Patents

Literature

615results about "Coating impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-hydrophobic nanometer transparent coating and preparation method thereof

ActiveCN104987520AExcellent superhydrophobic propertiesHigh transparencyCoatings with pigmentsFibre treatmentOrganic solventUltrasonic dispersion

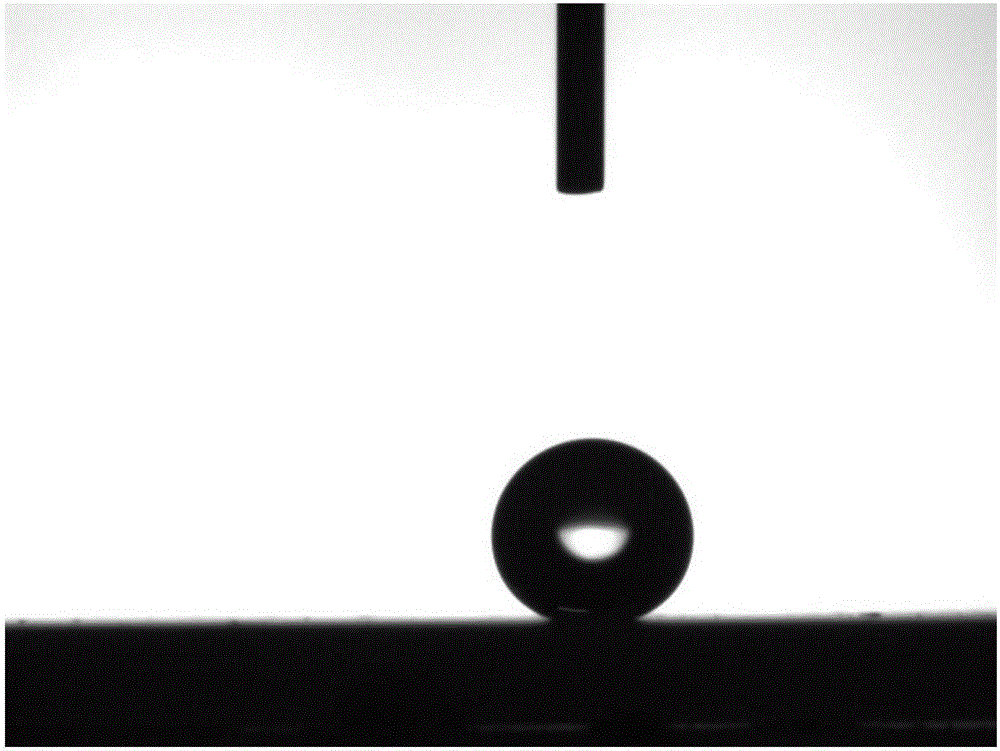

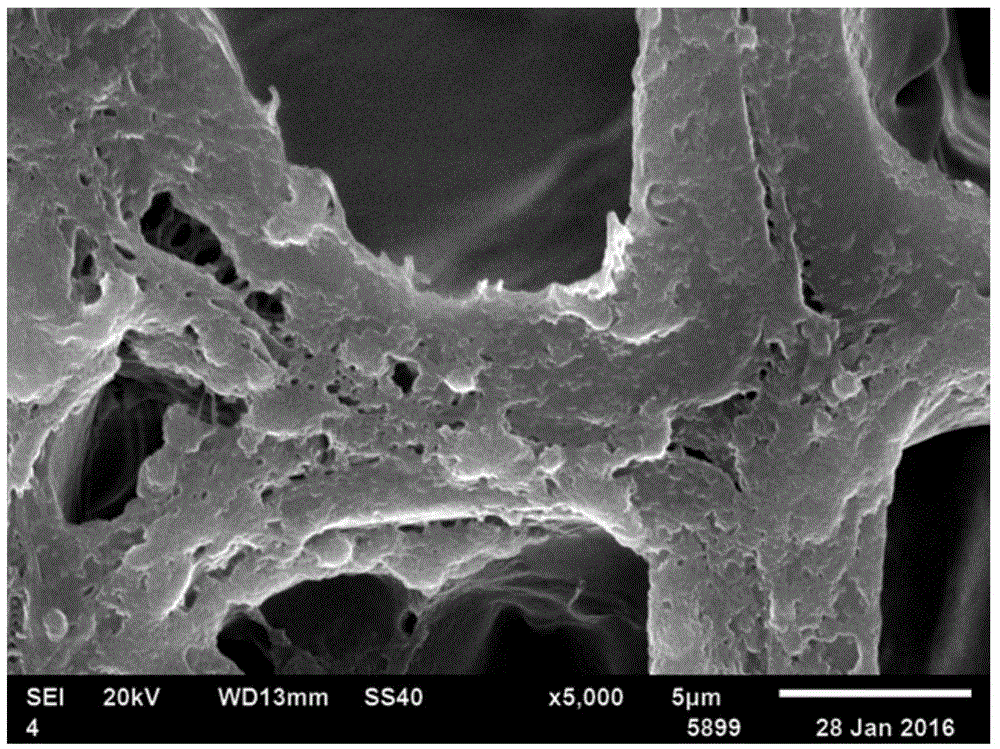

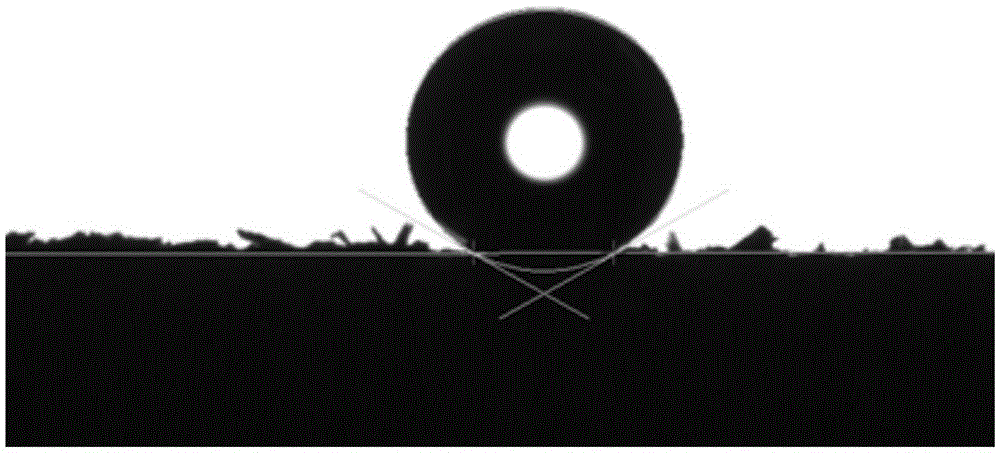

The invention provides a super-hydrophobic nanometer transparent coating and a preparation method thereof and belongs to the technical field of super-hydrophobic paint. The method includes the steps that firstly, a first category of inorganic nanometer particles are added into an organic solution, and ultrasonic dispersion is performed; secondly, dispersing agents and a second category of inorganic nanometer particles are added, and ultrasonic dispersion is performed so that a dispersion solution can be obtained; crosslinking agents and additives are added in the dispersion solution, ultrasonic dispersion is performed, finally, low-surface energy polymers are added, mixtures are evenly mixed, and transparent and clear super-hydrophobic paint is obtained; the surface of a solid base materials is coated with the transparent and clear super-hydrophobic paint, and the super-hydrophobic nanometer transparent coating is obtained through low-temperature thermal drying and curing. The super-hydrophobic performance of the super-hydrophobic nanometer transparent coating prepared through the method is excellent, the contact angle can be 160 degrees, the rolling angle is 1-7 degrees, the super-hydrophobic nanometer transparent coating can be sprayed to the surfaces of most of common materials, the morphology of the surfaces of the materials are not changed, and the application prospects and the application potency are very wide.

