Patents

Literature

124 results about "Photochromic lens" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photochromic lenses are optical lenses that darken on exposure to specific types of light of sufficient intensity, most commonly ultraviolet (UV) radiation. In the absence of activating light the lenses return to their clear state. Photochromic lenses may be made of glass, polycarbonate, or another plastic. They are principally used in eyeglasses that are dark in bright sunlight, but clear in low ambient light conditions. They darken significantly within about a minute of exposure to bright light, and take somewhat longer to clear. A range of clear and dark transmittances is available.

Photochromic film, photochromic lens comprising the same, and method of manufacturing photochromic lens

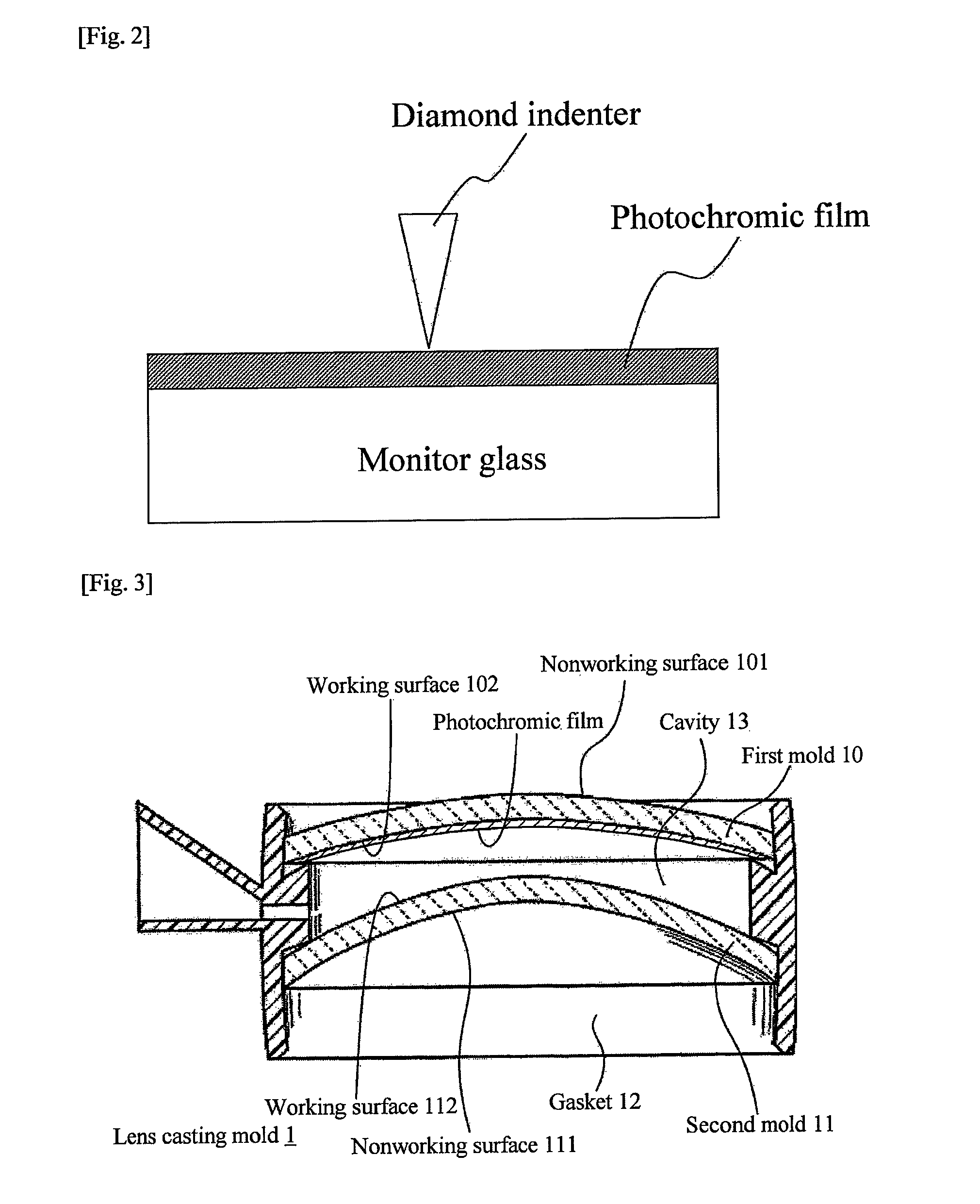

ActiveUS20090316246A1Good photoresponse performanceImprove featuresDecorative surface effectsOptical articlesPhotochromic lensHardness

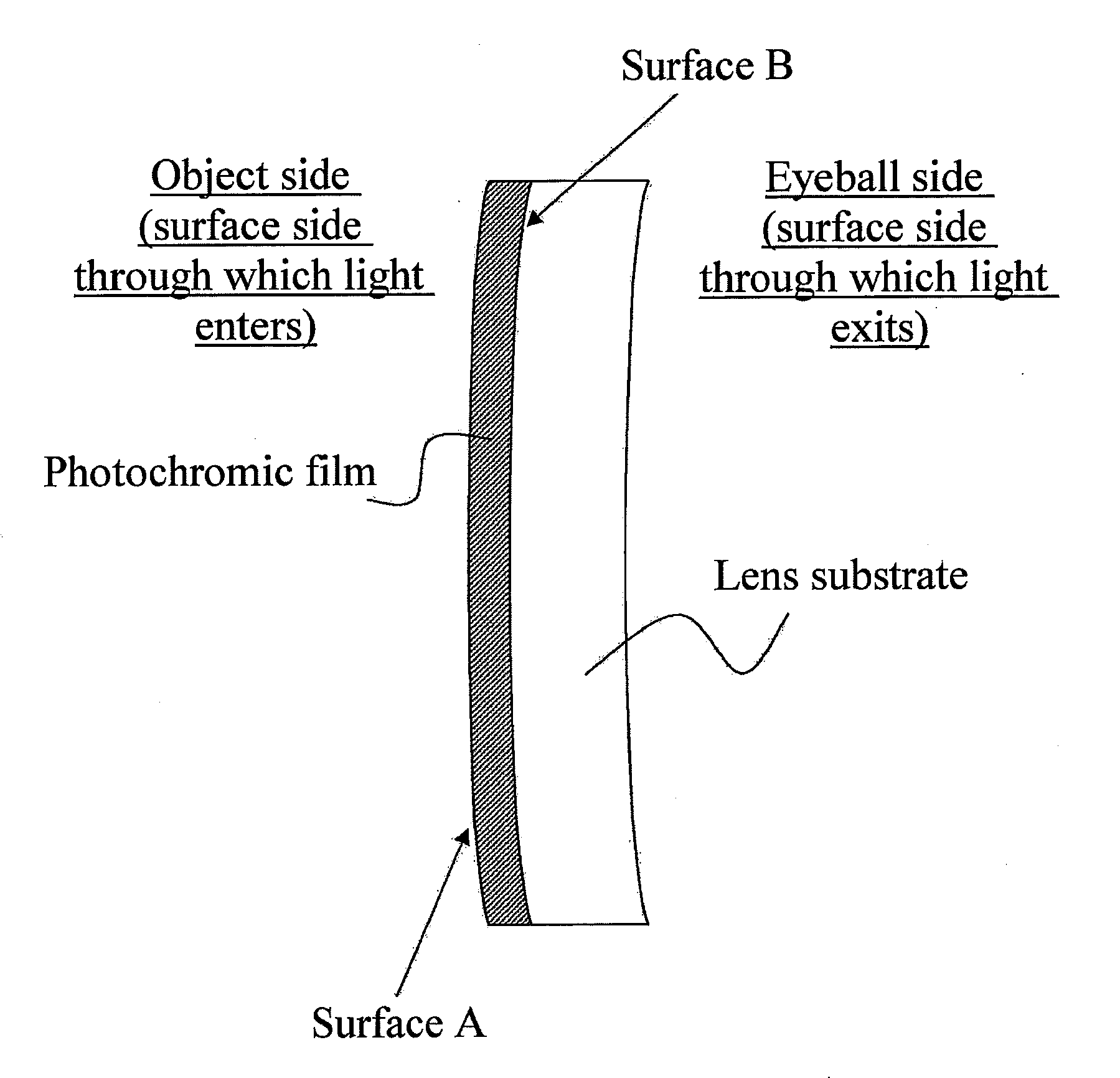

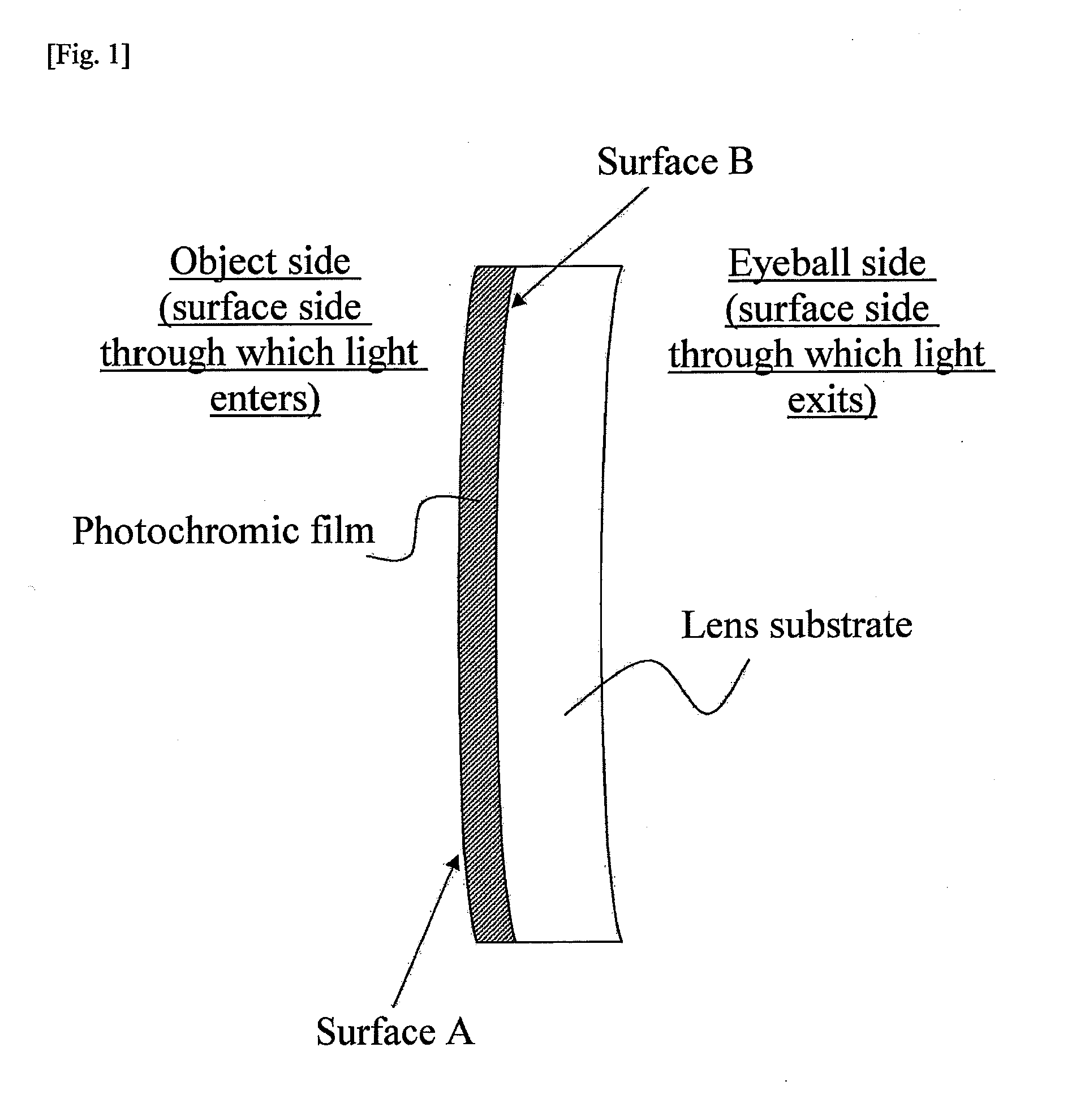

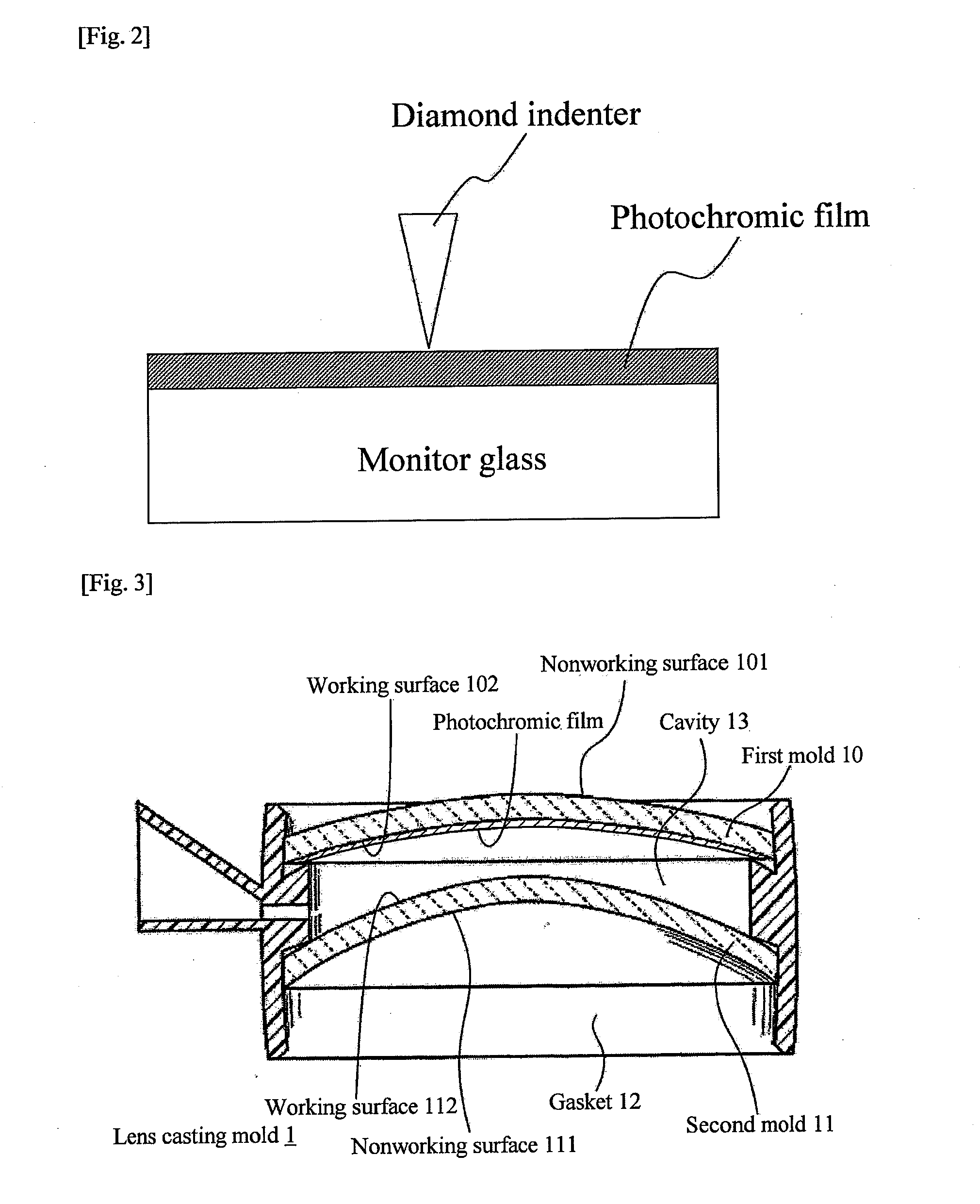

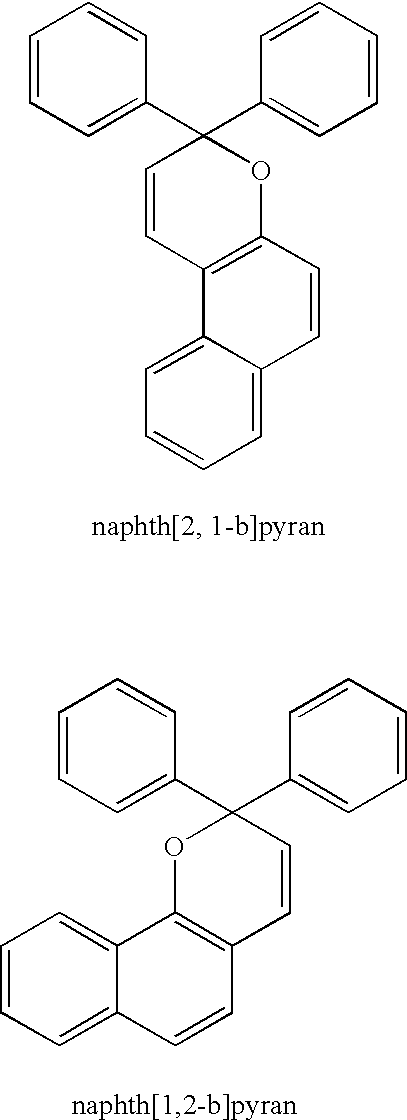

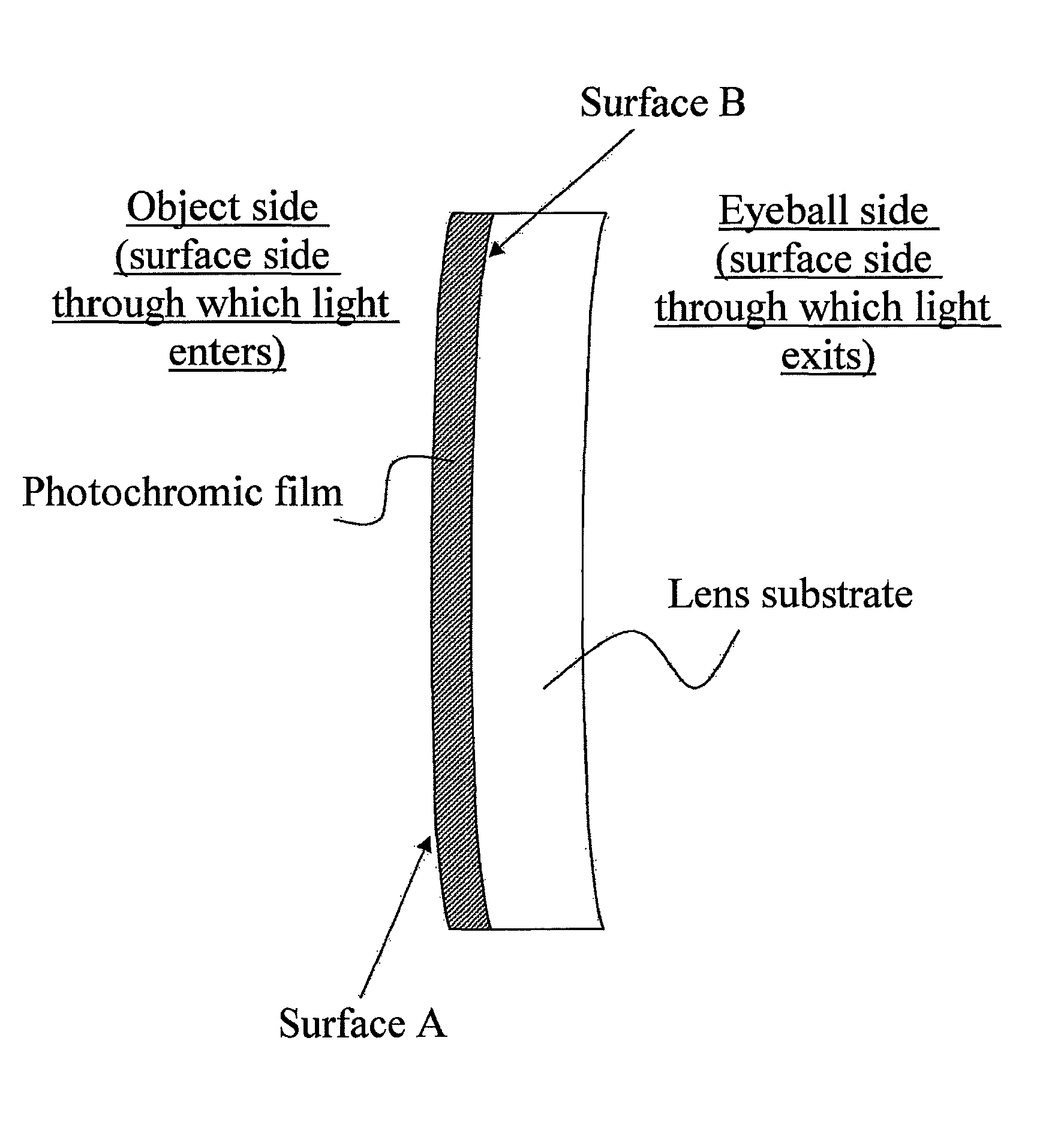

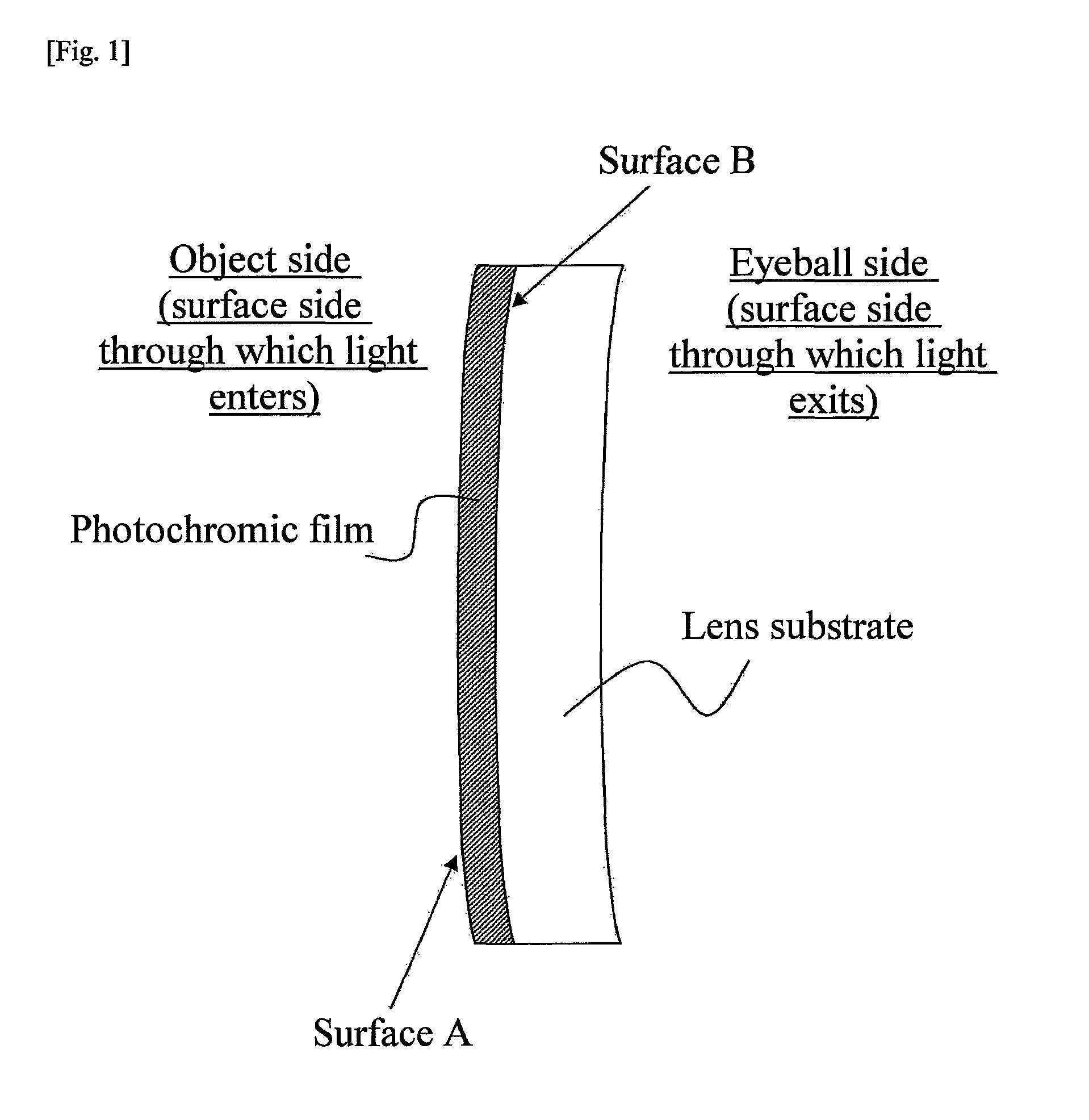

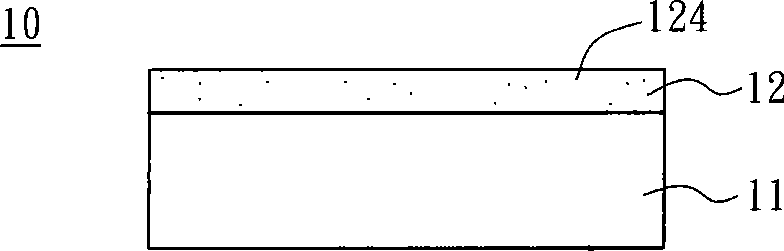

The present invention relates to a photochromic film comprising a photochromic dye and a resin component. The photochromic film has a nanoindentation hardness of equal to or greater than 800 nm on at least one of surfaces, surface A, thereof. The present invention further relates to a method of manufacturing a photochromic lens. The method of manufacturing a photochromic lens of the present invention comprises forming a photochromic film having a nanoindentation hardness ranging from 500 to 5000 nm on an outermost surface thereof as well as having a smaller nanoindentation hardness on a surface facing a first mold than that on the outermost surface by coating a photochromic liquid comprising a photochromic dye and a curable component on one surface of the first mold for formation of one of surfaces of a lens and subjecting the photochromic liquid to curing treatment, and a photochromic lens comprising a photochromic film on a lens substrate is obtained by means of the above first mold.

