Patents

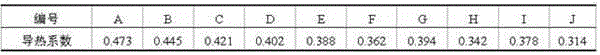

Literature

175results about How to "Good heat and sound insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for continuously producing environment-protection light gypsum wall material by using industrial residue

InactiveCN101134345AGuaranteed smoothRealize mechanized continuous productionSolid waste managementMixing operation control apparatusSlagSlurry

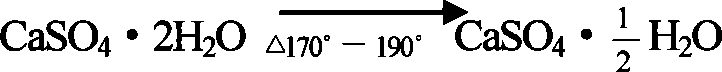

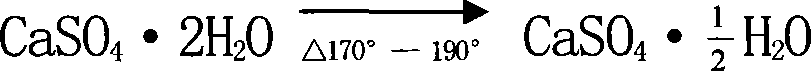

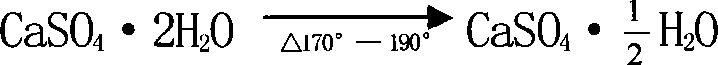

The present invention discloses process of producing light wall material with industrial solid waste, carbon residue, fly ash, natural gypsum, lime, cement and small amount of chemical material in a continuous production line. The production process includes the following steps: washing ardealite, adding lime for neutralizing, mixing ardealite in 70 wt% and natural gypsum in 30 wt%, dewatering, air drying, calcining, grinding, ageing and other step to prepare beta type semi-hydrated gypsum powder; mixing semi-hydrated gypsum powder, phosphate slag or carbon residue, fly ash, cement and small amount of chemical material in certain weight proportion; adding water to form slurry and forming light wall block.

Owner:洪光

Waste rubber powder mixed model steel fiber reinforced lightweight aggregate concrete and preparation method thereof

InactiveCN104926239APromote resource utilizationImprove performanceSolid waste managementFiberWaste rubber

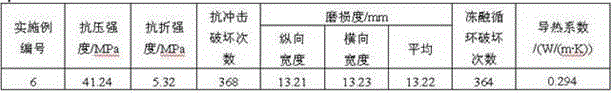

The invention relates to concrete and a preparation method, in particular to Waste rubber powder mixed model steel fiber reinforced lightweight aggregate concrete and preparation method thereof. The concrete per cubic meter is made of raw materials comprising, by weight, 14%-25% of cement, 0.1%-0.6% of model steel fibers, 0.03%-1.75% of rubber powder, 22%-45% of fine sand, 27%-50% of fly ash ceramsite, 6%-12.9% of net water content and 0%-0.03% of water reducing agents. The old rubber powder and the model steel fibers are mixed into the lightweight aggregate concrete, so that performance advantages of two kinds of materials can be given to full play, on the other hand, the old rubber powder is added in the model steel fiber reinforced lightweight aggregate concrete, vibration energy can be more effectively absorbed, impact performance and bend toughness of the lightweight aggregate concrete can be enhanced remarkably, and meanwhile, frost resistance, corrosion resistance and abrasion resistance of the model steel fiber reinforced lightweight aggregate concrete can be improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

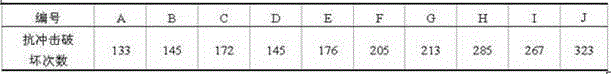

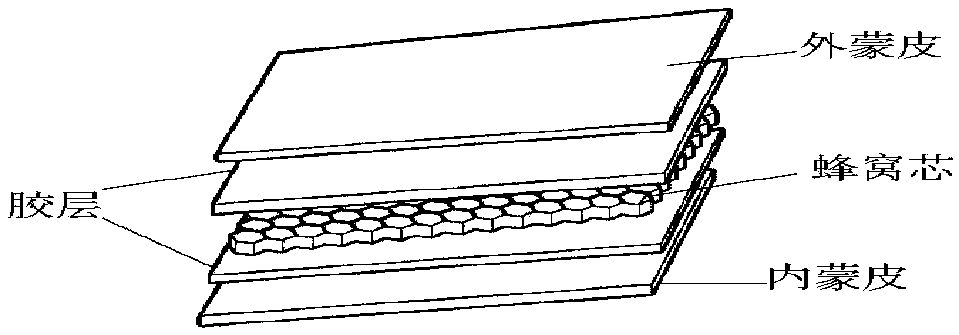

Reinforcement honeycomb panel filled with polyurethane combined material and preparation method thereof

InactiveCN101210446AImprove protectionHigh strengthLamination ancillary operationsLaminationPolyesterHoneycomb

A reinforced cellular plank filled with polyurethane composite and a method for fabricating such a plank belong to the technical field of cellular plank and aim to provide a high-strength, thermal-insulating, soundproof and reinforced cellular plank filled with polyurethane composite. The technical proposal includes two panels, a cellular core and the filling material of polyurethane composite; the cellular core is positioned between the two panels, filled with the filling material of polyurethane composite, and agglutinated with the panels by the polyurethane composite composed of polyurethane and polyester in the weight ratio of (1-3) : (1-3). The fabricating method includes preparing the polyurethane composite, applying the composite to the panels, combining the cellular core with the panels, compression and heating process. The invention can be applied to fabricate furniture and building materials and produces such beneficial effects as high strength, good damp-proof, thermal-insulating and soundproof performance, light weight, saving lumber, environment-friendliness, as well as low manufacture and transportation costs.

Owner:周能

Cotton stalk artificial boards and its production method

ActiveCN101544010ASolve hard to cut offSolve the crushing problemAldehyde/ketone condensation polymer adhesivesFlat articlesAdhesiveEngineering

The present invention relates to a cotton stalk artificial board and its production method. Its raw materials are the separated cotton stalk bast and cotton stalk core. After the cotton stalk bast is degummed, cotton stalk bast fiber will be generated. Cotton stalk particle boards and cotton stalk fiberboards are produced by using cotton stalk core and cotton stalk bast fiber as raw materials and using MDI or UF resin as adhesive. The beneficial effect of the present invention: in current production of cotton stalk boards, cotton stalk is pulverized and directly used as raw material, and agglomeration, fire and other defects may happen during production. In comparison, the present invention eliminates these defects and solves the problems of low product strength, and has high moisture regain and low fiber quality.

Owner:姜景文 +2

Halogen-free flame-retardant polyethylene foaming plastic and preparation method

InactiveCN102020801AImprove flame retardant performancePrevent volatilizationEnvironmental resistanceHigh pressure

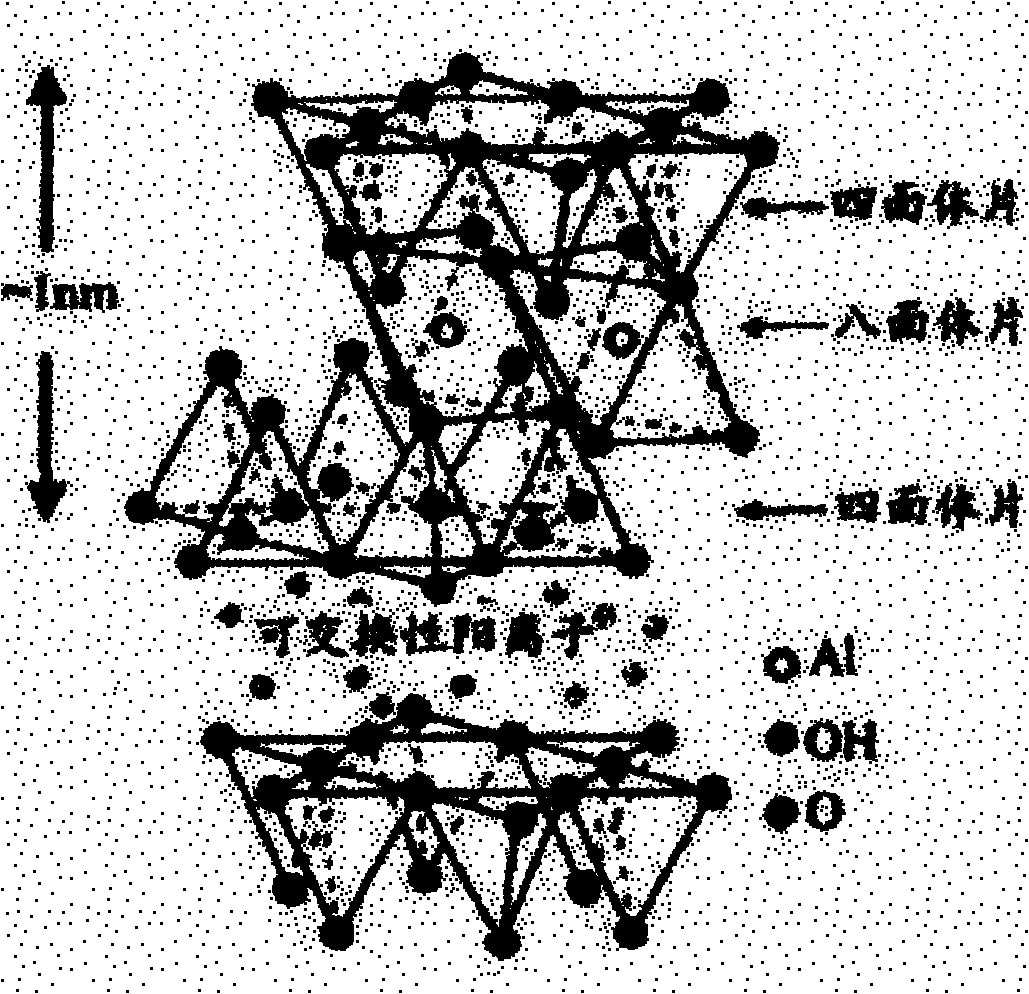

The invention discloses halogen-free flame-retardant polyethylene foaming plastic and a preparation method. The halogen-free flame-retardant polyethylene foaming plastic comprises the following components in parts by weight: 15-40 parts of dicumyl peroxide and high pressure polyethylene fusion in the mass ratio of 1:15-25, 20-60 parts of fusion of ADC (Azobisformami-de) foaming agent and high pressure polyethylene in the mass ratio of 1:1.5-3.5, 3-20 parts of fusion of BDPI type P-N halogen-free flame retardant and high pressure polyethylene fusion in the mass ratio of 1:3-5, 5-25 parts of fusion of nano organic montmorillonite, KH-570 type organosilicon coupling agent and high pressure polyethylene fusion in the mass ratio of 1:0.05-0.15:3-5; 0.5-5 parts of ethylene vinylacetate copolymer and 0.5-5 parts of polyethylene color master batch. The halogen-free flame-retardant polyethylene foaming plastic is halogen-free and flame-retardant, meets the firefighting and environmentally-friendly requirements and has the characteristics of high oxygen index, favorable strength, strong strength, strong absorbing impact loading capability and the like.

Owner:安吉鼎烽塑料有限公司

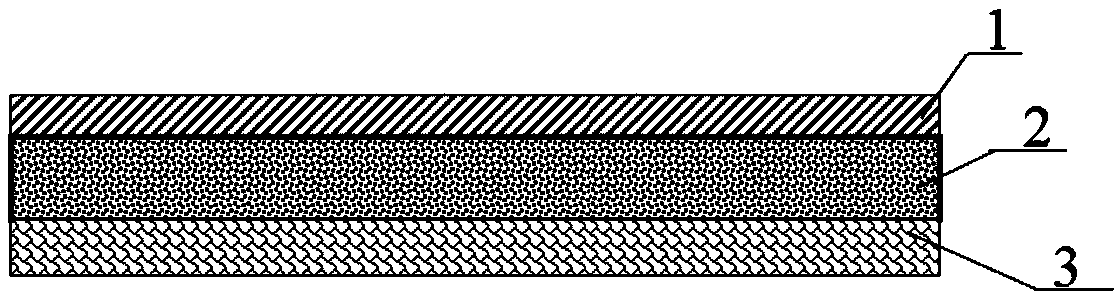

Light epoxy foam-based sandwich plate and preparation method thereof

InactiveCN108705829AGood noise reduction performanceGood adhesionSynthetic resin layered productsGlass/slag layered productsThermal insulationFire retardant

The invention relates to a light epoxy foam-based sandwich plate. The plate comprises an exterior panel, an epoxy foam core and an inner skin from outside to inside in sequence, and the epoxy foam core is formed by foaming an epoxy foam-based composite material which is prepared from a two-component system with a component A and a component B at the weight ratio being 100:(30-80), wherein the component A is prepared from 100 parts of epoxy resin, 5-20 parts of flame retardant, 1-10 parts of foaming agent and 0.5-1.5 parts of coupling agent, and the component B is prepared from 1-100 parts of curing agent, 1-10 parts of foaming agent, 0.5-5 parts of flame retardant and 1-10 parts of curing accelerator. Accordingly, the plate is prepared through a secondary on-site foaming process method, byconducting foaming after placing is conducted for 4-24 h at room temperature, reacting is conducted for 1-3 h at 110-140 DEG C, and secondary foaming and curing molding are conducted. Accordingly, integrated completion of filling, encapsulation and bonding can be achieved, the epoxy foam-based sandwich plate is easy to mold and is not limited by the sandwich plate shape and type, the thermal insulation, sound insulation and flame retardant properties are achieved while weight lightening is achieved, no toxic gas is generated in the case of fire, the good environmental-friendly performance isachieved, and the plate can be used for densely populated places.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

Aerated concrete block and preparation method thereof

InactiveCN107216102AHigh compressive strengthGood heat and sound insulationCeramic shaping apparatusCeramicwareBenzoic acidSlag

The invention discloses an aerated concrete block and a preparation method thereof, and relates to the technical field of building materials. The aerated concrete block is prepared from the following raw materials: modified pulverized fuel ash, slag Portland cement, kaolin, polypropylene fibers, baryta feldspar powder, aerated aluminum powder, heulandite powder, tetrachloroisophthalonitrile emulsion, benzoic acid, ethyl paraben, dimethyl sulfoxide, an early strength agent, a water reducing agent, a water addition agent, a foaming agent and a foam stabilizer. The preparation method comprises the steps of firstly, evenly stirring and mixing the raw materials to prepare slurry, then carrying out pouring, initial curing treatment, cutting and autoclaved curing on the slurry to obtain the aerated concrete block. The aerated concrete block is high in compression strength, good in heat resistance and sound insulation, small in drying shrinkage value, excellent in water resistance, simple to prepare, wide in raw material sources, and low in cost, thus being suitable for being popularized and used.