Owner:BEIHANG UNIV

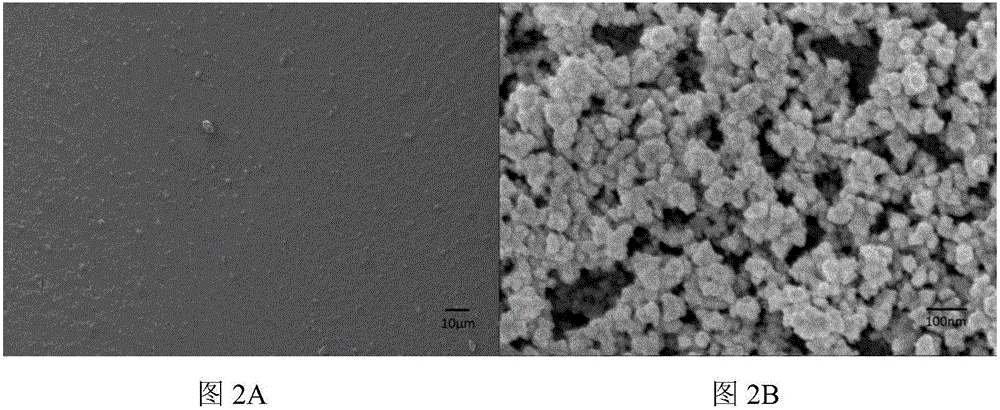

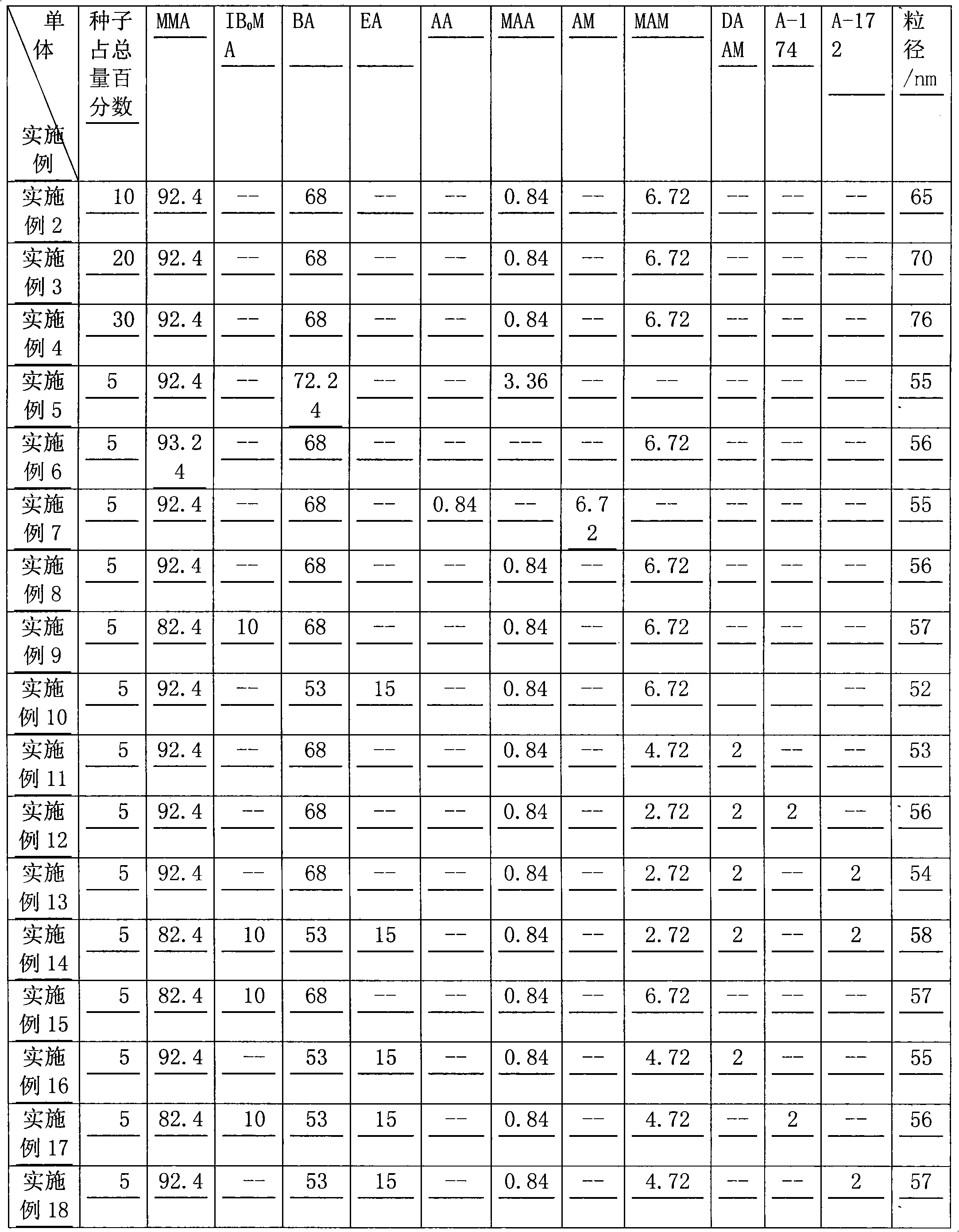

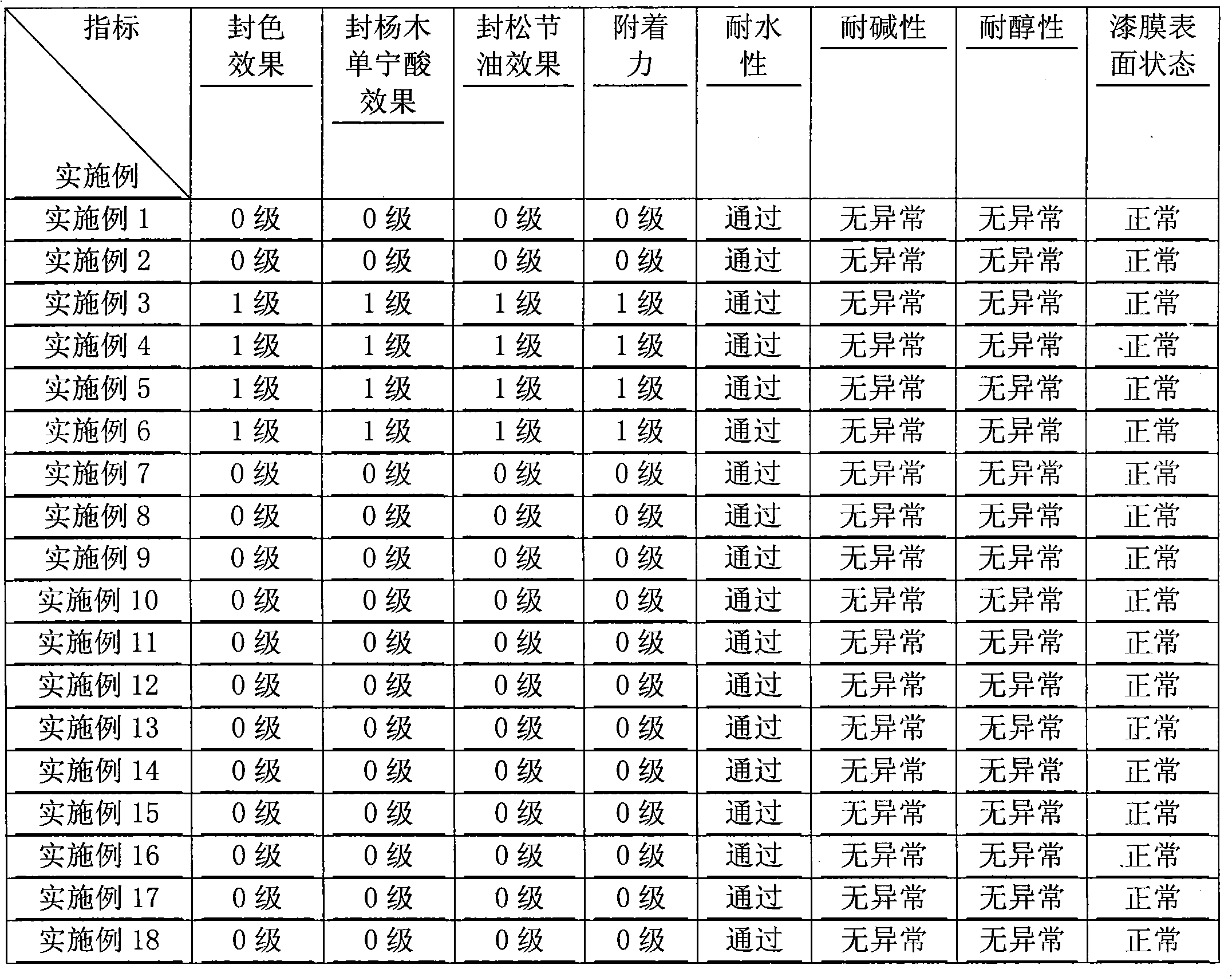

Aqueous acrylic acid series wooden ware sealing paint and method for preparing special emulsion thereof

InactiveCN101817906ASmall particle sizeImprove permeabilityCoating impregnationCoatingsFiberCoating system

The invention relates to aqueous acrylic acid series wooden ware sealing paint and a method for preparing special emulsion thereof. Nano emulsion with small particle diameter and narrow distribution is prepared by using an acrylic acid monomer containing multiple polar groups as a raw material. Multiple aids are added into the emulsion serving as a basic film-forming substance to form the novel aqueous wooden ware sealing paint. The polar functional groups on polymer molecule chains have good wetting property on wood, emulsion particles are easy to permeate into wood fiber conduits and quickly form films in conduit holes, and the paint can effectively prevent the moisture in the aqueous wooden ware paint from permeating into the wood and solves the problem of surface gully caused by the water-swelling wood; and meanwhile, the paint also can effectively seal the substances which are extremely easy to permeate to the outside such as turpentine, tannin and the like acknowledged in the wooden ware industry, and solves common problems for wide application of the aqueous wooden ware paint. The aqueous sealing paint also can be used for a solvent type paint coating system, and effectively prevents a large amount of solvent in the solvent type paint from penetrating into the wood during coating.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparation of superhydrophobic timber on the basis of sol-gel method