Owner:HOYA CORP

Photochromic polyurethane laminate

ActiveUS20050233153A1Improve fatigue resistanceGood dimensional stabilityLamination ancillary operationsSynthetic resin layered productsPhotochromic lensThermoplastic polyurethane

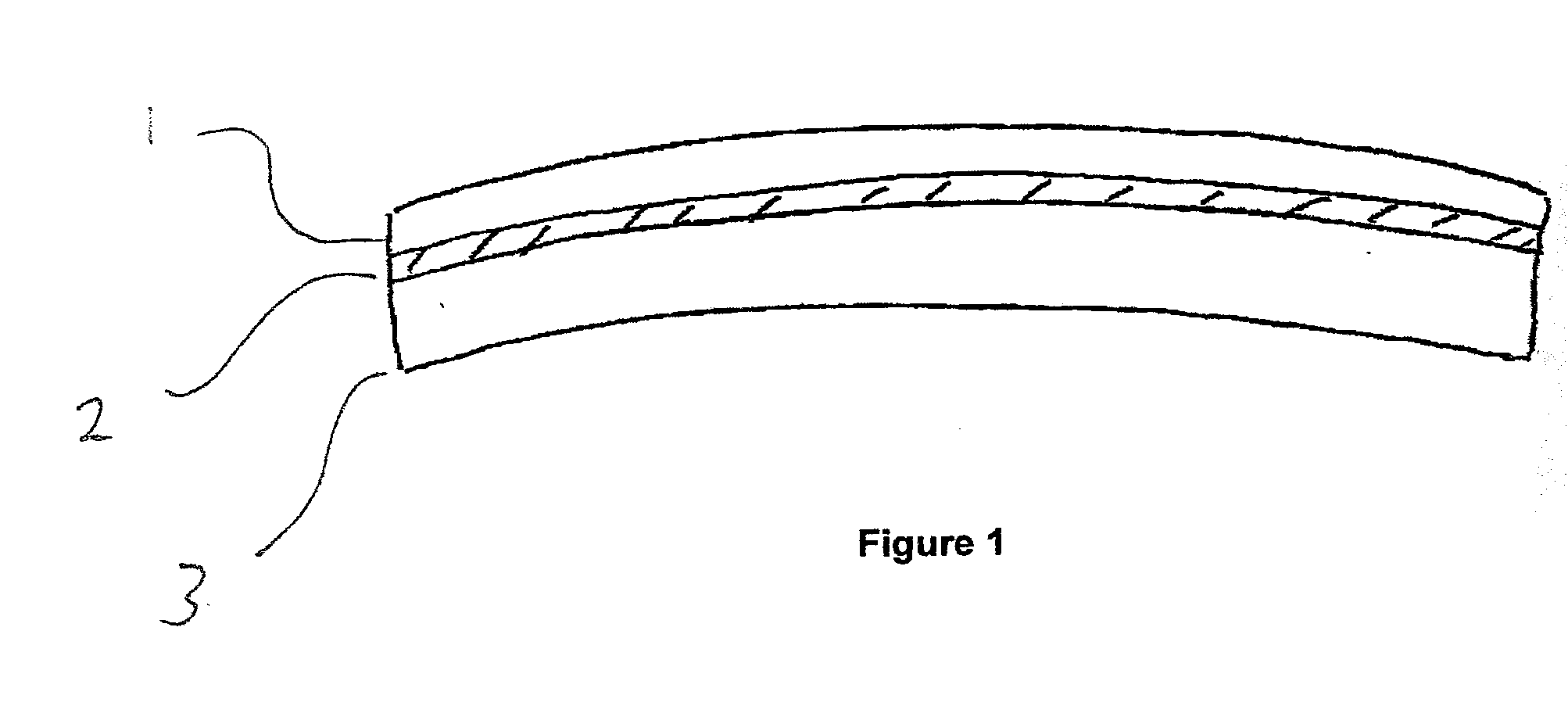

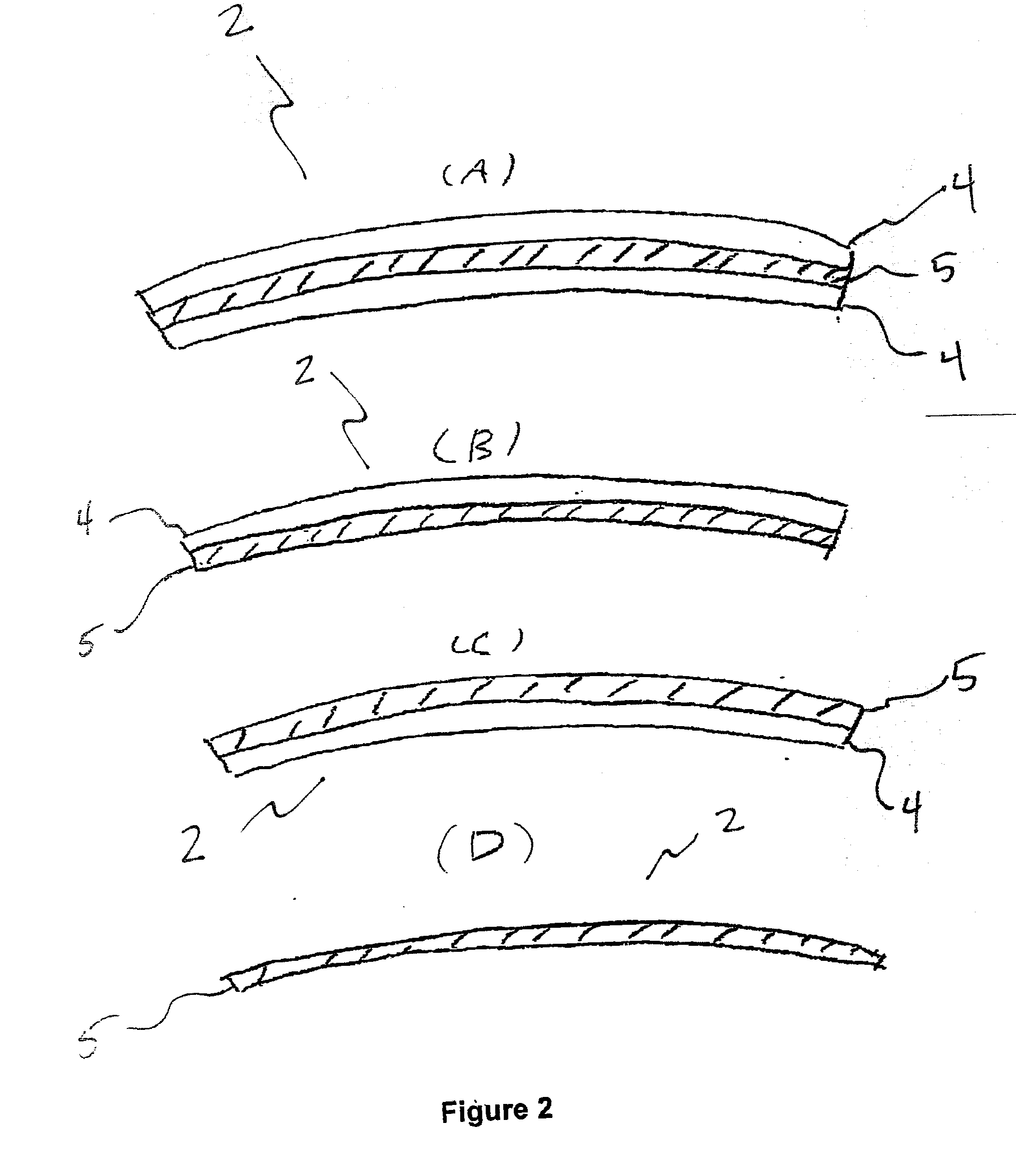

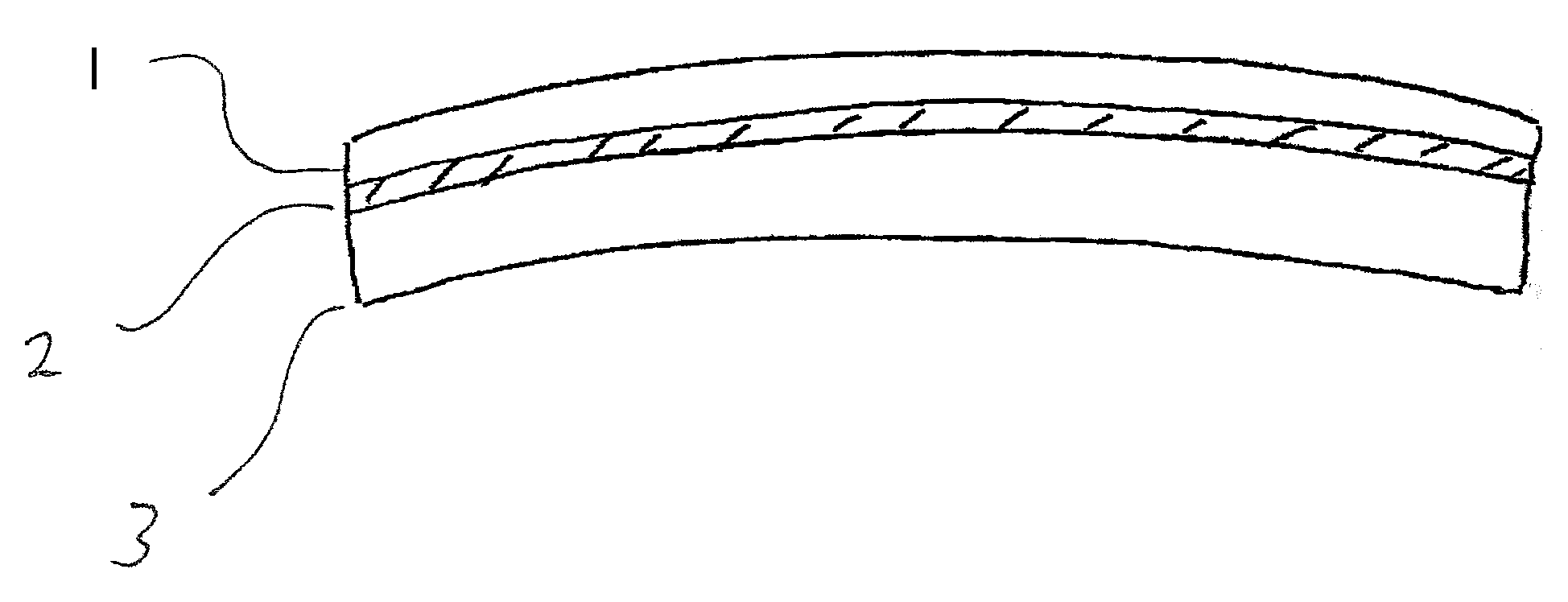

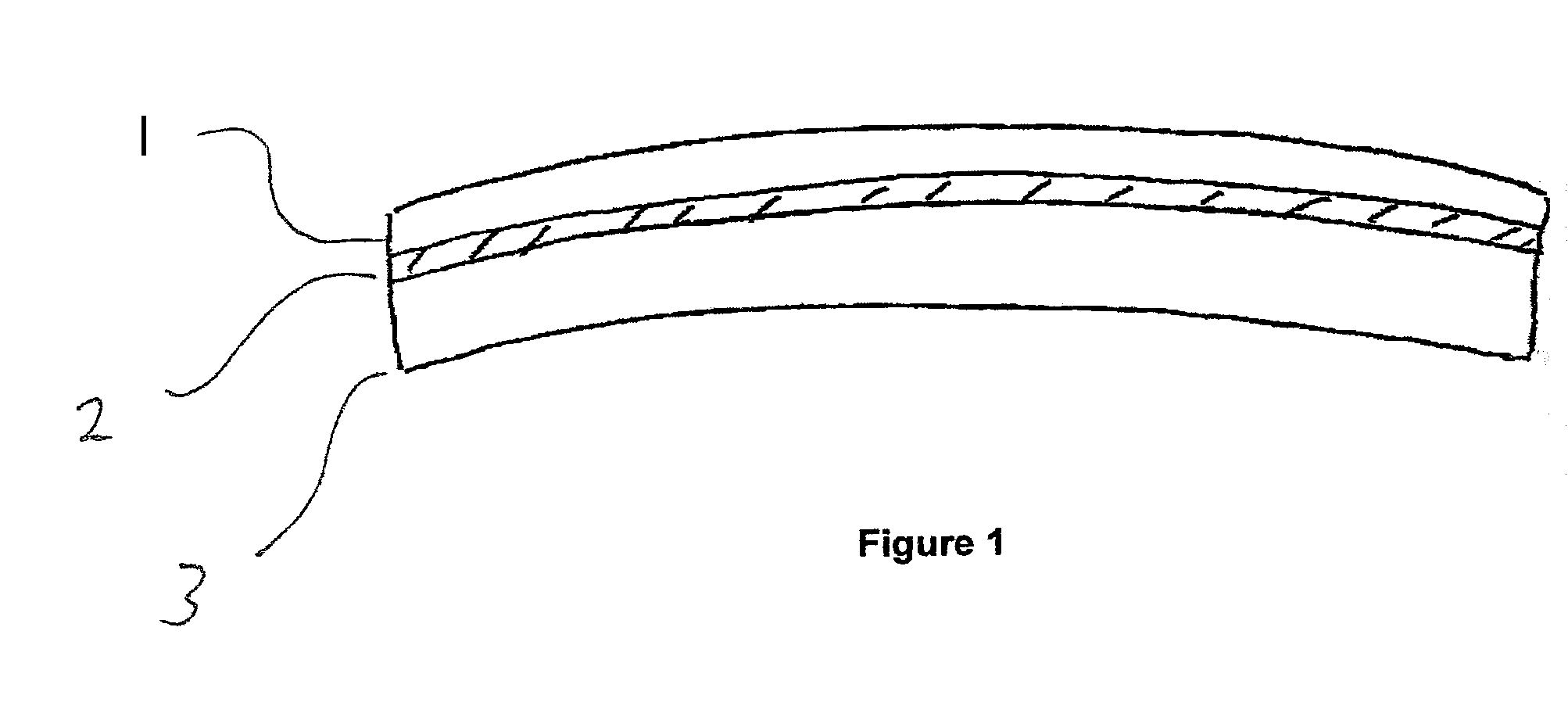

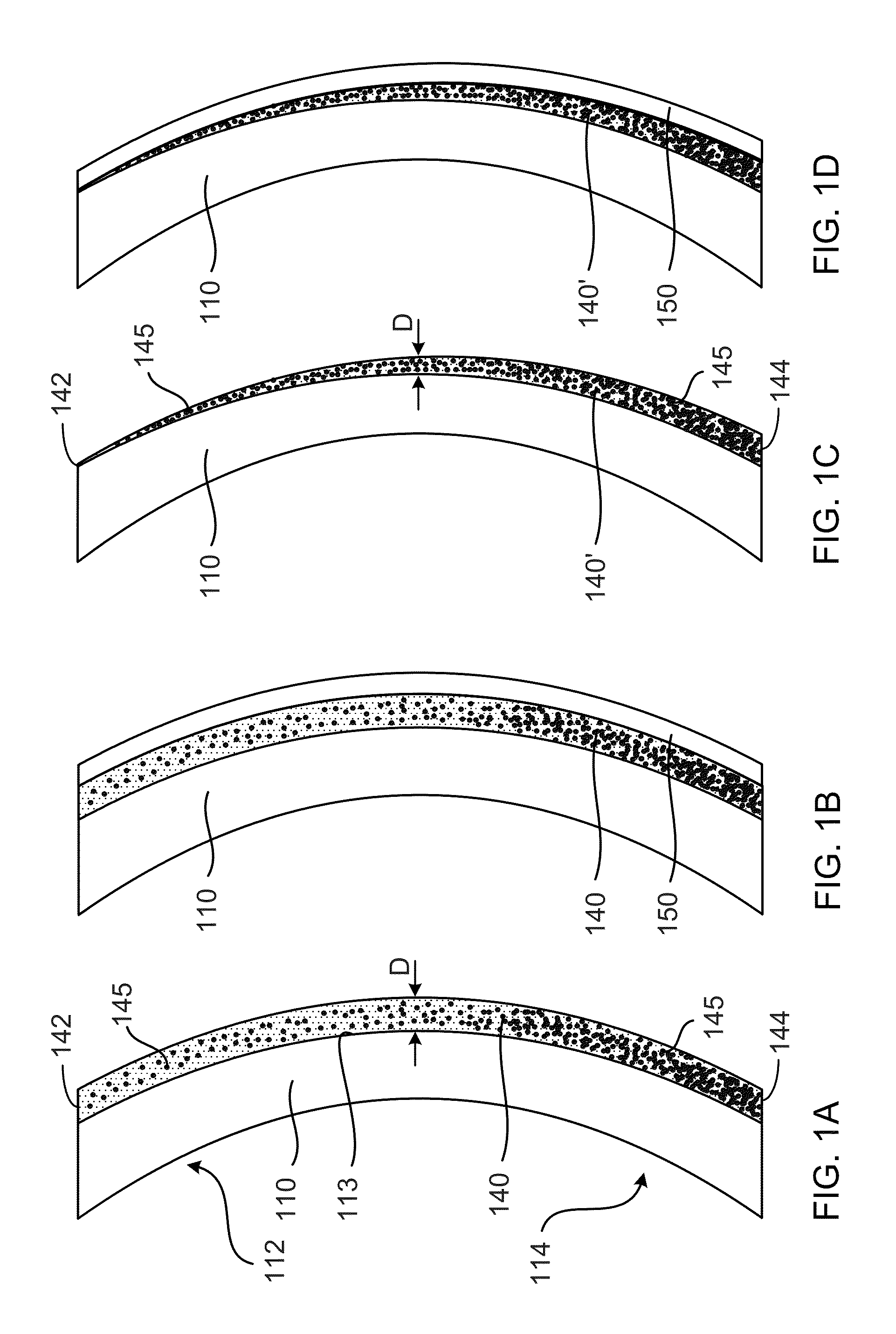

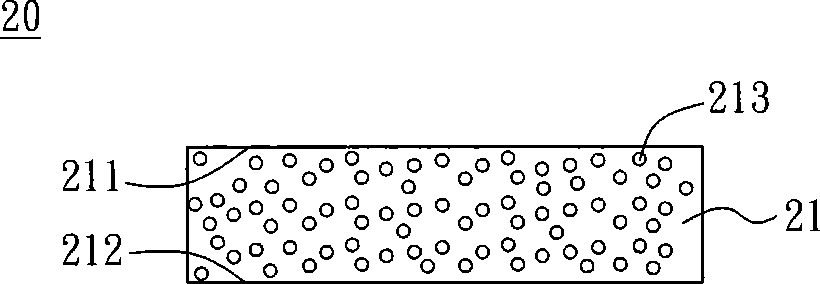

A photochromic polyurethane laminate that is constructed to solve certain manufacturing difficulties involved in the production of plastic photochromic lenses is disclosed. The photochromic laminate includes at least two layers of a resinous material and a photochromic polyurethane layer that is interspersed between the two resinous layers and which contains photochromic compounds. The polyurethane layer is formed by curing a mixture of a solid thermoplastic polyurethane, at least one isocyanate prepolymer, at least one photochromic compound, and a stabilizing system.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Photochromic contact lenses and methods for their production

The invention provides a photochromic composition for use in tinting contact lenses in which the binding polymer used is capable of forming an interpenetrating polymer network with the lens material. When the photochromic compositions of the invention are applied to uncured lens material that is subsequently cured, the binding polymer forms an interpenetrating polymer network with the lens material embedding the photochromic compound within the lens material resulting in a stable, photochromic lens.

Owner:MOLOCK FR F +3

Polarized contrast enhancing sunglass lens

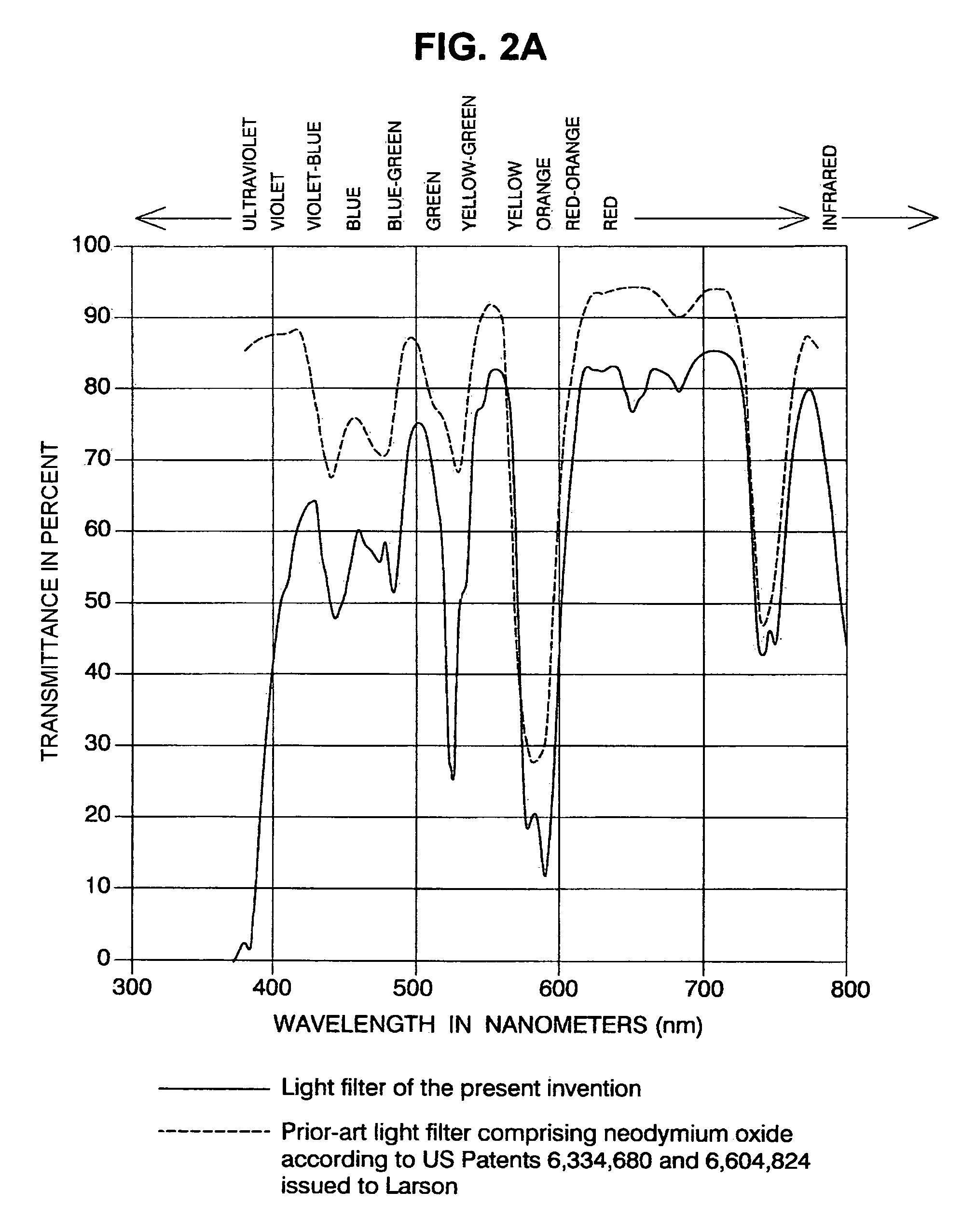

InactiveUS7597441B1Promotes accurate color perceptionHigh light transmittanceSpectales/gogglesOptical partsUv spectrumUltraviolet

The invention is a polarized sunglass lens that utilizes a multiband contrast enhancer comprised of three rare-earth oxides to provide relatively high peak transmittance in portions of the red and green spectrum, relatively lower transmittance for the blue spectrum, and very low transmittance for the UV spectrum. The lens provides enhanced perception of colors, heightened contrast, and improved visual acuity. The inclusion of vanadium pentoxide in the lens provides attenuation of the UV spectrum, thus protecting the user's eyes and the internal layers and colorants from UV-induced damage. The front lens element can be either the multiband contrast enhancer or a photochromic lens element.

