Color-changing lens

A technology for color-changing lenses and photochromic materials, applied in the field of lenses with color-changing function, can solve problems such as inconvenience and general products have no structure, and achieve the effects of maintaining visual comfort, increasing the scope of application and high penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

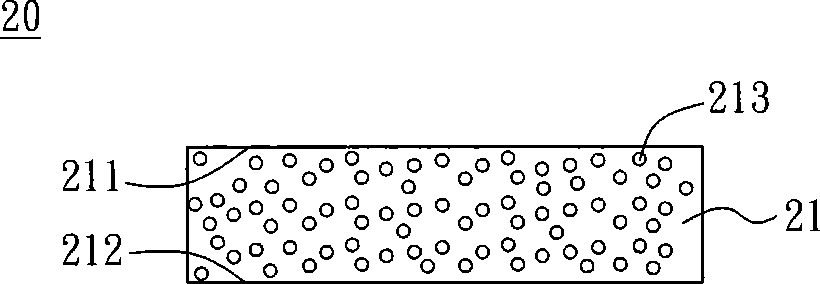

[0041] refer to figure 2 As shown, a photochromic lens 20 according to the first embodiment of the present invention includes a body 21 . The body 21 has a first side 211 and a second side 212 , and the second side 212 is opposite to the first side 211 . The body 21 includes at least one photochromic material 213 .

[0042] The body 21 has a weight percentage of the photochromic material 213 ranging from 0.05% to 5%, wherein a preferred ratio is between 0.1% and 0.7%. In this embodiment, in order to prevent the photochromic material 213 from mixing into the main body 21 and interacting with the binder, the photochromic material 213 can be pre-coated into capsules by physical or chemical methods and then mixed into the binder . After the photochromic material 213 is mixed into the binder, the main body 21 is made by, for example but not limited to, injection molding.

[0043] The material of the body 21 can be glass or polymer, and the polymer can include thermosetting pol...

no. 2 example

[0047] Please refer to Figure 4 As shown, another photochromic lens 20a according to the second embodiment of the present invention includes a main body 21a.

[0048] The main body 21a is different from the above-mentioned main body 21 in that: the main body 21a further has a base color material 214 with a weight percentage between 0.1% and 5%. Under the condition that the main body 21a maintains high light transmittance without changing the transmittance, it can still provide a base color effect. When the color of the main body 21a changes, it visually produces an overlapping effect with the base color, and presents a different color on the photochromic lens 20a. In this embodiment, yellow is used as an example for the background color. Of course, the background color can be replaced by other colors or mixed and matched by colors and double-layer to multi-layer mix-and-match designs can be used to obtain different colors and concentrations according to actual needs. The ph...

no. 3 example

[0050] Please refer to Figure 5 As shown, another photochromic lens 20b according to the third embodiment of the present invention includes a body 21 and a functional layer 22b. Since the main body 21 has been described in detail in the first embodiment, it will not be repeated here.

[0051] The functional layer 22b can be disposed on the first side 211 and / or the second side 212 of the body 21 by, for example but not limited to, soaking, deposition, spraying, coating or pasting. In this embodiment, the functional layer 22b is disposed on the first side 211 and the second side 212 of the body 21 as an example for illustration, but it is not intended to limit the present invention. The function of the functional layer 22b can be selected from anti-reflection (anti-reflection), waterproof (water-proofing), anti-fog (anti-fog), anti-scratch (anti-scratch), anti-ultraviolet (anti-UV) and other functions. The group formed by the combination.

[0052] In order to prevent the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com