Owner:肥西县碧涛建材有限公司

Method for producing laminated shell fabric of full window blind

InactiveCN110802898AImproves UV resistanceGood anti-aging performanceLamination ancillary operationsDomestic upholsteryBlow moldingPolymer science

The invention discloses a method for producing a laminated shell fabric of a full window blind. The laminated shell fabric of the full window blind comprises a first base fabric layer, a first adhesive layer, a TPU black shading film, a second adhesive layer and a second base fabric layer, wherein surfaces of both the first base fabric layer and the second base fabric layer have patterns formed through embossing. The laminated shell fabric of the full window blind is produced according to the following steps: base fabric treating, TPU black shading film preparing, first-step hot-pressing laminating and second-step hot-pressing laminating. According to the method for producing the laminated shell fabric of the full window blind, disclosed by the invention, the TPU black shading film is produced by using an extruding blow molding method, then, is subjected to hot-pressing laminating with the first base fabric layer subjected to degreasing and cleaning treatment and then is subjected to hot-pressing laminating with the second base fabric layer, and thus, the whole production process is environmentally friendly and pollution-free. Phenyl salicylate and titanium dioxide are employed inthe TPU black shading film, so that the laminated shell fabric has good ultraviolet resistance and aging resistance. Furthermore, the laminated shell fabric also has good heat and sound insulating effects.

Owner:HAINING SANLIAN TEXTILE CO LTD

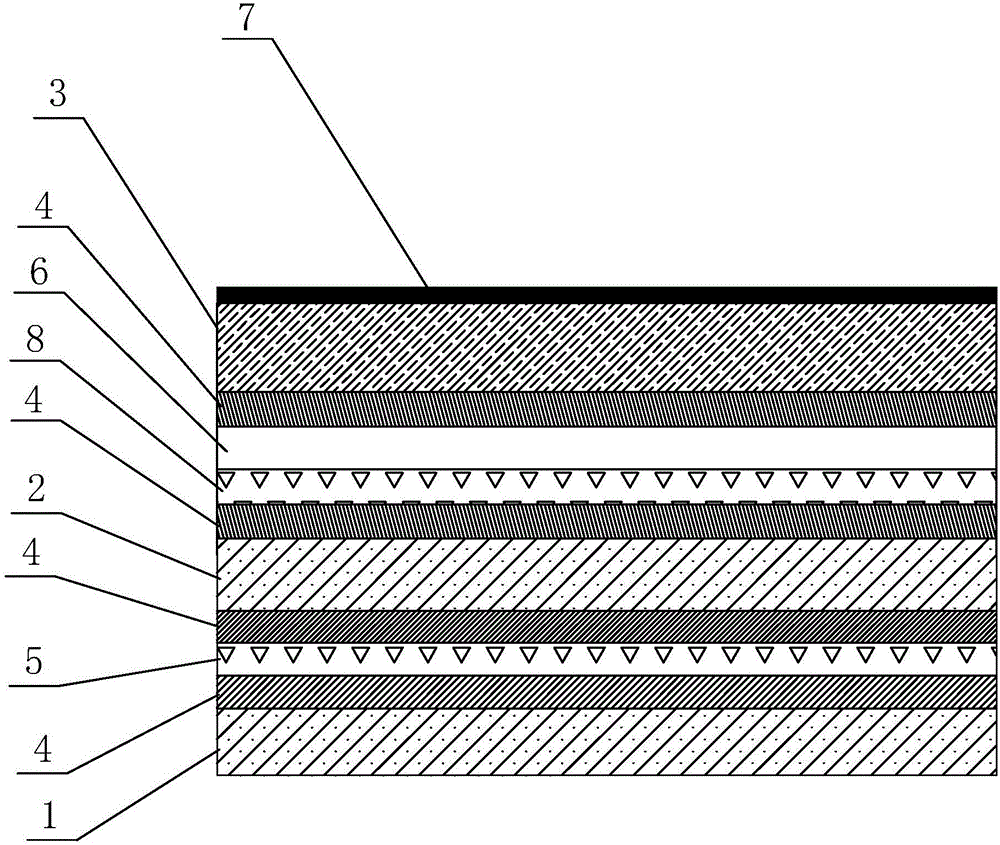

Multilayer composite board for construction and manufacturing method thereof

InactiveCN102691376AImprove performanceGood heat and sound insulationRoof covering using slabs/sheetsFloorsInsulation layerMaterials science

The invention relates to a multilayer composite board for construction, which is sequentially provided with a concrete layer for fiber reinforcement, a stress dispersion layer, a waterproof layer, a polyurethane foam temperature preservation layer, a waterproof layer, a stress dispersion layer, a concrete layer with fiber reinforcement, a heat insulation layer and a reflection layer from inside to outside, and each layer has specific materials and thickness. The multilayer composite board for construction provided by the invention has excellent performances, favorable heat insulation and sound insulation effects, light weight and good waterproof effect.

Owner:JIANGSU LONGHAI CONSTR ENG GRP CO LTD +1

Heat insulation composte material in use for new type architecture

InactiveCN1562863AGood heat and sound insulationImproves UV protectionSolid waste managementAlkali freeSulfate

The new type heat insulation compound material used for building is composed of magnesium oxide and magnesium chloride materials which are added modifier in, phosphoric acid, trisodium phosphate, oxalic, sulmiac, ferrous sulfate, lignin calcium sulphonic acid, strong glue, alkali-free glass fibre, water-proof powder rice chaff powder, talcum powder, Taibai powder and water etc. which are produced to a new type material used for building with action of heat-protecting, sound-insulating and water-proofing.

Owner:周谟国

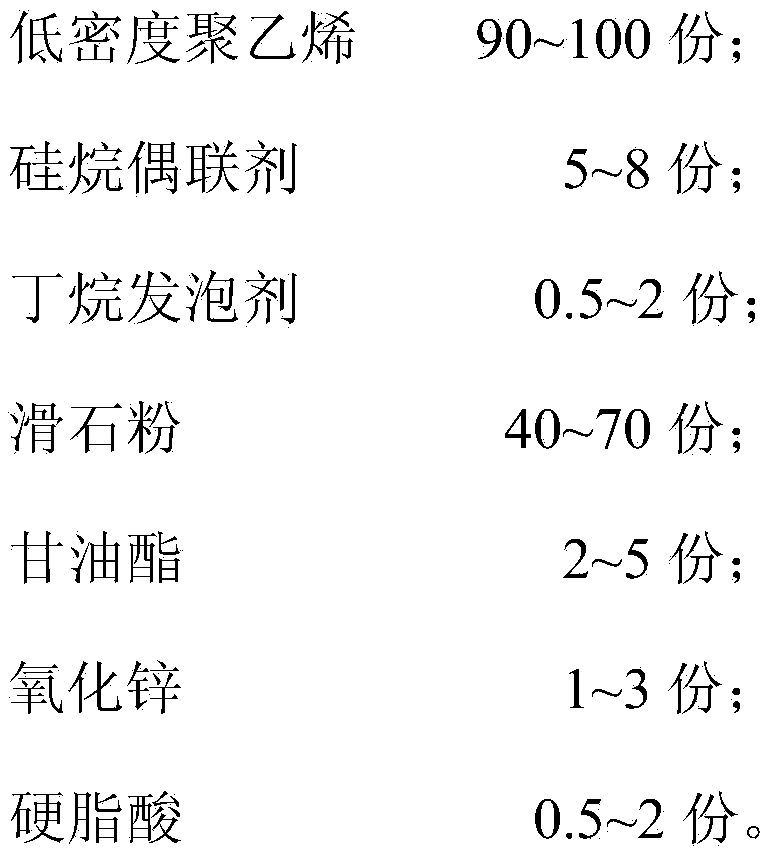

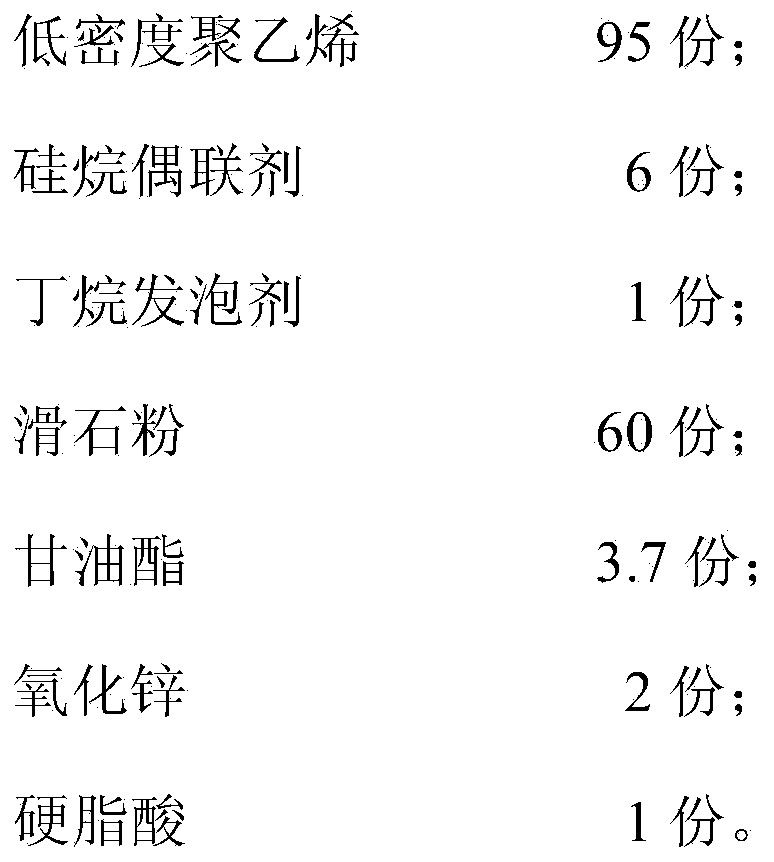

EPE material for crawling pad, preparation method of EPE material and crawling pad

InactiveCN104403173AFine and uniform cellsFlexibleSynthetic resin layered productsLow-density polyethyleneFoaming agent

The invention discloses an EPE material for a crawling pad, a preparation method of the EPE material and the crawling pad. The EPE material comprises the following components in parts by mass: 90-100 parts of low density polyethylene, 5-8 parts of a silane coupling agent, 0.5-2 parts of a butane foaming agent, 40-70 parts of talcum powder, 2-5 parts of glyceride, 1-3 parts of zinc oxide and 0.5-2 parts of stearic acid. The crawling pad prepared from the EPE material is favorable in water resistance, is flexible, light and elastic, can absorb and disperse external impact force through bending to achieve a buffer effect, overcomes the defects of deformation and poor rebound resilience, and meanwhile, has a thermal insulating effect and is easy to clean.

Owner:SUZHOU JIUDING

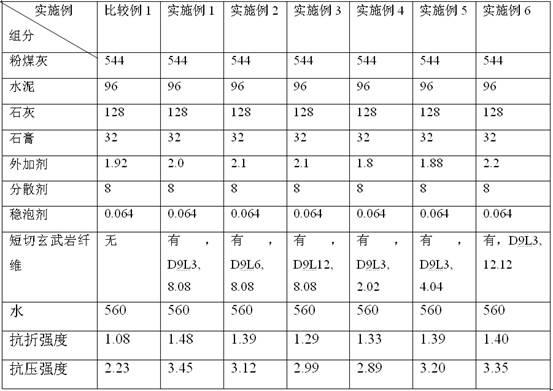

Process method for chopped fiber reinforced aerated concrete

InactiveCN102092999AHigh strengthDoes not affect heat retentionAutoclaved aerated concreteInorganic chemical compound

The invention discloses a process method for chopped fiber reinforced aerated concrete. A process for sequentially coating resin and inorganic compound particles on a fiber surface and adding coated chopped fibers and a dispersing agent into mixed slurry of autoclaved aerated concrete before the resin is cured is adopted, so that heat resistance and alkali resistance are improved, the bonding problem of the chopped fibers and a substrate and the dispersing problem of the chopped fibers are solved, and the reinforcing function of the chopped fibers can be brought into full play during high-temperature and high-pressure curing of the autoclaved aerated concrete. The aerated concrete reinforced by the method can keep the original light and heat preservation properties, and has the advantage of high intensity. By the reinforcing method, the formula of the original aerated concrete is not required to be changed; and the method is simple and practicable.

Owner:SOUTHEAST UNIV

Self-adhesive waterproofing membrane for metal roof and manufacturing method thereof

InactiveCN108084917ASuperior super aging resistanceGood chemical resistanceNon-macromolecular adhesive additivesRoof covering using flexible materialsThermal expansionSelf adhesive

The invention provides a self-adhesive waterproofing membrane for a metal roof. The self-adhesive waterproofing membrane for the metal roof comprises a base layer, a butyl rubber pressure-sensitive adhesive self-adhesive layer and a release film which are sequentially arranged, wherein the butyl rubber pressure-sensitive adhesive self-adhesive layer comprises the following components in parts by weight: 3 to 5 parts of PIB of which the molecular weight is 10,000 to 100,000, 2 to 4 parts of EPDM, 16 to 20 parts of butyl rubber, 18 to 23 parts of light calcium carbonate, 4 to 6 parts of white carbon black, 24 to 28 parts of PIB of which the molecular weight is 1000 to 3500, 18 to 22 parts of petroleum resin C5, 1 to 3 parts of polyethylene wax, 1 to 3 parts of white cement, 0.5 to 1 part ofan antioxidant, 1 to 2 parts of a coupling agent, and 1 to 2 parts of other additives. Butyl rubber pressure-sensitive adhesive of the invention is a permanent non-drying solid type stable material, has creep and self-healing properties, does not have the phenomenon of edge warping on seams, and can resist the thermal expansion and contraction of a color steel plate and displacement caused by theexternal vibration and the problems of steam leakage and water seepage because fasteners of metal roof nails and the like penetrate through a waterproof layer.