Owner:FARWIG MICHAEL J

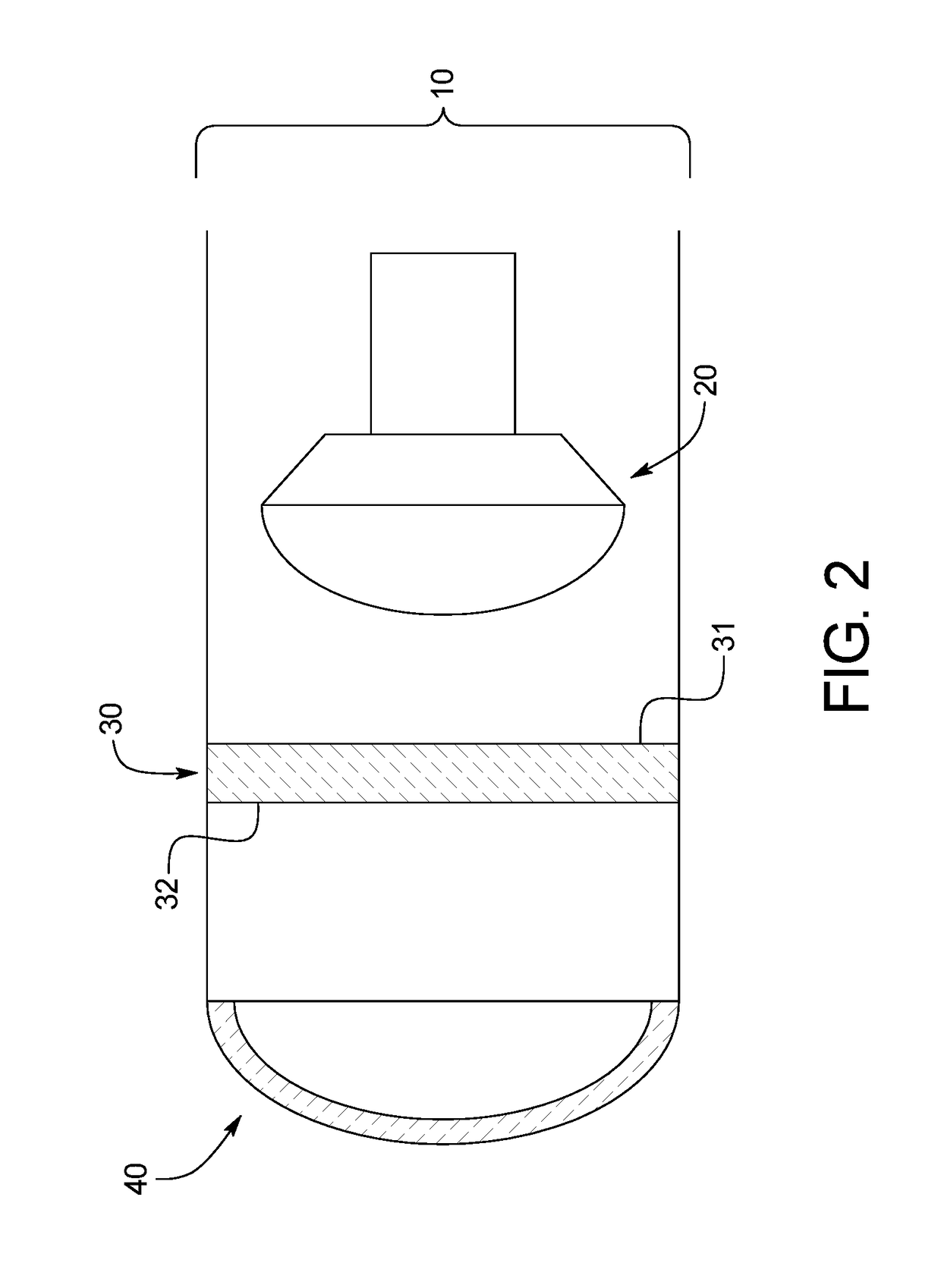

Injection molding of lens

InactiveUS7077985B2Good photochromic efficiency and durabilityGood effectSpectales/gogglesSynthetic resin layered productsPhotochromic lensInjection molding machine

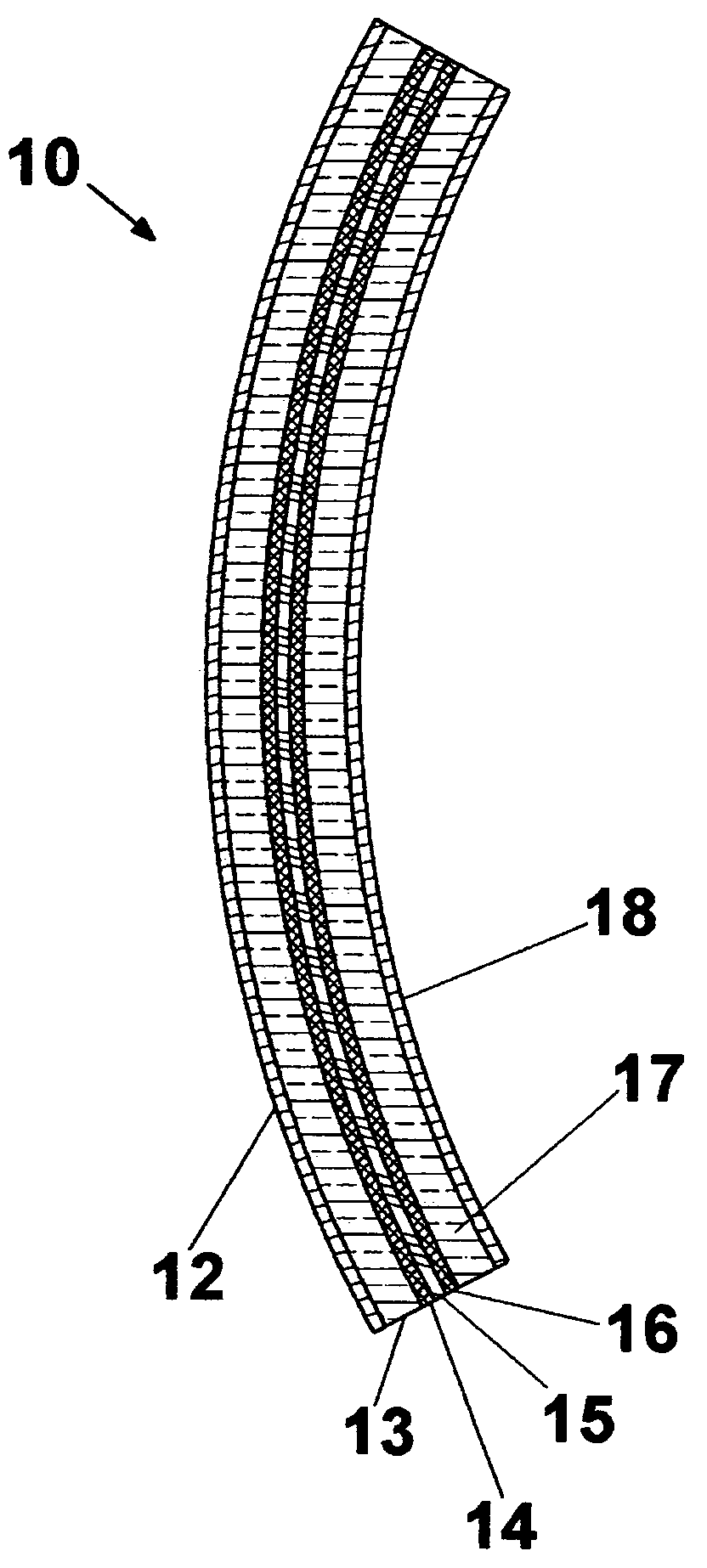

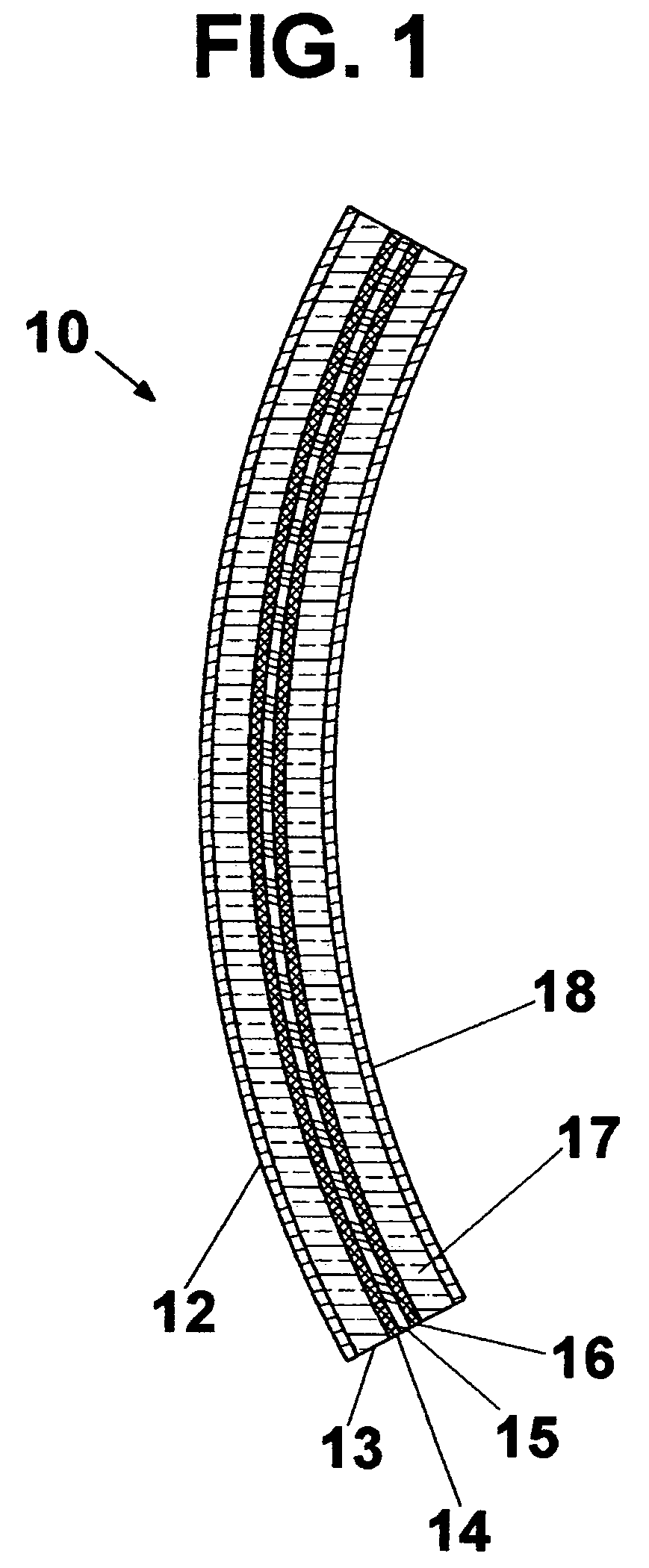

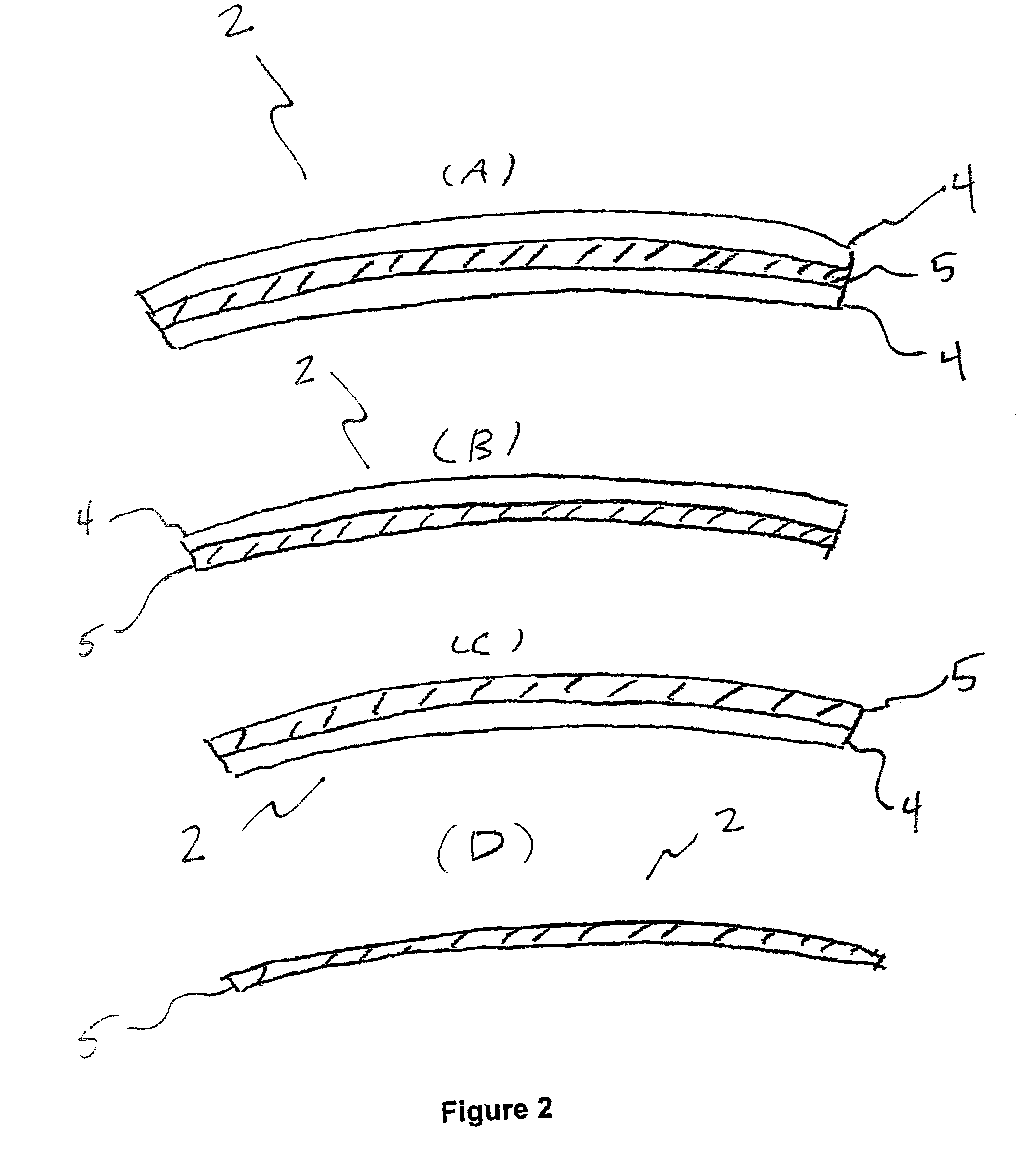

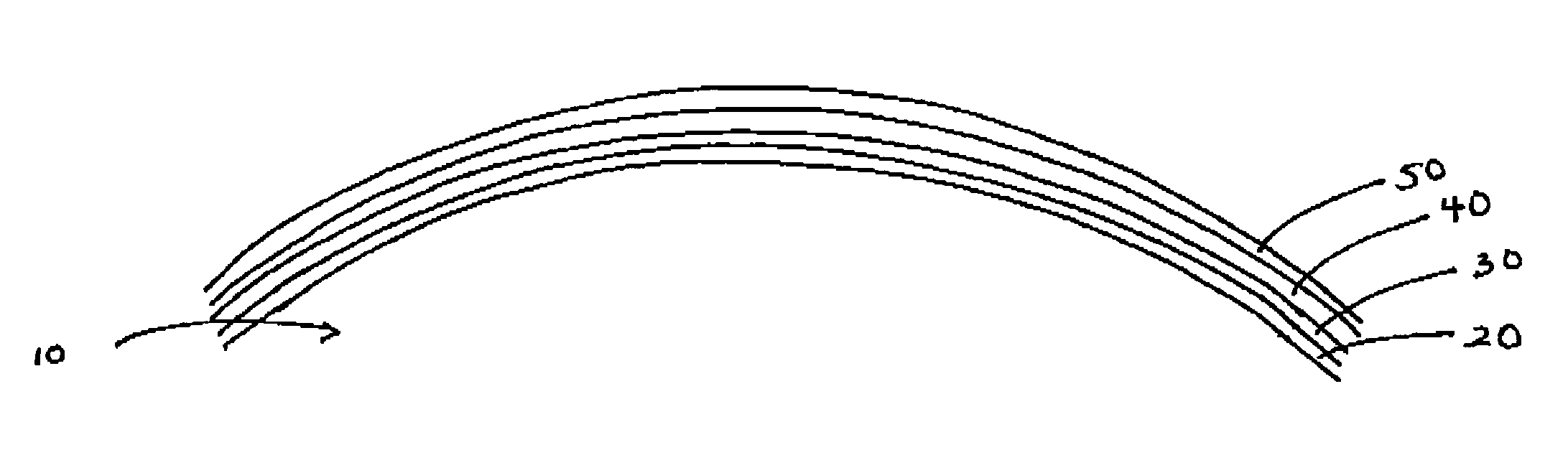

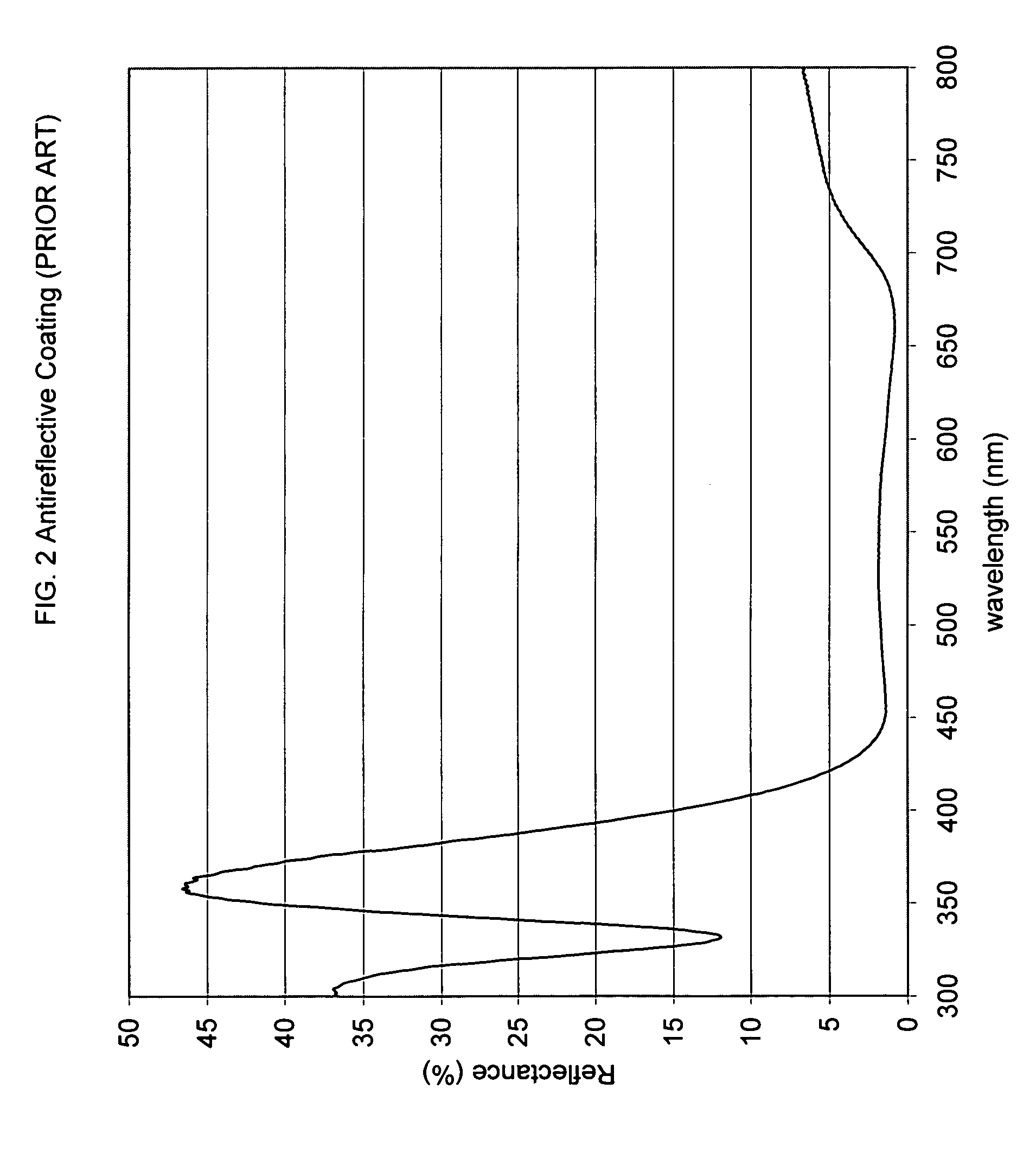

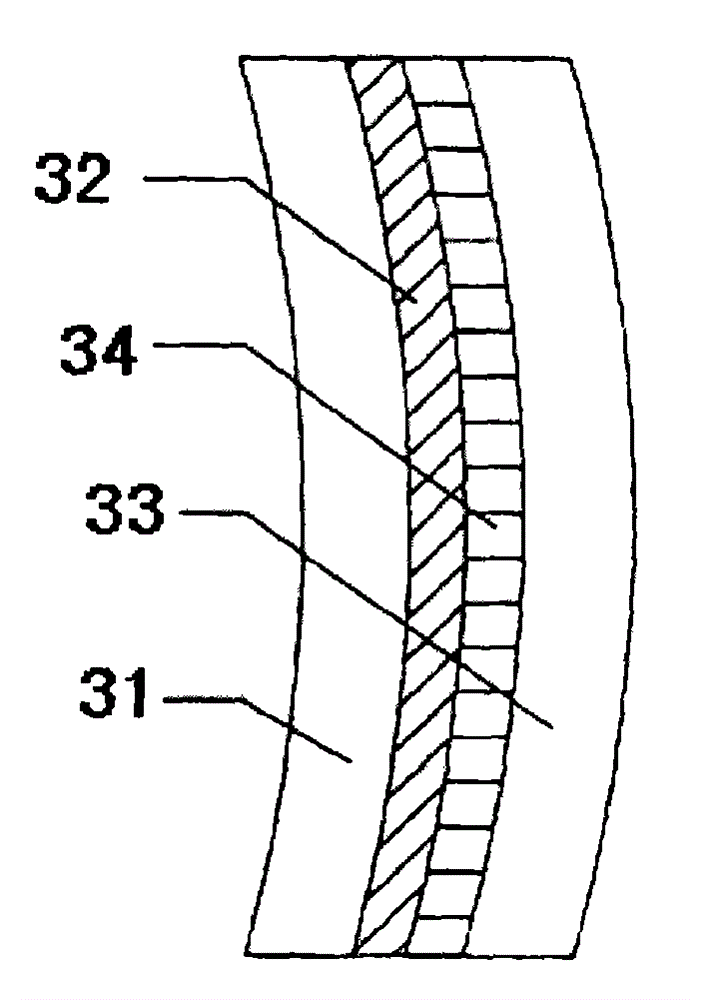

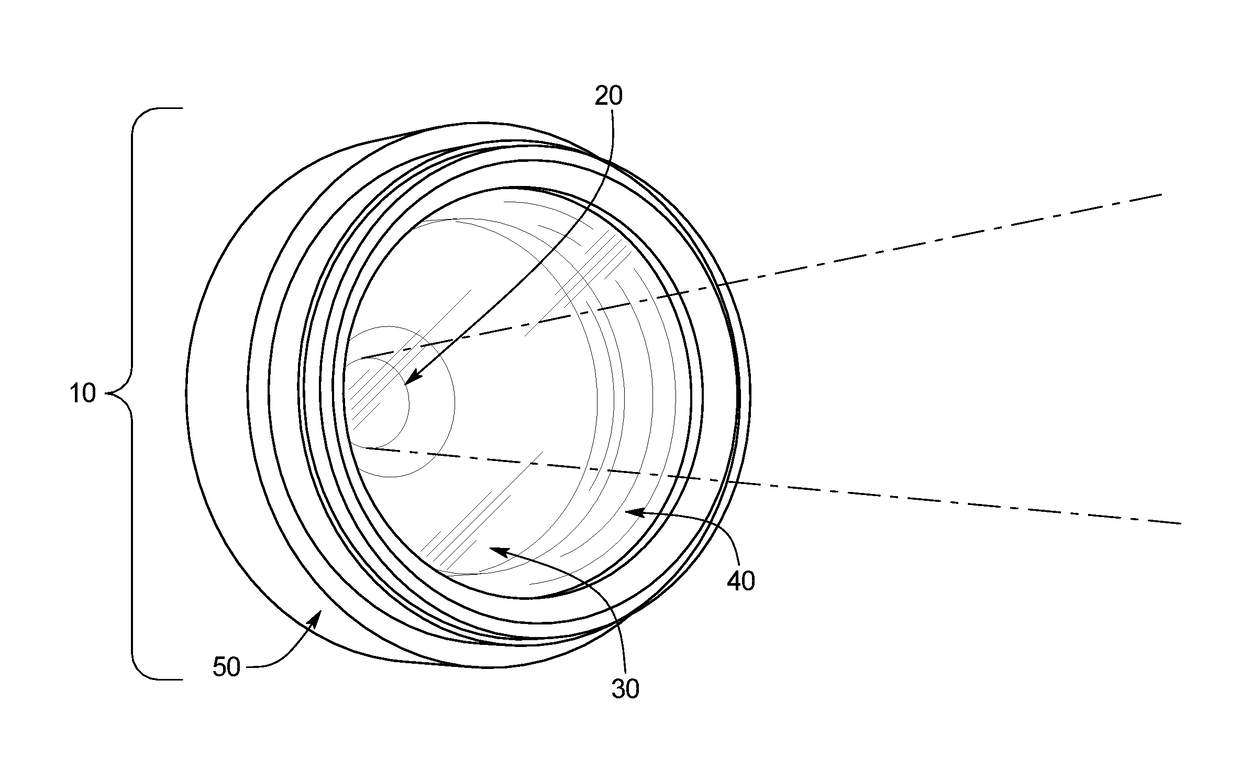

A flat or curved photochromic laminate structure and a plastic photochromic lens blank can be produced in a simple and efficient manner from relatively low-cost polymeric sheet materials. These laminates can be used to provide goggles, face shields, windows, window coverings, skylights, and optical lenses having efficient, uniform and high quality photochromic properties. The use of a polyesterurethane as the binder for the photochromic material has been found to improve the performance of the photochromic material. There may be a desire to have a protective exterior layer (e.g., an abrasion resistant layer) in combination with the lens system, but that may be provided in various methods. In the case of using the laminate in a goggle application, the laminate may be hard coated on one or both outer surfaces with an abrasion resistant coating, antireflective coating, and / or an anti-fog hard coating.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Photochromic Lens

ActiveUS20070122626A1Good resistance to photochromic dye fatigueReduce the amount requiredSynthetic resin layered productsOptical articlesPhotochromic lensLens plate

A cast photochromic lens including a photochromic film and a cast resin, curable by heat or radiation.

