Patents

Literature

48 results about "Polyurethane laminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane laminate (PUL, thermal stretch, fuzzy rubber) is a compound fabric made by laminating a cloth fabric to one or both sides of a thin film of polyurethane. Polyurethane laminated fabrics have a wide range of applications in medical, automotive and garment uses.

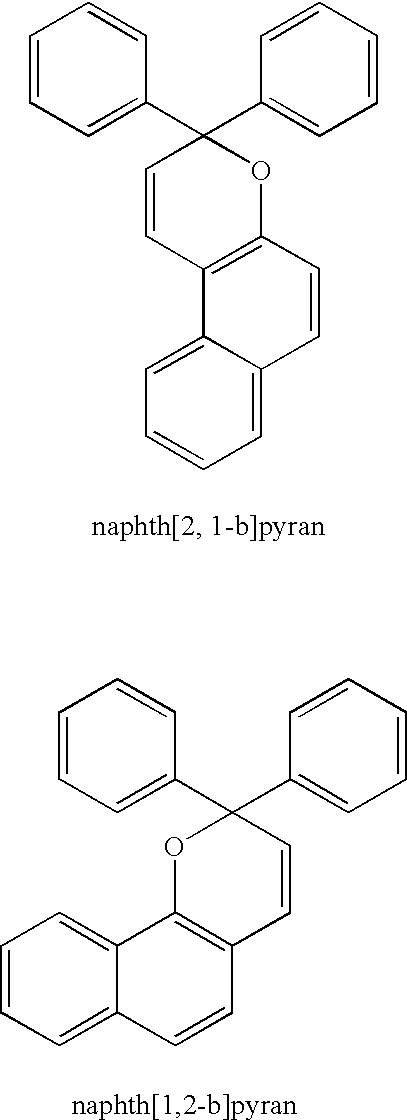

Photochromic polyurethane laminate

ActiveUS20050233153A1Improve fatigue resistanceGood dimensional stabilityLamination ancillary operationsSynthetic resin layered productsPhotochromic lensThermoplastic polyurethane

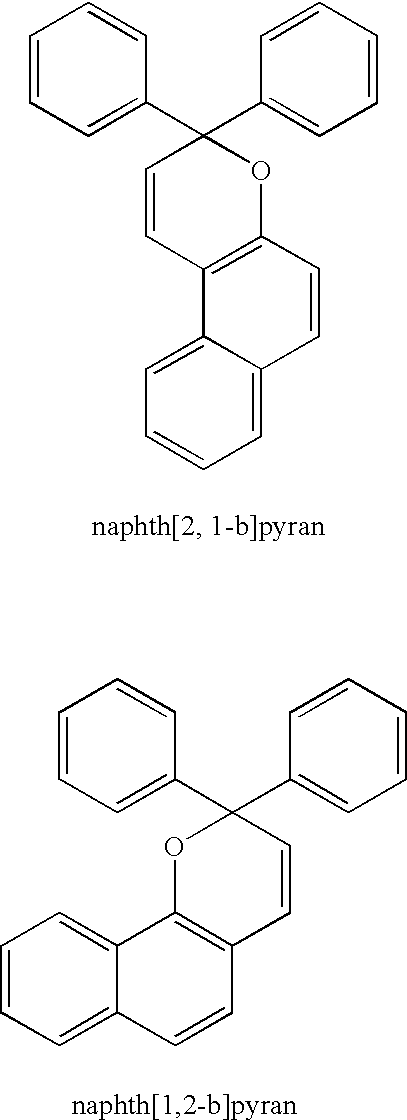

A photochromic polyurethane laminate that is constructed to solve certain manufacturing difficulties involved in the production of plastic photochromic lenses is disclosed. The photochromic laminate includes at least two layers of a resinous material and a photochromic polyurethane layer that is interspersed between the two resinous layers and which contains photochromic compounds. The polyurethane layer is formed by curing a mixture of a solid thermoplastic polyurethane, at least one isocyanate prepolymer, at least one photochromic compound, and a stabilizing system.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Photochromic Polyurethane Laminate

ActiveUS20130004775A1Improve propertiesHigh mechanical strengthSynthetic resin layered productsLaminationPolyurethane laminatePrepolymer

