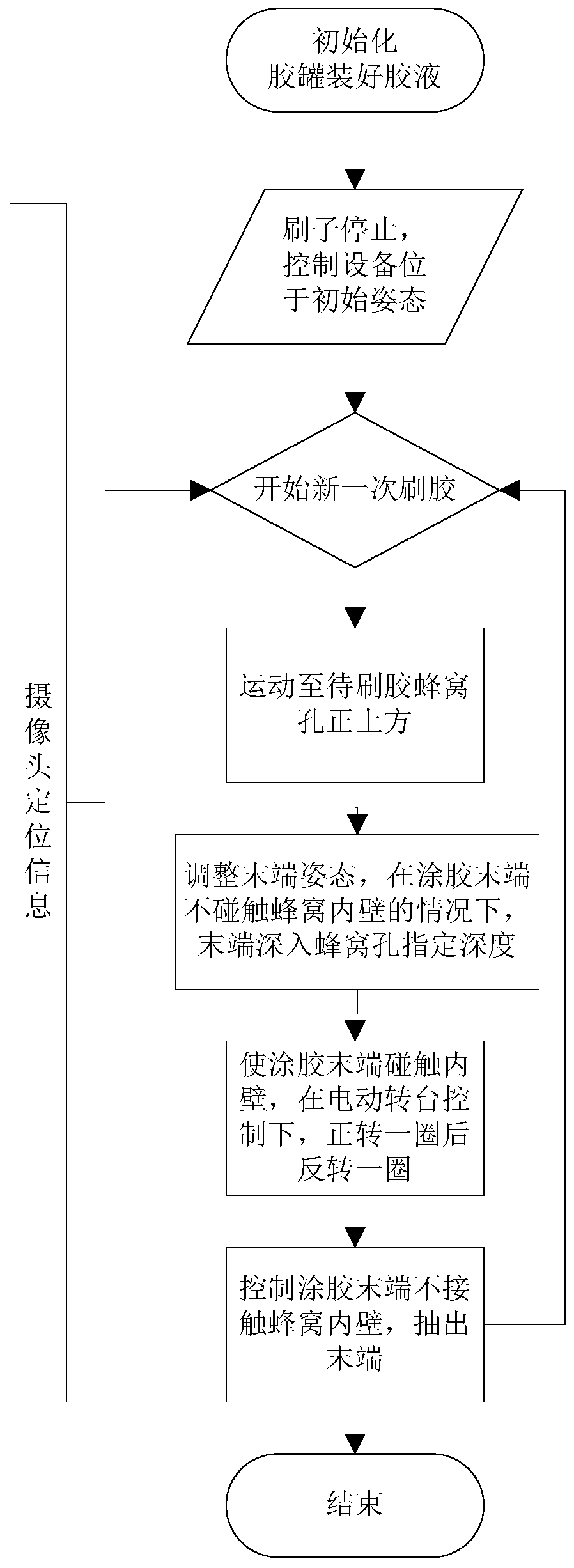

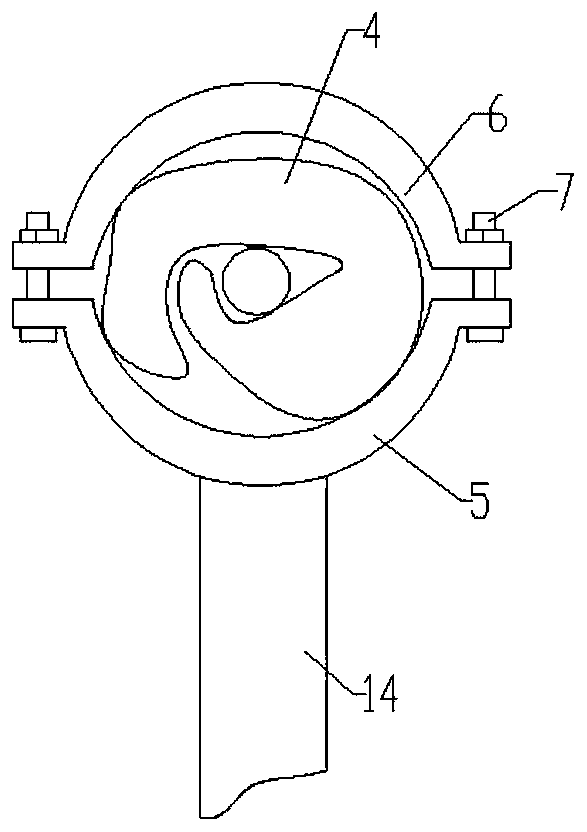

Mechanism for gluing honeycomb inner walls of honeycomb profile

ActiveCN111530705AIntegrity guaranteedPrecisely adjust the amount of glue in a single applicationLiquid surface applicatorsCoatingsHoneycombScrub brushes

The invention relates to a mechanism for gluing honeycomb inner walls of a honeycomb profile. Gluing of the honeycomb inner walls of the honeycomb profile is an important procedure of automatic processing of a composite honeycomb muffler cap, and the mechanism is used for the gluing process of the inner walls of honeycomb holes. A brush of a gluing head is of an eccentric structure, meanwhile thebrush can discharge glue only in one direction, a long and thin rod of the gluing head is an elastic unit, thus the glue discharging position of the brush makes contact with the honeycomb inner wallsall the time during rotation of the gluing head, and it is ensured that one circles of the honeycomb inner walls can be fully glued. Under control of a glue supplying system, the one-time gluing amount and the gluing speed can be accurately adjusted, and the phenomena of glue leakage and glue interruption are avoided.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

