Preparation method of titanium-based composite material thermal protection skin structure

A titanium-based composite material and thermal protection technology, which is applied in the field of preparation of titanium-based composite thermal protection skin structures, can solve the problems of low withstand temperature, high density, complicated preparation process, etc. Thermal effect, effect of simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

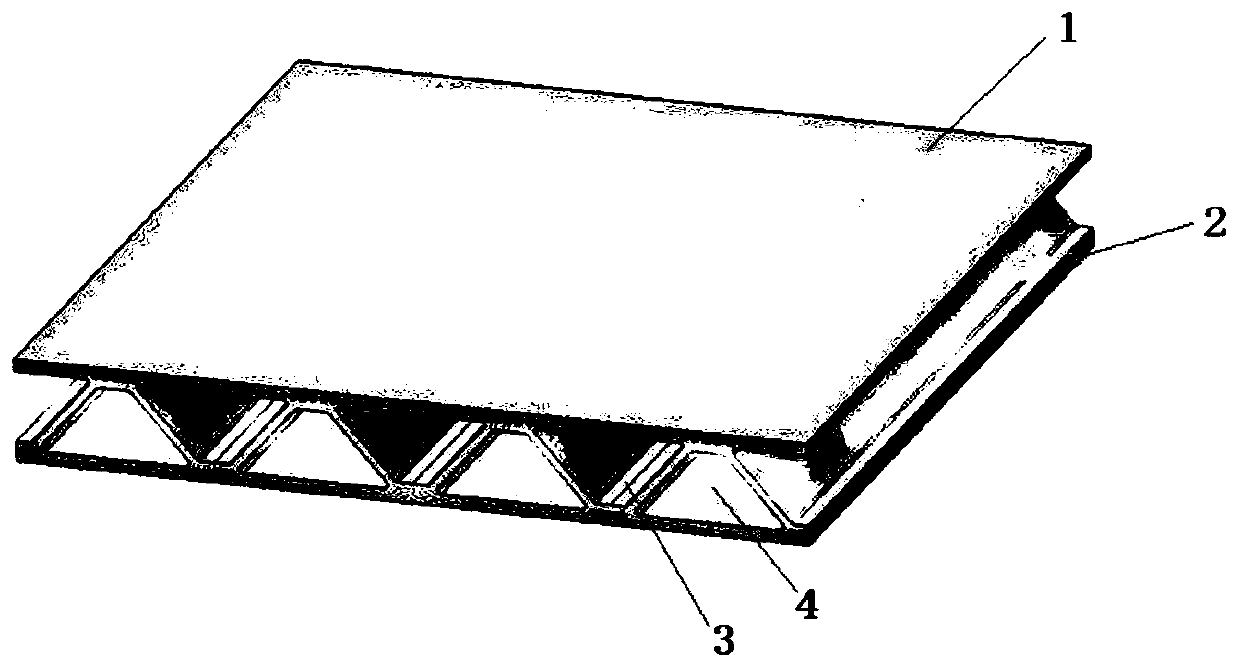

[0029] A titanium matrix composite thermal protection skin structure, such as figure 1 As shown, it includes an upper panel 1 of titanium matrix composite material, a lower panel 2 of titanium alloy, and a sandwich structure 3 of titanium alloy, wherein the interlayer is filled with heat insulating material 4 .

[0030] A method for preparing a thermal protection skin structure of a titanium-based composite material, comprising the following steps:

[0031] (1) Put the titanium alloy foil in an ultrasonic cleaner, add acetone to clean, remove surface stains, and then place it in alcohol to remove residual acetone;

[0032] (2) Pickling and degreasing the titanium alloy plate. The titanium alloy plate includes a titanium alloy core plate and a titanium alloy lower plate. The components of the acid solution used are as follows: hydrofluoric acid 130mL / L, sulfuric acid 230mL / L, hydrogen peroxide 220mL / L , magnesium silicate 45g / L, 2-picoline 0.5g / L, sodium dodecylbenzenesulfonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com