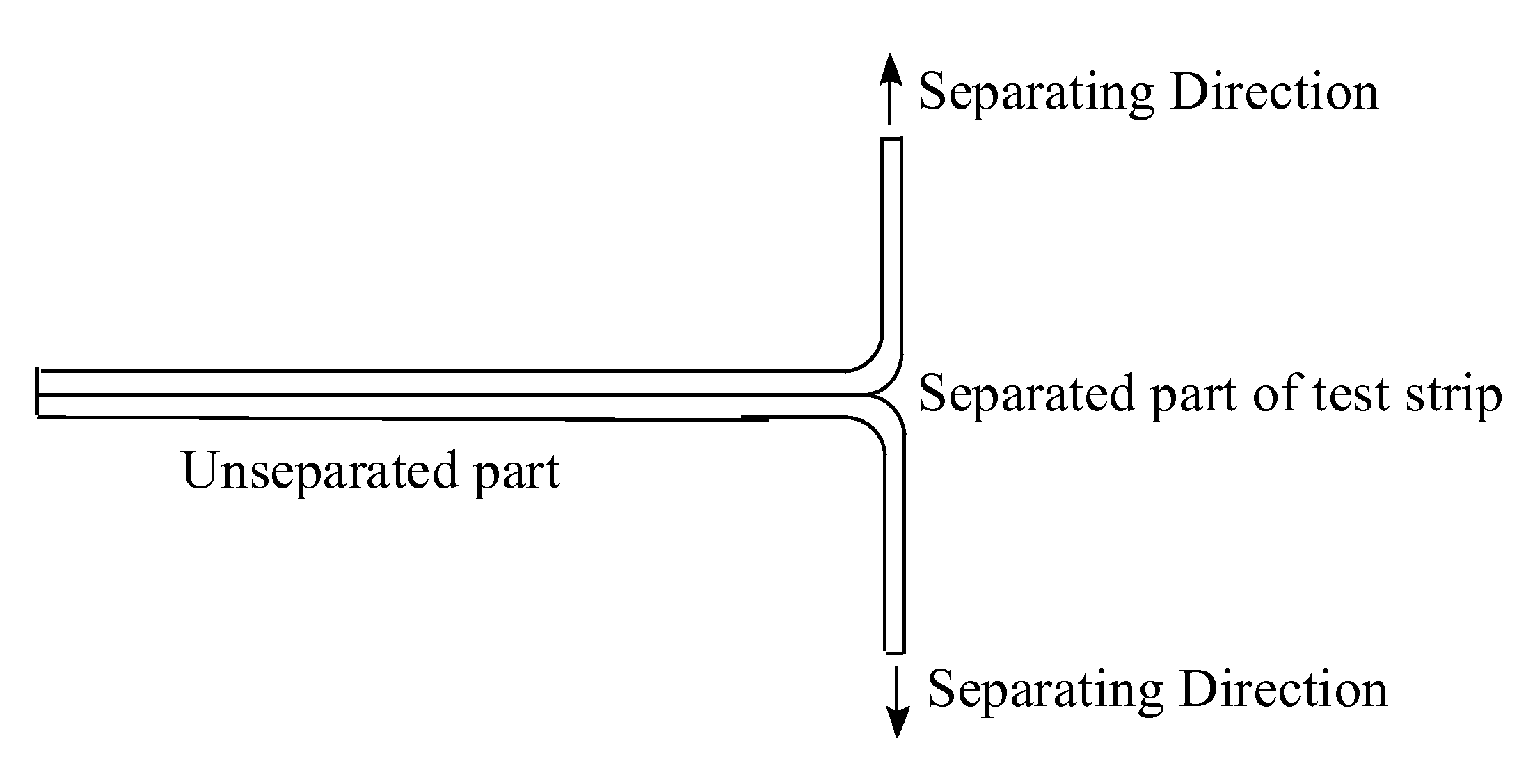

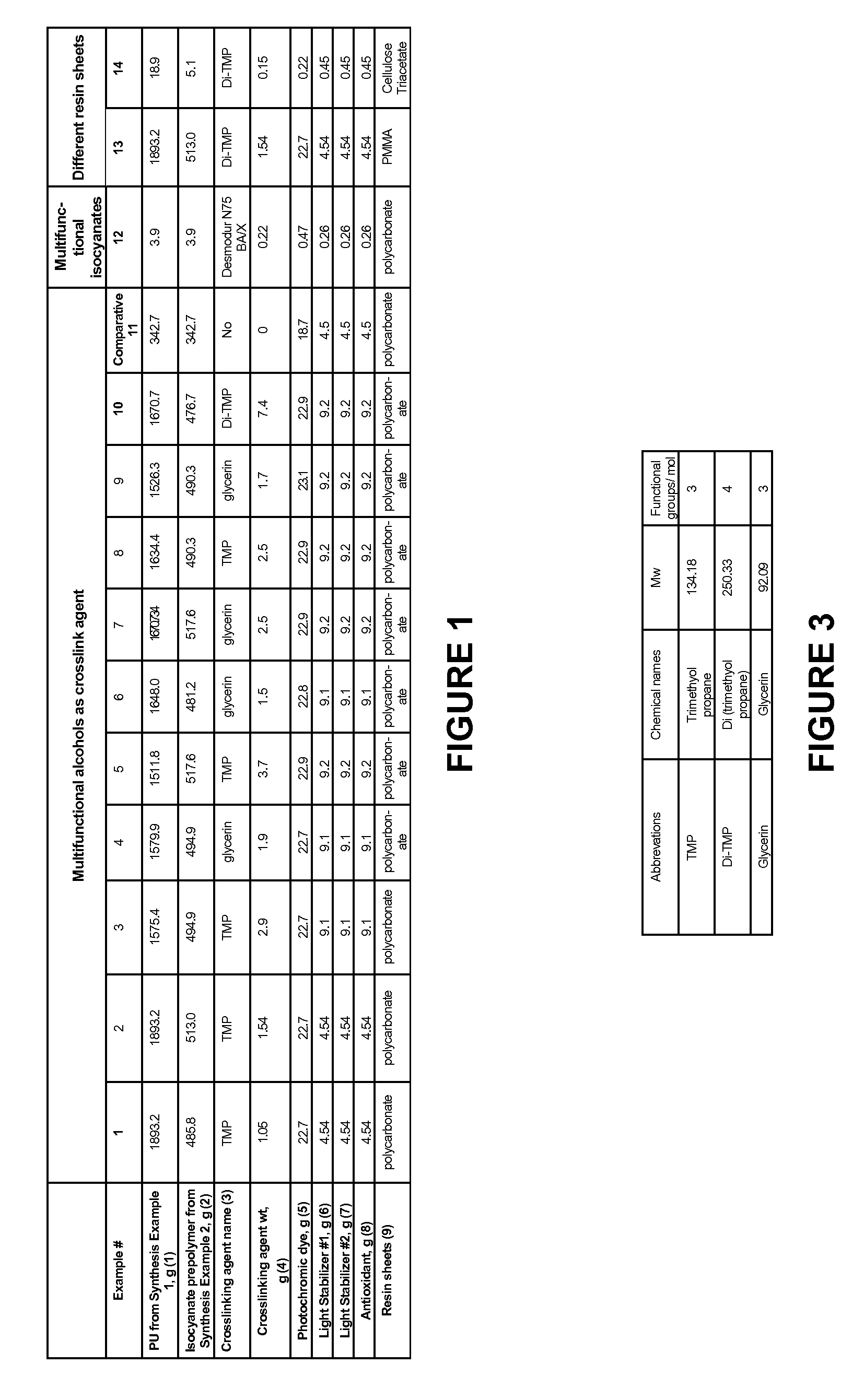

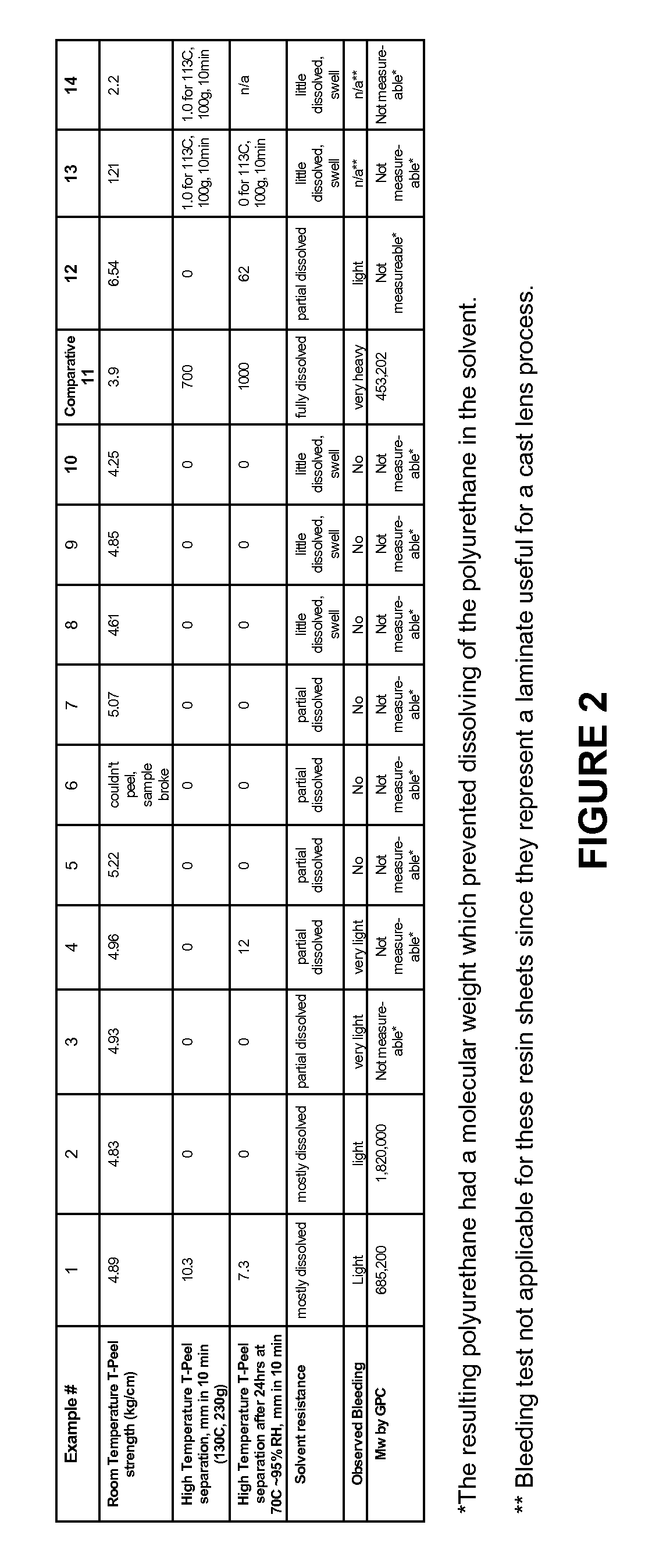

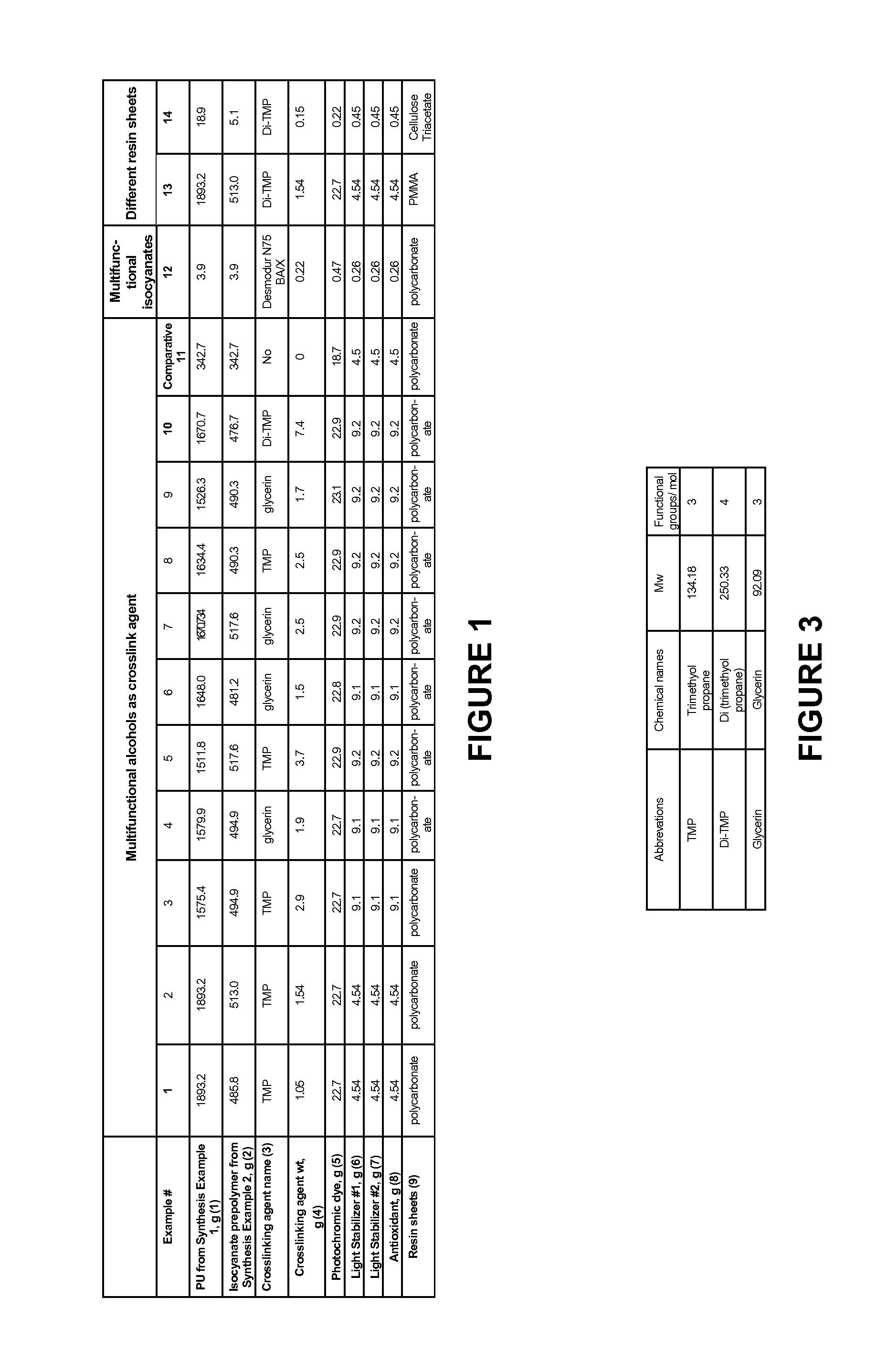

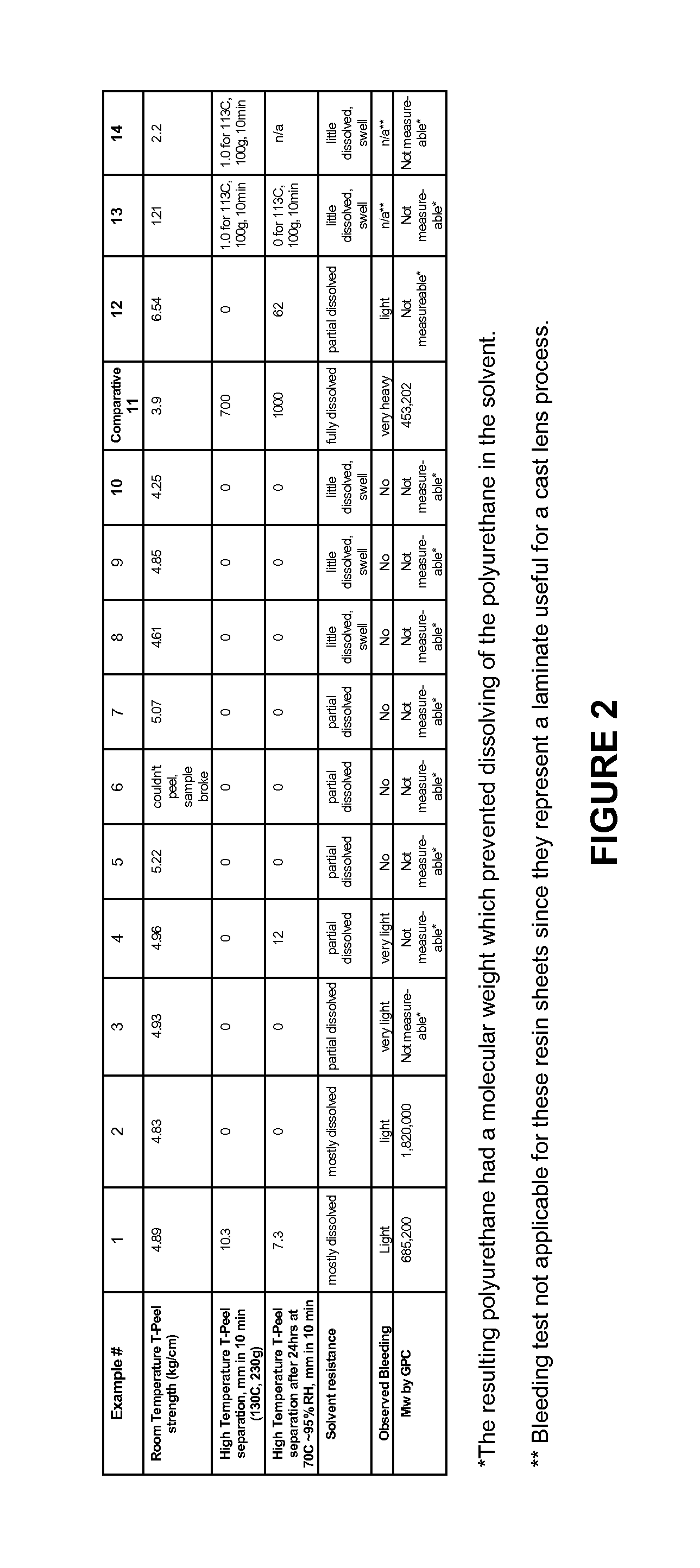

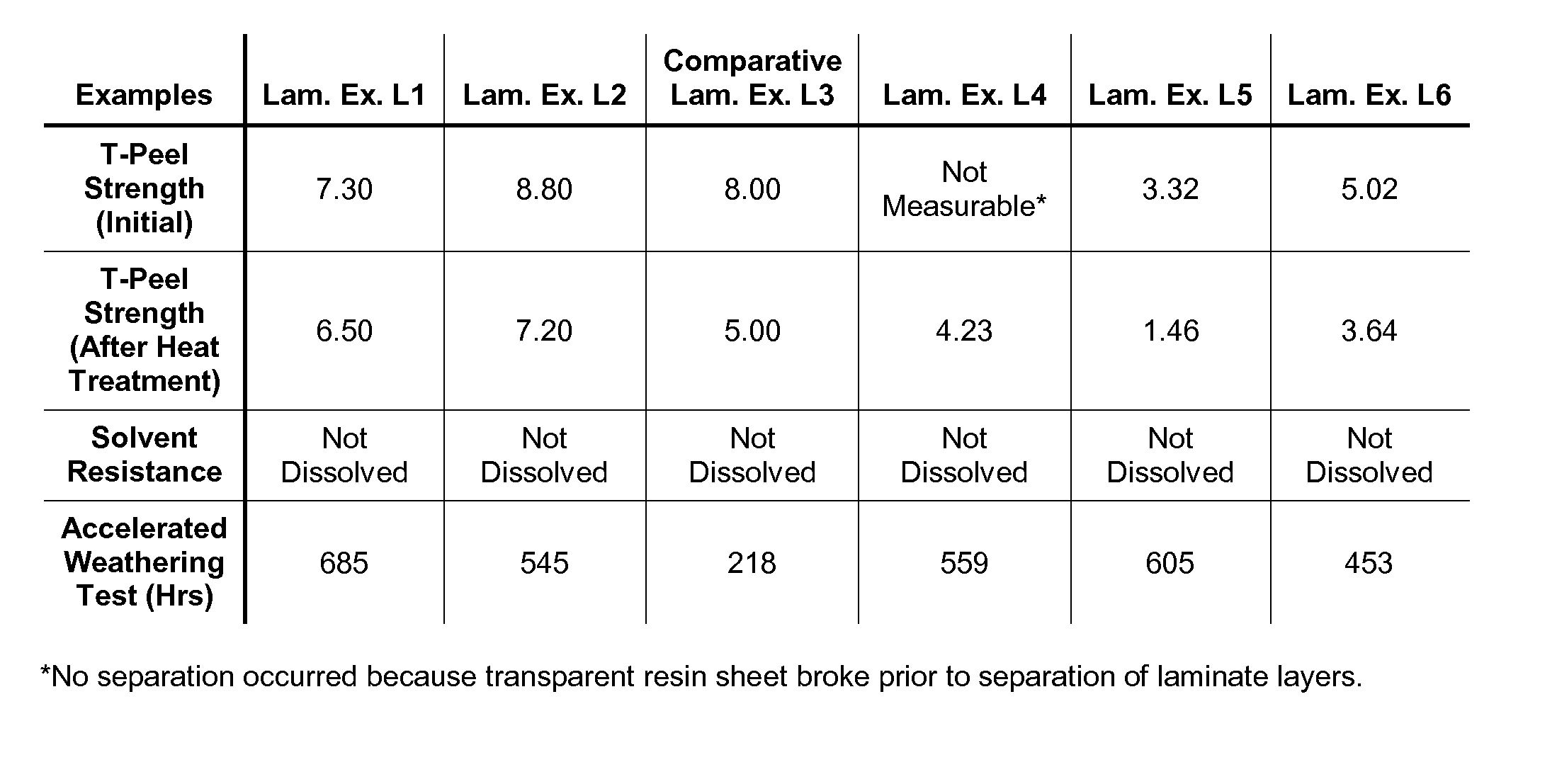

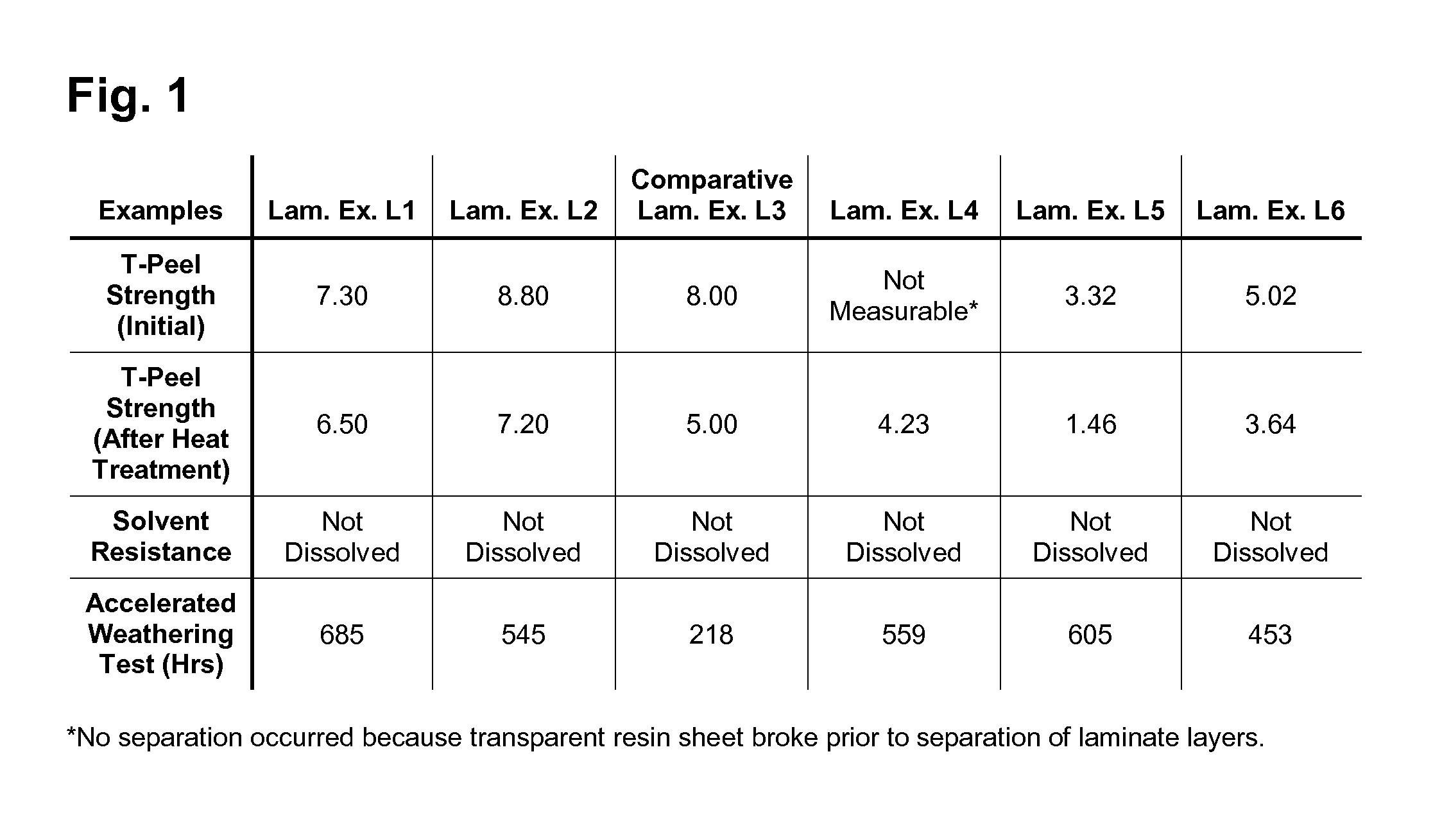

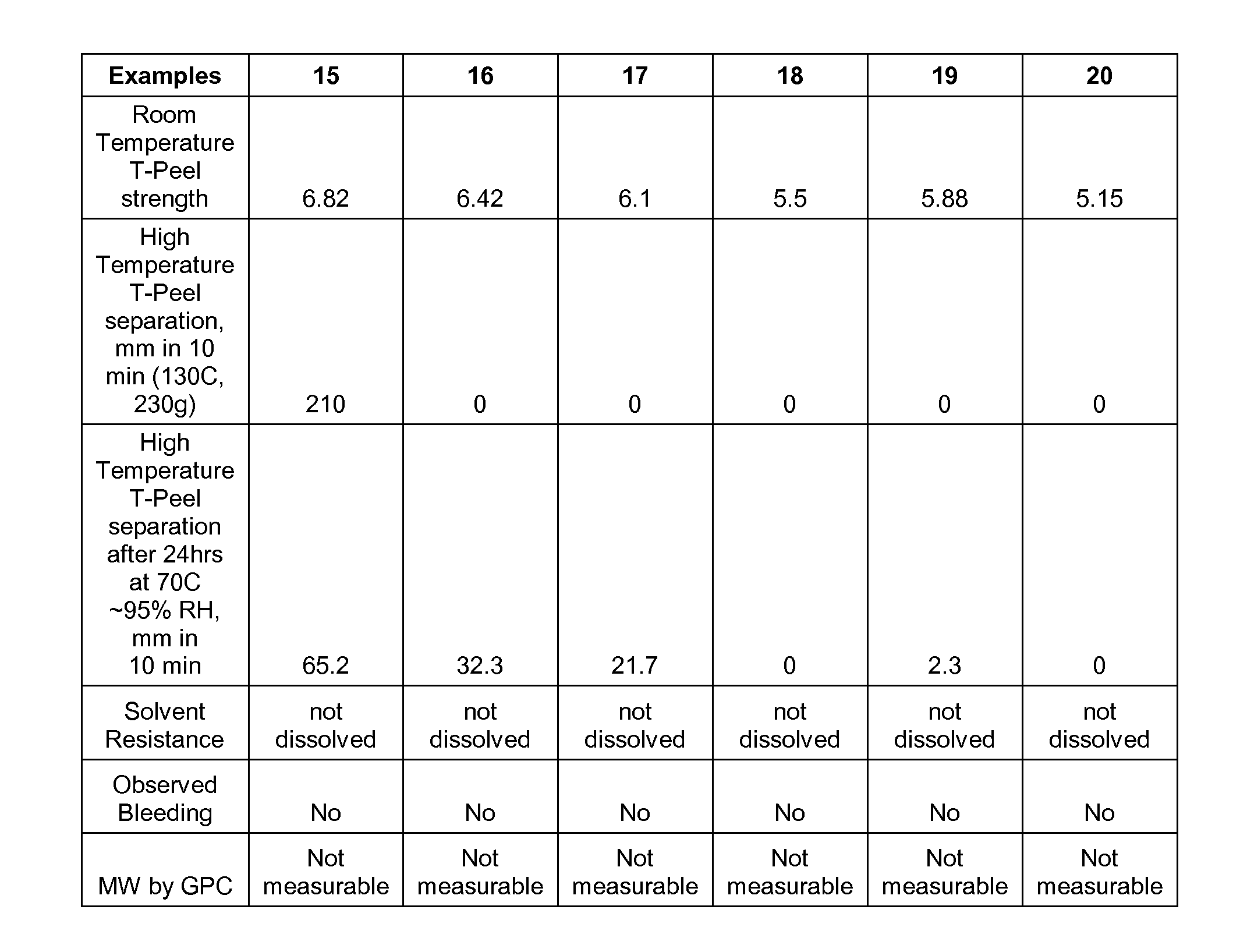

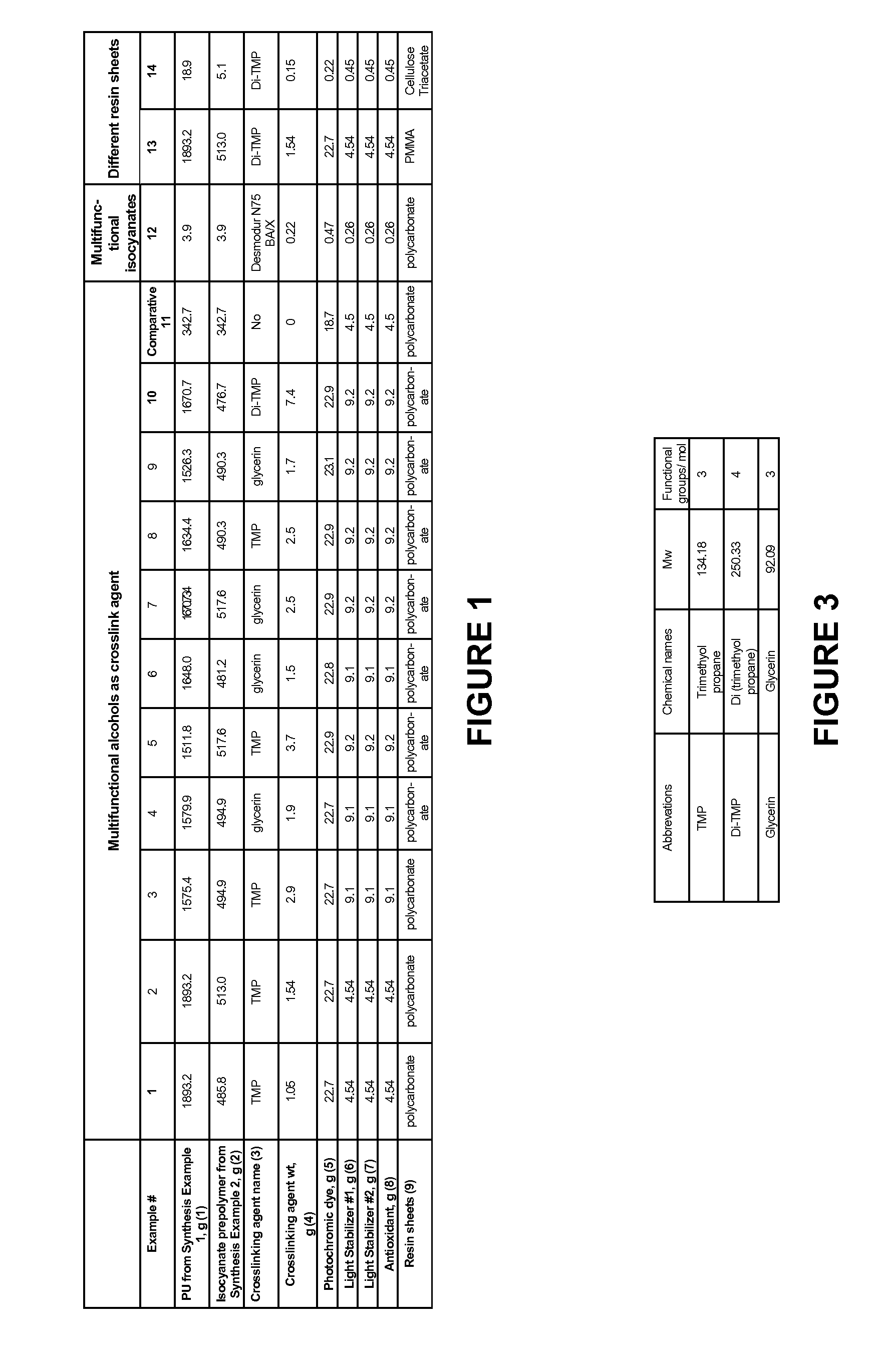

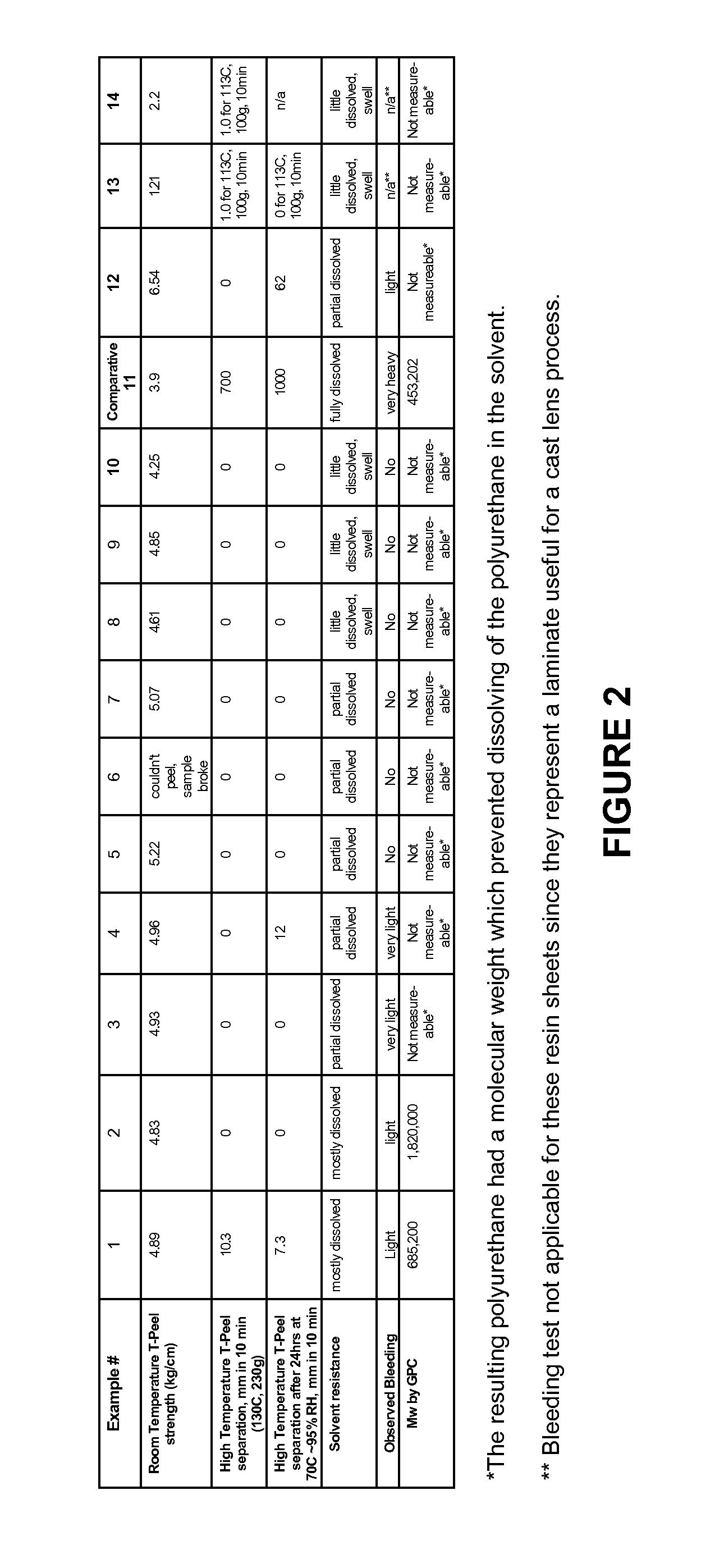

A photochromic polyurethane laminate wherein the photochromic polyurethane layer of the laminate has been crosslinked with a isocyanate-active prepolymer using a crosslinking agent. The crosslinking agent is formulated to have at least three functional groups that are reactive with functional groups of the polyurethane or of the isocyanate-active prepolymer. A method of making the photochromic polyurethane laminate includes steps of causing the crosslinking.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Photochromic polyurethane laminate

ActiveUS9081130B1Improve propertiesHigh mechanical strengthSynthetic resin layered productsLaminationPolyurethane laminatePrepolymer

Photochromic polyurethane laminates and methods for the formation of same wherein the photochromic polyurethane layer of the laminate has been crosslinked with a isocyanate-active prepolymer using a crosslinking agent. The crosslinking agent is formulated to have at least three functional groups that are reactive with functional groups of the polyurethane or of the isocyanate-active prepolymer.

