Aqueous sealant system, wood product and method for sealing wood substrate

A water-based sealing agent and system technology, applied in wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of difficult to control cross-linking reaction, complicated preparation method of water-based sealing agent, high manufacturing cost, etc., and achieve excellent physical and chemical properties, Excellent sealing or barrier properties, long-lasting sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation of the film-forming resin composition of the present invention can be realized by any suitable mixing method known to those skilled in the art. For example, a film-forming resin composition can be prepared by adding the aqueous emulsion, fillers and additional additives (if any) to a container, and stirring the resulting mixture until homogeneous. Additional water may be added during the preparation of the film-forming resin composition, if desired. The amount of additional water should be added to the total weight of the aqueous emulsion.

[0045] As used herein, the term "polyisocyanate hardener" refers to polyisocyanate compounds, isocyanate oligomers, or combinations thereof. The polyisocyanate hardener contains two or more isocyanate functional groups, which can undergo chain extension and crosslinking reactions with active hydrogen polymers, thereby forming a three-dimensional network structure in the seal coat.

[0046] Suitable polyisocyanate h...

Embodiment 1

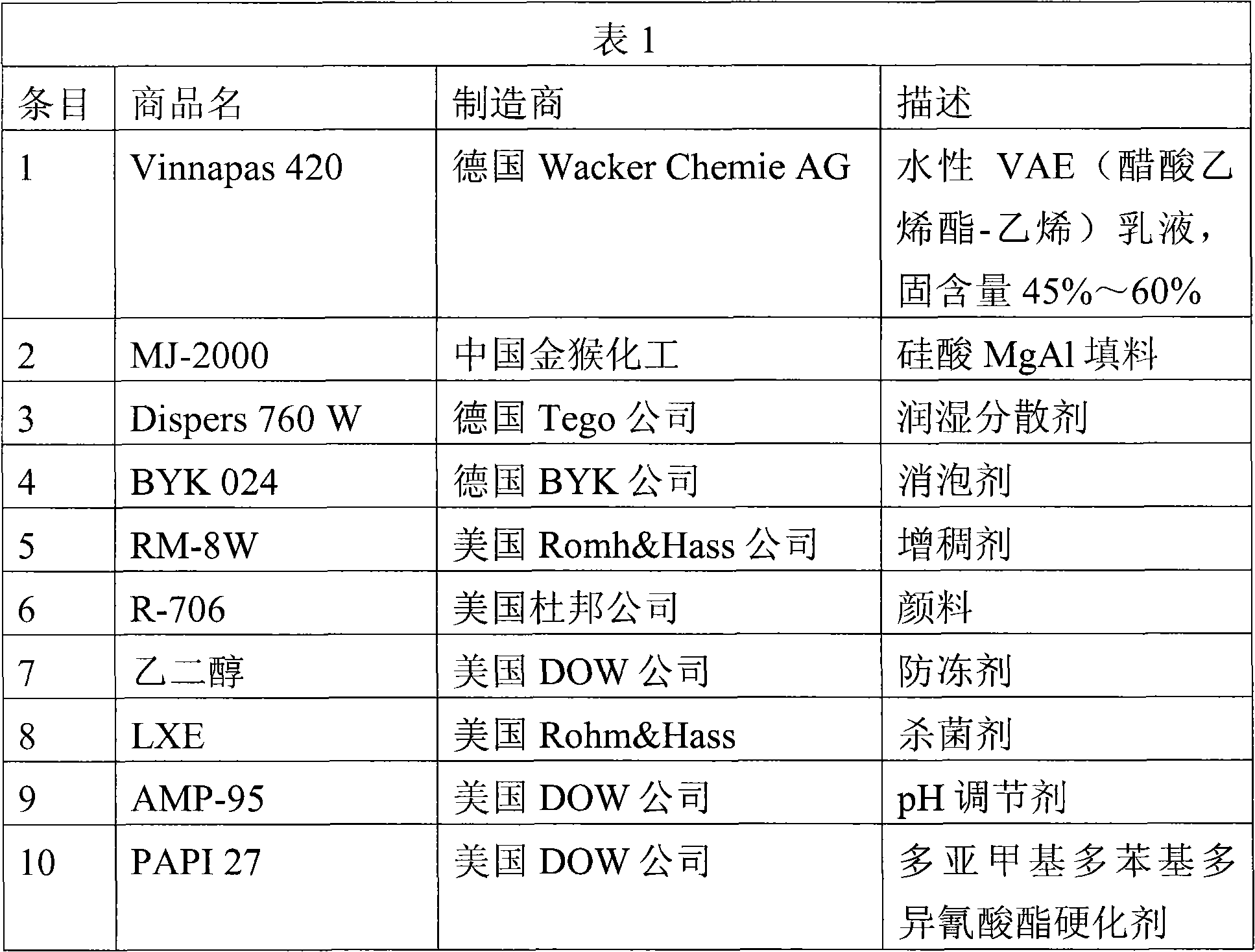

[0094] Preparation of film-forming resin composition

[0095] 20kg Vinnapas 420, 0.4kg Dispers 760W, 0.5kg BYK 024, 3kg ethylene glycol, 16.4kg water and 0.2kg fungicide were added to the mixing vessel and mixed, then stirred at 300-600rpm until homogeneous. Next, 2 kg of R-706, 58 kg of MJ-2000 and 0.5 kg of RM-8W were added to the above mixture under stirring. The resulting mixture was stirred for 15-20 min, and then the pH regulator AMP-95 was slowly added dropwise to adjust the pH to 7-9. The result is a film-forming resin composition.

[0096] Preparation of an aqueous closed system

[0097] The film-forming resin composition thus prepared was mixed with PAPI 27 (a polymethylene polyphenyl polyisocyanate hardener from DOW Corporation) in a weight ratio of 100:9 before use.

[0098] Apply and evaluate aqueous sealer systems

[0099] Two oak boards (each with a size of 40cm×60cm) were polished with 400 mesh sandpaper to remove stains, burrs and dust on the surface...

Embodiment 2

[0104] Preparation of film-forming resin composition

[0105] 20kg Vinnapas 420, 0.4kg Dispers 760W, 0.5kg BYK 024, 3kg ethylene glycol, 16.4kg water and 0.2kg fungicide were added to the mixing vessel and mixed, then stirred at 300-600rpm until homogeneous. Next, 2 kg of R-706, 58 kg of MJ-2000 and 0.5 kg of RM-8W were added to the above mixture under stirring. The resulting mixture was stirred for 15-20 min, and then the pH regulator AMP-95 was slowly added dropwise to adjust the pH to 7-9. The result is a film-forming resin composition.

[0106] Preparation of an aqueous closed system

[0107] The film-forming resin composition thus prepared was mixed with PAPI 27 (polymethylene polyphenyl polyisocyanate hardener from DOW Corporation) in a weight ratio of 100:5 before use.

[0108] Apply and evaluate aqueous sealer systems

[0109] Two oak boards (each with a size of 40cm×60cm) were polished with 400 mesh sandpaper to remove stains, burrs and dust on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com