Owner:DANDONG SANGUAN WATERPROOF MATERIAL CO LTD

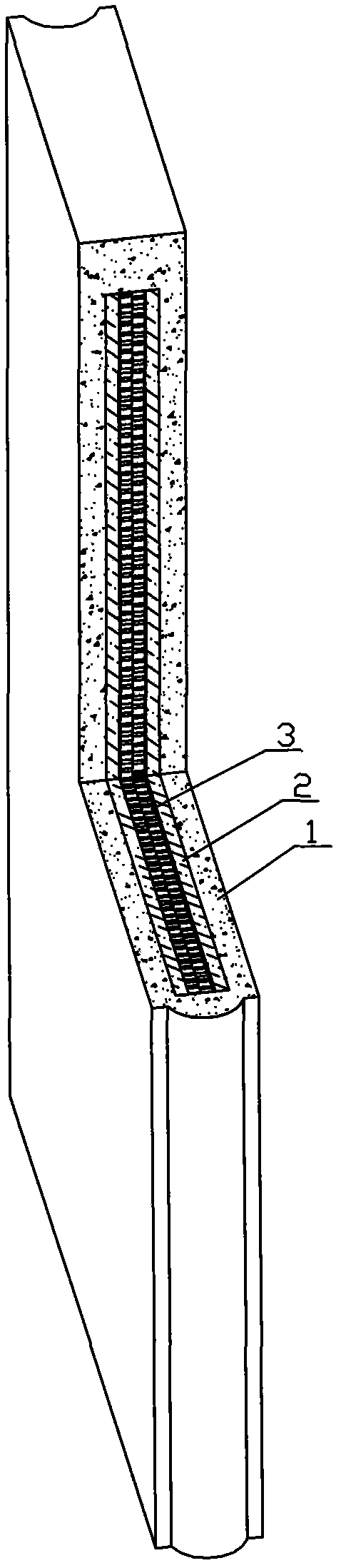

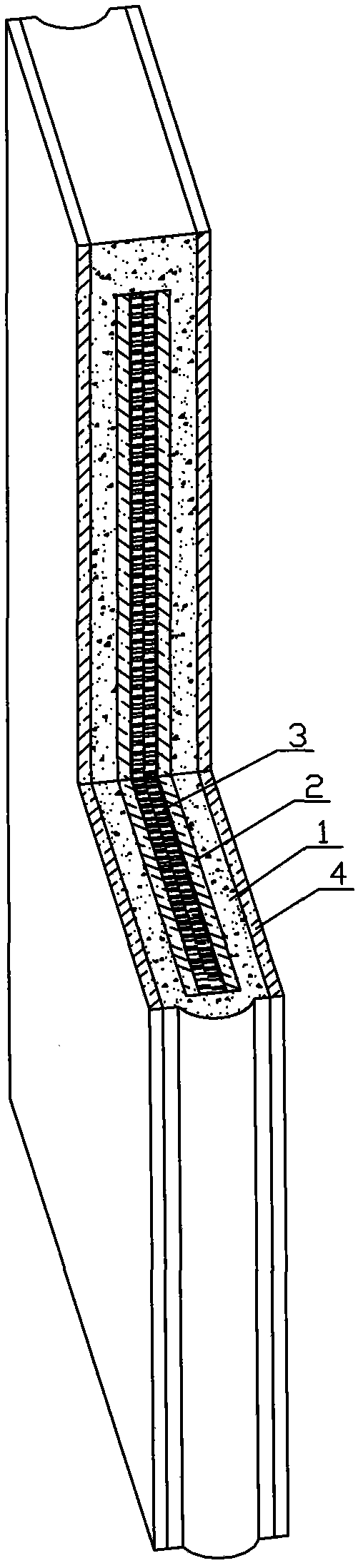

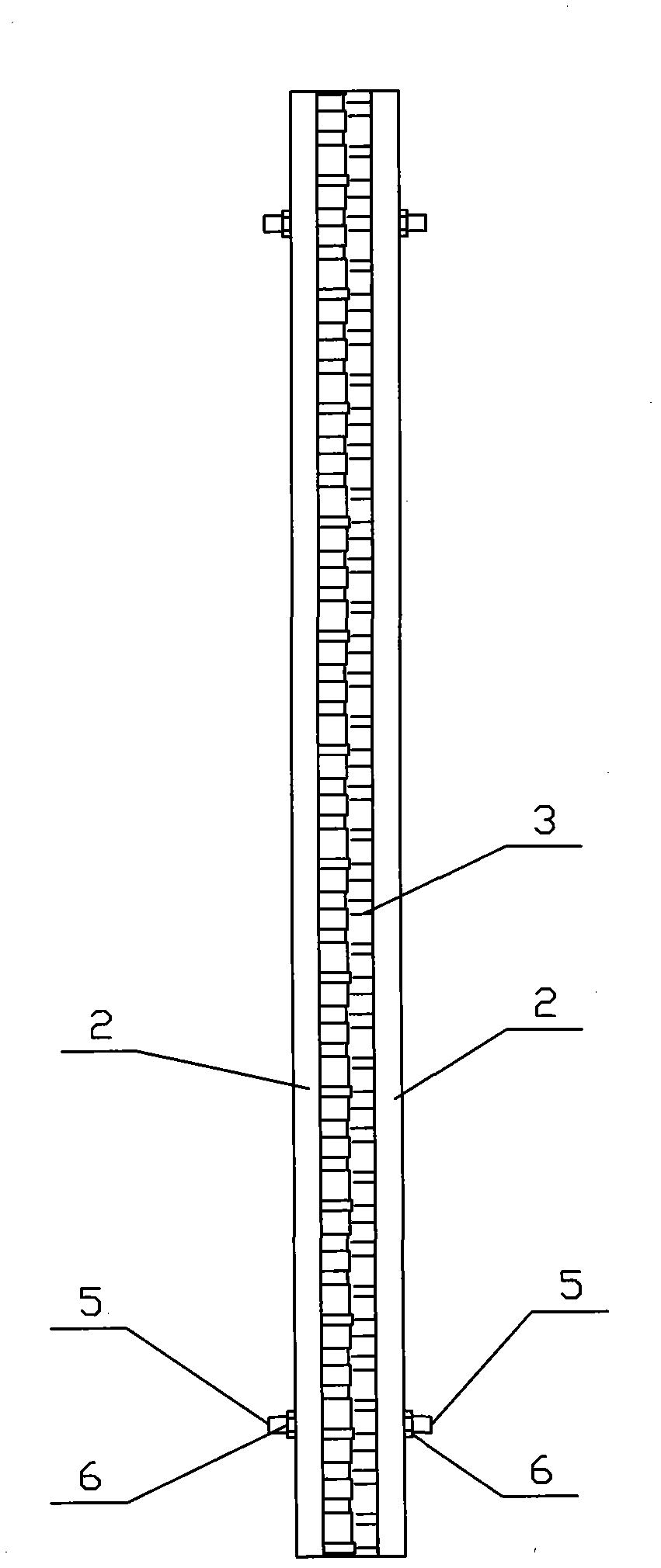

Heat-sound insulating lightweight concrete composite wallboard and manufacturing method thereof

ActiveCN102002985AOutstanding FeaturesHighlight significant progressClimate change adaptationCeramic shaping apparatusFiberThin slab

The invention relates to building material and provides a heat-sound insulating lightweight concrete composite wallboard and a manufacturing method thereof. The heat-sound insulating lightweight concrete composite wallboard comprises a light aggregate concrete layer and a heat-sound insulating layer arranged in the light aggregate concrete layer; and the heat-sound insulating layer is formed by filling the heat-sound insulating material layer between two fiber reinforced cement sheets. A manufacturing process of the composite wallboard comprises the following steps: A, fixedly connecting the two fiber reinforced cement sheets and the heat-sound insulating material layer filled between the two fiber reinforced cement sheets by a connecting piece to form the heat-sound insulating layer; B, putting the heat-sound insulating layer into a die cavity; C, pouring the light aggregate concrete into gaps of the die cavity; and D, demoulding to obtain the heat-sound insulating lightweight concrete composite wallboard. The invention has the following outstanding substantial characteristics and obvious progresses: the manufacturing process can realize the use of cotton-like heat-sound insulating material and ensures that the performance of the cotton-like heat-sound insulating material is not damaged during the processing so that the composite wallboard has higher heat-sound insulating performance and light weight.

Owner:广州益群板业有限公司

Foamed brick and processing method thereof

The invention relates to a foamed brick and a processing method thereof. The foamed brick is prepared from the following raw materials in parts by weight: 20-30 parts of fine stone sand, 10-20 parts of coal ash, 20-30 parts of 42.5-grade rapid hardening portland cement, 15-20 parts of quick lime, 10-15 parts of general coal ash ceramisite, 6-10 parts of sodium silicate, 1-3 parts of a concentrated high foam agent, 2-5 parts of calcium chloride, 5-8 parts of reinforcing glass fiber silks, 2-3 parts of an organic silicone water repellent, 0.2-0.3 part of vermiculite, 0.6-0.8 part of graphite and a proper amount of water. The processing method comprises the following steps: (1) mixing the materials and stirring to form mortar; (2) performing injection molding. The foamed brick is low in cost, very good in heat insulation property, sound insulation property and fire prevention property, and relatively high in strength.

Owner:贵州省恒威新型建材有限责任公司

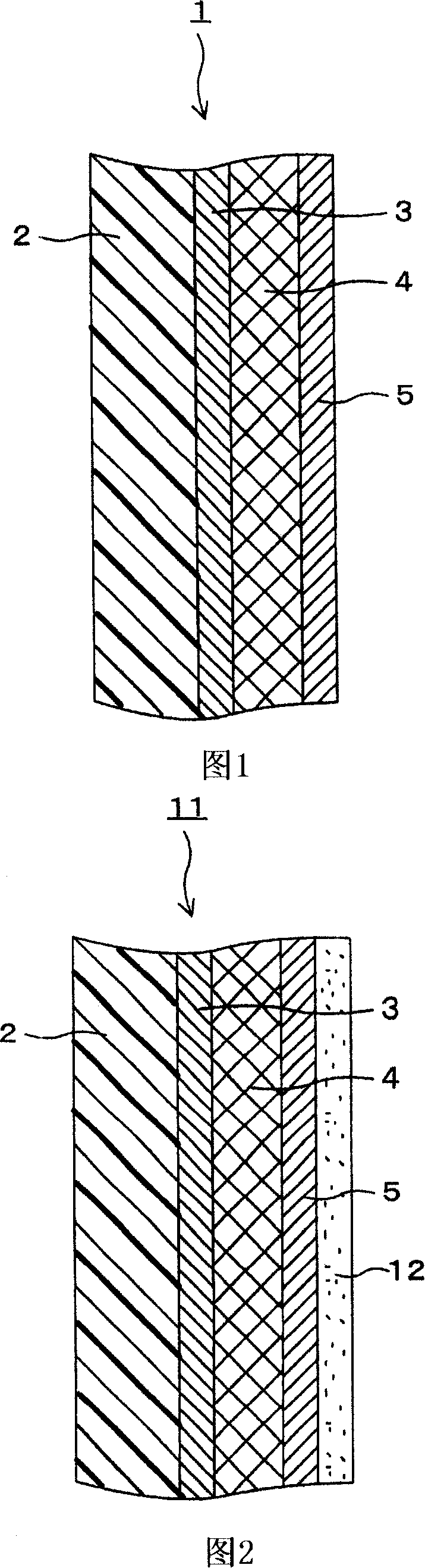

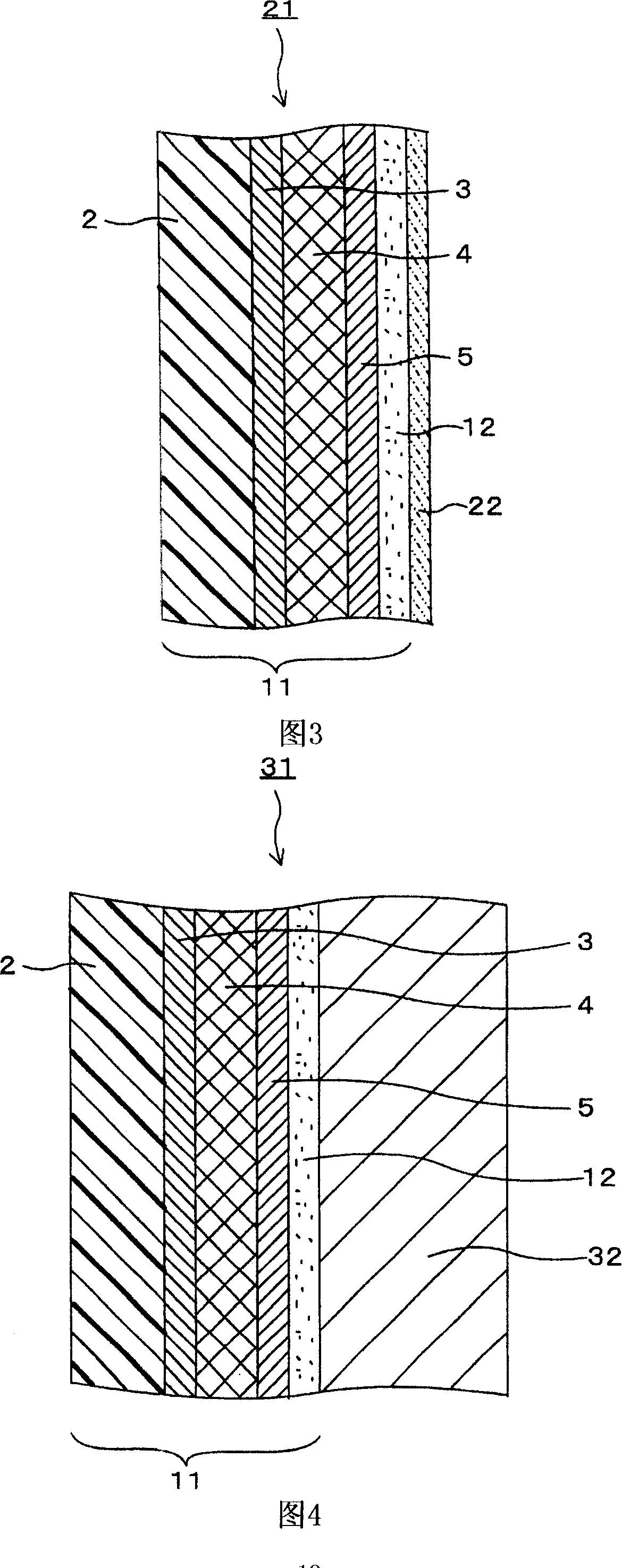

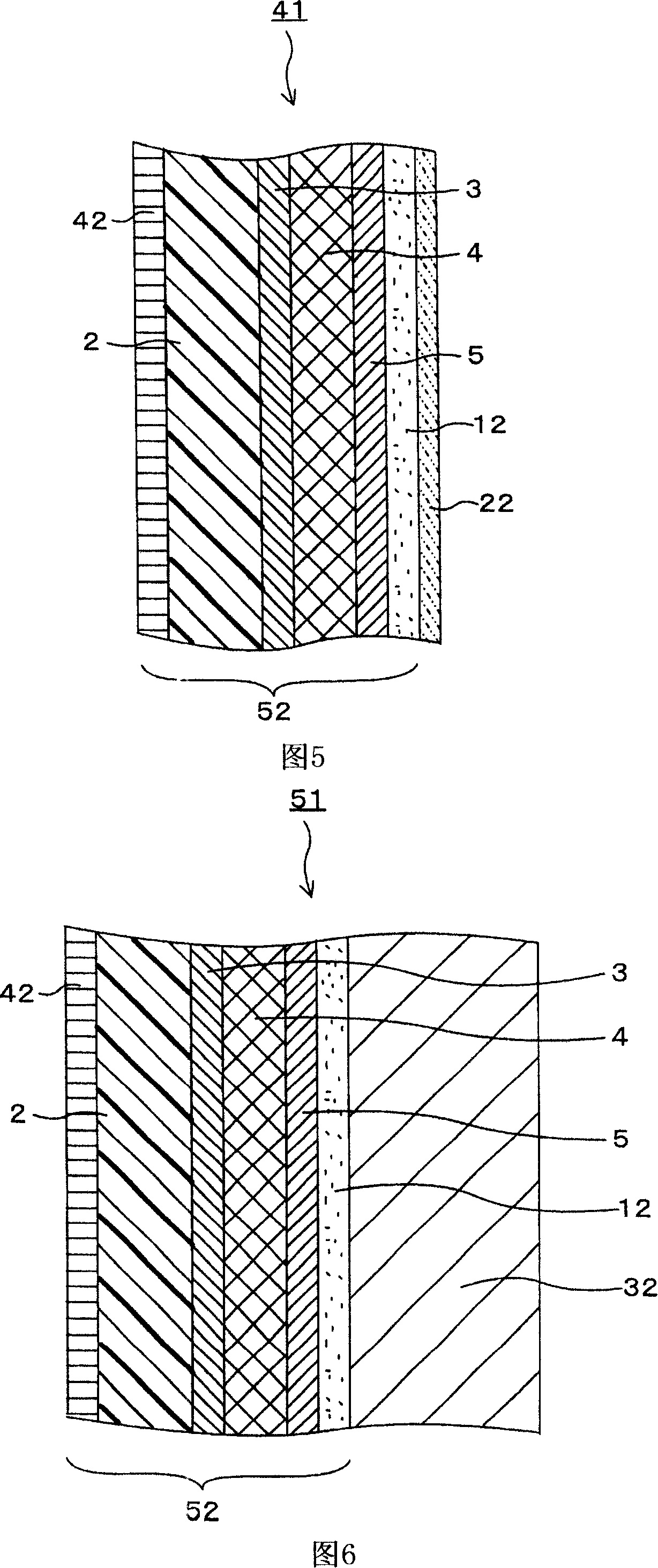

Decoration plate and its construction structure

InactiveCN101152821AImprove the decorative effectShorten working timeNatural patternsDecorative surface effectsManufacturing cost reductionEngineering