Owner:HOYA OPTICAL LABS OF AMERICA INC +1

Photochromic film, photochromic lens comprising the same, and method of manufacturing photochromic lens

ActiveUS7999989B2Good photoresponse performanceImprove featuresOptical articlesCoatingsPhotochromic lensHardness

The present invention relates to a photochromic film comprising a photochromic dye and a resin component. The photochromic film has a nanoindentation hardness of equal to or greater than 800 nm on at least one of surfaces, surface A, thereof. The present invention further relates to a method of manufacturing a photochromic lens. The method of manufacturing a photochromic lens of the present invention comprises forming a photochromic film having a nanoindentation hardness ranging from 500 to 5000 nm on an outermost surface thereof as well as having a smaller nanoindentation hardness on a surface facing a first mold than that on the outermost surface by coating a photochromic liquid comprising a photochromic dye and a curable component on one surface of the first mold for formation of one of surfaces of a lens and subjecting the photochromic liquid to curing treatment, and a photochromic lens comprising a photochromic film on a lens substrate is obtained by means of the above first mold.

Owner:HOYA CORP

Injection molding of lens

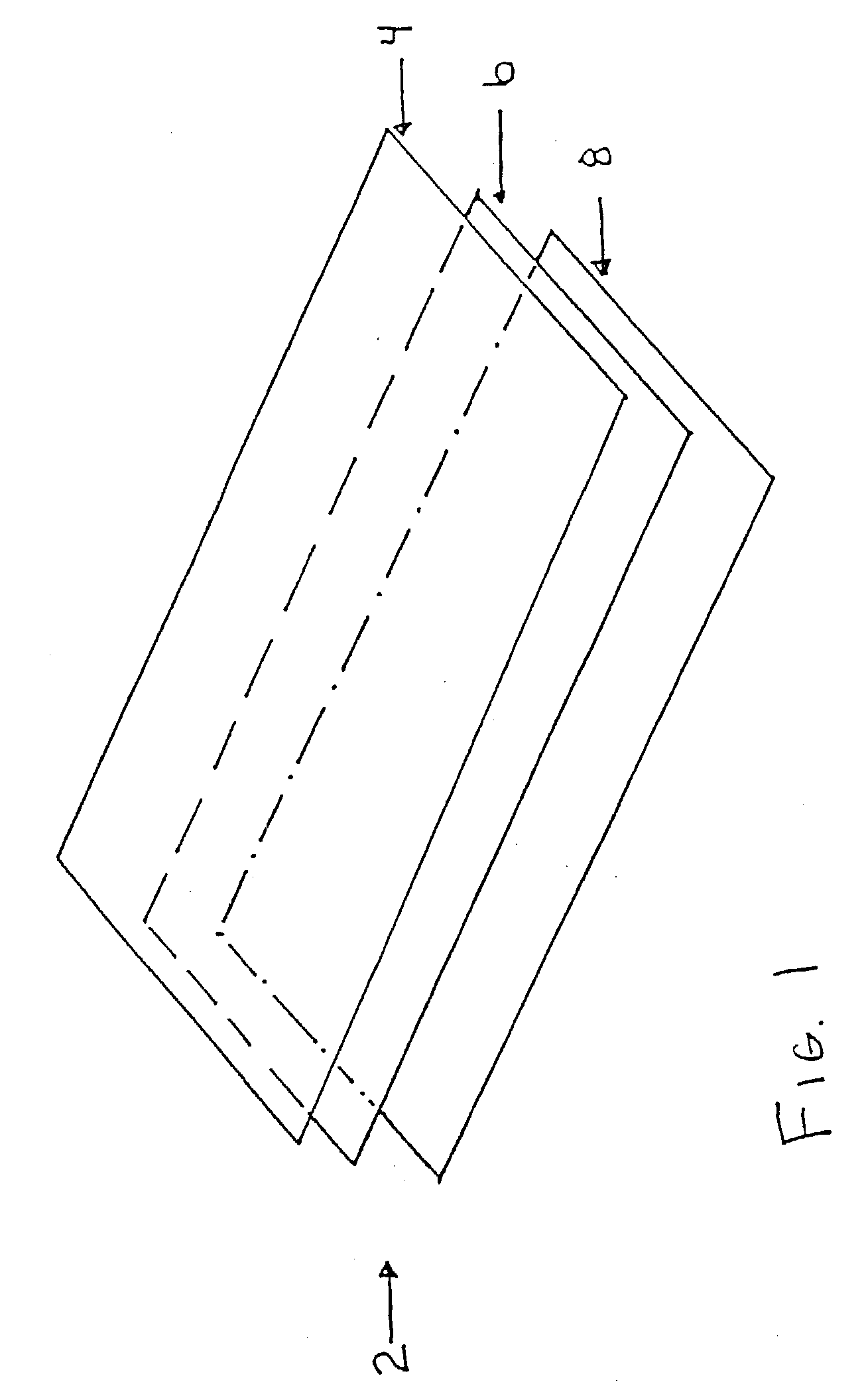

InactiveUS20030214080A1Reduce distortionReduce strainSpectales/gogglesSynthetic resin layered productsPhotochromic lensInjection molding machine

A flat or curved photochromic laminate structure and a plastic photochromic lens blank can be produced in a simple and efficient manner from relatively low-cost polymeric sheet materials. These laminates can be used to provide goggles, face shields, windows, window coverings, skylights, and optical lenses having efficient, uniform and high quality photochromic properties. The use of a polyesterurethane as the binder for the photochromic material has been found to improve the performance of the photochromic material. There may be a desire to have a protective exterior layer (e.g., an abrasion resistant layer) in combination with the lens system, but that may be provided in various methods. In the case of using the laminate in a goggle application, the laminate may be hard coated on one or both outer surfaces with an abrasion resistant coating, antireflective coating, and / or an anti-fog hard coating.

Owner:HOYA OPTICAL LABS OF AMERICA INC

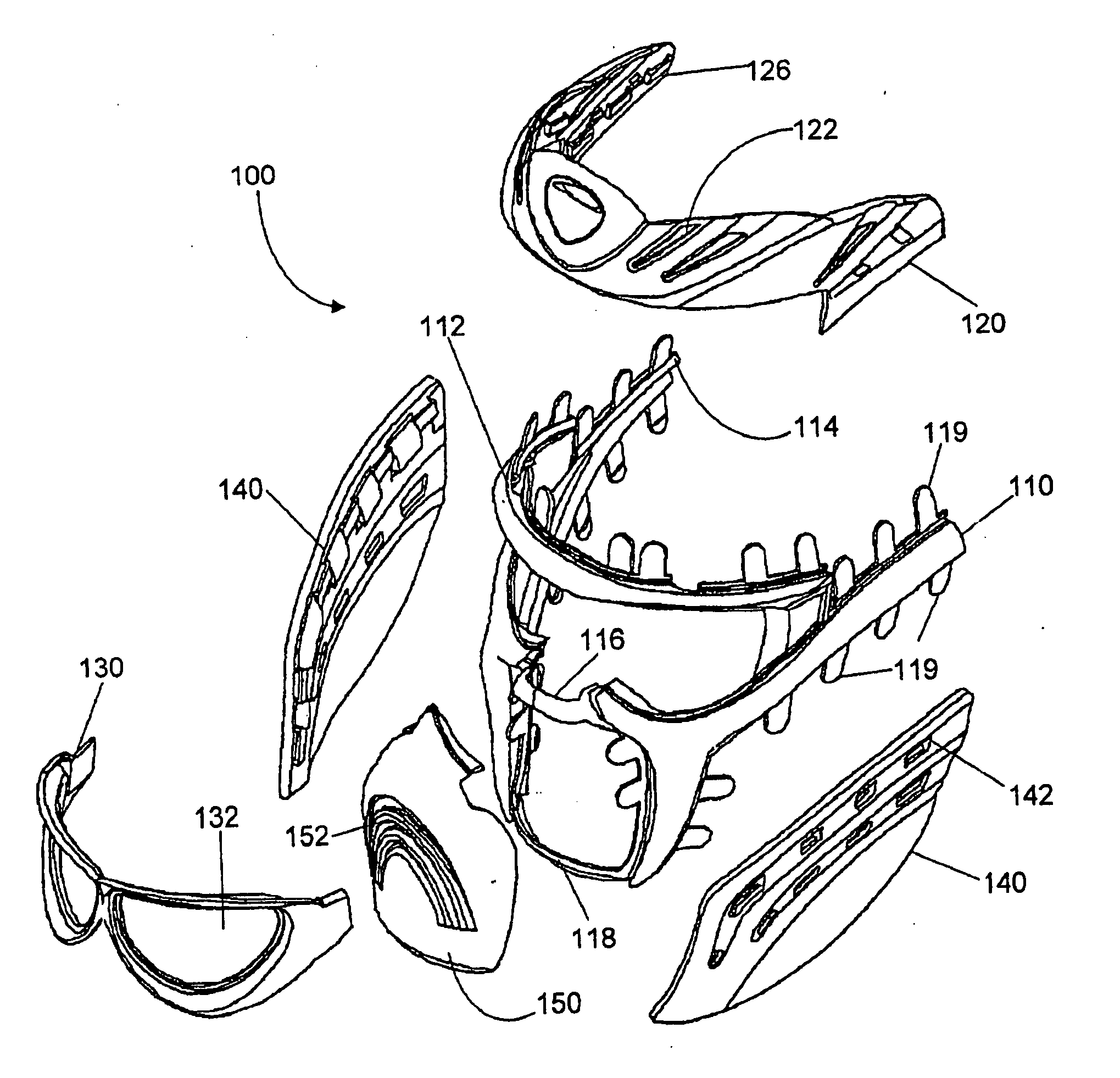

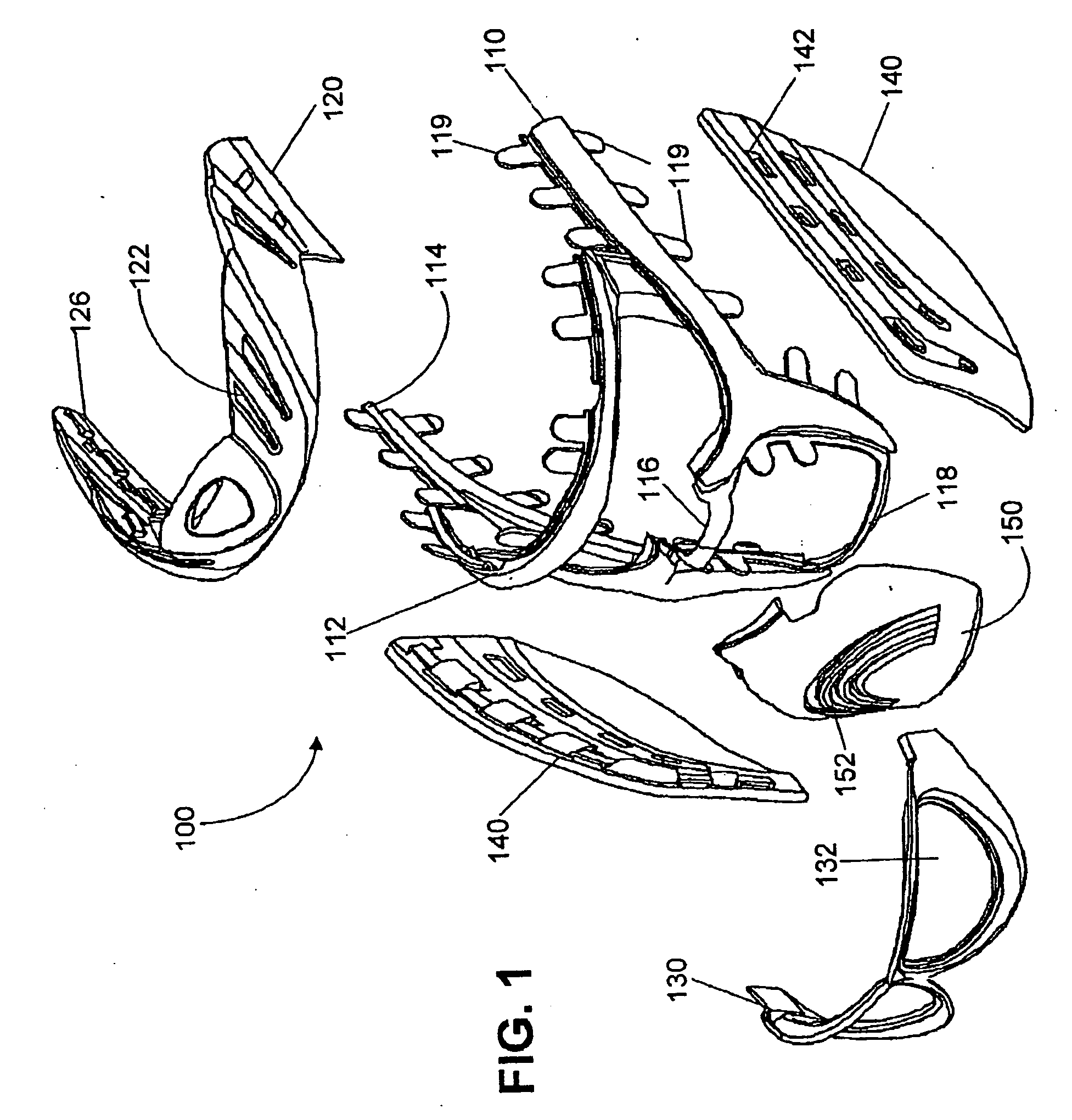

Modular mask system

A modular mask system comprises a frame for fitting over a user's head, and a set of interchangeable mask components. Each interchangeable mask components can be removeably attachable to the frame. Each of the interchangeable mask components is one of a top panel, a side panel assembly, an eyepiece and a nosepiece. The interchangeable side panel assemblies can be different sizes to accommodate the user's face or have different patterns or have different configurations of ventilation holes. The interchangeable eyepieces allow the user to choose from dual lenses and a single shield. The eyepieces can include optically powered lenses, shaded lenses, dual lenses tinted lenses, photochromatic lenses and polarized lenses.