InactiveCN105599077AHas a superhydrophobic surfaceEasy to operateWood treatment detailsPretreated surfacesSilica nanoparticlesSilanes

The present invention pertains to a method for preparation of superhydrophobic timber on the basis of a sol-gel method, and the method is as follows: (1), silica sol synthesis, to be more specific, materials are prepared in the volume ratio of ammonia to anhydrous ethanol to ethyl orthosilicate of 1:15 to 17:1; (2), hydrophobic modification of monodispersed nano silica sol, to be more specific, hexadecyl trimethoxysilane, or triethoxysilane-1H, 1H, 2H, 2H-heptadecafluorodecyl silane is used for hydrophobic modification of the synthesized monodispersed nano silica sol, and the hydrophobic agent promotes mutual aggregation of nanoparticles to promote the formation of aggregates of silica nanoparticles; and (3) timber coating processing, to be more specific, the timber surface is coated with the hydrophobically modified silica sol solution by dipping or spraying process. Contact angles of the processed timber surface and water droplets are greater than 150 degrees, roll angles are less than 10 degrees, and a superhydrophobic film has good resistance to acid and alkali erosion and stability in high-humidity environment. The method is simple in operation, less demanding on equipment, and capable of scale production, and has wide market prospects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

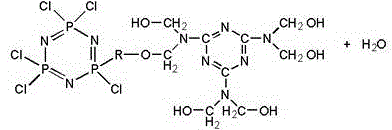

Preparation method of chitin metal salt wood preservative and its application

InactiveCN1459466AGood chemical stabilityImproves loss resistanceCoating impregnationCoatingsWater insolublePreservative

A chitosan-metal salt chelate as the wood preservative is prepared through dispersing chitosan or its derivative in water, dispersing at least one salt of Cu, Zn, or rare-earth metal in it, heating to 36-60 deg.C for 1.5-5 hr to obtain water-insoluble chelate, and adding at least one dilute acid to become water soluble while regulate its pH value to 2-6.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Preparation method of organic-inorganic hybrid super-hydrophobic and oleophobic wood modifier with mold-proof, sterilization, anti-flaming and weather-proof properties

ActiveCN105619558AImproved antiseptic performanceGood weather resistanceWood treatment detailsCoating impregnationWater basedEdible oil

The invention relates to a preparation method of a wood modifier, in particular to a preparation method of an organic-inorganic hybrid super-hydrophobic and oleophobic wood modifier with mold-proof, sterilization, anti-flaming and weather-proof properties, and belongs to the field of preparation of wood modifiers. The preparation method aims to solve the technical problems that existing wood modifiers have high toxicity, special peculiar smells and poor run-away resisting capacity, pollute the environment and are simplex in function. The preparation method comprises the steps that organoalkoxysilane, deionized water and absolute ethyl alcohol are mixed; a functional reagent A is added for a reaction; a functional reagent B is added for a reaction; a fluorine-containing silane coupling agent is added for a reaction; a water-based fluorine-containing high-molecular compound, a curing agent and a functional reagent C are added, the mixture is stirred, and the modifier is obtained. The static water contact angle of the surface of wood modified by the modifier can reach 150 degrees or above, and the rolling angle is smaller than 10 degrees. The edible oil contact angle of the modified wood surface can reach 120 degrees or above, and modified wood surface has the oleophobic characteristic. In addition, the corrosion prevention and sterilization performance of the modified wood is improved by 90% or above, the weather resistance of the modified wood is improved by 10 times, and the anti-flaming performance of the modified wood is also remarkably improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Aqueous sealant system, wood product and method for sealing wood substrate

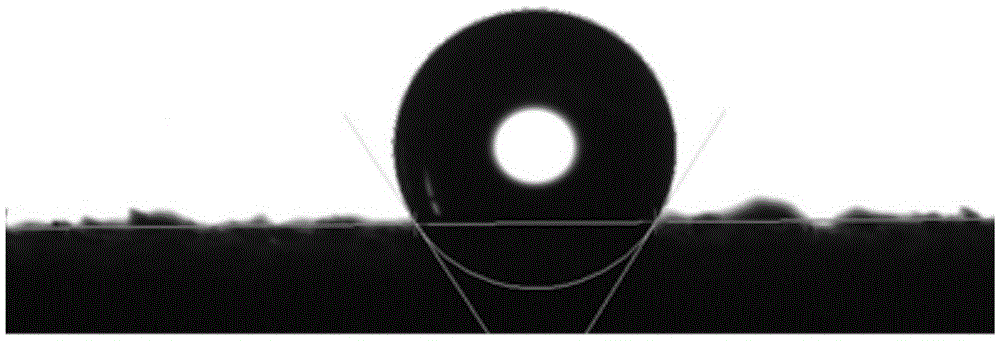

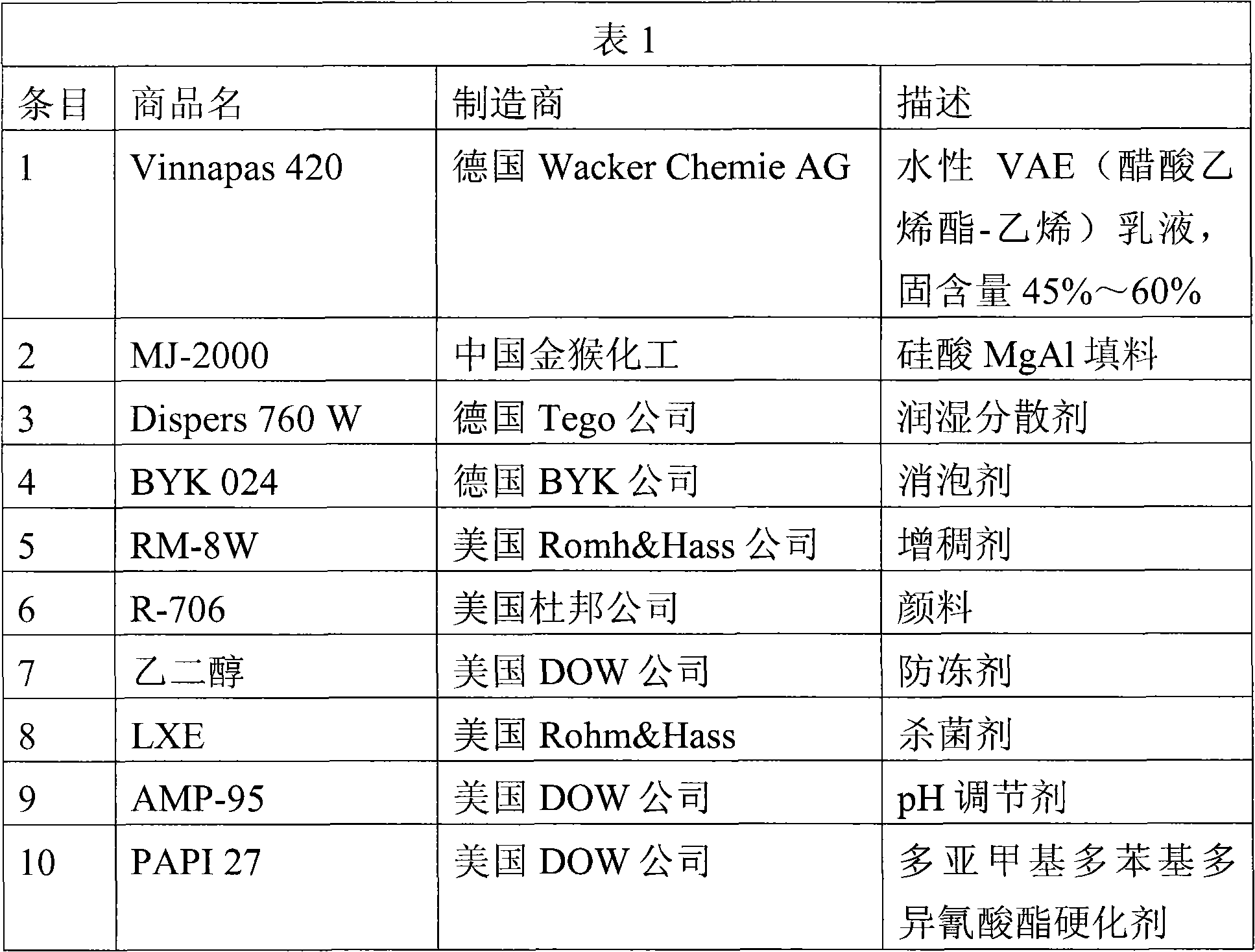

InactiveCN102115630AEasy to closeImprove barrier propertiesLayered productsWood treatment detailsHydrogenEmulsion

The invention relates to an aqueous sealant system, a wood product and a method for sealing a wood substrate, in particular to an aqueous sealant system, a wood product sealed by the aqueous sealant system and a method for sealing a wood substrate by using the aqueous sealant system. The aqueous sealant system comprises: (a) a film forming resin composition which comprises an active hydrogen polymer-containing aqueous emulsion, a filler and an optionally-added additive, and (b) a polyisocyanates hardener, wherein the weight ratio of the film forming resin composition (a) to thepolyisocyanates hardener (b) is 100:3-100:10.

