Temperature-sensitive reversible color wooden material and manufacturing method thereof

A technology of wood materials and manufacturing methods, which is applied in the direction of impregnating wood, manufacturing tools, wood impregnation, etc., can solve the problems of material surface damage, time-consuming and labor-consuming, etc., and achieve good dimensional stability, high sensitivity to color change, and stable color change performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of wooden materials

[0026] The wood material can be pre-treated before impregnation or directly impregnated. Microwave, steam and other pretreatment of wood materials can help to open the blocked channels that hinder the flow of fluid inside the wood, and help the thermochromic agent to fill the micro-voids in the wood material and transfer to deeper parts inside the wood material.

[0027] (2) Preparation of thermochromic agent

[0028] Crystal violet lactone is used as the leuco agent, bisphenol A is used as the color developer, and n-dodecyl alcohol is used as the solvent. First take a certain amount of dodecyl alcohol and add it to the dipping tank, such as 50kg, then take crystal violet lactone and bisphenol according to the leucochromant, developer, solvent mass ratio 1: (0.1-30): (1-200) Add A into the dipping tank, such as 50kg of crystal violet lactone and 10kg of bisphenol A, and stir well to make the three ingredients mix evenly, and then ...

Embodiment 2

[0040] (1) Preparation of wooden materials

[0041] The wood material to be impregnated is subjected to steam pretreatment, the steam temperature is 180°C, and the treatment time is 10 minutes. After treatment, the wood is dried to a moisture content of 8-12%.

[0042] (2) Preparation of thermochromic agent

[0043] Heat-sensitive red and heat-sensitive yellow are selected as leucochrome, bisphenol A is used as color developer, and n-hexadecanol is used as solvent to prepare thermochromic agent.

[0044] (3) Impregnation of wood materials

[0045] Ultrasonic impregnation treatment is carried out on the wood material, the impregnation temperature is 70°C, the impregnation time is 3h, and the ultrasonic power is 120W.