The present invention provides a decoration plate which can improve the decoration effect by adjusting the defined color tune and transparence, is approximate in appearance viewed from the decoration plate and a transparent plate, and can reduce the manufacturing cost. The decoration plate (1) is provided with a transparent plate (2); a first printing layer (3) which is printed with decoration print by keeping a predetermined transparence on the local or whole surface of the single side of the transparent plate (2); a dyed layer (4) which is on the surface of the first printing layer (3), can keep predetermined transparence and is colored to predetermined color; and a second printing layer (5) which is printed with decoration print by keeping predetermined transparence on the local or whole surface of the surface of the dyed layer (4).

Owner:森田真帆

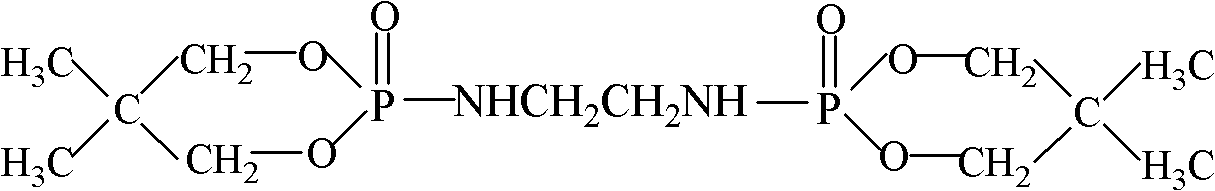

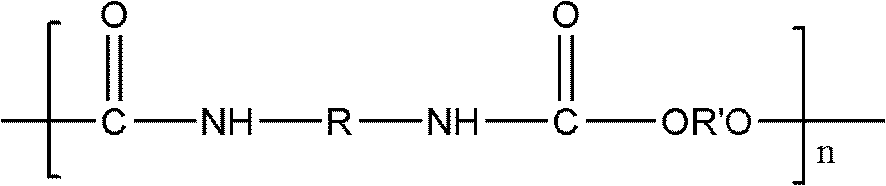

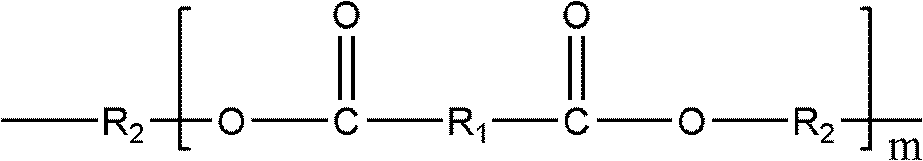

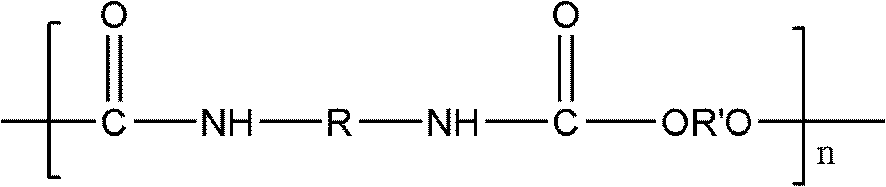

Polyurethane foaming plastic and its preparation method

ActiveCN102766326AGet rid of dependenceImprove protectionUltimate tensile strengthChemical resistance

The invention belongs to the technical field of materials and discloses a polyurethane foaming plastic and its preparation method. The polyurethane foaming plastic has the constitutional repeating unit as defined in the specification, wherein R is selected as shown in the specification; R' has the constitutional repeating unit as shown in the specification; R1 and R2 are respective selected as shown in the specification; n=1-1000; m=1-100; o=2-11; and p=2-13. The invention also discloses the preparation method of the above polyurethane foaming plastic. The polyurethane foaming plastic disclosed in the invention has advantages of light weight, excellent heat insulation and sound insulation performance, good chemical resistance and temperature toleration and high mechanical strength, and is widely applied in furniture, train, automobile and heat insulation and sandwich supporting materials.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Lithium slag hollow brick and making method thereof

The invention discloses a lithium slag cored brick. The brick is made by using the following raw materials, by weight, 20-30 parts of fly ash, 20-25 parts of lithium slag, 10-15 parts of coal slag, 15-17 parts of lime, 2-4 parts of gypsum, 10-15 parts of light calcium powder, 10-15 parts of self made concrete, 4-6 parts of attapulgite, 2-3 parts of cement clinker, 8-10 parts of an aluminum phosphate solution with the concentration of 4-5%, 1-2 parts of alumina, 1-2 parts of nanometer carbon powder, 5-8 parts of a quartz fiber, 0.2-0.5 parts of glycerol and 18-20 parts of water. The hollow brick made in the invention has the advantages of light weight, high strength, clay saving, fuel saving, improvement of the heat and sound insulation performances of the brick, realization of recycling of the lithium slag, reduction of the pollution to environment, and changing of wastes into valuables.

Owner:WUHE DINGSHUN NEW BUILDING MATERIAL

Halogen-free flame retardant polyethylene cable material and preparation method thereof

InactiveCN103351507AIncrease stickinessHigh strengthPlastic/resin/waxes insulatorsInsulated cablesAluminateLow-density polyethylene

The invention relates to a halogen-free flame retardant polyethylene cable material and a preparation method thereof. The cable material is characterized by being made of the following raw materials by weight part: 34-36 of high density polyethylene, 12-14 of linear low density polyethylene, 3-4 of zirconium diboride, 2-3 of titanium diboride, 12-14 of an ethylene-methyl acrylate copolymer (EMA 1209AC), 45-48 of attapulgite, 24-26 of sepiolite, 1-2 of an ECHO.A thiadiazole derivative, 3-4 of zinc stearate, 1-2 of an accelerator DTDM, 1-2 of an anti-aging agent OD, 5-8 of stearic acid monoglyceride butyral, 2-3 of N-2-(aminoethyl)-3-aminopropyl trimethoxysilane, 2-3 of isopropyl distearoyloxy aluminate, 1-2 of an antioxidant DSTP, 1-2 of diphenylamine, 4-6 of didodecanol ester, 5-8 of butadiene, 12-14 of zinc borate, and 6-8 of modified diatomite. The ethylene-methyl acrylate copolymer involved in the invention has excellent adhesiveness, and the strength of the cable material is greatly improved. The cable material provided in the invention has the advantages of high temperature resistance, halogen-free and flame retardant properties, high oxygen index, good heat and sound insulation, and strong impact load absorption ability, etc.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

Cotton stalk artificial boards and its production method

ActiveCN101544010BImprove surface wettabilityImprove bonding performanceAldehyde/ketone condensation polymer adhesivesFlat articlesAdhesiveEngineering

The present invention relates to a cotton stalk artificial board and its production method. Its raw materials are the separated cotton stalk bast and cotton stalk core. After the cotton stalk bast is degummed, cotton stalk bast fiber will be generated. Cotton stalk particle boards and cotton stalk fiberboards are produced by using cotton stalk core and cotton stalk bast fiber as raw materials andusing MDI or UF resin as adhesive. The beneficial effect of the present invention: in current production of cotton stalk boards, cotton stalk is pulverized and directly used as raw material, and agglomeration, fire and other defects may happen during production. In comparison, the present invention eliminates these defects and solves the problems of low product strength, and has high moisture regain and low fiber quality.

Owner:姜景文 +2

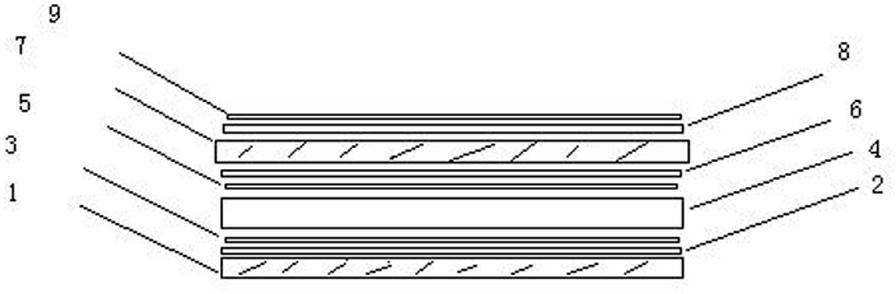

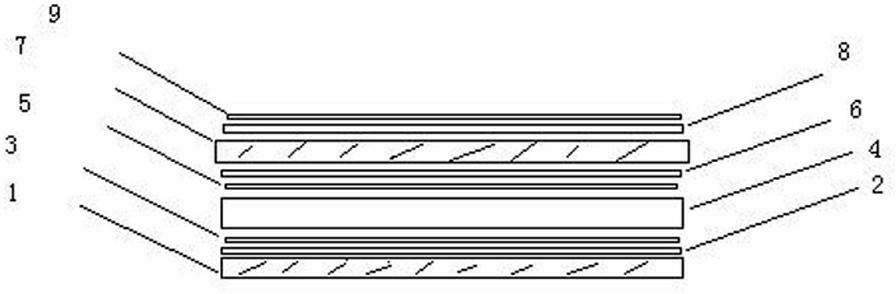

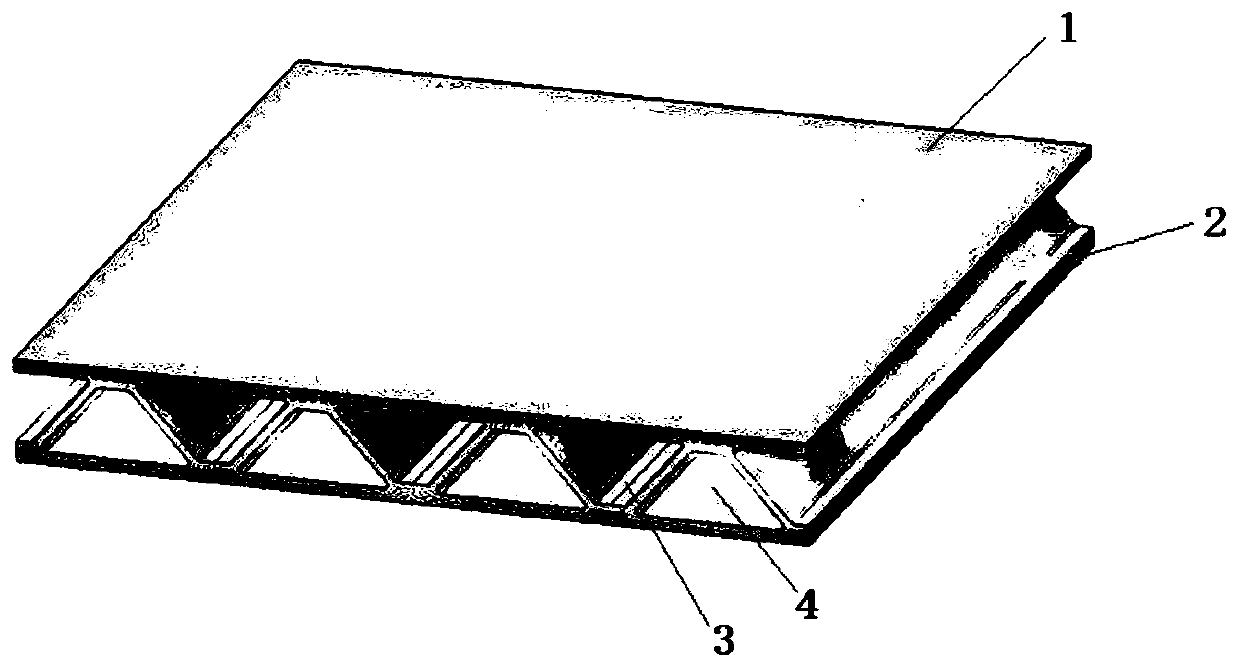

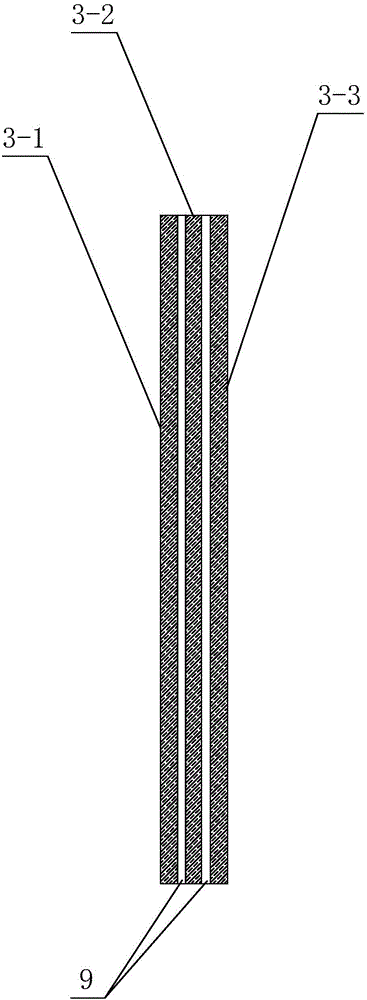

Suspended film hollow glass, manufacturing method, continuous production device and application

PendingCN111827845ASimple processEasy to manufactureSolar heating energyDomestic cooling apparatusAdhesiveHigh productivity

The invention belongs to the technical field of hollow glass, and discloses suspended film hollow glass, a manufacturing method, a continuous production device and application. Spacer frames are bonded to corresponding peripheral positions of front glass and rear glass, the edge of the upper end of a suspended film is fixed between every two adjacent spacer frames in a bonding or welding or clamping manner, the lower end of each suspended film is fixedly connected with a bottom rod with the length matched with the width of the suspended film, and the bottom rods are fixed to the lower ends ofthe spacer frames. Cavities are formed between the suspended films and the front and rear glass and between the suspended films respectively. Spaces formed by the front glass, the rear glass and the outer sides of the spacer frames are fully covered with a structural adhesive, and the double-cavity or multi-cavity suspended film hollow glass is formed after solidification of the structural adhesive. The suspended film hollow glass can be conveniently manufactured by a simple process at a low cost and high productivity and has good heat insulation and sound insulation effects, the packaging width of the glass edge is equivalent to that of existing hollow glass, and the inherent breathing phenomenon of the hollow glass can be effectively relieved.