Owner:REVISION EYEWEAR

Method for producing laminated photochromic lenses

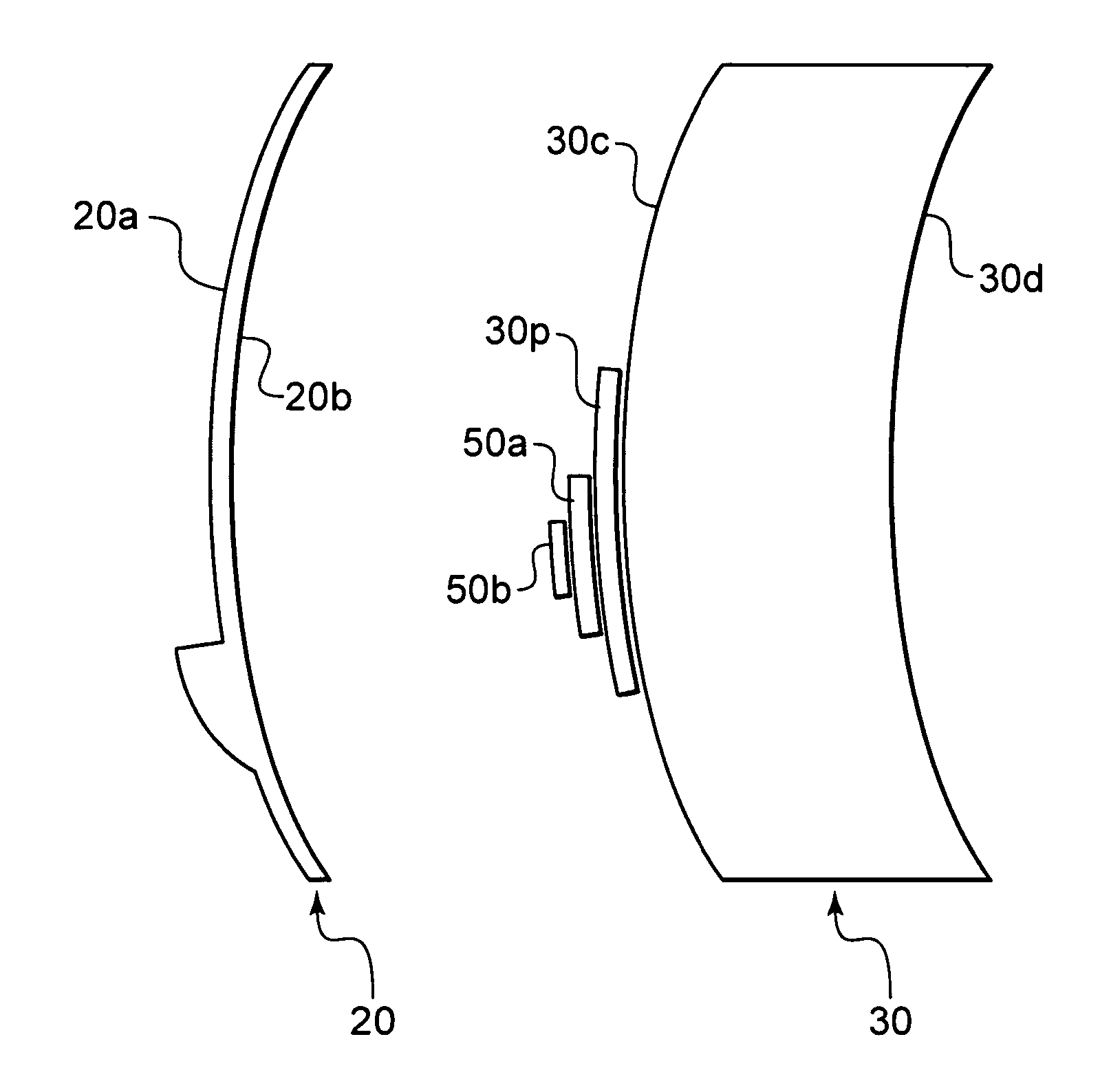

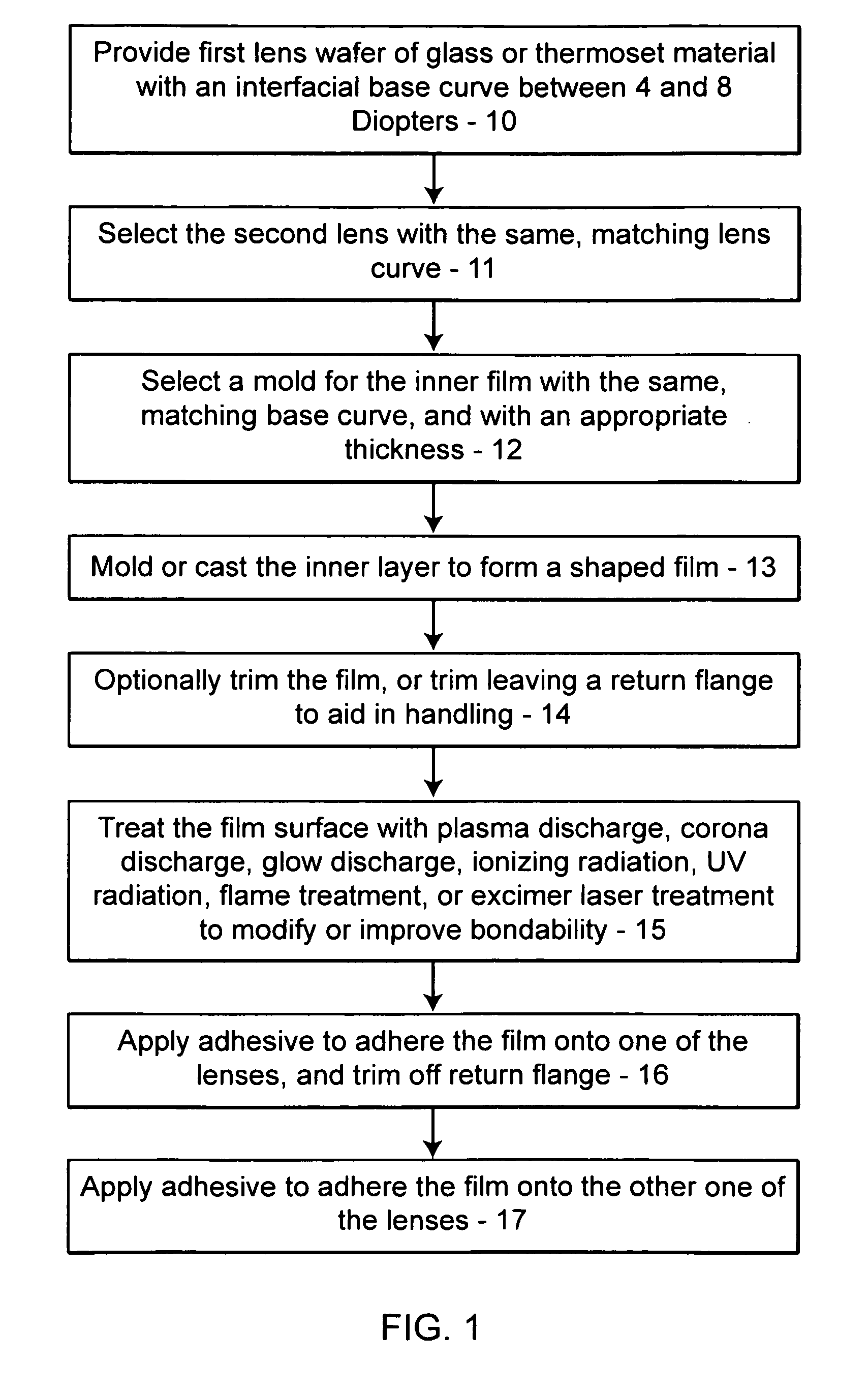

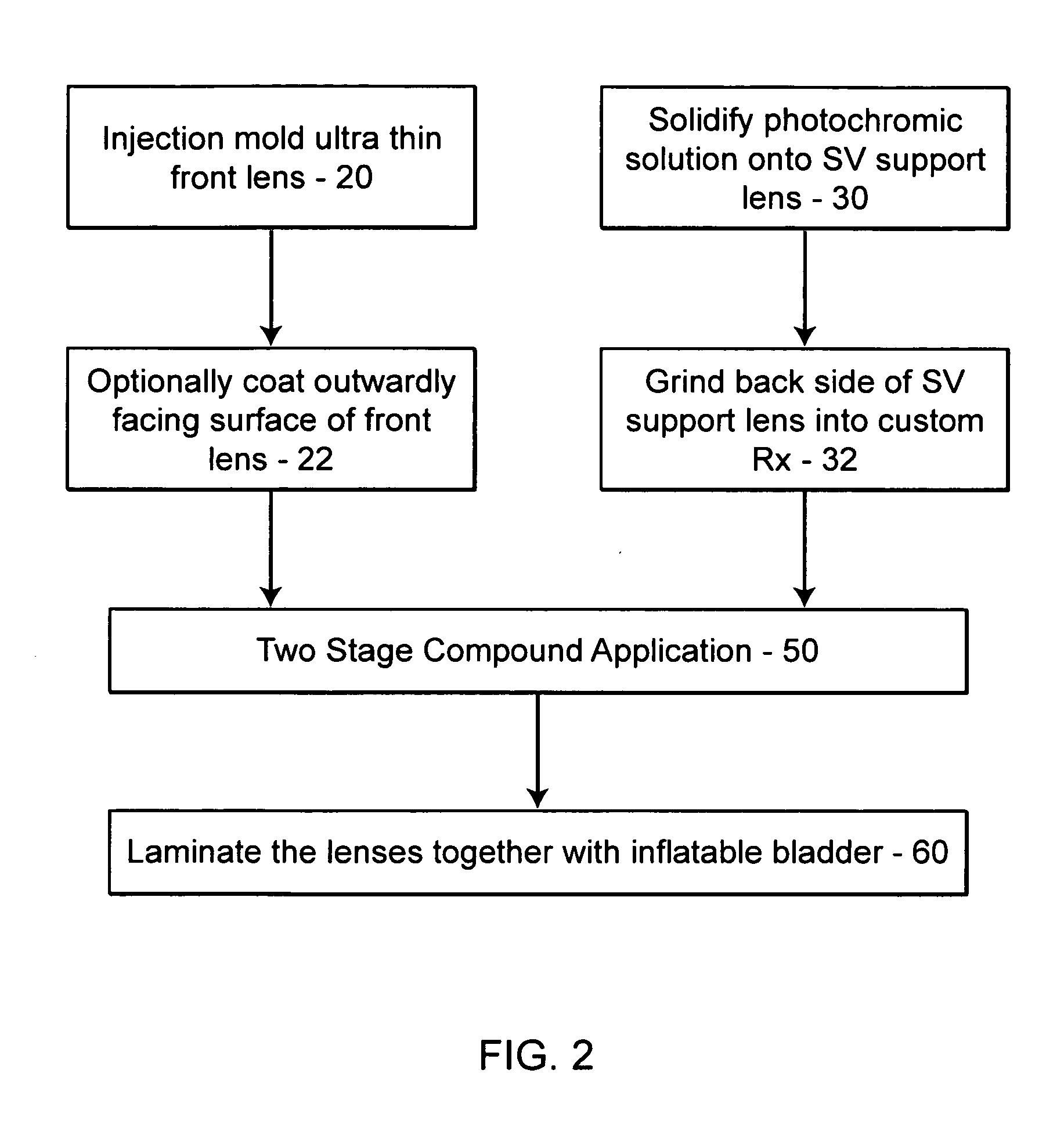

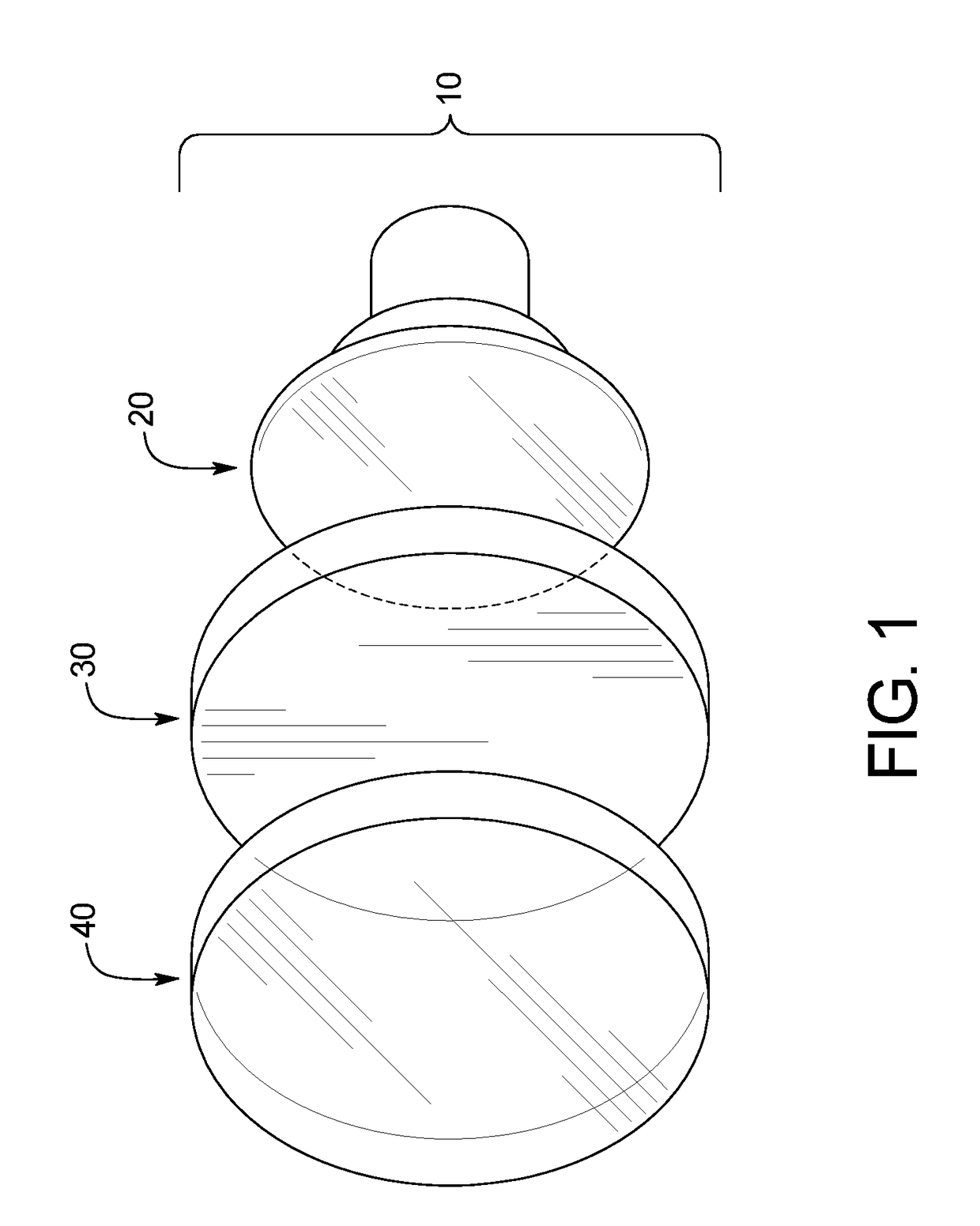

A method for laminating an optical assembly and the optical assembly formed thereby. An ultra thin lens is injection molded and may include a bifocal feature. A support lens, e.g. of the single vision type, is provided with a photochromic coating. A flexible two stage compound application process prepares the two lenses for lamination.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Photochromic lens

ActiveUS7858001B2Easy to useImprove the immunitySynthetic resin layered productsOptical articlesPhotochromic lensLens plate

Owner:HOYA OPTICAL LABS OF AMERICA INC +1

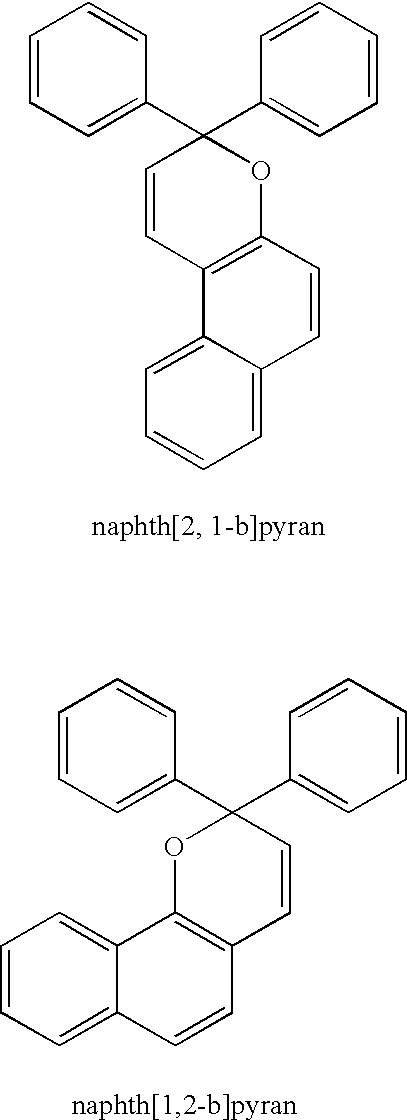

Lenses with graded photochromic, molds and methods of making same

InactiveUS20150231839A1Facilitate outdoor readingEasy to readOptical articlesCoatingsPhotochromic lensOptoelectronics

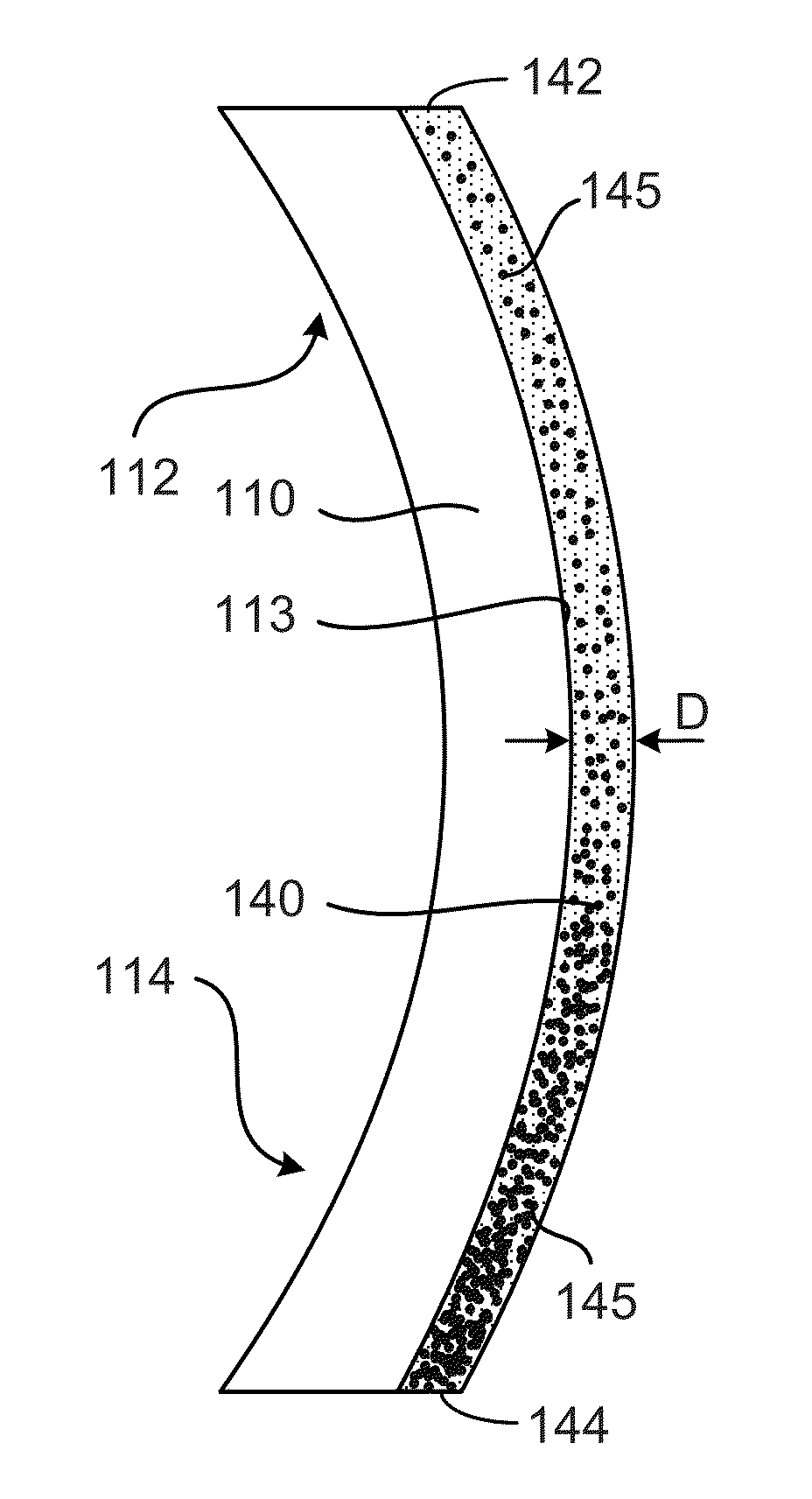

Certain aspects of the invention are directed to a photochromic lens having a graded or variable tint, methods and molds of making the same. In one embodiment, the photochromic lens includes a lens element having a upper portion and a lower portion; and a UV-absorbing layer formed of a UV-absorbing material on a surface of the lens element, such that the UV-absorbing material is more concentrated at the lower portion of the lens element and less concentrated at the upper portion, thereby allowing more UV light to strike the photochromic at the upper portion of the lens element than at the lower portion. The lens element comprises a photochromic composition.

Owner:QSPEX TECH INC

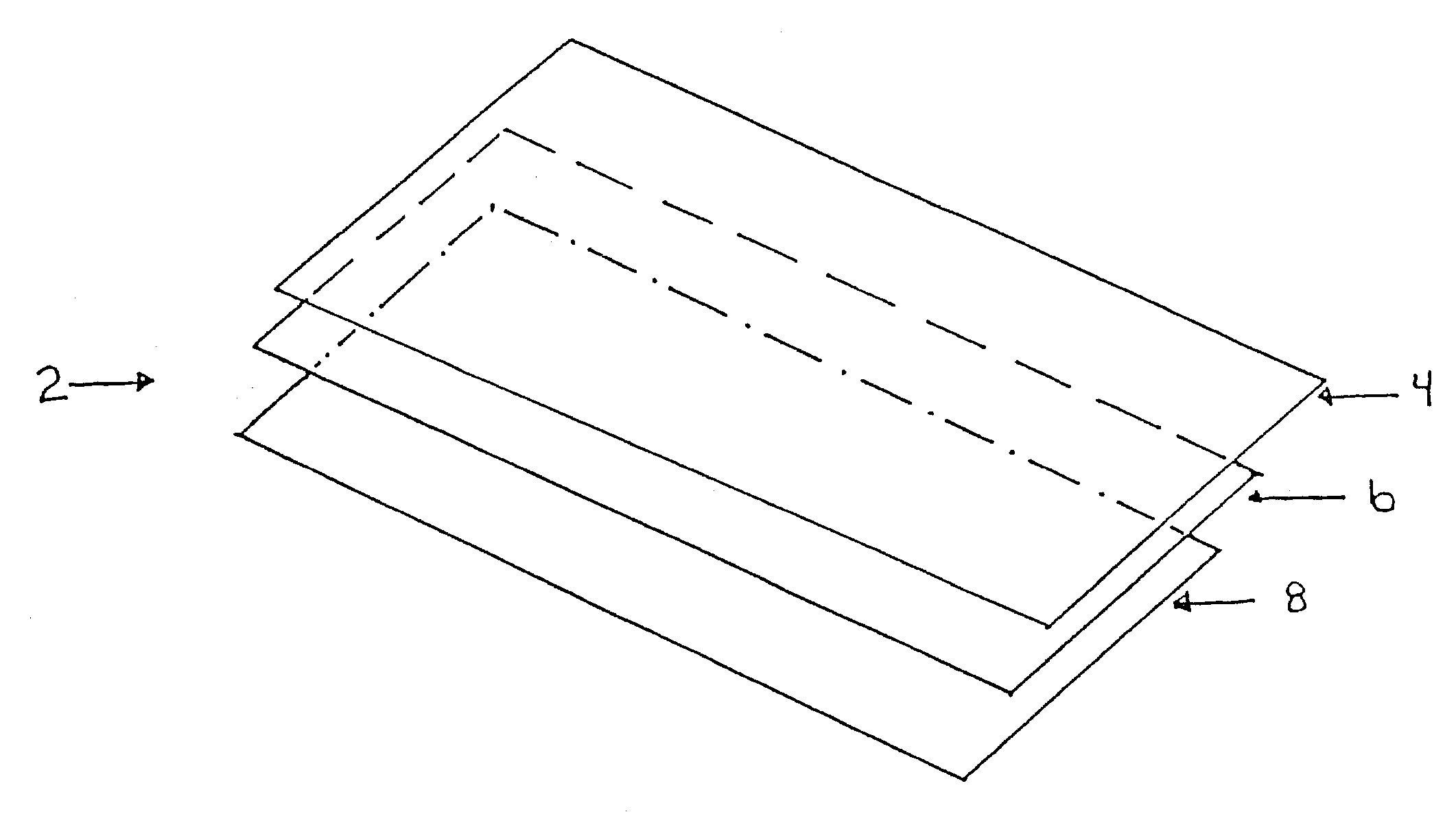

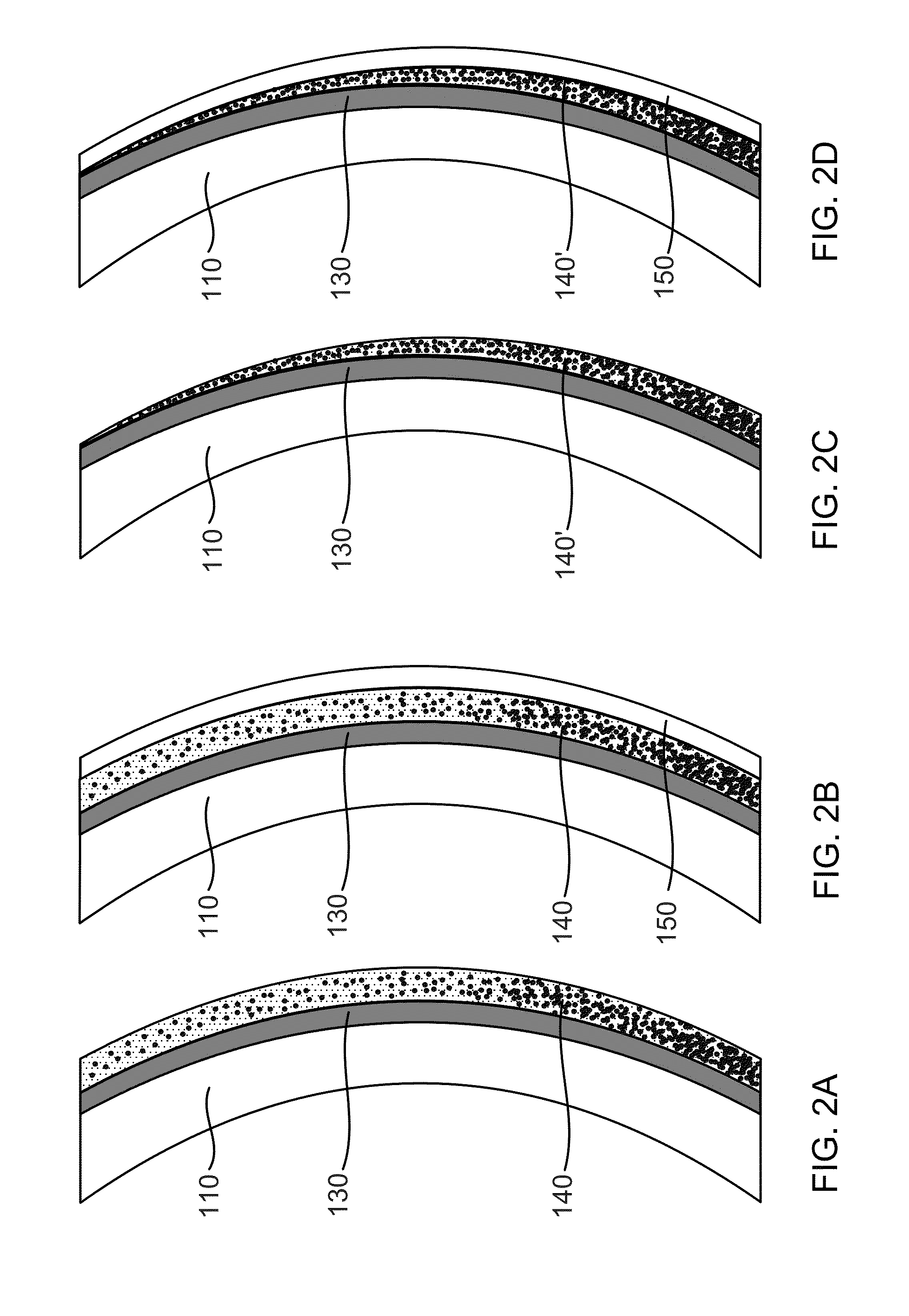

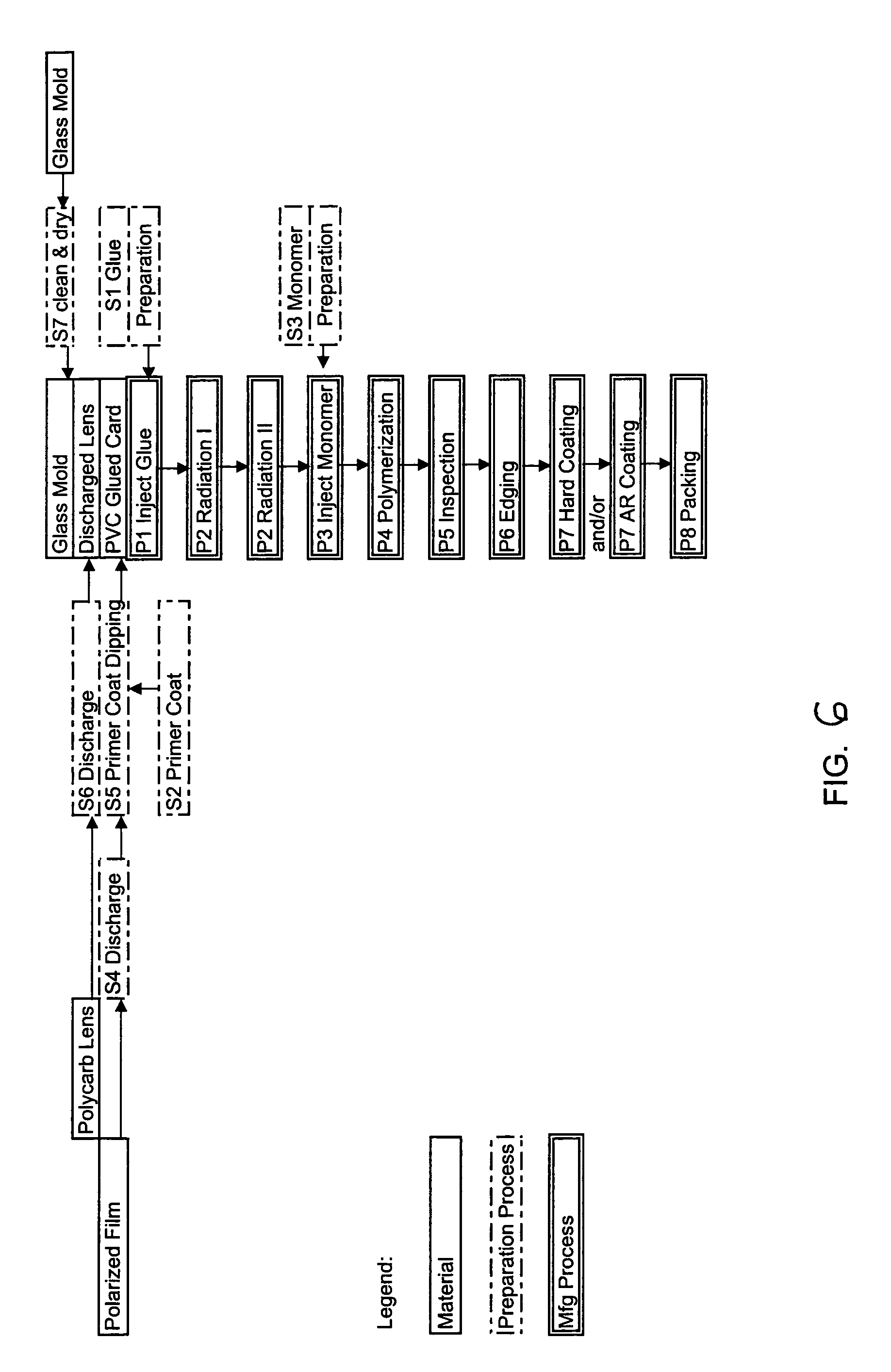

Method of forming polarized or photochromic lenses by fusing polycarbonate with other plastic materials

The invention provides techniques for making polycarbonate or plastic lenses. In one exemplary embodiment, for example, an electrical discharge is applied to a polarized film surface and a treatment applied on the polarized film to make a glue card. An adequate amount of adhesive glue is spread between the polarized film glue card and a polycarbonate lens, and a one-unit lens is formed by photochemical reaction technology. Thermosetting monomer is poured between the unit lens and a glass mold, and heated evenly to create a solid one-piece lens. The thermosetting monomer may be a photochromic or transparent monomer. These or substantially similar techniques may be used to produce polycarbonate polarized lenses, polycarbonate photochromic lenses, polycarbonate photochromic polarized lenses, plastic polarized lenses, plastic photochromic lenses, and plastic photochromic polarized lenses.