Owner:GUANGDONG HUARUN PAINT CO LTD

Wood preserving composition for treatment of in-service poles, posts, piling, cross-ties and other wooded structures

ActiveUS20080193640A1Improve stabilityLow toxicityBiocideInorganic active ingredientsPreservativeFluoride

This invention discloses a wood preservative composition for the supplemental or remedial treatment of in-service poles, posts, piling, cross ties and other wooden structures. The wood preservative composition comprises copper 8-hydroxyquinolate (oxine copper) in combination with a boron compound or a fluoride compound.

Owner:OSMOSE UTILITIES SERVICES

Method for improving mechanical stability of super-hydrophobic film on wood surface

ActiveCN105563577AHigh mechanical strengthEasy to operateWood treatment detailsPretreatment apparatusEpoxySilanes

The invention belongs to a method for improving mechanical stability of a super-hydrophobic film on a wood surface, which comprises the steps of: (1) coating the wood surface with a layer of transparent epoxy resin bottom layer to fill the concave structures on the wood surface so as to obtain a smooth surface; (2) preparing a silicon dioxide nanoparticle / epoxy resin / triethyloxy-1H,1H,2H,2H-heptadecyl fluoro decyl silane organic-inorganic composite coating solution; and (3) carrying out multiple immersion coating treatment on the wood provided with the epoxy resin bottom layer with the composite solution to obtain enough coating thickness, and heating for curing to obtain the super-hydrophobic wood. The wood treated by the method has the super-hydrophobic surface with high mechanical strength, and has good mechanical stability and durability. The method is used for solving the problems that the super-hydrophobic wood film layer prepared by the traditional method has poor stability and relatively short service life, is simple in operation, easy to realize and low in cost, can be used for scale production, and has good application prospects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Method for improving performance of superhigh temperature heat-treated wood

ActiveCN101774195APlay a protective effectAvoid or reduce strength lossCoating impregnationCoatingsBorideAqueous solution

The invention belongs to the field of wood modification, in particular to a method for improving the performance of superhigh temperature heat-treated wood. In the method, boride is selected to prepare aqueous solution; then, the wood is impregnated with the boride aqueous solution to ensure that the drug-loading rate of the boride in the wood is between 2.8 and 12kg / m3; after air drying, the wood is dried and heated to realize improvement of the performance of the superhigh temperature heat-treated wood. The method has simple process and low cost, and pretreats the wood by using the boride before heat treatment so as to play roles in protecting the wood, reducing degradation of hemicellulose and the like, avoiding or reducing strength loss of the wood in high temperature heat treatment, making up the defect that the heat-treated wood does not resist worm damage, and improving the application value of the heat-treated wood.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Method for mfg. sterilizing nano plates

InactiveCN1792581AImprove anti-corrosion performanceImprove mildew resistanceWood treatment detailsCoating impregnationPolymer scienceLacquer

A nano-antibacterial board is prepared through treating basic board by the dispersed liquid of nano-Ag and nano-TiO2, mixing nano-Ag, nano-TiO2, stabilizer and disperser with paint, stirring, coating the mixture on the treated board, treating a surface paper in a nano-Ag dispersed liquid, sticking it on painted board, and hot pressing.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Method for processing lumber-core board

InactiveCN1796069AQuality improvementGuaranteed curing qualityWood treatment detailsCoating impregnationTrappingPulp and paper industry

The present invention relates to a production process of veneered strip-glued board. Said process includes the following steps: sawing raw material to obtain squared timber, drying, defining thickness and processing double faces, making strips by using multiblade saw, making board, coating adhesive, matching board, forced cooling, first sanding, sticking transverse single board, prepressing, hot-pressing, forced cooling, secondary sanding, sticking surface board, secondary prepressing, secondary hot-pressing, cutting edge, third sanding, sorting finished products and putting the finished products into storage. The urea-formaldehyde adhesive formula used in the adhesive-coating process is formed from (by weight portion) 100 portions of low-formaldehyde urea-formaldehyde resin, 20-35 portions of filling agent, 5-10 portions of formaldehyde trapping agent and 0.4-1.0 portion of solidifying agent.

Owner:CHANGLIN WOOD IND

Method for smearing wood wax oil on surface of wood product

InactiveCN103182725AIncrease exerciseIncrease oil intakeCoating impregnationCoatingsWaxEnvironmentally friendly

The invention relates to a method for smearing wood wax oil on the surface of a wood product, which comprises the following steps: 1, smoothening; 2, smearing the wood wax oil; 3, kneading a wax oil coating on the surface; 4, wiping floating oil; 5, drying; 6, repeating the steps 2-5 for one or two times; 7, polishing till the hand feeling is smooth; and 8, spraying polishing wax, polishing and entering a next assembly process. By using the method, the crack of the wood product can be effectively prevented, and the service life is prolonged; the operation is simple, and materials, labors and oil are saved; the wood wax oil is a green and environmentally-friendly coating and a low-carbon environmentally-friendly product; and by using the method, the wide application of the wood wax oil can be promoted, and an important significance on environment friendliness is realized.

Owner:张克广

Super-hydrophobic composite coating, and preparation method and application thereof

ActiveCN108017958AImprove hydrophobicityImprove wear resistanceWater-repelling agents additionCellulose coatingsSilica particleWhiskers

The invention provides a super-hydrophobic composite coating. The super-hydrophobic composite coating comprises nano cellulose whiskers and hydrophobically modified silicon dioxide compounded on the nano cellulose whiskers. The invention also provides a preparation method and application of the super-hydrophobic composite coating. Through the structure that the silica particles are compounded on the nano cellulose whiskers, lasting wear resistance is provided for the super-hydrophobic coating. The coating has a simple preparation process, and can be conveniently used for preparing a super-hydrophobic coating.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Anti-cracking method for woods

ActiveCN106426449ALipophilicImprove immersionWood treatment detailsPretreatment apparatusBatch operationPulp and paper industry

The invention relates to the technical field of wood processing, in particular to an anti-cracking method for woods. The anti-cracking method includes the steps: a, treating raw woods: firstly taking raw woods needing to prevent cracks, drying in the shade, and cutting the raw woods into plates; b, drying the plates: drying by the aid of a pressure reducing and drying method to obtain the dried plates; c, performing anti-cracking treatment: soaking the dried plates by the aid of wood anti-cracking agents, taking out and placing for 10-36h under the pressurized environments, moving the plates into a room, and drying in the shade; d, preparing wood finished products: preparing the wood finished products according to needs, painting the wood anti-cracking agents on the surfaces of the wood finished products for 1-5 times, and drying in the shade to obtain anti-cracking woods. The anti-cracking method has the advantages that the method is green and environmentally friendly, the treated woods are good in anti-cracking effect and durability, and cracking rate of the treated woods is reduced. The whole production process is controllable and nontoxic, and the anti-cracking method is applicable to batch operation of factories.