Owner:INSIGHT EQUITY A P X L P DBA VISION EASE LENS +1

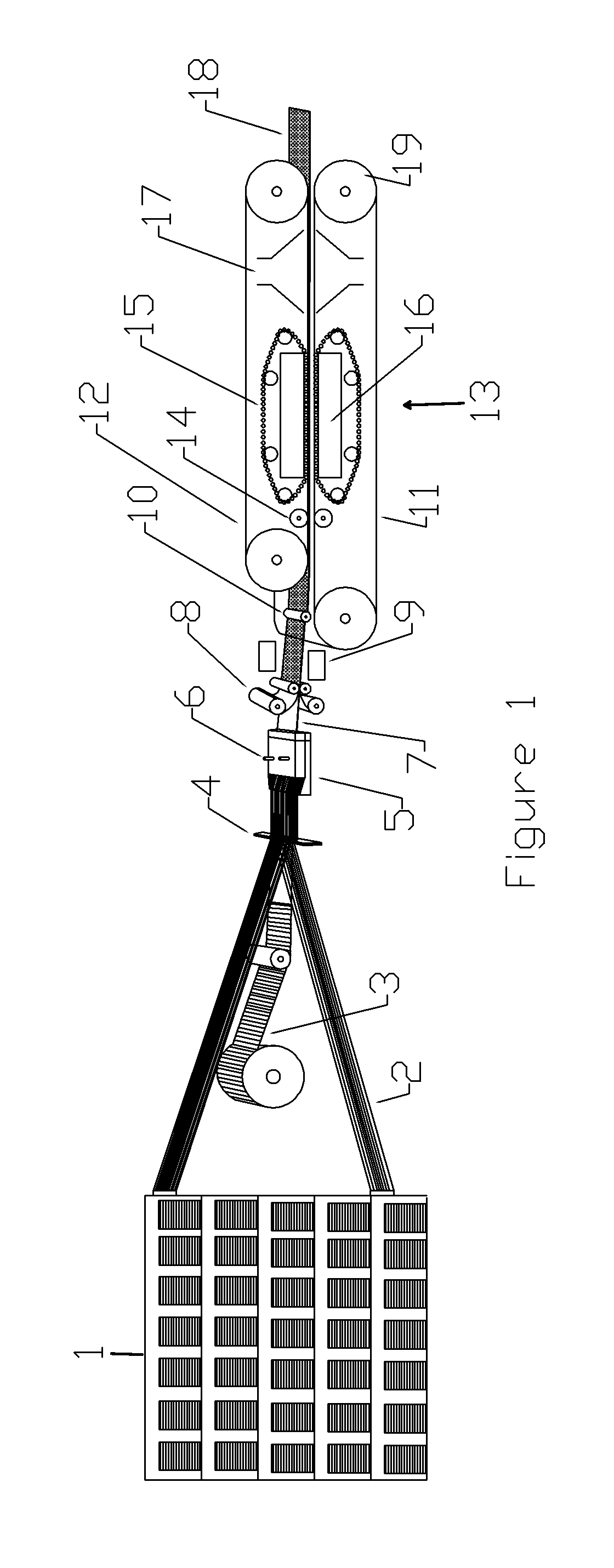

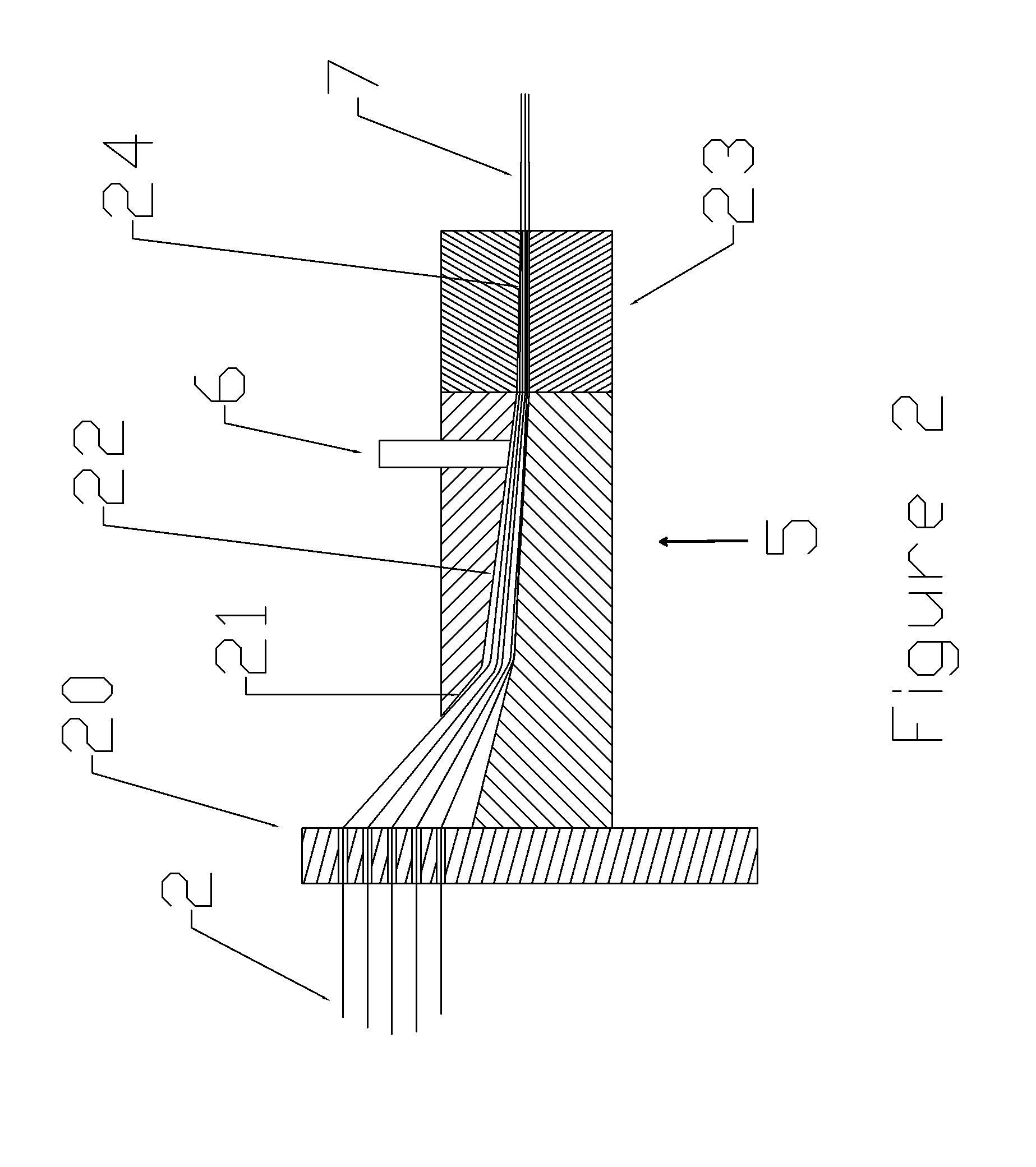

Polyurethane laminates made with a double belt press

InactiveUS20130115412A1Excellent Adhesive PropertiesFine surfaceSynthetic resin layered productsPaper/cardboard layered productsComposite laminatesResin matrix

A fiber reinforced composite laminate with fibers generally oriented along two major axes and having a polyurethane resin matrix suitable for reinforcing wood based substrates such as trailer / container flooring, glulams, plywood, particle boards, laminated veneer lumber, and oriented strand board, is provided. The laminate is produced by pulling the fibers through a resin injection box, where a polyurethane resin is injected into the box to wet the fibers. The polyurethane resin wetted fiber layer is then covered with a release media on the top and bottom sides of the layer. The sandwich of fiber, resin and release media is fed to a double belt press capable of applying pressure and heat to consolidate and cure the laminate. The laminate thus made can be thinner than 0.080 inch and provides excellent flatness compared to pultruded thin laminates.

Owner:HAVCO WOOD PRODS

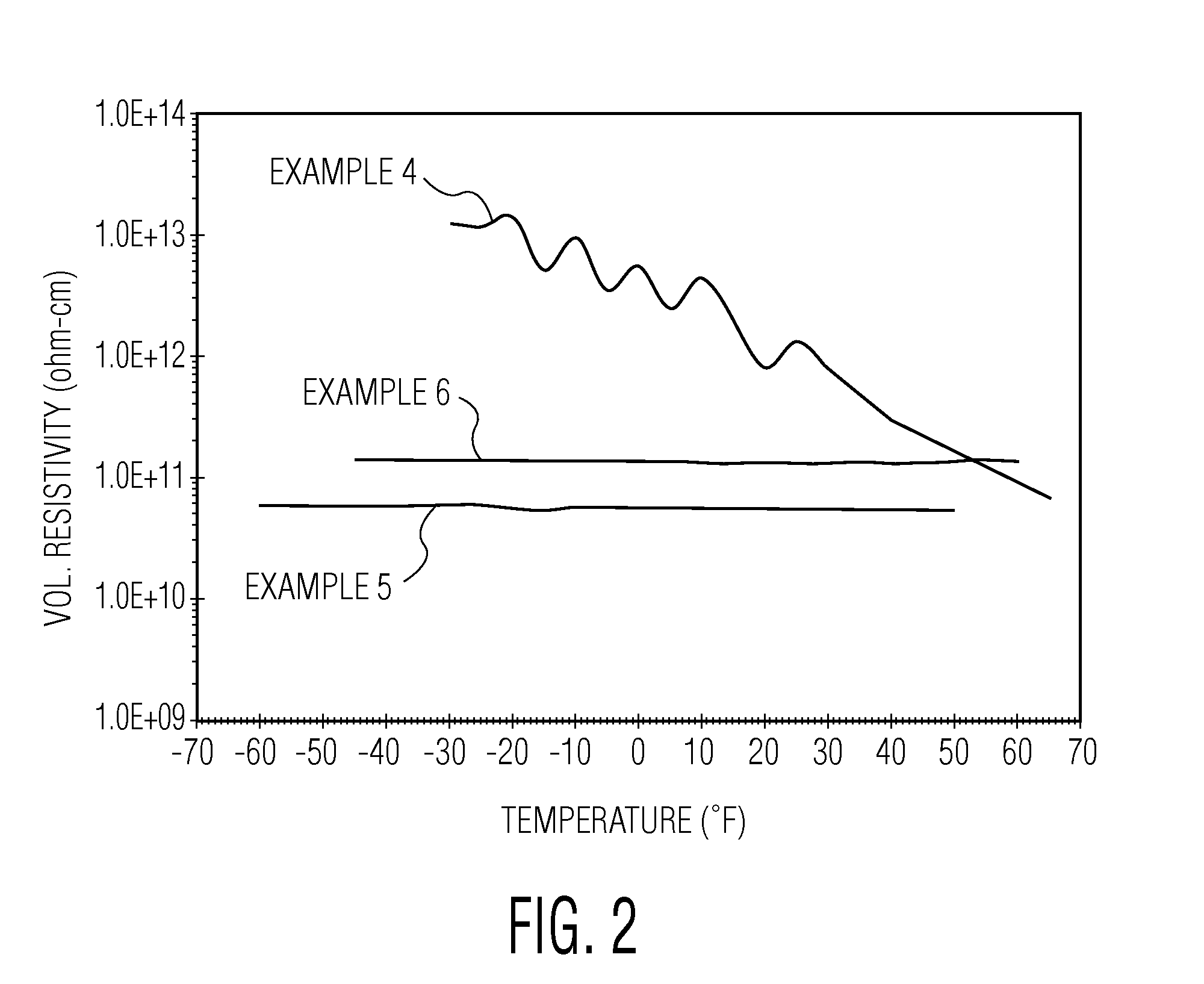

Transparent polyurethane protective coating, film and laminate compositions with enhanced electrostatic dissipation capability, and methods for making same

ActiveUS20120021209A1Conductive layers on insulating-supportsRecord information storageConductive materialsAirframe

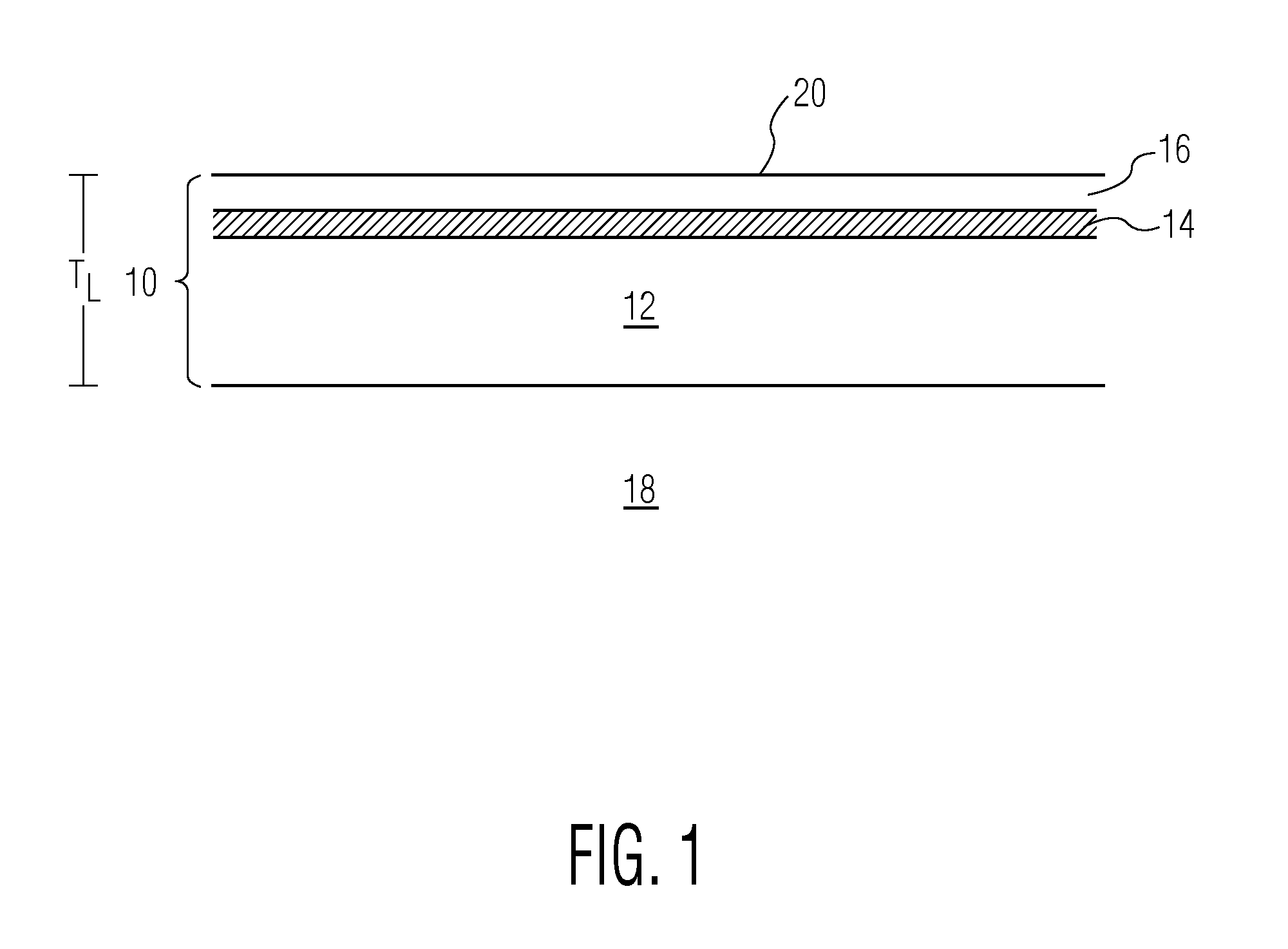

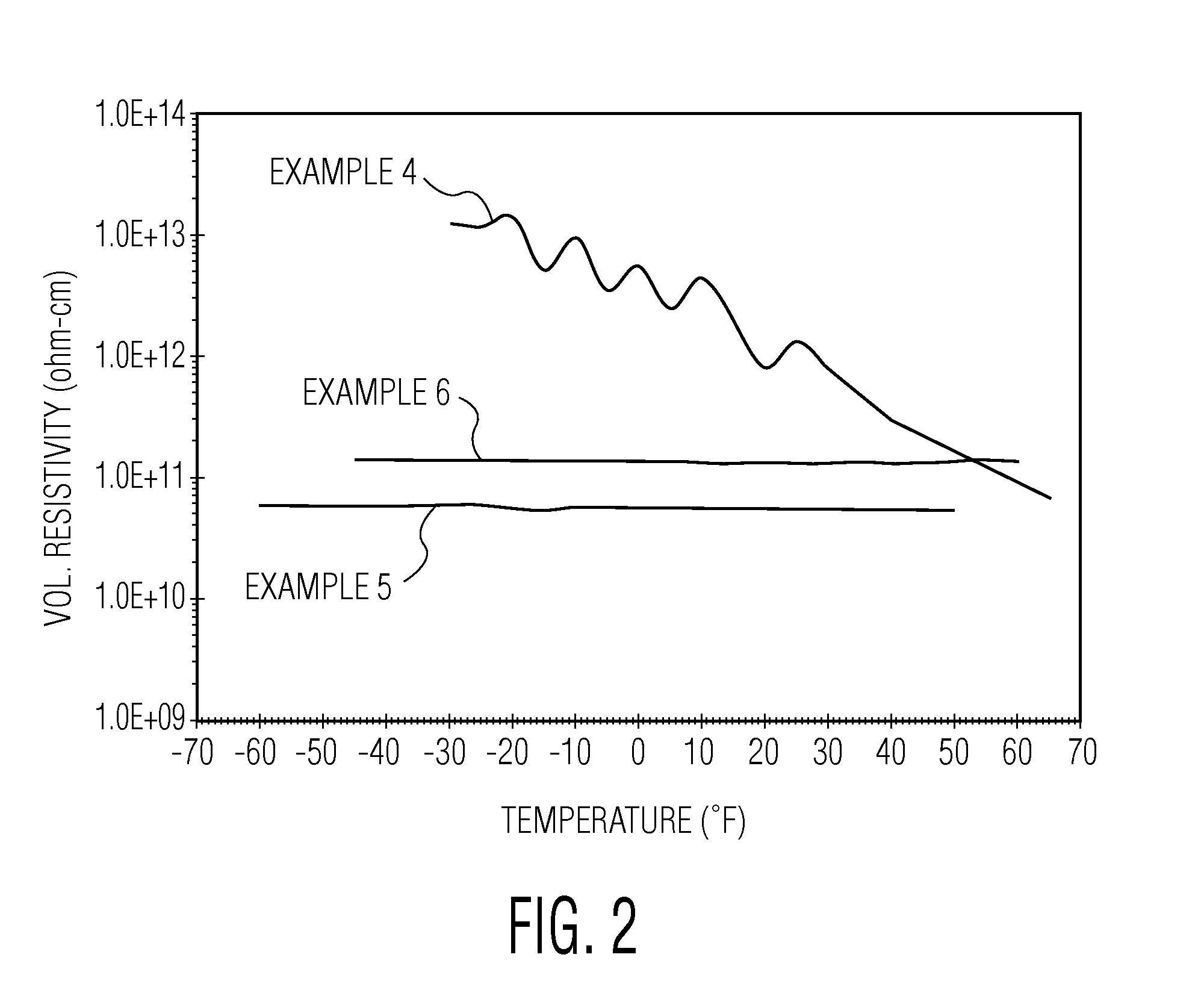

The present invention is embodied in a transparent, polyurethane laminate or multi-layer coating comprising a first transparent polyurethane layer, a middle conductive material layer disposed on the first transparent polyurethane layer, and a second transparent polyurethane layer disposed on the conductive layer. In one embodiment, the subject invention addresses the problem of static charge buildup on aircraft transparencies by allowing charge to drain through the second transparent polyurethane layer to the conductive material layer and then to the edge of the conductive material layer, where it is mated to the airframe. The present invention is also embodied in a method for forming a transparent polyurethane laminate on a transparent substrate and a method for forming a free-standing laminate.