Owner:POLYLITE TAIWAN

Photochromic polyurethane laminate

ActiveUS8298671B2Fine surfaceImprove uniformityLamination ancillary operationsSynthetic resin layered productsPhotochromic lensThermoplastic polyurethane

A photochromic polyurethane laminate that is constructed to solve certain manufacturing difficulties involved in the production of plastic photochromic lenses is disclosed. The photochromic laminate includes at least two layers of a resinous material and a photochromic polyurethane layer that is interspersed between the two resinous layers and which contains photochromic compounds. The polyurethane layer is formed by curing a mixture of a solid thermoplastic polyurethane, at least one isocyanate prepolymer, at least one photochromic compound, and a stabilizing system.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Bifocal lens spectralite

The invention relates to a bifocal lens spectralite which belongs to the technical field of spectralites and mainly solves the problems of big swell factors and poor water resistance and wear resistance of the prior bifocal and optical correcting lens. The spectralite is characterized by containing the following contents according to the weight percentage: 20-50 of SiO2, 2-25 of B2O3, 25-60 of PbO, 0-10 of Al2O3, 0-10 of TiO2, 0-5 Li2O, 0-5 of Na2O, 0-5 of K2O, 0-5 of ZrO2, 0-5 of ZnO, 0-5 of CaO, 0-5 of SrO, 0-10 of BaO, 0-5 of La2O3, and 0.2-1 of Sb2O3, wherein sigma (Li2O, Na2O and K2O) is smaller than or equal to 12 percent and larger than or equal to 0; and sigma (CaO, SrO and BaO) is smaller than or equal to 15 percent and larger than or equal to 0. The bifocal lens spectralite has the optical characteristics with the refractivity (nd) of 1.59-1.71 and the abbe number (Upsilon d) of 30-43, and is particularly suitable for being melted with GBS photochromic lens glass and made into a bifocal photochromic lens. The invention is mainly used for manufacturing the bifocal lens spectralite.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

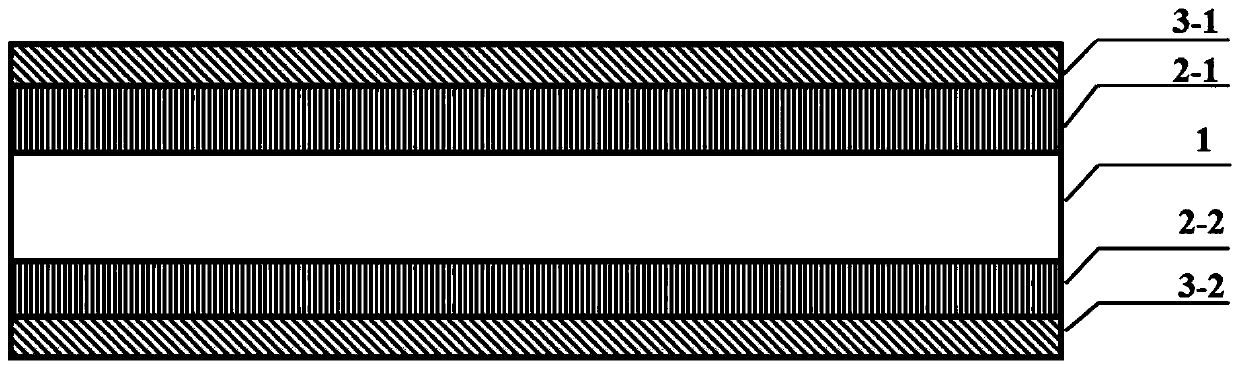

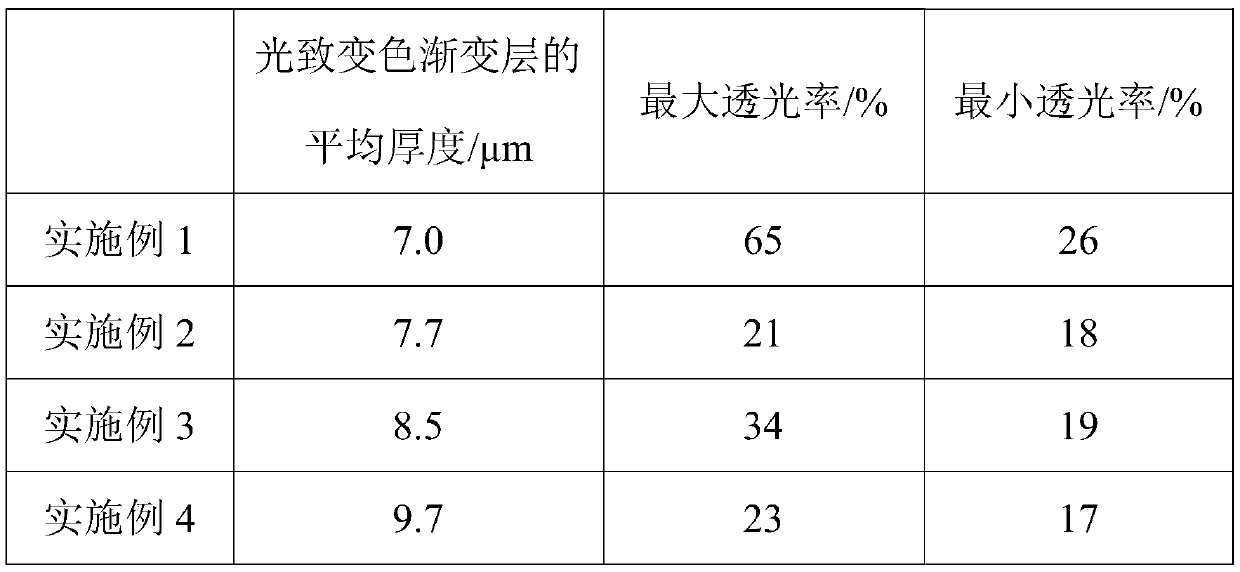

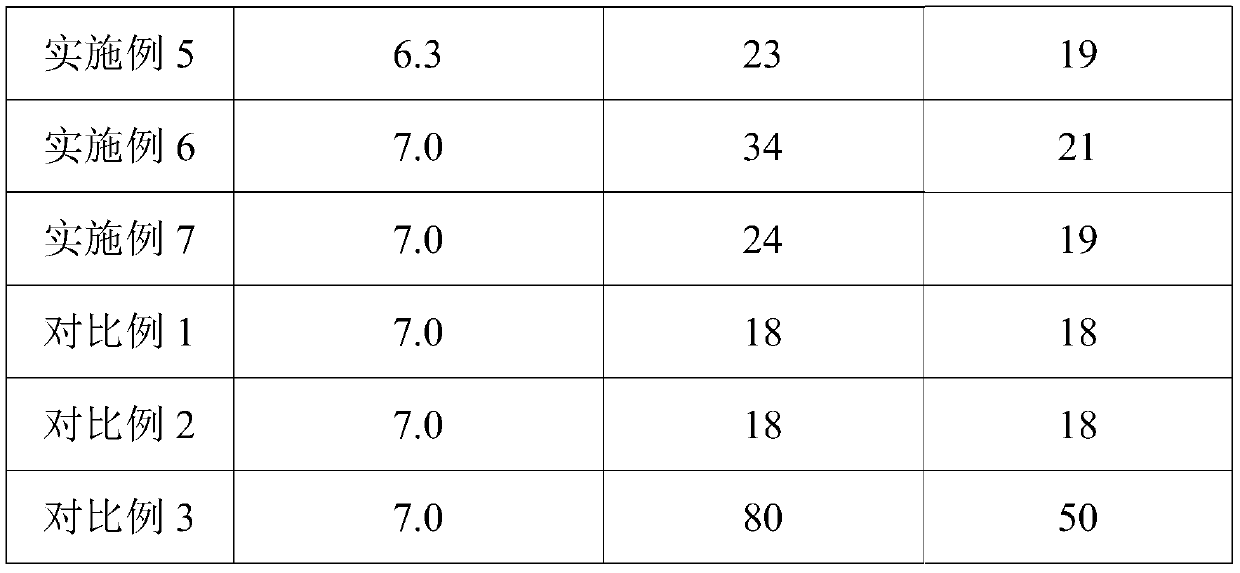

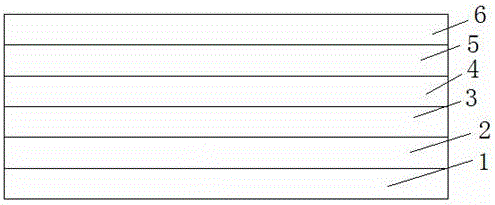

Photochromic lens and preparation method and application thereof

PendingCN110596911ATo achieve a gradient effectProtect from glareOptical partsMulticolor effect coatingsPhotochromic lensDip-coating

The invention provides a photochromic lens, and a preparation method and an application thereof. The photochromic lens comprises a substrate, a first photochromic gradient layer, a second photochromicgradient layer, a first hard reinforcing layer and a second hard reinforcing layer. Firstly, the first photochromic gradient layer and the second photochromic gradient layer endow the photochromic lens with the properties of being colorless and transparent under indoor light intensity and becoming dark under outdoor sunlight activation; and secondly, through adopting a color fading treatment process, the photochromic lens presents different photochromic depths under the activation of sunlight, the gradual change effect of the photochromic lens is realized through the transition between different photochromic depths, the requirements of a user for different photochromic depths when the user looks near and far outdoors are met, and the discomfort brought to the user due to sudden change ofthe color depth is avoided. The photochromic lens can be obtained by adopting a layer-by-layer dip-coating, lifting and curing method, the preparation process is simple, and the photochromic lens hasa wide industrialization prospect.

Owner:SHANGHAI CONANT OPTICS CO LTD

Photochromic paint, preparation method thereof, photochromic lens and preparation process of photochromic lens

InactiveCN106833338AFast fadingImprove antioxidant capacityPolyurea/polyurethane coatingsOptical partsPhotochromic lensRainbow

The invention discloses photochromic paint, a preparation method thereof, a photochromic lens and a preparation process of the photochromic lens. The photochromic paint is prepared from components in parts by mass as follows: 20-50 parts of isocyanate compounds, 20-30 parts of polythiol compounds, 1-5 parts of a catalyst, 0.1-2 parts of a leveling agent, 30-50 parts of a solvent and 1-10 parts of color-changing powder. The photochromic paint makes the photochromic lens quickly discolor or change colors, has good oxidation resistance and anti-fatigue performance, has no rainbow grains and provides the lens with a color changing function.

Owner:杜鹏

Polymerization curable composition

ActiveUS20060182977A1Maintain good propertiesHigh color densitySynthetic resin layered productsDomestic articlesPhotochromic lensHeat resistance

A polymerization curable composition comprising a specific polyfunctional polymerizable monomer having a hard molecular structure with an L-scale Rockwell hardness of its homopolymer of 60 or more, a specific polyfunctional polymerizable monomer and a photochromic compound, a photochromic lens substrate composed of a cured product of the polymerization curable composition, and a lens comprising the photochromic lens substrate. The substrate and lens show excellent photochromic properties such as high color development density and high fading rate, and the cured product has excellent substrate properties such as hardness, heat resistance and impact resistance as well as strength (toughness) that allows for its use in rimless spectacles.

Owner:TOKUYAMA CORP

Plastic photochromic lens and method for preparation thereof

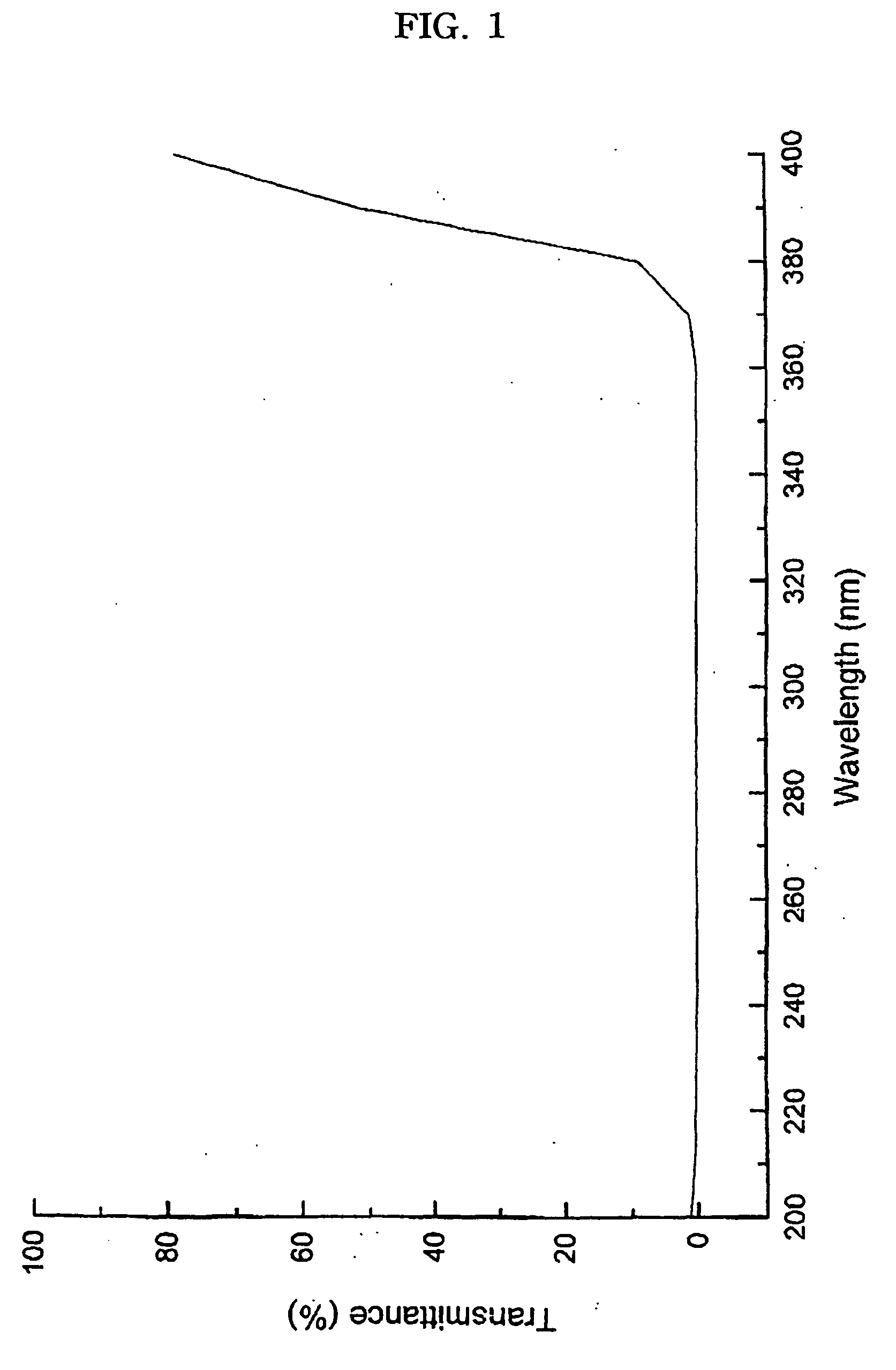

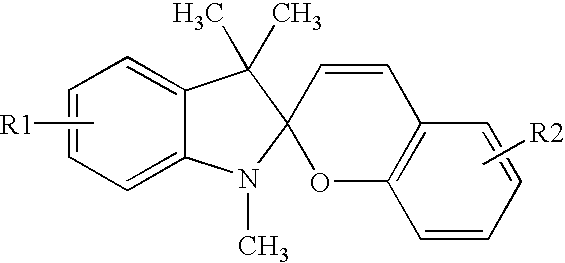

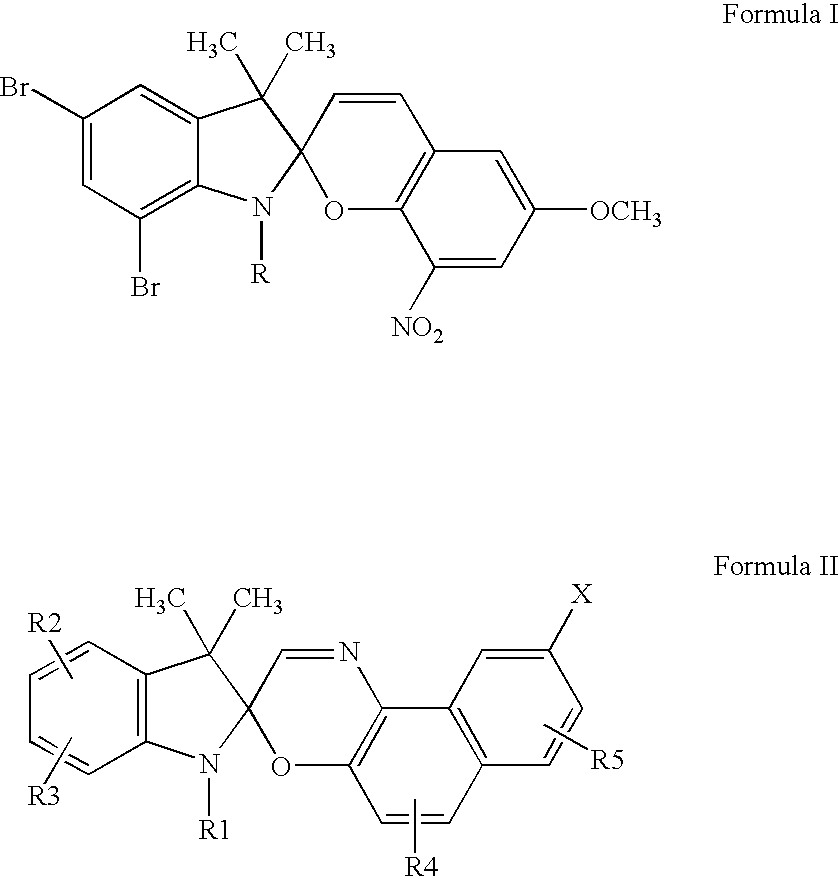

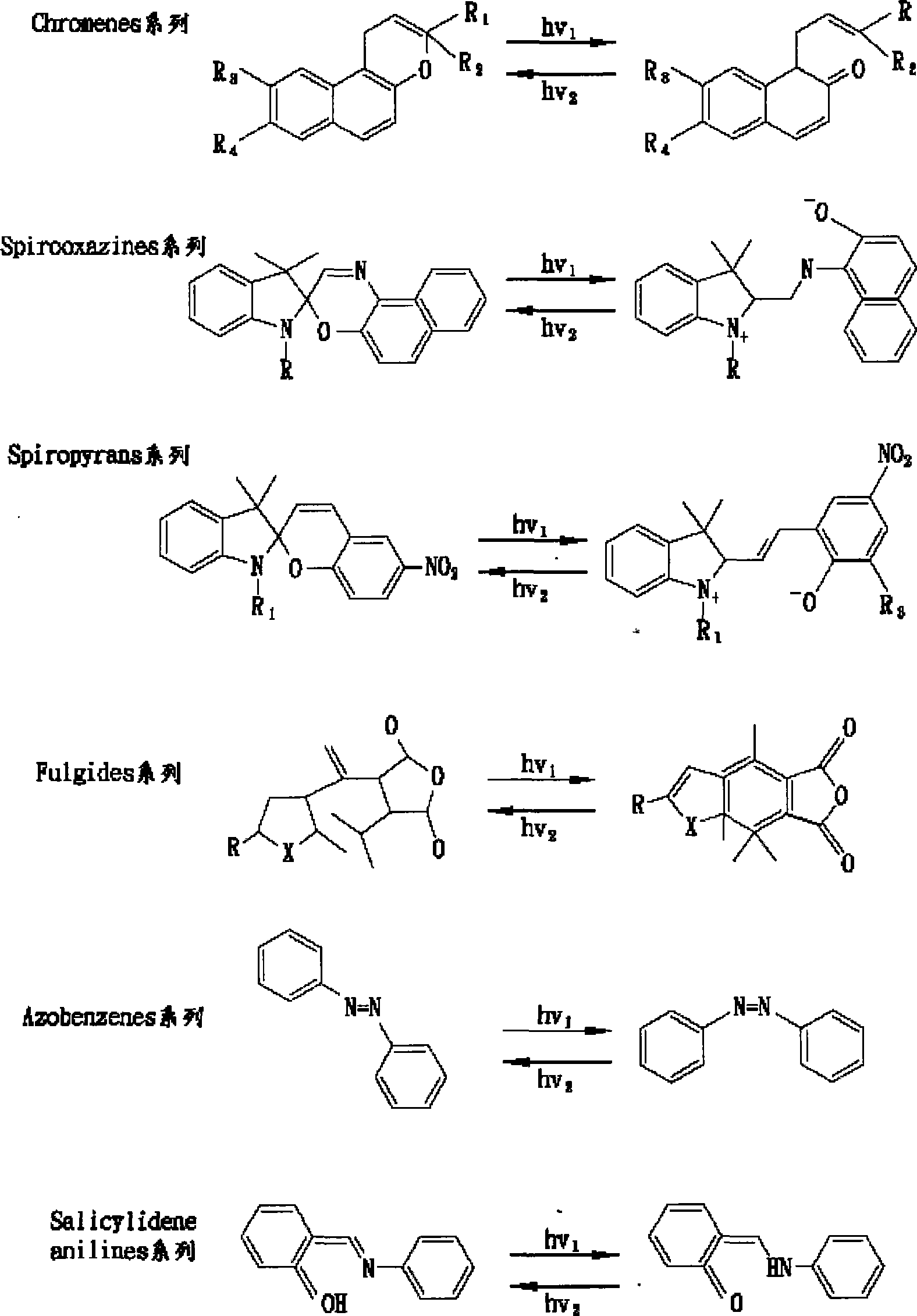

InactiveUS20050202267A1Easy to produceShort variable timeSpiro-condensed pyran compound compositionsSynthetic resin layered productsPhotochromic lensUltraviolet

Disclosed is a coating composition for a plastic photochromic lens and the plastic photochromic lens coated with the same. The coating composition includes a spiropyran photovariable color compound and / or spirooxazine photovariable color compound dissolved in toluene, and an acryl based binder. The plastic photochromic lens coated with the coating composition has advantages of short variable time, and good adhesion of the coating composition to the plastic lens and UV prevention effect without an undesirable haze phenomenon.

