Photochromic lens and manufacturing method thereof

A photochromic, lens technology, applied in optics, optical components, coatings, etc., can solve the problems of short service life, low surface hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

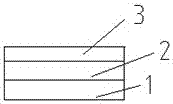

[0043] Such as figure 1 Shown, a kind of photochromic lens, it comprises optical substrate 1, photochromic layer 2 and protective layer 3 successively from bottom to top;

[0044] The components contained in the photochromic coating forming the photochromic layer 2 and the weight percentage of each component are as follows:

[0045] Photochromic compound: 3%;

[0046] Polyisocyanate crosslinking agent: 30%;

[0047] Polyol: 32.5%;

[0048] Solvent: 30%;

[0049] The rest are additives; in this embodiment, the additives have:

[0050] Catalyst: 1%

[0051] Antioxidant: 1%

[0052] Leveling agent: 0.5%

[0053] Adhesion promoter: 2%; of course, additives can be arbitrarily selected from thermal initiators, polymerization inhibitors, catalysts, antioxidants, leveling agents, adhesion promoters, hindered amine light stabilizers and heat stabilizers.

[0054] Among them, polyol is specifically a mixture of acrylic polyol, polyether polyol and polycarbonate polyol, acrylic p...

Embodiment 2

[0073] Such as figure 1 Shown, a kind of photochromic lens, it comprises optical substrate 1, photochromic layer 2 and protective layer 3 successively from bottom to top;

[0074] The components contained in the photochromic coating forming the photochromic layer 2 and the weight percentage of each component are as follows:

[0075] Photochromic compound: 10%;

[0076] Polyisocyanate crosslinking agent: 25%;

[0077] Polyol: 30%;

[0078] Solvent: 25%;

[0079] The rest are additives; in this embodiment, the additives have:

[0080] Catalyst: 3%

[0081] Antioxidant: 1%

[0082] Leveling agent: 1%

[0083] Thermal Initiator 1%

[0084] Inhibitor 1%

[0085] HALS 1%

[0086] Heat Stabilizer 1%

[0087] Adhesion promoter: 1%; of course, additives can be arbitrarily selected from thermal initiators, polymerization inhibitors, catalysts, antioxidants, leveling agents, adhesion promoters, hindered amine light stabilizers and heat stabilizers.

[0088] Wherein, polyol is s...

Embodiment 3

[0107] Such as figure 1 Shown, a kind of photochromic lens, it comprises optical substrate 1, photochromic layer 2 and protective layer 3 successively from bottom to top;

[0108] The components contained in the photochromic coating forming the photochromic layer 2 and the weight percentage of each component are as follows:

[0109] Photochromic compound: 7%;

[0110] Polyisocyanate crosslinking agent: 25%;

[0111] Polyol: 30%;

[0112] Solvent: 28%;

[0113] The rest are additives; in this embodiment, the additives have:

[0114] Catalyst: 5%

[0115] Antioxidant: 2%

[0116] Leveling agent: 1 %

[0117] Adhesion promoter: 1%;

[0118] Inhibitor; 1%; of course, additives can be arbitrarily selected from thermal initiators, inhibitors, catalysts, antioxidants, leveling agents, adhesion promoters, hindered amine light stabilizers and heat stabilizers.

[0119] Wherein, polyol is specifically the mixture of polyether polyol and polycarbonate polyol, polyether polyol is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com