Owner:GKN AEROSPACE TRANSPARENCY SYST

Photochromic polyurethane laminate

ActiveUS8298671B2Fine surfaceImprove uniformityLamination ancillary operationsSynthetic resin layered productsPhotochromic lensThermoplastic polyurethane

A photochromic polyurethane laminate that is constructed to solve certain manufacturing difficulties involved in the production of plastic photochromic lenses is disclosed. The photochromic laminate includes at least two layers of a resinous material and a photochromic polyurethane layer that is interspersed between the two resinous layers and which contains photochromic compounds. The polyurethane layer is formed by curing a mixture of a solid thermoplastic polyurethane, at least one isocyanate prepolymer, at least one photochromic compound, and a stabilizing system.

Owner:HOYA OPTICAL LABS OF AMERICA INC

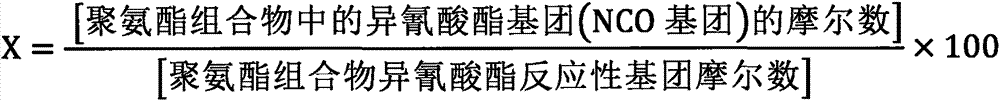

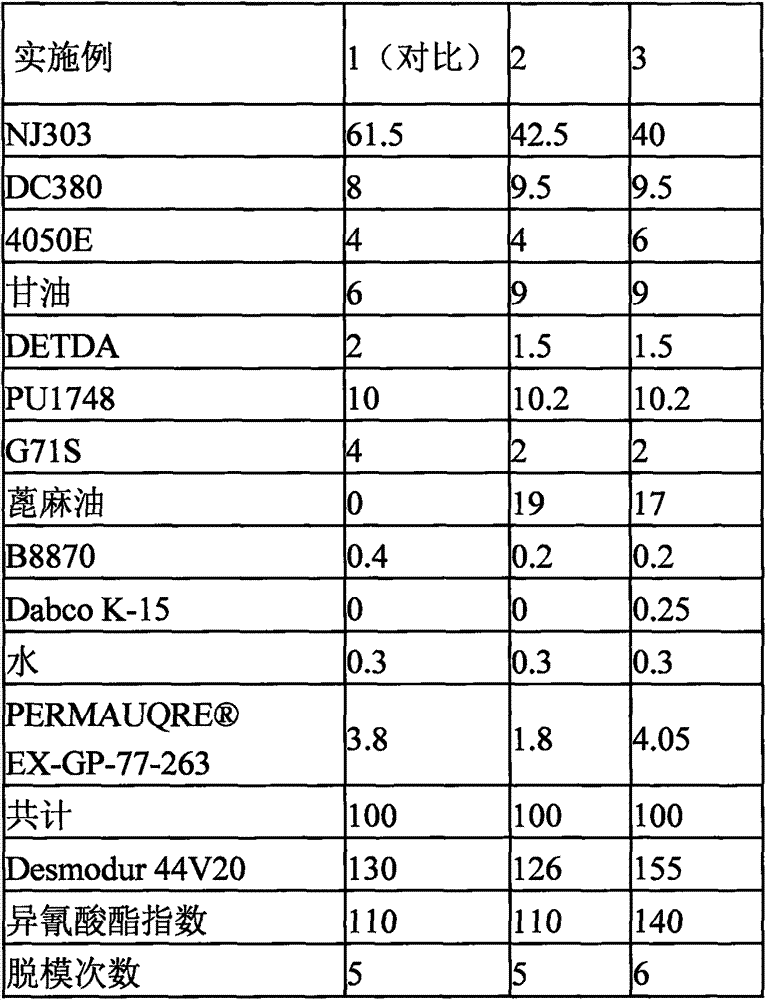

Polyurethane laminated moulding product and preparation method thereof

ActiveCN107512057ASynthetic resin layered productsPaper/cardboard layered productsPolyurethane laminateFibrous layer

The invention relates to a polyurethane laminated moulding product, the polyurethane laminated moulding product comprises a core layer and an enhanced fibrous layer arranged on at least one side of the core layer, By applying a polyurethane resin composition on one layer or multilayer enhanced fibrofelts or enhanced fabrics, and the polyurethane resin is solidified, and the enhanced fibrous layer is formed. The polyurethane laminated moulding product has good mold release property and productivity.

Owner:COVESTRO DEUTSCHLAND AG

Photochromic Polyurethane Laminate

ActiveUS20140272426A1Improve propertiesEnhanced network structurePhotosensitive materialsSynthetic resin layered productsPolyurethane laminatePhotochromism

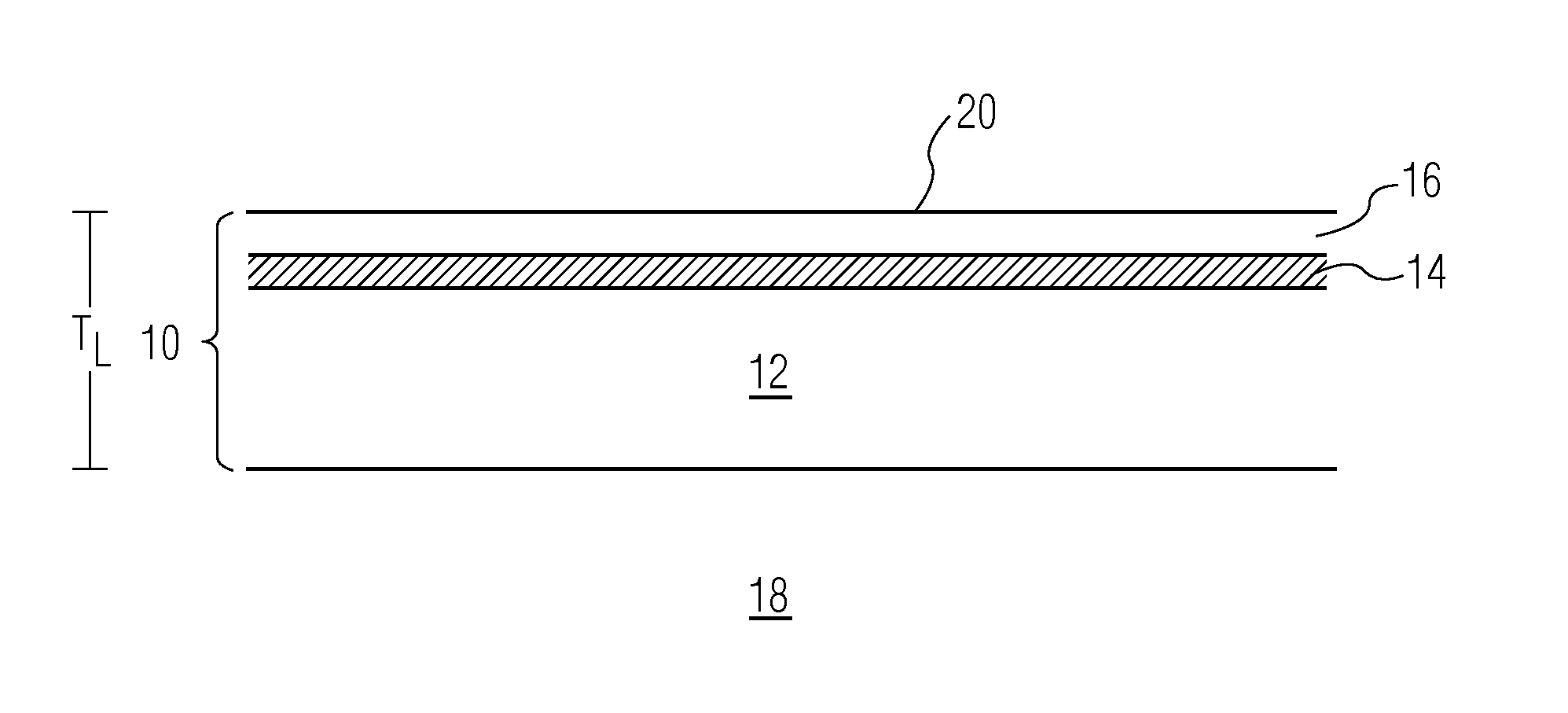

Photochromic polyurethane laminates and methods for the formation of same wherein a photochromic polyurethane layer of the laminate is interposed between two primer coated transparent resin sheets.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Photochromic polyurethane laminate

ActiveUS9163108B2Improve propertiesHigh mechanical strengthSynthetic resin layered productsLaminationPolyurethane laminatePrepolymer

A photochromic polyurethane laminate wherein the photochromic polyurethane layer of the laminate has been crosslinked with a isocyanate-active prepolymer using a crosslinking agent. The crosslinking agent is formulated to have at least three functional groups that are reactive with functional groups of the polyurethane or of the isocyanate-active prepolymer. A method of making the photochromic polyurethane laminate includes steps of causing the crosslinking.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Photochromic Polyrethane Laminate

ActiveUS20150309209A1Improve propertiesHigh mechanical strengthSynthetic resin layered productsOptical articlesPrepolymerPolyurethane laminate

Photochromic polyurethane laminates and methods for the formation of same wherein the photochromic polyurethane layer of the laminate has been crosslinked with a isocyanate-active prepolymer using a crosslinking agent. The crosslinking agent is formulated to have at least three functional groups that are reactive with functional groups of the polyurethane or of the isocyanate-active prepolymer.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Water dyeing method of semi-polyurethane leather

InactiveCN103938460AReduce dosageReduce pollutionLamination ancillary operationsSynthetic resin layered productsOrganic solventSurface layer

The invention discloses a water dyeing method of semi-polyurethane leather. The water dyeing method of the semi-polyurethane leather comprises the steps that (1) a polyurethane surface layer sizing agents are coated on release paper and then put into a drying oven to be dried; (2) five to ten weight percent of foaming layer sizing agents are coated; (3) an adhesive layer is coated, the thickness of the adhesive layer is 0.05-0.1 mm, and then the adhesive layer is put into the drying oven to be dried; (4) base leather is obtained by stripping and coiling the release paper, surface treatment is carried out, and then a semi-polyurethane leather finished product is obtained. The water dyeing method of the semi-polyurethane leather selects water-borne adhesives, the use quantity of organic solvents in the making process of the semi-polyurethane leather is reduced, and environmental pollution is relieved. The semi-polyurethane leather made through the method is pure white in appearance, good in product performance, good in hand feeling and suitable for being used for making gloves, clothes, cases and the like.

Owner:浙江新富来实业有限公司

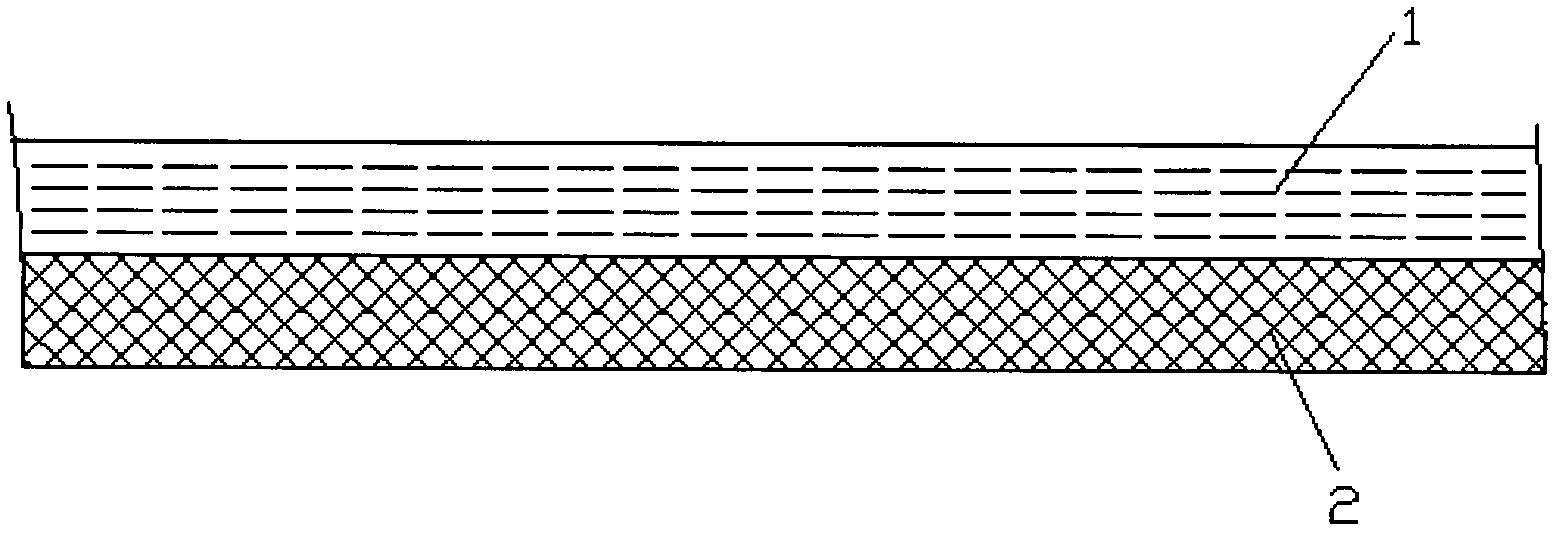

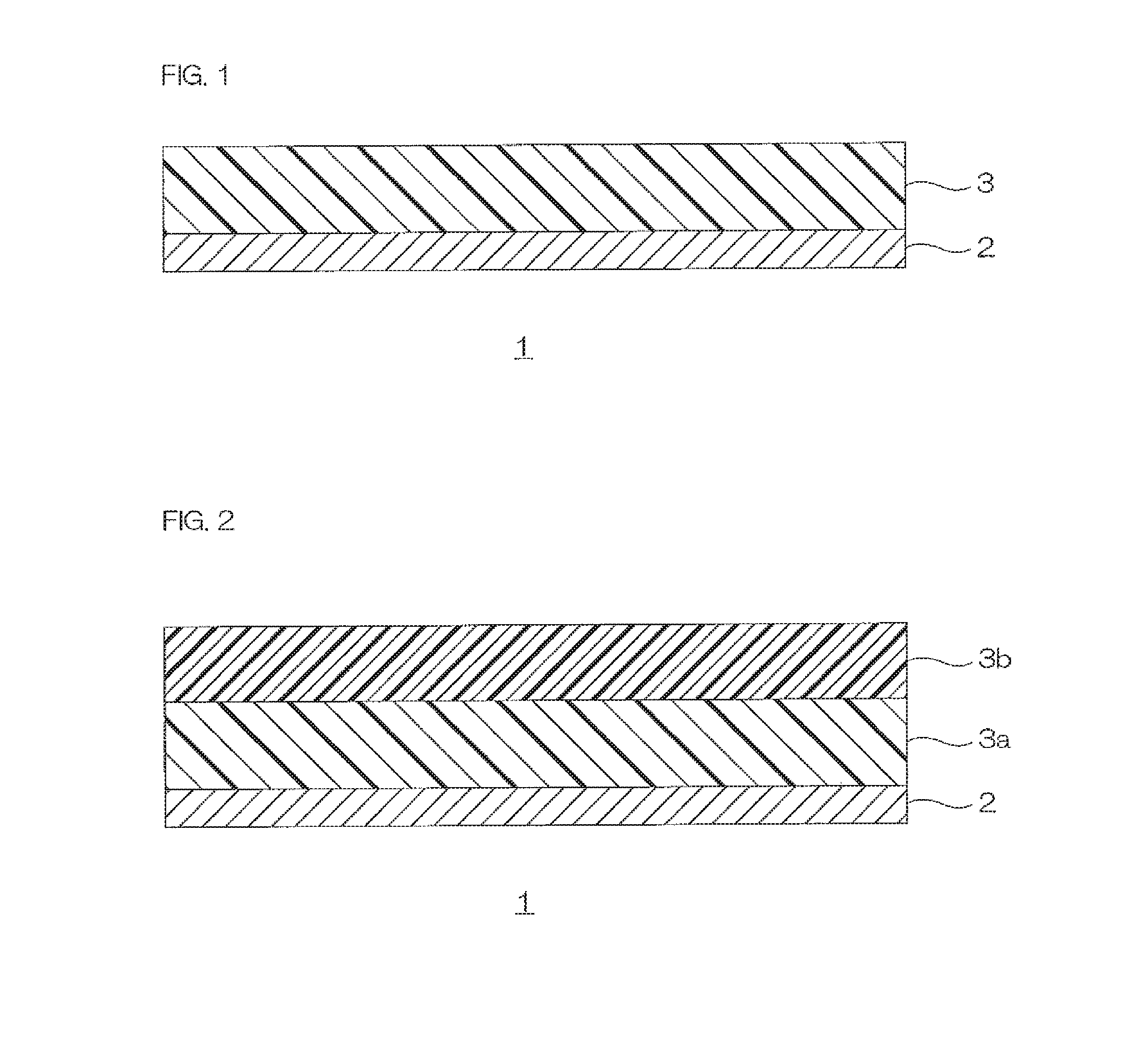

Polyurethane composite film

InactiveCN103009741ABreathableMoisture permeabilitySynthetic resin layered productsComposite filmEngineering

The invention discloses a polyurethane composite film comprising a polyurethane layer and a polytetrafluoroethylene layer. The polyurethane layer comprises two opposite sides, and the polytetrafluoroethylene layer is positioned on one side of the polyurethane layer. A layer of textile fabric can be composed on one or both of the outer sides of the composite film. The composite film is air-permeating and moisture-permeating, and has high wear resistance. According to the invention, the quality of composite clothing fabric formed by the composite film and textile product is effectively improved, and performance requirements on functional clothing fabric are satisfied.