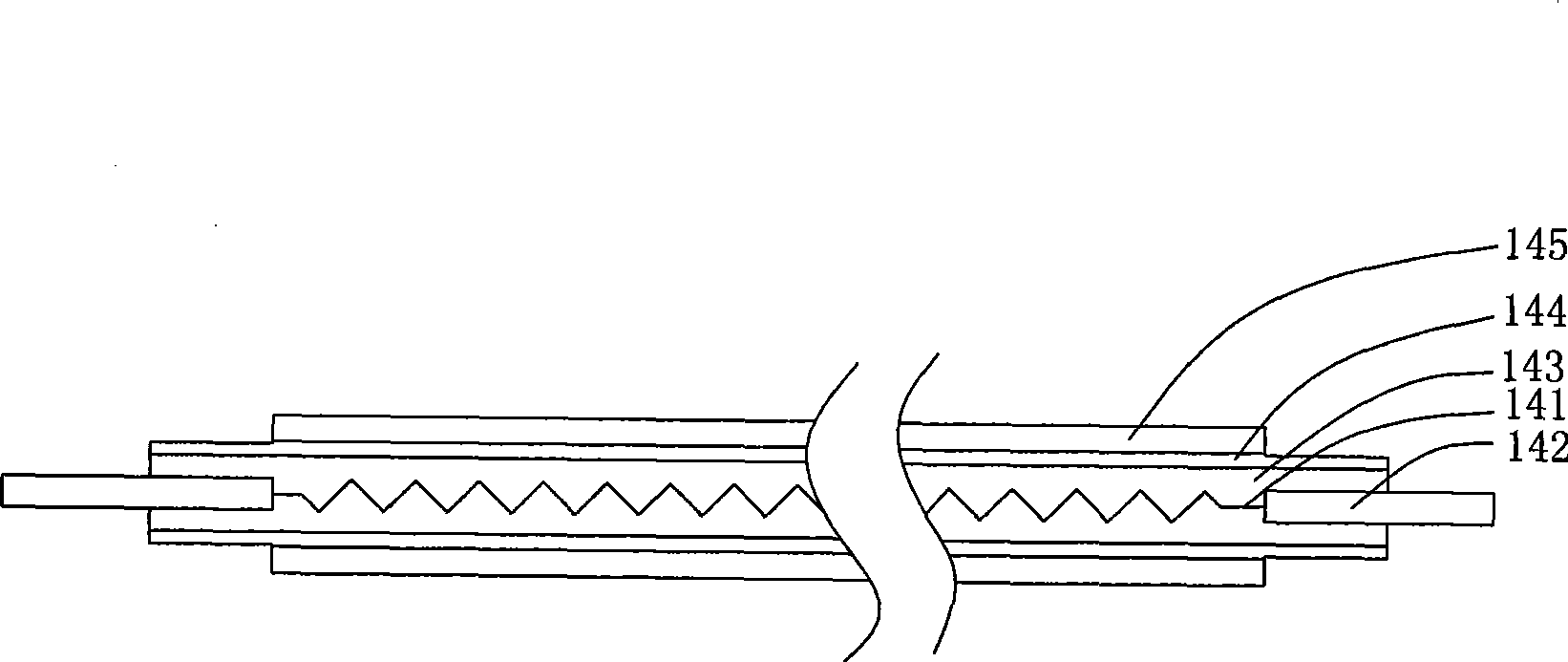

Gluer, temperature control device and heat conduction mechanism

InactiveCN101422981AIncrease contact areaGuaranteed glue qualityControlling laminationLaminationEngineeringHot pressing

The invention discloses a gluing machine and a temperature control device and a heat conducting mechanism thereof. The gluing machine comprises a rubber roll used for hot pressing against sheets, a heating unit for heating the rubber roll, the temperature control device comprising a control circuit and a temperature sensor, a heat conducting plate comprising a plane which is attached to a plane detection end of the temperature sensor and a cambered surface which is attached to the surface of the rubber roll. The output end of the control circuit is connected with the heating unit to control the work of the heating unit. The output end of the temperature sensor is connected with the input end of the control circuit for transmitting the temperature information of the rubber roll to the control circuit and the input end of the temperature sensor is the plane detection end. The invention can rapidly detect the temperature of the rubber roll of the gluing machine and accurately control the temperature.

Owner:SHENZHEN QIXIN GRP LLC

Method for compressing and compacting wood materials

ActiveCN108177209ASolve easy discolorationFix stability issuesWood veneer joiningColor changesSpecific modulus

The invention discloses a method for compressing and compacting wood materials, and belongs to the field of wood material production and preparation. According to the method for compressing and compacting the wood materials, the wood materials are subjected to hot-pressing and setting treatment under the vacuum condition, and the processed wood materials are large in specific modulus, and the technical problems that, in an existing wood material compressing and compacting technology, the hot-pressing and setting time of is long, manufacturing efficiency is low, the color changes, and the sizeis not stable are solved; and the wood materials are subjected to compressing and compacting manufacture under the vacuum condition, so that bonding strength of the wood materials laminated with glueis also improved.