Owner:WEIHAI RUNFENG GLASS

Building exterior wall heat-preservation material and preparation method thereof

InactiveCN105130371AGood insulation effectGood heat insulation and sound insulationBuilding materialPerlite

The invention discloses a building exterior wall heat-preservation material and a preparation method thereof, and belongs to the technical field of building materials. The building exterior wall heat-preservation material comprises the following raw materials in parts by weight: 35-45 parts of expanded perlite, 10-20 parts of water glass, 10-20 parts of fly ash, 1-3 parts of a foaming agent, 0.8-1.2 parts of polyvinyl alcohol, 10-30 parts of water, 1.2-2 parts of boron fiber and 2-6 parts of calcined kaolin. The building exterior wall heat-preservation material provided by the invention has the advantages of being good in heat preservation effect as well as thermal and sound insulation effects, low in water absorbability, resistant to low temperature as well as acid and alkali, and the like; the preparation method is simple and the building exterior wall heat-preservation material is suitable for scale production.

Owner:广西路佳道桥勘察设计有限公司

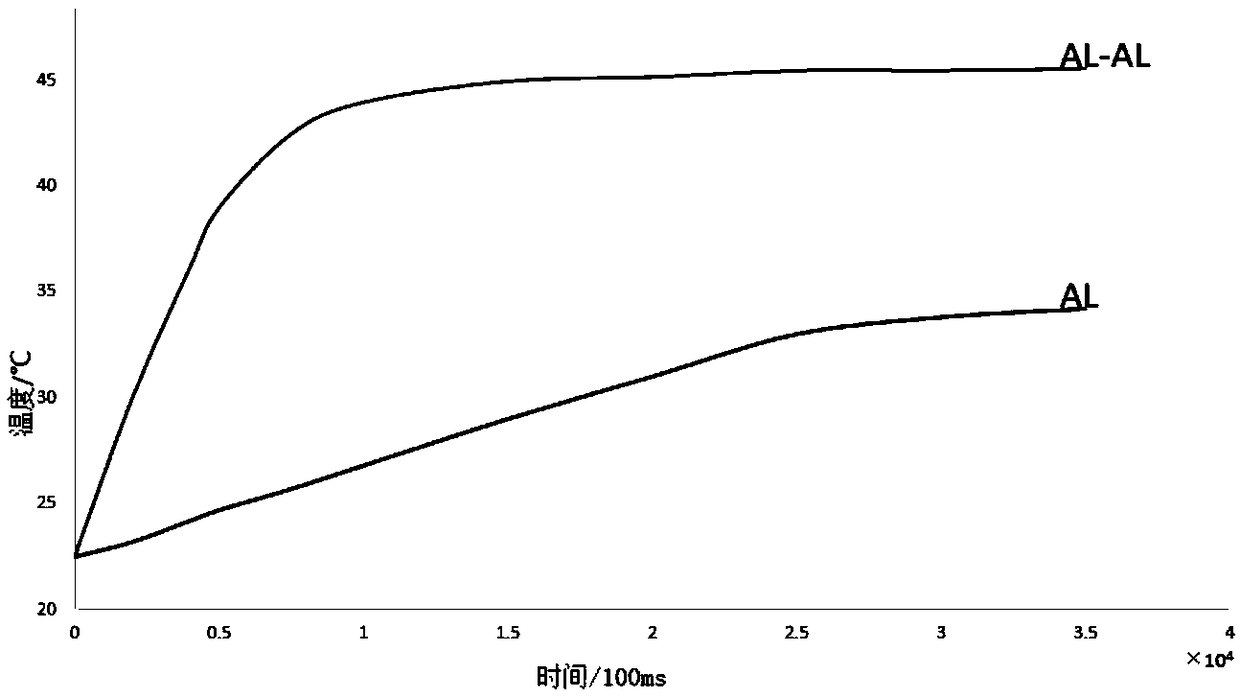

Preparation method of titanium-based composite material thermal protection skin structure

ActiveCN110527933AHigh temperature resistanceGood for weight lossTitanium matrix compositesThermal insulation

The invention provides a preparation method of a titanium-based composite material thermal protection skin structure. SiC fiber cloth, a titanium alloy foil and a titanium alloy plate are laid to prepare a prefabricated blank including alternately arranged siC fiber cloth and titanium alloy foils, a titanium alloy core plate and a titanium alloy lower plate coated with soldering flux that are arranged in sequence from top to bottom; the prefabricated blank is placed in a vacuum hot pressing furnace to be subjected to high-temperature and high-pressure treatment, argon is introduced, superplastic forming is conducted under the conditions that the forming temperature is 870-940 DEG C, the maximum atmospheric pressure is 3.6 MPa, and the time is 80-120 min, finally, the titanium alloy sandwich structure is filled with the thermal insulation material, and a finished product is obtained. The titanium-based composite material thermal protection skin structure prepared by the method is high in tolerable temperature, the sandwich structure is beneficial to weight reduction of the skin structure and subsequent filling of a thermal insulation material, and aerogel filling is beneficial to improvement of the thermal insulation effect of the skin structure.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