Owner:昆山华富新材料股份有限公司

Photochromic Polyurethane Laminate

ActiveUS20160011337A1Improve propertiesHigh mechanical strengthSynthetic resin layered productsOptical articlesPolyurethane laminatePrepolymer

A photochromic polyurethane laminate wherein the photochromic polyurethane layer of the laminate has been crosslinked with a isocyanate-active prepolymer using a crosslinking agent. The crosslinking agent is formulated to have at least three functional groups that are reactive with functional groups of the polyurethane or of the isocyanate-active prepolymer. A method of making the photochromic polyurethane laminate includes steps of causing the crosslinking.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Transparent polyurethane protective coating, film and laminate compositions with enhanced electrostatic dissipation capability, and methods for making same

ActiveUS9580564B2Conductive layers on insulating-supportsRecord information storageConductive materialsPolyurethane laminate

Owner:GKN AEROSPACE TRANSPARENCY SYST

Steel tile roof system with cold-formed thin-walled steel structure

PendingCN106149986AGuaranteed reliabilityImprove waterproof performanceRoof covering using slabs/sheetsRoof covering insulationsHigh resistanceCold formed

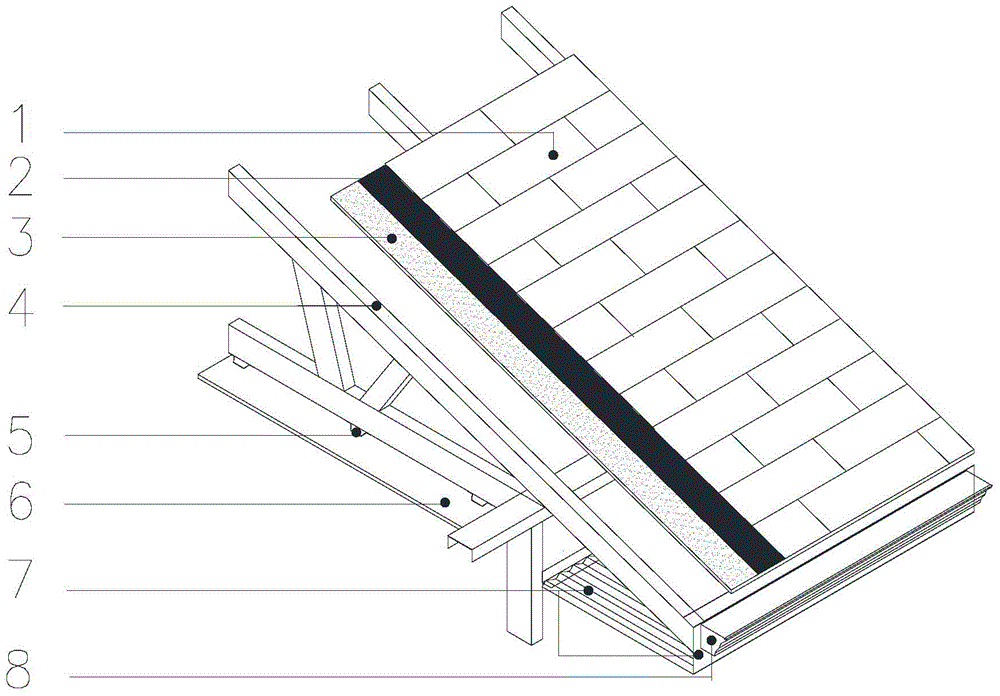

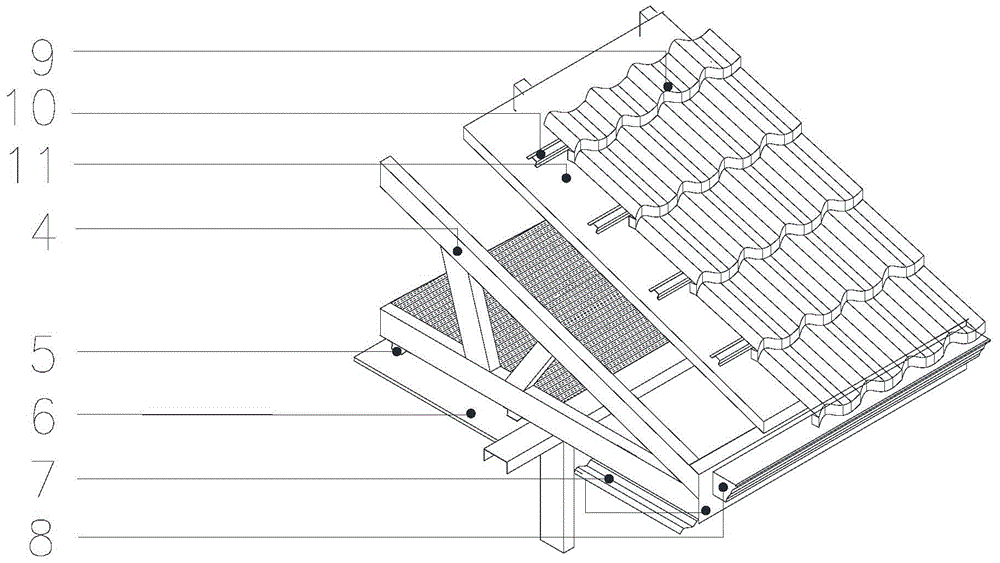

The invention relates to a steel tile roof system with a cold-formed thin-walled steel structure. The system comprises a gypsum board, secondary purlines and a cold-formed thin-walled steel truss, wherein the cold-formed thin-walled steel truss is erected on the gypsum board by the secondary purlines. The system also comprises a polyurethane laminated composite plate, roof purlines and steel tiles, wherein the polyurethane laminated composite plate is fixed on the cold-formed thin-walled steel truss by screws; the quantity of the roof purlines is more than one; the roof purlines are horizontally disposed on the polyurethane laminated composite plate in parallel; multiple layers of the steel tiles are disposed in succession from bottom to top and form a stair shape; and the steel tiles are connected to the purlines by screws. In comparison with the prior art, the system provided by the invention has the advantages of high intensity, high rigidity, good heat insulation performance and high resistance to winds and earthquakes, etc.

Owner:SHANGHAI BESTSTEEL STEEL STRUCTURE BUILDING

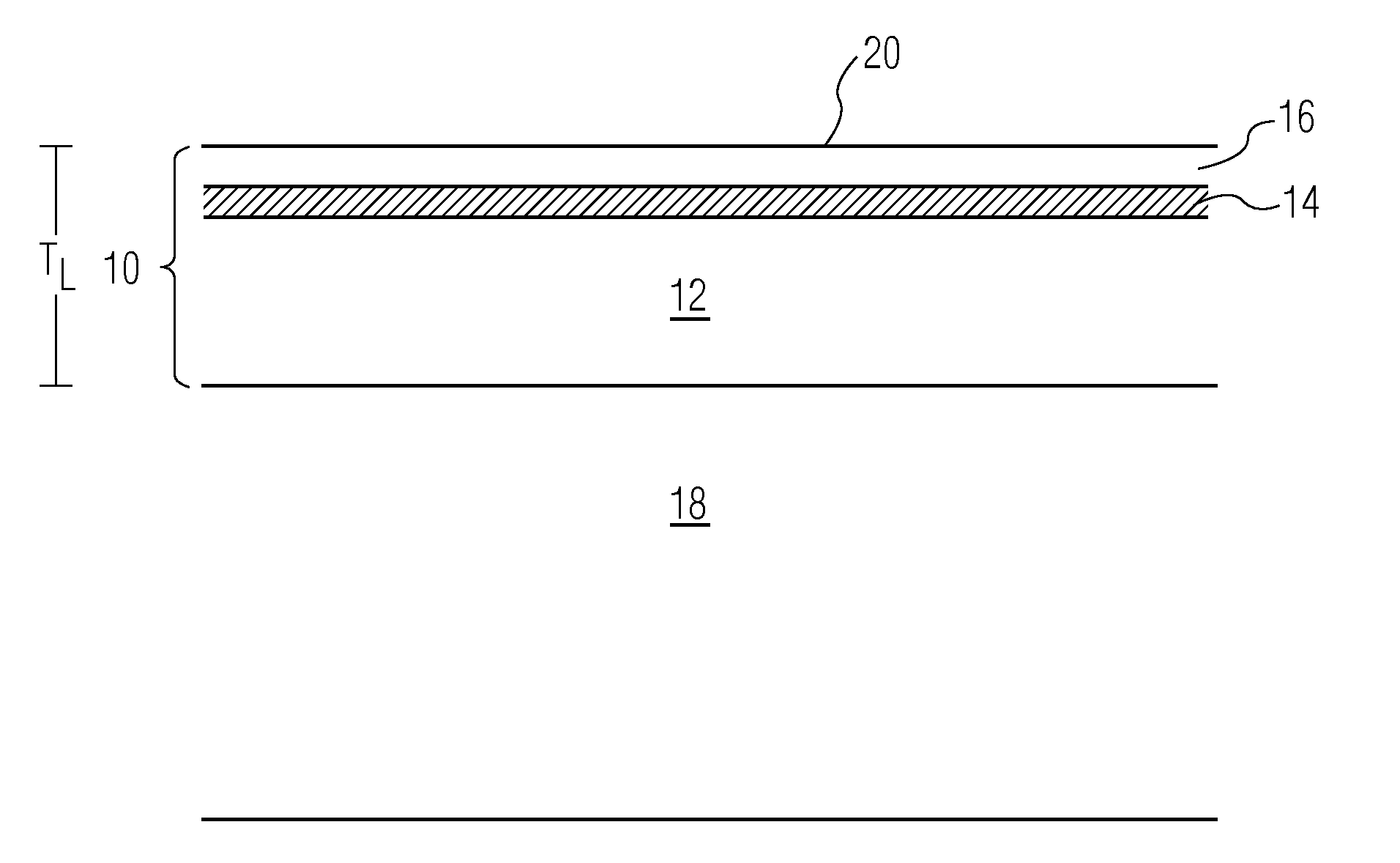

Polyurethane dispersion and polyurethane laminate

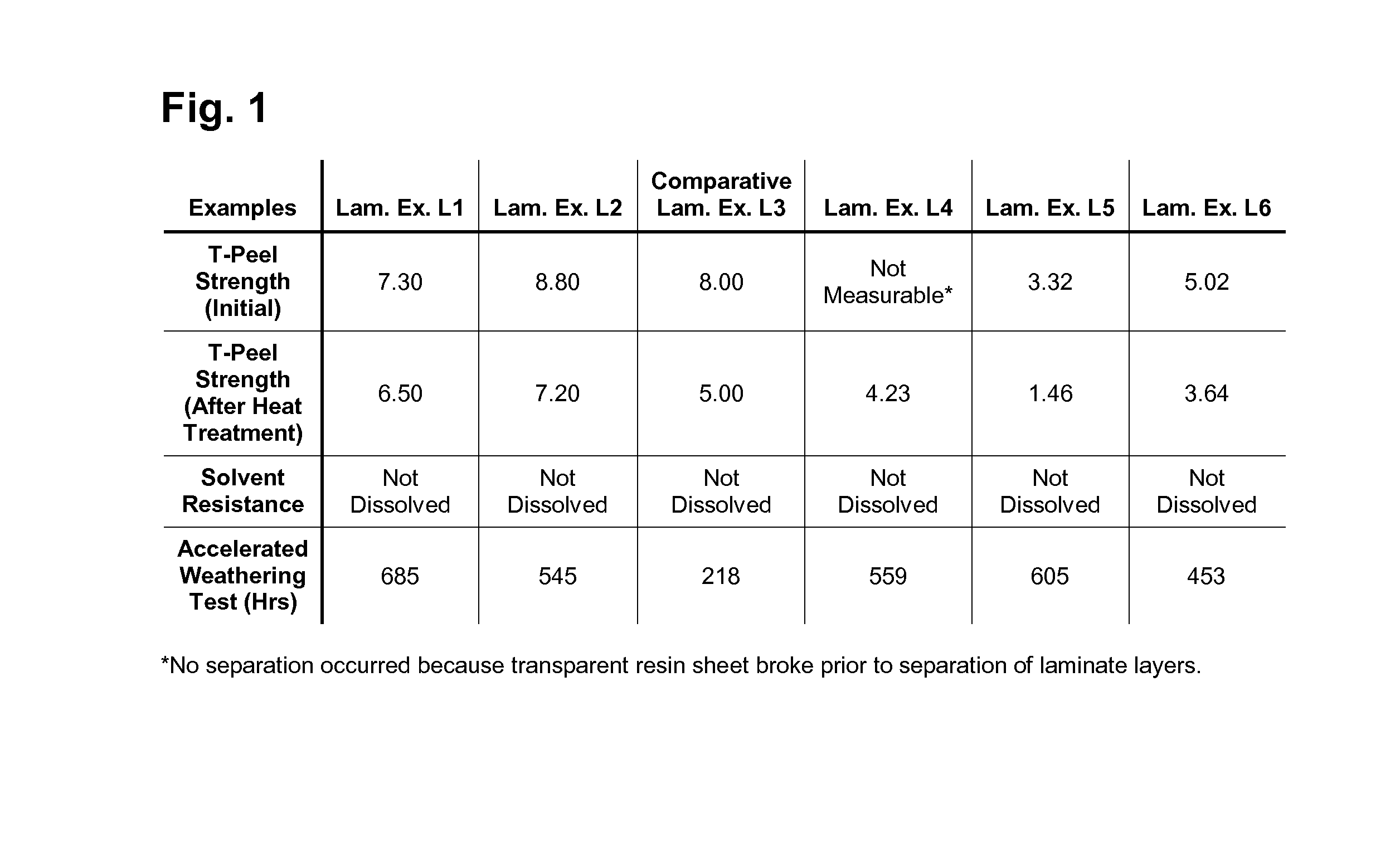

ActiveUS20160159965A1Dispersion property can be ensuredExcellent gas barrier performancePolyurea/polyurethane coatingsXylylenePolyurethane dispersion

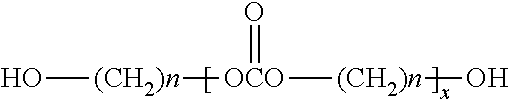

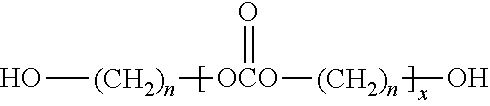

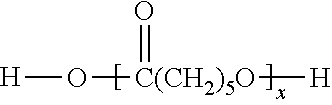

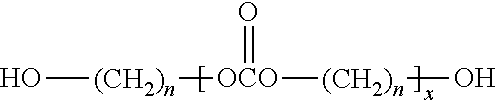

A polyurethane dispersion is a polyurethane dispersion in which polyurethane resin produced by reaction of an isocyanate group-terminated prepolymer with a chain extender is dispersed in water. The isocyanate group-terminated prepolymer is produced by at least allowing a polyisocyanate component containing xylylene diisocyanate and / or hydrogenated xylylene diisocyanate to react with a polyol component containing diol having 2 to 6 carbon atoms, a low-molecular-weight polyol having a functionality of three or more, and an active hydrogen group-containing compound containing a hydrophilic group. The chain extender contains an alkoxysilyl compound having a primary amino group, or a primary amino group and a secondary amino group, and the molar ratio of the hydroxyl group in the low-molecular-weight polyol having a functionality of three or more is less than 25% relative to a total mol 100% of the hydroxyl group in the polyol component.