Owner:NANJING FORESTRY UNIV

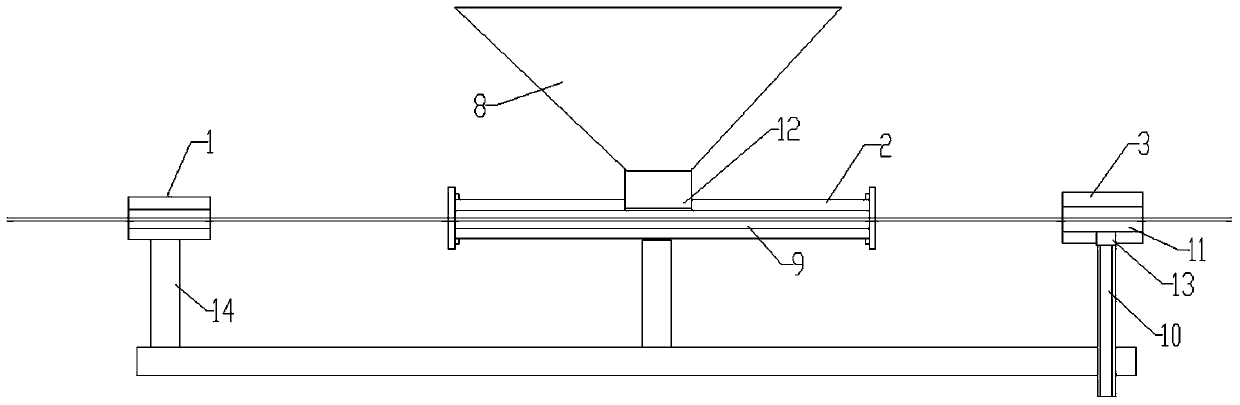

Packaging carton gluing machine

InactiveCN103600513ASimple structureReduce manufacturing costBox making operationsPaper-makingProduction lineCarton

The invention provides a packaging carton gluing machine so as to solve the problem that the gluing efficiency is low during short run production of packaging cartons or rework of the packaging cartons, and relates to the field of carton package production equipment. The packaging carton gluing machine comprises a power part and a machine frame part. The power part comprises a transmission case and a motor fixed onto one side of the transmission case, two gluing rollers are installed on the other side of the transmission case, the two gluing rollers are the upper roller and the lower roller respectively, a glue pump is fixed to the machine frame part and a glue outlet of the glue pump is arranged on the roller surface of the lower roller. The packaging carton gluing machine is simple in structure and low in manufacturing cost, can overcome the defect that a full-automatic packaging carton production line is not suitable for short run production, can be used during gluing rework or short run production of the cartons, greatly improves the gluing efficiency compared with manual gluing, and can well guarantee the gluing quality.

Owner:安徽南峰润邦绿色包装股份有限公司

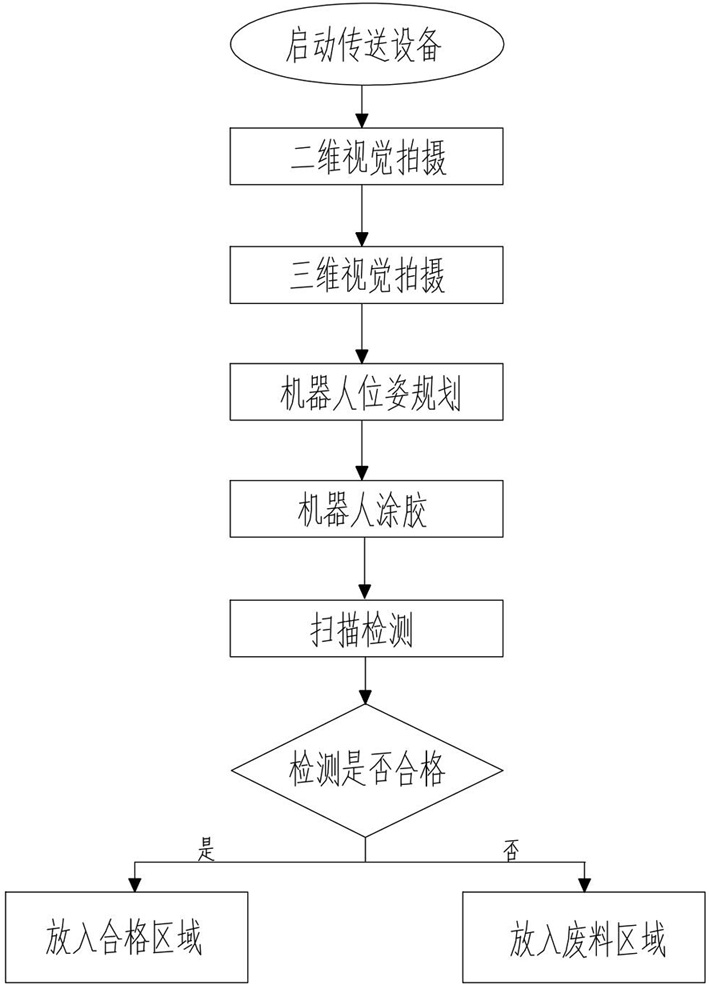

Robot gluing path planning method

InactiveCN113290556AIncrease productivityReduce product defect rateProgramme-controlled manipulatorLiquid surface applicatorsContour matchingEngineering