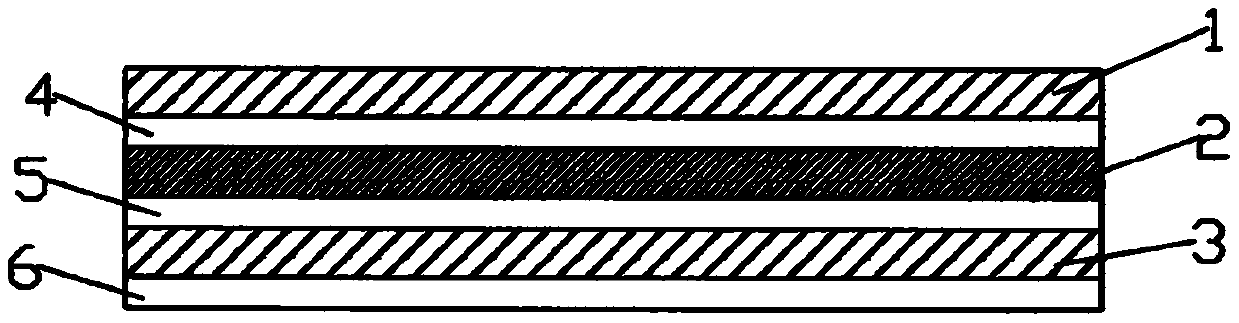

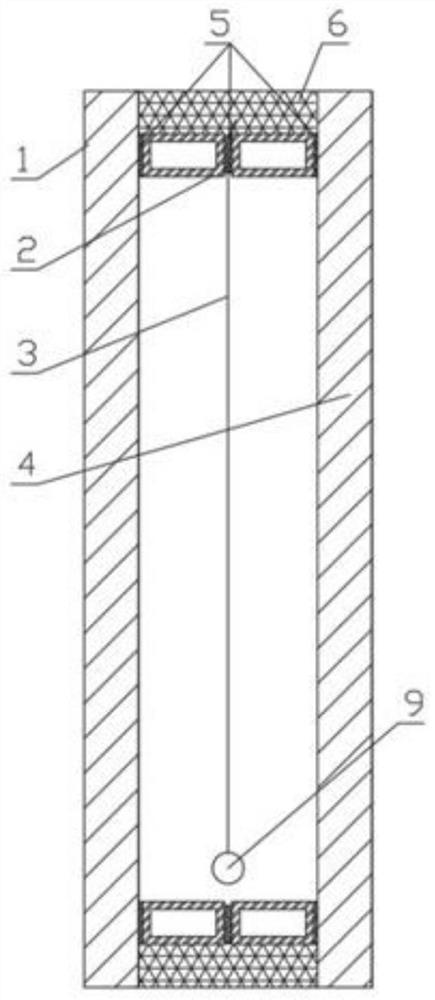

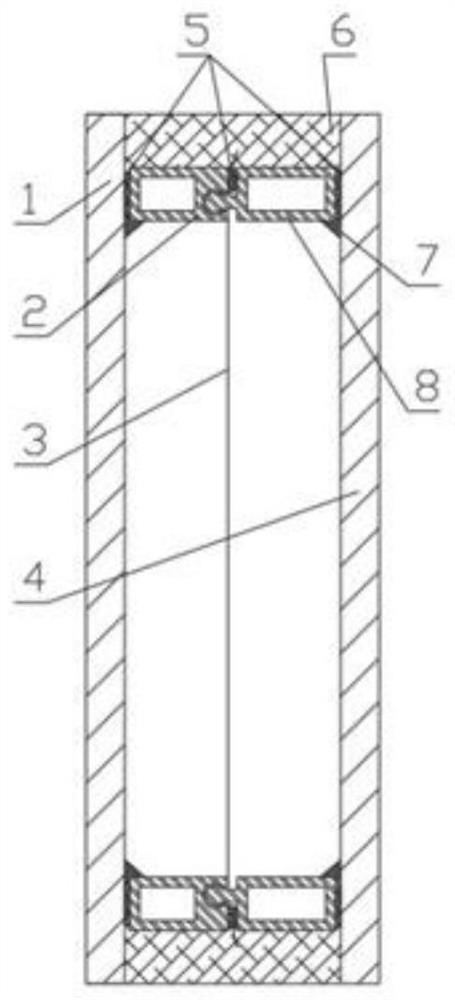

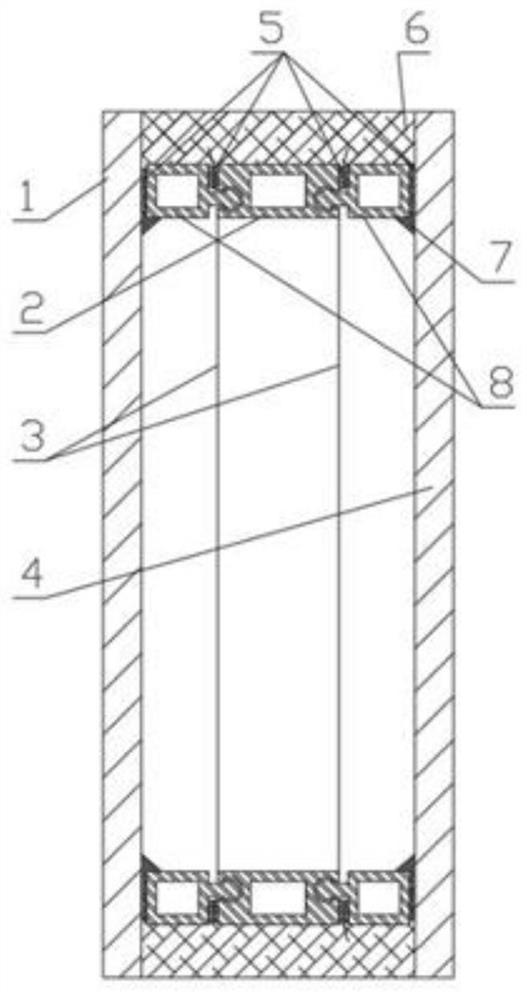

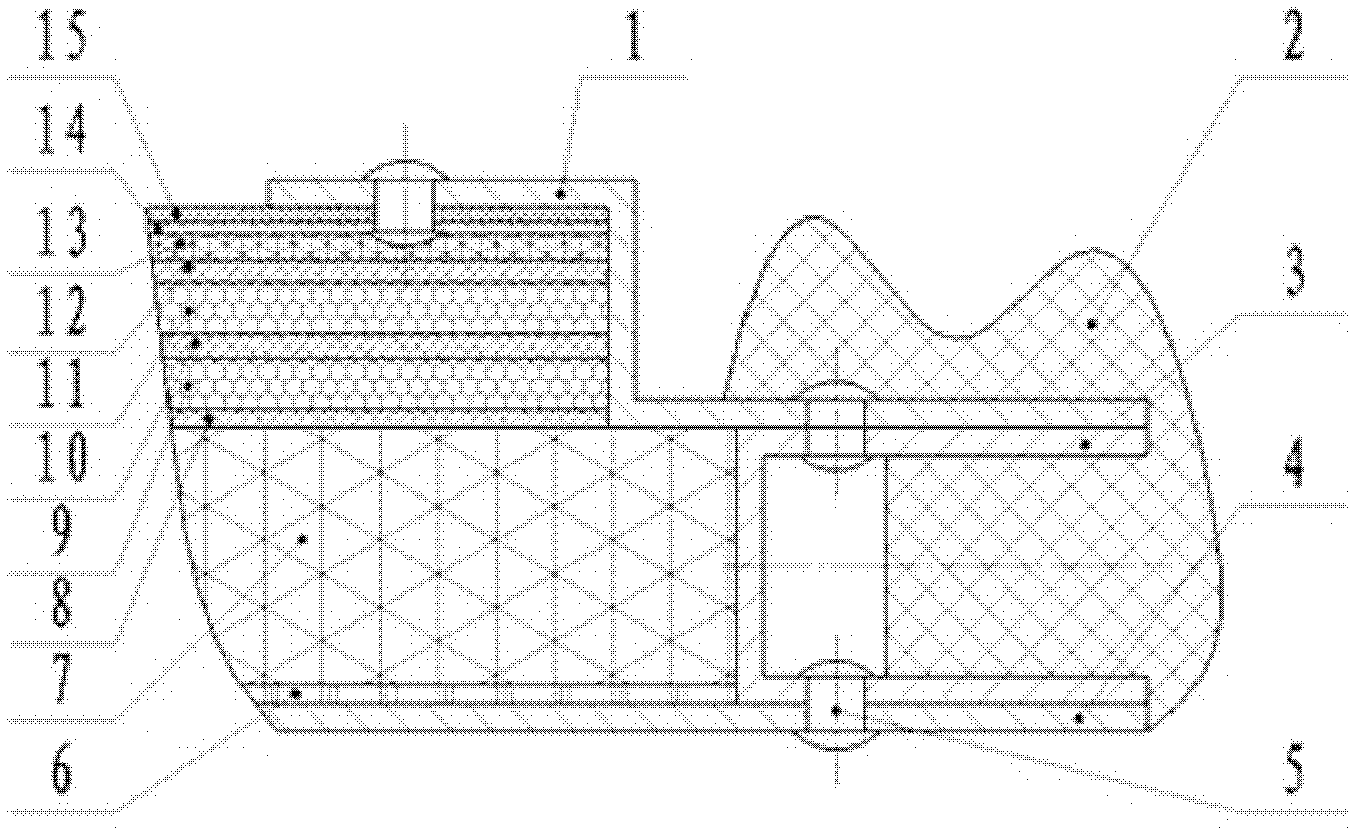

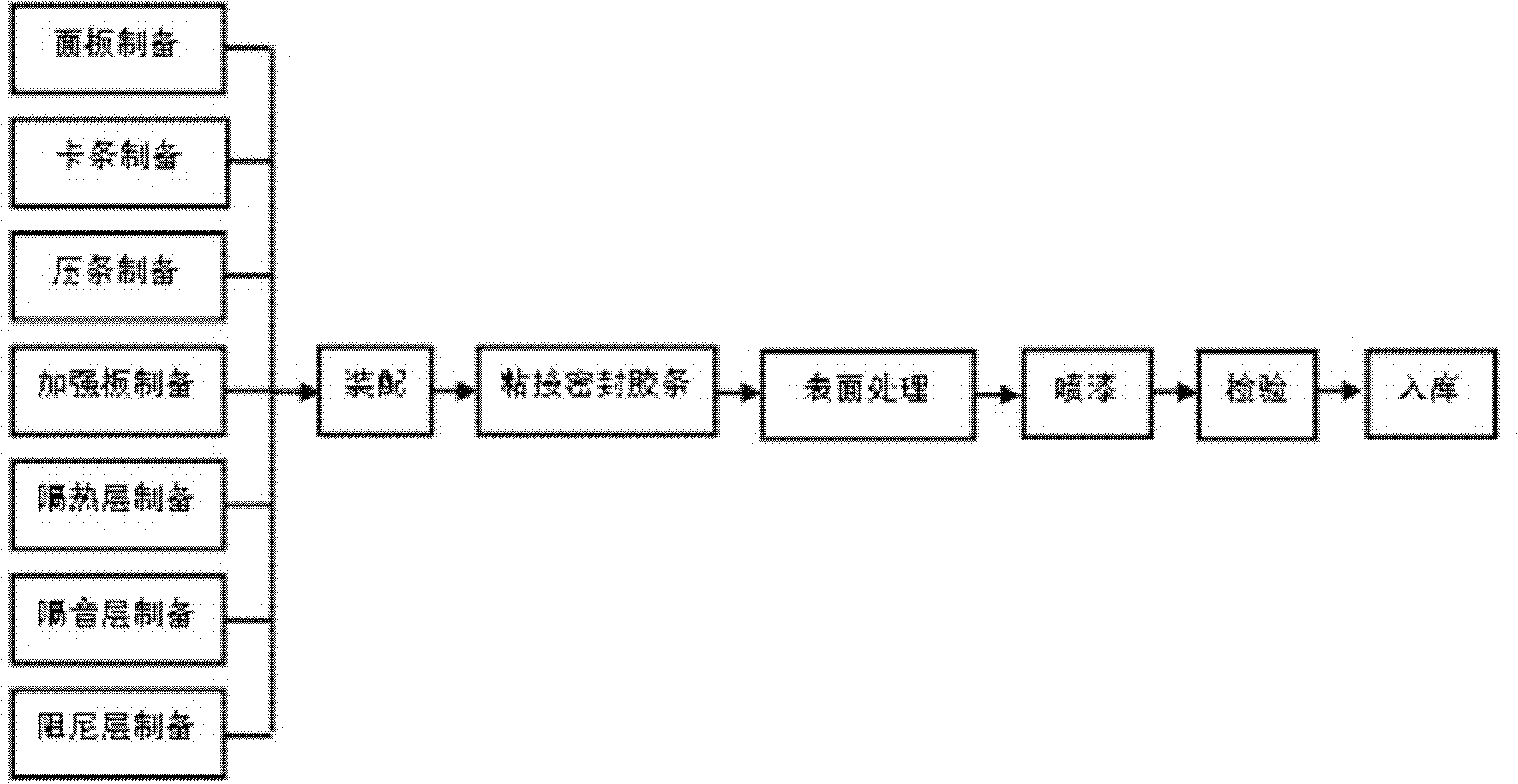

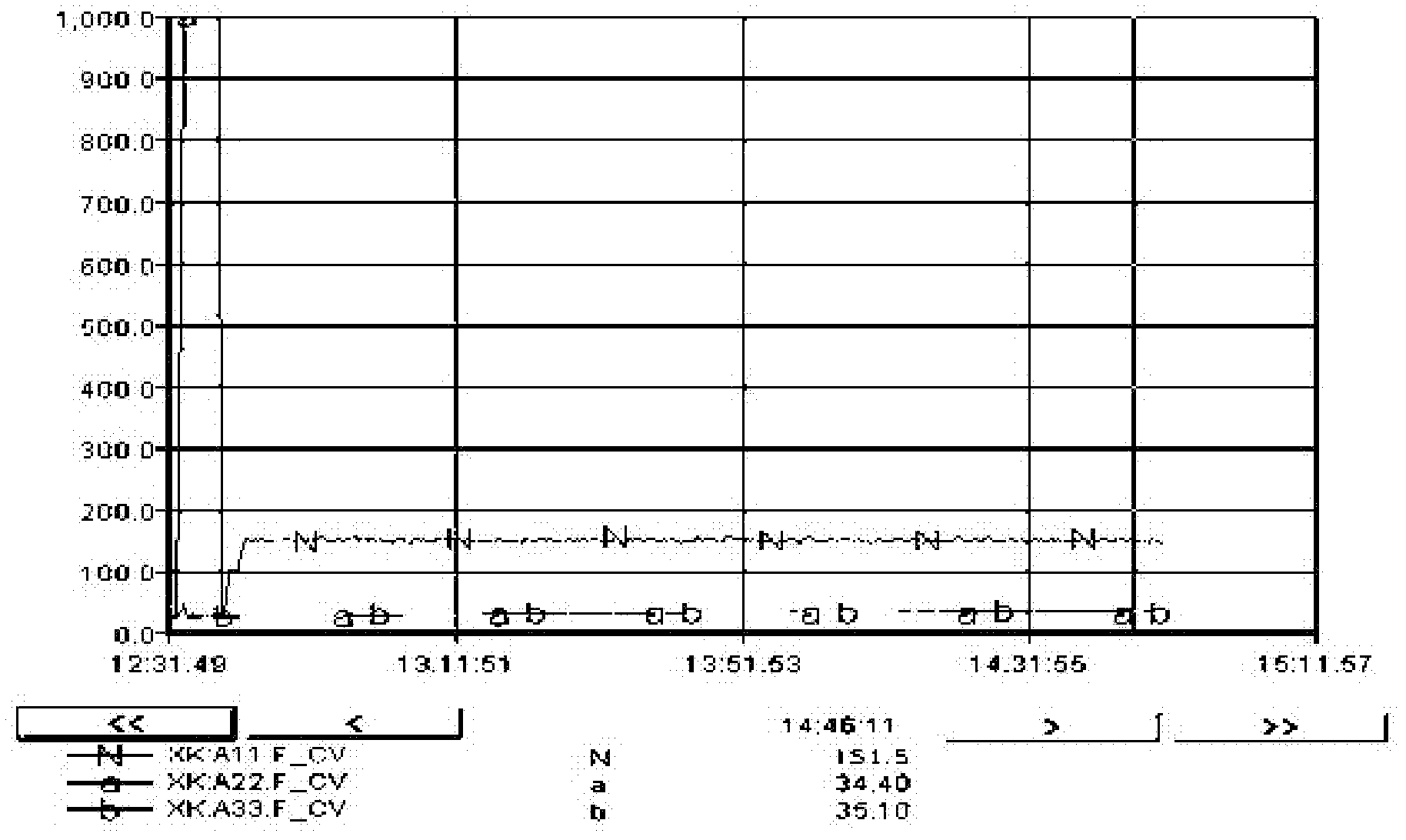

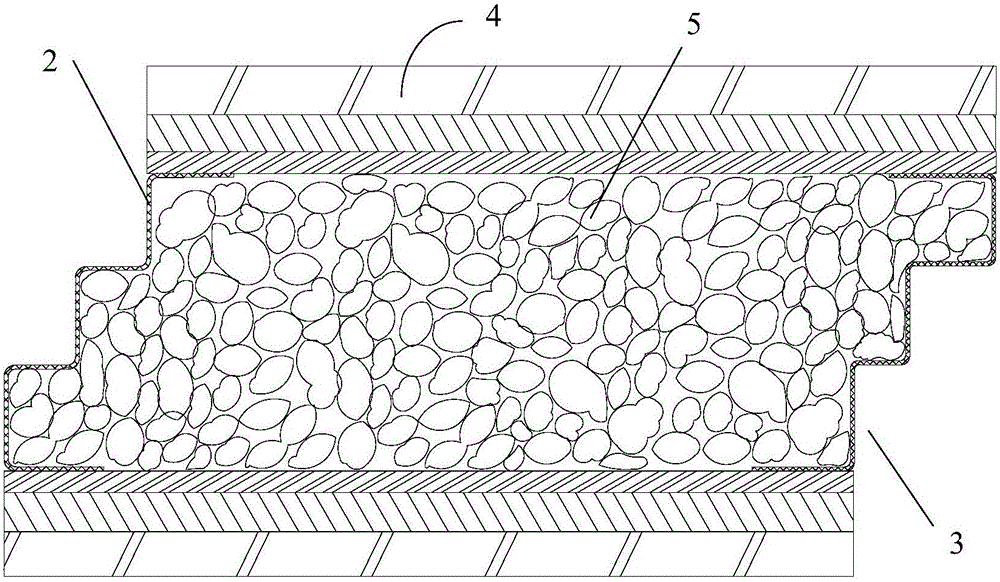

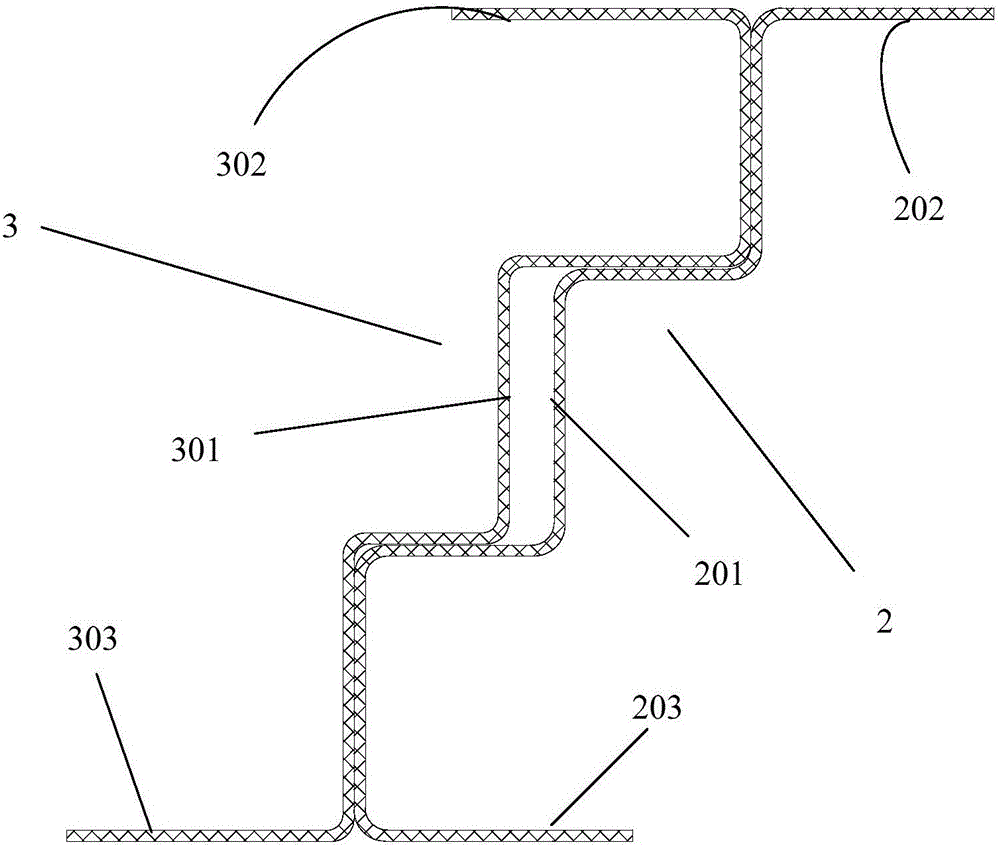

Restrained damping heat and sound insulation device and preparation method thereof

ActiveCN102865778AGuaranteed thermal and acoustic insulationFirmly connectedArmoured vehiclesEngineeringMechanical engineering

A restrained damping heat and sound insulation device is characterized by comprising a sealed shell and heat and sound insulation functional composite materials filled in the shell. A preparation method of the restrained damping heat and sound insulation device includes preparation, assembly and sealing of the heat and sound insulation functional composite materials and the shell. Reliable connection between a sealing material and a heat and sound insulation plate is ensured, the end face and the periphery of a power cabin truss of an engine are doubly sealed and prevented from directly contacting with open flame, flame resistance and vibration resistance are high, the restrained damping heat and sound insulation device is fixed by screwing or riveting during assembly, welding deformation is avoided, and heat and sound insulation effects are ensured.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

