Inorganic photochromic powder, and preparation method and application thereof

A photochromic and powder technology, applied in the field of materials, can solve the problems of slow fading speed of photochromic materials and limited practical application of photochromic materials, and achieve the effects of excellent light regulation efficiency, good absorption capacity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] In one embodiment, the preparation method comprises the following steps:

[0044] 1) Preparation of metal oxides with photochromic properties;

[0045] 2) Oxidizing the metal oxide to obtain the inorganic photochromic powder.

[0046] In another embodiment, the preparation method includes: adding an oxidizing agent during the preparation of the metal oxide with photochromic properties to obtain the inorganic photochromic powder.

[0047] It should be pointed out that the present invention does not make any limitation on the preparation method of metal oxides with photochromic properties, and can be prepared by hydrothermal method, solvothermal method, solid phase synthesis method, water bath method, oil bath method, chemical deposition method prepared by other methods.

[0048] Specifically, after the metal oxide is prepared, the metal oxide is oxidized to obtain the inorganic photochromic powder of the present invention; or, in the process of preparing the metal oxide,...

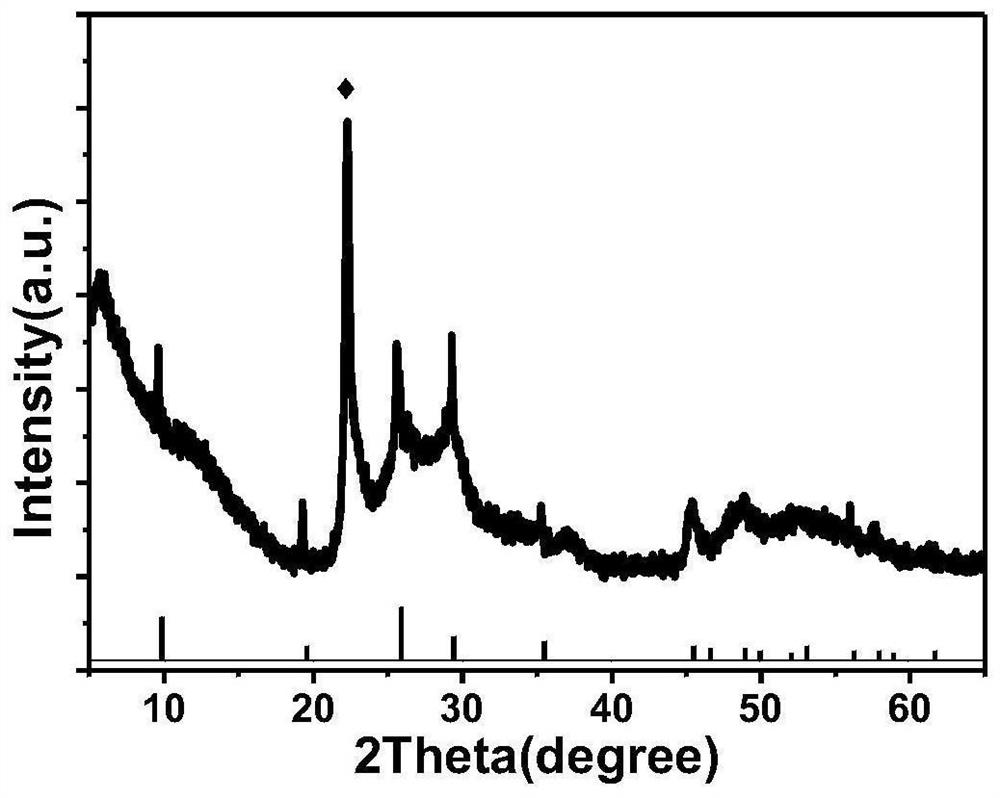

Embodiment 1

[0079] The inorganic photochromic powder of this embodiment is prepared according to the following method:

[0080] 1) Take the S1 in Comparative Example 1 to prepare an S1 aqueous solution whose mass concentration is 10%;

[0081] 2) Spread 1ml of S1 aqueous solution on the glass slide, move the glass slide to a constant temperature oven with an oxidizing atmosphere, set the temperature of the constant temperature oven at 50°C, keep it warm for 12 hours, take it out, and collect the sample powder on the glass slide in Together, the sample is named S1-1.

[0082] The oxidizing atmosphere is formed by taking 1 ml of hydrogen peroxide solution with a mass concentration of 10% and spraying it into the oven.