Owner:南通华尔利亚木业有限公司

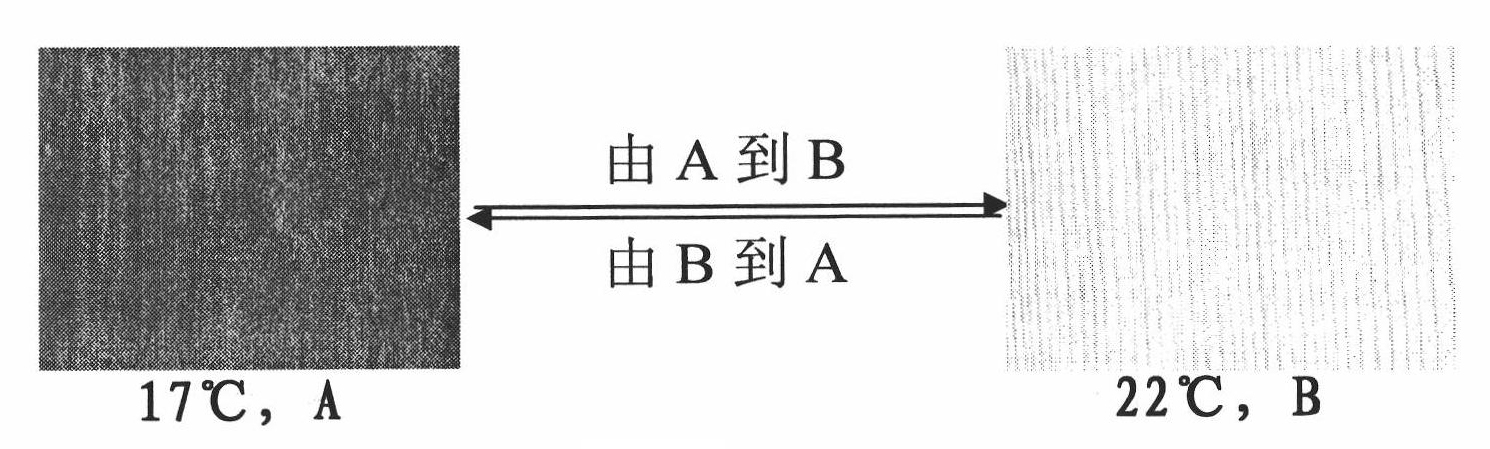

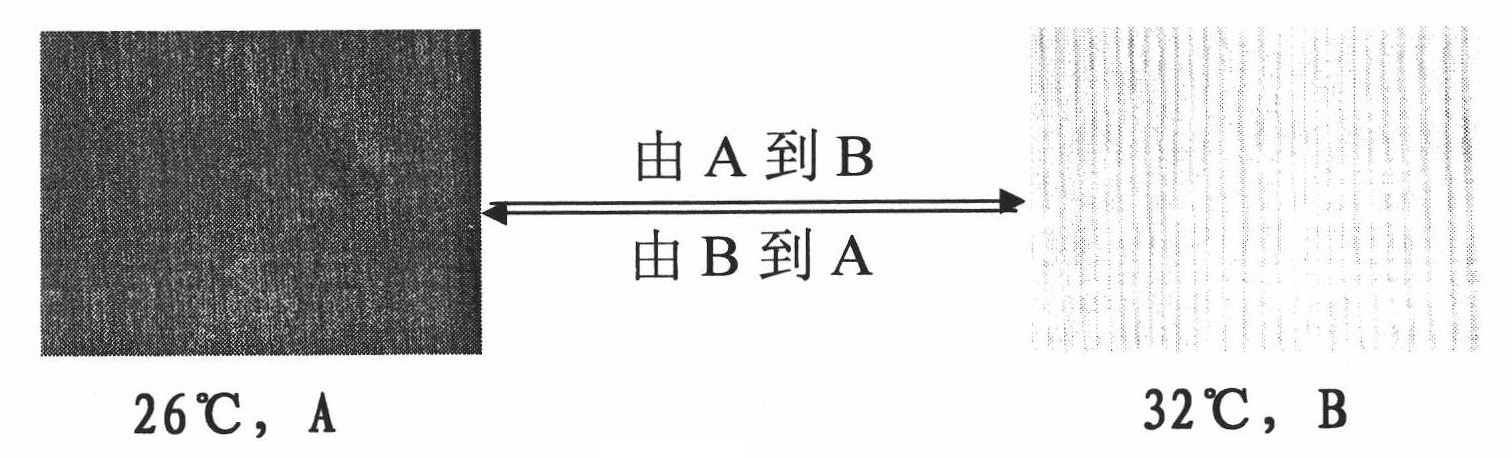

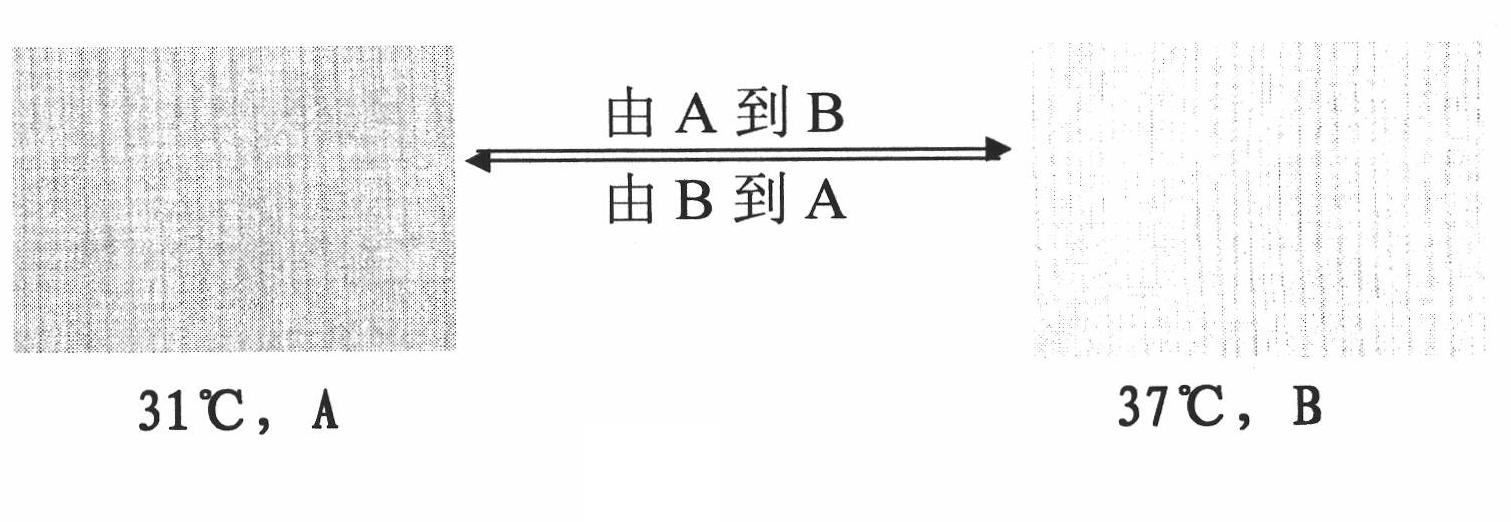

Temperature-sensitive reversible color wooden material and manufacturing method thereof

InactiveCN101817192AImprove color changing performanceHigh sensitivity to discolorationCoating impregnationCoatingsAdditive ingredientColor changes

The invention discloses a temperature-sensitive reversible color wooden material and a manufacturing method thereof. The surface of the temperature-sensitive reversible color wooden material is provided with a temperature-sensitive reversible color functional layer; the functional layer is formed by dipping temperature colour-changing agent into the wooden material from the surface and remaining the agent in the pore of wooden material; the temperature-sensitive reversible color functional layer can be reversibly changed into another color from one color along with the change of temperature in a preset temperature zone. The wooden material of the invention can be used as wooden structure material and can be used as wooden facing material. The invention also discloses a special temperature colour-changing agent which mainly comprises procrypsis agent, colour-developing agent and solvent, wherein the procrypsis agent determines color change, the colour-developing agent determines color change shade, and the solvent determines color change temperature; the proportion of three ingredients is adjusted to control color, color change degree and color change temperature zone of temperature colour-changing wooden material.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Color smoking treatment technology for wood modification face layer

ActiveCN105729597ADrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSmoking treatment

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

Method for inducing wood discoloration by using chemical color-changing agent

ActiveCN109434993AImprove color saturationStrong sense of hierarchyWood treatment detailsThermal wood treatmentColor saturationColor changes

The invention discloses a method for inducing wood discoloration by using a chemical color-changing agent. The method comprises the following steps that firstly, a precursor substance solution is coated on the surface of wood, then the surface of the wood is coated with the color-changing agent after drying, and drying is carried out again to complete the color change of the wood to obtain a finished product. According to the method, the color saturation after chemical color change of the wood can be improved, so that the color of the wood is more easy to display after the wood is subjected tothe color change, the excellent permeability performance is achieved, the bonding strength of the wood color-changing layer is higher, the loss resistance is better, moreover, the displayed color isnatural and beautiful, the texture is clearer, the layering sense is stronger, and the color is richer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Flame-retardant oriented strand board

ActiveCN105619565ASolving Diversity Matching ProblemsWell-Matched SynergiesWood treatment detailsWood veneer joiningChlorideEngineering