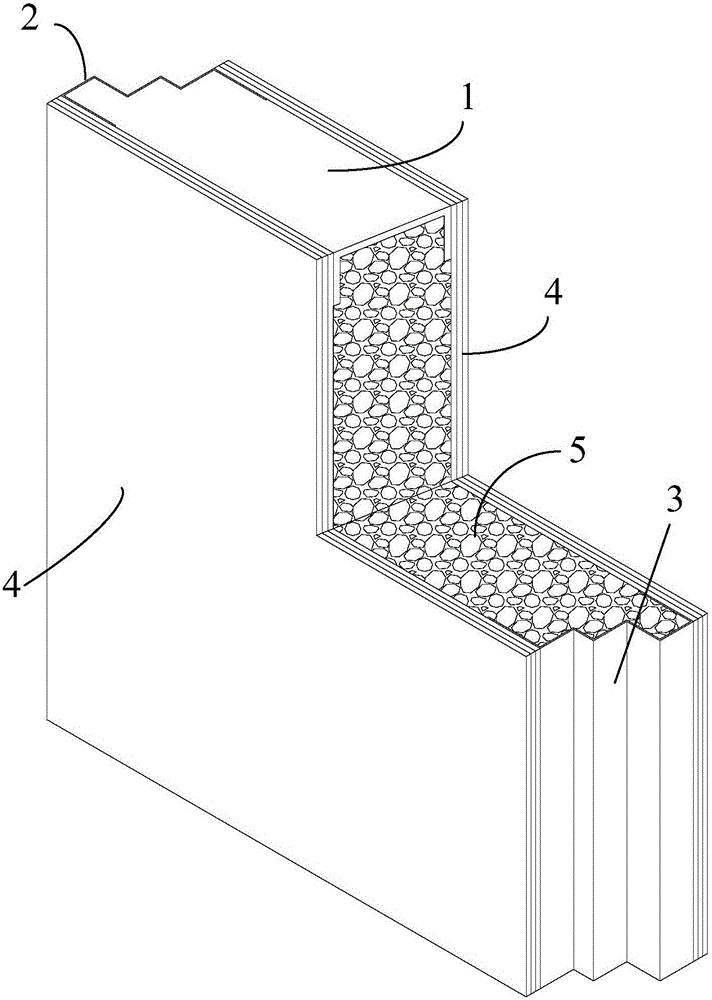

Fire-resistant lightweight particles and polyurethane filled wall panel and production method

InactiveCN107435385AHigh wall strengthImprove insulation effectWallsHeat proofingPolygonal lineEngineering

The invention discloses a fire-resistant lightweight particles and polyurethane filled wall panel. The wall panel comprises support frames, a first edge, a second edge, a wall panel and a heat-insulating layer; two support frames are parallelly arranged up and down as a top surface and a base surface of the wall panel; two ends of the first edge and the second edge are fixed at two ends of the two support frames as two connecting surfaces of the wall panel; adjacent wall panels are spliced through the first edge and the second edge and a fold line sound insulation and heat insulation path is formed; the support frames, the first edge and the second edge are spliced to form a wall panel skeleton; the wall panel boards are installed at two sides of the wall panel skeleton and are spliced to form a hollow structure; fire-resistant lightweight particles and polyurethane are used as heat insulation material which the hollow structure is filled with. The invention also discloses a method for producing the above wall panel, comprising following steps: splicing a square box structure, spraying and filling and mounting reserved panels. The invention relates to the field of buildings. The invention provides a reused wall panel which has good heat insulation and sound insulation and high fire-resistance and production method.

Owner:BEIJING NEW BUILDING MATERIALS PLC

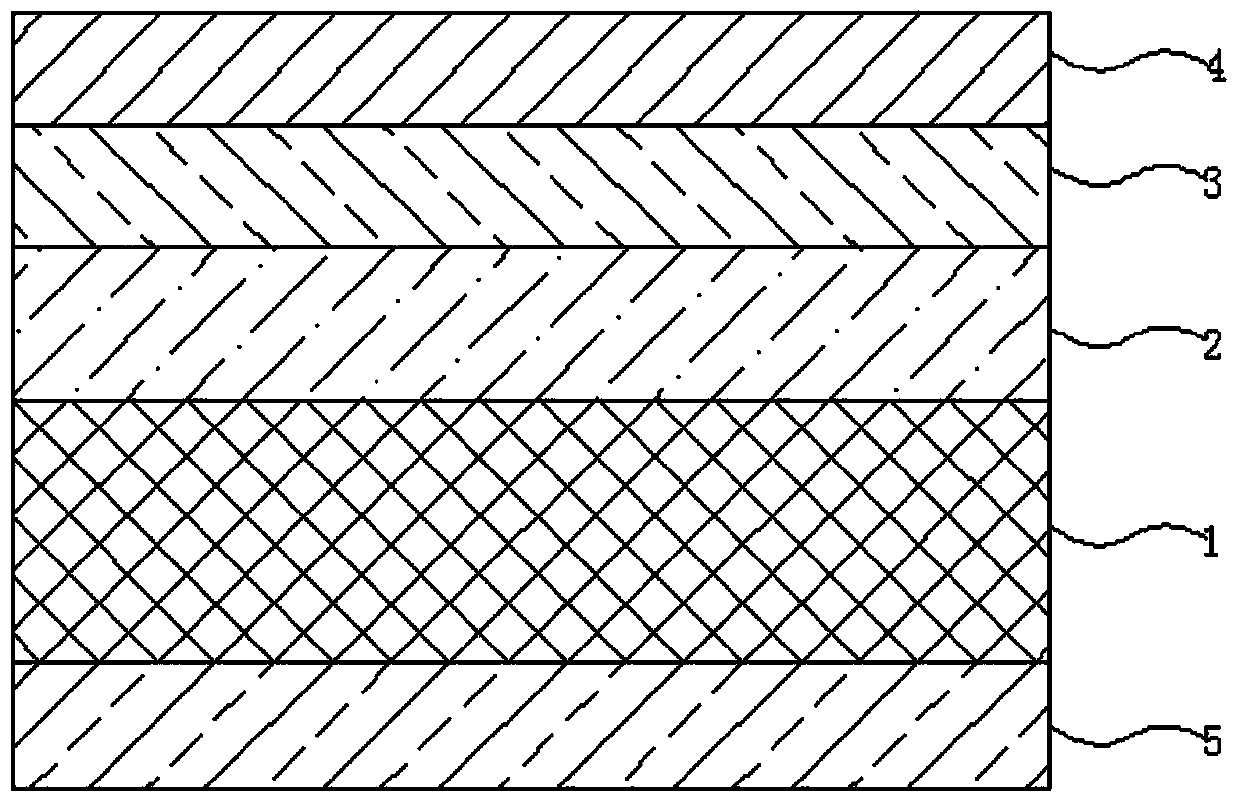

Laminated composite glass

InactiveCN106761237AHigh transparencyImprove impact resistanceGlass/slag layered productsUnits with parallel planesMetallurgyShock resistance

The invention discloses a laminated composite glass. The laminated composite glass comprises a first glass layer and is characterized in that the surface of the first glass layer is successively provided with a metal interlayer, a second glass layer, a hollow layer, and a third glass layer; the first glass layer and the metal interlayer, the metal interlayer and the second glass layer are bounded and compounded through an adhesive layer, the third glass layer is a hollow glass, and a low radiation layer is deposited on the surface of the hollow glass. The laminated composite glass comprises three glass layers, the outer layer is a glass layer hollow glass, and the surface of the hollow glass is provided with the low radiation layer, the metal interlayer is arranged between the first glass layer and the second glass layer, and therefore the laminated glass has the advantages of good permeability, shock resistance and safety, and has good radiation protection, heat insulation and sound insulation effect, therefore effectively improves the service performance of the laminated glass.

Owner:QINZHOU ZHONGBO GLASS CO LTD

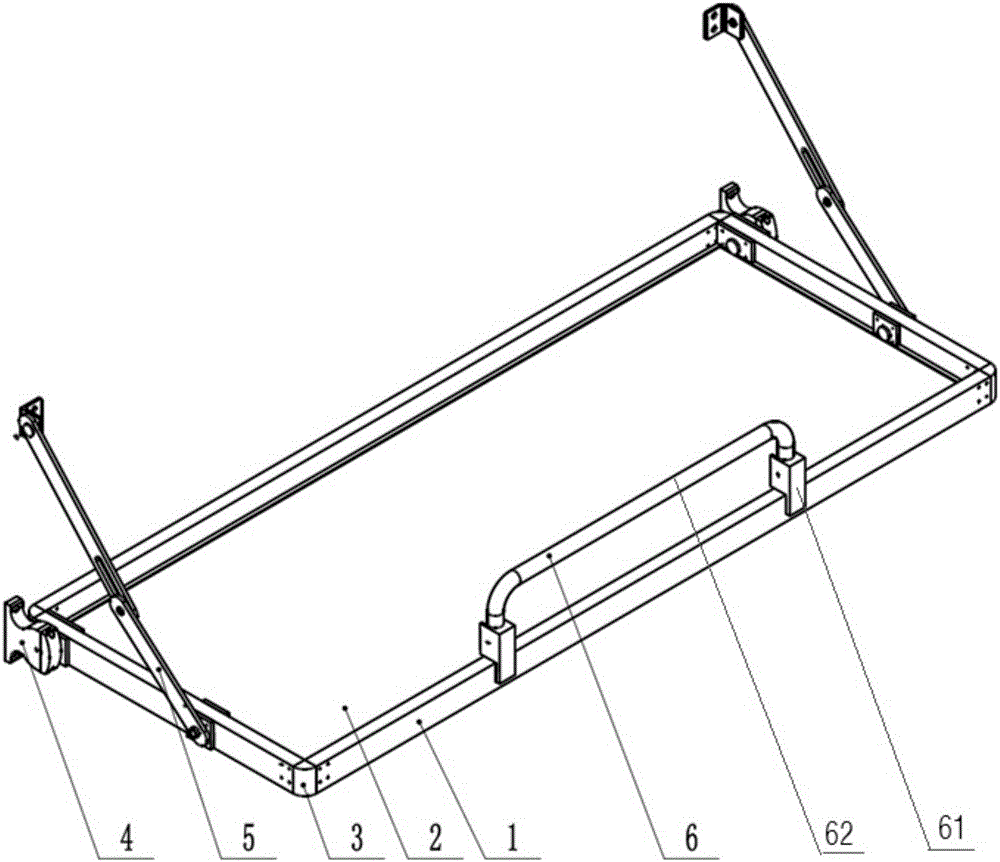

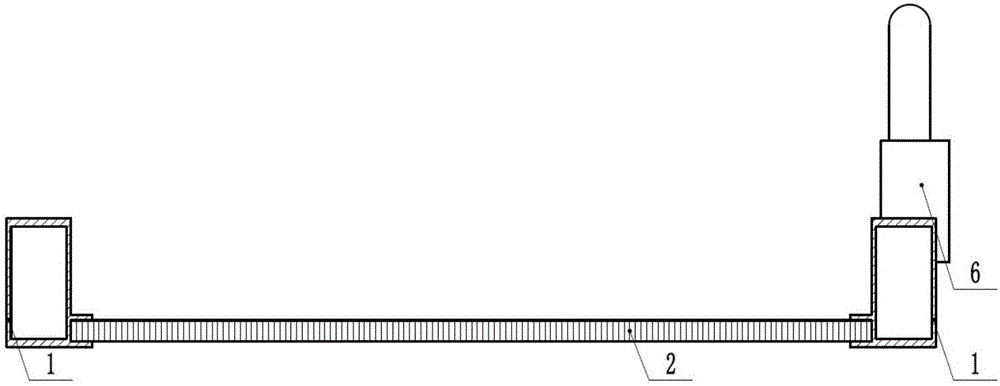

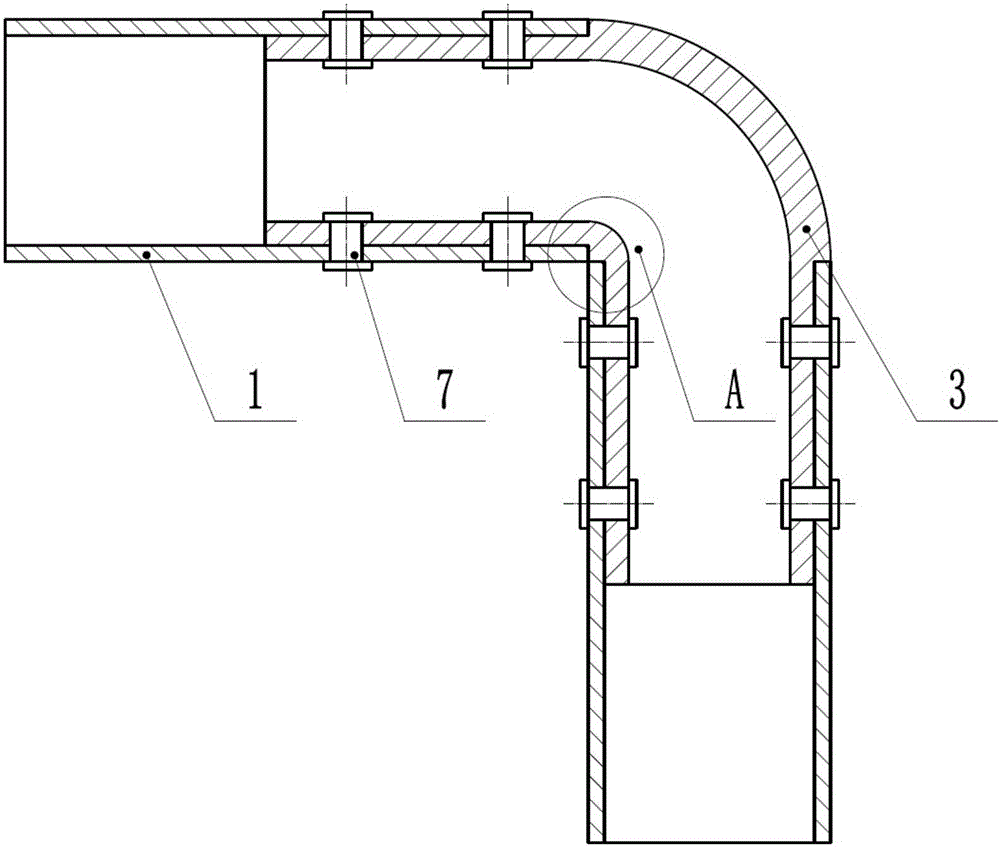

Lightweight turnover sleeper

The invention relates to a lightweight turnover sleeper which comprises a sleeper body, folding rods and hanging pieces. The sleeper body comprises a sleeper skeleton and a sleeper plate mounted on the sleeper skeleton. The sleeper skeleton comprises four edge beams which are connected end to end. Slots matched with the sleeper plate are formed in the inner sides of the edge beams. The sleeper plate is mounted in the slots. The sleeper skeleton is rotatably connected with the edge beams. One ends of the folding rods are rotatably connected with the corresponding edge beams, and the other ends of the folding rods are provided with mounting bases. The folding rods are rotatably connected with the mounting bases. The sleeper body, the hanging pieces and the folding rods are made from magnesium alloys. The turnover sleeper is manufactured through lightweight design and is low in density, high in specific strength and specific rigidity, and good in damping shock absorption performance, machining performance and size stability; and the hanging pieces are matched with the folding rods, the bearing strength of the sleeper in a horizontal status is fully considered, the turnover structure is simple and reliable, the flexible and reliable turnover structure can decrease the occupancy rate of the service space, and the lightweight turnover sleeper is suitable for all kinds of complex environments.