Owner:MITSUI CHEM INC

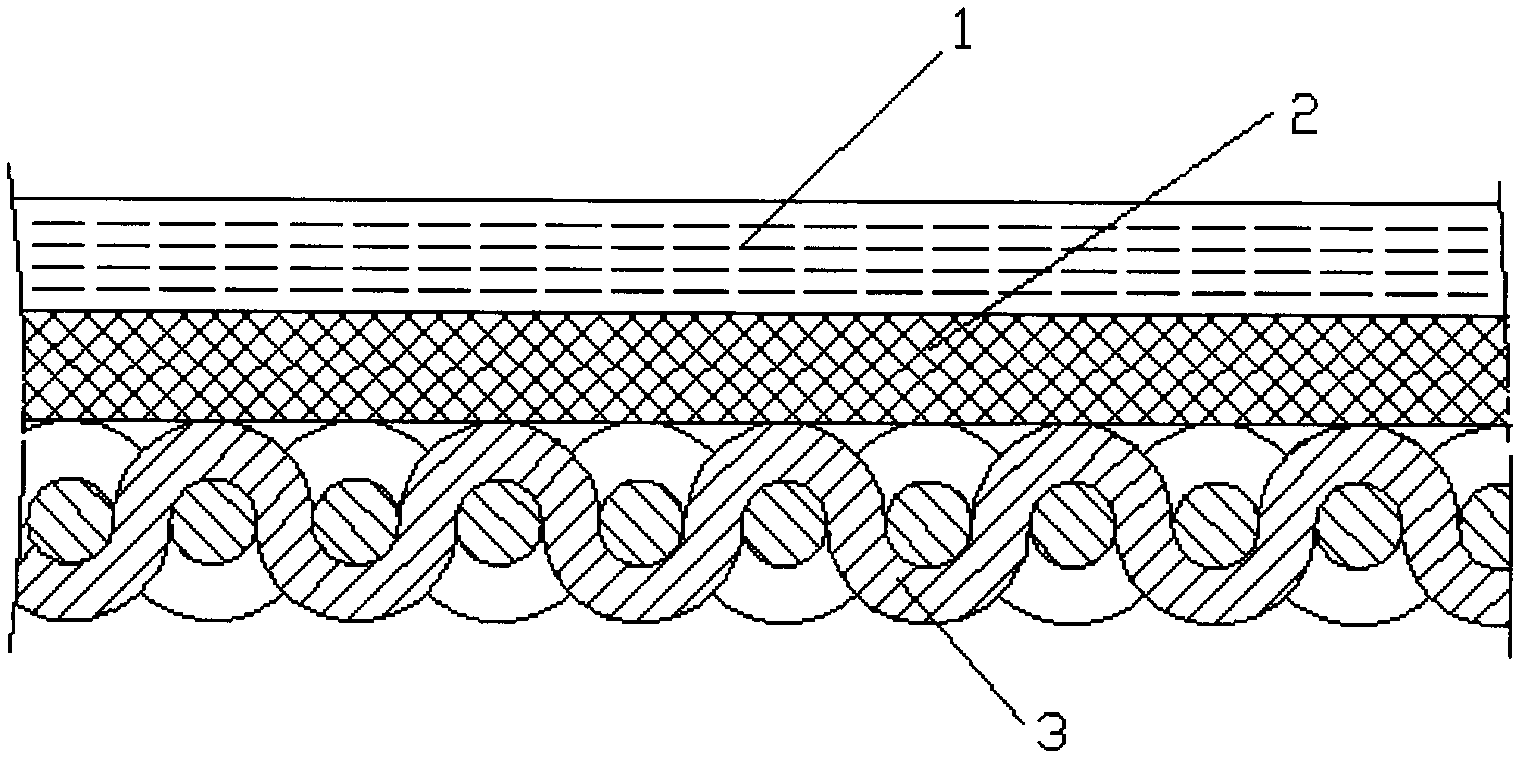

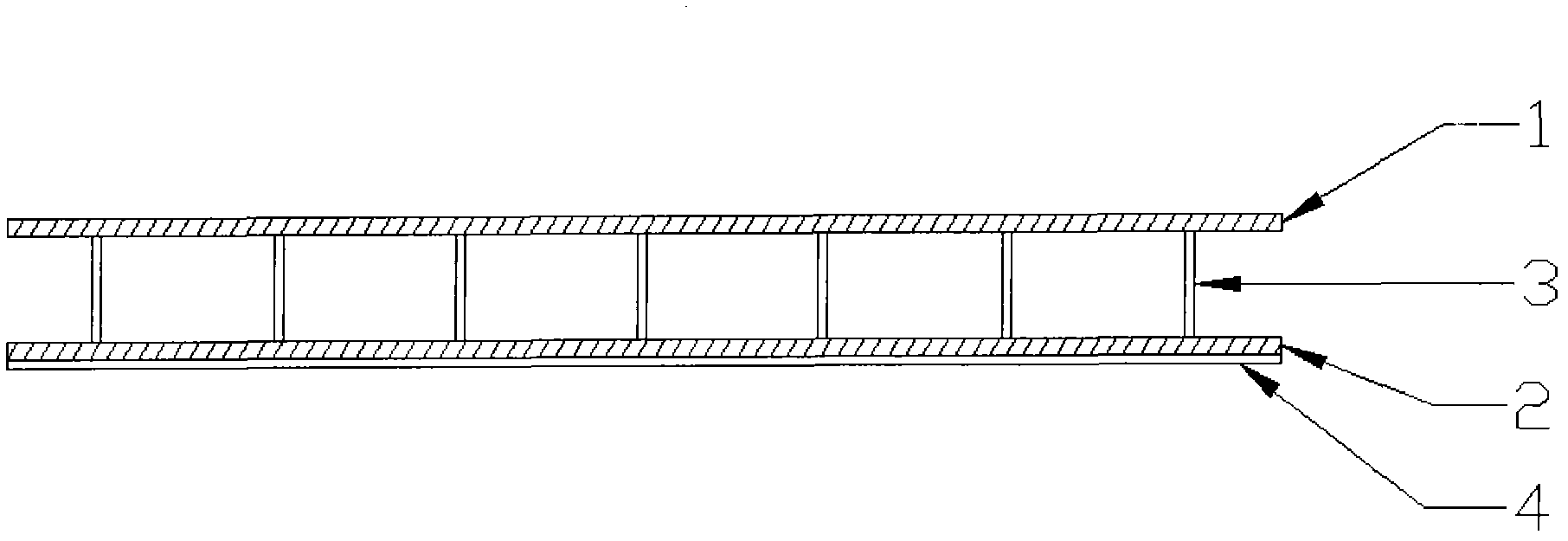

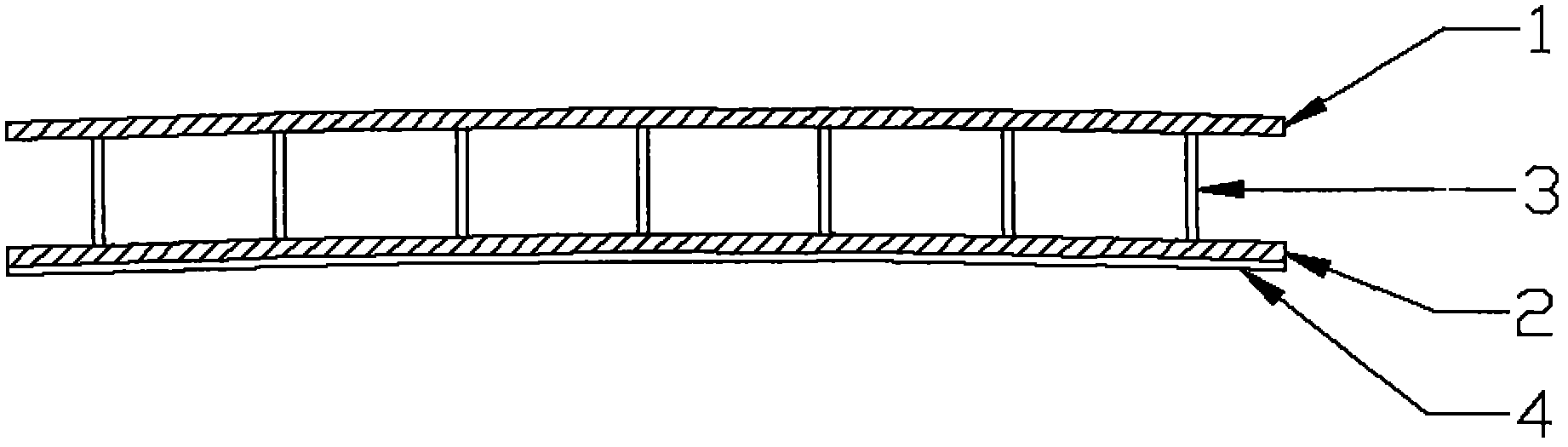

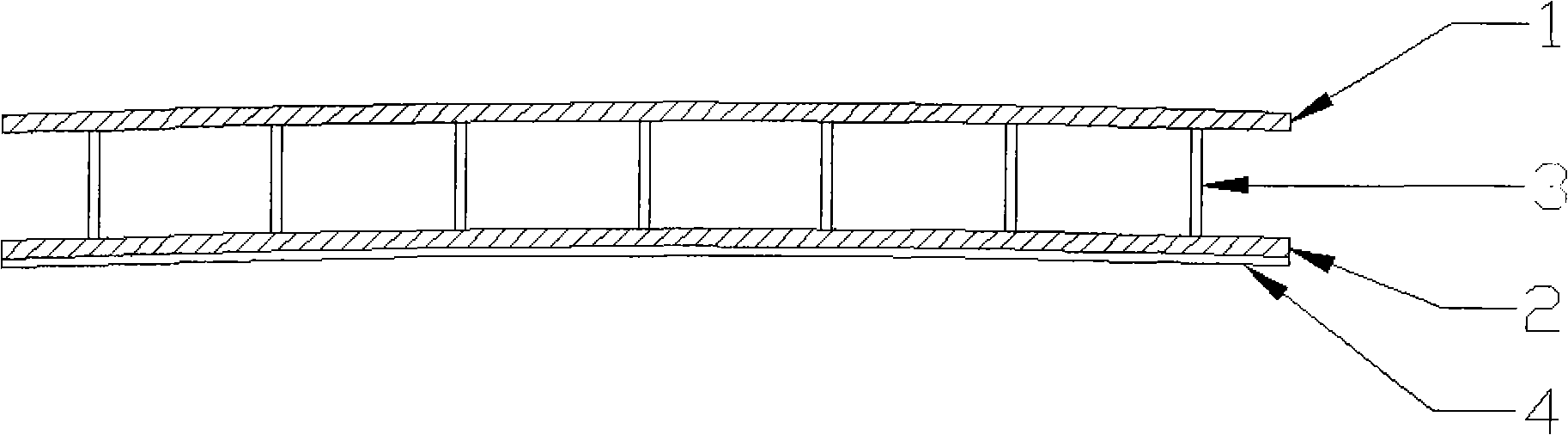

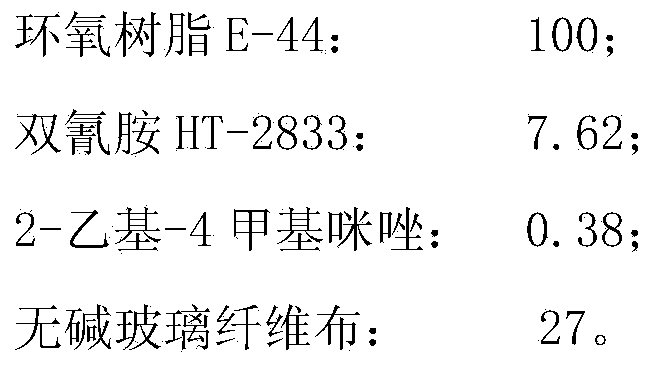

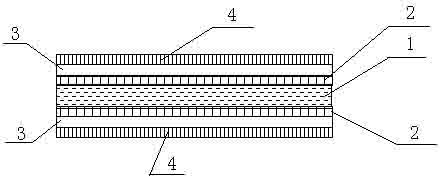

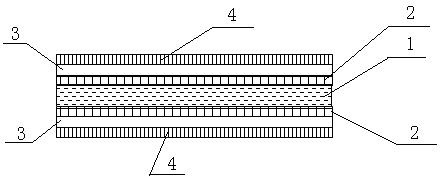

Glass fiber-reinforced polyurethane sun roof and production method thereof

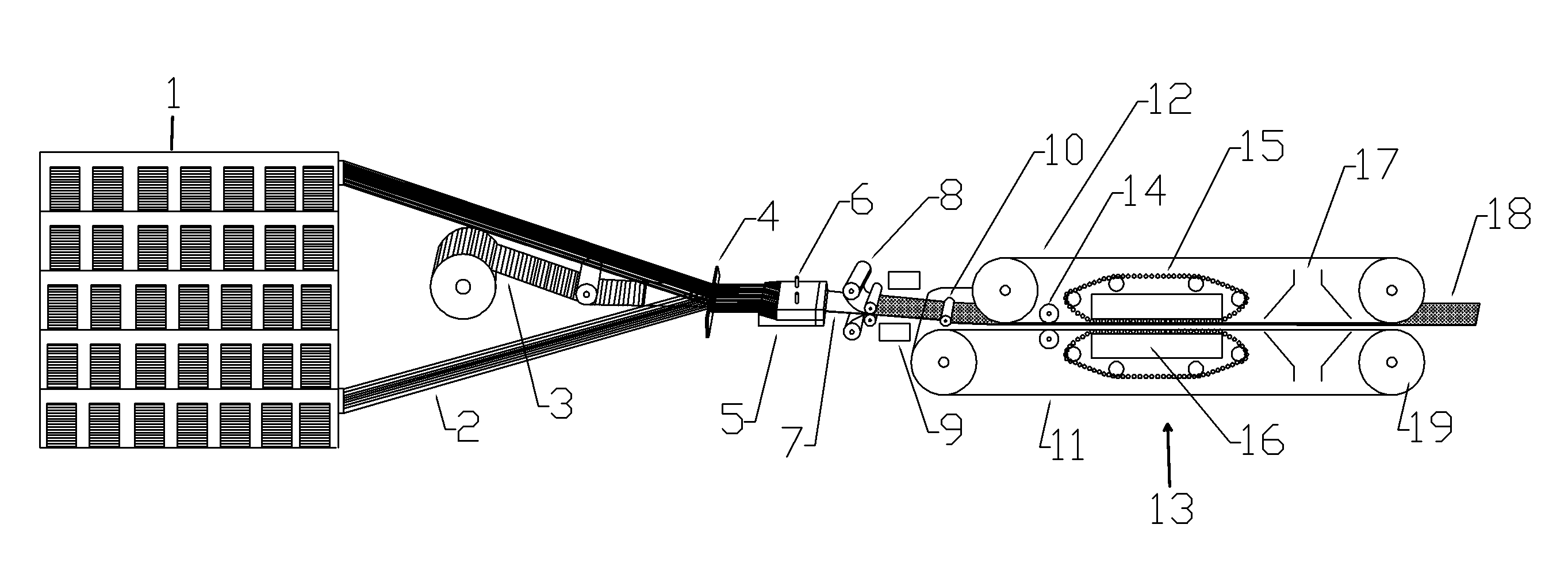

ActiveCN102126418AChange arcRadian meets the requirementsSynthetic resin layered productsLaminationGlass fiberHoneycomb

The invention discloses a glass fiber-reinforced polyurethane sun roof and a production method thereof. The production method is characterized by comprising the following steps of: laying materials according to an order of a nonwoven fabric layer, a glass fiber felt layer, a honeycomb paper layer and a glass fiber felt layer neatly; spraying polyurethane materials on front and back sides of the materials; feeding the materials sprayed with the polyurethane materials into a mold; reacting under the action of the temperature and the pressure of the mold to bond the materials into a whole by thepolyurethane materials so as to produce a polyurethane product. The structure of the polyurethane product is that: an upper glass fiber-reinforced polyurethane layer (1) and a lower glass fiber-reinforced polyurethane layer (2) are positioned above and below the honeycomb paper layer (3) respectively; and a nonwoven fabric-reinforced polyurethane layer (4) is positioned below the lower glass fiber-reinforced polyurethane layer (2), and also can be positioned above the upper glass fiber-reinforced polyurethane layer (1). By the polyurethane sun roof produced by the method of adding the nonwoven fabric layer besides the glass fiber felt layer, the radian of the product can be changed, so that the radian of the product meets requirements, cost is saved and the quality of the product is improved simultaneously.

Owner:YANTAI ZHENGHAI HIGH TECH

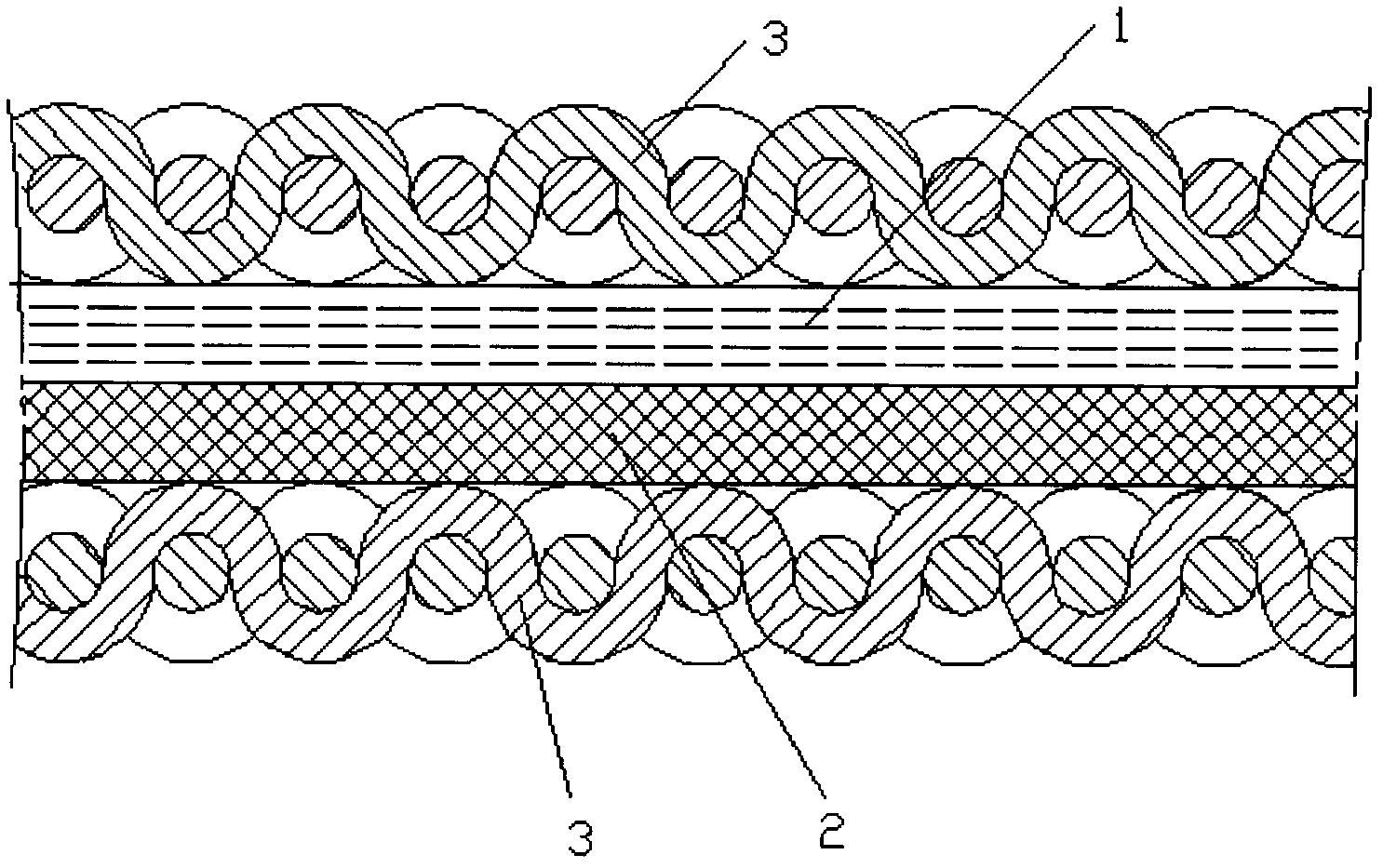

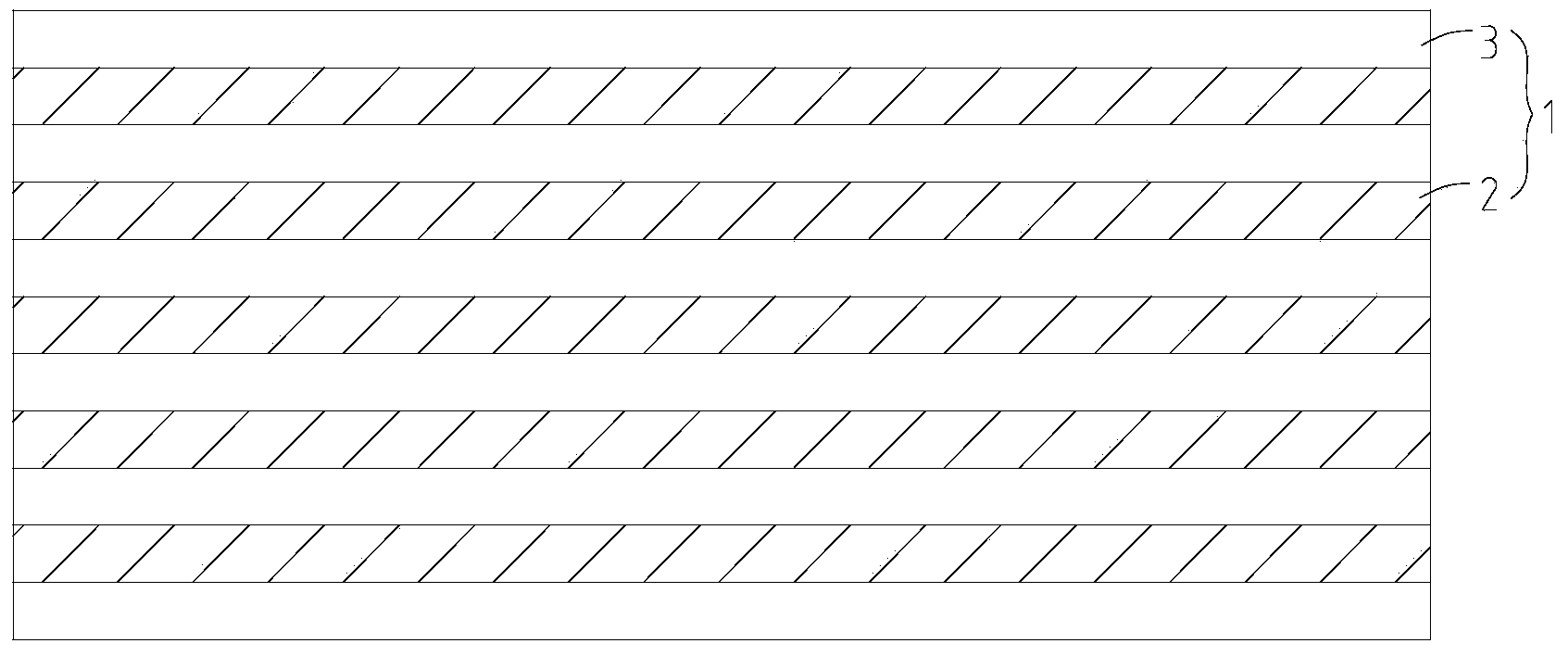

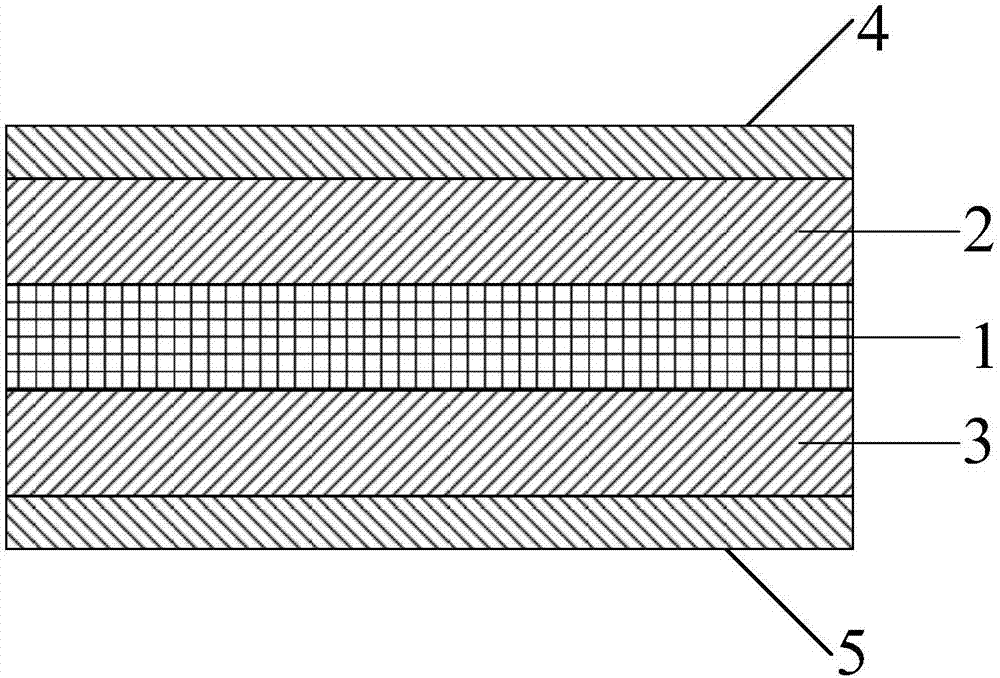

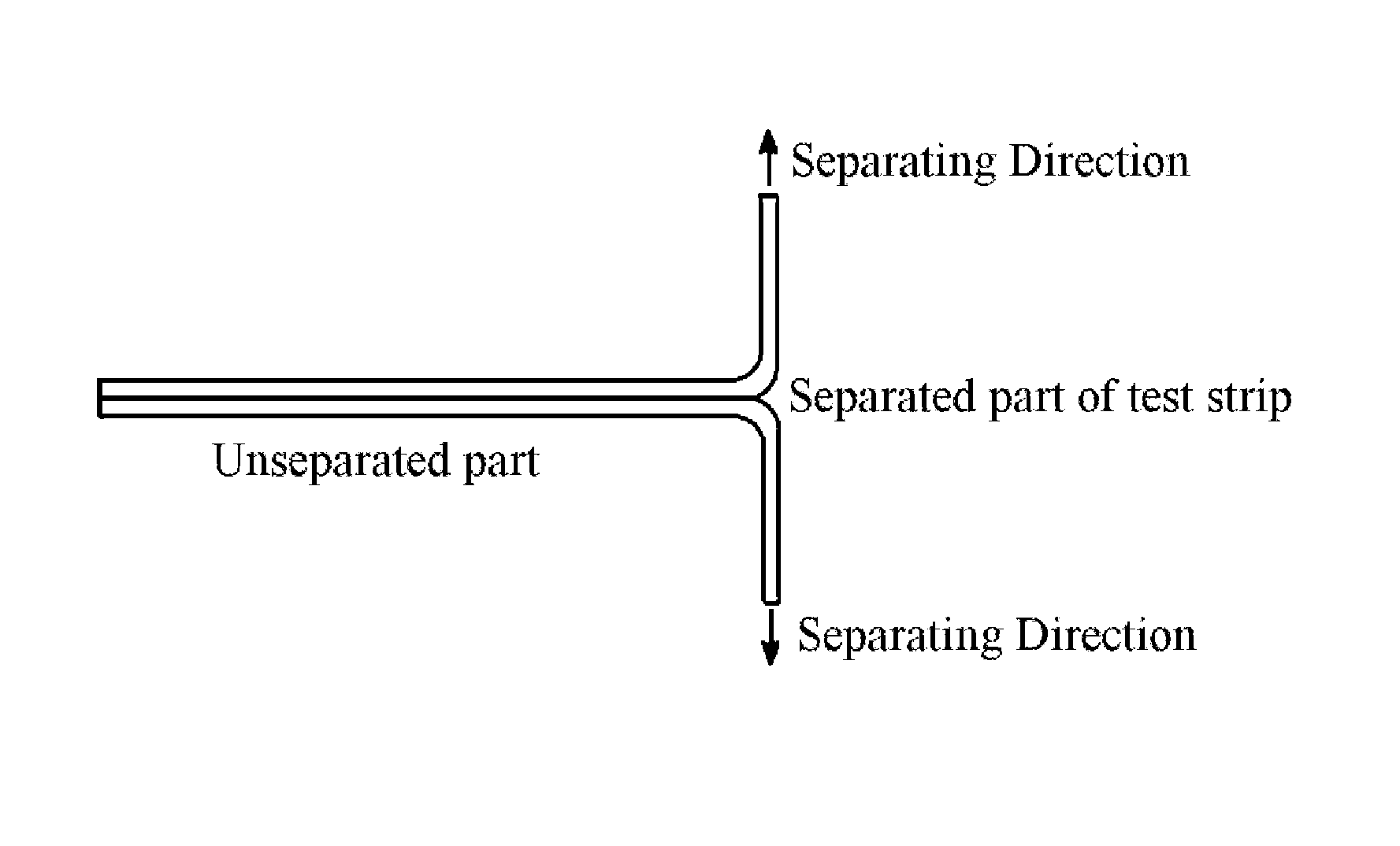

Fiber reinforced epoxy resin/polyurethane laminated seismic insulation support and preparation method thereof

InactiveCN103742579AImprove mechanical propertiesIncrease dampingRubber-like material springsEpoxyPolyurethane elastomer

The invention relates to the technical field of seismic insulation, and particularly relates to a fiber reinforced epoxy resin / polyurethane laminated seismic insulation support. The support comprises a support body which is formed by alternately overlaying and bonding fiber reinforced epoxy resin plates and polyurethane elastic body plates. The support is low in cost and simple in construction technology, with the pressure stress limiting value being smaller than that of a laminate steel plate rubber support, and is applicable to low-rise buildings, multi-rise buildings, bridges, industrial equipment and valuable cultural objects in small towns, villages and mountainous areas. The invention also discloses a manufacture method of the fiber reinforced epoxy resin / polyurethane laminated seismic insulation support.