[0046] (4) Treatment after impregnation of wood materials

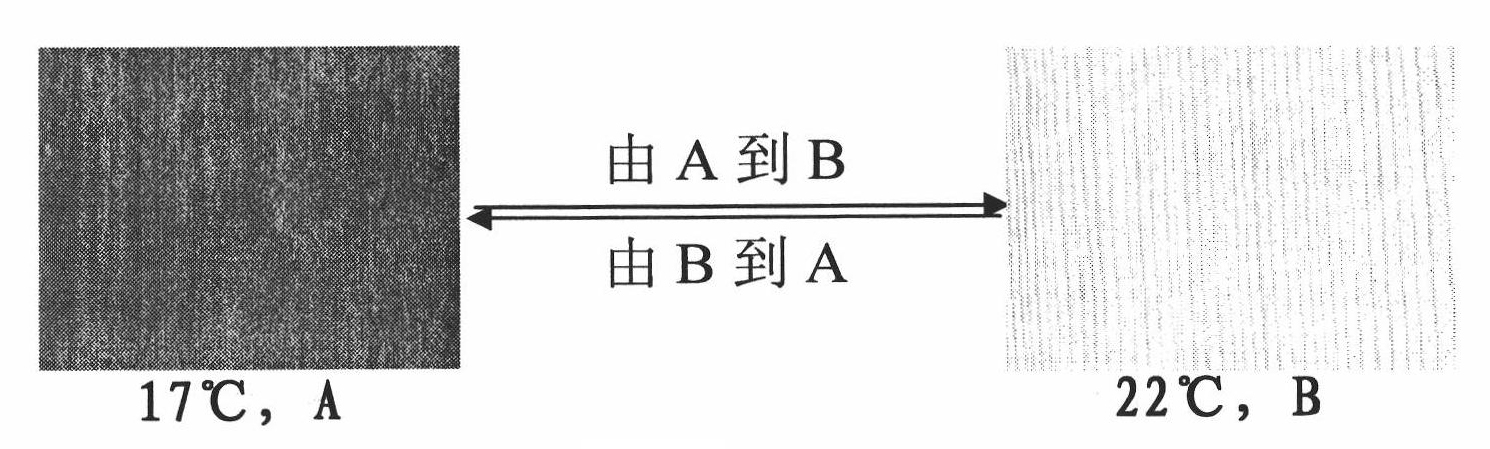

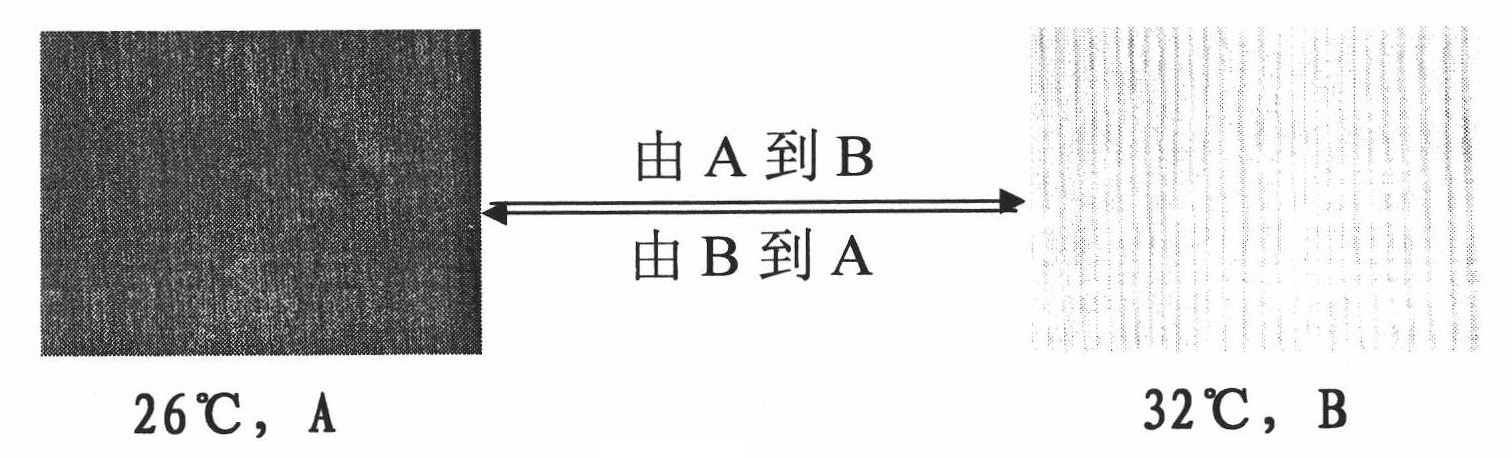

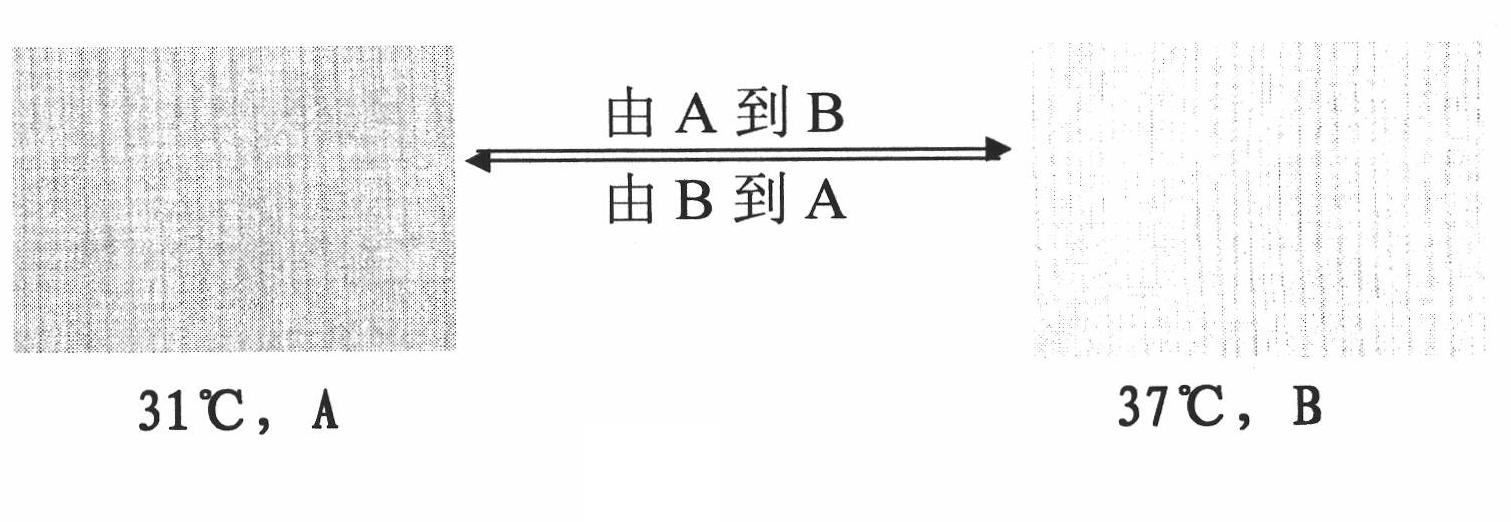

[0047] Wash the impregnated wood material with clean water at 50-100°C and dry it to obtain figure 2 Temperature-sensitive reversible discoloration of wood material shown.

[0048] The temperature...

Embodiment 3

[0050] (1) Preparation of wooden materials

[0051] Control the moisture content of the wood to 20-40%, and use microwaves to pretreat the wood. Microwave pretreatment of wood, without destroying the structure of the wood itself, can dredge as many channels in the wood as possible that hinder the flow of fluid, and improve the penetration depth, penetration uniformity and integrity of the thermochromic agent on the wood substrate . The ideal wood impregnation effect can be obtained by controlling the microwave radiation power density at 0.1-10w / cm3, the radiation temperature at 80°C-120°C, and the radiation time at 1-30min.

[0052] (2) Preparation of thermochromic agent

[0053] Thermosensitive red and thermosensitive green are selected as leucochromic agents, bisphenol A is used as color developer, and n-tetradecyl alcohol is used as solvent to prepare thermochromic agent.

[0054] (3) Impregnation of wood materials

[0055] Carry out vacuum impregnation treatment on woo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com