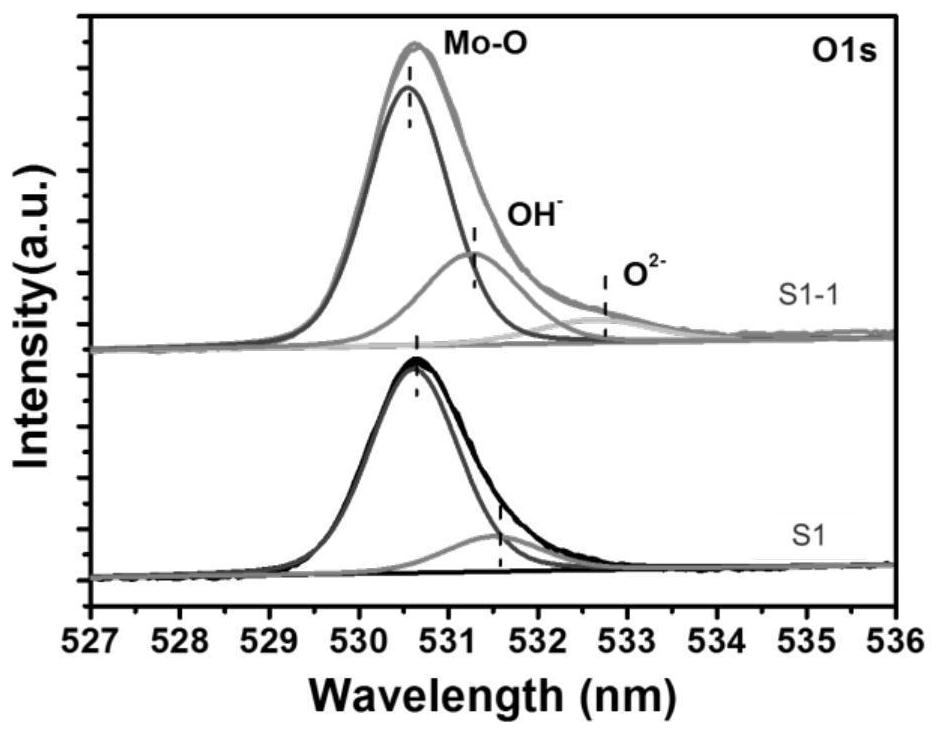

[0083] X-ray photoelectron spectroscopy analysis of S1 and S1-1

[0084] figure 2 It is the comparison chart of XPS analysis of S1 in Comparative Example 1 of the present invention and S1-1 in Example 1. From figure 2 It can be seen that, compared with the unoxidized ...

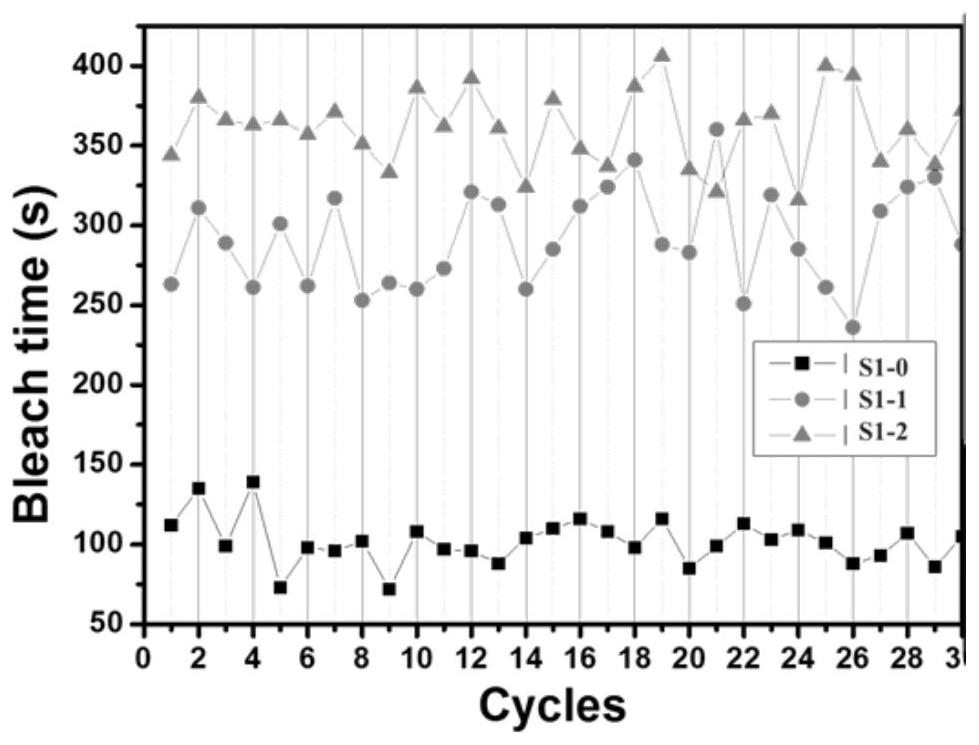

Embodiment 2

[0086] The inorganic photochromic powder of this embodiment is prepared according to the following method:

[0087] 1) Take the S1 in Comparative Example 1 to prepare an S1 aqueous solution whose mass concentration is 10%;

[0088] 2) Spread 1ml of S1 aqueous solution on the glass slide, move the glass slide to a constant temperature oven with an oxidizing atmosphere, set the temperature of the constant temperature oven at 50°C, keep it warm for 12 hours, take it out, and collect the sample powder on the glass slide in Together, the samples were named S1-0.

[0089] The oxidizing atmosphere is formed by taking 1 ml of hydrogen peroxide solution with a mass concentration of 30% and spraying it into the oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com