The invention relates to boards, in particular to a flame-retardant oriented strand board. The flame-retardant oriented strand board comprises a core layer oriented four-layer laying flame-retardant strand layer and facing layers which are pressed and glued to the upper surface and the lower surface of the core layer oriented four-layer laying flame-retardant strand layer correspondingly. A fire retardant in the flame-retardant strand layer is a magnesium-aluminum nano layered double metal hydroxide fire retardant. The fire retardant comprises, by molar mass, 1-5 parts of magnesium chloride, 0.5-1.2 parts of aluminum chloride, 0.5-1 part of sodium hydroxide and 0.6-1.3 parts of sodium carbonate. The facing layers are made of anyone of decorative paper, veneer or engineered veneer. When the facing layers are made of the decorative paper, balancing layers are further pressed and glued between the core layer oriented four-layer laying flame-retardant strand layer and the facing layers. The engineered veneer with the required thickness is formed by slicing functional engineered wood. The flame-retardant strand layer is vivid in decoration effect, low in cost and good in formaldehyde purifying effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Method for willow artwork dyeing through natural indigo pigment

ActiveCN107253249AGood colorGood spotlightRadiation/waves wood treatmentWood treatment detailsSteepingDistillation

The invention discloses a method for willow artwork dyeing through a natural indigo pigment. The method comprises the following aspects that (1) indigo extraction is conducted, specifically, a plant raw material is subjected to crushing, fermentation, water soluble extraction and low-temperature drying, and the indigo pigment is prepared; (2) acid-alkali steeping is conducted, specifically, a hydrochlric solution with the concentration being 0.3-0.4% and a sodium hydroxide solution with the concentration being 0.25-0.3% are used to steep a willow artwork correspondingly; (3) cooking for impurity removal is conducted, specifically, impurities in the willow artwork is removed through cooking; (4) steaming for dyeing is conducted, specifically, the indigo pigment with the mass being 11-13% that of distillation boiler water is added, and steam dyeing is conducted; (5) low-temperature drying is conducted, specifically, the dyed willow artwork is dried; (6) infrared color fixing is conducted, specifically, the willow artwork is wrapped through mixed slurry and placed under infrared lamplight with the illumination intensity being 470-520 lux for color fixing; (7) ultraviolet inspection is conducted, specifically, the willow artwork subjected to color fixing is placed under an ultraviolet lamp, and the color fixing condition is inspected; and (8) tung oil layer coating is conducted, specifically, the willow artwork qualified after inspection is coated with tung oil, and after drying, the willow artwork with the natural indigo pigment is prepared.

Owner:阜南县宏达工艺品厂

Production method of antiseptic fire-retardation artificial board

InactiveCN101491904AGuaranteed log propertiesTo achieve comprehensive safety anti-corrosion flame retardant effectOther plywood/veneer working apparatusWood treatment detailsSpray coatingEngineering

The invention relates to a method for producing an antiseptic and flame-retarding artificial board, which comprises: 1) a step of preparing soaking solution, in which a flame-retarding antiseptic agent and water are mixed and stirred according to a ratio of 1:1; 2) a step of preparing a core board; 3) a step of paving a board; 4) a step of prepressing, in which the board is prepressed under a pressure of 5 to 6kgf / cm for one hour to be made into a bland board; 5) a step of hot pressing, which is carried out under a pressure of 10kg / cm and at a temperature of between 120 and 140 DEG C; 6) a step of forming the blank board and a veneer through hot press molding, in which the whole formed blank board is placed in a roll coating machine again to be coated with glue on the surface and is adhered with the veneer, and then the blank board and the veneer are set and sized by a prepress for one hour and pressed in a hot press and heated for 5 to 10 minutes at a temperature of 110 DEG C; 7) a step of polishing and trimming; and 8) a step of spray coating a panel. The method has the advantage that the artificial board produced by the method has ensured wood properties and achieves an overall safe, antiseptic and flame-retarding effect.

Owner:沈孜明

Composition and method for finishing surface of preservative-treated wood engineering material used outdoors

InactiveCN103013328AResist decayResist mildewAnti-corrosive paintsCoating impregnationLoss rateOrganic film

The invention relates to a composition and method for finishing thwe surface of a preservative-treated wood engineering material used outdoors. The composition comprises an organo-silicon polymer, a holy polymer resin, a titanic oxide, an organic solvent component and a monomer mixture. An organic film is formed on the surface of the preservative wood engineering material through a surface finishing technology so that the surface ornamental feature of the wood engineering material is increased, simultaneously the preservative wood engineering material is endowed with good water-resisting property and weather resistance property, the outdoor use performance of the preservative wood engineering material is increased, the service life of the preservative wood engineering material is effectively prolonged, and the damage to environments is reduced. The preservative wood engineering material obtained by the invention has the advantages that the loss rate of an effective constituent copper is reduced from above 90% to 8%-15%, wherein the loss rate of the copper in an untreated material is above 90%, and after aging tests, the chromaticity indexes delta a*, delta b*, luminosity equation delta L* and chromatism delta E*of the surface of the treated material are obviously less than that of the untreated material, the weight loss rate of the treated material is 5%-8%, and the strength loss of the treated material is 5%-12%.

Owner:TIANJIN UNIV OF SCI & TECH

Method for making artificial pine heartwood

This invention relates to the production of artificial pine heartwood. More particularly, the invention relates to a method for treating sapwood from trees of the family Pinaceae with rosin and / or a rosin derivative in order to give the treated sapwood physical and esthetic properties similar to that exhibited by yellow pine heartwood.

Owner:MEADWESTVACO CORP

Method for mould and moth preventing for bamboo product

InactiveCN107283576AEasy to useIncrease viscosityWood treatment detailsReed/straw treatmentDiseaseSludge

The invention relates to the technical field of bamboo artware processing, and discloses a method for mould and moth preventing for a bamboo product. The method comprises the following steps that firstly, newly-cut bamboo is wrapped by sludge in a pond, the sludge contains abundant nutrients suitable for growth of parasites, meanwhile, the viscous force is very large, the sludge has very strong adsorption force, disease pests and mould hidden in the bamboo are wrapped and adsorbed, and substances, causing insect damage and mould, in a bamboo body are transferred out; secondly, fumigated bamboo is placed in alums water to be immersed, alums has a very good restraining function on various gram negative and positive cocci and bacilli, Chinese herbal medicine liquid is used for fumigation after immersing, and it can be guaranteed that the bamboo product is not damaged by mould or moths for a long term through essential oil generated by the Chinese herbal medicine liquid; and thirdly, waterproof varnish is applied to the processed bamboo product, and the longer service life can be kept.

Owner:阜南县中信柳木工艺品有限公司

Drying method for wood

InactiveCN106393342AFast dryingStable Quantitative ProductionRadiation/waves wood treatmentWood treatment detailsMicrowaveWood plank

The invention discloses a drying method for wood. The drying method comprises the following steps that A, the wood is pre-planed, and the wood is cut into boards with the same size; B, the pre-planed wood is soaked with brine; C, the wood soaked with the brine is wrapped with tin foil paper and baked; D, the baked wood is coated with a wood anti-cracking agent, and then the wood is subjected to microwave and ultrasonic drying; and E, the wood obtained after microwave and ultrasonic drying is performed is subjected to thermal convection drying. By the adoption of the drying method for the wood, the moisture in the wood can be dried effectively, and the moisture content of the wood is less than 8.5% and meets the dry standard; the phenomena of cracking, deformation, bending and warping of the wood and the like can be avoided; the drying speed of the wood can be increased effectively, the time is shortened, the cost is lowered, and the stable mass production of the wood is achieved; and the quality of the obtained wood is stable, and the error between the moisture content and the target moisture content of dried products is small.

Owner:玉溪万德能源技术有限公司

Manufacturing method of insect-resistant and moisture-proof composite wooden door

InactiveCN108858638ANon-perishableNot easy to stirWood treatment detailsWood veneer joiningNatural resinAdhesive

The invention discloses a manufacturing method of an insect-resistant and moisture-proof composite wooden door. The manufacturing method comprises the following steps: spraying insect powder onto straw and reed straw for dispelling insects for 3 days or above in order to kill internal worm eggs and dispel internal worms; then, drying the straw and reed straw, and smashing into granules; performingACQ preservative treatment on the granular raw material to prevent the raw material from decaying easily; uniformly mixing the raw material through natural resin in order to condense the granular material; repeatedly paving and pressing on a flat board with a fence; laminating and drying the middle part with an adhesive to form a multilayer solid regenerated board. When a door core is manufactured with the multilayer board, cracking is prevented compared with the conventional wooden door. The whole door core board is a solid regenerated board made of the straw and the reed straw, so that theregenerated board is low in density, is light in mass and is convenient to transport, waste utilization is realized, and meanwhile the problem of cracking of the conventional wooden door is solved.

