Strong-inhibition and strong-blockage aluminum-based anti-collapse water-based drilling fluid

A drilling fluid and strong suppression technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as difficult to use on a large scale, difficult to overcome, mud logging interference, etc., to achieve fewer types, convenient maintenance, and simple preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 4% base slurry + 0.3% CPAM + 3% polyamine + 1.0% PAC-L + 0.3% XC + 3% SD-505 + 1.2% aluminum-based anti-slump agent;

[0030] Prepare strong suppression and strong blocking aluminum-based anti-slump drilling fluid system: add 400mL of fresh water to a tall stirring cup, turn on the mixer and add 4g of sodium bentonite, 1.2g of cationic polyacrylamide, and 12g of amine inhibitors while stirring at 5000r / min , 4.0g low-viscosity polyanionic cellulose, 1.2g xanthan gum, 12g mineral oil lubricant SD-505, 4.8g aluminum-based plugging and anti-slump agent. Each treatment agent is added at intervals of 10 minutes, all added and stirred for 30 minutes.

Embodiment 2

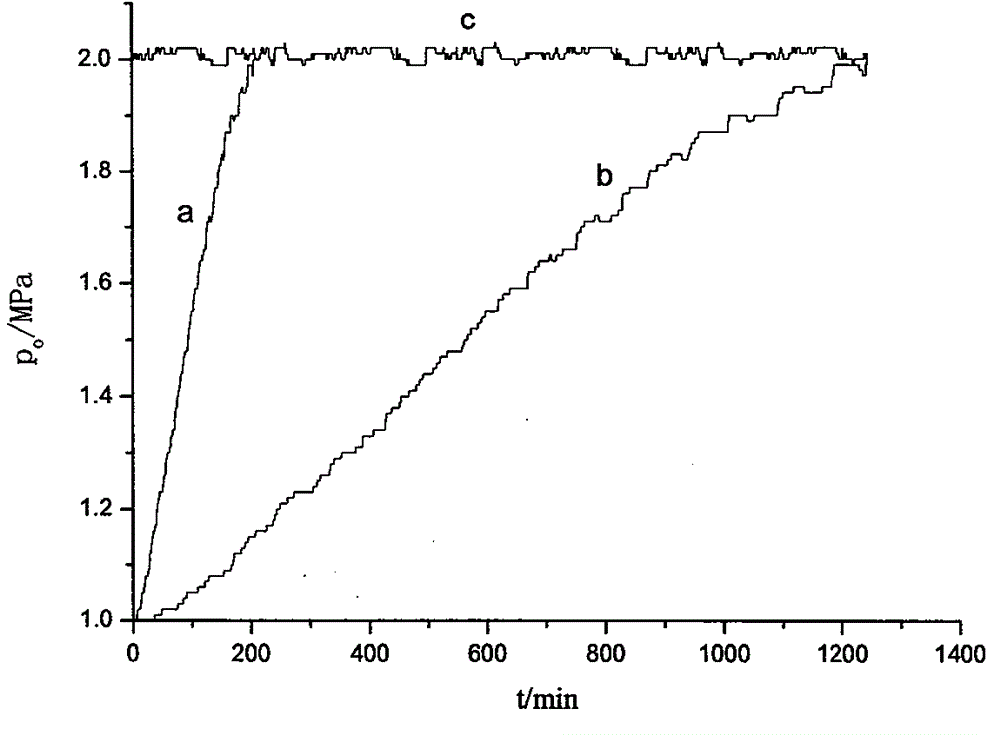

[0032] Evaluation of plugging performance of aluminum-based plugging and anti-slump agent: mainly for the test steps of retarding pressure transfer performance, briefly described as: (1) Simulate formation water (200g / L salt solution) to saturate and balance the rock sample, and restore the original formation of the rock sample Water state; (2) Pore pressure transfer (PT) experiments were carried out under the conditions of formation water (200g / L salt solution) / mudstone / formation water (200g / L salt solution). During the experiment, the axial pressure is 5MPa, the confining pressure is 5MPa, the upward pressure is 2MPa, and the downward pressure is 1MPa. The pressure change with time after the downstream test liquid is locked is monitored.