Owner:YUJINTECH21 +1

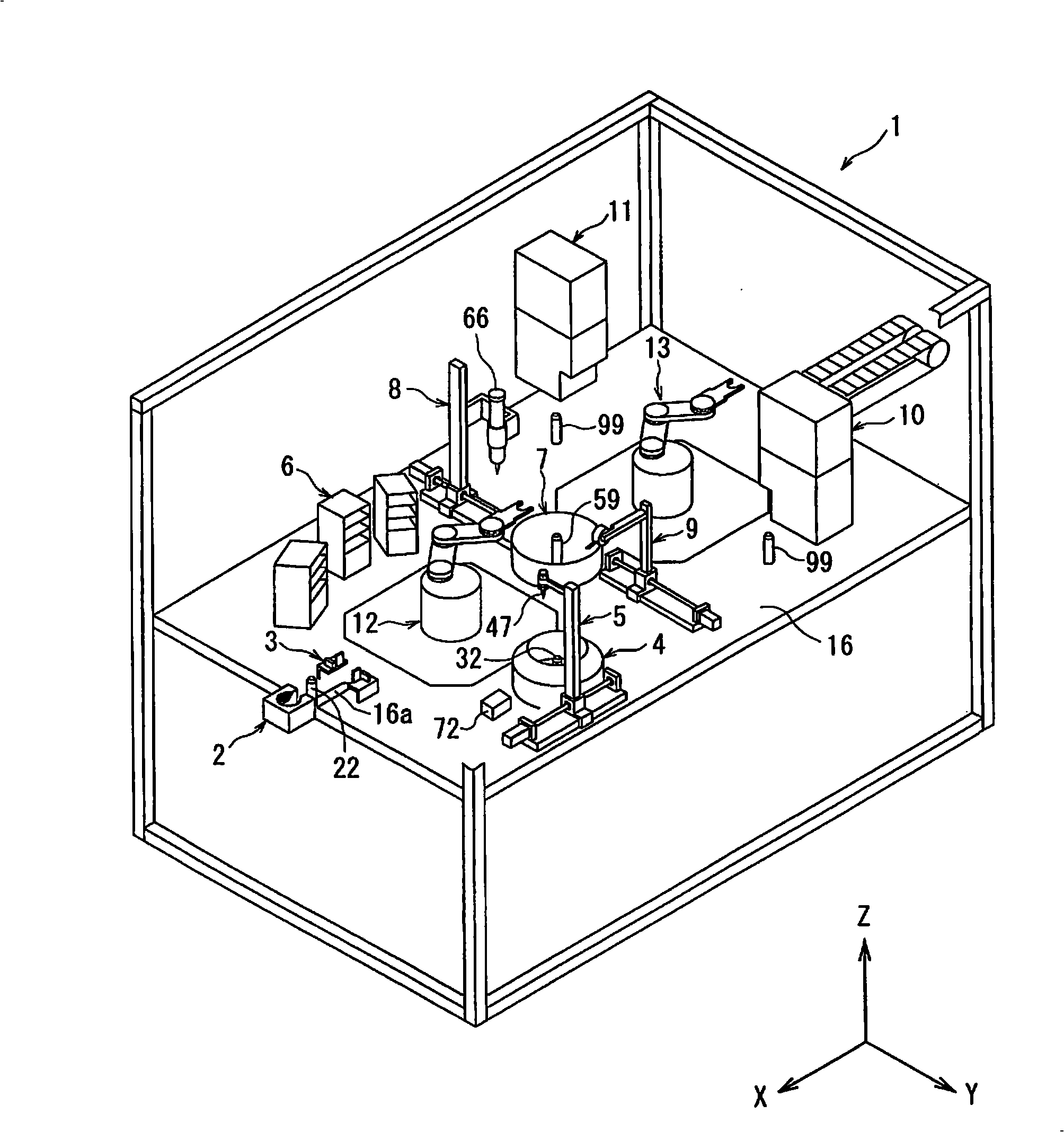

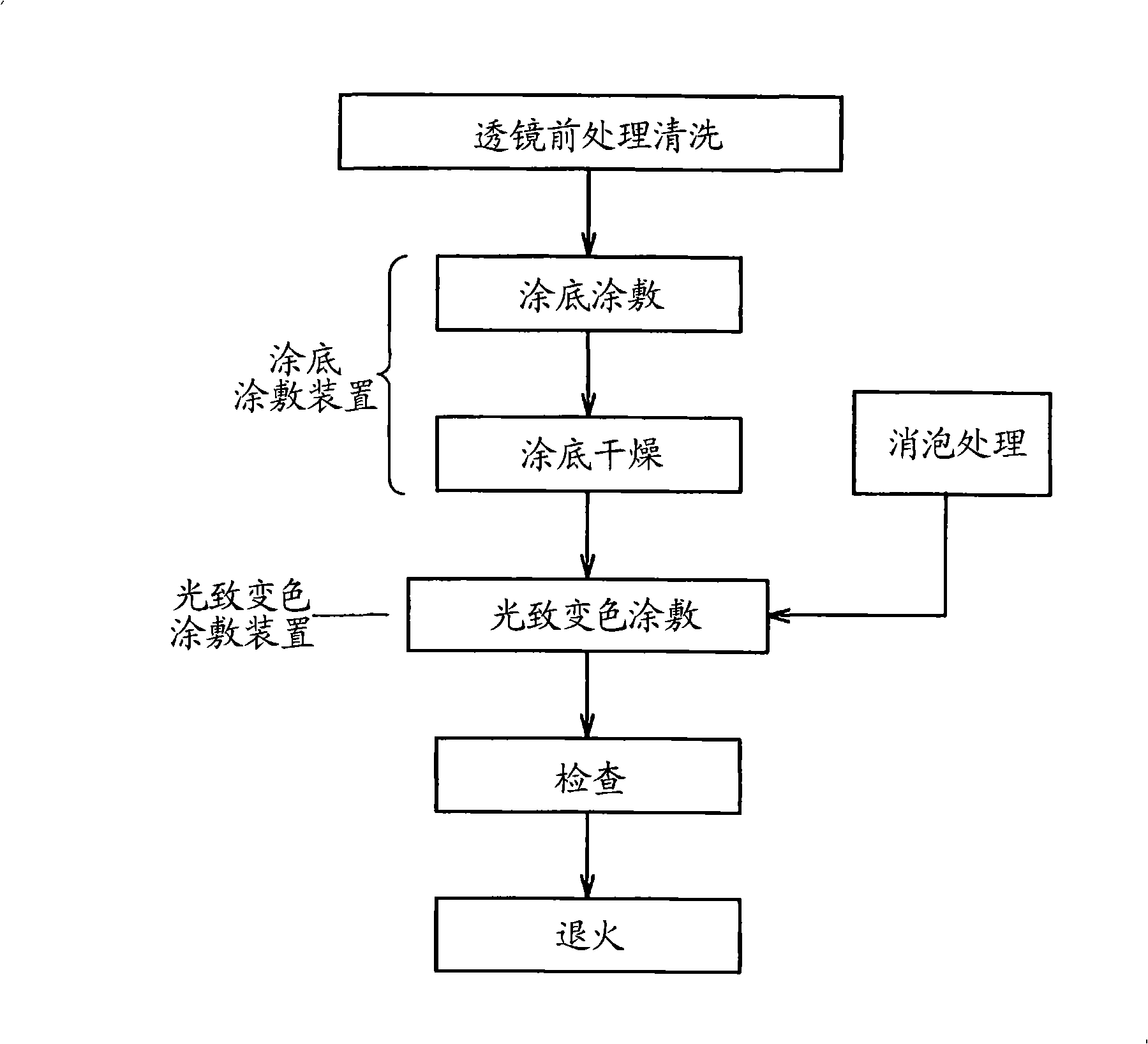

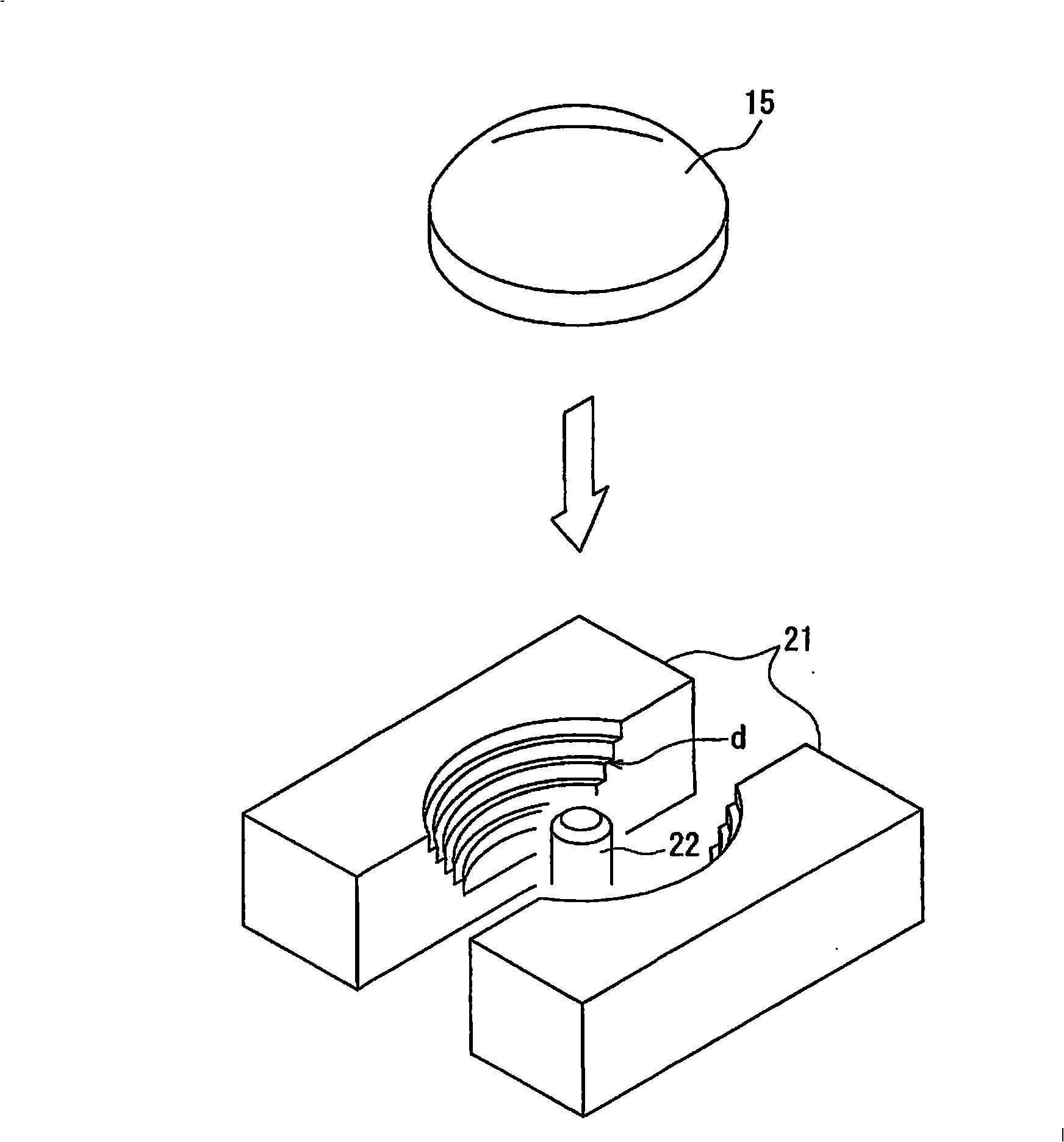

Coater

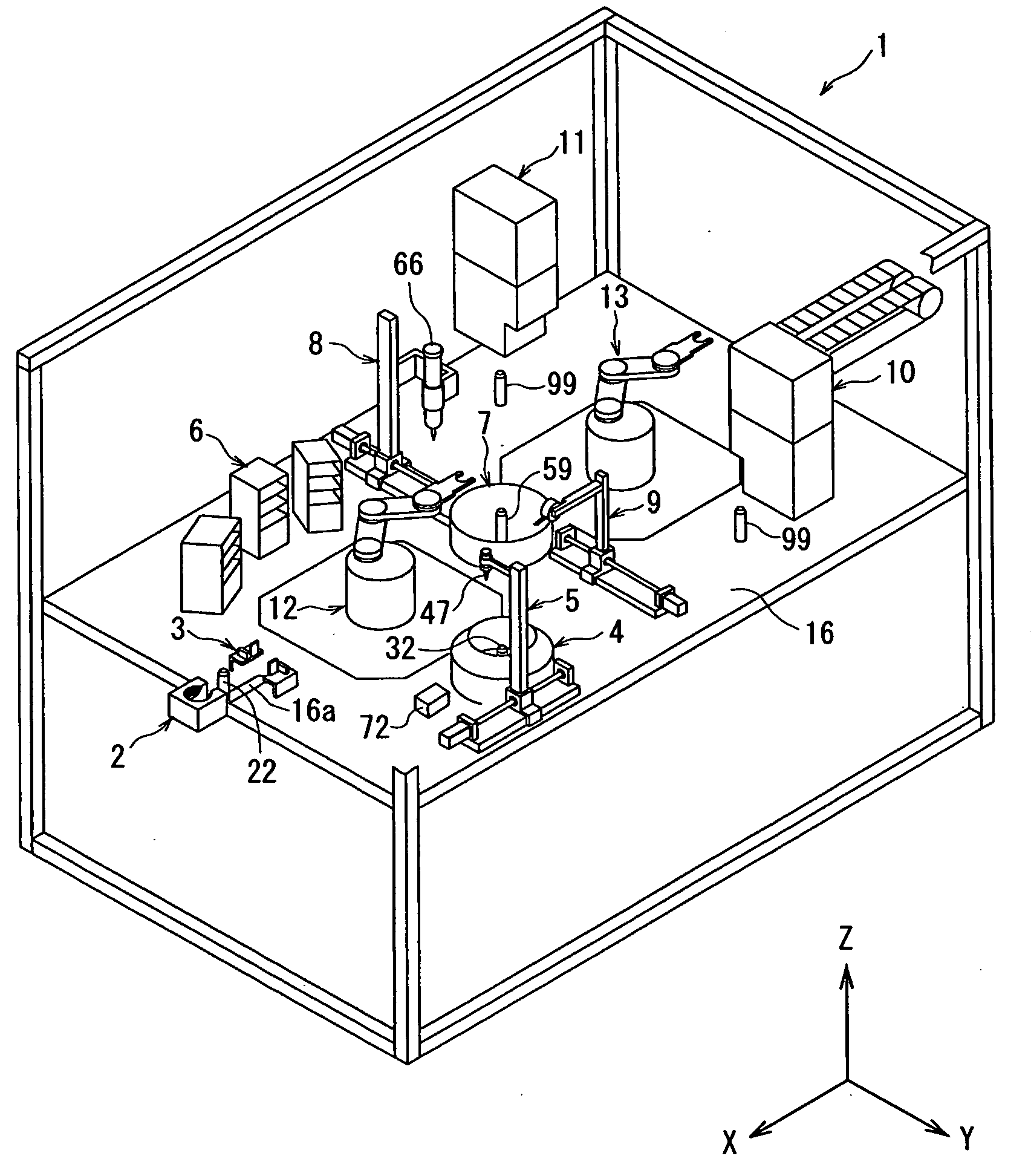

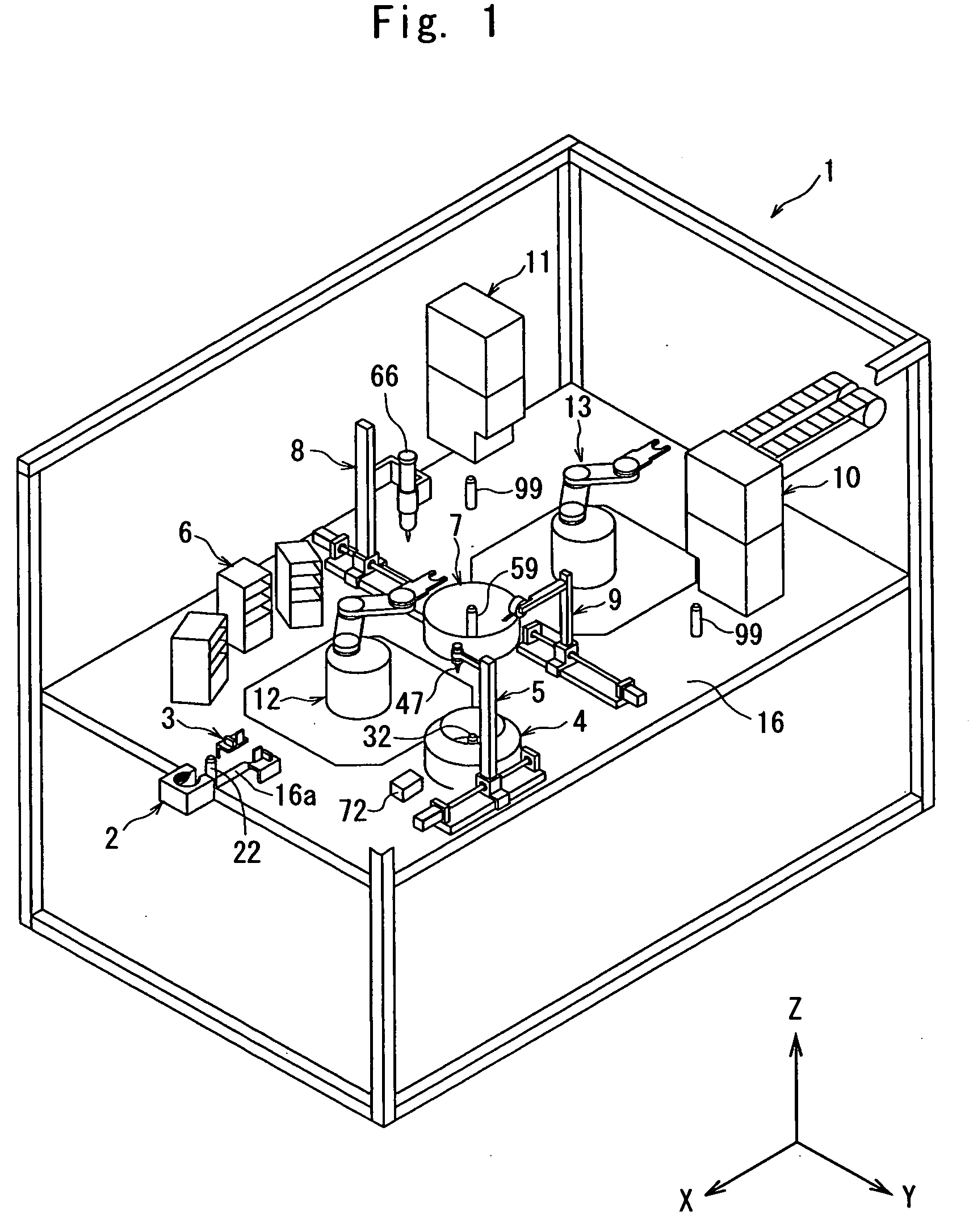

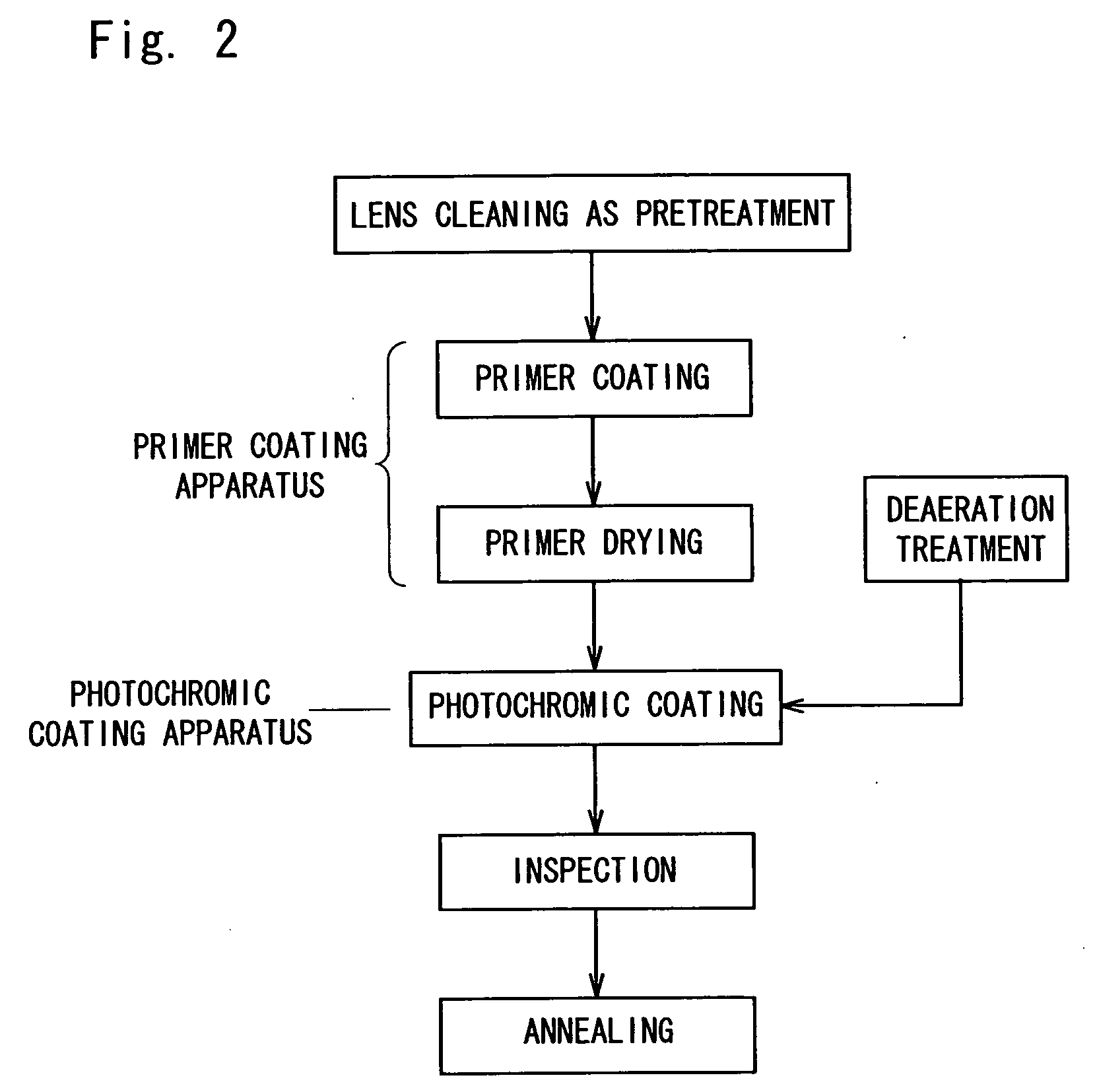

A coater for forming a stable photochromic coating film. In the path of one handling device, the lens support shafts of a lens height measuring sensor, a primer-side lens support, and a lens drying box are provided; and in the path of the other handling device, and the lens support shafts of a UV device are provided. The lens support shafts of the primer-side lens support are provided in the paths of both handling devices. In a coater, a centering device, a lens height measuring device, a primer liquid coating device, a primer spin device, a drying device, a photochromic liquid coating device, a photochromic spin device, a UV device, and lens transfer means having a pair of handling devices are provided. In this coater, the lens support sections of the centering device, the lens height measuring device, the primer spin device, and the drying device are arranged in the path of one of the handling devices of the lens transfer means, the lens support section of the UV device is disposed in the other handling device of the lens transfer means, and the lens support sections of the photochromic spin device are arranged in the paths of both handling devices of the lens transfer means. Therefore, many photochromic lens can be efficiently fabricated.

Owner:TOKUYAMA CORP

Photochromic lens and manufacturing method thereof

InactiveCN107043594AGood weather resistanceImprove heat resistancePolyurea/polyurethane coatingsOptical elementsPhotochromic lensProtection layer

The invention discloses a photochromic lens and a manufacturing method thereof. The photochromic lens consists of an optical substrate, a photochromic layer and a protective layer from bottom to top in sequence, wherein photochromic paint for forming the photochromic layer contains the following components in percentage by weight: 3-10% of a photochromic compound and the balance of polyurethane resin to 100%.

Owner:JIANGSU MAAT OPTICAL CO LTD

Coating Apparatus

ActiveUS20090133625A1Prevent solidificationLiquid surface applicatorsMovable spraying apparatusPhotochromic lensEngineering

The present invention provides a coating apparatus which can form a stable photochromic coating film. In the invention, a centering device, a lens height measuring device, a primer fluid applicator device, a primer spinning device, a drying device, a photochromic fluid applicator device, a photochromic spinning device, a UV device and a lens transport means comprising a pair of handling devices are provided to a coating apparatus. In the coating apparatus, it is possible to produce many photochromic lenses more efficiently by arranging devices and the lens transport means in such a manner that lens support portions of the centering device, the lens height measuring device, the primer spinning device, and the lens drying device are disposed inside the track of one handling device of the lens transport means, lens support portions of the UV device are disposed inside the track of the other handling device of the lens transport means, and the lens support portion of the photochromic spinning device is disposed inside both of the tracks.

Owner:TOKUYAMA CORP

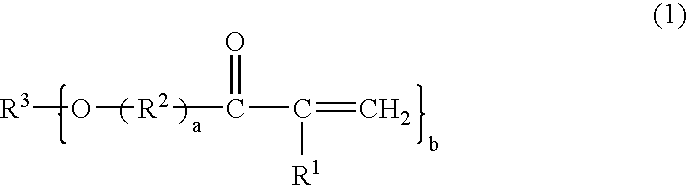

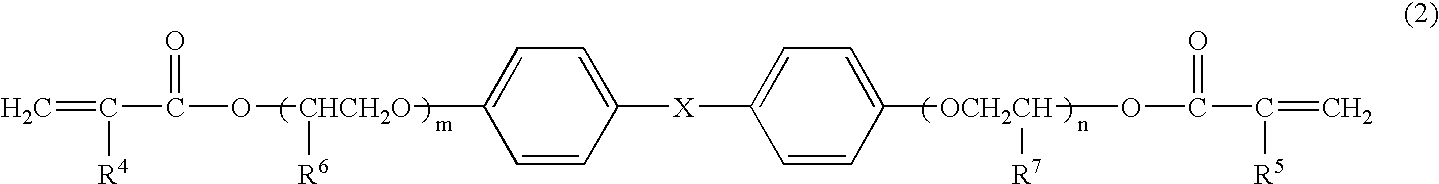

Photochromic lens for eye glasses

ActiveUS20140198296A1Increase refractive powerReduce thicknessOptical partsOptical elementsUses eyeglassesPhotochromic lens