Owner:CHENGDU TIANTIAN WOOD IND CO LTD

Blue stain and mildew preventing processing method for masson pine timber

InactiveCN102672772APrevent discolorationGood antibacterial effectCoating impregnationCoatingsSnow moldSolvent

The invention relates to a blue stain and mildew preventing processing method for masson pine timber. The method comprises the steps of: agitating 0.05-0.15% of thiophanate-methyl, 0.05-0.15% of carbendazim and 0.50-1.00% of double alkyl chain quaternary ammonium salt, with a solvent which is water or 75% alcohol uniformly to prepare a blue stain and mildew preventing liquid for masson pine timber; then quenching the masson pine timber naturally dried by the blue stain and mildew preventing liquid for masson pine timber for 10-20min; or processing fresh pine by way of painting or spraying, naturally drying the fresh pine and spraying for 2-3 times, and then stacking the masson pine timber processed by the blue stain and mildew preventing liquid for masson pine timber in an open type and naturally drying. The method provided by the invention can effectively inhibit propagation of various blue-stain fungi and moulds on the masson pine timber, has remarkable antibacterial effect and is simple in operational process with low processing cost, low using concentration of insecticide and low toxicity.

Owner:GUANGXI FORESTRY RES INST

Wood preserving composition for treatment of in-service poles, posts, piling, cross-ties and other wooded structures

ActiveUS8221797B2Low toxicityImprove stabilityBiocideInorganic active ingredientsPreservativeFluoride

This invention discloses a wood preservative composition for the supplemental or remedial treatment of in-service poles, posts, piling, cross ties and other wooden structures. The wood preservative composition comprises copper 8-hydroxyquinolate (oxine copper) in combination with a boron compound or a fluoride compound.

Owner:OSMOSE UTILITIES SERVICES

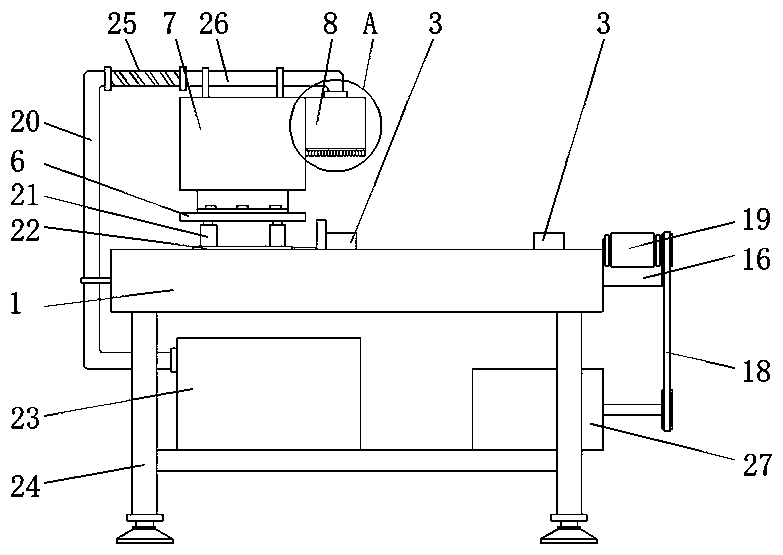

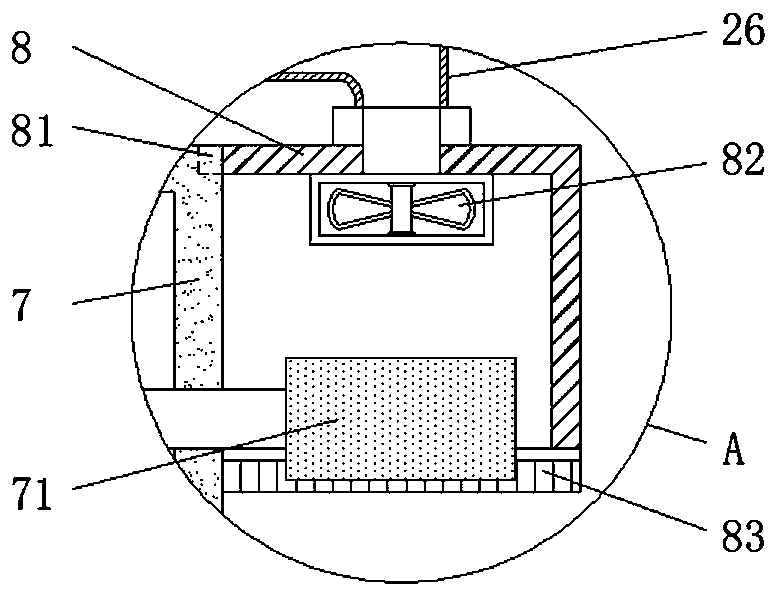

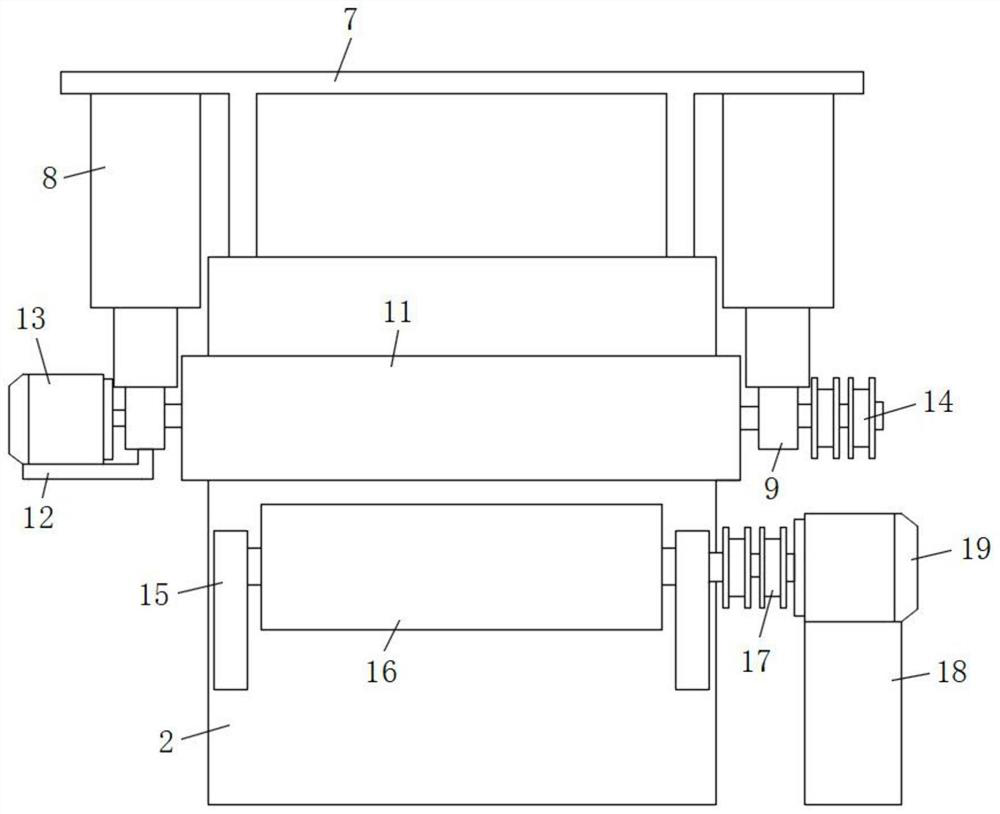

Efficient wood veneer trimming technology and trimming device

ActiveCN109648426AShorten the processing flowShorten the production cycleEdge grinding machinesOther plywood/veneer working apparatusWood veneerLacquer

The invention discloses an efficient wood veneer trimming technology and a trimming device, and belongs to the field of wood trimming. The efficient wood veneer trimming technology comprises the following steps of 1 wood veneer finishing coat spraying, 2 wood veneer cutting, 3 wood veneer edge finishing coat spraying, 4 wood veneer edge sealing and 5 wood veneer trimming. According to the efficient wood veneer trimming technology, UV finishing coat treatment is conducted on wood veneer, UV finishing coat is cured into a film after being subjected to ultraviolet irradiation, the process that ina traditional technology, after the wood veneer is preliminarily ground, primer coat spraying is conducted, and then finishing coat spraying is conducted is effectively reduced, the processing process is effectively reduced, the production period is shortened, therefore, the production cost is reduced, and the production efficiency is improved by 5-10 times; and in addition, the wood veneer is cut, the UV finishing coat wood veneer edge is sealed, therefore, wood veneer edge processing is effectively reduced, the edges and corners of the wood veneer are fully protected through the UV finishing coat wood veneer edge, and damage of the UV finishing coat wood veneer edges and corners is reduced.