[0033] According to the pressure transfer curve, the permeability of shale can be calculated according to the following formula:

[0034] k = μβVL A ln ...

Embodiment 3

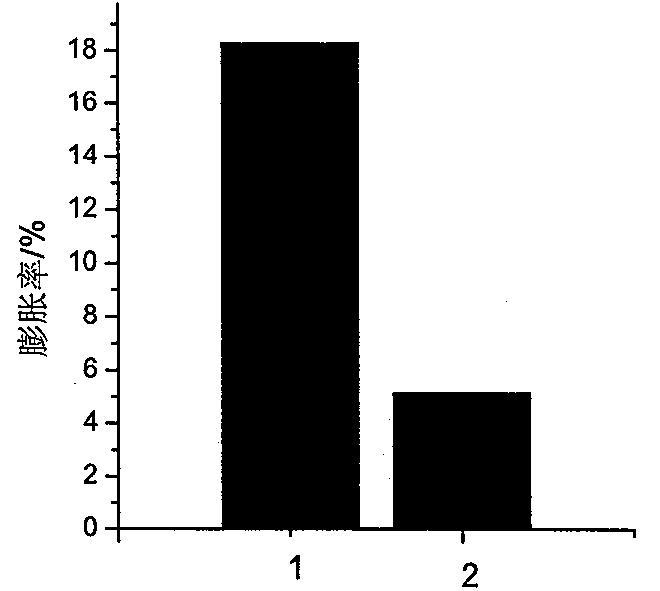

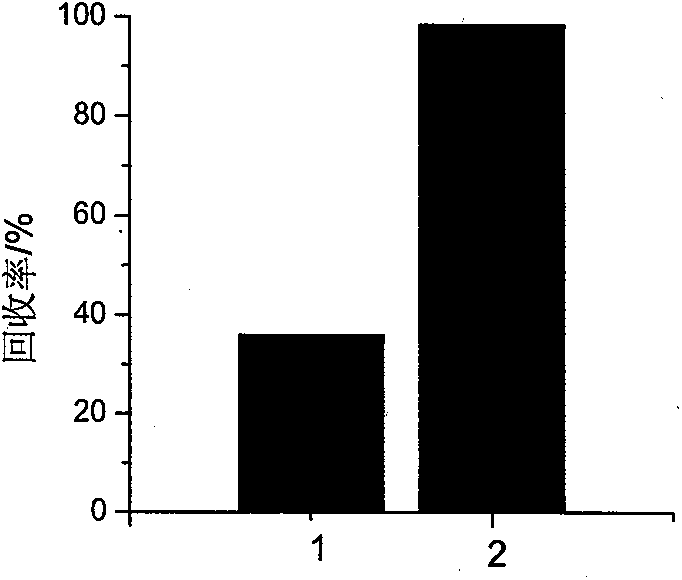

[0038] Rheological fluid loss and inhibition evaluation of strong inhibition and strong plugging aluminum-based anti-slump drilling fluid system: Determination of rheological and fluid loss properties of strong inhibition and strong plugging aluminum-based anti-slump drilling fluid system before and after aging at 120℃ / 16h And its rolling dispersion recovery rate, hydration expansion rate, the results are shown in Table 1 and figure 2 and image 3 . Strong inhibition and strong plugging of aluminum-based anti-slump drilling fluid system, the viscosity before and after aging has little change, and the rheological properties are excellent; the API fluid loss before and after aging is low, the fluid loss is excellent, and the rock sample hydrates and expands The rate of deionized water is greatly reduced, and the recovery rate is greatly increased, indicating that it can improve the hydration expansion and hydration dispersion inhibition of the system.

[0039] Table 1 Rheolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com