Owner:GUANGZHOU UNIVERSITY

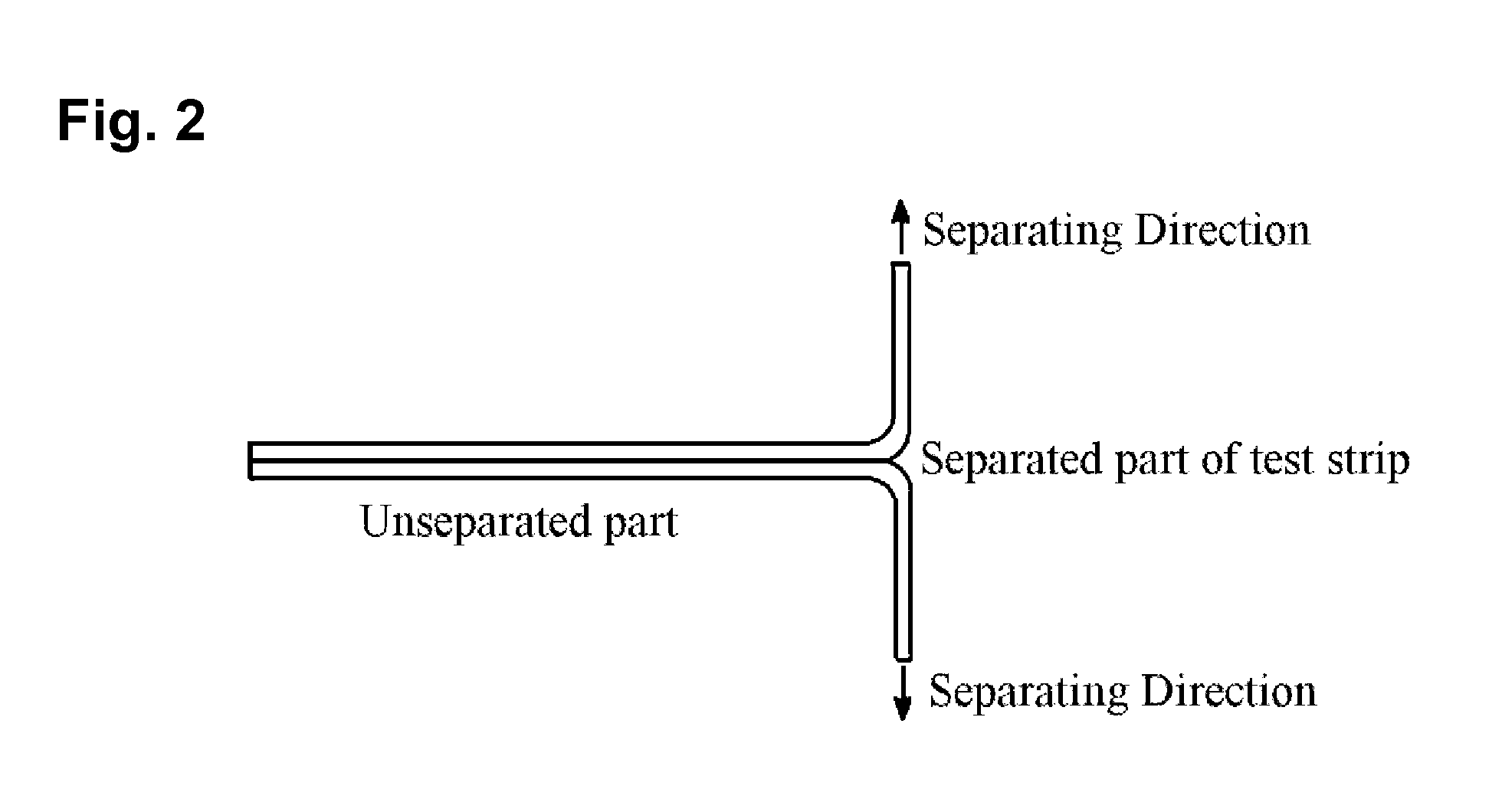

Complex self-adhesive elastic bandage and manufacturing method thereof

InactiveCN107157655AEasy to bandage and fixEasy to tearNon-adhesive dressingsPlastersFiberVolumetric Mass Density

The invention discloses a complex self-adhesive elastic bandage and a manufacturing method thereof. The complex self-adhesive elastic bandage comprises an upper non-woven fabric layer and a lower non-woven fabric layer, wherein a polyurethane filament layer is sandwiched between the upper non-woven fabric layer and the lower non-woven fabric layer, and a bandage substrate is formed by combining the upper non-woven fabric layer, the polyurethane filament layer and the lower non-woven fabric layer; complex adhesive layers are coated on the front side of the upper non-woven fabric layer and on the back side of the lower non-woven fabric layer; the complex adhesive layers include polyisoprene and polyacrylate; the non-woven fabric layers make use of a polypropylene non-woven fabric; fibers of the polypropylene non-woven fabric are in directional alignment in a longitudinal direction, and a longitudinal arrangement proportion of the fibers of the polypropylene non-woven fabric is 70-90%; polyurethane filaments of the polyurethane filament layer are subjected to 60-120D specification; and warp-wise density of the polyurethane filaments is 7-11 polyurethane filaments / inch. The bandage, which is telescopic in a transverse direction, can be stretched by 20-40%, so that binding and fixing on special parts are facilitated; and the bandage has an easy-to-tear property in both transverse and longitudinal direction, with clear and tidy torn surfaces.

Owner:SUZHOU MEDSPORT PROD

Photochromic polyurethane laminate

ActiveUS9440419B2Improve propertiesEnhanced network structurePhotosensitive materialsSynthetic resin layered productsPolyurethane laminatePhotochromism

Photochromic polyurethane laminates and methods for the formation of same wherein a photochromic polyurethane layer of the laminate is interposed between two primer coated transparent resin sheets.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Metal-polyurethane laminate

InactiveCN1421313AImprove sound absorptionImprove deep drawing qualitySynthetic resin layered productsLaminationPolymer sciencePolyurethane laminate

The present invention relates to laminates comprising metal and compact or cellular polyurethane resins, to processes for the production of these laminates, and to the production of molded articles comprising these laminates.