Owner:DONGGUAN ZHONGJIN FURNITURE CO LTD

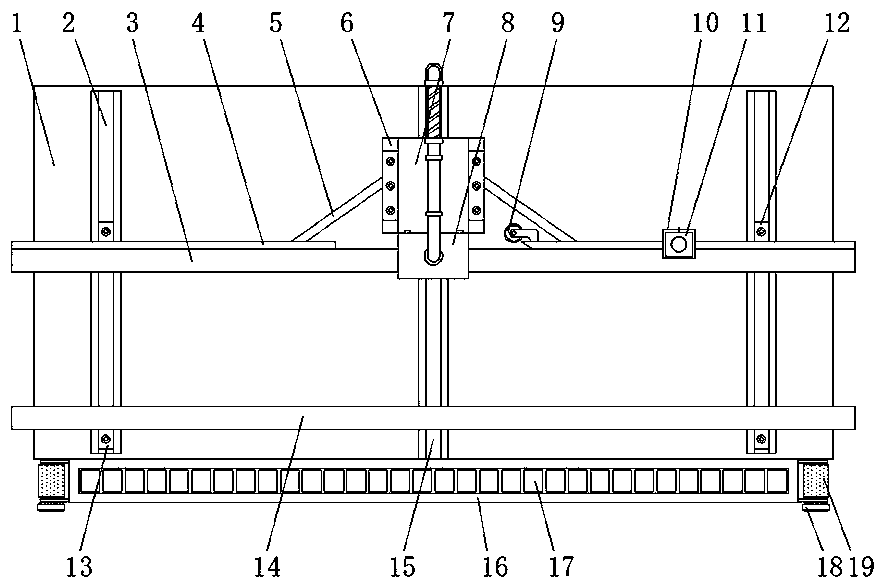

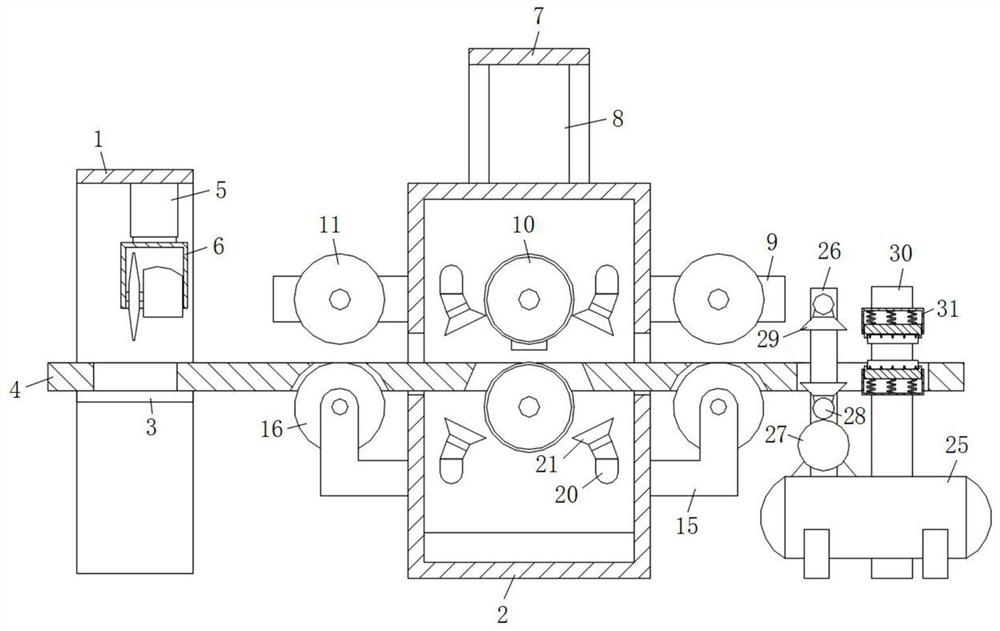

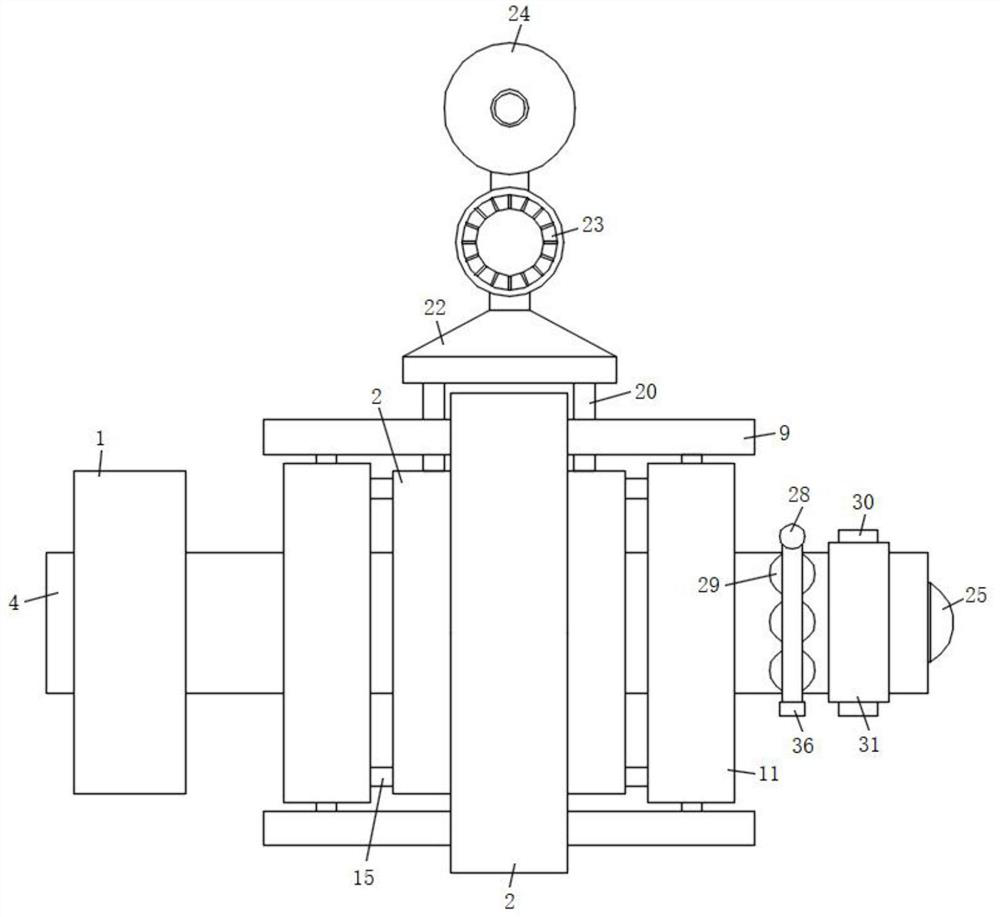

Wood board surface machining treatment device

InactiveCN112496909AContinuous processing is easy to operateAchieve double-sided grindingGrinding drivesProfiling/shaping machinesPolishingWood plank

The invention discloses a wood board surface machining treatment device which comprises a cutting frame and a polishing chamber; a supporting plate is further fixedly connected to the middle of the inner wall of the front end and the middle of the inner wall of the rear end of the cutting frame, rectangular holes are formed in the two sides of a polishing chamber in a penetrating mode, and a working plate is further fixedly connected between the bottom faces of the interiors of the rectangular holes and the top face of the supporting plate; a first air cylinder is fixedly connected to the inner top face of the cutting frame through screws, a cutting machine is fixedly connected to the output end of the first air cylinder through screws, a mounting frame is fixedly connected to the outer top face of the polishing chamber, second air cylinders are fixedly connected to the front side and the rear side of the bottom face of the mounting frame through screws, and mounting strips are fixedlyconnected to the output ends of the second air cylinders through screws; and polishing rollers are rotatably connected to the middles of the two mounting strips and the lower sides of the inner wallsof the front end and the rear end of the polishing chamber correspondingly, and first pushing rollers are further rotatably connected to the two sides of the two mounting strips. The wood board surface machining treatment device is reasonable in design and stable, continuous machining operation of wood boards is easy and convenient, double-face polishing and waxing operation of the wood boards can be achieved at the same time, and the working efficiency of wood board machining is greatly improved.

Owner:怀宁县三兴木业有限公司

Process for machining antiquing floors by using low-grade boards

InactiveCN107116656AIncrease sales valueConsistent colorBelt grinding machinesCoating impregnationMaterial defectEngineering

The invention relates to a process for machining antiquing floors by using low-grade boards. The process comprises the following steps: low-grade board blanks are machined as plain plates; the surface polishing and the defect port rounding are performed on material defects by using an angle grinding piece, a steel wire disc and a grinding wheel in sequence; then, putty is coated in cracks to fill and level up the cracks; the plain plates are machined by adopting more than two antiquing treatment processes of scraping, wire drawing, dimpling, dull knife machining, relief machining, carbon combustion machining and chemical change machining; and natural oil or wax oil is brushed on the surfaces of the plain plates for airing to obtain finished products. The process uses the boards with such material defects as dead knots, bark pockets, insect holes, mineral lines and cracks and discarded by the industry as raw materials to prevent the wood wastes, finishes natural material defects, and fills the putty to form an artistic effect; and the antiquing treatment process is used for forming the natural antiquing effect on the surfaces of the floors to improve the floor sale additional value.

Owner:湖北燕加隆木制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com