The invention relates to a robot gluing path planning method, which comprises the following steps of: starting conveying equipment, and driving a to-be-glued object by a conveying belt to enter a two-dimensional visual shooting area; then, photographing the to-be-glued object by a camera in the two-dimensional visual shooting area, and comparing two-dimensional drawings in a database according to the photographed picture so as to identify the corresponding product type; after collection is completed in the two-dimensional visual shooting area, driving the to-be-glued object by the conveying equipment to enter a three-dimensional visual shooting area, scanning the to-be-glued object by three-dimensional shooting equipment to obtain shape and size parameters of the to-be-glued object, and performing contour matching and comparison according to a database three-dimensional model to determine a gluing position; planning the pose of a robot by control equipment, and at the moment, the robot starting to perform gluing operation on the to-be-glued object; and driving the gluing object by the conveying equipment to enter a scanning detection area. According to the invention, the robot gluing path planning method, which is high in gluing precision, high-efficiency in mechanical gluing operation and wide in application range, can be provided.

Owner:苏州明图智能科技有限公司

Clamp for gluing pentagonal prism

InactiveCN102707410AReduce manufacturing costSimple production processMountingsManufacturing technologyEngineering

The invention discloses a clamp for gluing a pentagonal prism. The clamp comprises a baseplate, wherein two lateral plates are parallelly arranged on the baseplate; the space between the two lateral plates is equal to the width of the pentagonal prism; a back end plate is arranged between the two lateral plates on the baseplate; a pressing plate is movably arranged at the tops of the two lateral plates; a front end plate is also arranged on the baseplate; one side of the front end plate is in contact with the end surfaces of the two lateral plates; a plurality of positioning bolts are arranged on the side of each lateral plate close to the front end plate; a plurality of positioning bolts are also arranged on the front end plate; and one end of the pressing plate is rotatably arranged on one of the lateral plates, and the other end is detachably connected with the other lateral plate through the positioning bolts. The clamp provided by the invention has the advantages of low manufacturing cost and simple manufacturing technology, ensures the gluing quality of the pentagonal prism and simultaneously promotes the processing efficiency.