Owner:BAYER AG

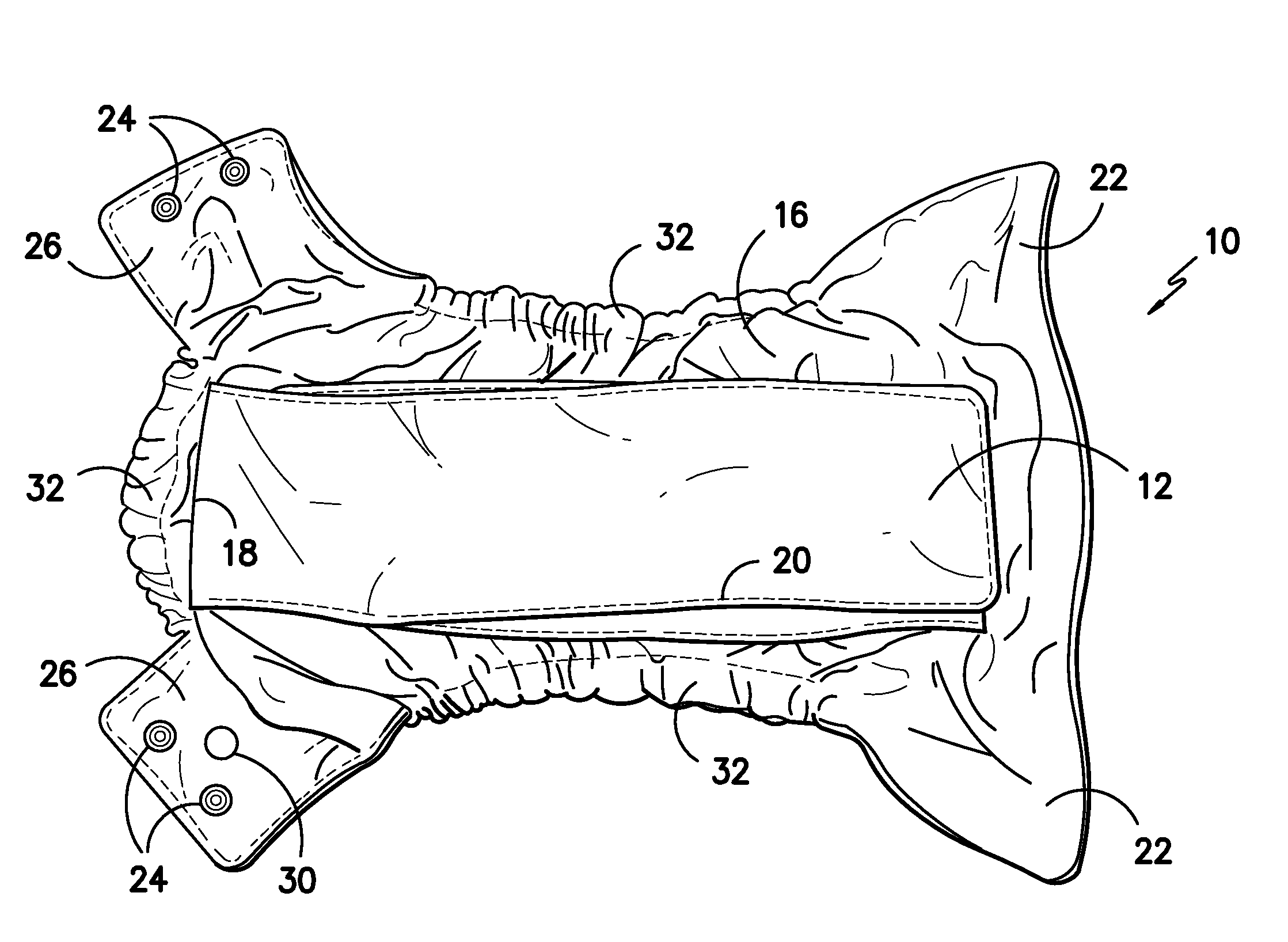

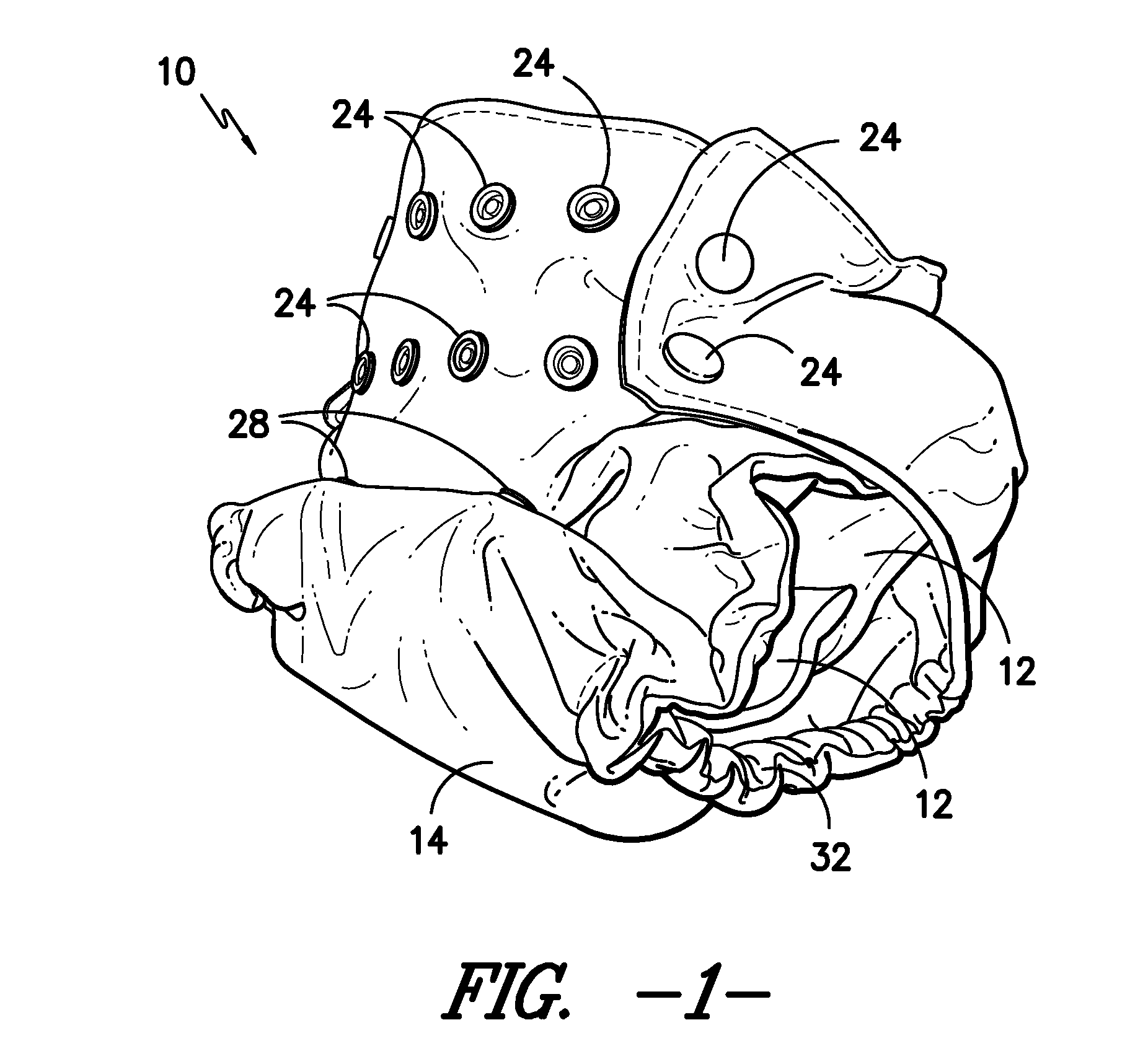

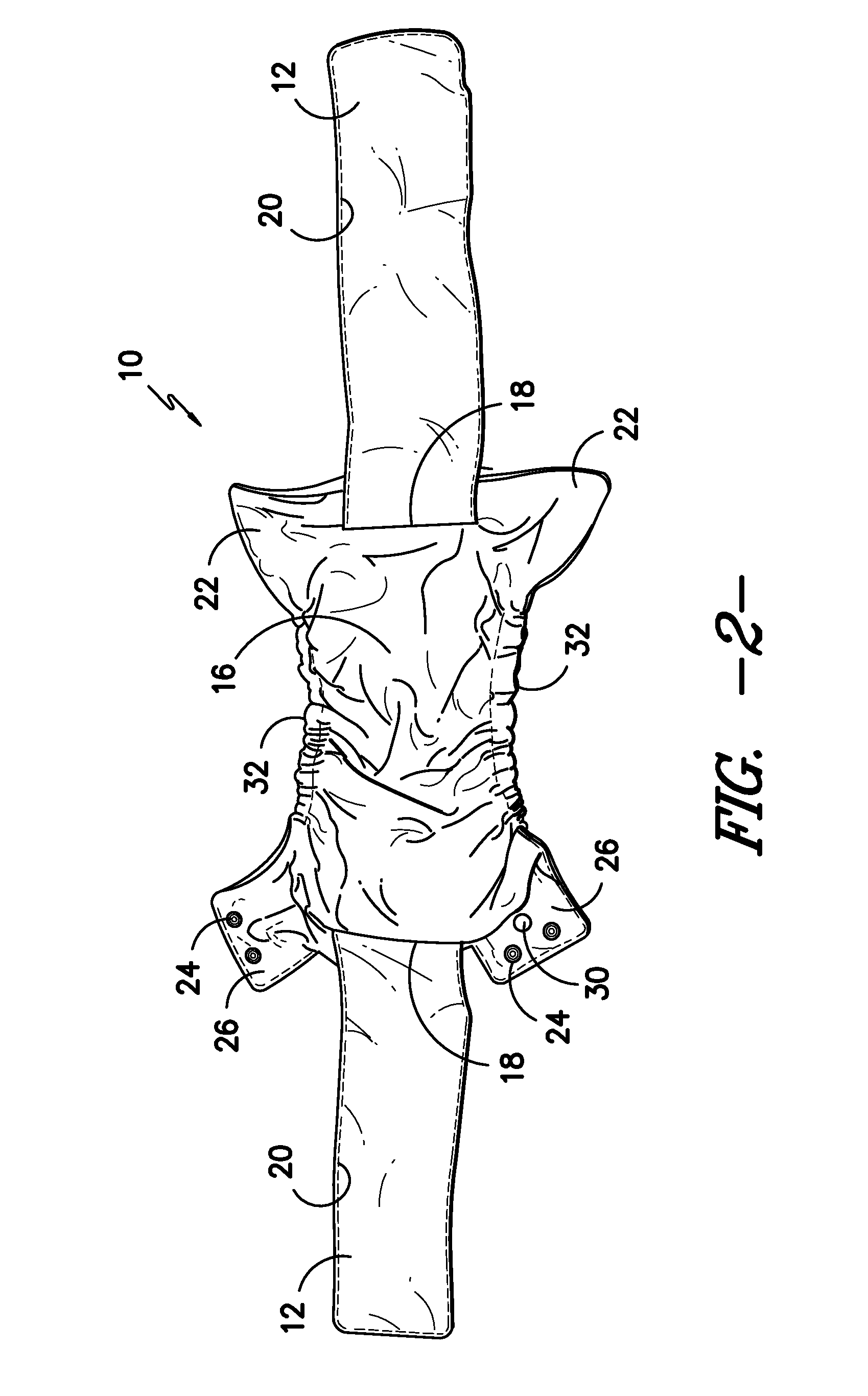

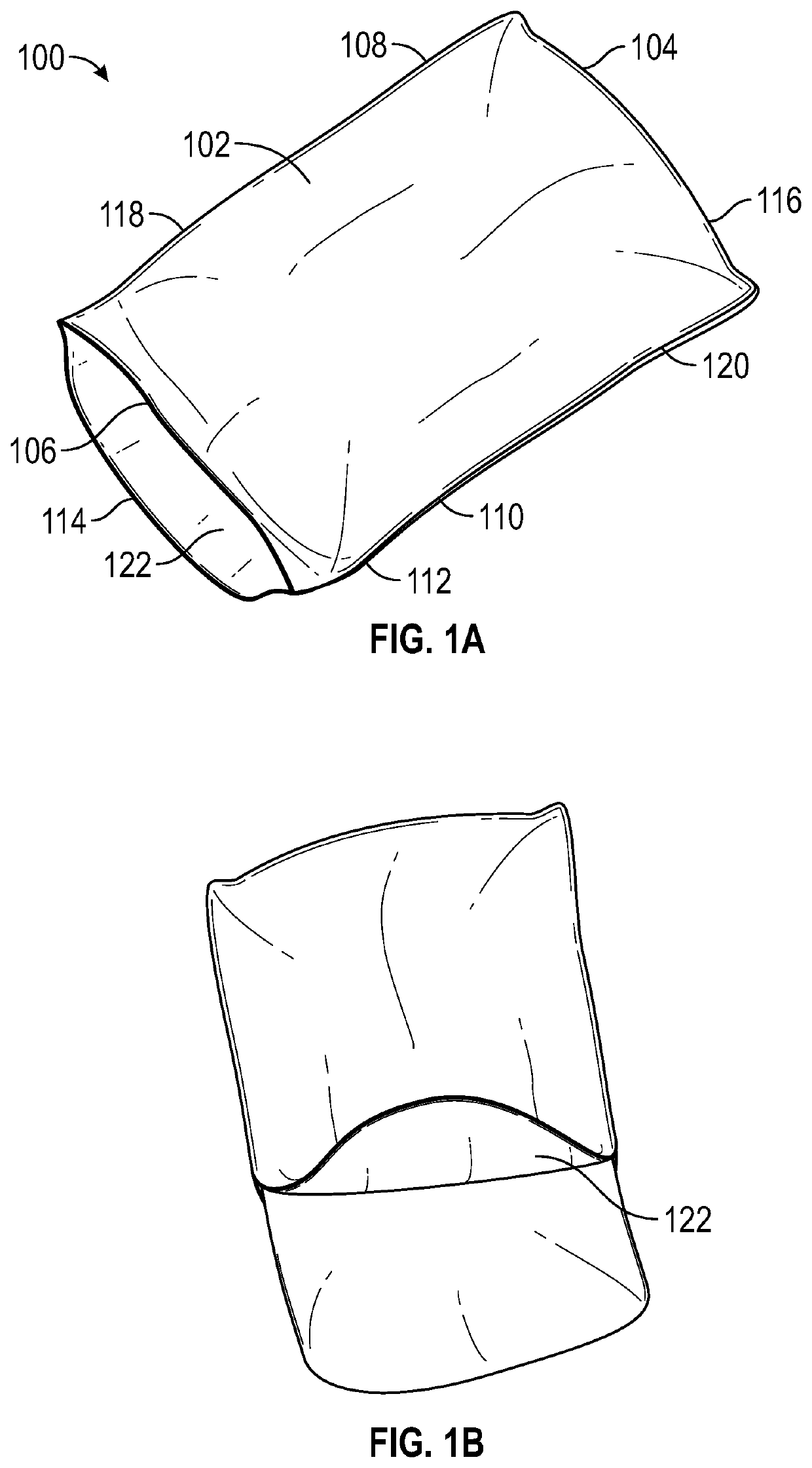

Cloth diaper

ActiveUS20130053805A1Shorten the timeReducing energy usageBaby linensTamponsEngineeringMechanical engineering

A reusable, cloth diaper of singular construction is provided. The diaper is generally shaped like a classic hourglass configuration, and includes a pair of absorbent flaps in a cross-flap configuration on an inner portion thereof, wherein one flap is attached to a rear portion of the diaper and the other flap is attached to a front portion of the diaper, each adjacent to the child's waist. The outer layer of the diaper is preferably made from a blend of bamboo and cotton, and includes a polyurethane laminate layer on the inner surface of the outer layer. The diaper construction further includes means for adjusting waist and crotch sizes, as well as storage snap means for securing the diaper into a rolled up storage and transport configuration.

Owner:CATOE JENNY K

Polyurethane composite plate

InactiveCN102350840AGood heat and sound insulationNo pollution in the processSynthetic resin layered productsVehicle componentsThermal insulationAdhesive

The invention discloses a polyurethane composite plate, which comprises a polyurethane plate, phenolic resin and a non-woven fabric, wherein the phenolic resin is compounded between the polyurethane plate and the non-woven fabric. The polyurethane composite plate has good thermal insulation and sound insulation effects without dust pollution; a great amount of adhesive is not required to be added in the preparation process, so thick odor in the pressing process is avoided; and the product is light.

Owner:LIYANG SHANHU IND CO LTD

Steel plate/polyurethane laminated seismic-isolation support and manufacturing method thereof

InactiveCN103758212AIncrease dampingImprove fatigue resistanceBridge structural detailsShock proofingPolyurethane elastomerMetallurgy

The invention relates to the technical field of seismic isolation, in particular to a steel plate / polyurethane laminated seismic-isolation support which comprises a support body. The support body is formed by alternately laminating and bonding steel plates and polyurethane elastomer plates. Compared with a steel plate / rubber laminated seismic-isolation support, the steel plate / polyurethane laminated seismic-isolation support is lower in production process, higher in quality and excellent in performance and can be used as a seismic-isolation structure of buildings, bridges, industrial equipment and valuable cultural relics. The invention further relates to a manufacturing method of the steel plate / polyurethane laminated seismic-isolation support.

Owner:GUANGZHOU UNIVERSITY

A steel plate/polyurethane laminated shock-isolation bearing and its manufacturing method

InactiveCN103758212BIncrease dampingImprove fatigue resistanceBridge structural detailsShock proofingPolyurethane elastomerMetallurgy

Owner:GUANGZHOU UNIVERSITY

Absorbent pillowcase

Owner:PEGUES SONYA

Photochromic polyurethane laminate

ActiveUS9726785B2Improve propertiesHigh mechanical strengthSynthetic resin layered productsOptical articlesPolyurethane laminatePrepolymer

Photochromic polyurethane laminates and methods for the formation of same wherein the photochromic polyurethane layer of the laminate has been crosslinked with a isocyanate-active prepolymer using a crosslinking agent. The crosslinking agent is formulated to have at least three functional groups that are reactive with functional groups of the polyurethane or of the isocyanate-active prepolymer.

Owner:HOYA OPTICAL LABS OF AMERICA INC

Production method of polyurethane composite plate

InactiveCN102877555AHigh hardnessImprove adhesionSynthetic resin layered productsHeat proofingProduction lineFoam polyurethanes

The invention discloses a production method of a rigid-foam polyurethane composite plate. According to the production method, a layer of polymer sheet is arranged on each of two sides of rigid-foam polyurethane, non-woven fabrics are arranged in the polymer sheets. The production method comprises the following steps of: producing the polymer sheets by using adhesive, inorganic powder and the non-woven fabrics; foaming polyisocyanate and combined polyether to produce a polyurethane plate by using a polyurethane production line and compositing the polymer sheets to the two sides of the polyurethane plate at the same time, thus obtaining the polyurethane composite plate. When used, the rigid-foam polyurethane composite plates are cut according to required size firstly, and then the cut rigid-foam polyurethane composite plates are spliced and adhered to walls, thus obtaining seamless integrated heat-insulating walls.

Owner:天津市艾迪聚氨酯工业有限公司

Making method of comfortable polyurethane foam

The invention discloses a simple-operating process and low-cost making method of comfortable polyurethane foam. The method comprises the following steps: (1) producing a polyurethane foaming die according to a predetermined shape; (2) cutting a polyurethane hot-melt film to form the predetermined shape, and thermally compounding the cut polyurethane hot-melt film with a foam slice to form a thermally-compounded foam slice; and (3) cooling the thermally-compounded foam slice obtained in step (2), placing the cooled thermally-compounded foam slice in the polyurethane foaming die obtained in step(1), then pouring a polyurethane foam raw material, and taking out the obtained material 6-8 min later in order to obtain the comfortable polyurethane foam. The method improves the comfortableness ofthe polyurethane foam, and has the advantages of simple operating process, low cost, suitableness for large-scale production, and great practical significance.

Owner:JILIN UNIV +1

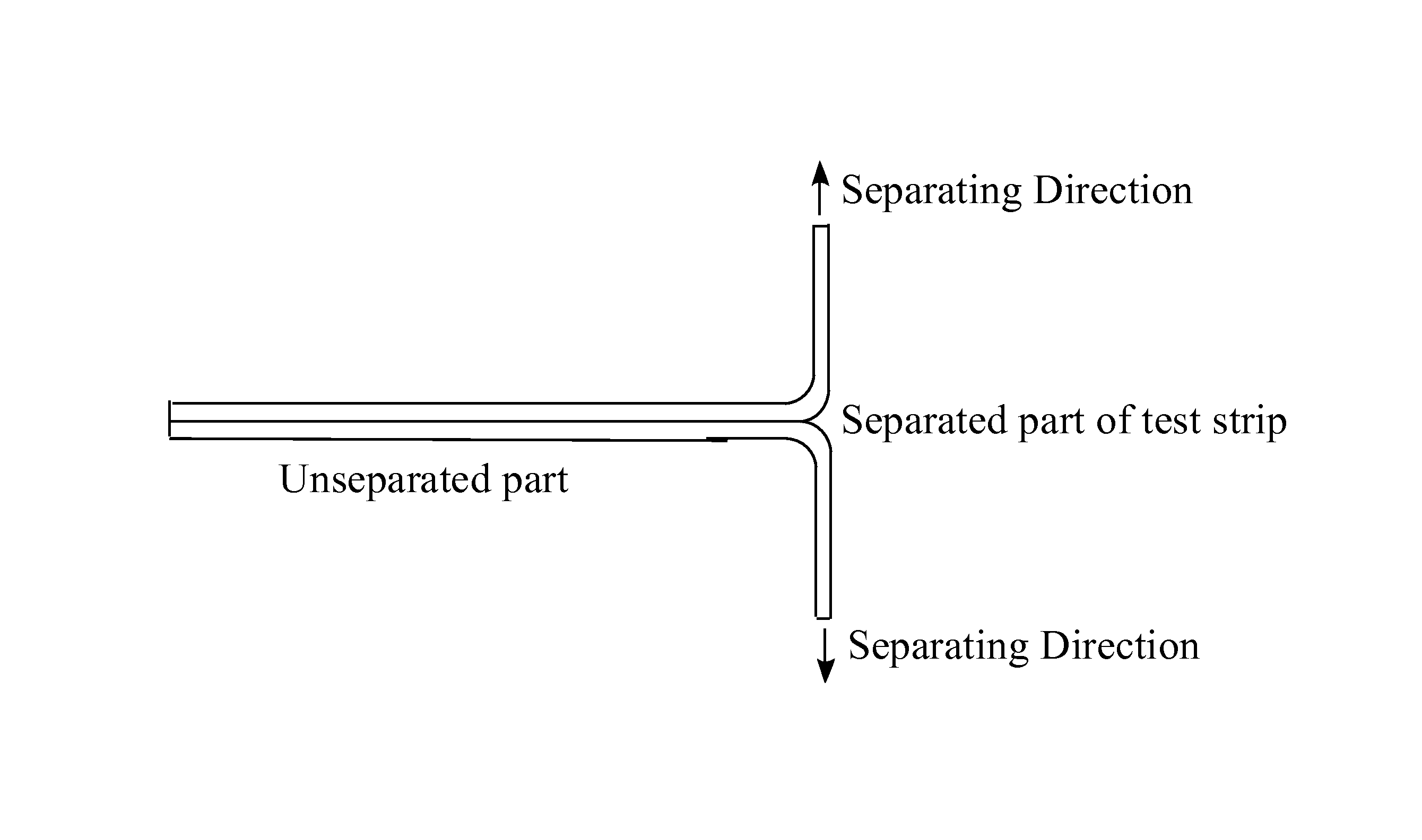

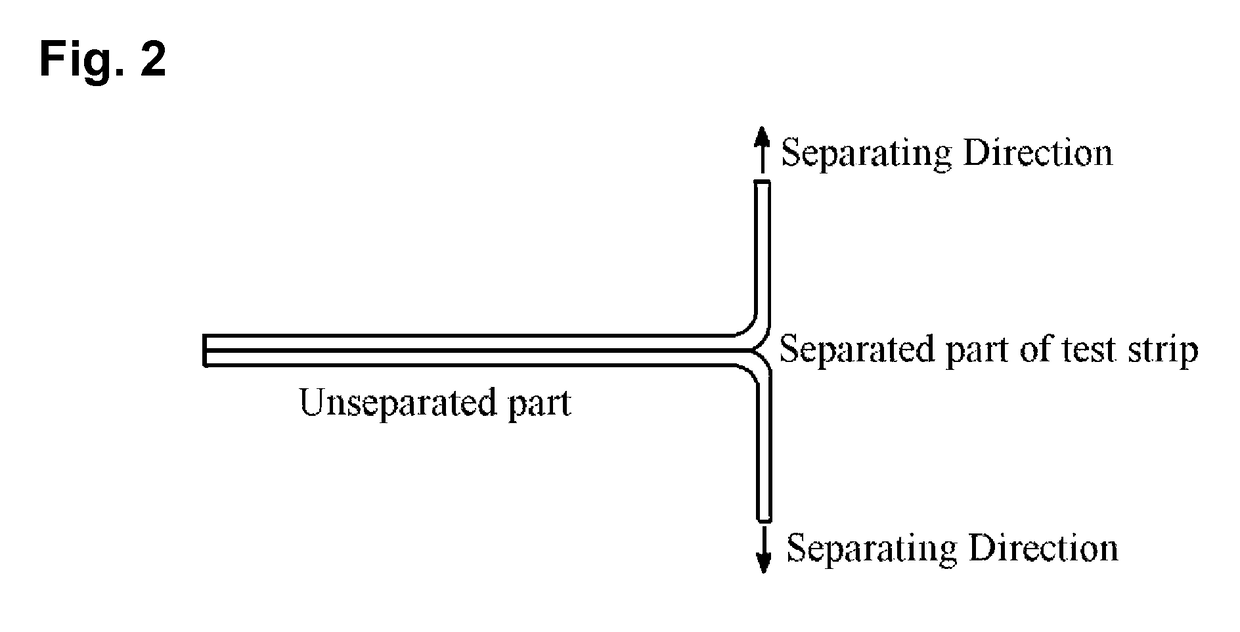

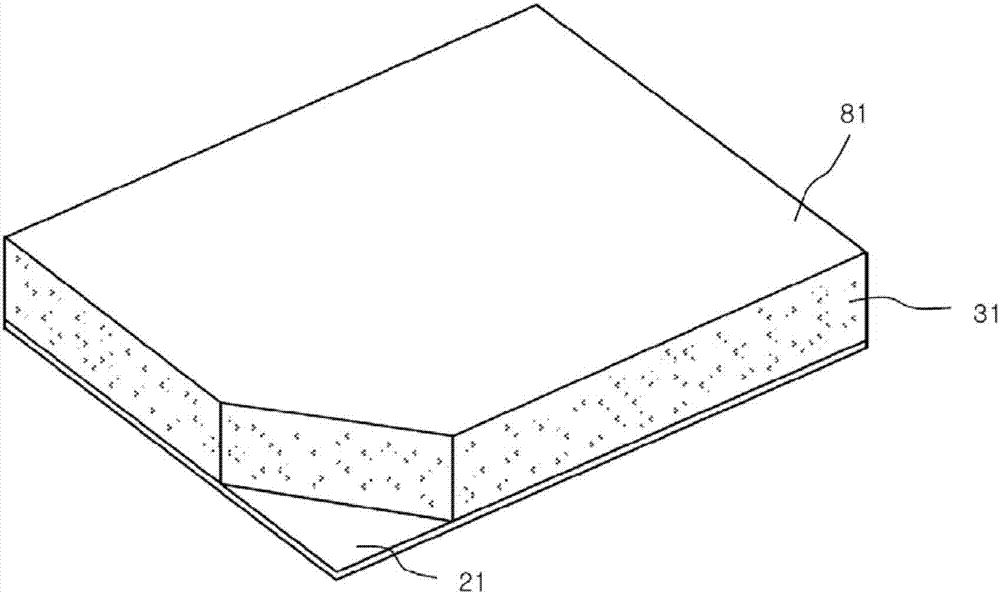

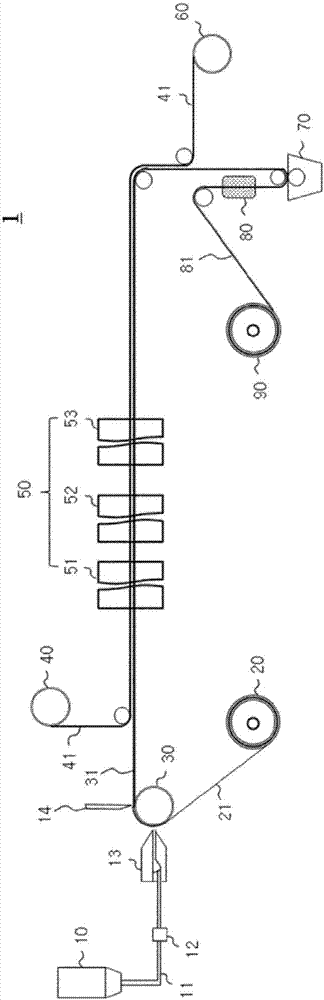

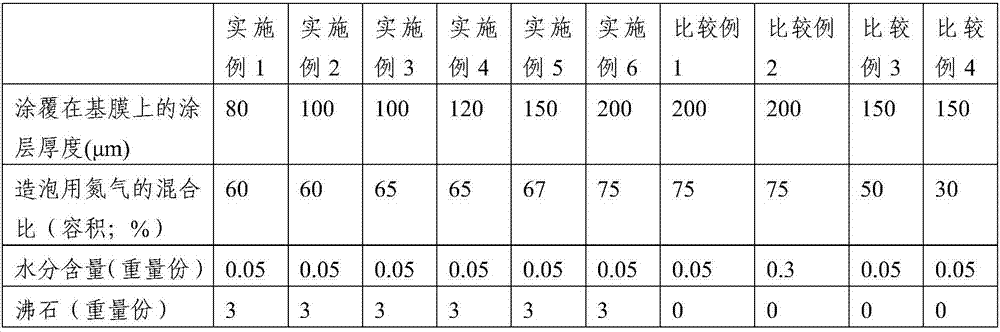

Thin film polyurethane foam laminate and method for manufacturing same

InactiveCN107206765ALess agglutination between poresSynthetic resin layered productsLaminationMicrosphereMoisture

The present invention relates to a thin film polyurethane foam laminate and a method for manufacturing the same, the method comprising the steps of: (a) generating a foam composition of a gas-liquid mixture by feeding, as raw materials for a foam composition without using water, which is a chemical foaming agent, polyol, isocyanate, a moisture absorbent, micro hollow spheres, and an additive into a mixer, followed by mechanical foaming through a foaming gas; (b) supplying the mechanically foamed gas-liquid mixture from the mixer to a discharger connected to a connection tube; (c) coating the gas-liquid mixture, which is discharged from the discharger, on a first base film to a predetermined thickness; (d) attaching a second base film on a surface of the gas-liquid mixture coated on the first base film, and hardening the resultant structure with the attached second base film in a thermal hardener, thereby generating a polyurethane foam layer; (e) releasing the second base film after the completing of the thermal hardening step, coating a coating agent on a surface of the hardened polyurethane foam layer, and then laminating a coating film using a UV hardener; and (f) collecting the polyurethane foam laminate with the laminated coating film, using a collection roll. A low-density polyurethane foam laminate having a very thin thickness, which is required by a sealing member and a buffer applied to an electronic device, can be molded by: adding, in the foaming composition, zeolite as a moisture absorbent for absorbing residual moisture and micro hollow spheres causing less aggregation between cells; performing mechanical foaming using nitrogen as a foaming gas; and then performing thermal hardening. Therefore, the low density molding is suitable for a sealing material and cushioning material of an electronic device, where a polyurethane foam laminate with super thin thickness is required.

Owner:SJ FOAMWORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com