Laminated composite glass

A composite glass and interlayer technology, applied in parallel glass structures, glass/slag layered products, layered products, etc., can solve the problems that cannot meet the requirements of sound insulation, impact resistance, and safety, and achieve the effect of improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with specific embodiments and drawings, but it is not intended to limit the present invention.

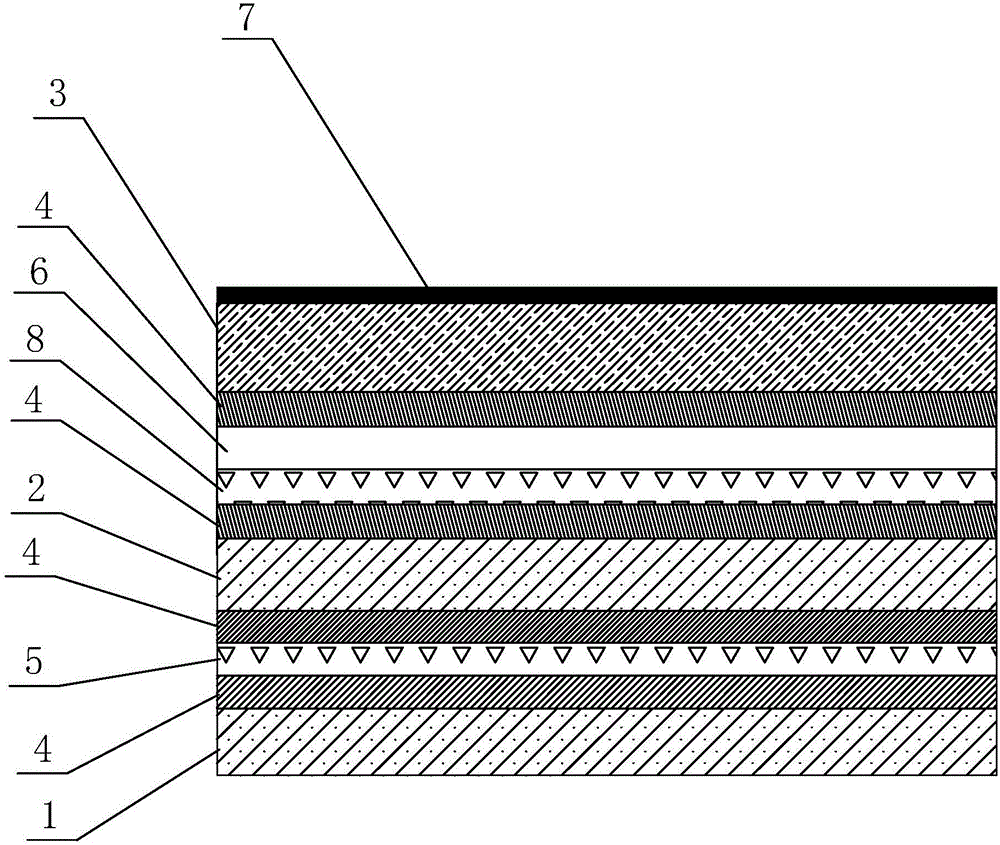

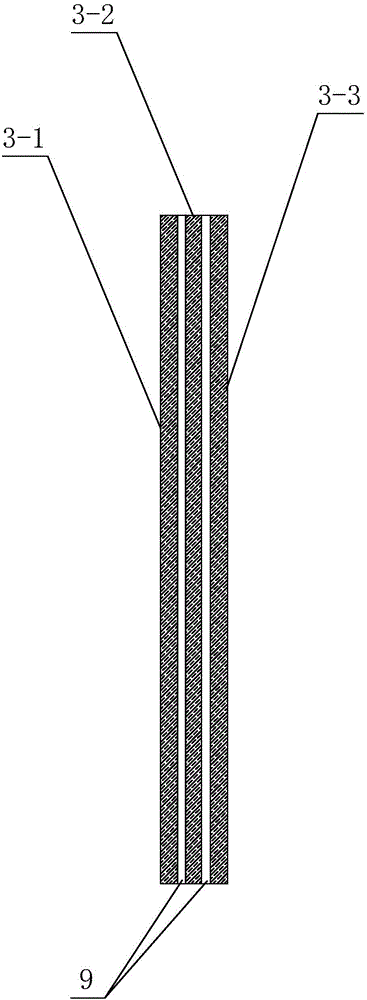

[0019] Such as figure 1 As shown, a laminated composite glass includes a first glass layer 1, and the surface of the first glass substrate 1 is sequentially provided with a metal interlayer 5, a second glass layer 2, a hollow layer 6, and a third glass layer from bottom to top. Layer 3. Wherein, between the first glass layer 1 and the metal interlayer 5, between the metal interlayer 5 and the second glass layer 2 are bonded and compounded by the adhesive layer 4, and between the second glass layer 2 and the hollow layer 6, the hollow The layer 6 and the third glass layer 3 are bonded and compounded by the adhesive layer 4, and the third glass layer 3 is insulating glass, and a low-emissivity layer 7 is deposited on the surface of the insulating glass.

[0020] The metal interlayer 5 may specifically be a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com