Owner:ZHANGJIAGANG CITY OPTICAL INSTR

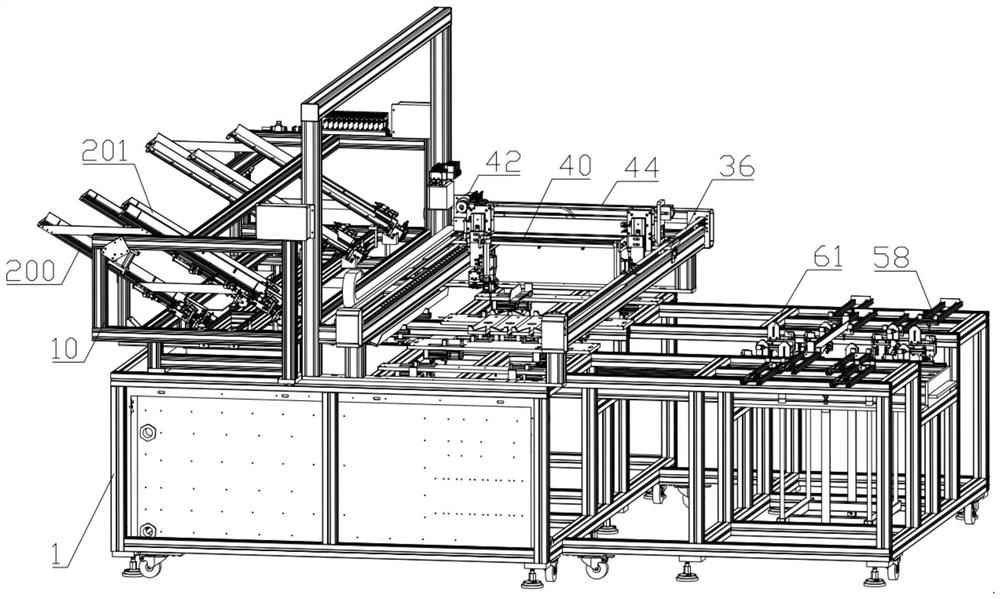

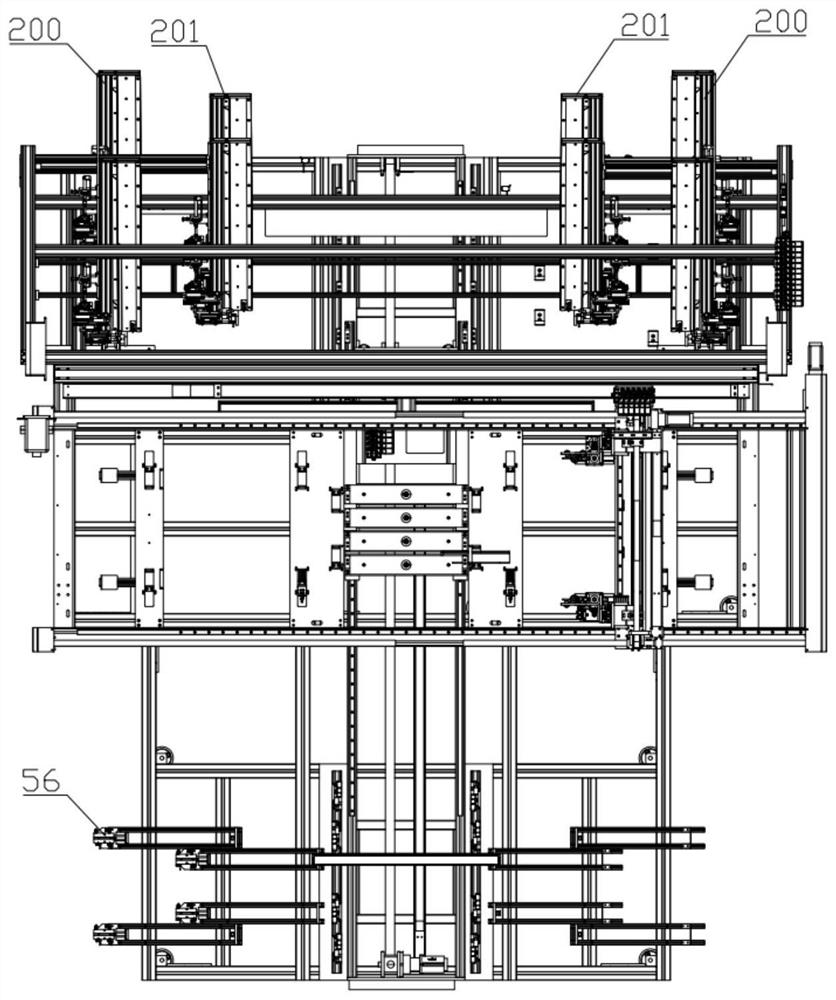

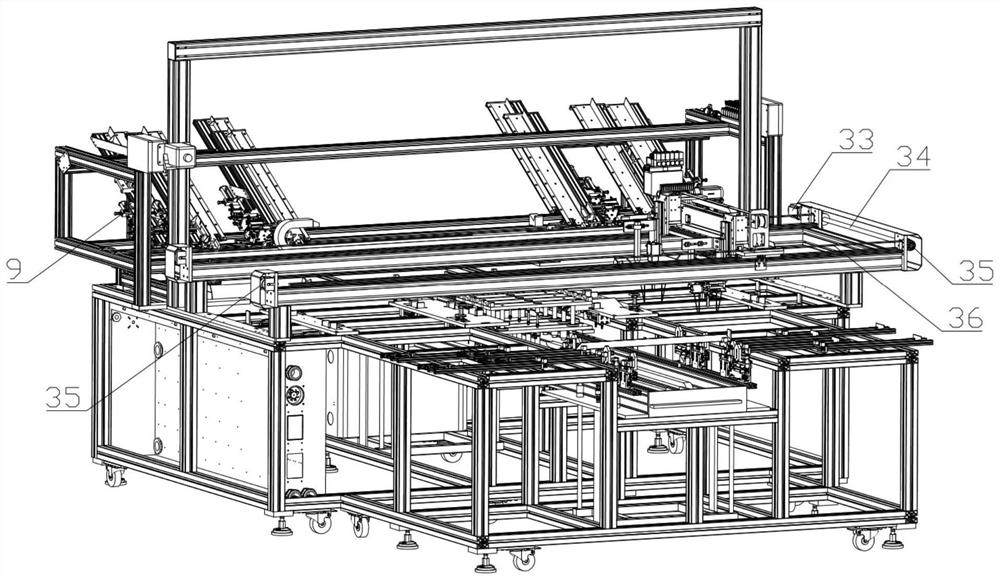

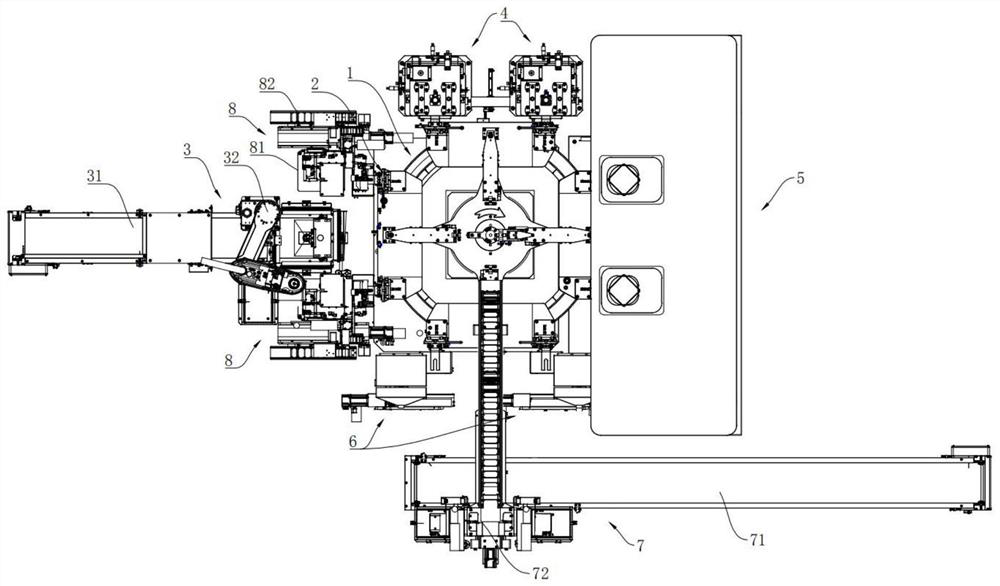

Efficient flexible double-gluing-head frame gluing machine

ActiveCN112934612AGuaranteed practicality and efficiencyImprove work efficiencyLiquid surface applicatorsCoatingsManufacturing engineeringIndustrial engineering

The invention discloses an efficient flexible double-gluing-head frame gluing machine. At present, a frame gluing machine integrating discharging of a storage bin, feeding of a transfer platform, gluing of a gluing system, discharging of the transfer platform and frame restoration does not exist. According to a double-load displacement separation feeding device disclosed by the invention, fallen materials of a storage bin falling device are conveyed to the double-glue-head gluing device for gluing, and a glued frame is conveyed to a frame restoration device for restoration. According to the gluing machine, the processes of discharging of the storage bin, feeding of the transfer platform, gluing of the gluing system, discharging of the transfer platform and frame restoration are integrated; The storage bin falling device realizes ordered falling of frames with different lengths and different widths; the double-glue-head gluing device is provided with a double-nozzle rotary gluing head and is provided with an online bilateral detection device, so that the application range is widened, and the gluing efficiency is improved; and the frame restoration device at the rear end of the gluing area meets the requirements of the industry on the arrangement and posture of the glued frame, and meanwhile, the working efficiency of a production line is further improved.

Owner:上海盛普流体设备股份有限公司 +1

Winding device and square power battery cell winding machine

PendingCN111106394APrevent tamperingGuarantee the quality of gluingFinal product manufactureSecondary cellsWinding machinePower battery

The invention provides a winding device and a square power battery cell winding machine. The winding device is provided with a winding station, a rubberizing station and a discharging station. The winding device comprises a winding head, and the winding head is provided with three winding needles. The three winding needles are respectively located at the winding station, the rubberizing station and the discharging station, and the winding needles are provided with limiting pieces. The winding device further comprises a first limiting unit which comprises a first rail. The first rail is arranged at the front end of the winding head. The first rail extends from the winding station to the discharging station in the rotating direction of the winding head. A first limiting face is formed on theface, facing the front end of the winding head, of the first rail. The projection of the first end of the first rail and the projection of the limiting piece at the winding station are staggered in the axial direction of the winding head, and the projection of the second end of the first rail and the projection of the limiting piece at the discharging station are staggered. The invention furtherprovides the square power battery cell winding machine provided with the winding device. The winding device and the square power battery cell winding machine can prevent the winding needles from moving in the axial direction of the winding needles in the reversing process of the winding head.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

