Photochromic paint, preparation method thereof, photochromic lens and preparation process of photochromic lens

A photochromic and coating technology, used in polyurea/polyurethane coatings, coatings, optics, etc., can solve the problems of prone to rainbow patterns and affecting the optical properties of lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

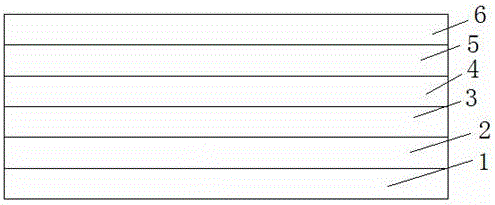

Image

Examples

Embodiment 1

[0040] A kind of photochromic coating, the component that it contains and the mass parts of each component are as follows:

[0041] Isocyanate compounds: 20 parts;

[0042] Polymercaptan compound: 29 parts;

[0043] Catalyst: 5 parts;

[0044] Leveling agent: 1 part;

[0045] Solvent: 40 parts;

[0046] Color changing powder: 5 parts.

[0047] The isocyanate compound is a blocked 1,6-hexamethylene diisocyanate trimer.

[0048] The polythiol compound is pentaerythritol mercaptopropionate.

[0049] The catalyst is an organotin compound.

[0050] The catalyst is dibutyltin dilaurate.

[0051] The leveling agent is BYK-333; the solvent is toluene.

[0052] The step of the preparation method of photochromic coating contains:

[0053] The materials were prepared according to the parts by mass of each component, and each component was added into a stirring tank for stirring, and the stirring was continued for 60 minutes, and then filtered through a 0.1 micron capsule filter ...

Embodiment 2

[0070]The preparation method of the photochromic coating, the photochromic lens and the preparation process thereof in this embodiment are basically the same as those in Example 1, except that the formula of the photochromic coating is as follows:

[0071] A kind of photochromic coating, the component that it contains and the mass parts of each component are as follows:

[0072] Isocyanate compounds: 25 parts;

[0073] Polymercaptan compound: 15 parts;

[0074] Catalyst: 1 part;

[0075] Leveling agent: 0.1 part;

[0076] Solvent: 30 parts;

[0077] Color changing powder: 1 part.

[0078] The isocyanate compound is a blocked 1,6-hexamethylene diisocyanate trimer. .

[0079] The polythiol compound is pentaerythritol mercaptopropionate.

[0080] The catalyst is an organotin compound.

[0081] The catalyst is dibutyltin dilaurate.

[0082] The leveling agent is BYK-333; the solvent is toluene.

Embodiment 3

[0084] The preparation method of the photochromic coating, the photochromic lens and the preparation process thereof in this embodiment are basically the same as those in Example 1, except that the formula of the photochromic coating is as follows:

[0085] A kind of photochromic coating, the component that it contains and the mass parts of each component are as follows:

[0086] Isocyanate compounds: 20 parts;

[0087] Polymercaptan compound: 25 parts;

[0088] Catalyst: 5 parts;

[0089] Leveling agent: 2 parts;

[0090] Solvent: 50 parts;

[0091] Color changing powder: 10 parts.

[0092] The isocyanate compound is isophorone diisocyanate.

[0093] The polythiol compound is trimethylolpropane tris(3-mercaptopropionate).

[0094] The catalyst is an organotin compound.

[0095] The catalyst is dibutyltin di(dodecylsulfide) or dibutyltin diacetate.

[0096] The leveling agent is BYK-333; the solvent is toluene.

[0097] The photochromic lenses prepared in the above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com