Owner:CHENGDU TIANZHI LIGHTWEIGHTING TECH CO LTD

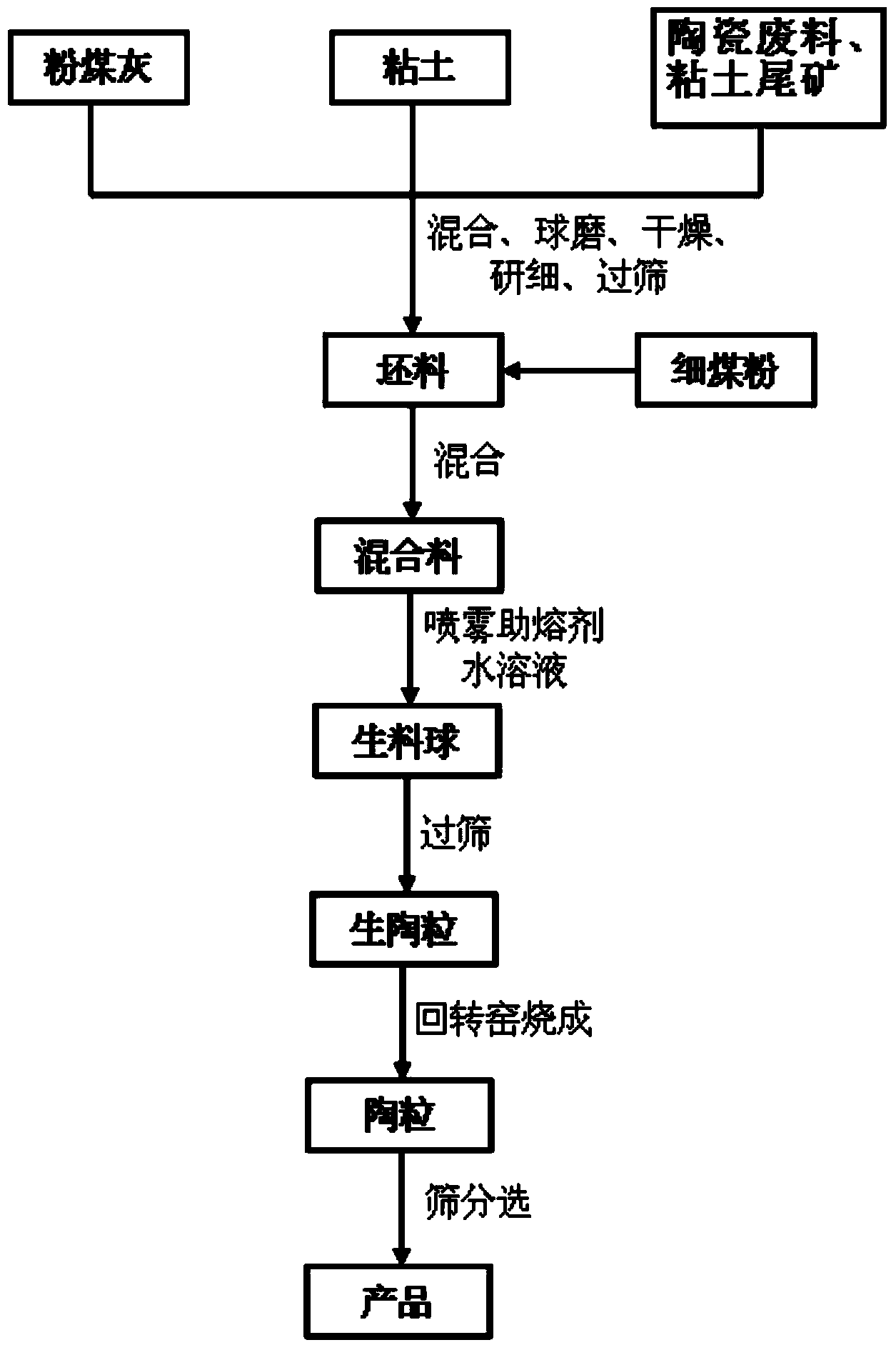

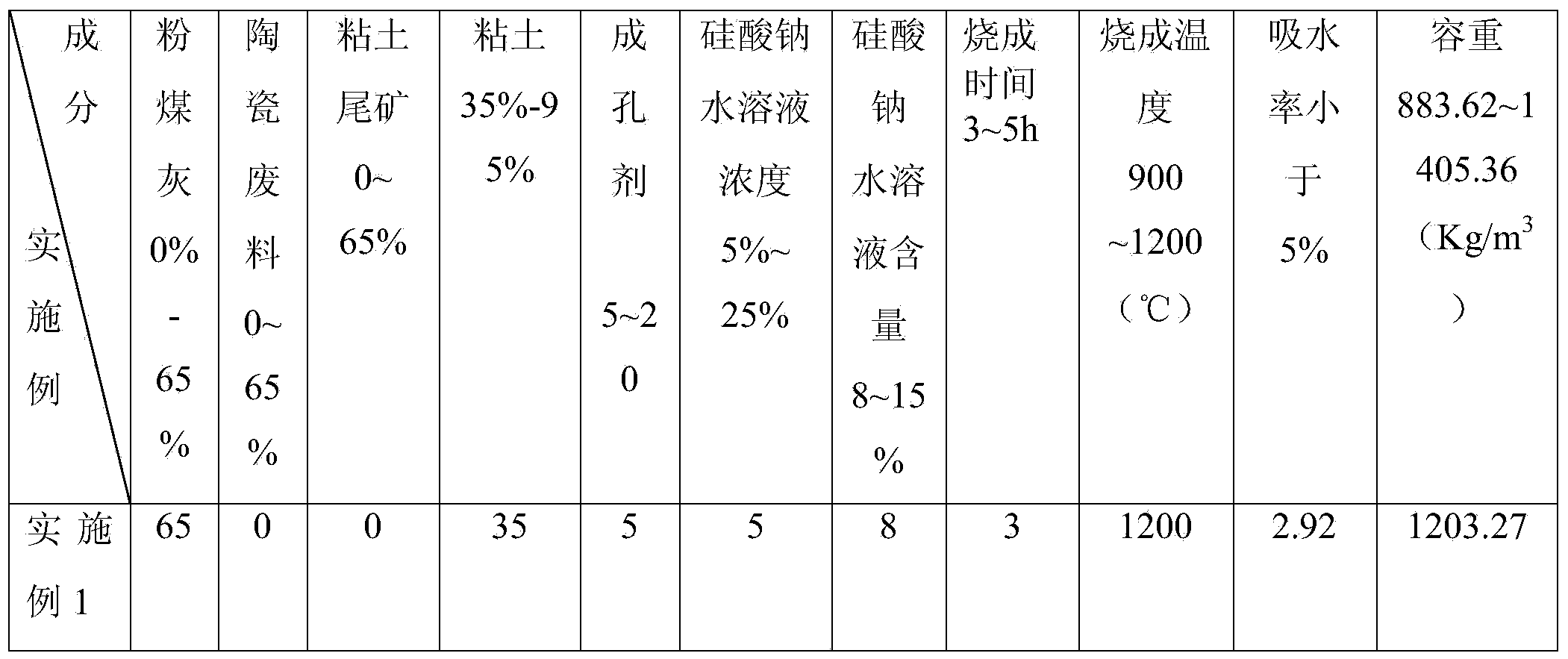

Sodium silicate surface co-sintered light ceramsite and preparation method thereof

ActiveCN104291786ALow costSimple processCeramic materials productionCeramicwareSurface layerHigh volume manufacturing

The invention relates to sodium silicate surface co-sintered light ceramsite and a preparation method thereof. The light ceramsite and the preparation method have the beneficial effects that by spraying a 5-25% sodium silicate solution step by step, during drying, sodium ions dissolved in water diffuse toward the surfaces along with the moisture and gather on the shells of surfaces of raw meal nodules, the sodium ions on the surface layers react with other matters in the sintering process to form fusible matters, thus playing a role of co-sintering agents, and the content of the sodium ions in the co-sintering agents below the surface layers of the raw meal nodules is very low; the ceramsite sintered at a surface layer sintering temperature has relatively low water absorption but the unsintered density of core regions below the surface layers is lower, so that the light ceramsite with low water absorption and low overall density is finally obtained; the problems that the ceramsite not only requires low water absorption and high strength but also requires light volume weight are solved; the preparation method of the sodium silicate surface co-sintered light ceramsite is simple in process and safe to operate, can be used for volume production and is low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

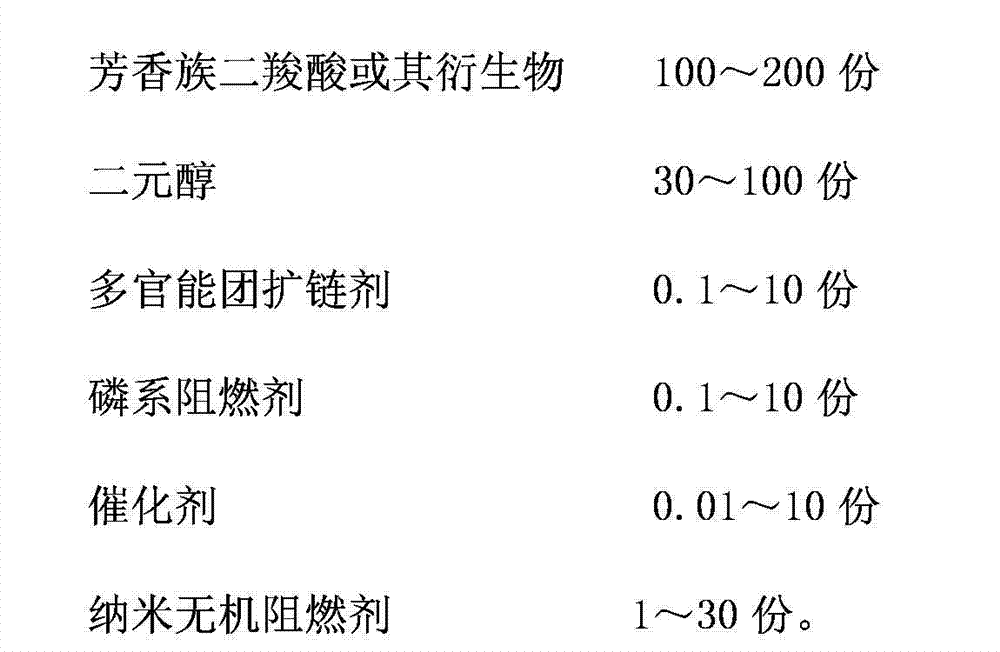

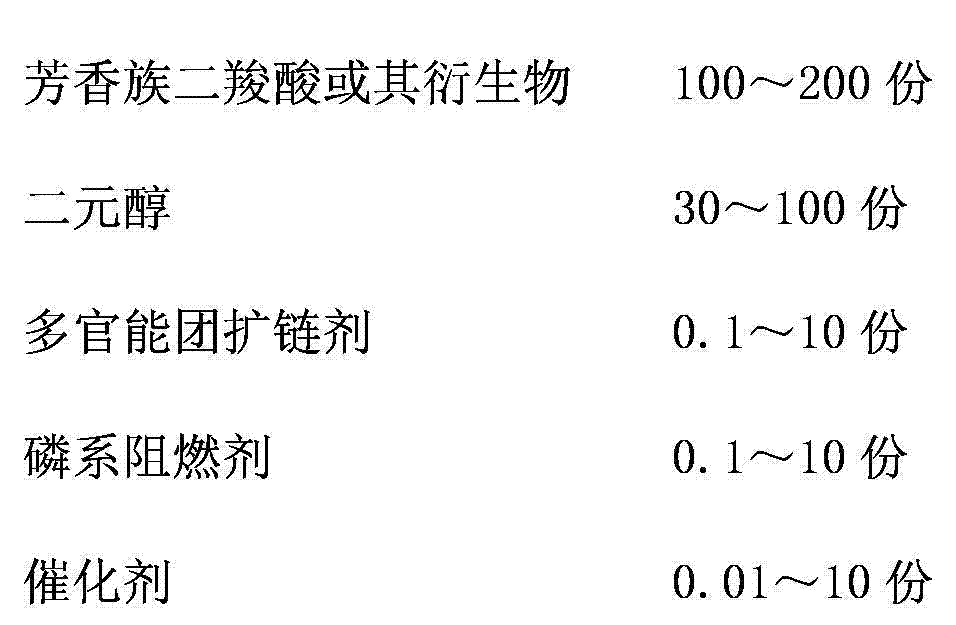

Foamable flame-retarding polyester capable of being used for supercritical CO2 and preparation method and application thereof

The invention provides a foamable flame-retarding polyester capable of being used for supercritical CO2 and a preparation method and an application thereof. The foamable flame-retarding polyester capable of being used for supercritical CO2 is prepared by using aromatic dicarboxylic acid or its derivative, dihydric alcohol and multiple function group chain extender and phosphorus flame retardant and nano inorganic fire retardant as raw materials, carrying out direct esterification melt polycondensation in the presence of a catalyst to obtain a long-chain branching flame-retarding polyester. The polyester of the invention has the advantages of light weight, large specific strength, large rigidity, good electrical insulating property, excellent heat insulation and sound insulation properties, etc, and is mainly used in building industry.

Owner:BLUETOP JIANGSU NEW MATERIAL +1

Environmentally-friendly exterior wall heat insulation material and preparation method thereof

InactiveCN105254271AImprove insulation effectGood heat and sound insulationSolid waste managementCeramicwareBuilding materialVolcanic ash

The invention discloses an environmentally-friendly exterior wall heat insulation material and a preparation method thereof, and belongs to the technical field of building materials. The material comprises, by weight, 20-40 parts of meerschaum, 5-15 parts of water glass, 5-15 parts of fly ash, 5-15 parts of volcanic ash, 1-3 parts of a foaming agent, 0.8-1.2 parts of polyvinyl alcohol, 10-30 parts of water, 10-20 parts of a thickener and 2-6 parts of calcined kaolin. The environmentally-friendly exterior wall heat insulation material has the advantages of good heat insulation effect, good heat and sound insulation effects, small water imbibitions, low temperature resistance, and acid and alkali resistance; and the preparation method is simple, and is suitable for large scale production.

Owner:广西路佳道桥勘察设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com