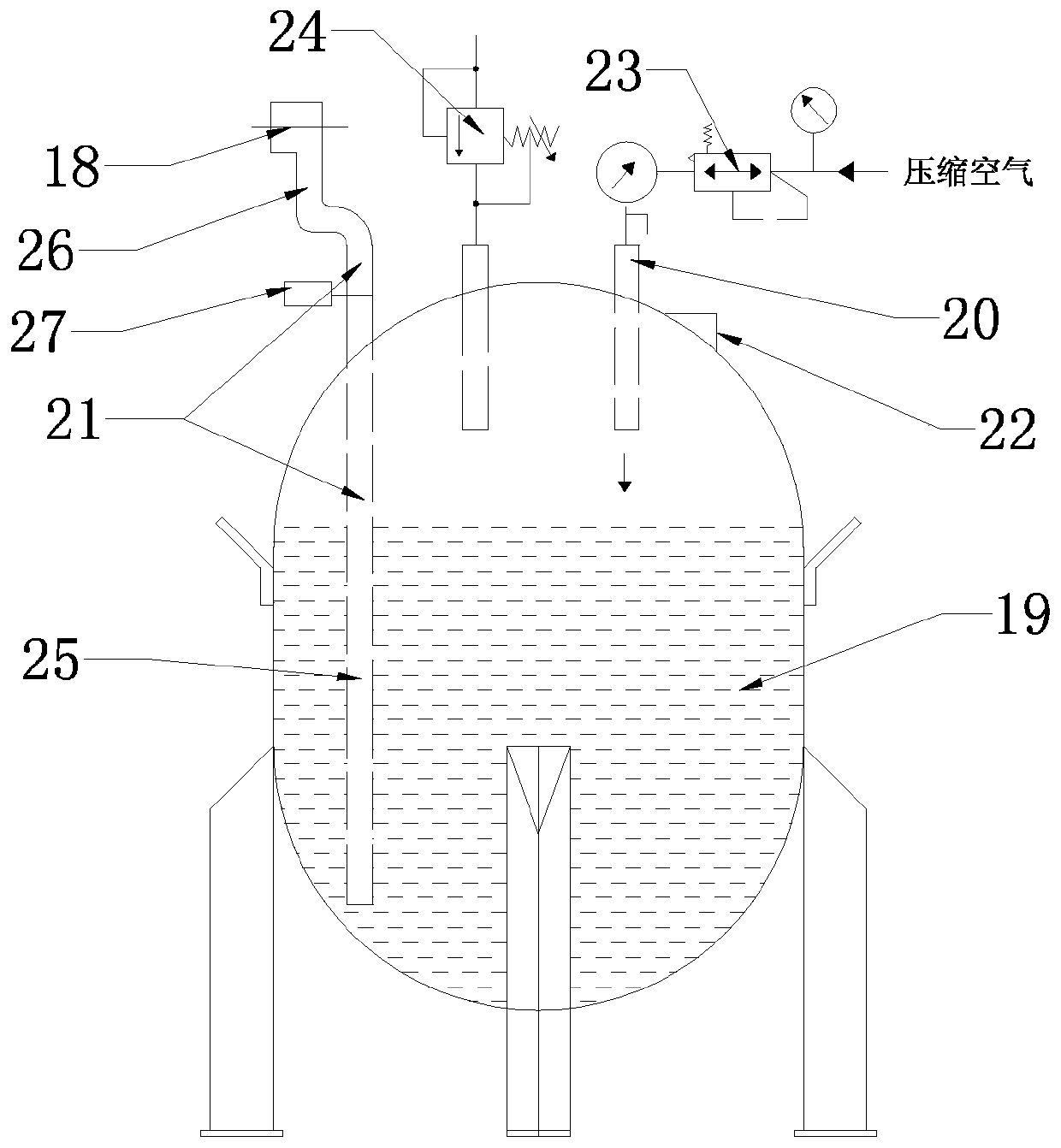

Novel glue applying device and method for steel wire

PendingCN110976201AGuaranteed stabilityReduce manufacturing costPretreated surfacesCleaning using toolsAdhesive glueAir pump

The invention provides a novel glue applying device for a steel wire. The novel glue applying device comprises a foreign substance remover, a glue applicator and a dryer which are arranged on a devicebody in sequence; the foreign substance remover includes a foreign substance removal component fixed by a clamping assembly; the glue applicator is provided with a glue storage hopper; a first wire guide slot arranged in the glue applicator communicates with the glue storage hopper; the dryer is connected with a vent pipe; a second wire guide slot arranged in the dryer communicates with the ventpipe; and air is supplied to the vent pipe by an air pump. The novel glue applying device is simple in structure and reasonable in design, and can perform continuous operation; by applying the device,foreign substances on the surface of the steel wire can be effectively removed and glue is evenly applied; meanwhile, it still can be guaranteed that the glue is rapidly dried and solidifies, and theglue and the steel wire are bonded more firmly; and the novel glue applying device has high operating efficiency and high quality.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Gluing machine

ActiveCN111992441AAvoid the risk of interference contaminationGuaranteed smoothnessFinal product manufacturePretreated surfacesMechanical engineeringIndustrial engineering

The invention discloses a gluing machine. The gluing machine comprises a conveying device, a product bearing device, a feeding device and a gluing device, wherein the product bearing device is connected with the conveying device; the feeding device and the gluing device are sequentially arranged along the conveying path of the conveying device; the gluing device comprises an upper glue dripping mechanism and a lower glue dripping mechanism; the glue dripping end of the upper glue dripping mechanism and the glue dripping end of the lower glue dripping mechanism are arranged in a staggered manner; the feeding device feeds products to the product bearing device; the conveying device conveys the product bearing device to pass the position between the upper glue dripping mechanism and the lowerglue dripping mechanism; and the upper glue dripping mechanism and the lower glue dripping mechanism conduct glue dripping on the products in sequence. According to the gluing machine, the glue dripping end of the upper glue dripping mechanism and the glue dripping end of the lower glue dripping mechanism are arranged in the staggered manner, then the upper glue dripping mechanism and the lower glue dripping mechanism conduct glue dripping on the products in sequence, the risk of mutual interference pollution of the upper glue dripping mechanism and the lower glue dripping mechanism is avoided, and therefore the gluing smoothness and the gluing quality are guaranteed.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Glue outlet control method of gluing machine and glue outlet control device

InactiveCN106694324AAvoid wastingAvoid pollutionLiquid surface applicatorsCoatingsInlet pressureMetering pump