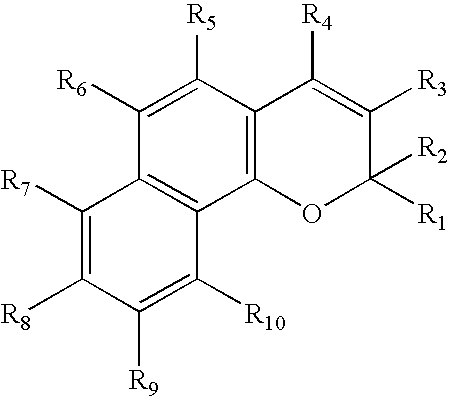

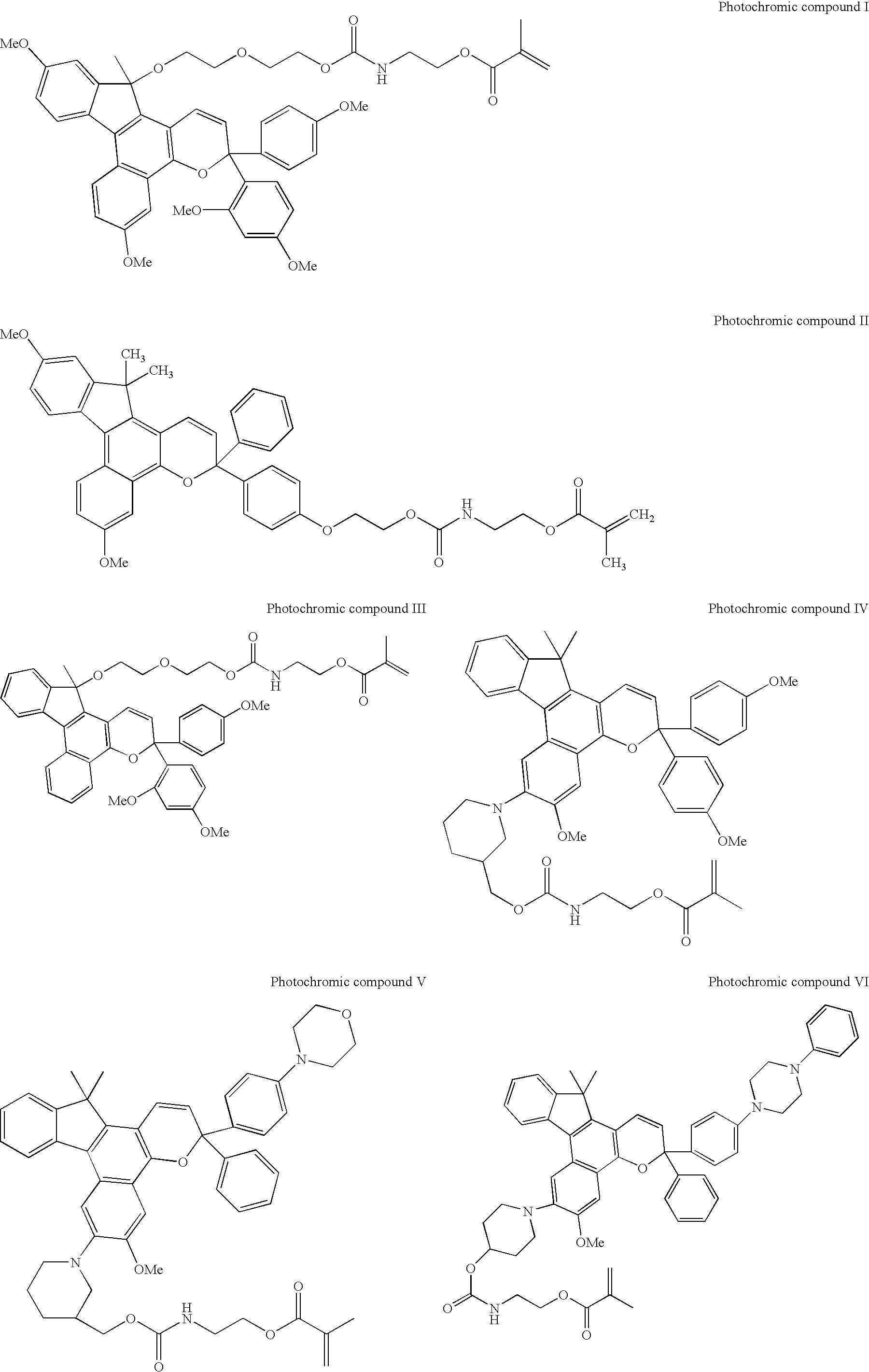

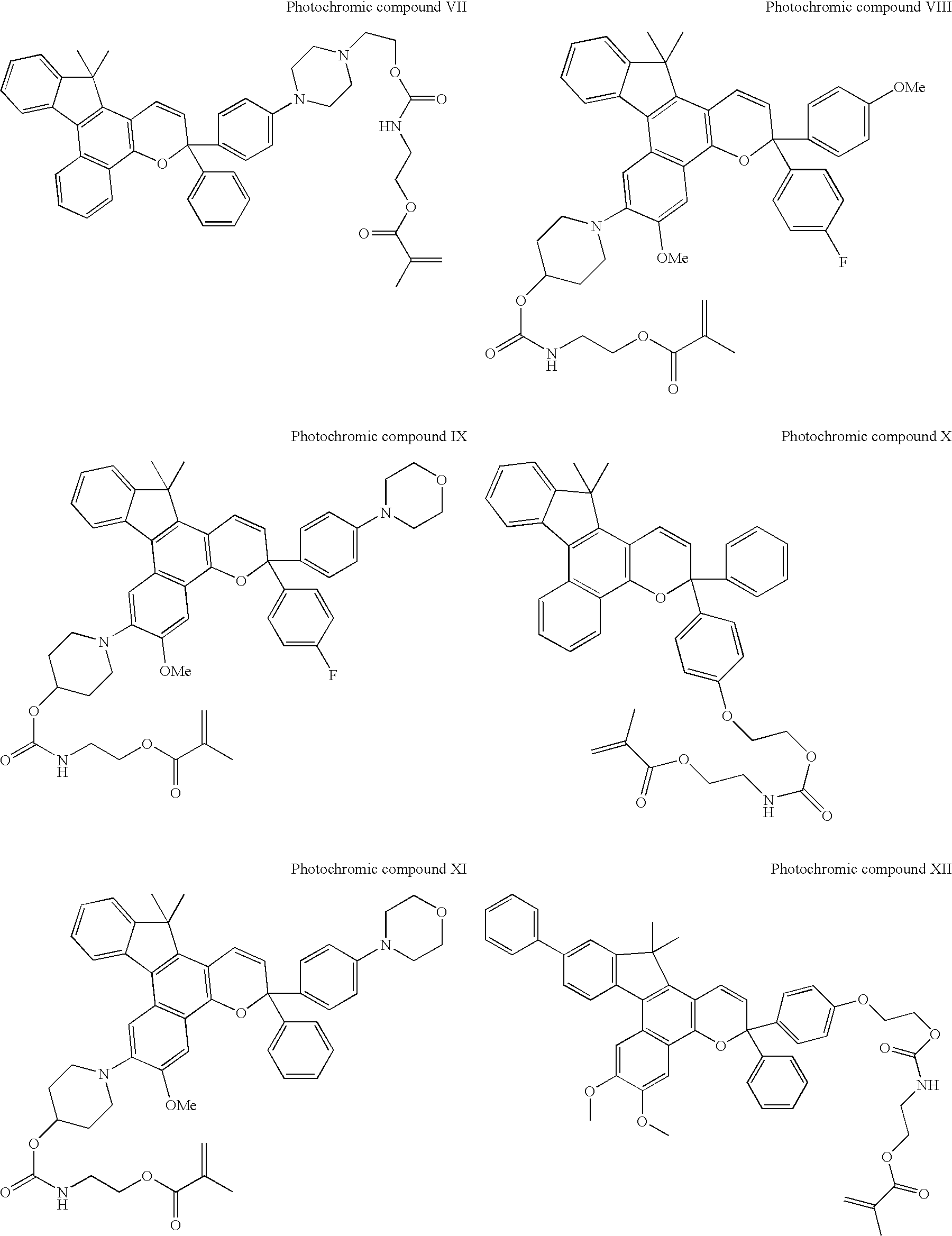

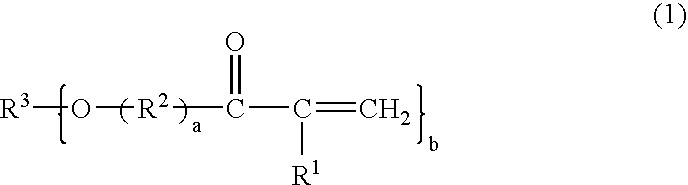

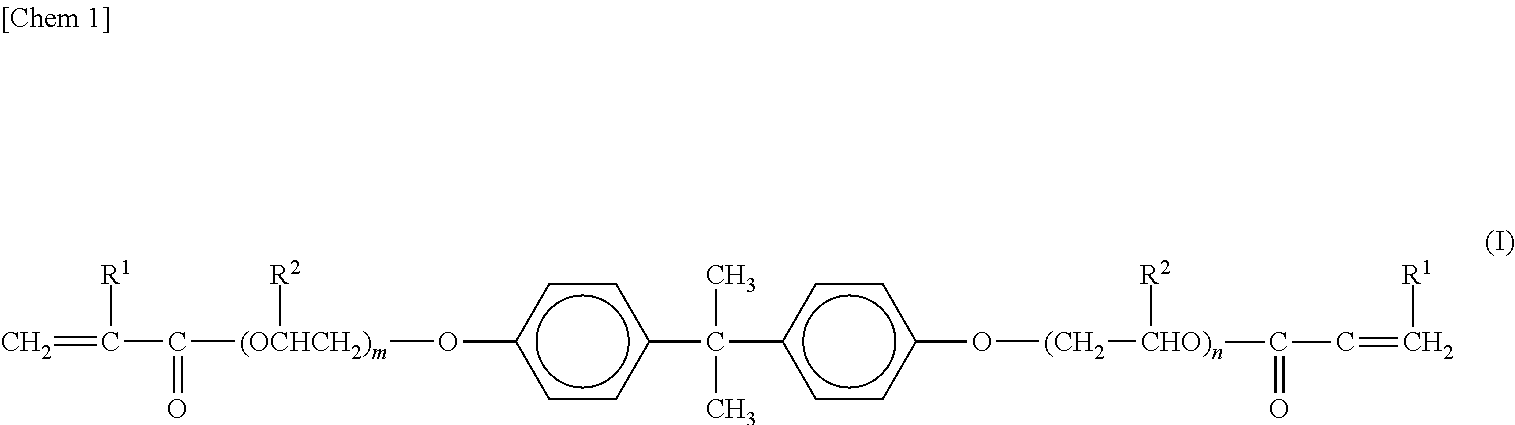

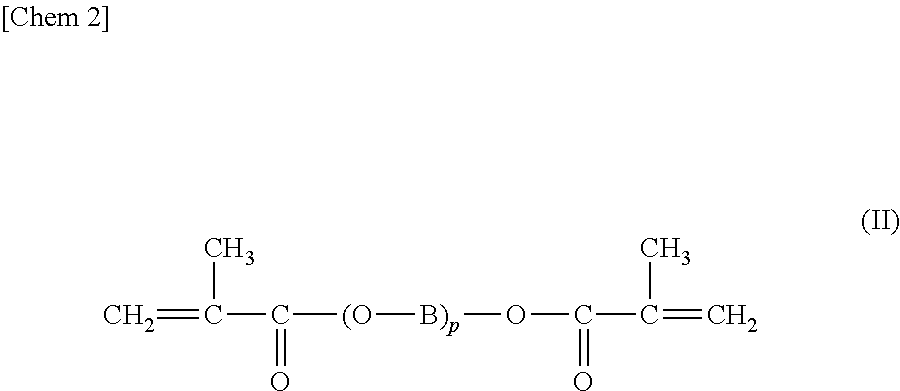

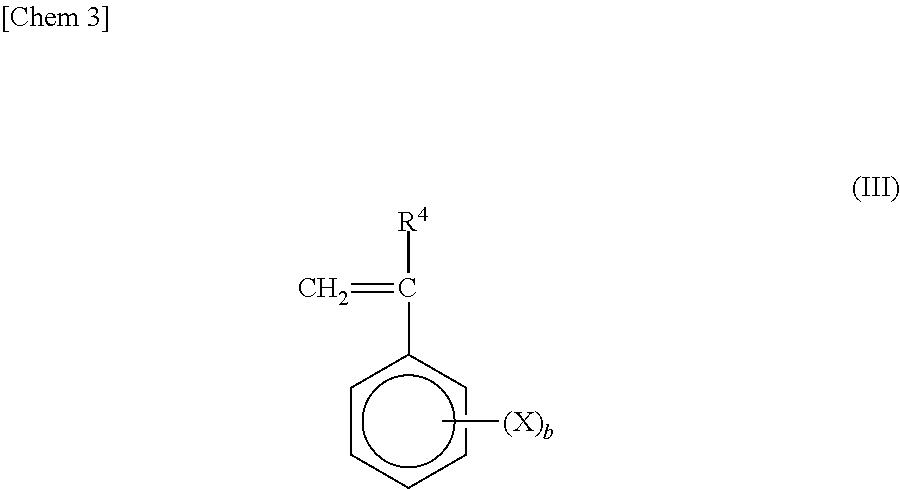

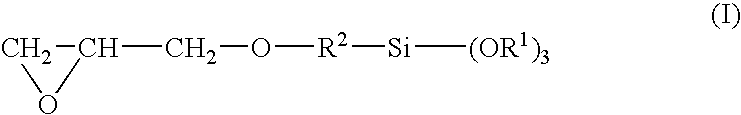

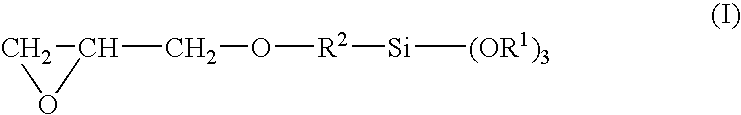

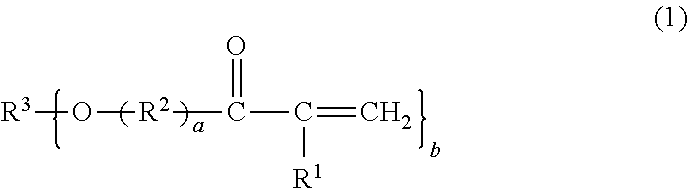

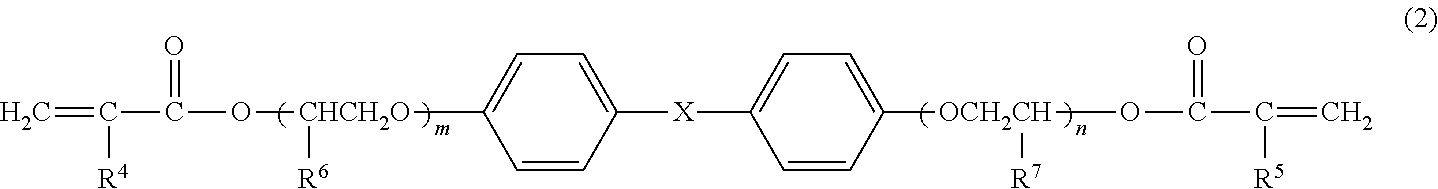

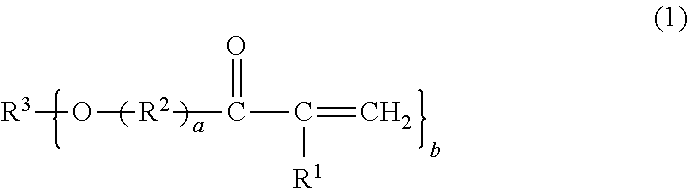

[Problem] To provide a photochromic lens for eye glasses, which has a high refractive index and excellent light-controlling properties and has such a constitution that the weight and thickness of the lens can be reduced. [Solution] Provided is a photochromic lens for eye glasses, which is produced by polymerizing a polymerizable composition prepared by dissolving a photochromic compound into a monomer mixture comprising a first radically polymerizable monomer represented by general formula (I), a second radically polymerizable monomer represented by general formula (II) and divinylbenzene that has a purity of 50% or more and contains a divinylbenzene component and an ethylvinylbenzene component at a total content of 90% or more.

Owner:HOYA CORP

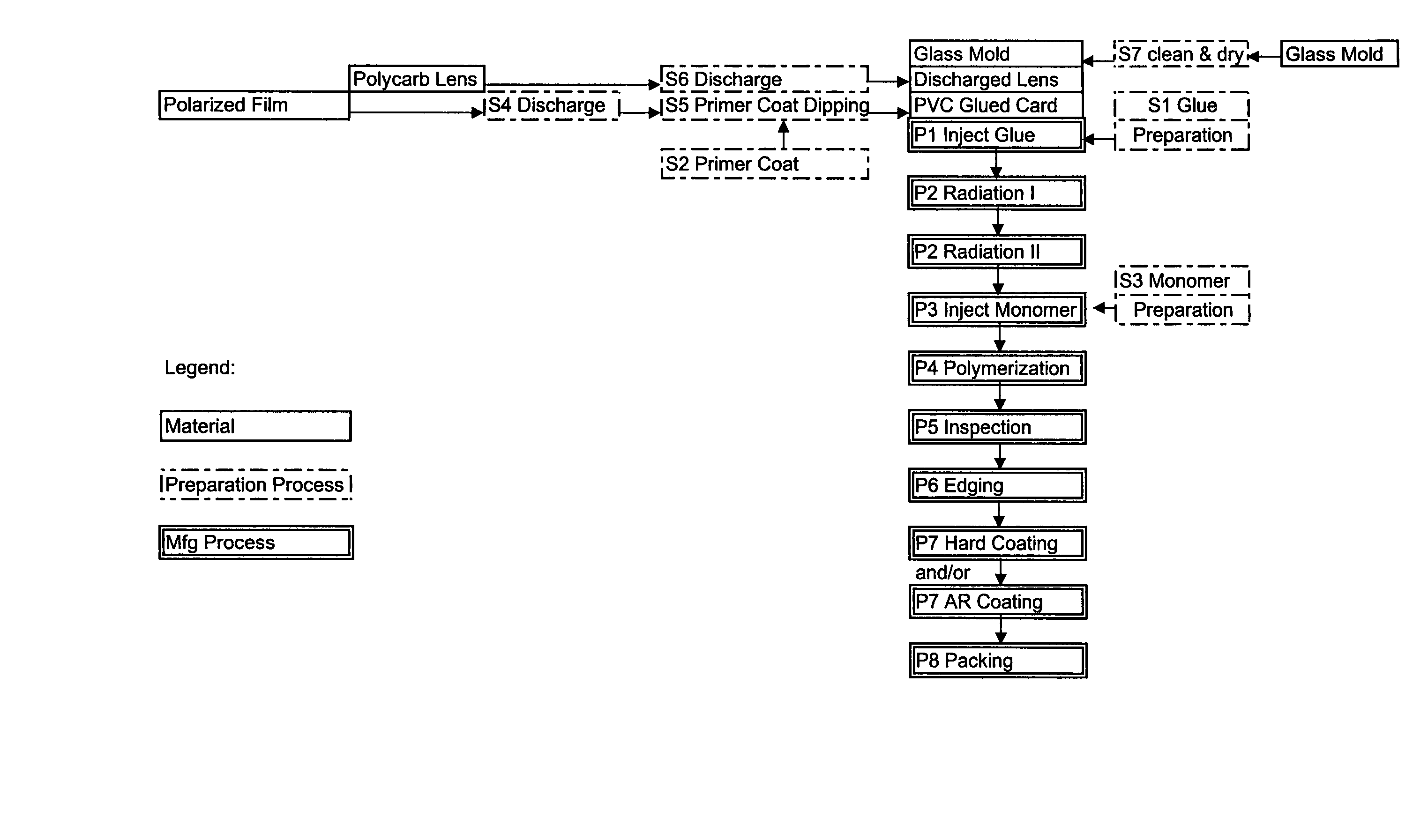

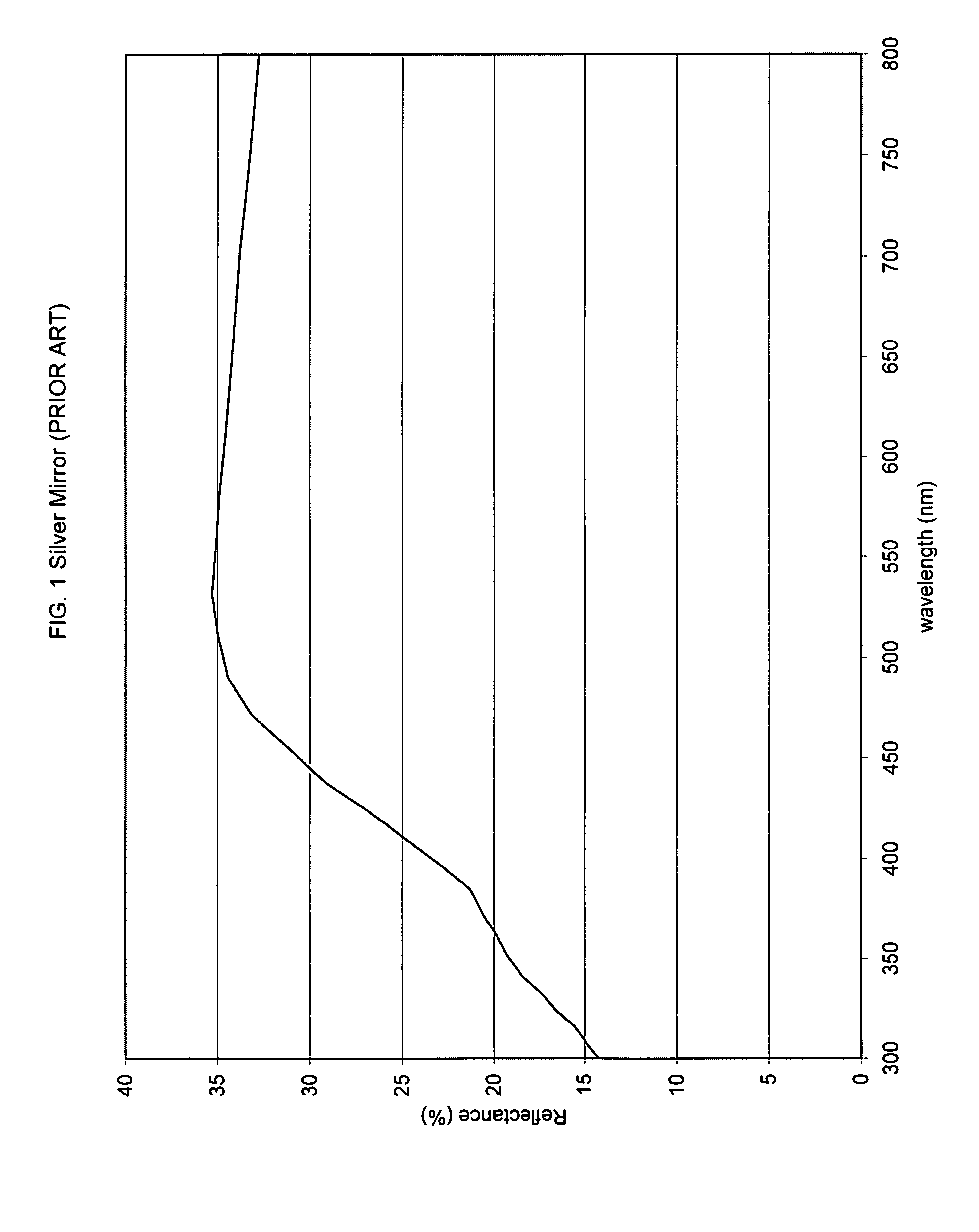

Multilayer interference filter for photochromic lenses

ActiveUS7633681B2Not adversely affect original photochromic activityMirrorsOptical filtersPhotochromic lensBiological activation

A multi-layer thin film is provided preferably for use with photochromic lenses, wherein the thin film comprises a plurality of layers, preferably including dielectric layers, selected and arranged so as to reflect less than about 6 percent of the UVA rays in a range of about 315 to 400 nm, more preferably about 350 to 380 nm. The thin film preferably has an activation value greater than 25%.

Owner:INERCAST USA INC

Color-changing lens

InactiveCN101419301AReduce penetrationPenetration changes automaticallyTenebresent compositionsOptical partsPhotochromic lensColor changes

The invention relates to a photochromic lens, which comprises a body. The body is provided with a first side and a second side arranged opposite to the first side. The body contains at least one photochromic material. The photochromic lens reduces the transmitting degree of light to maintain visual comfort under strong light, and does not reduce the transmitting degree of the light under the dark light to provide high transmittance by applying the photochromic material. Compared with the prior art, the photochromic lens can automatically change the transmitting degree with strong-weak change of the light for maintaining visual comfort. In the production aspect, the photochromic lens can be applied to the prior production equipment, and widens the application range of the equipment.

Owner:PRODISC TECH INC

Plastic photochromic lenses for glasses and process for their production

InactiveUS6913357B2High light transmittanceGood lookingEye diagnosticsTenebresent compositionsMethacrylatePhotochromic lens

A method of manufacturing plastic photochromic lenses includes obtaining a lens by polymerizing and curing a monomer mixture. The monomer mixture includes one of monofunctional and bifunctional methacrylic ester monomers, a trifunctional methacrylic ester monomer and a photochromic dye. Then, radiation including ultraviolet radiation is directed onto a surface of the lens obtained so that the radiation activates the surface of the lens to break down macromolecular chains of the surface of the lens. A composition including an organic silicon compound and a colloidal metal oxide is coated onto the surface of the lens exposed to the radiation. The composition coated is cured to obtain a hard surface film.

Owner:HOYA CORP

Photochromic lens substrate

InactiveUS8012596B2Maintain good propertiesHigh color densitySynthetic resin layered productsDomestic articlesPhotochromic lensHeat resistance

A polymerization curable composition comprising a specific polyfunctional polymerizable monomer having a hard molecular structure with an L-scale Rockwell hardness of its homopolymer of 60 or more, a specific polyfunctional polymerizable monomer and a photochromic compound, a photochromic lens substrate composed of a cured product of the polymerization curable composition, and a lens comprising the photochromic lens substrate.The substrate and lens show excellent photochromic properties such as high color development density and high fading rate, and the cured product has excellent substrate properties such as hardness, heat resistance and impact resistance as well as strength (toughness) that allows for its use in rimless spectacles.

Owner:TOKUYAMA CORP

Light-sensitive photochromic lens

ActiveCN102944940AImprove stabilityImprove antioxidant capacitySynthetic resin layered productsOptical partsResponse sensitivityMaterial Design

The invention relates to a light-sensitive photochromic lens. The lens comprises a transparent substrate, an ultraviolet absorption layer, a light-sensitive photochromic layer, a light absorption indication layer and a transparent antireflection layer. According to the light-sensitive photochromic lens provided by the invention, due to the film layer structure, the material design and the structural design of the lens, the lens is good in light-sensitive photochromic effect, the film layer has excellent stability, oxidation resistance and fatigue resistance and high response sensitivity on ultraviolet light, and when the ultraviolet excitation conditions disappear, the lens is quick in recovery speed and long in service life.

Owner:JIANGSU MAAT OPTICAL CO LTD

Photochromic headlamp

ActiveUS20170363787A1Unsightly depressionVehicle headlampsOptical signallingPhotochromic lensOne-way mirror

Owner:ACHEFF BEN GEORGE

Polyurethane photochromic lens and preparation method thereof

InactiveCN109369855AGood mechanical propertiesImprove mechanical propertiesOptical partsPolyesterPropanoic acid

The invention discloses a polyurethane photochromic lens and a preparation method thereof. The lens comprises the raw materials: polyester diol, isophorone diisocyanate, 2,2-dimethylol propionic acid,methyl methacrylate, styrene, an initiator, glycerol, 3-mercaptopropionic acid, methylbenzene, p-toluenesulfonic acid, a photochromic material and a UV adsorbent. The preparation method comprises thesteps: firstly, mixing glycerol, 3-mercaptopropionic acid, methylbenzene and p-toluenesulfonic acid to carry out a reaction to prepare a curing agent; then, adding polyester diol, isophorone diisocyanate and 2,2-dimethylol propionic acid into a mixed solution of methyl methacrylate and styrene, carrying out mixing, then, adding the curing agent, the photochromic material and the UV adsorbent, andcarrying out stirring to prepare mixed slurry; and pouring the mixed slurry into a die, and placing the die into an air curing furnace to carry out primary curing and secondary curing to obtain the polyurethane photochromic lens. The prepared lens has excellent photochromic and mechanical properties and can be widely applied.

Owner:苏新智能标签(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com