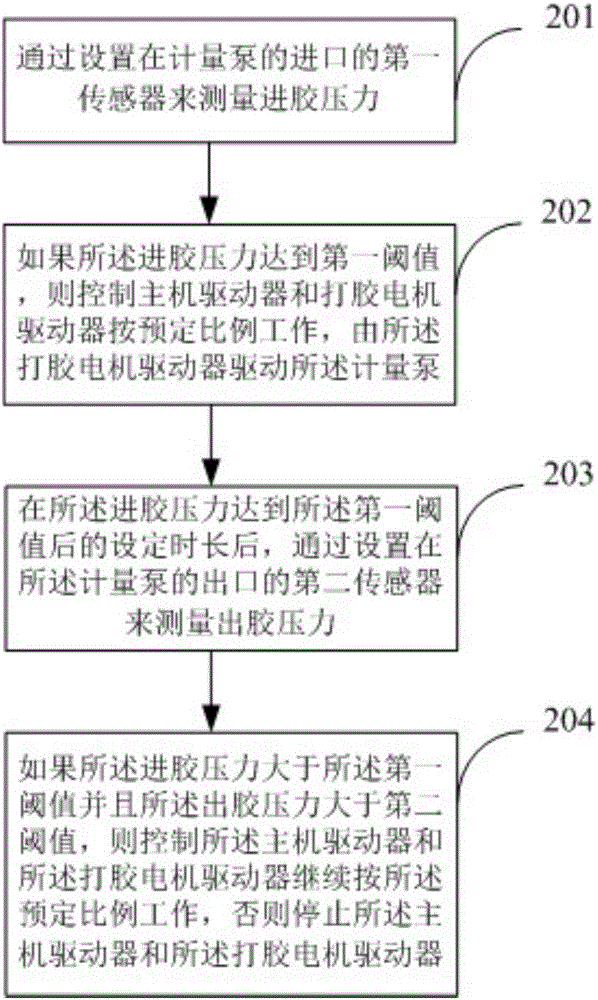

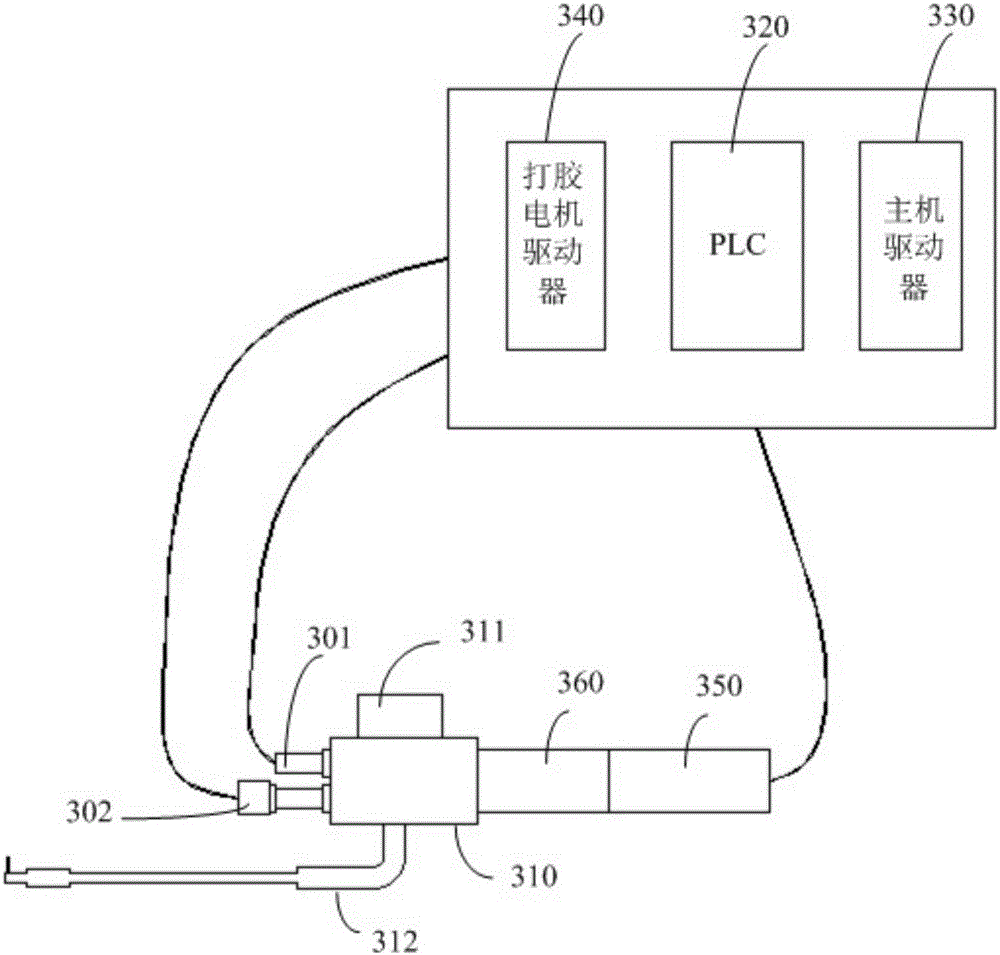

The invention provides a glue outlet control method of a gluing machine and a glue outlet control device, accurate and clean glue outlet control is provided for field gluing operation, the gluing quality is improved and the glue waste and the environmental pollution are prevented. The glue outlet control method of the gluing machine comprises the following steps that a first sensor arranged in an inlet of a metering pump is used for measuring the glue inlet pressure; if the glue inlet pressure reaches a first threshold, a host machine drive and a gluing motor drive are controlled to work according to a preset ratio, and the gluing motor drive drives the metering pump; after the glue inlet pressure reaches the first threshold for a set time length, a second sensor arranged in an outlet of the metering pump is used for measuring the glue outlet pressure; if the glue inlet pressure is higher than the first threshold, and the glue outlet pressure is higher than the second threshold, the host machine drive and the gluing motor drive are controlled to continuously work according to the preset ratio; and otherwise, the host machine drive and the gluing motor drive are stopped.

Owner:东方诚建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com